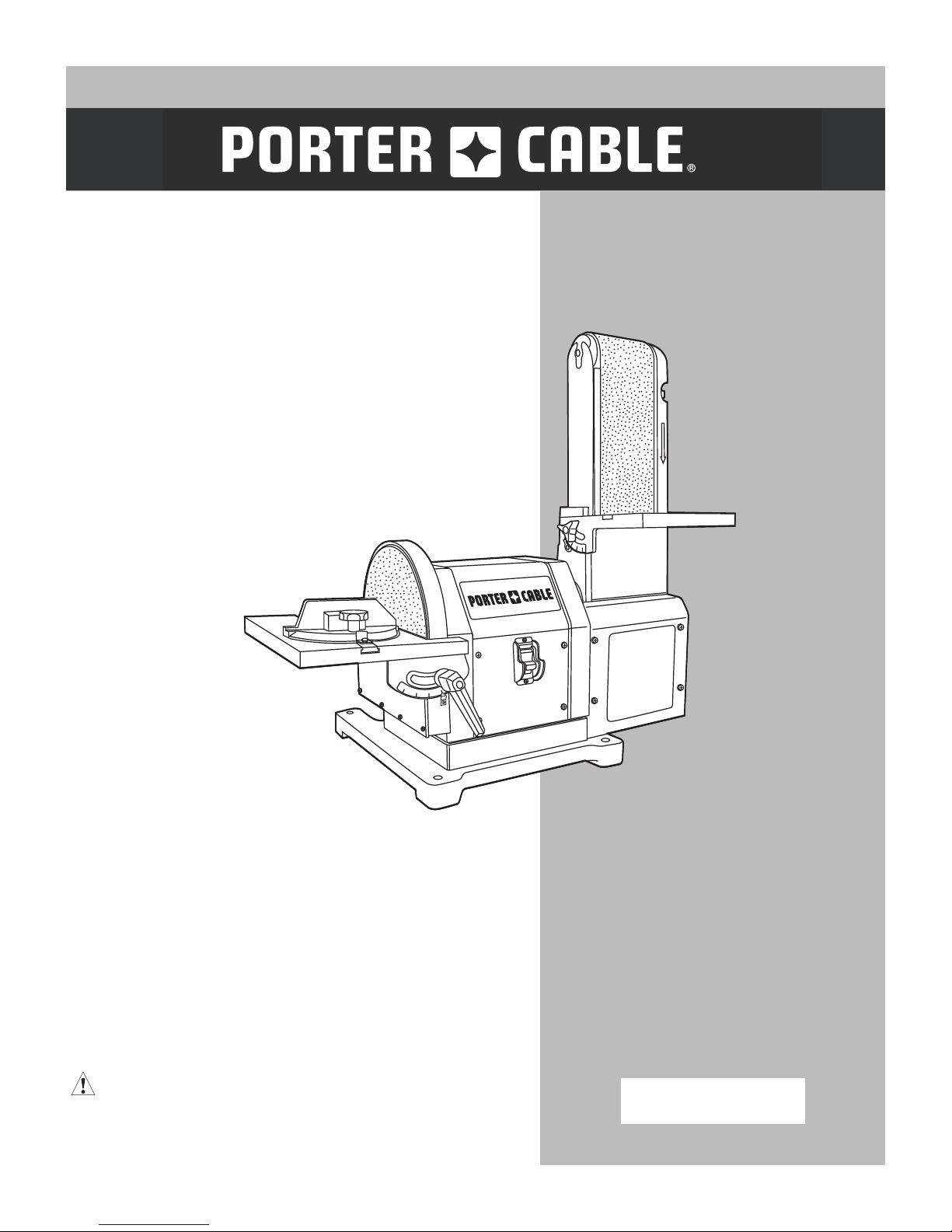

Porter-Cable PCB420SA Instruction Manual

ON

OFFONOFF

4 IN. x 8 IN. (102 MM x 203 MM)

BELT / DISC SANDER

PONCEUSE À BANDE/DISQUE DE

102 MM x 203 MM (4 PO x 8 PO)

LIJADORA DE CORREA / DISCO DE

102 MM x 203 MM (4 PULG. x 8 PULG.)

Instruction Manual

Manuel d’instructions

Manual de instrucciones

www.portercable.com

INSTRUCTIVO DE OPERACIÓN, CENTROS

DE SERVICIO Y PÓLIZA DE GARANTÍA.

ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

CATALOG NUMBER

PCB420SA

1

TABLE OF CONTENTS

SECTION PAGE

PRODUCT SPECIFICATIONS .........................................................................................................................

CALIFORNIA PROPOSITION 65 ..................................................................................................................... 2

SAFETY GUIDELINES - DEFINITIONS ........................................................................................................... 3

POWER TOOL SAFETY .................................................................................................................................. 4

BELT / DISC SANDER SAFETY ....................................................................................................................... 5

ELECTRICAL REQUIREMENTS AND SAFETY .............................................................................................. 6

TOOLS NEEDED FOR ASSEMBLY .................................................................................................................

CARTON CONTENTS ...................................................................................................................................... 7

KNOW YOUR BELT / DISC SANDER...............................................................................................................

ASSEMBLY AND ADJUSTMENTS................................................................................................................... 10

OPERATION .................................................................................................................................................... 14

MAINTENANCE ............................................................................................................................................... 16

TROUBLESHOOTING GUIDE.......................................................................................................................... 18

ACCESSORIES AND ATTACHMENTS ........................................................................................................... 19

PARTS LIST ..................................................................................................................................................... 20

WARRANTY ..................................................................................................................................................... 24

2

7

9

PRODUCT SPECIFICATIONS

MOTOR BELT

Amps ....................... 5 AMP Speed ...................... 2160 FPM (No load)

Voltage .................... 120 V Size ......................... 4 in. wide x 36 in. long

Hz ........................... 60

Horsepower ............ 3/4 HP (Max. Developed) DISC

Speed ..................... 3450 RPM (No load) Speed ..................... 3450 RPM (No load)

Type......................... Induction Size ......................... 8 in. diameter (203 mm)

BELT WORKTABLE 6-11/16 in. x 4-15/16 in. DISC WORKTABLE 10-25/64 in. x 5-29/32 in.

MITER GAUGE

(170 mm x 125 mm)

0 ~ 60° Right / Left

DUST EXHAUST PORT

(102 mm x 914 mm)

(264 mm x 150 mm)

2-1/2 in. O.D. (63.5 mm)

!

WARNING

To avoid electrical hazards, fire hazards or damage to the tool, use proper circuit protection. Use a seperate electrical

circuit for your tools. This sander is wired at the factory for 110-120 Volt operation. It must be connected to a 110-120

Volt / 5 Ampere time delay fuse or circuit breaker. To avoid shock or fire, replace power cord immediately if it is worn,

cut or damaged in any way.

CALIFORNIA PROPOSITION 65

!

WARNING

Some dust created by power sanding, sawing, grinding, drilling and other construction activities contains

chemicals know to the state of California to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

● Lead from lead-based paints,

● Crystalline silica from bricks and cement and other masonry products, and

● Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction

activities. Wear protective clothing and wash exposed areas with soap and water. Allowing dust to get into

your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

!

WARNING

protection appropriate for the dust exposure. Direct particles away from face and body.

2010/10

Use of this tool can generate and/or disperse dust, which may cause serious and

permanent respiratory or other injury. Always use NIOSH/OSHA approved respiratory

2

Printed in China

SAFETY GUIDELINES - DEFINITIONS

WARNING ICONS

Your power tool and its Instruction Manual may contain “WARNING ICONS” (a picture symbol intended to alert

you to, and/or instruct you how to avoid, a potentially hazardous condition). Understanding and heeding these

symbols will help you operate your tool better and safer. Shown below are some of the symbols you may see.

SAFETY ALERT: Precautions that involve your safety.

PROHIBITION

WEAR EYE PROTECTION: Always wear safety goggles or safety glasses with side shields.

WEAR RESPIRATORY AND HEARING PROTECTION: Always wear respiratory and hearing protection.

READ AND UNDERSTAND INSTRUCTION MANUAL: To reduce the risk of injury, user and all bystanders

must read and understand instruction manual before using this product.

KEEP HANDS AWAY FROM BLADE: Failure to keep your hands away from the blade will result in serious

personal injury.

SUPPORT AND CLAMP WORK

!

DANGER

!

WARNING

!

CAUTION

CAUTION

SANDING LEAD BASED PAINT:

Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the contaminated dust. The

greatest danger of lead poisoning is to children and pregnant women. Since it is difficult to identify whether or not a

paint contains lead without a chemical analysis, we recommend the following precautions when sanding any paint:

PERSONAL SAFETY:

No children or pregnant women should enter the work area where the paint sanding is being done until all clean up

●

is completed.

● A dust mask or respirator should be worn by all persons entering the work area. The filter should be replaced daily

or whenever the wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust and fumes should be used. Ordinary painting

masks do not offer this protection. See your local hardware dealer for the proper (NIOSH approved) mask.

● NO EATING, DRINKING or SMOKING should be done in the work area to prevent ingesting contaminated paint

particles. Workers should wash and clean up BEFORE eating, drinking or smoking. Articles of food, drink, or

smoking should not be left in the work area where dust would settle on them.

ENVIRONMENTAL SAFETY:

● Paint should be removed in such a manner as to minimize the amount of dust generated.

● Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils thickness.

● Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

CLEANING AND DISPOSAL:

● All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the duration of the sanding

project. Vacuum filter bags should be changed frequently.

● Plastic drop cloths should be gathered up and disposed of along with any dust chips or other removal debris. They

should be placed in sealed refuse receptacles and disposed of through regular trash pick-up procedures. During

clean up, children and pregnant women should be kept away from the immediate work area.

All toys, washable furniture and utensils used by children should be washed thoroughly before being used again.

●

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result in minor

or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

3

POWER TOOL SAFETY

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THIS POWER TOOL

Safety is a combination of common sense, staying alert

and knowing how to use your power tool.

!

WARNING

To avoid mistakes that could cause serious injury,

do not plug the tool in until you have read and

understood the following.

1. READ and become familiar with the entire

Instruction Manual. LEARN the tool’s

application, limitations and possible hazards.

2. KEEP GUARDS IN PLACE and in working order.

3. REMOVE ADJUSTING KEYS AND WRENCHES.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning ON.

4. KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

5. DO NOT USE IN DANGEROUS ENVIRONMENTS.

Do not use power tools in damp locations, or expose

them to rain or snow. Keep work area well lit.

6. KEEP CHILDREN AWAY. All visitors and

bystanders should be kept a safe distance from work

area.

7. MAKE WORKSHOP CHILD PROOF with padlocks,

master switches or by removing starter keys.

8. DO NOT FORCE THE TOOL. It will do the job better

and safer at the rate for which it was designed.

9. USE THE RIGHT TOOL. Do not force the tool or an

attachment to do a job for which it was not designed.

10. USE PROPER EXTENSION CORDS. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

An undersized cord will result in a drop in line

voltage and in loss of power which will cause the tool

to overheat. The table on page 6 shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gauge. The smaller the gauge number, the heavier

the cord.

11. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets or other

jewelry which may get caught in moving parts.

Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

NOTE: Glasses or goggles not in compliance with

ANSI Z87.1 could seriously injure you when they

break.

13. WEAR A FACE MASK OR DUST MASK.

Sanding operation produces dust.

14. SECURE WORK. Use clamps or a vise to

hold work when practical. It is safer than

using your hand and it frees both hands to

operate the tool.

15. DISCONNECT TOOLS FROM POWER SOURCE

before servicing, and when changing accessories

such as blades, bits and cutters.

16. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure switch is in the OFF position

before plugging the tool in.

17. USE RECOMMENDED ACCESSORIES.

Consult this Instruction Manual for recommended

accessories. The use of improper accessories may

cause risk of injury to yourself or others.

18. NEVER STAND ON THE TOOL. Serious injury

could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

19. CHECK FOR DAMAGED PARTS. Before further

use of the tool, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function

– check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

20. NEVER LEAVE THE TOOL RUNNING

UNATTENDED. TURN THE POWER “OFF”. Do not

walk away from a running tool until the blade comes

to a complete stop and the tool is unplugged from

the power source.

21. DO NOT OVERREACH. Keep proper footing and

balance at all times.

22. MAINTAIN TOOLS WITH CARE. Keep tools sharp

and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

23. DO NOT use power tool in presence of flammable

liquids or gases.

24. DO NOT operate the tool if you are under the

influence of any drugs, alcohol or medicationn that

could affect your ability to use the tool properly.

12. ALWAYS WEAR EYE PROTECTION. Any

power tool can throw foreign objects into

the eyes and could cause permanent eye

damage. ALWAYS wear Safety Goggles

(not glasses) that comply with ANSI Safety standard

Z87.1. Everyday eyeglasses have only impact–

resistant lenses. They ARE NOT safety glasses.

25. Dust generated from certain materials can be

hazardous to your health. Always operate sander

in well-ventilated area and provide for proper dust

removal.

26. WEAR HEARING PROTECTION to reduce

the risk of induced hearing loss.

4

BELT / DISC SANDER SAFETY

1. USE sander on horizontal surfaces only. Operating

the sander when mounted on non-horizontal

surfaces might result in motor damage.

2. TO STOP it from tipping over or moving when in

use, the sander must be securely fastened to a

bench top or supporting surface.

3. PLACE the sander so neither the user nor

bystanders are forced to stand in line with the

abrasive belt or disc.

4. MAKE SURE the sanding belt is installed in the

correct direction. See directional arrow on back of

belt.

5. ALWAYS have the tracking adjusted properly so the

belt does not run off the pulleys.

6. DO NOT USE sanding belts or discs that are

damaged, torn or loose. Use only correct size

sanding belt and disc. Narrower belts uncover parts

that could trap fingers.

7. MAKE SURE there are no nails or foreign objects in

the part of the workpiece to be sanded.

8. ALWAYS HOLD the workpiece firmly when sanding.

Keep hands away from sanding belt or disc. Sand

only one workpiece at a time.

9. ALWAYS HOLD the workpiece firmly on the table

when using the disc sander and when using the belt

sander.

10. ALWAYS SAND ON THE DOWNWARD SIDE

of the sanding disc when using the disc sander.

Sanding on the upward side of the disc could cause

the workpiece to fly out of position, resulting in

injury.

15. DO NOT sand with the workpiece unsupported.

Support the workpiece with the backstop or table.

Plan your work support.

16. NEVER USE ANOTHER PERSON as additional

support for a workpiece longer or wider than the

table.

17. ALWAYS remove scrap pieces and other objects

from the table, backstop or belt before turning the

sander ON.

18. NEVER perform layout, assembly or set-up work on

the table while the sander is operating.

19. NEVER use solvents to clean plastic parts. Solvents

could dissolve or otherwise damage the material.

Use only a soft damp cloth to clean plastic parts.

20. SHOULD any part of your sander be missing,

damaged, or fail in any way, or any electrical

components fail to perform properly, shut off switch

and remove plug from power source outlet. Replace

missing, damaged or failed parts before resuming

operation.

21. NEVER PULL THE POWER CORD out of the

receptacle by pulling on the cord. Keep cords away

from heat, oil and sharp edges.

22. HAVE AN ELECTRICIAN REPLACE OR REPAIR

damaged or worn cords immediately.

23. This tool is not approved for use for any material

other than wood and wood products.

11. ALWAYS maintain a minimum clearance of 1/16

inch (1.6 mm) or less between the table or backstop

and the sanding belt or disc.

12. DO NOT sand pieces of material that are too small

to be safely supported.

13. KEEP fingers away from where the belt goes into

the dust trap.

14. WHEN sanding a large workpiece, provide

additional support at table height.

5

ELECTRICAL REQUIREMENTS AND SAFETY

POWER SUPPLY AND MOTOR SPECIFICATIONS

!

WARNING

To avoid electrical hazards, fire hazards, or damage

to the tool, use proper circuit protection. Use a

seperate electrical circuit for your tool. Your sander

is wired at the factory for 120 V operation. Connect

to a 120 V, 5 Amp circuit and use a 5 Amp time delay

fuse or circuit breaker. To avoid shock or fire, if

power cord is worn, cut, or damaged in any way,

have it replaced immediately.

GROUNDING INSTRUCTIONS

!

WARNING

This tool must be grounded while in use to protect

the operator from electrical shock.

IN THE EVENT OF A MALFUNCTION OR

BREAKDOWN, grounding provides a path of least

resistance for electric currents and reduces the risk of

electric shock. This tool is equipped with an electrical

cord that has an equipment-grounding conductor

and a grounding plug. The plug must be plugged

into a matching receptacle that is properly installed

and grounded in accordance with all local codes and

ordinances.

DO NOT MODIFY THE PLUG PROVIDED. If it will not

fit the receptacle, have the proper receptacle installed

by a qualified electrician.

IMPROPER CONNECTION of the equipment grounding

conductor can result in risk of electric shock. The

conductor with the green insulation (with or without

yellow stripes) is the equipment grounding conductor.

If repair or replacement of the electrical cord or plug is

necessary, do not connect the equipment grounding

conductor to a live terminal.

CHECK with a qualified electrician or service person

if you do not completely understand the grounding

instructions, or if you are not certain the tool is properly

grounded.

USE only 3-wire extension cords that have

three-pronged grounding plugs with three-pole

receptacles that accept the tool’s plug. Repair or

replace damaged or worn cords immediately.

Use a separate electrical circuit for your tool. This circuit

must not be less than #18 wire and should be protected

with a 5 Amp time lag fuse. Before connecting the motor

to the power line, make sure the switch is in the off

position and the electric current is rated the same as the

current stamped on the motor nameplate. Running at a

lower voltage will damage the motor.

GUIDELINES FOR EXTENSION CORDS

USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. Use an

extension cord heavy enough to carry the current your

product will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power, overheating

and burning out of the motor. The table below shows

the correct size to use depending on cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

Make sure your extension cord is properly wired and in

good condition. Always replace a damaged extension

cord or have it repaired by a qualified technician before

using it. Protect your extension cords from sharp

objects, excessive heat and damp or wet areas.

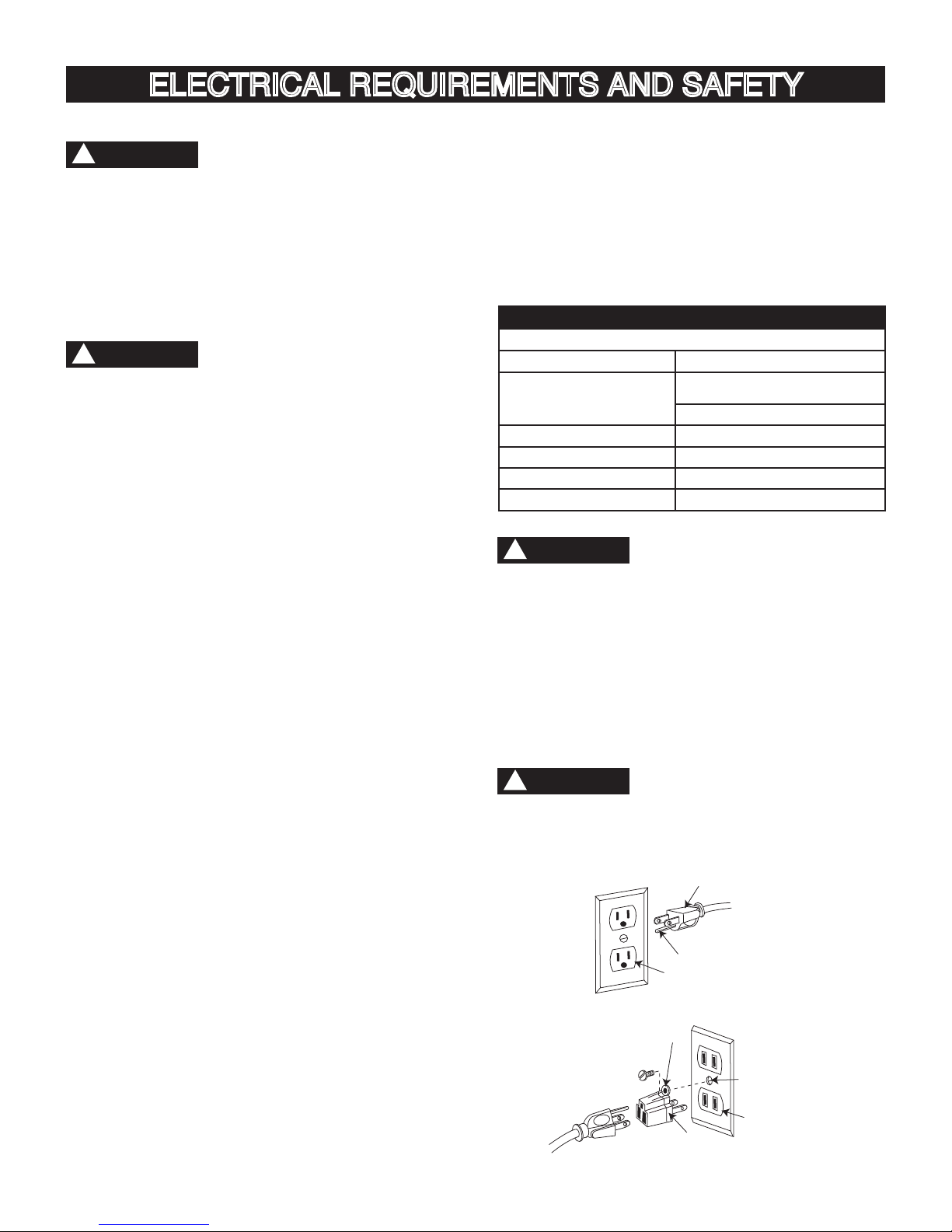

MINIMUM GAUGE FOR EXTENSION CORDS (AWG)

(When using 120 volts only)

Ampere Rating Total length of Cord

More Than Not More Than 25 50 100 150 ft.

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

!

WARNING

(7.62 15.24 30.48 45.72 m)

AWG- American Wire Gauge

This tool is for indoor use only. Do not expose to

rain or use in damp locations.

This tool is intended for use on a circuit that has a

receptacle like the one illustrated in Fig. 1. Fig. 1 shows

a three-pronged electrical plug and receptacle that

has a grounding conductor. If a properly grounded

receptacle is not available, an adapter (Fig. 2) can be

used to temporarily connect this plug to a two-contact

grounded receptacle. The adapter (Fig. 2) has a rigid

lug extending from it that MUST be connected to a

permanent earth ground, such as a properly grounded

receptacle box.

!

CAUTION

In all cases, make certain the receptacle is properly

grounded. If you are not sure, have a qualified

electrician check the receptacle.

Fig. 1

Three-Pronged Plug

Grounding Prong

Properly Grounded

Three-Pronged Receptacle

Fig. 2

Grounding Lug

Make sure this is

connected to a

known ground.

Two-Pronged

Receptacle

Adapter

6

TOOLS NEEDED FOR ASSEMBLY

CARTON CONTENTS

Supplied Not Supplied

5 mm hex key

Phillips screwdriver

Adjustable wrench

Combination square

Level

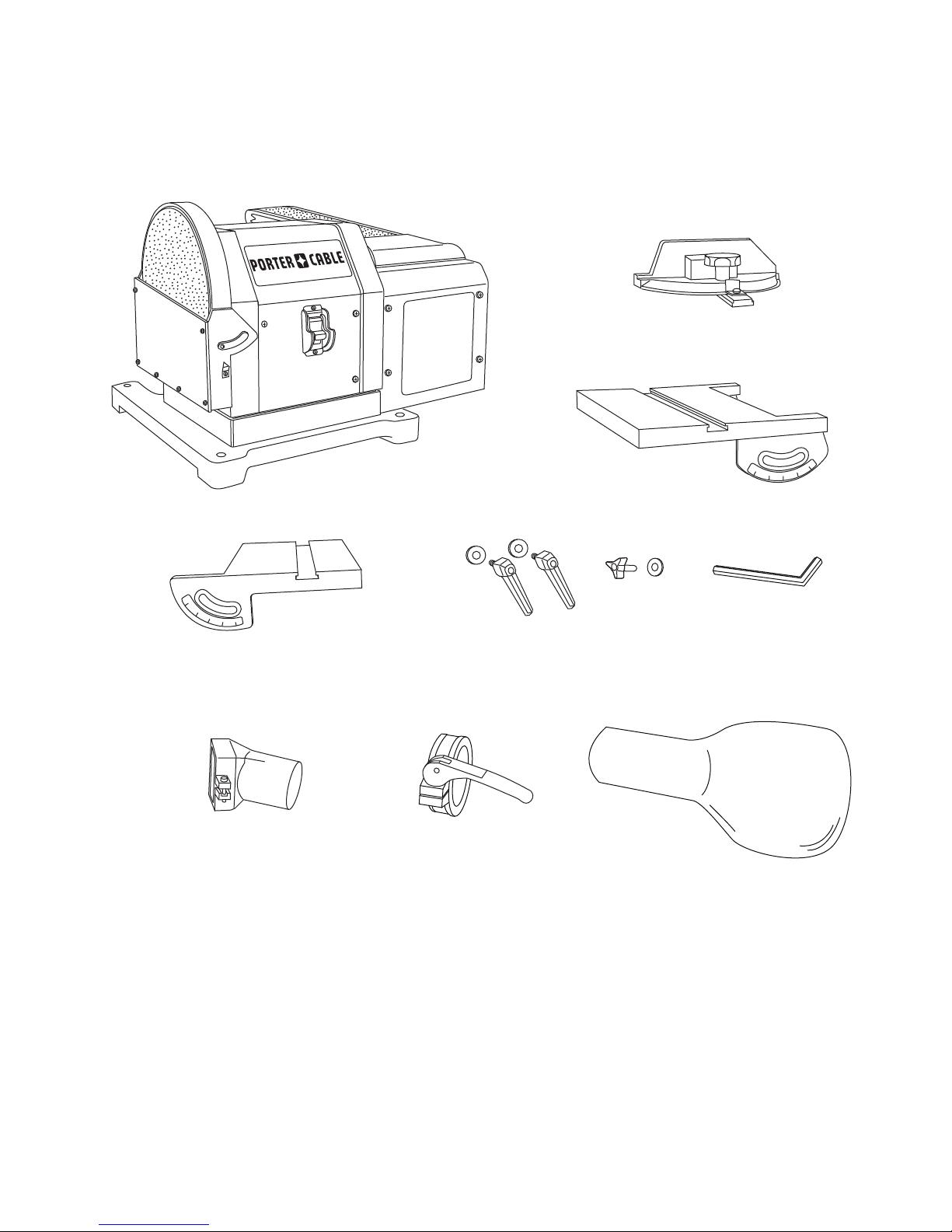

UNPACKING AND CHECKING CONTENTS

Carefully unpack the belt / disc sander and all its parts,

and compare against the list below and the illustration

on the next page. Place the belt / disc sander on a

secure surface and examine it carefully.

!

WARNING

• To avoid injury from unexpected starting or electrical

shock, do not plug the power cord into a source of

power during unpacking and assembly. This cord

must remain unplugged whenever you are adjusting/

assembling the sander.

• The sander is heavy and should be lifted with

care. To avoid injury, get assistance to help lift the

sander.

• If any part is missing or damaged, do not attempt

to assemble the sander, or plug in the power cord

until the missing or damaged part is correctly

replaced.

TABLE OF LOOSE PARTS

ITEM DESCRIPTION QUANTITY

A.

Belt / disc sander

B.

Miter gauge

C.

Disc worktable

D.

Belt worktable

E.

Hardware bag

Handles & washers

Knob & washer

Hex key

F.

Dust exhaust port

G.

Bag clamp

H.

Dust bag

1

1

1

1

2 each

1 each

1

1

1

1

7

UNPACKING YOUR BELT / DISC SANDER

ON

OFF

B

A

C

D E

F G H

8

Loading...

Loading...