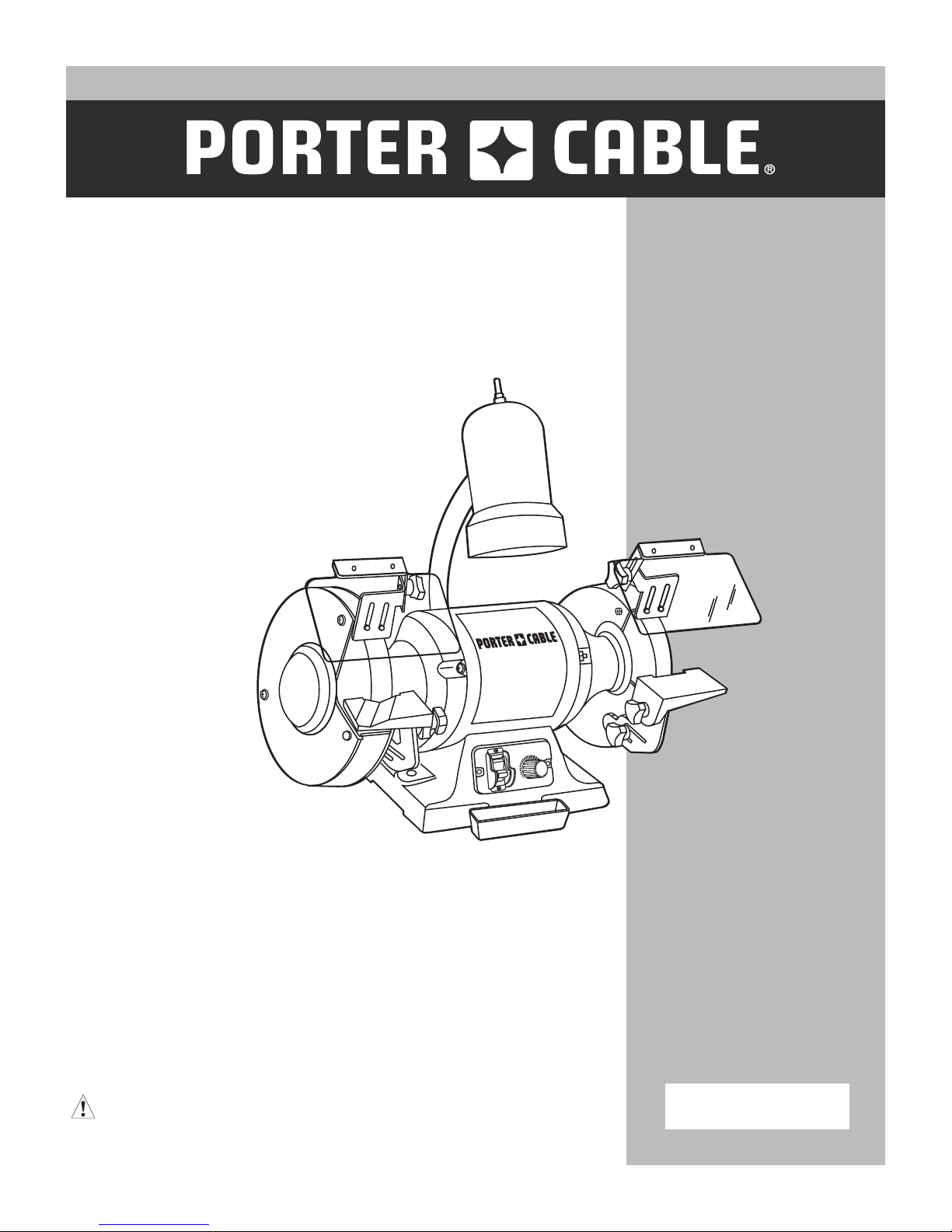

Porter-Cable 6 IN. (150 MM) VARIABLE SPEEDGRINDER WITH WORKLIGHT, PCB575BG, PCB525BG Instruction Manual

N

O

F

F

O

L

H

6 IN. (150 MM) VARIABLE SPEED

GRINDER WITH WORKLIGHT

MEULE À VITESSE VARIABLE DE

150 MM (6 PO) AVEC BALADEUSE

AMOLADORA DE VELOCIDAD

VARIABLE DE 150 MM (6 PULG.)

CON LUZ DE TRABAJO

Instruction Manual

Manuel d’instructions

Manual de instrucciones

www.portercable.com

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

CATALOG NUMBER

PCB525BG

1

TABLE OF CONTENTS

SECTION PAGE

PRODUCT SPECIFICATIONS .......................................................................................................................

CALIFORNIA PROPOSITION 65 ...................................................................................................................

SAFETY GUIDELINES - DEFINITIONS .........................................................................................................

POWER TOOL SAFETY .................................................................................................................................

BENCH GRINDER SAFETY ...........................................................................................................................

ELECTRICAL REQUIREMENTS AND SAFETY ............................................................................................

TOOLS NEEDED FOR ASSEMBLY ...............................................................................................................

CARTON CONTENTS ....................................................................................................................................

KNOW YOUR BENCH GRINDER ..................................................................................................................

ASSEMBLY AND ADJUSTMENTS .................................................................................................................

OPERATION .................................................................................................................................................. 13

MAINTENANCE ............................................................................................................................................. 15

TROUBLESHOOTING GUIDE........................................................................................................................

ACCESSORIES AND ATTACHMENTS ..........................................................................................................

PARTS LIST ...................................................................................................................................................

WARRANTY ...................................................................................................................................................

2

2

3

4

5

7

8

8

9

10

16

17

18

20

PRODUCT SPECIFICATIONS

MOTOR WHEEL

Power source ........ 120 V AC, 60 HZ, 2.5 A Diameter .......................... 6 in. (150 mm)

Horsepower ...........

Speed ....................

Type.......................

Shaft diameter ...... 1/2 in. (12.7 mm)

Switch ....................

1/3 HP

2000 ~ 3400 RPM Hole ................................. 1/2 in. (12.7 mm)

Induction LIGHT BULB (not included) 40 W (maximum)

ON/OFF

Face ................................ 3/4 in. (20 mm)

!

WARNING

To avoid electrical hazards, fire hazards or damage to the tool, use proper circuit protection. Use a separate electrical

circuit for your tools. The grinder is wired at the factory for 110-120 Volt operation. It must be connected to a 120 V,

2.5 AMP branch circuit and use a 2.5 AMP time delay fuse or circuit breaker. To avoid shock or fire, replace power cord

immediately if it is worn, cut or damaged in any way.

CALIFORNIA PROPOSITION 65

!

WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals known to the state of California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemical: work in a well ventilated area, and work with approved safety equipment, such as

those dust masks that are specially designed to filter out microscopic particles. Avoid prolonged contact with

dust from power sanding, sawing, grinding, drilling, and other construction activities. Wear protective clothing

and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

!

WARNING

Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or

other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure.

Direct particles away from face and body.

2010/01

2

Printed in China

SAFETY GUIDELINES - DEFINITIONS

WARNING ICONS

Your power tool and its Instruction Manual may contain “WARNING ICONS” (a picture symbol intended to alert

you to, and/or instruct you how to avoid, a potentially hazardous condition). Understanding and heeding these

symbols will help you operate your tool better and safer. Shown below are some of the symbols you may see.

SAFETY ALERT: Precautions that involve your safety.

PROHIBITION

WEAR EYE PROTECTION: Always wear safety goggles or safety glasses with side shields.

READ AND UNDERSTAND INSTRUCTION MANUAL: To reduce the risk of injury, user and all bystanders

must read and understand instruction manual before using this product.

KEEP HANDS AWAY FROM BLADE: Failure to keep your hands away from the blade will result in serious

personal injury.

SUPPORT AND CLAMP WORK

!

DANGER

!

WARNING

!

CAUTION

CAUTION

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

3

POWER TOOL SAFETY

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THIS POWER TOOL

Safety is a combination of common sense, staying alert

and knowing how to use your power tool.

!

WARNING

To avoid mistakes that could cause serious injury,

do not plug the tool in until you have read and

understood the following.

1. READ and become familiar with the entire

Instruction Manual. LEARN the tool’s

application, limitations and possible hazards.

2. KEEP GUARDS IN PLACE and in working order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning ON.

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

5. DO NOT USE IN DANGEROUS ENVIRONMENTS.

Do not use power tools in damp locations, or expose

them to rain or snow. Keep work area well lit.

6. KEEP CHILDREN AWAY. All visitors and bystanders

should be kept a safe distance from work area.

7. MAKE WORKSHOP CHILD PROOF with padlocks,

master switches or by removing starter keys.

8. DO NOT FORCE THE TOOL. It will do the job better

and safer at the rate for which it was designed.

9. USE THE RIGHT TOOL. Do not force the tool or an

attachment to do a job for which it was not designed.

10. USE PROPER EXTENSION CORDS. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

An undersized cord will result in a drop in line

voltage and in loss of power which will cause the tool

to overheat. The table on page 7 shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier

the cord.

11. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

ANSI Z87.1 could seriously injure you when they

break.

13. WEAR A FACE MASK OR DUST MASK. Sawing

operation produces dust.

14. SECURE WORK. Use clamps or a vise to

hold work when practical. It is safer than

using your hand and it frees both hands to

operate the tool.

15. DISCONNECT TOOLS FROM POWER SOURCE

before servicing, and when changing accessories

such as blades, bits and cutters.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in the OFF position

before plugging the tool in.

17. USE RECOMMENDED ACCESSORIES.

Consult this Instruction Manual for recommended

accessories. The use of improper accessories may

cause risk of injury to yourself or others.

18. NEVER STAND ON THE TOOL. Serious injury

could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

19. CHECK FOR DAMAGED PARTS. Before further

use of the tool, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function

– check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

20. NEVER LEAVE THE TOOL RUNNING

UNATTENDED. TURN THE POWER “OFF”. Do

not walk away from a running tool until the grinding

wheels come to a complete stop and the tool is

unplugged from the power source.

21. DO NOT OVERREACH. Keep proper footing and

balance at all times.

22. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

23. DO NOT use power tool in presence of flammable

liquids or gases.

24. DO NOT operate the tool if you are under the

influence of any drugs, alcohol or medication that

could affect your ability to use the tool properly.

12. ALWAYS WEAR EYE PROTECTION. Any

power tool can throw foreign objects into

the eyes and could cause permanent eye

damage. ALWAYS wear Safety Goggles

(not glasses) that comply with ANSI Safety standard

Z87.1. Everyday eyeglasses have only impact–

resistant lenses. They ARE NOT safety glasses.

NOTE: Glasses or goggles not in compliance with

25. Dust generated from certain materials can be

hazardous to your health. Always operate tool in

well-ventilated area and provide for proper dust

removal.

26. WEAR HEARING PROTECTION to reduce the risk

of induced hearing loss.

4

BENCH GRINDER SAFETY

1. Wear eye protection that complies with ANSI

Z87.1 specifications.

2. Use grinding wheels suitable for the speeds of the

grinder.

3. Stand beside the bench grinder during start-up, not

facing directly in front.

4. Do not remove the wheel guard.

5. Do not use the grinding wheel to cut anything.

6. Do not use anything to stress the grinding wheel.

7. Use a grinding wheel dressing tool to shape or

remove glaze from grinding wheels.

8. Adjust distance between wheel and tool rest to

maintain 1/8 inch (3.2 mm) or less separation as

the diameter of the wheel decreases with use.

9. Connect to a supply circuit protected by a circuit

breaker or time-delay fuse.

10. Secure the bench grinder to its supporting surface

to prevent the grinder from tipping over, sliding, or

walking on its supporting surface.

A. Replace a cracked wheel immediately.

B. Always use the guards and eye shields.

C. Do not overtighten the wheel nut.

D. Use only flanges furnished with this grinder.

11. Always inspect grinding wheels prior to use

for cracks, missing pieces, etc. Replace wheel

immediately before use.

12. USE ONLY GRINDING WHEELS that comply with

ANSI B7.1 and rated greater than 3450 RPM.

13. GUARD AGAINST ELECTRICAL SHOCK by

preventing body contact with grounded surfaces.

For example: pipes, radiators, ranges, refrigerator

enclosures.

17. NEVER stand or have any part of your body in line

with the path of the wheel.

18. DO NOT USE TOOL IF SWITCH DOES NOT

TURN IT ON AND OFF. Have defective switches

replaced by an authorized service center.

19. DO NOT TURN THE MOTOR SWITCH ON AND

OFF RAPIDLY. This could cause the wheel to

loosen and create a hazard. Should this ever

occur, stand clear and allow the wheel to come to

a complete stop. Disconnect your grinder from the

power supply and retighten the wheel nut securely.

20. RISK OF INJURY DUE TO ACCIDENTAL

STARTING. Do not use in an area where children

may be present.

21. NEVER START THE GRINDER when the wheel is

in contact with the workpiece.

22. SECURE WORK. Always hold the workpiece firmly

against the work rest.

23. DO NOT USE THE BENCH GRINDER if the flange

nut or clamp nut is missing or if the spindle shaft is

bent.

24. FREQUENTLY clean grinding dust from beneath

the grinder.

25. DO NOT OPERATE THIS TOOL WHILE UNDER

THE INFLUENCE OF DRUGS, ALCOHOL OR

ANY MEDICATION.

26. ALWAYS STAY ALERT. Do not allow familiarity

(gained from frequent use of your grinder) to cause

a careless mistake. ALWAYS REMEMBER that a

careless fraction of a second is sufficient to inflict

severe injury.

27. STAY ALERT AND EXERCISE CONTROL. Watch

what you are doing and use common sense. Do not

operate the tool when you are tired. Do not rush.

14. DO NOT use wheels with incorrect size holes.

NEVER use wheel washers or wheel screws that

are defective or incorrect, and NEVER touch a

grinding wheel or other moving parts.

15. NEVER reach to pick up a workpiece, a piece of

scrap, or anything else that is in or near the grinding

path of the wheel.

16. AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause your

hand to move into the wheel. ALWAYS make sure

you have good balance.

28. SAVE THESE INSTRUCTIONS. Refer to them

frequently and use them to instruct other users.

If you loan someone this tool, loan them these

instructions also.

29. ALWAYS EASE THE WORKPIECE AGAINST THE

ABRASIVE WHEEL when starting to grind. A harsh

impact can break the wheel. Use light pressure

when starting to grind. Too much pressure on a cold

wheel can cause the wheel to crack.

30. USE ONLY FLANGES furnished with this bench

grinder.

5

BENCH GRINDER SAFETY

31. IF ANY PART OF THIS GRINDER IS MISSING or

should break, bend, fail in any way, or should any

electrical component fail to perform properly, shut

off the power switch, remove the machine plug from

the power surce and have damaged, missing, or

failed parts replaced before resuming operation.

32. SAFETY SHIELD AND SPARK DEFLECTOR. The

safety shields and spark deflectors are adjustable

for operator convenience. Operating the grinder

without these features attached could result in

serious injury. Do not grind with the safety shield

raised. Always wear safety glasses for personal

protection.

33. WORK REST. The work rests are independently

adjustable to compensate for wheel wear. Before

grinding, make certain the work rests are adjusted

properly. Generally, the object being ground is done

slightly above the center of the grinding wheel.

34. Lawn mower blades are usually sharpened on only

one edge and dressed up slightly on the other.

Perform this sharpening process on both cutting

ends of the blade. After sharpening, balance the

blade by removing additional material.

6

ELECTRICAL REQUIREMENTS AND SAFETY

POWER SUPPLY AND MOTOR SPECIFICATIONS

!

WARNING

To avoid electrical hazards, fire hazards, or damage

to the tool, use proper circuit protection. Use a

separate electrical circuit for your tool. Your grinder

is wired at the factory for 120 V operation. Connect

to a 120 V, 2.5 Amp circuit and use a 2.5 Amp time

delay fuse or circuit breaker. To avoid shock or fire,

if power cord is worn, cut, or damaged in any way,

have it replaced immediately.

GROUNDING INSTRUCTIONS

!

WARNING

This tool must be grounded while in use to protect

the operator from electrical shock.

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN, grounding provides a path of least

resistance for electric currents and reduces the risk of

electric shock. This tool is equipped with an electrical

cord that has an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into a matching receptacle that is properly installed

and grounded in accordance with all local codes and

ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not

fit the receptacle, have the proper receptacle installed

by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electric shock. The

conductor with the green insulation (with or without

yellow stripes) is the equipment grounding conductor.

If repair or replacement of the electrical cord or plug is

necessary, do not connect the equipment grounding

conductor to a live terminal.

CHECK with a qualified electrician or service person

if you do not completely understand the grounding

instructions, or if you are not certain the tool is properly

grounded.

USE only 3-wire extension cords that have

three-pronged grounding plugs with three-pole

receptacles that accept the tool’s plug. Repair or

replace damaged or worn cords immediately.

Use a separate electrical circuit for your tool. This circuit

must not be less than #18 wire and should be protected

with a 2.5 Amp time lag fuse. Before connecting the

motor to the power line, make sure the switch is in the

off position and the electric current is rated the same as

the current stamped on the motor nameplate. Running

at a lower voltage will damage the motor.

GUIDELINES FOR EXTENSION CORDS

USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. Use an

extension cord heavy enough to carry the current your

product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power, overheating

and burning out of the motor. The table below shows

the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

Make sure your extension cord is properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified technician before

using it. Protect your extension cords from sharp

objects, excessive heat and damp or wet areas.

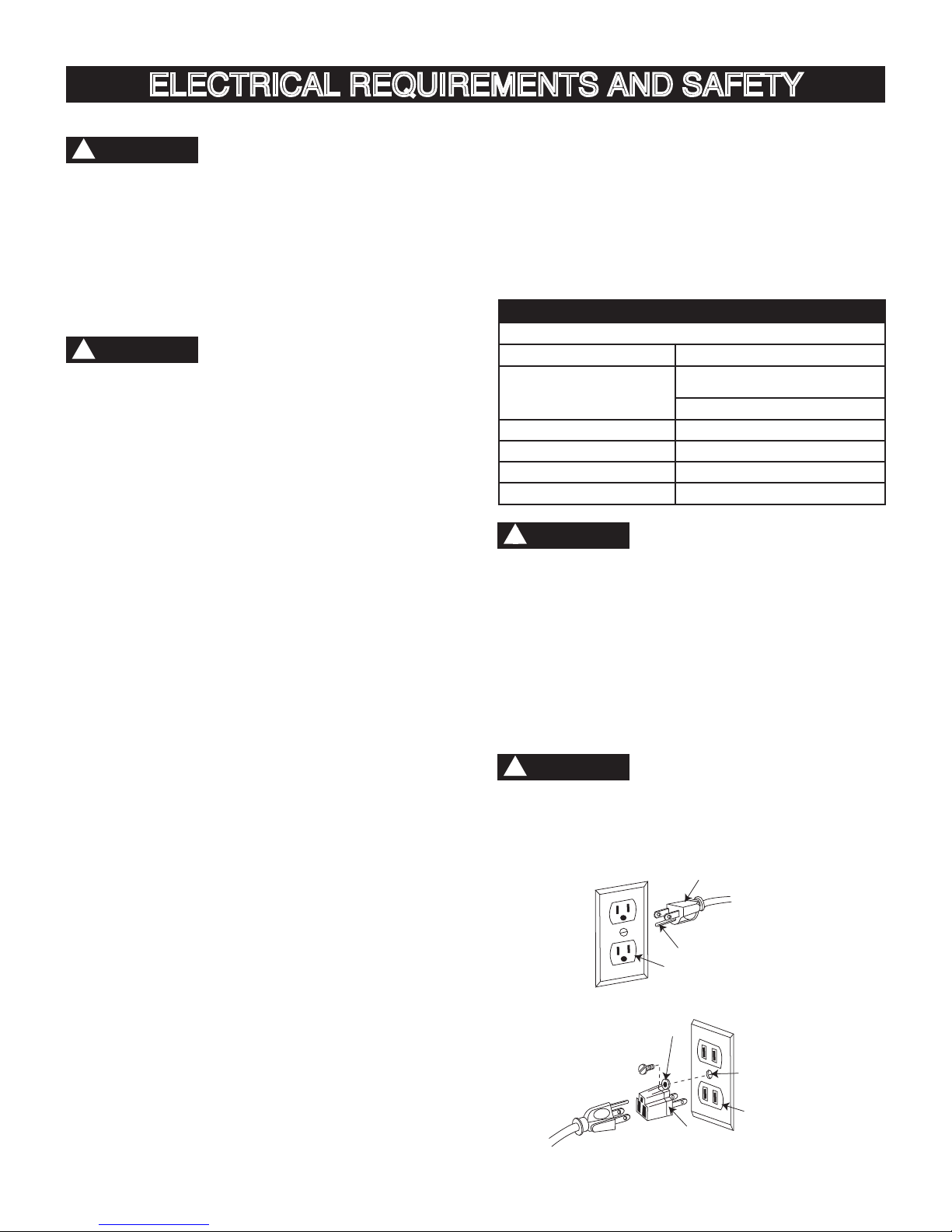

MINIMUM GAUGE FOR EXTENSION CORDS (AWG)

(When using 120 volts only)

Ampere Rating Total length of Cord

More Than Not More Than 25 50 100 150 ft.

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

!

WARNING

(7.62 15.24 30.48 45.72 m)

AWG- American Wire Gauge

This tool is for indoor use only. Do not expose to rain or

use in damp locations.

This tool is intended for use on a circuit that has a

receptacle like the one illustrated in Fig. 1. Fig. 1 shows

a three-pronged electrical plug and receptacle that has a

grounding conductor. If a properly grounded receptacle

is not available, an adapter (Fig. 2) can be used to

temporarily connect this plug to a two-contact grounded

receptacle. The adapter (Fig. 2) has a rigid lug extending

from it that MUST be connected to a permanent earth

ground, such as a properly grounded receptacle box.

!

CAUTION

In all cases, make certain the receptacle is properly

grounded. If you are not sure, have a qualified

electrician check the receptacle.

Fig. 1

Three-Pronged Plug

Grounding Prong

Properly Grounded

Three-Pronged Receptacle

Fig. 2

Grounding Lug

Make sure this is

connected to a

known ground.

Two-Pronged

Receptacle

Adapter

7

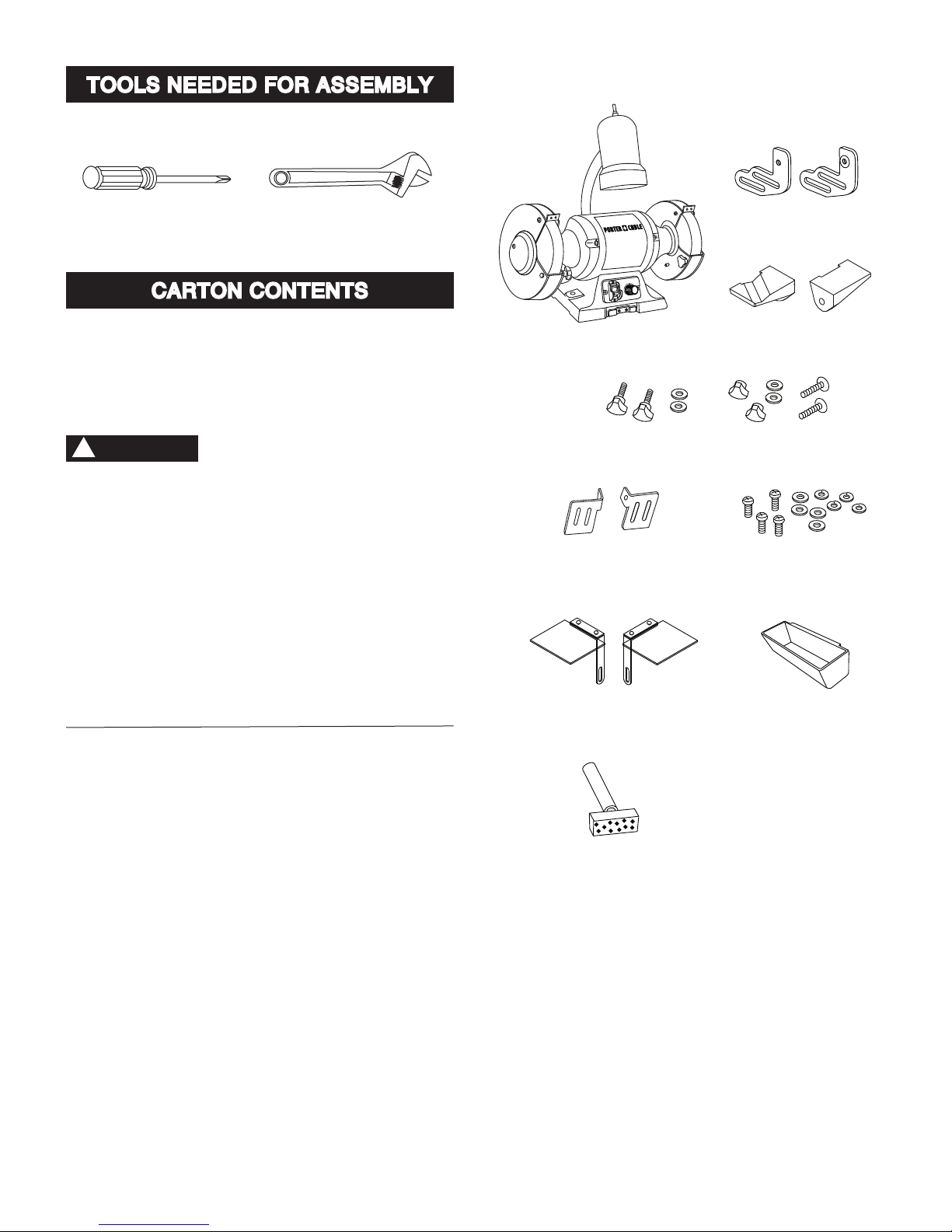

TOOLS NEEDED FOR ASSEMBLY

A

B

E

G

F

C

D

H

I

ON

OFF

L

H

Not supplied

Adjustable wrench Phillips screwdriver

CARTON CONTENTS

UNPACKING AND CHECKING CONTENTS

Carefully unpack the grinder and all its parts, and

compare against the list below and the illustration to the

right. With the help of an assistant place the grinder on

a secure surface and examine it carefully.

!

WARNING

● To avoid injury from unexpected starting or electrical

shock, do not plug the power cord into a source of

power during unpacking and assembly. This cord

must remain unplugged whenever you are adjusting/

assembling the grinder.

●

The grinder is heavy and should be lifted with care.

If needed, get the assistance of someone to lift and

move the grinder.

●

If any part is missing or damaged, do not attempt

to assemble the grinder, or plug in the power cord

until the missing or damaged part is correctly

replaced.

UNPACKING YOUR BENCH GRINDER

TABLE OF LOOSE PARTS

ITEM

DESCRIPTION QUANTITY

A. Bench grinder 1

B. Tool rest mounting bracket 2

C. Tool rest 2

D. Tool rest & eye shield hardware

bag

Locking knob / flat washer

Locking nut knob / flat washer /

carriage bolt

E. Spark guards 2

F. Spark guard hardware bag

Phillips screw 4

Lock washer 4

Flat washer 4

G. Right / left eye shields 1 each

H. Coolant tray 1

I. Wheel dressing tool 1

2 each

2 each

8

N

O

F

F

O

L

H

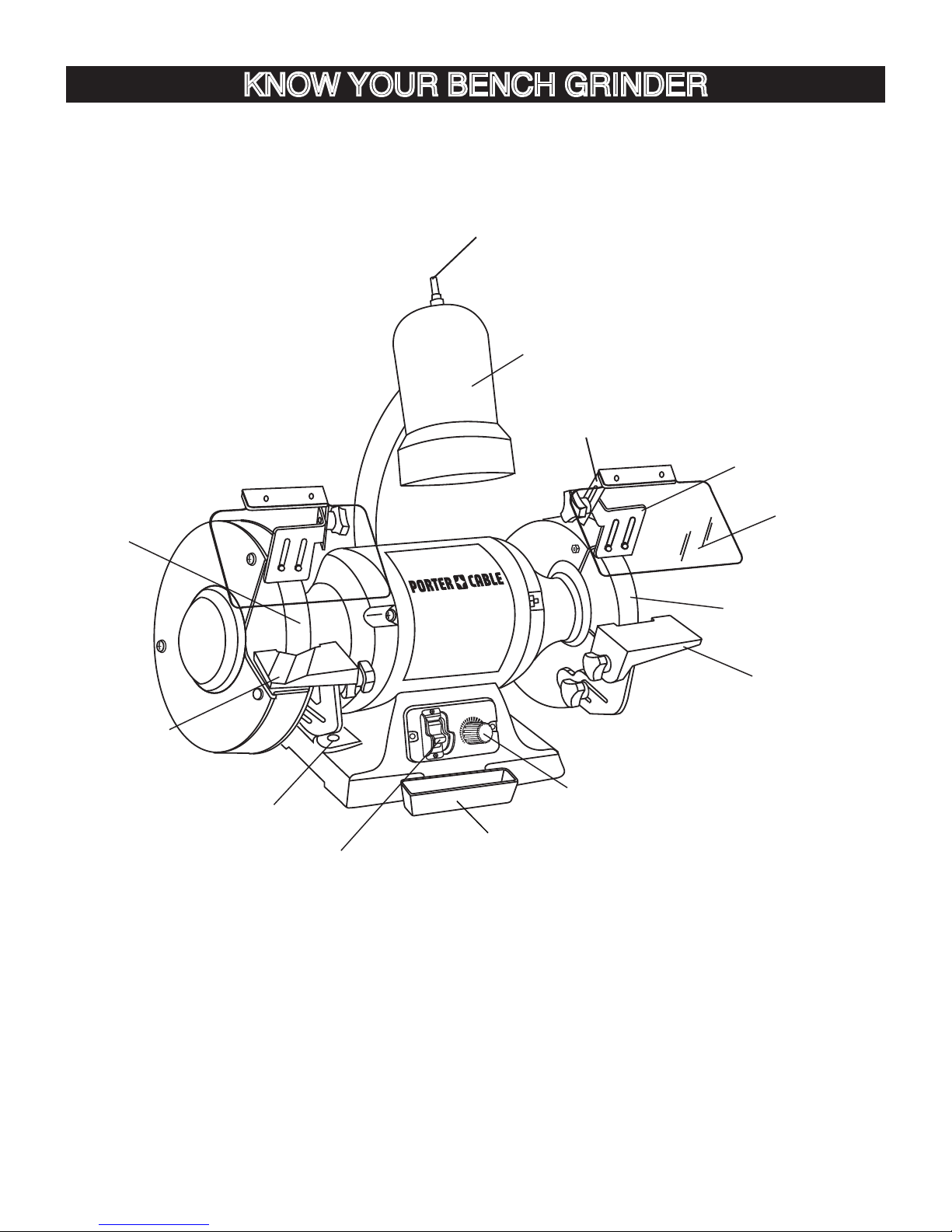

KNOW YOUR BENCH GRINDER

Worklight ON/OFF switch

Worklight

Eye shield mounting bracket

Spark guard

Medium grinding

wheel (60 Grit)

Left tool rest

(V-Grooved)

Mounting hole

Eye shield

Coarse grinding

wheel (36 Grit)

Right tool rest

Variable speed control knob

Coolant tray

ON/OFF switch

9

ASSEMBLY AND ADJUSTMENTS

O

N

O

F

F

L

H

O

N

O

F

F

L

H

Estimated Assembly Time: 10 - 20 minutes.

!

CAUTION

To avoid injury, make sure all parts are assembled

and adjusted properly before plugging the grinder

into a power outlet and turning it ON.

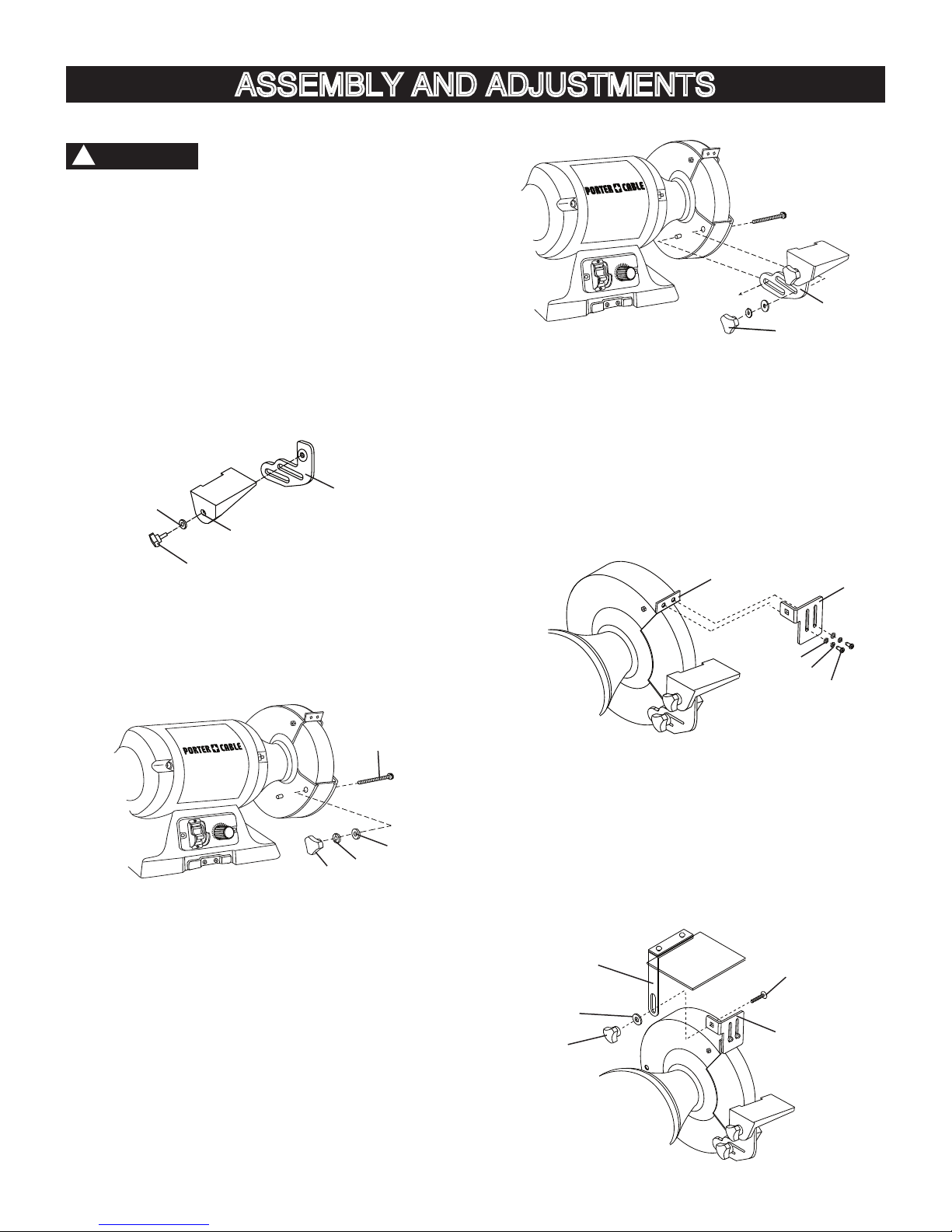

INSTALLING TOOL RESTS (FIG. A, B, C )

1. Bag “D” - Insert the lock knob (1) through

the flat washer (2) and the right side tool rest (3)

to the right side tool rest mounting bracket (4) as

shown.

NOTE: The grooved tool rest mounts on the left side

of grinder.

Fig. A

4

2

3

1

2. Remove the knob (5), lock washer (6) and flat

washer (7) from the carriage bolt (8) on the lower

portion of the wheel guard.

Fig. B

Fig. C

9

5

INSTALLING THE SPARK GUARDS (FIG. D)

1. Bag “F” - Attach the right spark guard (1) to the

extended pad (2) of guard by using the bolts (3),

spring washers (4) and flat washers (5).

2. Repeat for the left side spark guard.

NOTE: As the wheel wears down, the spark guards

must be re-adjusted to maintain a 1/16 in. (1.6 mm)

distance.

Fig. D

2

5

4

3

1

8

7

6

5

3. Attach the tool rest assembly (9) to the grinder as

shown.

4. Replace the washers and the lock knob (5).

5. Repeat the procedure for the left side tool rest.

NOTE: When in use, the tool rests should be

adjusted to within 1/8 in. (3.2 mm) of the grinding

wheel or other accessory being used.

INSTALLING THE EYE SHIELDS (FIG. E)

1. Bag “D” - Attach the right eye shield (1) to the spark

guard (2) by using the locking nut knob (3), lock

washer (4) and the carriage bolt (5).

2. Repeat for left side eye shield.

NOTE: Adjust eye shields to appropriate distance

from tool rests avoiding interference when operation.

Fig. E

1

5

4

3

2

10

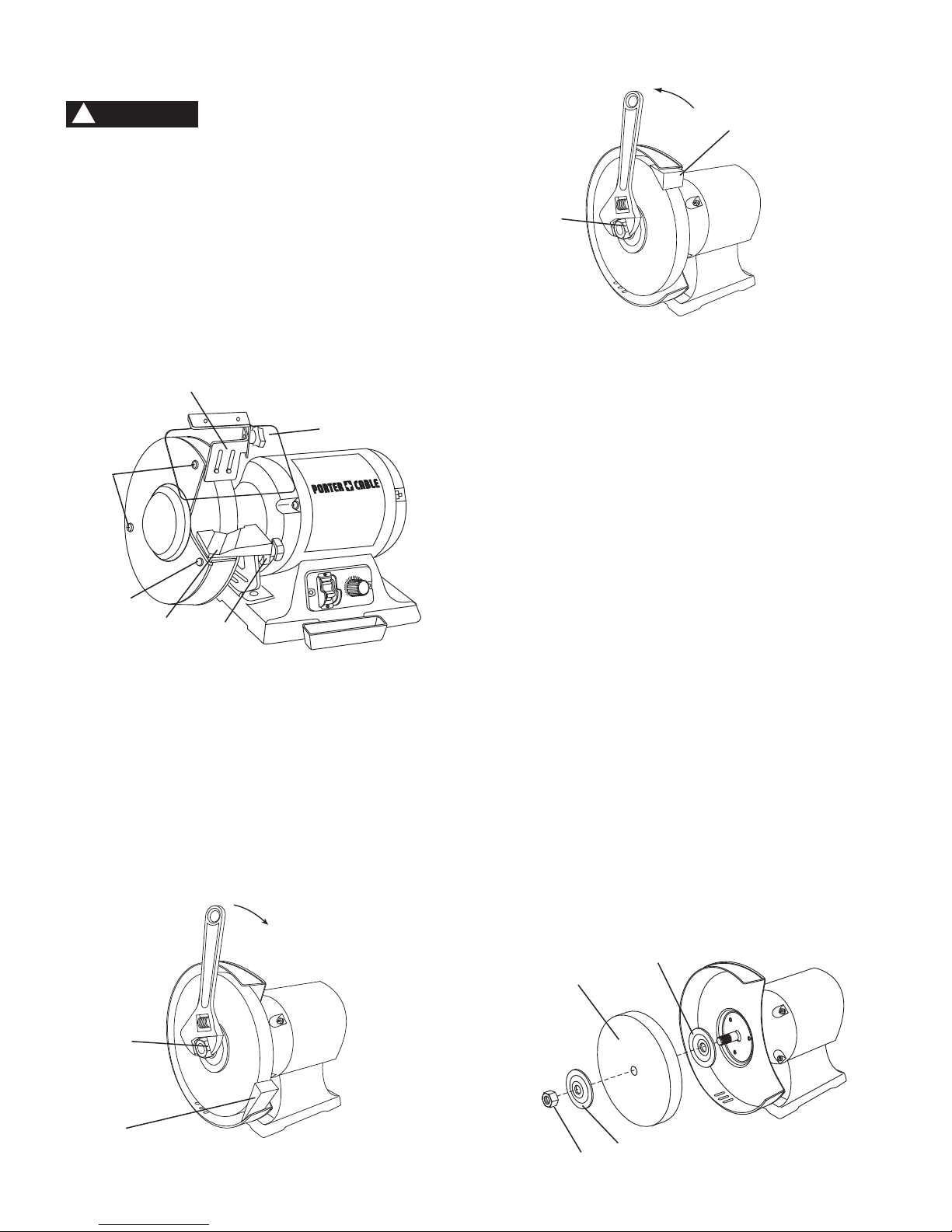

CHANGING GRINDING WHEELS (FIG. F, G, G-1, H)

!

CAUTION

Turn off and unplug the bench grinder. Use only

grinding wheels that measure 6 inches (150 mm) in

diameter. This tool has 1/2 inch (12.7 mm) arbors on

both sides.

1. Raise the eye shield (1) out of the way and place the

spark guard (6) in its highest setting.

2. Loosen the knob (2) and remove the tool rest

assembly (3) and carriage bolt (4).

3. Remove the two screws (5) from the left side wheel

cover and then remove the outer cover.

Fig. F

6

1

5

ON

H

L

4

3

2

OFF

4. To prevent wheel rotating, place a wood wedge (7)

(not supplied) between the wheel and the wheel

cover as shown in Fig. G.

NOTE: Using a metal object, like a screwdriver, is

not recommended as it may damage the grinding

wheel.

5. Remove the hex nut (8) (as shown in Fig. G), the

wheel flange (9) and the wheel (10). (Fig. H)

Fig. G

Fig. G-1

7

Wood wedge

8

Tighten

NOTE: The nut on the right side of the grinder has

a standard right-hand thread (turn counterclockwise

to loosen). The one on the left side has a left-hand

thread (turn clockwise to loosen). Both wheel nuts

tighten when turning toward the rear of the grinder and

loosen when turning toward the front of the grinder.

6. Inspect the wheel (10) for cracks, chips or any

other visible damage (other than normal wear) and

discard if such damage is found. Inspect the blotter/

cardboard disc for damage. If the blotter is missing

or severely damaged, replace it with a piece of thin

cardboard or blotter paper cut in the same shape.

NEVER USE A GRINDING WHEEL WITHOUT A

BLOTTER.

7. Install the new wheel or other accessory. Make sure

both wheel flanges (9) are in place with the concave

sides toward wheels. (Fig. H)

8. Place a wood wedge (7) (not supplied) between the

wheel and the wheel cover as shown in Fig. G-1.

NOTE: Do not overtighten the nut as this can crack

the grinding wheel (10).

9. Replace the wheel cover and screws.

10. Adjust the tool rest to 1/8 in. (3.2 mm) away from the

wheel and tighten securely.

11. Reattach and adjust the eye shield to a point

between your eyes and the wheel.

12. Set the spark guard 1/16 in. (1.6 mm) away from the

wheel.

8

7

Wood wedge

Loosen

11

Fig. H

10

9

9

8

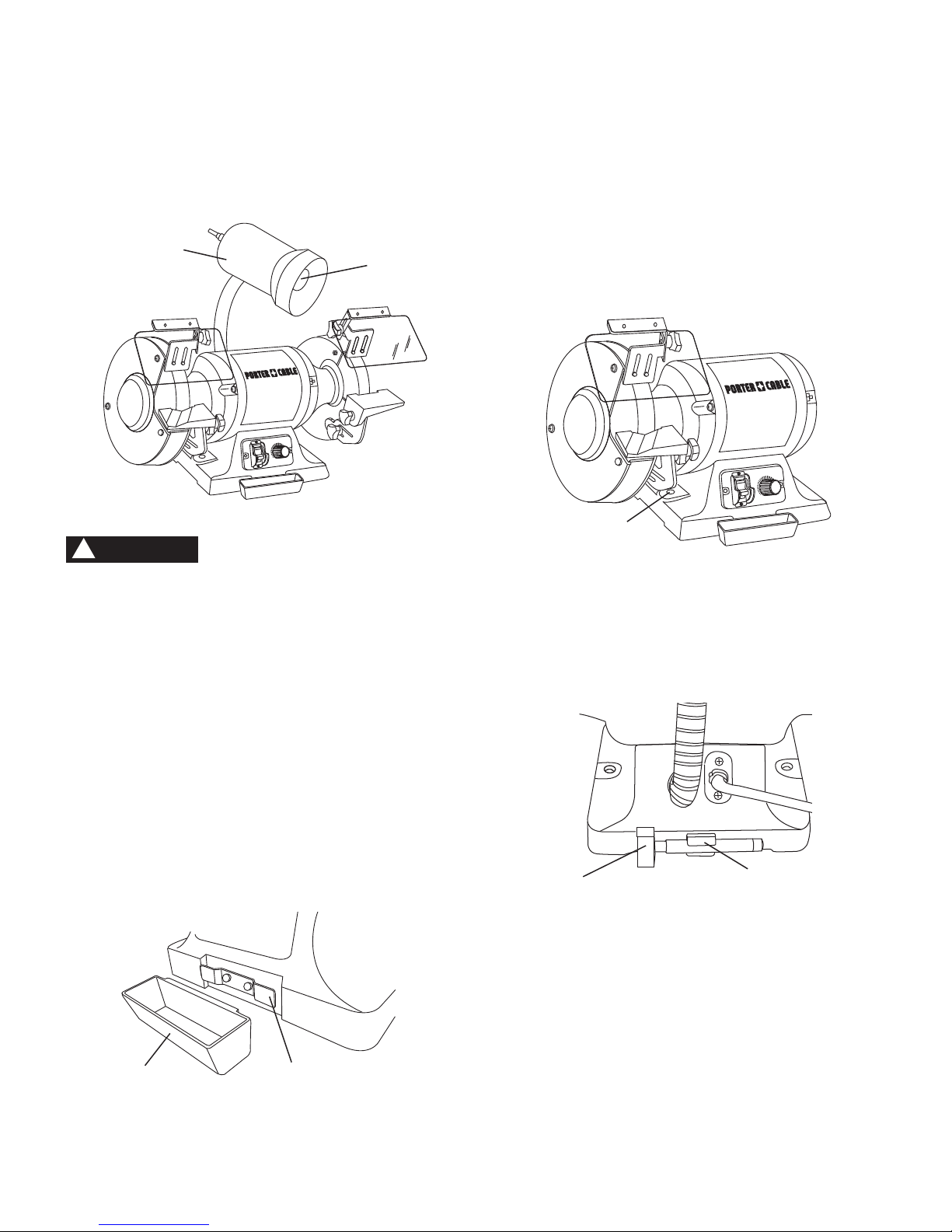

REPLACING THE BULB (FIG. I)

ON

OFF

L

H

ON

OFF

L

H

NOTE: Bulb is not included.

1. Remove the light bulb (1) from lampshade (2).

2. Install the new light bulb (40 W bulb maximum) into

lampshade (2).

Fig. I

2

1

MOUNTING THE TOOL ON A WORKBENCH (FIG. K)

NOTE: We highly recommend that you bolt this bench

grinder securely to a workbench to gain maximum

stability for your machine.

1. Using the base of the bench grinder as a template,

mark the bench through the holes in the casting.

2. Bolt the bench grinder on the bench with bolts,

washers and nuts. Note that these fasteners are not

supplied with the machine.

Fig. K

!

CAUTION

• To avoid injury from an accidental start, make

sure the switch is in the OFF position and the

plug is not connected to a power outlet.

• To prevent injury resulting from heat of the

light bulb, never touch the light bulb until it has

completely cooled.

• To prevent electric shock, never touch any part

of the light bulb when the plug is connected to a

power outlet.

• It is recommended to use a vibration-resistant

light bulb for this grinder.

INSTALLING THE COOLANT TRAY (FIG. J)

1. Hang the coolant tray (1) on the clips (2).

Fig. J

Hole in casting

WHEEL DRESSING TOOL STORAGE (Fig. L)

Storage clips (1) for the wheel dressing tool (2) are

located on the rear of the grinder.

Fig. L

2 1

1

2

12

OPERATION

ON

OFF

L

H

REMOVE

TO LOCK

ON

OFF

L

H

L

H

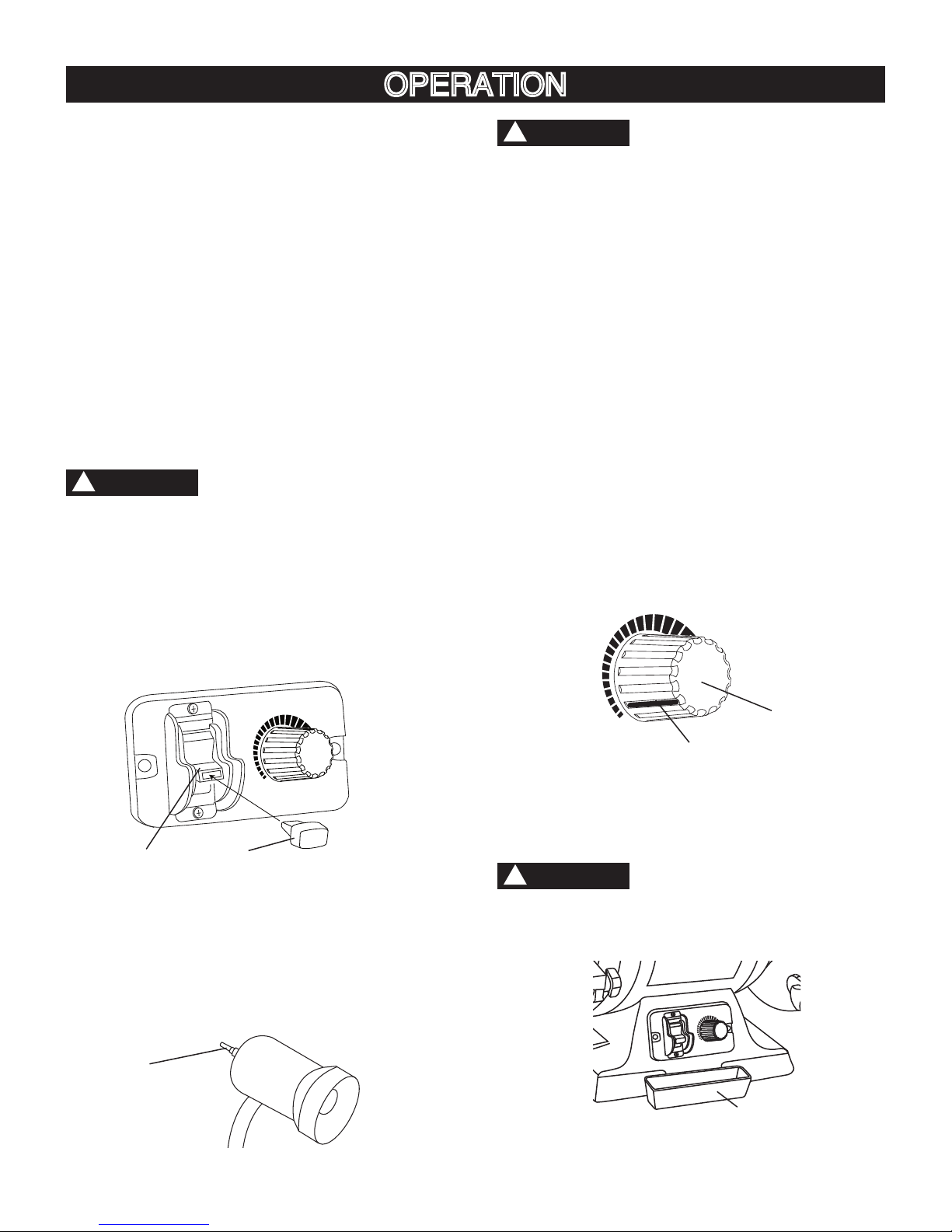

STARTING AND STOPPING THE GRINDER (FIG. M)

The “ON / OFF” switch has a removable, black plastic

key. With the key removed from the switch, unauthorized

and hazardous use by children and others is minimized.

1. To turn the grinder “ON”, insert key (1) into the slot

of the switch (2), and move the switch to the “ON”

position.

2. To turn the grinder “OFF”, move the switch to the

“OFF” position.

3. To lock the switch in the “OFF” position, grasp the

end, of the switch key, and pull it out.

4. With the switch key removed, the switch will not

operate.

5. If the switch key is removed while the grinder

is running, it can be turned “OFF” but cannot be

restarted without inserting the switch key.

!

CAUTION

Always lock the switch “OFF” when the grinder is

not in use. Remove the key and keep it in a safe

place. In the event of a power failure, blown fuse, or

tripped circuit breaker, turn the switch “OFF” and

remove the key, preventing an accidental startup

when the power comes on.

!

CAUTION

• To avoid injury from an accidental start, make

sure the switch is in the OFF position and the

plug is not connected to a power outlet.

• To prevent injury resulted from heat of the light

bulb, never touch the light bulb until it has

completely cooled.

• To prevent electric shock, never touch any part

of the light bulb when the plug is connected to a

power outlet.

• It's recommended to use a vibration-resistant

light bulb for this grinder.

ADJUSTING THE SPEED OF GRINDER (FIG. O)

Your grinder is equipped with a variable speed control

knob. The speed of the grinder may be adjusted by

simply rotating the variable speed control knob (1).

1. To increase speed, rotate the variable speed control

knob (1) clockwise.

2. To reduce speed, rotate the variable speed control

knob (1) counterclockwise.

Fig. O

Fig. M

2

1

USING THE WORKLIGHT (FIG. N)

1. To turn the worklight "ON", rotate the worklight

switch (1) counterclockwise.

2. To turn the worklight "OFF", rotate the worklight

switch (1) clockwise.

Fig. N

1

1

pointer

COOLING WORKPIECE (FIG. P)

The coolant tray (1) allows you to cool overheated

workpieces. Simply pull upward the tray and half fill with

appropriate coolant, such as water.

!

CAUTION

Do not overfill the coolant tray.

Fig. P

1

13

GENERAL OPERATION

!

CAUTION

Keep all bystanders a safe distance away from

the tool and not in direct line, front or back of the

grinder.

1. Your bench grinder has a medium wheel (60 grit)

for medium material removal and general purpose

grinding, and a coarse wheel (36 grit) for fast material

removal.

2. To operate the bench grinder, always wear safety

glasses and turn the tool on while standing at the side

and not in front of the grinder. Allow it to reach full

speed before grinding.

3. Hold the work piece firmly against the tool rest. Hold

very small pieces with pliers or other suitable clamps.

4. Feed the work piece smoothly and evenly into the

grinding wheel.

5. Move the work piece slowly and avoid jamming the

work piece against the wheel. If the wheel tends

to slow down from excessive force, you should

occasionally release the pressure to let the wheel

return to full speed.

6. Grind only on the face of the grinding wheel and

never the side of it. (Some wheels are designed

for side grinding and will say so on their blotters/

cardboard disc.)

!

CAUTION

Prolonged grinding will cause most materials

to become hot. Use care when handling such

materials.

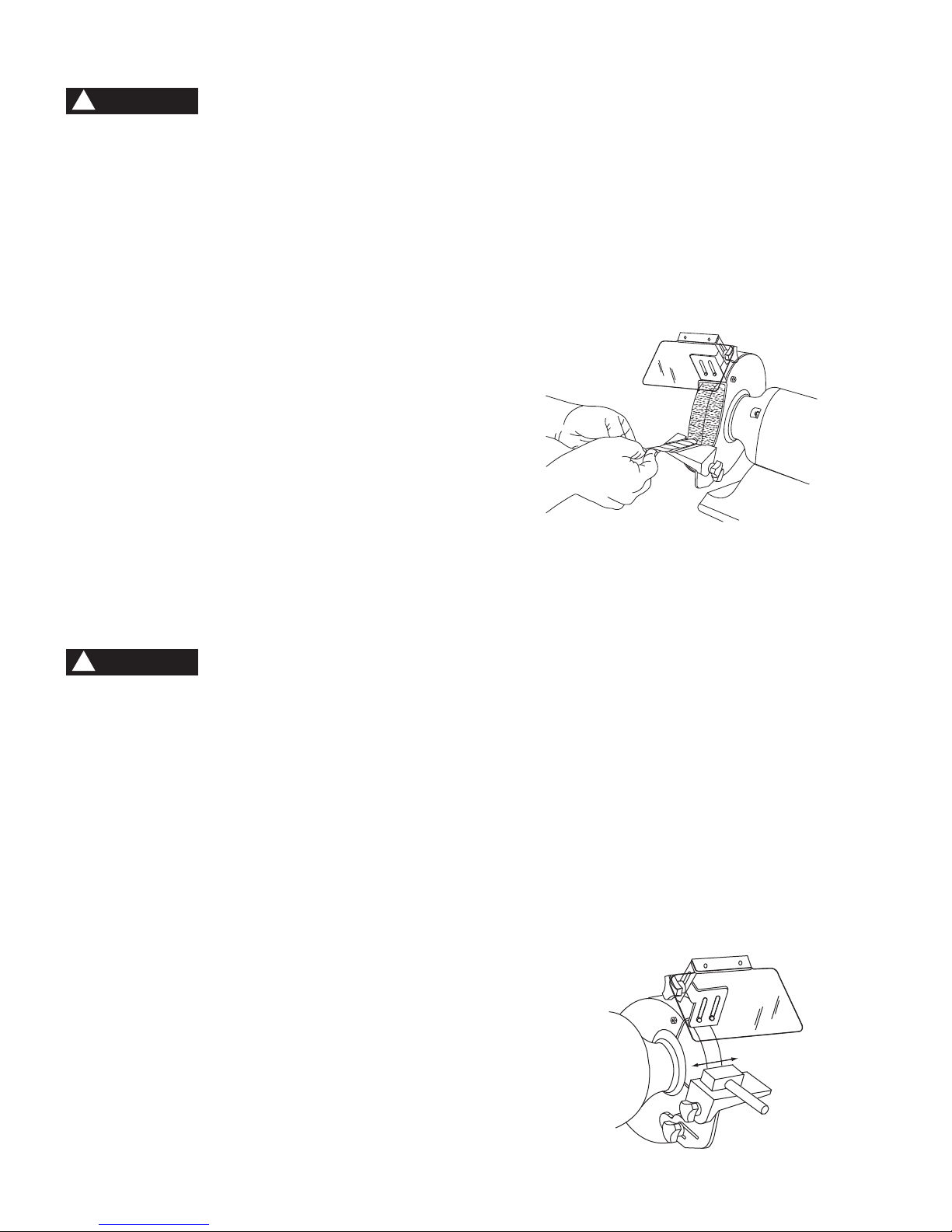

TWIST DRILL BITS (FIG. Q)

Drill bits are best sharpened on a sharpening jig,

available at most hardware stores, but can be “dressed

up” on your grinder. Begin on one side of the point at

the existing angle, then twist the bit while maintaining a

constant angle with grinding surface. Sharpen only the

tip. This technique requires considerable practice, so

take your time and make a few “dry runs” first with the

grinder off. Be sure to maintain the original cutting edge

angle as this is important to the efficiency of your bits.

One tool rest has a V-groove that is correctly angled for

most drill bits.

Fig. Q

LAWN MOWER BLADES

Lawn mower blades are usually sharpened on only

one side and dressed up slightly on the other. After

sharpening, be sure to balance the blade by removing

additional material from the heavy end. There are a

number of inexpensive cone balancers on the market

for this purpose. Unbalanced blades can cause serious

crank shaft damage to your lawn mower. Always remove

spark plug wires from the mower before servicing the

blades to prevent accidental starting.

SCISSORS

If possible, take the scissors apart to make the

sharpening operation easier and safer. Remove material

only from the outside surface and work from the heavy

end of the blade toward the tip.

KNIVES

Remove metal from both faces of most knives, working

from the heavy end of the blade toward the tip.

SCREWDRIVERS

The end of a properly sharpened screwdriver will be

a perfect rectangle, absolutely flat and perpendicular

to the center line of the shank. The two sides and two

faces will taper outward from the edge of the shoulder

or shank. They should be flat with intersecting faces

perpendicular. Hold each face of the screwdriver against

the wheel to true it up, then ease the end straight into

the stone to grind it true.

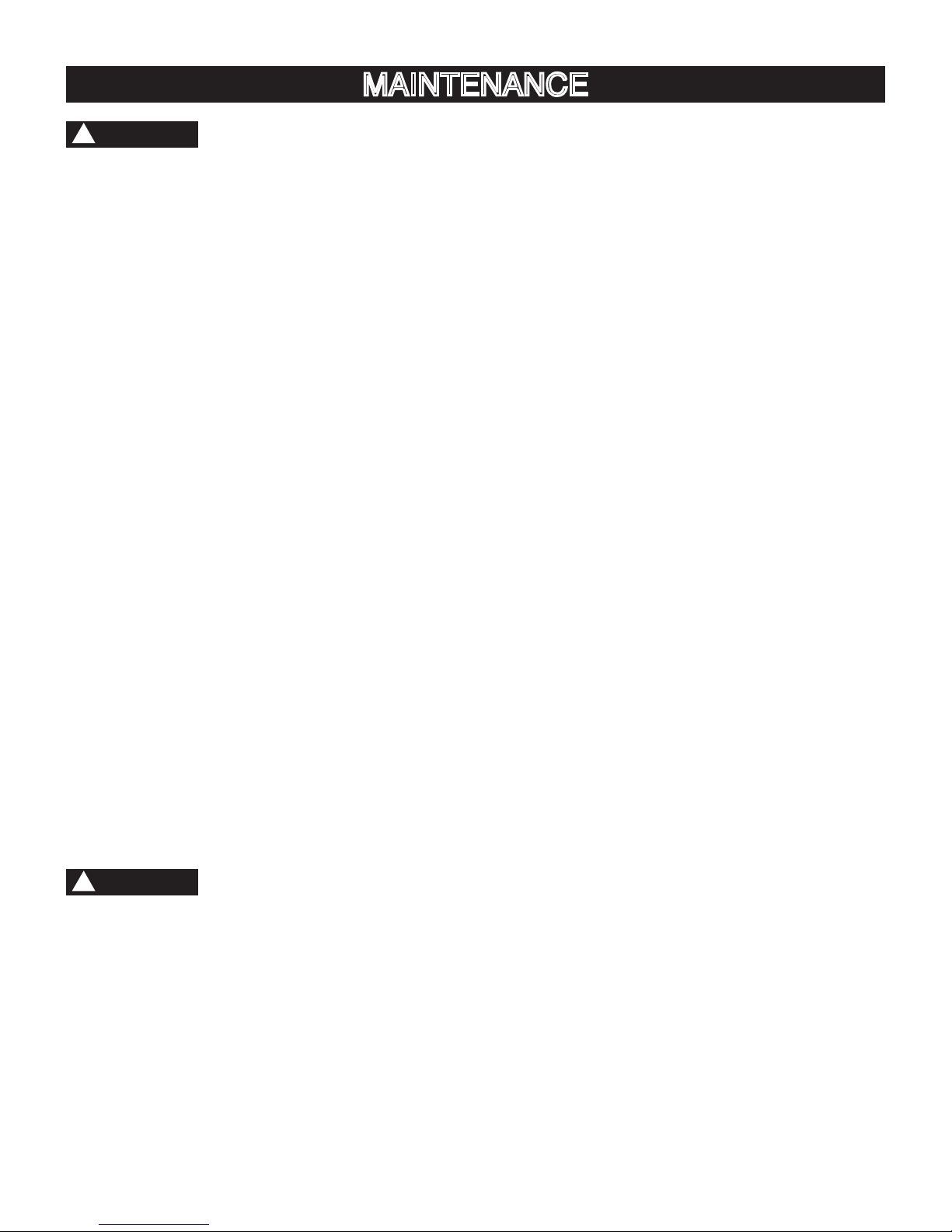

DRESSING A GRINDING WHEEL (FIG. R)

A wheel dressing tool is provided with the grinder. Bring

the dressing tool forward on the tool rest until it touches

the high point on the face of the wheel. Dress the wheel

by moving the dressing tool back and forth. Repeat this

operation until the face of the grinding wheel is clean

and the corner of the wheel is square. NOTE: DO NOT

use the wheel dressing tool on wire wheels.

Fig. R

14

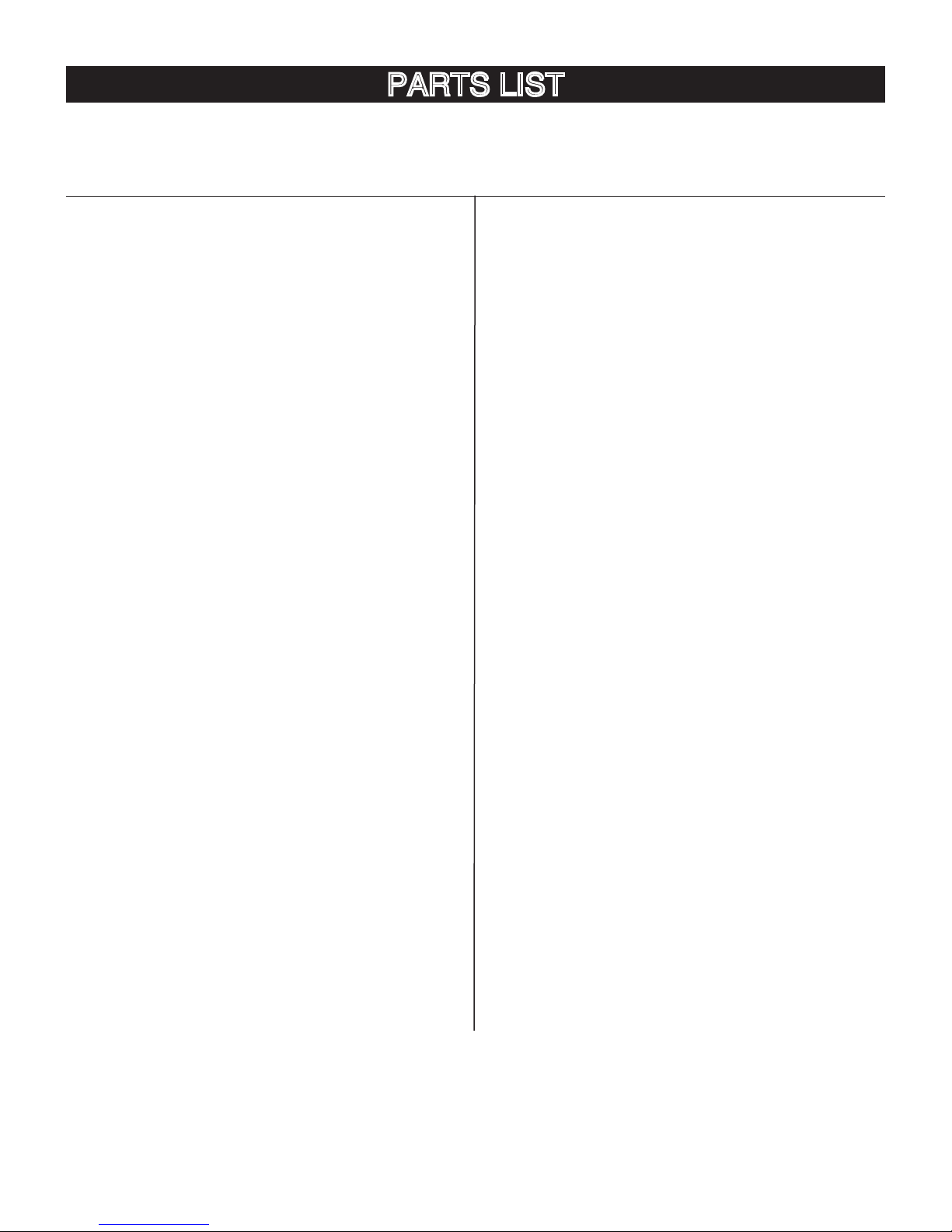

MAINTENANCE

!

CAUTION

For your own safety, turn switch “OFF” and remove

plug from power source outlet before adjusting and

maintaining your bench grinder. If power cord is

worn, cut or damaged in any way, have it replaced

immediately.

GENERAL

1. Regularly check the tool and use a soft brush to

remove accumulated dust. Wear safety goggles to

protect your eyes while cleaning.

2. If the body of the grinder needs cleaning, wipe it

down with a soft, damp cloth. A mild detergent can

be used. Do not use alcohol, petrol or other similar

cleaning agents. Do not make contact with the

grinding wheels with any damp cloth.

3. Always make sure the eyeshields are transparent

and not blocking the view of the grinding wheel.

4. In normal use, grinding wheels may become cracked,

grooved, rounded at the edges, chipped, out of true

or loaded with foreign material. Cracked wheels

should be replaced IMMEDIATELY. While any of the

other conditions can be remedied with a dressing tool

(included), new wheels sometimes require dressing

to make them round.

5. If you must replace a wheel be sure to obtain one

with a safe rated speed at least as high as the “NO

LOAD” RPM marked on your grinder’s nameplate.

Replacement wheels must have a 1/2 in. (12.7 mm)

center hole, 6 in. (150 mm) diameter and should be

a maximum of 3/4 in. (20 mm) wide. Test new wheels

for cracks and maintain the existing sequence of

retaining hardware. Be sure the tool is unplugged

before attempting repairs.

!

CAUTION

• Never use caustic agents to clean the plastic

parts of the tool.

• Water must never come into contact with the

grinder.

• The use of any other accessories is not

recommended and may result in serious injury.

15

TROUBLESHOOTING GUIDE

!

WARNING

To avoid injury from an accidental start, turn the switch OFF and always remove the plug from the power source before

making any adjustments.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service website at www.portercable.

com. You can also order parts from your nearest Porter-Cable Factory Service Center or Porter-Cable Authorized

Warranty Service Center. Or, you can call our Customer Care Center at (888) 609-9779.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about Porter-Cable, its

factory service centers or authorized warranty service centers, visit our website at www.portercable.com or call our

Customer Care Center at (888) 609-9779. All repairs made by our service centers are fully guaranteed against

defective material and workmanship. We cannot guarantee repairs made or attempted by others.

You can also write to us for information at Power Tool Specialists, 684 Huey Road, Rock Hill, SC 29730

(888) 609-9779 - Attention: Product Service. Be sure to include all of the information shown on the nameplate of your

tool (model number, type, serial number, etc.).

PROBLEM PROBLEM CAUSE SUGGESTED CORRECTIVE ACTION

Motor will not run. 1. Not plugged into power outlet.

2. Switch and key not in ON position.

3. Motor cord cut or abraded.

4. Plug on cord is faulty.

5. Faulty motor.

6. Fuse on circuit breaks open.

Grinding wheel vibrates or

shakes.

1. Grinding wheel is not fixed properly.

2. Other.

1. Plug it into the power outlet.

2. Insert key and turn the switch ON.

3. Contact Porter-Cable Service Center

or Authorized Service Station for repair

or replacement.

4. Contact Porter-Cable Service Center

or Authorized Service Station for repair

or replacement.

5. Contact Porter-Cable Service Center

or Authorized Service Station for repair

or replacement.

6. Re-set; may be too many machines on

line.

1. Adjust grinding wheel properly.

See ADJUSTMENT section.

2. Contact Porter-Cable Service Center

or Authorized Service Station for repair

or replacement.

For assistance with your product, visit our website at www.portercable.com for a list of service centers, or call the

Porter-Cable Customer Care Center at (888) 609-9779.

16

ACCESSORIES AND ATTACHMENTS

AVAILABLE ACCESSORIES

!

WARNING

Since accessories, other than those offered by PorterCable, have not been tested with this product, use of

such accessories with this tool could be hazardous.

To reduce the risk of injury, only Porter-Cable

recommended accessories should be used with this

product.

A complete line of accessories is available from your

Porter-Cable Factory Service Center or a PorterCable Authorized Warranty Service Center. Please

visit our Web Site www.portercable.com for a catalog

or for the name of your nearest supplier.

!

WARNING

Do not use any accessory unless you have completely

read the Instruction Manual for that accessory.

17

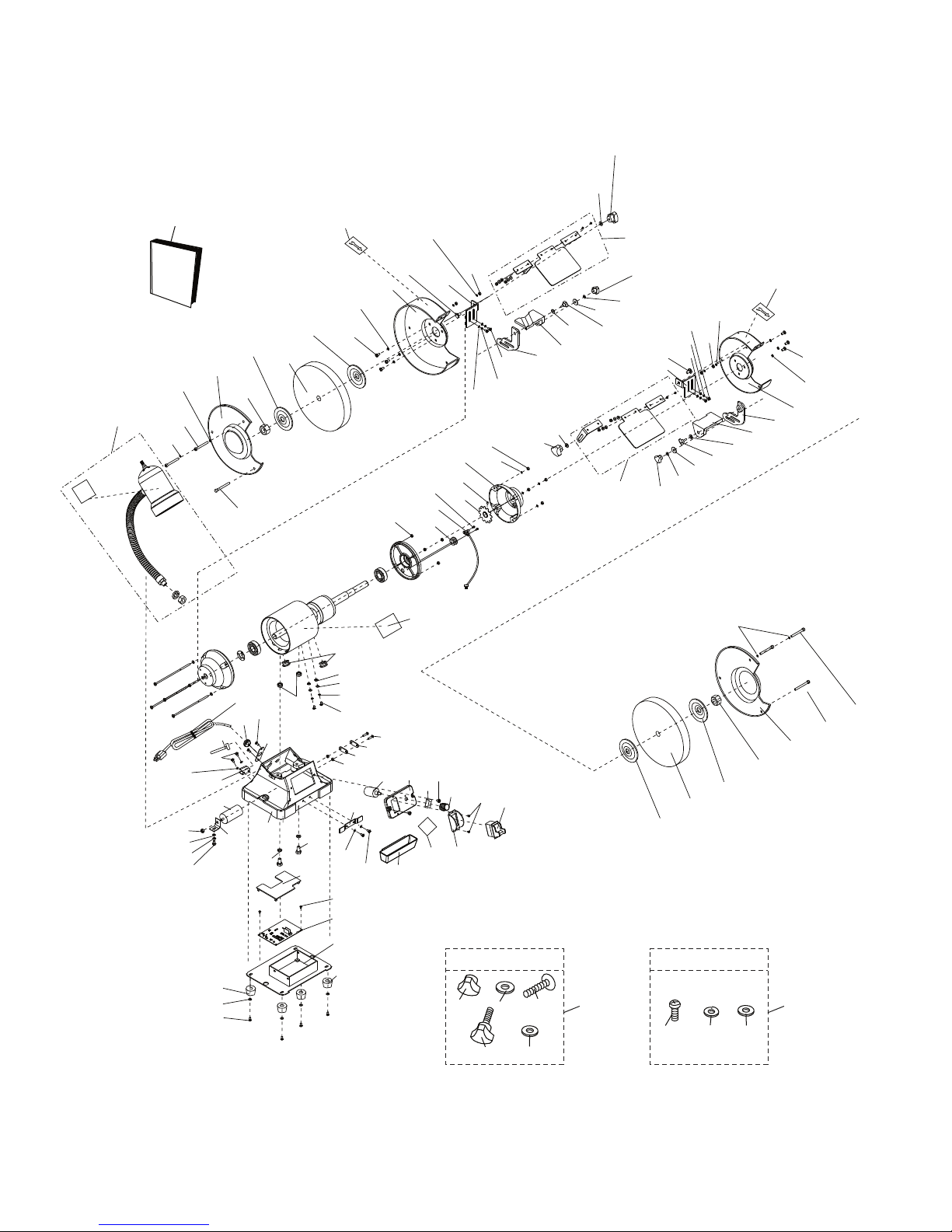

PARTS LIST

6 IN. (150 MM) VARIABLE SPEED GRINDER WITH WORKLIGHT

PARTS LIST

I.D. DESCRIPTION SIZE QTY I.D. DESCRIPTION SIZE QTY

X4AZ LAMP ASSEMBLY 1 X49R WHEEL 36# 1

X4AT PHILLIPS SCREW (WHITE) M5X16 4 X49Q CAPACITOR SUPPORT 1

X4AR BASE COVER 1 X49P HEX NUT (WHITE) M12 1

X4AQ PC BOARD 1 X49N RIGHT SAFTY GUARD COVER 1

X4AP PHILLIPS SCREW (WHITE) ST2.9X5 2 X49M CARRIAGE BOLT M5X51 2

X4AN PC BOARD COVER 1 X49L PHILLIPS SCREW M5X48 4

X4AM PHILLIPS SCREW (WHITE) M6X18 2 X49C SENSOR 1

X4AL LOCK WASHER (WHITE) D6 2 X49B PLATE 1

X4AK RUBBER FOOT 4 X49A RIGHT END CAP 1

X4AJ LOCK WASHER D5 16 X499 LOCK NUT M5 2

X4AH CAPACITOR 1 X498 FLAT WASHER D5 10

X4AG BASE 1 X494 PHILLIPS SCREW M4x12 4

X4AF CORD CLIP FIXING PLATE 1 X493 RIGHT SPARK SHIELD 1

X4AE CORD CLIP 1 X492 CARRIAGE BOLT M6x12 2

X4AD PHILLIPS SCREW M4X8 4 X491 PHILLIPS SCREW (WHITE) M4x8 3

X4AC CORD & PLUG 1 X490 RIGHT SAFETY GUARD 1

X4AB SPECIAL NUT M6 2 X48Z RIGHT FIXED WORK REST 1

X4AA CORD BUSHING 3 X48Y RIGHT MOVABLE WORK REST 1

X4A9 TOOTHED LOCK WASHER D4 6 X48X I TYPE HEX NUT (WHITE) M12 1

X4A8 LOCK WASHER D4 9 X48W LOCKING KNOB M6x17 2

X4A7 HEX NUT M4 10 X48V BIG FLAT WASHER (WHITE) D5 4

X4A6 FIX PLATE 1 X48U LEFT SAFETY GUARD COVER 1

X4A5 MOUNTING PLATE 1 X48T LEFT SAFETY GUARD 1

X4A4 PHILLIPS SCREW M4X25 2 X48S WHEEL 60# 1

X4A3 SPEED CONTROLER 1 X48R LEFT FIXED WORK REST 1

X4A2 SWITCH PLATE 1 X48Q LEFT MOVABLE WORK REST 1

X4A1 PHILLIPS SCREW M5X10 14 X48L PHILLIPS SCREW M2.5X8 2

X4A0 SPEED CONTROL KNOB 1 X48K PHILLIPS SCREW M4x6 1

X4B5 FLAT WASHER (WHITE) D4 7 X48J FLAT WASHER D6 2

X4B4 BIG FLAT WASHER D5 2 X48H LEFT SPARK SHIELD 1

X4B3 STANDARD SPRING WASHER (WHITE) D4 2 X48G WHEEL DRESSING TOOL 1

X4B2 I TYPE HEX NUT (WHITE) M4 4 X48F WHEEL DRESSING CLIP 1

X4B1 RIGHT EYE SHIELD ASSEMBLY 1 X48D VARIABLE SPEED LABEL 1

X4B0 LEFT EYE SHIELD ASSEMBLY 1 X48C DATA LABEL 1

X4C5 RUB COVER 1 X48B ROTATION LABEL 2

X49Z SWITCH GUARD 1 X48A INSTRUCTION MANUAL 1

X49Y PHILLIPS SCREW M3X10 2

X49X SWITCH 1

X49W COOLANT TRAY 1 HARDWARE BAG

X49V I TYPE HEX NUT M5 5 X4C9

X49U LOCK NUT M6 2 X4C8

X49T COOLANT TRAY CLIP 1

X49S FLANGE 4

TOOL REST & EYE SHIELD HARDWARE BAG

SPARK GUARD HARDWARE BAG

1

1

18

6 IN. (150 MM) VARIABLE SPEED GRINDER WITH WORKLIGHT

X4AT

X4AR

X4A

Q

X4AP

X4AN

X4AM

X4AL

X4AK

X4AH

X4A

G

X4AF

X4AE

X4A

C

X4AB

X4AA

X4A9

X4B5

X4B3

X4B5

X4A7

X4A6

X4A5

X4A4

X49S

X49R

X49P

X49N

X49M

X49L

X49C

X49B

X49A

X48J

X493

X4AJ

X4A1

X490

X48Z

X48Y

X48W

X4AJ

X4B4

X499

X48U

X48X

X48J

X48R

X48Q

X4A1

X491

X49S

X49S

X49S

X4A7

X4A8

X48L

X4AA

X4B2

X4AJ

X4AJ

X492

X498

X49L

X49M

X4A1

X48H

X49U

X499

X4AJ

X48W

X4B4

X498

X4A3

X4A2

X4A1

X4A0

X49Z

X49Y

X49X

X49W

X4AD

X4A9

X49T

X49U

X48S

X48T

X48K

X49V

X491

X49Q

X4A8

X49V

X4AJ

X4AJ

X49V

X492

X498

X4A1

X4A1

X4AJ

X498

X498

X48V

X498

X4AD

X48F

X48D

X48C

X48B

X48B

X4AK

X4A9

X498

X4AZ

X48G

MANUAL

INSTRUCTION

X48A

X4B0

X4B1

D. Hardware Bag F. Hardware Bag

X49U

2

X48J

2

X492

2

X4C9 X4C8

X4C5

X4A1

4

X498

4

X4AJ

4

X498

2

X48W

2

SCHEMATIC

19

WARRANTY

THREE YEAR LIMITED WARRANTY

PORTER-CABLE will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of

purchase. This warranty does not cover part failure due to normal wear or tool abuse. For further detail of warranty coverage and

warranty repair information, visit www.portercable.com or call (888) 609-9779. This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, PORTER-CABLE tools are covered by our:

1 YEAR FREE SERVICE: PORTER-CABLE will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

90 DAYS MONEY BACK GUARANTEE: If you are not completely satisfied with the performance of your PORTER-CABLE Power

Tool for any reason, you can return it within 90 days from the date of purchase with a receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, see country

specific warranty information contained in the packaging, call the local company or see website for warranty information.

To register your tool for warranty service visit our website at www.portercable.com.

WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call (888) 609-9779 for a free replacement.

The following are PORTER-CABLE trademarks for one or more power tools and accessories: a gray and black color scheme; a “four

point star” design; and three contrasting/outlined longitudinal stripes. The following are also trademarks for one or more

Porter-Cable and Delta products: 2 BY 4®, 890TM, Air America®, AIRBOSSTM, Auto-Set®, B.O.S.S.®, Bammer®, Biesemeyer®,

Builders Saw®, Charge Air®, Charge Air Pro®, CONTRACTOR SUPERDUTY®, Contractor’s Saw®, Delta®, DELTA®, Delta Industrial®.

DELTA MACHINERY & DESIGNTM, Delta Shopmaster and Design®, Delta X5®, Deltacraft®, DELTAGRAM®, Do It. Feel it.®, DUAL

LASERLOC AND DESIGN®, EASY AIR®, EASY AIR TO GOTM, ENDURADIAMOND®, Ex-Cell®, Front Bevel Lock®, Get Yours While

the Sun Shines®, Grip to Fit®, GRIPVACTM, GTF®, HICKORY WOODWORKING®, Homecraft®, HP FRAMER HIGH PRESSURE®,

IMPACT SERIESTM, Innovation That Works®, Jet-Lock®, Job Boss®, Kickstand®, LASERLOC®, LONG-LASTING WORK LIFE®, MAX

FORCETM, MAX LIFE®, Micro-Set®, Midi-Lathe®, Monsoon®, MONSTER-CARBIDETM, Network®, OLDHAM®, Omnijig®, PC EDGE®,

Performance CrewTM, Performance Gear®, Pocket Cutter®, Porta-Band®, Porta-Plane®, Porter-Cable®, Porter-Cable Professional

Power Tools®, Powerback®, POZI-STOPTM, Pressure Wave®, PRO 4000®, Proair®, Quicksand and Design®, Quickset II®, QUIET

DRIVE TECHNOLOGYTM, QUIET DRIVE TECHNOLOGY AND DESIGNTM, Quick-Change®, QUIK-TILT®, RAPID-RELEASETM,

RAZOR®, Redefining Performance®, Riptide®, Safe Guard II®, Sand Trap and Design®, Sanding Center®, Saw Boss®, Shop Boss®,

Sidekick®, Site Boss®, Speed-Bloc®, Speedmatic®, Stair Ease®, Steel Driver Series®, SUPERDUTY®, T4 & DESIGN®,

THE AMERICAN WOODSHOP®, THE PROFESSIONAL EDGE®, Thin-Line®, Tiger Saw®, TIGERCLAW®, TIGERCLAW AND

DESIGN®, Torq-Buster®, TRU-MATCH®, T-Square®, Twinlaser®, Unifence®, Uniguard®, UNIRIP®, UNISAW®, UNITED STATES SAW®,

Veri-Set®, Versa-Feeder®, VIPER®, VTTM, VT RAZORTM, Water Driver®, WATER VROOM®, Waveform®, Whisper Series®, X5®, YOUR

ACHIEVEMENT. OUR TOOLS.

also be registered in other countries. Other trademarks may apply.

®

, Trademarks noted with ® are registered in the United States Patent and Trademark Office and may

PORTER-CABLE and the PORTER-CABLE logo are registered trademarks of PORTER-CABLE and are used under license. All

rights reserved.

Power Tool Specialists, Inc.

684 Huey Road, Rock Hill, SC 29730

(888) 609-9779

www.portercable.com

20

Loading...

Loading...