Porter-Cable PIN138 Instruction Manual

PIN NAILER

Cloueuse de goupilles

Clavadora

Instruction manual

Manuel d'instructions

Manual de'instrucciones

Française : Page 15

Español: Página 30

www.deltaportercable.com

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

ANTES DE USAR EL PRODUCTO.

LÉASE ESTE INSTRUCTIVO

1 - ENG

PIN138

IMPORTANT SAFETY INSTRUCTIONS

FOR PNEUMATIC TOOLS

SAVE THESE INSTRUCTIONS

below, should be followed to avoid the risk of death or serious injury. Read all instructions

before operating the tool.

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

When using any pneumatic tool, all safety precautions, as outlined

DEFINITIONS - SAFETY GUIDELINES

result in death or serious injury.

Indicates an imminently hazardous situation which, if not avoided, will

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially haz ard ous situation which, if not avoided, may

result in minor or mod er ate injury.

Indicates a practice not related to personal injury which, if not avoid-

ed, may result in property damage.

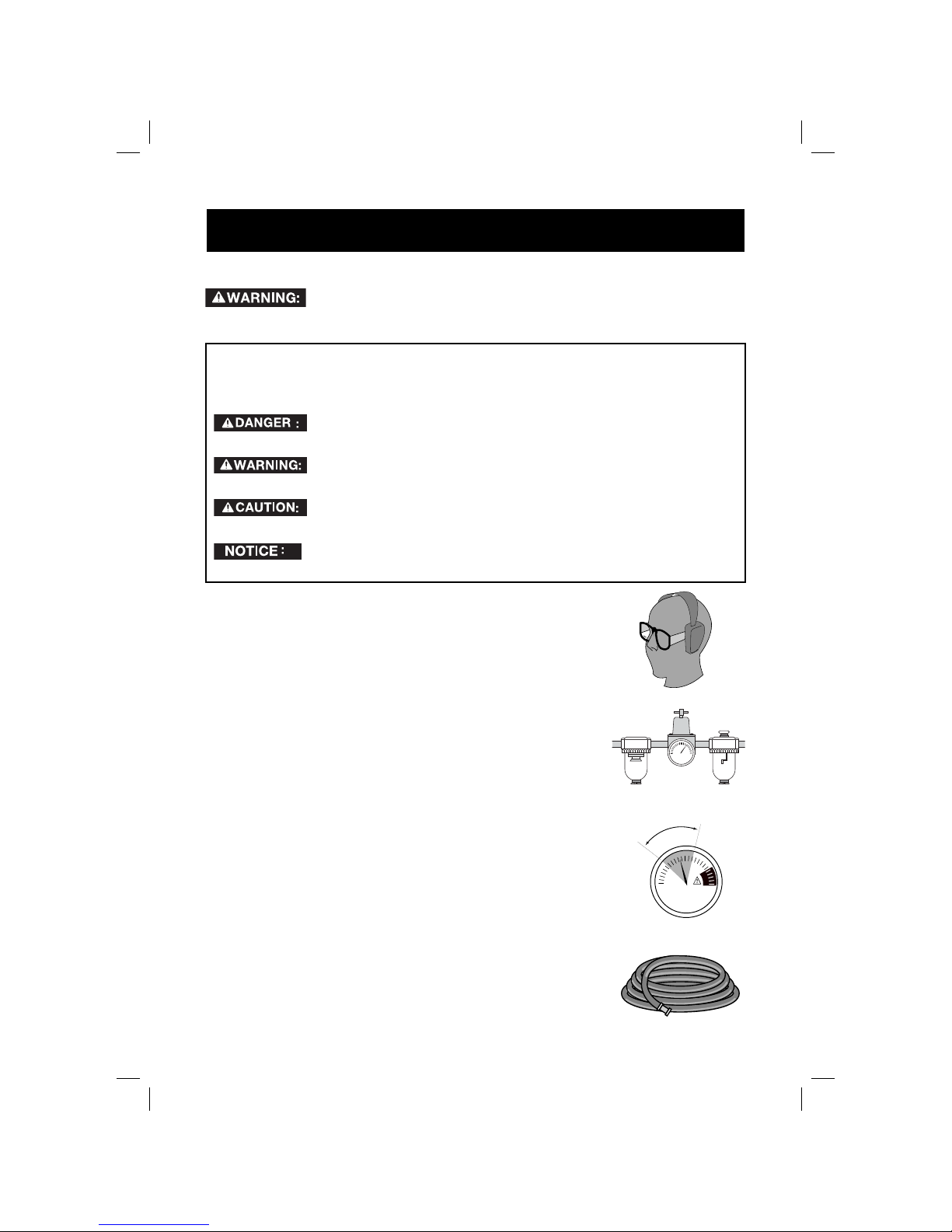

• Actuating tool may result in flying debris, collation

material, or dust which could harm operator’s eyes.

Operator and others in work area MUST wear safety

glasses with side shields. These safety glasses must

conform to ANSI Z87.1 requirements (approved glasses

have “Z87” printed or stamped on them). It is the employer’s

responsibility to enforce the use of eye protection equipment

by the tool operator and other people in the work area.

(Fig.A)

• Always wear appropriate personal hearing and other

protection during use. Under some conditions and

duration of use, noise from this product may contribute

to hearing loss. (Fig. A)

• Use only clean, dry, regulated air. Conden sation from an air

compressor can rust and damage the internal workings of the

tool. (Fig. B)

• Regulate air pressure. Use air pressure compatible with

ratings on the nameplate of the tool. [Not to exceed

100psi (6.9 bar).] Do not connect the tool to a compressor

rated at over 175 psi. The tool operating pressure must

never exceed 175 psi even in the event of regulator failure.

(Fig.C)

• Only use air hose that is rated for a maximum working

pressure of at least 150 psi (10.3 bar) or 150% of the

maximum system pressure, which ever is greater. (Fig.D)

Fig. A

Fig. B

Fig. C

70 psi

4.9 bar

Fig. D

2 - ENG

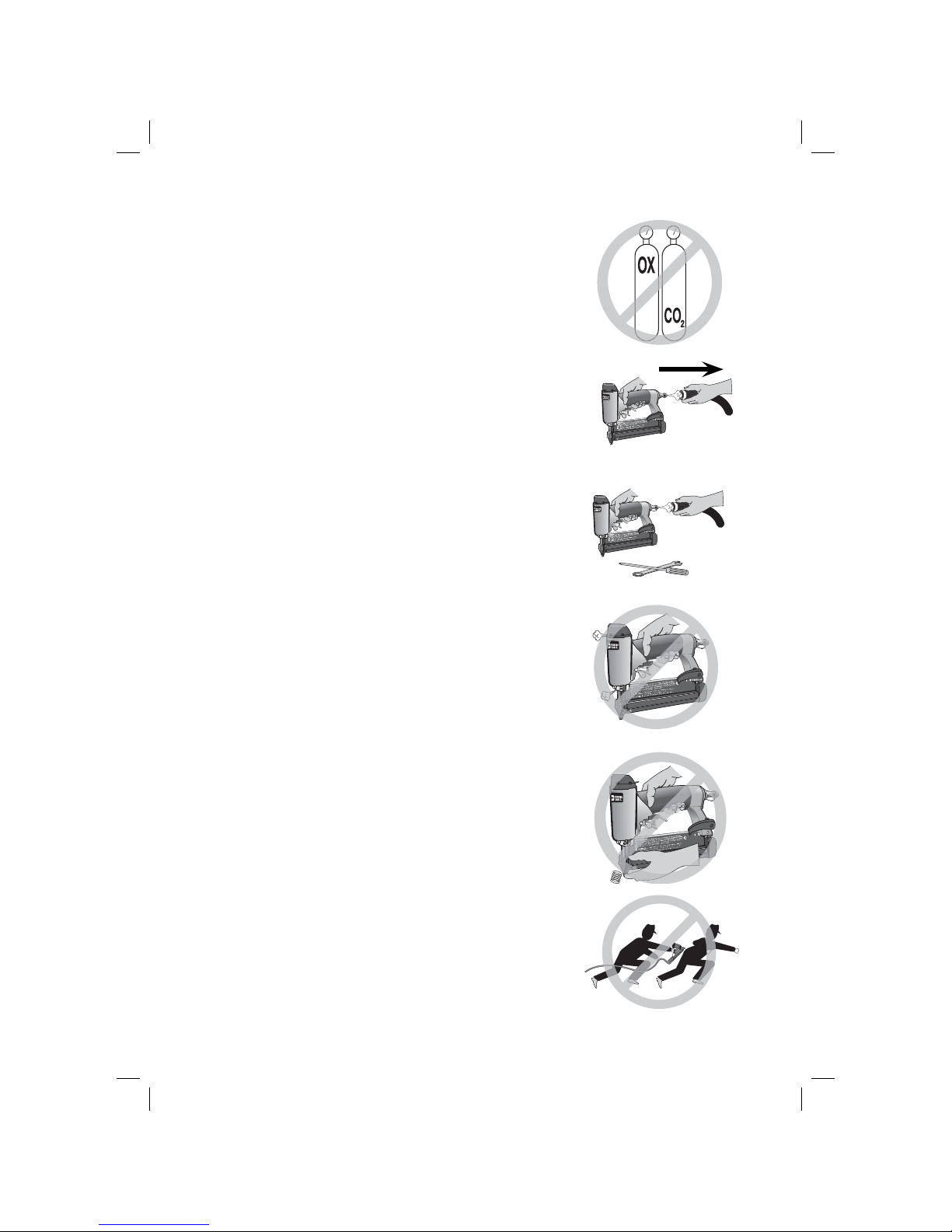

• Do not use bottled gases to power this tool. Bottled

compressed gases such as oxygen, carbon dioxide,

nitrogen, hydrogen, propane, acetylene or air are not

for use with pneumatic tools. Never use combustible

gases or any other reactive gas as a power source for

this tool. Danger of explosion and/or serious personal

injury may result. (Fig. E)

• Use couplings that relieve all pressure from the tool when

it is disconnected from the power supply. Use hose

connectors that shut off air supply from compressor

when the tool is disconnected. (Fig.F)

• Disconnect tool from air supply when not in use. Always

disconnect tool from air supply and remove fasteners

from magazine before leaving the area or passing the

tool to another operator. Do not carry tool to another

work area in which changing location involves the

use of scaffoldings, stairs, ladders, and the like, with

air supply connected. Do not make adjustments,

remove magazine, perform maintenance or clear

jammed fasteners while connected to the air supply.

(Fig. G)

• Connect tool to air supply before loading fasteners to

prevent a fastener from being fired during connection.

The tool driving mechanism may cycle when tool is

connected to the air supply. Do not load fasteners

with trigger or safety trigger depressed to prevent

unintentional firing of a fastener.

• Do not remove, tamper with, or otherwise cause the

tool or trigger to become inoperable. Do not tape or

tie trigger in the on position. Make daily inspections for

free movement of trigger. Uncontrolled discharge could

result.

• Inspect tool before use. Do not operate a tool if

any portion of the tool or trigger is inoperable,

disconnected, altered, or not working properly.

Leaking air, damaged parts or missing parts should

be repaired or replaced before use. Refer to Repairs.

(Fig.H)

• Do not alter or modify the tool in any way. (Fig. I)

• Always assume that the tool contains fasteners.

• Do not point the tool at co-workers or yourself at any

time. No horseplay! Work safe! Respect the tool as a

working implement. (Fig. J)

• Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to

lose control. When tool is not in use, it should be locked

in a safe place, out of the reach of children.

• Remove finger from trigger when not driving

fasteners.

• Never carry tool with finger on trigger. Accidental

discharge could result.

Fig. E

Fig. F

Fig. G

Fig. H

Fig. I

Fig. J

3 - ENG

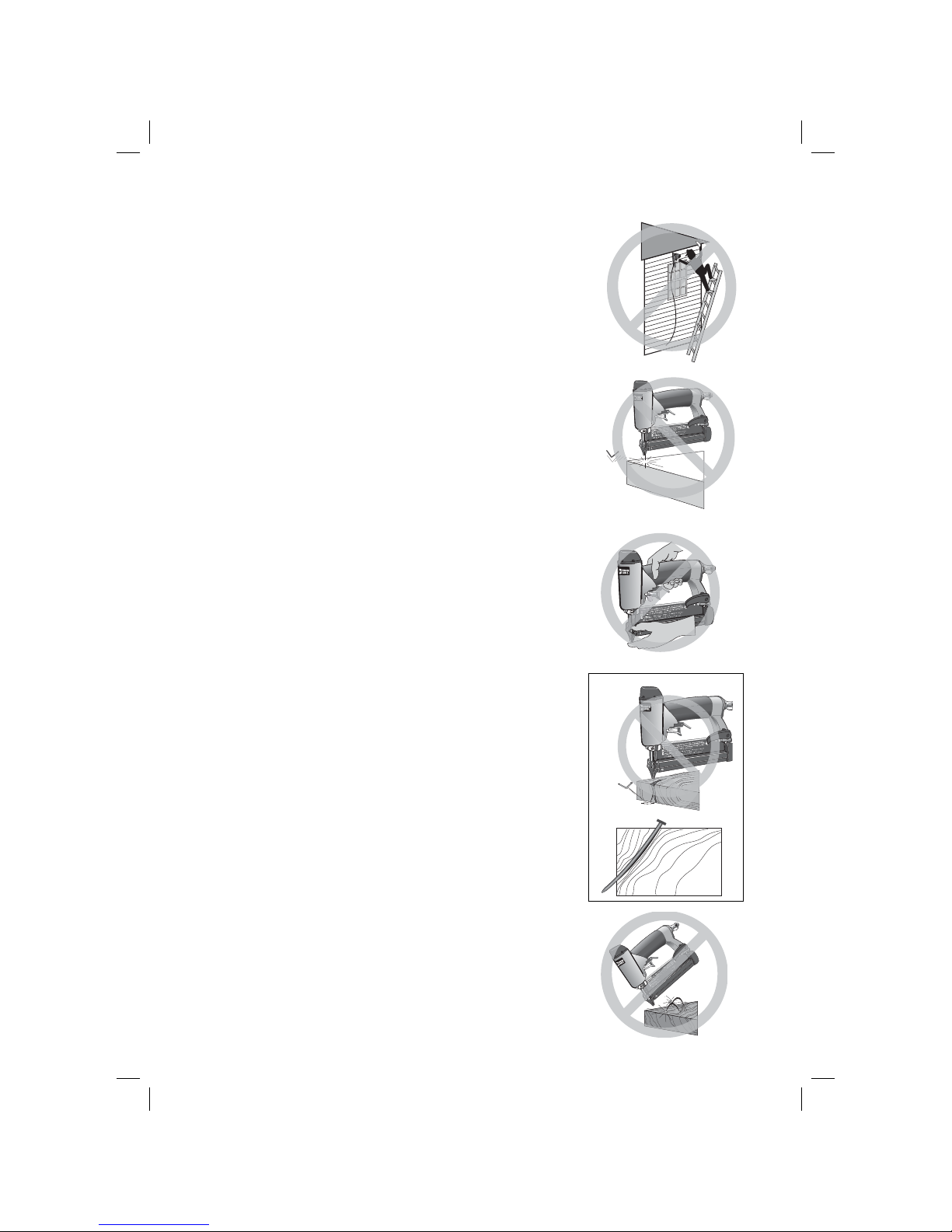

• Do not overreach. Maintain proper footing and balance

at all times. Loss of balance may cause personal injury.

(Fig. K)

• Make sure hose is free of obstructions or snags.

Entangled or snarled hoses can cause loss of balance

or footing.

• Use the tool only for its intended use. Do not discharge

fasteners into open air, concrete, stone, extremely

hard woods, knots or any material too hard for the

fastener to penetrate. Do not use the body of the tool

or top cap as a hammer. Discharged fasteners may follow

unexpected path and cause injury. (Fig. L)

• Always keep fingers clear of nosepiece to prevent injury

from inadvertent release of nails. (Fig. M)

• Refer to the Maintenance and Repairs sections for

detailed information on the proper maintenance of the

tool.

• Always operate the tool in a clean, lighted area. Be

sure the work surface is clear of any debris and be

careful not to lose footing when working in elevated

environments such as rooftops.

• Do not drive fasteners near edge of material. The

workpiece may split causing the fastener to ricochet,

injuring you or a co-worker. Be aware that the nail

may follow the grain of the wood (shiner), causing it to

protrude unexpectedly from the side of the work material.

Drive the nail perpendicular to the grain to reduce risk of

injury. (Fig. N)

• Do not drive nails onto the heads of other fasteners

or with the tool at too steep an angle. Personal injury

from strong recoil, jammed fasteners, or ricocheted

nails may result. (Fig. O)

• Be aware of material thickness when using the nailer. A

protruding nail may cause injury.

• Be aware that when the tool is being utilized at

pressures on the high end of its operating range,

nails can be driven completely through thin or very

soft work material. Make sure the pressure in the

compressor is set so that nails are set into the material

and not pushed completely through. (Fig. P)

• Keep hands and body parts clear of immediate work

area. Hold workpiece with clamps when necessary to

keep hands and body out of potential harm. Be sure

the workpiece is properly secured before pressing the

nailer against the material. (Fig. Q)

• Do not use tool in the presence of flammable dust, gases

or fumes. The tool may produce a spark that could ignite

gases causing a fire. Driving a nail into another nail may

also cause a spark. (Fig. R)

• Keep face and body parts away from back of the tool

cap when working in restricted areas. Sudden recoil can

result in impact to the body, especially when nailing

into hard or dense material. (Fig. S)

4 - ENG

Fig. K

Fig. L

Fig. M

Fig. N

Fig. O

• Grip tool firmly to maintain control while allowing tool

to recoil away from work surface as fastener is driven.

• Do not actuate the tool unless the tool is placed firmly

against the workpiece. (Fig. T)

• DEPTH ADJUSTMENT: To reduce risk of serious injury

from accidental actuation when attempting to adjust

depth, ALWAYS:

• Disconnect air supply.

• Avoid contact with trigger during adjustments.

• Do not drive nails blindly into walls, floors or other

work areas. Fasteners driven into live electrical wires,

plumbing, or other types of obstructions can result in

injury. (Fig. U)

• Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool

while tired or under the influence of drugs or alcohol.

A moment of inattention while operating power tools may

result in serious personal injury.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other

masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

Use of this tool can generate and/or disburse

dust, which may cause serious and permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure. Direct particles

away from face and body. Always operate tool in wellventilated area and provide for proper dust removal. Use

dust collection system wherever possible.

ALWAYS USE SAFETY GLASSES. Everyday

eyeglasses are NOT safety glasses. Also use face or dust

mask if operation is dusty. ALWAYS WEAR CERTIFIED

SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA respiratory protection.

Before operating this tool, carefully read all instructions

in Important Safety Instructions.

Fig. P

Fig. Q

Fig. R

Fig. S

Fig. T

Fig. U

5 - ENG

Loading...

Loading...