Porter-cable PXCMLC3706056 User Manual

Single Stage, Belt Drive,

Electric Air Compressors

Compresseurs d’air

électriques à un étage à

entraînement par courroie

Compresores eléctricos de

aire, de una sola etapa y

accionamiento por correa

Instruction manual

Manuel d'instructions

Manual de instrucciones

Français : Page 31

Español: Página 60

PXCMLC3706056

200-2887_Rev. A_7-12

TABLE OF CONTENTS

SAFETY GUIDELINES .................................... 3-6

SPECIFICATION CHART ....................................6

OVERVIEW ..................................................... 6-7

Basic Air Compressor Components ......... 6-7

ASSEMBLY .........................................................7

Assembling the Compressor ........................7

TYPICAL INSTALLATION ................................ 8-9

COMPRESSOR CONTROLS ............................10

ELECTRICAL POWER REQUIREMENTS .........11

Electrical Wiring ..........................................11

Main Power Panel .......................................11

Main Power Disconnect Switch ..................11

Low Voltage Problems ................................11

Grounding Instructions ...............................11

MOTOR RESET SWITCH .................................12

OPERATING INSTRUCTIONS .................... 12-14

Break-in of the Pump ..................................12

Daily Startup ...............................................14

TABLE DES MATIÈRES

CONSIGNES DE SÉCURITÉ .................. 3, 31-33

TABLEAU DES SPÉCIFICATIONS ....................33

VUE D’ENSEMBLE ...........................................34

Éléments de base du compresseur d’air ....34

ASSEMBLAGE..................................................35

Assemblage du compresseur .....................35

INSTALLATION TYPIQUE ........................... 36-37

COMMANDES DU COMPRESSEUR ...............38

SPÉCIFICATIONS DE L’ALIMENTATION

ÉLECTRIQUES ........................................... 38-39

Câblage électrique ......................................38

Panneau de tension principale ...................39

Sectionneur de tension principale ..............39

Problèmes de tension trop basse ...............39

Instructions pour la mise à la terre .............39

REMISE EN MARCHE ET CÂBLAGE DU

MOTEUR .........................................................40

MODE D’EMPLOI ....................................... 40-44

Rodage de la pompe ..................................40

Shutdown....................................................14

MAINTENANCE .......................................... 15-18

Draining the Tank ........................................15

Checking the Oil .........................................15

Changing the Oil .........................................15

Belt Tension ................................................16

Pulley Alignment .........................................17

Cleaning the Air Filter .................................18

Checking the Relief Valve ...........................18

Testing for Leaks .........................................18

Storage .......................................................18

SERVICE INTERVAL .........................................18

TROUBLESHOOTING CHART ................... 19-20

PARTS DRAWINGS AND PARTS LISTS ..... 21-25

WARRANTY ................................................ 26-28

GLOSSARY OF TERMS ...................................29

PARTS AND SERVICE ......................................30

Mise en marche quotidienne ......................42

Arrêt ............................................................42

ENTRETIEN ................................................ 43-46

Vidange du réservoir ...................................43

Vérification du niveau d’huile ......................43

Vidange d’huile ...........................................43

Tension de la courroie .................................44

Alignement de la poulie ..............................45

Nettoyage du filtre à air ..............................46

Vérification de soupape de décharge .........46

Essai d’étanchéité.......................................46

Entreposage ................................................46

ENTRETIEN PÉRIODIQUE ................................46

DÉPANNAGE .............................................. 47-48

DESSIN DES PIÈCES ET LISTEDE PIÈCES ..49-53

GARANTIE .....................................................54-57

GLOSSAIRE DES TERMES ..............................58

PIÈCES ET RÉPARATIONS ...............................59

INDICE

PAUTAS DE SEGURIDAD ....................... 3, 60-62

TABLEAU DES SPÉCIFICATIONS ....................62

RESUMEN GENERAL.......................................63

Componentes básicos del compresor

de aire .........................................................63

MONTAJE .........................................................64

Montaje del compresor ...............................64

INSTALACION TIPICA ................................ 65-66

CONTROLES DEL COMPRESOR ....................67

REQUERIMIENTOS DE ALIMENTACIÓN

ELÉCTRICA ......................................................68

Cableado eléctrico ......................................68

Panel principal de alimentación ..................68

Interruptor principal de alimentación ..........68

Problemas causados por bajo voltaje ........68

Instrucciones de puesta a tierra .................68

RESTABLECIMIENTO Y CABLEADO DEL

MOTOR ............................................................69

INSTRUCCIONES OPERATIVAS ................ 69-70

Puesta en marcha inicial de la bomba .. 69-70

Arranque diario ...........................................70

Parada ........................................................70

MANTENIMIENTO ...................................... 72-75

Desagüe del tanque .........................................72

Verificación del nivel de aceite....................72

Cambio de aceite ........................................72

Tensión de la correa ....................................73

Alineación de la polea .................................74

Limpieza del filtro de aire ............................75

Revisión de la válvula de alivio ...................75

Detección de fugas .....................................75

Almacenamiento .........................................75

INTERVALOS DE SERVICIO .............................75

CUADRO DE DETECCIÓN DE FALLOS ..... 76-77

ESQUEMA DE LA PIEZAS Y LISTA DE LAS

PIEZAS ....................................................... 78-82

GARANTÍA .................................................. 83-85

GLOSARIO DE TERMINOS ..............................86

REPUESTOS Y SERVICIO ................................87

2- ENG

SAFETY GUIDELINES

The following information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

following symbols. Please read the manual and pay attention to these sections.

I DANGER

I WARNING

I CAUTION

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

CONSIGNES DE SÉCURITÉ

Les informations suivantes concernent VOTRE SÉCURITÉ et LA PROTECTION DU

MATÉRIEL CONTRE LES PANNES. Pour vous aider à identifier la nature de ces

informations, nous utilisons les symboles suivants. Veuillez lire le manuel et prêter

attention à ces sections.

I DANGER

I AVERTISSEMENT

I ATTENTION

DANGER POTENTIEL POUVANT ENTRAÎNER DE GRAVES

BLESSURES OU LA MORT.

DANGER POUVANT CAUSER DES BLESSURES

GRAVES VOIRE MORTELLES.

DANGER POUVANT CAUSER DES BLESSURES

MOYENNEMENT GRAVES OU L’ENDOMMAGEMENT

DE L’APPAREIL.

PAUTAS DE SEGURIDAD

La información que sigue se refiere a la protección de SU SEGURIDAD y la

PREVENCIÓN DE PROBLEMAS DEL EQUIPO. Como ayuda para reconocer esta

información, usamos los siguientes símbolos. Lea por favor el manual y preste

atención a estas secciones.

I PELIGRO

I ADVERTENCIA

I PRECAUCION

UN POSIBLE RIESGO QUE CAUSARÁ LESIONES GRAVES

O LA PÉRDIDA DE LA VIDA.

UN RIESGO POTENCIAL QUE PODRÍA PROVOCAR

GRAVES LESIONES O MUERTE.

UN RIESGO POTENCIAL QUE PODRIA PROVOCAR

LESIONES LEVES O DA—AR EL EQUIPO.

3 - ENG

WARNING

Read and understand all safety precautions in this manual before operating. Failure to

comply with instructions in this manual could result in personal injury, property damage,

and/or voiding of your warranty. The manufacturer WILL NOT be liable for any damage

because of failure to follow these instructions.

area. It is normal for the motor and

pressure switch to produce sparks while

operating. If sparks come into contact with

vapors from gasoline or other solvents,

they may ignite, causing fire or explosion.

Always operate the compressor in a well–

ventilated area. Do not smoke while

spraying. Do not spray where sparks or

flame are present. Keep compressor as far

from spray area as possible.

2. RISK OF BURSTING. Do not

weld, drill or modify the air tank

of this compressor. Welding or

modifications on the air

compressor tank can severely impair tank

strength and cause an extremely hazardous

condition. Welding or modifying the tank in

any manner will void the warranty.

3. RISK OF ELECTRICAL

SHOCK. Never use an electric

air compressor outdoors when

it is raining or on a wet surface,

as it may cause an electric shock.

4. RISK OF INJURY. This unit

starts automatically. ALWAYS

shut off the main power

disconnect, and bleed all

pressure from the system before servicing

the compressor, and when the compressor

is not in use. Do not use the unit with the

shrouds or belt guard removed. Serious

injury could occur from contact with

moving parts.

5. RISK OF BURSTING. Check

the manufacturer’s maximum

pressure rating for air tools and

accessories. Compressor outlet

pressure must be regulated so as to never

exceed the maximum pressure rating of the

tool. Relieve all pressure through the hose

before attaching or removing accessories.

1. RISK OF FIRE OR

EXPLOSION. Never

spray flammable

liquids in a confined

6. RISK OF BURNS. High

temperatures are generated by

the pump and manifold. To

prevent burns or other injuries,

DO NOT touch the pump, manifold or

transfer tube while the pump is running.

Allow them to cool before handling or

servicing. Keep children away from the

compressor at all times.

7. RISK TO BREATHING. Be

certain to read all labels when

you are spraying paints or toxic

materials, and follow the safety

instructions. Use a respirator mask if there

is a chance of inhaling anything you are

spraying. Read all instructions and be sure

that your respirator mask will protect you.

Never directly inhale the compressed air

produced by a compressor. It is not

suitable for breathing purposes.

8. RISK OF EYE INJURY.

Always wear ANSI Z87.1

approved safety goggles when

using an air compressor. Never point any

nozzle or sprayer toward a person or any

part of the body. Equipment can cause

serious injury if the spray penetrates the

skin.

9. RISK OF BURSTING. Do not

adjust the relief valve for any

reason. Doing so voids all

warranties. The relief valve has

been pre-set at the factory for the

maximum pressure of this unit. Personal

injury and /or property damage may result if

the relief valve is tampered with.

10. RISK OF BURSTING.Do not

use plastic or pvc pipe for

compressed air. Use only

gavanized steel pipe and fittings

for compressed air distribution lines.

11. RISK OF BURSTING.Failure

to properly drain condensed

water from air tank, causing rust

and thinning of the steel air

tank.

Drain air tank daily or after each use. If

air tank develops a leak, replace it

4- ENG

immediately with a new air tank or replace

the entire compressor.

12. RISK TO HEARING. Always

wear hearing protection when

using an air compressor. Failure

to do so may result in hearing loss.

13. The interconnect cord on

this product contains lead, a

chemical known to the State of

California to

cause cancer, and birth defects or other

reproductive harm. Wash hands after

handling.

NOTE: ELECTRICAL WIRING. Refer to

the air compressor’s serial label for the

unit’s voltage and amperage requirements.

Ensure that all wiring is done by a licensed

electrician, in accordance with the National

Electrical code.

DANGER

RISK OF BURSTING.

Air Tank: On February 26, 2002, the U.S. Consumer Product Safety Commission published Release # 02-108 concerning air compressor tank safety:

Air compressor receiver tanks do not have an infinite life. Tank life is dependent upon

several factors, some of which include operating conditions, ambient conditions, proper

installations, field modifications, and the level of maintenance. The exact effect of these

factors on air receiver life is difficult to predict.

If proper maintenance procedures are not followed, internal corrosion to the inner wall of

the air receiver tank can cause the air tank to unexpectedly rupture allowing pressurized

air to suddenly and forcefully escape, posing risk of injury to consumers.

Your compressor air tank must be removed from service by the end of the year shown on

your tank warning label.

The following conditions could lead to a weakening of the air tank, and result in a violent

air tank explosion:

WHAT CAN HAPPEN HOW TO PREVENT IT

• Failuretoproperlydraincondensedwater

from air tank, causing rust and thinning of

the steel air tank.

• Modificationsorattemptedrepairstothe

air tank.

• Unauthorizedmodificationstothesafety

valve, or any other components which

control air tank pressure.

• Drainairtankdailyoraftereachuse.Ifair

tank develops a leak, replace it immediately

with a new air tank or replace the entire

compressor.

• Neverdrillinto,weldormakeany

modifications to the air tank or its

attachments. Never attempt to repair a

damaged or leaking air tank. Replace with a

new air tank.

• Theairtankisdesignedtowithstand

specific operating pressures. Never make

adjustments or parts substitutions to alter the

factory set operating pressures.

WARNING

1. Drain the moisture from the tank on a daily basis. A clean, dry tank will help

prevent corrosion.

2. Pull the pressure relief valve ring daily to ensure that the valve is functioning

properly, and to clear the valve of any possible obstructions.

3. To provide proper ventilation for cooling, the compressor must be kept a

minimum of 12 inches (31 cm) from the nearest wall, in a well–ventilated area.

5 - ENG

4. To prevent damage to tank and compressor on stationary models, the

tank must be shimmed so the pump base is level within 1/8” to distribute

oil properly. All feet must be supported, shimming where necessary, prior to

attaching to the floor. Fasten all feet to floor. We also recommend the use of

vibration pads (094-0137) under tank feet.

5. Fasten the compressor down securely if transporting is necessary. Pressure

must be released from the tank before transporting.

6. Protect the air hose from damage and puncture. Inspect them weekly for

weak or worn spots, and replace if necessary.

7. To reduce the risk of electric shock, do not expose to rain. Store indoors.

WARNING

CALIFORNIA PROPOSITION 65 WARNING: This product contains chemicals

known to the State of California to cause cancer, birth defects and/or

reproductive harm.

SPECIFICATION CHART

MODEL NO.

RUNNING

H.P.

PXCMLC3706056 3.7

TANK

CAPACITY

GALLONS

60 (227,

1)

VOLTAGE/

AMPS/

PHASE

240/15/1

BASIC AIR COMPRESSOR COMPONENTS

The basic components of the air compressor are

the electric motor, pump, pressure switch and

tank (see Fig. 1). The tank may be vertical or

horizontal, varying in size and capacity.

The electric motor (see A) powers the pump.

The electric motor is equipped with an overload

protector to help prevent possible motor burnout.

If the motor becomes overheated, the overload

protector will shut it down. Should this occur,

allow the motor to cool for 10-15 minutes, then

press (never force) the motor reset switch to

restart the motor.

The pump (see B) compresses the air and

discharges it into the tank.

The tank (see C) stores the compressed air.

The pressure switch (see D) shuts down the

motor and relieves air pressure in the pump and

transfer tube when the air pressure in the tank

reaches the kick–out pressure. As compressed

6- ENG

KICK-IN

PRESSURE

105

(7,24 bar)

NOTE: See pages 8 & 9

for typical installation

of the 60 gallon model.

KICK-OUT

PRESSURE

135

(9,31 bar)

Fig. 1

air is used and the pressure level in the tank drops to the kick–in pressure, the

pressure switch restarts the motor automatically, without warning and the pump

resumes compressing air.

The air line outlet (see E). Connect 1/4” NPT air hose to this outlet.

ASSEMBLING THE COMPRESSOR

1. Unpack the air compressor. Inspect the unit for damage. If the unit has been damaged

in transit, contact the carrier and complete a damage claim. Do this immediately

because there are time limitations to damage claims.

The carton should contain:

• air compressor

• operator and parts manuals

2. Check the compressor’s serial label to ensure that you have received the model

ordered, and that it has the required pressure rating for its intended use.

3. Locate the compressor according to the following guidelines:

a. For optimum performance, locate the compressor close to the power panel, as

specified in ELECTRICAL POWER REQUIREMENTS, and as close as possible

to the place where the air will be used. This ensures maximum power to the

compressor and maximum air pressure to the tool. If both of these conditions

cannot be met, it is better to locate the compressor close to the power panel,

and use a longer air hose to reach the usage area.

b. The flywheel side of the compressor must be at least 12 inches (31 cm) from any

wall or obstruction, in a clean, well-ventilated area, to ensure sufficient air

flow and cooling.

c. In cold climates, locate the compressors in a heated building when not in use.

This will reduce problems with lubrication, motor starting and freezing of water

condensation.

d. Remove the compressor from the shipping pallet and place it on the floor or a

hard, level surface. The compressor must be level to ensure proper

lubrication of the pump and good drainage of the moisture in the tank.

I WARNING

an operating compressor. Operating the compressor while it is on the pallet will

void your warranty.

e. To prevent damage to tank and pump, the tank must be shimmed so the pump

is level within 1/8” per lineal foot maximum to distribute oil properly. Fasten to

floor and NEVER force tank feet to floor without shims when tightening. We also

recommend the use of vibration pads (094-0137) under tank feet (C).

4. Connect an air hose (not included) to the

compressor.

Risk of injury: The shipping pallet is not designed as a base for

C

7 - ENG

Fig. 2

A Air flow

B Feeder line

TYPICAL INSTALLATION

C Drain leg

D Moisture trap with drain

E Non–lubricated supply line

F 1/4 turn valve

G Bypass

H Air dryer or aftercooler

J Line filter

K Drip tee with drain

L Air/water filter with petcock

M Regulator

N Lubricator

P Quick coupler

R Air hose to tool

T Flexible air line

U Lubricated supply line

8- ENG

I WARNING

Risk of bursting, resulting in

I CAUTION

injury. Never use Plastic pipe for

compressed air.

Risk of property damage. Never use lubricator

for paint spraying or similar applications.

TYPICAL INSTALLATION

AIR DRYERS AND AFTER COOLERS

An air dryer or aftercooler is installed directly in the air line.

MOISTURE REMOVAL AND AIR FILTRATION

As the air cools, moisture will condense in the lines. This moisture

must be removed before it reaches the tool being used. To remove this

moisture, run the main air line downhill to a moisture trap and drain. Air/

water filters should also be installed in the positions shown.

AIR PRESSURE REGULATION

Install an air regulator in the drop line for each tool, to regulate air

pressure to that tool. Never exceed the maximum pressure rating of the

tool.

AIR LUBRICATION

Install an air lubricator only for those tools requiring lubrication. Do not

use a lubricator for paint spraying or similar applications. The oil will

contaminate the paint and ruin the job.

SHUT–OFF VALVES

Install shut–off valves in each drop line, to isolate the tool and its

accessories for servicing. You can also install a bypass line around an

accessory.

9 - ENG

COMPRESSOR CONTROLS

Refer to Fig. 3.

PRESSURE switch (see A)

This switch turns on the compressor. It is operated manually, but when in the

AUTO position, it allows the compressor to start up or shut down automatically,

without warning, upon air demand. ALWAYS set this switch to OFF when the

compressor is not being used, and before unplugging the compressor.

Pressure Relief Valve (see B)

If the pressure switch does not shut down the motor when pressure reaches

the preset level, this valve will pop open automatically to prevent over

pressurization. To operate manually, pull the ring on the valve to relieve air

pressure in the tank.

Tank Pressure Gauge (see C)

This gauge measures the pressure level of the air stored in the tank. It is not

adjustable by the operator, and does not indicate line pressure.

NOTE: Not all models are equipped with the following:

10- ENG

Fig. 3

ELECTRICAL POWER REQUIREMENTS

I WARNING

can result in electrical shock. The wiring should be done by a qualified

electrician.

Risk of electrical shock. Improper electrical grounding

ELECTRICAL WIRING

Refer to the air compressor’s serial label for the unit’s voltage and amperage

requirements. Ensure that all wiring is done by a licensed electrician, in

accordance with the National Electrical Code..

MAIN POWER PANEL

For best performance and reliable starting, the air compressor must be installed

on a dedicated circuit, as close as possible to the electrical power panel.

Provide circuit breaker or fuse protection at your main power panel. Use time

delay fuses on the circuit, because the compressor will momentarily draw

several times its specified amperage when first started.

NOTE: A circuit breaker is recommended. If the air compressor is connected to

a circuit protected by a fuse, use dual element time delay fuses (Buss Fusetron

type “T” only).

MAIN POWER DISCONNECT SWITCH

Install a main power disconnect switch in the line from the panel to the

compressor. The main power disconnect switch must be located near the

compressor, for ease of use and safety. When turned OFF, the main power

disconnect switch shuts off all power to the compressor. When it is turned ON,

the compressor will start and stop automatically, controlled by the pressure

switch.

LOW VOLTAGE PROBLEMS

Low voltage will cause difficult starting or an overload. Low voltage can be

caused by a low supply voltage from the local power company, other equipment

running on the same line, or inadequate wiring. If any other electrical devices are

drawing from the compressor’s circuit, it may fail to start.

Low voltage to the compressor can be caused by a supply wire of insufficient

gauge for the distance between the compressor and the power source. The

longer the distance, the larger the wire gauge (lower the number) must be, to

overcome the inherent voltage loss caused by the wire resistance. Refer to the

National Electrical Code to determine proper wire size for your circuit.

If the wiring is not adequate, the input voltage will drop by 20 to 40 volts at

startup. Low voltage or an overloaded circuit can result in sluggish starting that

causes the circuit breaker to trip, especially in cold conditions.

GROUNDING INSTRUCTIONS

This product must be connected to a grounded, metallic, permanent wiring

system, or an equipment - grounding terminal or lead on the product.

11 - ENG

MOTOR RESET SWITCH AND WIRING

I WARNING

pressing the reset switch to restart the motor.

If the motor shuts down because of overload, wait 10–15 minutes so the motor

can cool down, then press (NEVER force) the reset switch (see A) to restart the

motor (see Fig. 5).

Note: On stationary models not supplied with a power cord, the electrical power

must be wired into the pressure switch by a Licensed Electrician.

Ensure that all guards and shrouds are in place before

Fig. 5

A

OPERATING INSTRUCTIONS

BREAK-IN OF THE PUMP (Fig. 6)

1. Make sure the power is connected at the power panel.

2. Check the oil level in the pump (see “Checking the Oil” in the maintenance

section).

3. Open the petcock (see F).

I WARNING

may cause eye injury. Wear safety goggles when opening petcock.

Escaping air and moisture can propel debris that

4. Turn ON the main power disconnect switch. Turn the pressure switch to the

AUTO position (see D). The motor should start. Allow the compressor to run

for 30 minutes, to break in the internal parts.

NOTE: After about 30 minutes, if the unit does not operate properly, SHUT

DOWN IMMEDIATELY, and contact a qualified service center. DO NOT

return the unit to the store where it was purchased.

5. Shut OFF the main power disconnect. Close the petcock (see E). Connect

your air hose(s) to the tank outlet(s).

NOTE: As compressed air is used, the pressure switch will restart the motor

automatically to supply more compressed air to the tank.

12- ENG

Fig. 6

F

OPEN

13 - ENG

CLOSE

E

OPERATING INSTRUCTIONS

DAILY START-UP (Fig. 6)

1. Check the oil level in the pump (see “Checking the Oil” in the maintenance

section).

2. Make sure the main power disconnect switch is shut OFF.

3. Close the tank petcock (see E).

4. Turn ON the main power disconnect switch. Turn the pressure switch to the

AUTO position (see D). The pump will start filling the tank with air. When the

air pressure in the tank reaches the level preset at the factory, the pressure

switch will turn off the electric motor. As air is used and the pressure level in

the tank drops, the pressure switch will start the motor and the pump will

begin refilling the tank.

I WARNING

prevent burns or other injuries, DO NOT touch the pump or transfer

tube while the pump is running. Allow it to cool before handling or

servicing. Keep children away from the compressor at all times.

NOTE: If the unit does not operate properly, SHUT DOWN IMMEDIATELY, and

contact a qualified service center.

High temperatures are generated by the pump. To

SHUTDOWN (Fig. 6)

1. Turn the pressure switch to the OFF position (see C).

2. Shut OFF the main power disconnect switch.

3. Reduce pressure in the tank through the outlet hose. You can also pull the

tank safety valve ring (see G) and keep it open to relieve pressure in the

tank.

I WARNING

may cause eye injury. Wear safety goggles when opening petcock.

4. Open the petcock (see F) to allow moisture to drain from the tank.

Escaping air and moisture can propel debris that

14- ENG

MAINTENANCE

MAINTENANCE

I WARNING

before performing any service on the air compressor.

Regular maintenance will ensure trouble–free operation. Your electric powered

air compressor represents high–quality engineering and construction; however,

even high–quality machinery requires periodic maintenance. The items listed

below should be inspected on a regular basis

DRAINING THE TANK (Fig. 6)

To avoid personal injury, always shut off and unplug the

compressor and relieve all air pressure from the system

I WARNING

prevent corrosion of the tank from the inside, this moisture must

be drained at the end of every workday.

I WARNING

air pressure in the system and open the petcock on the bottom of

the tank to drain.

Condensation will accumulate in the tank. To

Be sure to wear protective eyewear. Relieve the

CHECKING THE OIL

Check the level of oil in the pump with the sight glass. The pump oil level must

be between A and B (See Fig. 7). Do not overfill or underfill.

NOTE: Use synthetic blend, non-detergent air compressor oil.

CHANGING THE OIL

Remove the oil plug (C) (Fig. 7) and drain the oil until it slows to a drip, then

close. Add oil to the pump by first removing the breather plug (E). Add oil until

the level viewed through the sight glass (D) is between FULL (A) and ADD (B).

Never overfill or underfill the pump.

NOTE: The compressor is pre-filled with synthetic oil. Use synthetic blend, nondetergent air compressor oil.

A = Full

B = Add

C = Oil drain plug

D = Oil level sight glass

E = Oil fill plug

15 - ENG

Fig. 7

MAINTENANCE

BELT TENSION AND PULLEY ALIGNMENT

I WARNING

compressor and relieve all air pressure from the system before performing

any service on the air compressor.

NOTE: Drive belt tensioning and pulley alignment are done at the same time.

They are discussed separately for clarity.

ADJUSTING DRIVE BELT TENSION

Proper belt tension and pulley alignment must be maintained for maximum drive

efficiency and belt life. The correct tension exists if a deflection (see A) of 1/2”

(13 mm) occurs by placing 5 lb (2.3 kg) of force (see B) midway between the

motor pulley and the pump flywheel (See Fig. 8). This deflection can be adjusted

by the following procedure. The pulley should be carefully aligned with the

flywheel, and all setscrews should be kept tight.

1. Remove the belt guard.

2. Loosen the motor mounting bolts.

3. Shift the motor to the point where the correct deflection exists.

4. Retighten the motor mounting bolts.

5. Check to ensure that the tension remained correct.

To avoid personal injury, always shut off and unplug the

6. Reinstall the belt guard. All moving parts must be guarded.

16- ENG

Fig. 8

MAINTENANCE

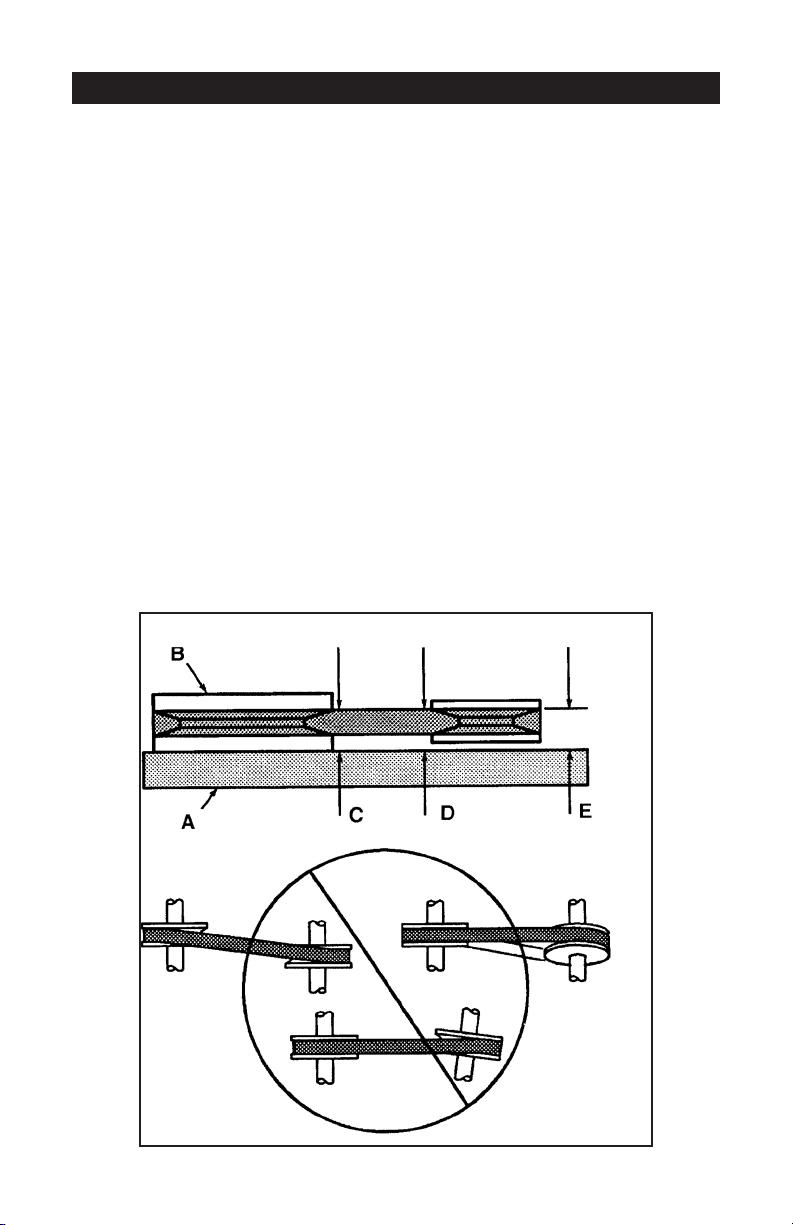

PULLEY ALIGNMENT

To check pulley alignment, remove the belt guard and place a straightedge

(see A) against the pump flywheel (see B) (See Fig. 9). Measure and record the

distance from the straightedge to the edge of the drive belt at point C. Then

measure the distance from the straightedge to the edge of the drive belt again

at points D and E. Both distances should be the same as at point C. If D or E

are different from C, there is a misalignment which must be corrected before

the compressor is run. To correct a pulley misalignment, use the following

procedure.

1. Remove the belt guard.

2. Loosen the motor mounting bolts.

3. Loosen the setscrew on the motor pulley.

4. Align the motor pulley with the pump flywheel (C = D = E).

5. Retighten the motor pulley setscrew.

6. Adjust the proper belt tension.

7. Retighten the motor mounting bolts.

8. Reinstall the belt guard. All moving parts must be guarded.

17 - ENG

Fig. 9

MAINTENANCE

CLEANING THE AIR FILTER

A dirty air filter will reduce the compressor’s performance and life. To avoid

any internal contamination of the pump, the filter should be cleaned frequently,

and replaced on a regular basis. Felt filters should be cleaned in warm, soapy

water, rinsed, and allowed to air dry before reinstallation. Paper filters should be

replaced when dirty. Do not allow the filter to become filled with dirt or paint. If

the filter becomes filled with paint, it should be replaced. Direct exposure to dirty

conditions or painting areas will void your warranty.

CHECKING THE RELIEF VALVE

Pull the relief valve daily to ensure that it is operating properly and to clear the

valve of any possible obstructions.

TESTING FOR LEAKS

Check that all connections are tight. A small leak in any of the hoses, transfer

tubes, or pipe connections will substantially reduce the performance of your air

compressor. If you suspect a leak, spray a small amount of soapy water around

the area of the suspected leak with a spray bottle. If bubbles appear, repair or

replace the faulty component. Do not overtighten any connections.

STORAGE

Before storing the compressor for a prolonged period, use an air blow gun to

clean all dust and debris from the compressor. Disconnect the power cord and

coil it up. Pull the pressure relief valve to release all pressure from the tank. Drain

all moisture from the tank. Clean the filter element and filter housing; replace the

element if necessary. Drain the oil from the pump crankcase and replace it with

new oil. Cover the entire unit to protect it from moisture and dust.

SERVICE INTERVAL

Perform the following maintenance at the intervals indicated below.

Inspect and clean air filter ..........................................................................Daily

Check pump oil level ...................................................................................Daily

Change pump oil .................................................... Every 100 operating hours

Use synthetic blend, non-detergent air compressor oil.

Operate the pressure relief valves .............................................................Daily

Check belt tension ................................................. Every 100 operating hours

Drain tank .....................................................................................................Daily

Check and tighten all bolts .................................. .Every 100 operating hours

(Do not overtighten)

18- ENG

TROUBLESHOOTING

Note: Troubleshooting problems may have similar causes and solutions.

PROBLEM POSSIBLE CAUSE SOLUTION

Excessive current

draw trips circuit

breaker of motor reset

switch

Compressor stalls Low voltage motor Furnish adequate power.

Low discharge

pressure

Compressor pump

knocking

Low voltage/motor

overload

Drive belt too tight Readjust belt tension

Restricted air passages Inspect and replace

Bad check valve Replace the check

Seized pump Contact authorized

Air leaks Tighten or replace

Leaking valves Contact authorized

Restricted air intake Clean or replace air filter

Blown gaskets Contact authorized

Worn piston rings or

cylinder

Loose engine pulley or

compressor flywheel

Low oil level in pump

crankcase

Excess carbon on valves

or top of piston

Check that power

supply is adequate and

that compressor is on

a dedicated circuit. If

using extension cord,

try using without.

If compressor is

connected to a circut

protected by a fuse, use

dual element time delay

fuses (Buss Fusetron

type “T” only).

transfer tubes or

check valve, as

required.

valve.

service center.

leaking fittings or

connections. Do not

overtighten.

service center.

element(s).

service center.

Contact authorized

service center.

Retighten pulley

and flywheel. Check

alignment.

Keep oil at proper level

at all times.

Contact authorized

service center.

19 - ENG

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Oil in discharge air Worn piston rings or

cylinder

Restricted air intake Clean or replace the air

Oil level too high Reduce to proper level.

Overheating Poor ventilation Relocate compressor to

Dirty cooling surfaces Clean all cooling

Restricted air passages Replace transfer tubes

Excessive belt wear Pulley out of alignment Realign pulley with

Improper belt tension Readjust.

Pulley wobbles Replace the pulley and

Compressor

won’t start in cold

temperatures

Too much back pressure

in tank

40W oil in crankcase Use synthetic blend,

Compressor too cold Move compressor to a

Contact authorized

service center.

filter element(s).

an area with cool, dry,

well circulated air, at

least 12 in. from nearest

wall.

surfaces thoroughly.

and/or unloader.

compressor flywheel.

check for a damaged

crankshaft or flywheel.

Open petcock when

starting motor.

nondetergent

air compressor oil.

warmer location.

20- ENG

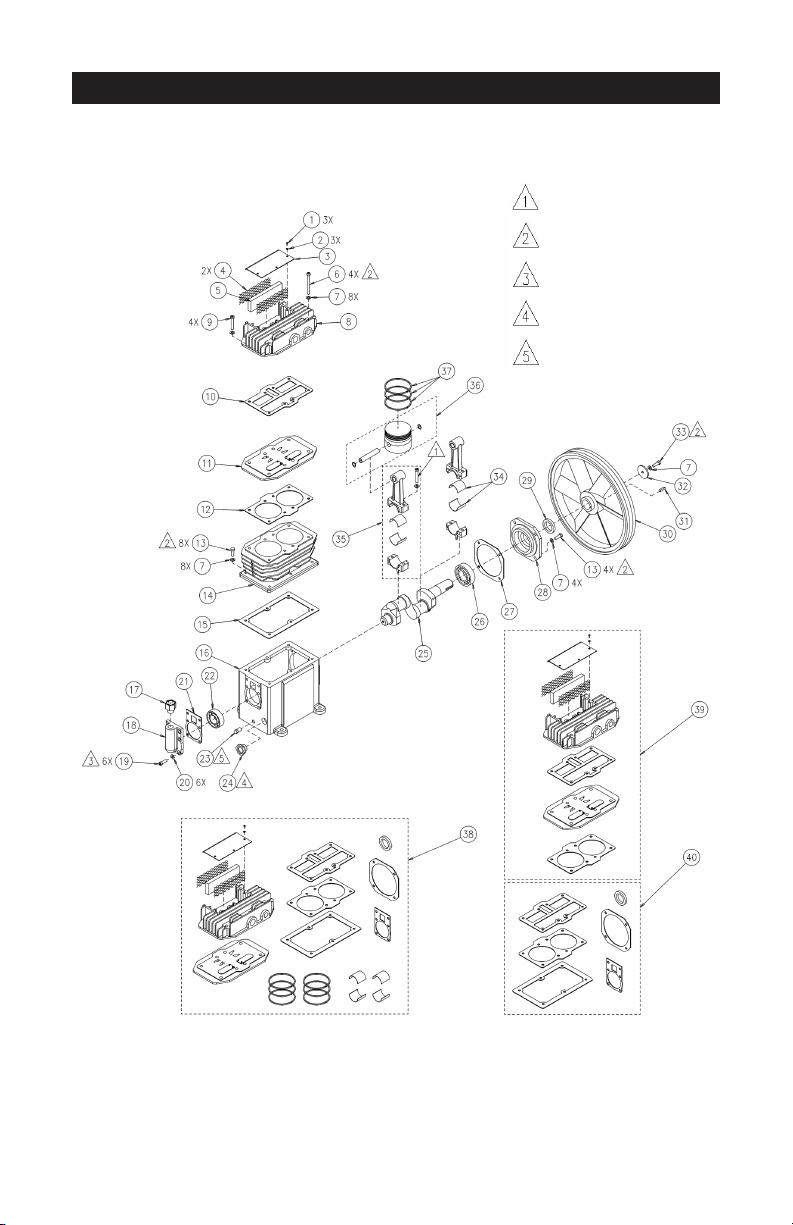

PARTS DRAWING

Notes:

Torque to 17-24 lb-in.

Torque to 125-150 lb-in.

PARTS LIST

Item Part No Qty Description

1 032-0025 1 Gauge, 300# 1/4” bottom connect

2 034-0226 1 Switch, pressure

includes items 3-4 & 7

3 071-0033 1 Strain relief

4 061-0216 1 Screw

5 136-0005 1 Valve, ASME

6 N/A 1 Plug, 1/4”

7 136-0090 1 Valve, bleeder

*N/A - These are standard parts available at your local hardware store.

21 - ENG

PARTS DRAWING

22- ENG

Note: Torque to

85-90 lb-in.

Note: Tighten

compression nut

handtight plus

1 full turn.

PARTS LIST

Item Part No Qty Description

1 125-0151 1 Beltguard (outer)

2 061-0114 5 Plastite screw

3 N/A 5 Bolt, 5/16-18 x 1/2

4 125-0152 1 Beltguard (inner)

5 N/A 1 Setscrew

6 146-0016 1 Key

7 007-0037 1 V-Belt, 4L-530

8 006-0108 1 Pulley

9 026-0188 1 Cord, interconnect

10 N/A 4 Bolt, 5/16-18 x .50

11 021-0242 1 Tank assembly

(includes items 11A-13)

11A 512-0041 1 Bushing, 2” NPSM x 1/4” NPT

513-0001 1 O-Ring 2”

11B 072-0006 1 Petcock

12 098-3870 1 Label, warning

13 512-0042 1 Bushing, 2” NPSM x 3/8” NPT

513-0001 1 O-Ring 2”

14 N/A 4 Bolt, 5/16”-18 x 1-1/4

15 040-0354 1 Pump assembly, 755H

(for pump replacement parts

see pages 24-25)

16 068-0092 1 Connector

17 058-0007 2 Nut, 3/8” O.D. tube

18 145-0313 1 Tube, transfer

19 145-0082 1 Tube, bleeder 1/4” x 28”

20 068-0002 1 Connector

21 031-0066 1 Check Valve, 1/2” x 3/8”

22 See page 21 1 Manifold assembly

23 N/A 1 Nipple, 1/4” x 2-1/2”

24 160-0342 1 Motor (See capacitor table below)

25 098-2856 1 Label, warning

*N/A - These are standard parts available at your local hardware store.

CAPACITORS

A.O. Smith

motor

capacitors

Better motor

capacitors

Start capacitor Start capacitor

166-0055

A.O. Smith p/n 16230135

166-0184

Better p/n 4080038

cover

166-029

A.O. Smith p/n 103987-01

166-0186

Better p/n 1020002

23 - ENG

Run capacitor Run capacitor

166-0120

A.O. Smith p/n 17586325

166-0185

Better p/n 4080011

cover

166-0121

A.O. Smith p/n 174589-005

166-0186

Better p/n 1020002

PARTS DRAWING

755H Pump

Assembly

Notes:

Torque to 25-27 lb-ft.

Torque to 14-16 lb-ft.

Torque to 9-12 lb-ft.

Torque to 8 lb-ft.

Torque to 5 lb-ft.

24- ENG

PARTS LIST

Item Part No Qty Description

1 N/A 3 Screw, M4 x 8

2 N/A 3 Lock washer, M4

3 042-0112 1 Inlet cover

4 118-0032 2 Screen

5 019-0220 1 Filter, felt

6 N/A 4 Screw, M8x60

7 N/A 16 Lock washer, M8

8 042-0108 1 Head assembly

9 N/A 4 Screw, M8x35

10 046-0283 1 Gasket, head

11 043-0180 1 Valve plate assy

(includes items 10 & 12)

12 046-0282 1 Gasket, cylinder

13 N/A 12 Screw, M8x20

14 050-0061 1 Cylinder

15 046-0281 1 Gasket, crankcase

16 049-0048 1 Crankcase (includes item 22)

17 056-0074 1 Breather

18 077-0185 1 Cap

19 N/A 6 Screw, M6 x 20

20 N/A 6 Lock washer, M6

21 046-0280 1 Gasket

22 051-0099 1 Bearing 205

23 N/A 1 Oil drain plug, 3/8” NPT

24 032-0072 1 Oil sight glass w/o-ring

25 053-0100 1 Crankshaft

26 051-0100 1 Bearing 206

27 046-0284 1 Gasket

28 077-0172 1 Carrier

29 046-0285 1 Oil seal

30 044-0064 1 Flywheel, 12” A groove

31 146-0026 1 Key, 5MM x 5 MM

32 N/A 1 Flywheel washer

33 N/A 1 Screw, M8 x 25

34 051-0098 2 pr Insert bearing

35 047-0086 2 Rod

36 048-0116 2 Piston assembly

37 054-0235 2 Ring Set

** Items are not available as replacement parts.

*N/A - These are standard parts available at your local hardware store.

Available Service Kits

Part No Description

38 165-0264 Overhaul kit

includes items 1-5, 8, 11, 34, 37 and 40

39 042-0116 Head and valve plate assy

includes items 1-5, 8, 10, 11 and 12

40 046-0279 Gaskets, complete set

includes items 10, 12, 15, 21, 27 and 29

040-0354 Pump assembly

includes items 1-37 excluding 30-33

25 - ENG

LIMITED WARRANTY

Porter-Cable Industrial Tools are warranted from date of purchase.

2 Year – Limited warranty on oil-lubricated air compressor pumps.

1 Year – Limited warranty on all other air compressor components.

This warranty is not transferable to subsequent owners.

Porter-Cable will repair or replace, without charge, at Porter-Cable’s option, any

defects due to faulty materials or workmanship. For further detail of warranty

coverage and warranty repair information, call 1-(888)-895-4549 or visit portercable.com. This warranty does not apply to accessories or damage caused

where repairs have been made or attempted by others. This warranty also does

not apply to merchandise sold by PORTER-CABLE which has been manufactured by and identified as the product of another company, such as gasoline

engines. Such manufacturer’s warranty, if any, will apply. ANY INCIDENTAL,

INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE OR EXPENSE THAT

MAY RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE

PRODUCT IS NOT COVERED BY THIS WARRANTY. Some states do not

allow the exclusion of limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. IMPLIED WARRANTIES,

INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF

ORIGINAL PURCHASE. Some states do not allow limitations on how long an

implied warranty lasts, so the above limitations may not apply to you.

What the Company Will Do: (the company) will cover parts and labor to rem-

edy substantial defects due to materials and workmanship during the first year

of ownership, with the exceptions noted below. Parts used in repair of whole

goods or accessories are warranted for the balance of the original warranty

period.

What is not covered Under This Warranty? Failures by the original retail

purchaser to install, maintain, and operate said equipment in accordance with

standard industry practices. Modifications to the product, or tampering with

components, or failure to comply with the specific recommendations of the

Company set forth in the owner’s manual, will render this warranty null and

void. The Company shall not be liable for any repairs, replacements, or adjustments to the equipment, or any costs for labor performed by the purchaser

without the Company’s prior written approval. The effects of corrosion, erosion,

surrounding environmental conditions, cosmetic defects, and routine maintenance items, are specifically excluded from this warranty. Routine maintenance

items such as: oil, lubricants, and air filters, as well as changing oil, air filters,

belt tensioning, etc… fall under the owner’s responsibility. Additional exclusions

include: freight damage, failures resulting from neglect, accident, or abuse,

induction motors when operated from a generator, oil leaks, air leaks, oil consumption, leaky fittings, hoses, petcocks, bleeder tubes, and transfer tubes.

• Thefollowingcomponentsareconsiderednormalwearitemsandare

not covered after the first year of ownership: Belts, sheaves, flywheels,

26- ENG

check valves, pressure switches, air unloaders, throttle controls,

electric motors, brushes, regulators, o-rings, pressure gauges, tubing,

piping, fittings, fasteners, wheels, quick couplers, gaskets, seals, air

filter housings, piston rings, connecting rods, and piston seals.

• Labor,servicecalls,andtravelcharges,arenotcoveredafterthefirst

year of ownership on stationary compressors (compressors without

handles, or wheels). Repairs requiring overtime, weekend rates, or any

other charges beyond the standard shop labor rate are not covered.

• Timerequiredfororientationtrainingfortheservicecentertogain

access to the product, or additional time due to inadequate egress.

• Damagecausedbyincorrectvoltage,improperlywired,orfailureto

have a certified licensed electrician install the compressor, will render

this warranty null and void.

• Damagecausedfrominadequatefiltermaintenance.

• Pumpwearorvalvedamagecausedbyusingoilnotspecified.

• Pumpwearordamagecausedbyanyoilcontamination.

• Pumpwearorvalvedamagecausedbyfailuretofollowproper

maintenance guidelines.

• Operationbelowproperoilleveloroperationwithoutoil.

• GasEngines,ifproductisequippedwithagasengine,seeengine

manual for specific engine manufacturer’s warranty coverage.

Parts purchased separately: The warranty for parts purchased separately

such as: pumps, motors, etc., are as follows:

From Date of Purchase

• Allsingle&twostagepumps 1year

• Electricmotors 90days

• Universalmotor/pump 30days

• Allotherparts 30days

• Noreturnauthorizationwillbeissuedforelectricalcomponentsonce

items are installed.

How do You Get Service? In order to be eligible for service under this war-

ranty you must be the original retail purchaser, and provide proof of purchase

from one of the Company’s dealers, distributors, or retail outlet stores. Portable

compressors or components must be delivered, or shipped, to the nearest

Authorized Service Center. All associated freight costs and travel charges must

be borne by the consumer. Please call our toll free number 1-888-895-4549 for

assistance.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY

ALSO HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF

ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE.

ALL IMPLIED WARRANTIES, INCLUDING ANY WARRANTY OF

27 - ENG

Loading...

Loading...