Porter-Cable PTS2 User Manual

IMPORTANT

Please make certain that the person who is

to use this equipment carefully reads and

understands these instructions before

starting operations.

Part No. D22719-028-3

High Speed Sander

Lijadora de alta

velocidad

IMPORTANT

Veuillez vous assurer que la personne qui

utilise cet outil lit attentivement et comprend

ces instructions avant de commencer à utiliser

l'outil.

Ponceuse haute vitesse

IMPORTANTE

Asegúrese de que la persona que va a usar esta

herramienta lea cuidadosamente y comprenda

estas instrucciones antes de empezar a

operarla.

ESPAÑOL: PÁGINA 9

FRANÇAIS: PAGE 17

Copyright © 2002 Porter-Cable Corporation

Instruction manual

Manual de

Instrucciones

Manuel d'instructions

MODEL PTS2

MODÈLE PTS2

MODELO PTS2

To learn more about Porter-Cable visit

our website at:

http://www.porter-cable.com

Pour de plus amples renseignements

concernant Porter-Cable, consultez

notre site Web à l'adresse suivante:

http://www.porter-cable.com

Para obtener más información sobre

Porter-Cable, visite nuestro sitio web en:

http://www.porter-cable.com

2- ENG

D22719

• Air powered equipment and power tools are capable of

propelling materials such as fasteners, metal chips, saw

dust, and other debris at high speed, which could result

in serious eye injury.

• Tool attachments can become loose or break and fly

apart propelling particles at the operator and others in

the work area.

• Abrasive tools such as sanders and grinders, rotating

tools such as drills, and impact tools such as nailers,

staplers, wrenches, hammers, and reciprocating saws

are capable of generating sparks which could result in

ignition of flammable materials.

• Never operate tools near flammable substances such

as gasoline, naptha, cleaning solvents, etc.

• Work in a clean, well ventilated area free of combustible

materials.

• Never use oxygen, carbon dioxide or other bottled

gases as a power source for air tools.

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF FIRE OR EXPLOSION

• Exceeding the maximum pressure rating of tools or

accessories could cause an explosion resulting in serious injury.

• Use compressed air regulated to a maximum pressure

at or below the rated pressure of any attachments.

• Never connect to an air source that is capable of

exceeding 200 psi.

• Always verify prior to using the tool that the air source

has been adjusted to the rated air pressure range.

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known (to the State of California) to cause

cancer, birth defects or other reproductive harm. Some example of these chemicals are:

●●

lead from lead-based paints

●●

crystalline silica from bricks and cement and other masonry products

●●

arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment,

always wear MSHA/NIOSH approved, properly fitting face mask or respirator when using such tools.

When using air tools, basic safety precautions should always be followed to reduce the risk of personal

injury.

SAFETY GUIDELINES - DEFINITIONS

indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

indicates a potentially hazardous situation which, if not

avoided,may result in minor or moderate injury

used without the safety alert symbol indicates potentially

hazardous situation which, if not avoided, may result in

property damage.

This manual contains

information that is

important for you to know and

understand. This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To

help you recognize this information, we use the symbols below.

Please read the manual and pay

attention to these sections.

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN

SERIOUS INJURY AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND

OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.WHEN USING AIR TOOLS, BASIC

SAFETY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE RISK OF PERSONAL

INJURY.

SAVE!

IMPORTANT SAFETY INSTRUCTIONS

SAVE!

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

3- ENG

D22719

• A wrench or a key that is left attached to a rotating part

of the tool increases the risk of personal injury.

• Tools left unattended, or with the air hose attached can

be activated by unauthorized persons leading to their

injury or injury to others.

• Air tools can propel fasteners or other materials

throughout the work area.

• Air tools can become activated by accident during

maintenance or tool changes.

• Remove air hose when tool is not in use and store tool

in secure location away from reach of children and or

untrained users.

• Use only parts, fasteners, and accessories

recommended by the manufacturer.

• Keep work area clean and free of clutter. Keep children

and others away from work area during operation of

the tool.

• Keep work area well lit.

• Remove air hose to lubricate or add grinding

attachments, sanding discs, drills, etc. to the tool.

• Never carry the tool by the hose.

• Avoid unintentional starting. Don't carry hooked-up tool

with finger on trigger.

• Repair servicing should be done only by an authorized

service representative.

• Using inflator nozzles for duster applications can cause

serious injury.

• DO NOT use inflator nozzles for duster applications.

• Remove adjusting keys and wrenches before turning

the tool on.

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF INJURY

• Always wear MSHA/NIOSH approved, properly fitting

face mask or respirator when using such tools.

• Long term exposure to noise produced from the operation of air tools can lead to permanent hearing loss.

• Always wear ANSI S3.19 hearing protection.

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF LOSS OF HEARING

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK TO BREATHING INHALATION HAZARD

• Always work in a clean, dry, well ventilated area.• Some materials such as adhesives and tar, contain

chemicals whose vapors could cause serious injury

with prolonged exposure.

• Abrasive tools, such as grinders, sanders, and cut-off

tools generate dust and abrasive materials which can

be harmful to human lungs and respiratory system.

• Air tools can cause the workpiece to move upon contact leading to injury.

• Loss of control of the tool can lead to injury to self or

others.

• Use clamps or other devices to prevent movement.

• Never operate tool while under the influence of drugs

or alcohol.

• Don't overreach. Keep proper footing and balance at all

times.

• Keep handles dry, clean, and free from oil and grease.

• Stay alert. Watch what you are doing. Use common

sense. Do not operate tool when you are tired.

• Poor quality, improper, or damaged tools such as

grinding wheels, chisels, sockets, drills, nailers,

staplers, etc., can fly apart during operation, propelling

particles throughout the work area causing serious

injury.

• Always use tool attachments rated for the speed of the

power tool.

• Never use tools which have been dropped, impacted or

damaged by use.

• Use only impact grade sockets on an impact wrench.

• Do not apply excessive force to the tool, let the tool

perform the work.

• Fasteners could ricochet or be propelled causing

serious injury or property damage.

• Never point discharge of tool at self or others.

• Do not pull trigger unless tool contact safety device is

against work surface.

• Never attempt to drive fasteners into hard surfaces

such as steel, concrete, or tile.

• Take care to avoid driving a fastener on top of another

fastener.

• Position tool carefully so that fasteners will be delivered

to the proper location.

4- ENG

D22719

• Tools which cut, shear, drill, staple, punch, chisel, etc.

are capable of causing serious injury.

• Tools which contain moving elements, or drive other moving tools, such as grinding wheels, sockets, sanding discs,

etc. can become entangled in hair, clothing, jewelry and

other loose objects, resulting in severe injury.

• Never wear loose fitting clothes, or apparel which

contains loose straps or ties, etc. which could become

entangled in moving parts of the tool.

• Remove any jewelry, watches, identifications, bracelets,

necklaces, etc. which might become caught by the

tool.

• Keep hands away from moving parts. Tie up or cover

long hair.

• Always wear proper fitting clothing and other safety

equipment when using this tool.

• Keep the working part of the tool away from hands and

body.

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF ENTANGLEMENT

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF CUT OR BURNS

• Improperly maintained tools and accessories can cause

serious injury.

Use only accessories identified by the manufacturer to

be used with specific tools.

• Use of an accessory not intended for use with the

specific tools, increases the risk of injury to persons.

• Maintain the tool with care.

• Keep a cutting tool sharp and clean. A properly

maintained tool, with sharp cutting edges reduces the

risk of binding and is easier to control.

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF INJURY (continued)

• Using air tools to attach electrical wiring can result in

electrocution or death.

• Never use nailer/staplers to attach electrical wiring

while energized.

• Avoid body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerators. There is an

increased risk of electric shock if your body is

grounded.

• Fasteners coming in contact with hidden electrical

wiring could cause electrocution or death.

• This tool is not provided with an insulated gripping

surface. Contact with a “live” wire will also make

exposed metal parts of the tool “live” and can result in

electrocution or death.

HAZARD

WHAT COULD HAPPEN HOW TO PREVENT IT

RISK OF ELETRIC SHOCK

• Thoroughly investigate the workpiece for possible

hidden wiring before performing work.

• Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that affects

the tool’s operation. If damaged, have the tool serviced

before using.

• There is a risk of bursting if the tool is damaged.

5- ENG

D22719

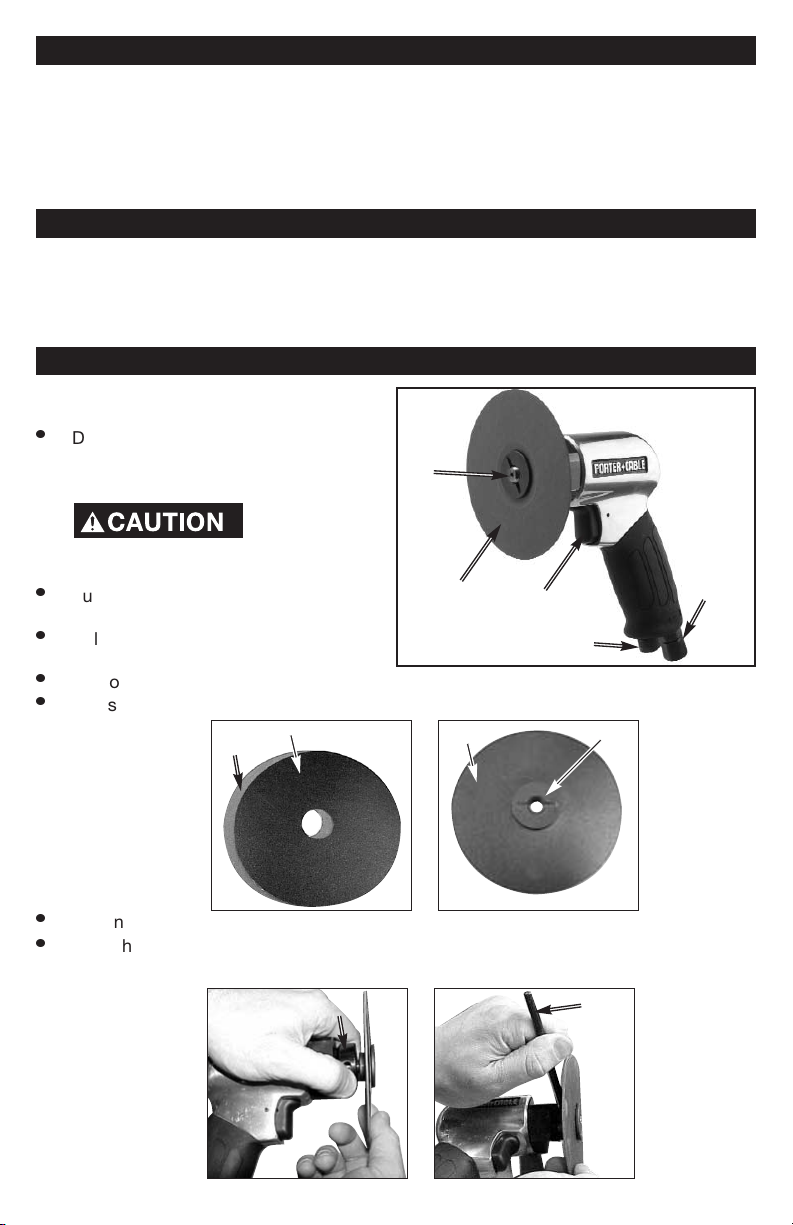

ASSEMBLY

SPECIFICATIONS

OPERATION

Free Speed (No Load) 18,000 RPM

Maximum Working Pressure 90 PSI

Pad Diameter 3”, 4.5”, and 5.5”

Air Inlet 1/4" NPT

Recommended Hose Size 3/8" I.D.

Air Consumption @ 90 PSI 12.5 SCFM

Accessories Required

IMPORTANT: Line pressure or hose inside diameter should be increased to compensate

for unusually long air hoses (over 25 feet). Minimum hose diameter should be 3/8” I.D.

and fittings should have 1/4” NPT thread.

Operation

Before each use:

l

Drain water from air compressor tank

and condensation from air lines. See

air compressor’s operators manual.

Disconnect

the tool from

the air supply before lubricating or

changing sandpaper disc.

l

Lubricate tool, see “Maintenance”

section in this manual.

l

Select the required sandpaper pad

(A) and sandpaper (B).

l

Remove pad nut (C).

l

Press pad nut (C) through sandpaper (B) and sandpaper pad (A).

l

Holding hub (D) assemble pad nut with sandpaper and sandpaper pad.

l

Place holding rod (E) into hole located on hub and tighten securely. NOTE: Holding

rod (E) is used to tighten or loosen hub.

Air Inlet

Pad

Nut

Trigger

Sandpaper

Pad with

Sandpaper

Regulator

Knob

B

A

A,B C

D

E

6- ENG

D22719

MAINTENANCE

l

Connect tool to air hose of recommended size. NOTE: The use of a quick connect

set makes connecting easier.

IMPORTANT: The use of air filters and air line lubricators is

recommended.

To use:

l

Turn air compressor on and allow air tank to fill.

l

7- ENG

D22719

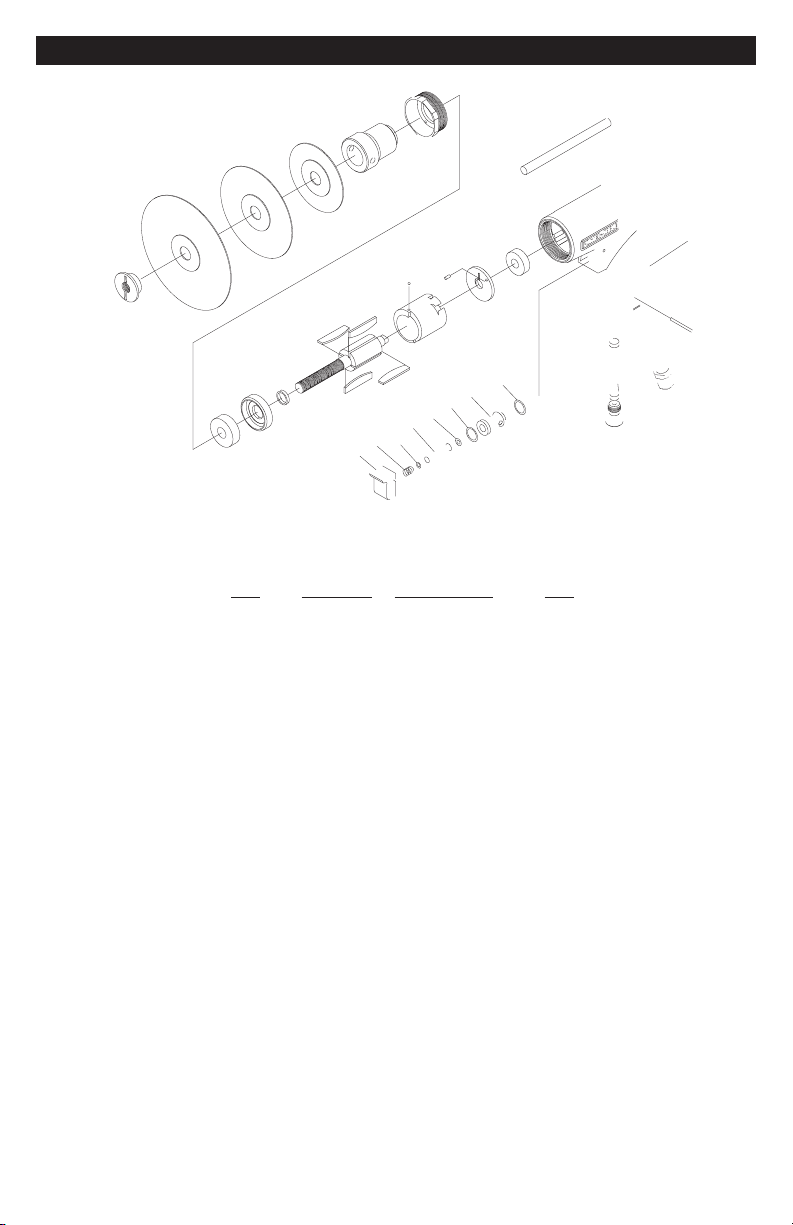

REPAIR PARTS

Ref

No. Part No. Description Qty

1 D25366 Adapter Lock Nut 1

18 + Trigger 1

19 + Spring 1

20 + O-Ring 1

21 + Trigger Pin 1

22 + O-Ring 1

23 + O-Ring 1

24 + Bushing 1

25 + O-Ring 1

31 + Spring Pin 1

32 D25368 Handle Grip 1

33 D25369 Adjust Bar 1

+ Only available in Trigger Repair Kit D25357

Note: Parts not listed are not serviceable.

33

25

24

23

22

21

19

20

18

32

31

8- ENG

D22719

LIMITED WARRANTY

PORTER-CABLE CORPORATION warrants to the original purchaser that all products covered under this warranty are

free from defects in material and workmanship. Products covered under this warranty include air compressors, air tools,

service parts, pressure washers, and generators, which have the following warranty periods:

3 YEARS - Limited warranty on 2-stage oil-free air compressor pumps that operate at 1725 RPM.

2 YEARS - Limited warranty on oil-lubricated air compressor pumps.

1 YEAR - Limited warranty on all other air compressor components.

2 YEARS - Limited warranty on electric generator alternators.

1 YEAR - Limited warranty on other generator components.

2 YEARS - Limited warranty on pneumatic air tools as described in Porter-Cable general catalog.

1 YEAR - Limited warranty on pressure washers used in consumer applications (i.e. personal residential household

usage only).

90 DAY - Pressure washers used for commercial applications (income producing) and service parts.

1 YEAR - Limited warranty on all accessories.

Porter-Cable will repair or replace, at Porter-Cable's option, products or components which have failed within the

warranty period.

Service will be scheduled according to the normal work flow and business hours at the service

center location, and the availability of replacement parts.

All decisions of Porter-Cable Corporation with regard to this

limited warranty shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

RESPONSIBILITY OF ORIGINAL PURCHASER (initial User):

• To process a warranty claim on this product, DO NOT return it to the retailer. The product must be evaluated by an

Porter-Cable Authorized Warranty Service Center. For the location of the nearest Porter-Cable Authorized Warranty

Service Center call 1-888-559-8550, 24 hours a day, 7 days a week.

• Retain original cash register sales receipt as proof of purchase for warranty work.

• Use reasonable care in the operation and maintenance of the product as described in the Owners Manual(s).

• Deliver or ship the product to the nearest Porter-Cable Authorized Warranty Service Center. Freight costs, if any, must

be paid by the purchaser.

• Air compressors with 60 and 80 gallon tanks will be inspected at the site of installation. Contact the nearest Porter-

Cable Authorized Warranty Service Center that provides on-site service calls, for service call arrangements.

• If the purchaser does not receive satisfactory results from the Porter-Cable Authorized Warranty Service Center, the

purchaser should contact Porter-Cable.

THIS WARRANTY DOES NOT COVER:

• Merchandise sold as reconditioned, used as rental equipment, and floor or display models.

• Merchandise that has become damaged or inoperative because of ordinary wear, misuse*, cold, heat, rain, excessive

humidity, freeze damage, use of improper chemicals, negligence, accident, failure to operate the product in

accordance with the instructions provided in the Owners Manual(s) supplied with the product, improper maintenance,

the use of accessories or attachments not recommended by Porter-Cable, or unauthorized repair or alterations.

* An air compressor that pumps air more than 50% during a one hour period is considered misuse because the air

compressor is undersized for the required air demand.

• Repair and transportation costs of merchandise determined not to be defective.

• Costs associated with assembly, required oil, adjustments or other installation and start-up costs.

• Expendable parts or accessories supplied with the product which are expected to become inoperative or unuseable

after a reasonable period of use, including but not limited to sanding disks or pads, saw and shear blades, grinding

stones, springs, chisels, nozzles, o-rings, air jets, washers and similar accessories.

• Merchandise sold by Porter-Cable which has been manufactured by and identified as the product of another

company, such as gasoline engines. The product manufacturer's warranty, if any, will apply.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM

ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT IS NOT COVERED BY THIS WARRANTY. Some

states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you.

• IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE. Some states do not allow

limitations on how long an implied warranty lasts, so the above limitations may not apply to you.

Porter-Cable Corporation

Jackson, TN USA

1-888-559-8550

Loading...

Loading...