Porter-Cable PC750RS, PC850RSO Instruction Manual

PC750RS Reciprocating Saw

PC850RSO Orbital Reciprocating Saw

Instruction manual

Manuel d'instructions

Manual de'instrucciones

www.portercable.com

INSTRUCTIVO DE OPERACIÓN,

CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA.

ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

Scie alternative PC750RS

Scie alternative à action orbitale PC850RSO

Sierra alternativa PC750RS

Sierra alternativa de acción orbital PC850RSO

CATALOG NUMBERS

PC750RS

PC850RSO

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 1

2

General Safety Rules

Read all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious injury. The term “power

tool” in all of the warnings listed below refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions

can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools.

Unmodified

plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions.

Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the

influence of drugs, alcohol or medication.

A moment of inattention while

operating power tool may result in serious personal injury.

b) Use safety equipment. Always wear eye protection.

Safety equipment such as

dust mask, non-skid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Avoid accidental starting. Ensure the switch is in the off-position before

plugging in.

Carrying power tools with your finger on the switch or plugging in

power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing

and gloves away from moving parts.

Loose clothes, jewelry or long hair can be

caught in moving parts. Air vents often cover moving parts and should also be avoided.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used.

Use of these devices

can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

:

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 2

3

b) Do not use the power tool if the switch does not turn it on and off.

Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools.

Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use.

Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of power tool,

taking into account the working conditions and the work to be performed.

Use of the power tool for operations different from those intended could result in a

hazardous situation.

5) Battery tool use and care

a) Ensure the switch is in the off position before inserting battery pack.

Inserting

the battery pack into power tools that have the switch on invites accidents.

b) Recharge only with the charger specified by the manufacturer.

A charger that

is suitable for one type of battery pack may create a risk of fire when used with

another battery pack.

c) Use power tools only with specifically designated battery packs.

Use of any

other battery packs may create a risk of injury and fire.

d) When battery pack is not in use, keep it away from other metal objects like

paper clips, coins, keys, nails, screws, or other small metal objects that can

make a connection from one terminal to another.

Shorting the battery terminals

together may cause burns or a fire.

e) Under abusive conditions, liquid may be ejected from the battery, avoid

contact. If contact accidentally occurs, flush with water. If liquid contacts

eyes, additionally seek medical help.

Liquid ejected from the battery may cause

irritation or burns.

6) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

SPECIFIC SAFETY RULES

• Hold power tools by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord.

Contact with a

"live" wire will make exposed metal parts of the tool "live" and shock the operator.

• Use clamps or another practical way to secure and support the work piece to a

stable platform.

Holding the work by hand or against your body leaves it unstable and

may lead to loss of control.

• Keep hands away from cutting area.

Never reach underneath the material for any

reason. Hold front of saw by grasping the contoured gripping area. Do not insert fingers

or thumb into the vicinity of the reciprocating blade and blade clamp. Do not stabilize the

saw by gripping the shoe.

• Keep blades sharp.

Dull blades may cause the saw to swerve or stall under pressure.

• Use extra caution when cutting overhead

and pay particular attention to overhead

wires which may be hidden from view

.

Anticipate the path of falling branches and debris

ahead of time.

• When cutting pipe or conduit

ensure that they are free from water, electrical wiring, etc.

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 3

4

ALWAYS

use safety glasses. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSAZ94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities contains chemicals known to the State of

California to cause cancer, birth defects or other reproductive harm.

Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water.

Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

Use of this tool can generate and/or disperse dust, which may

cause serious and permanent respiratory or other injury.

Always use

NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct

particles away from face and body.

Always wear proper personal hearing protection that conforms to

ANSI S12.6 (S3.19) during use.

Under some conditions and duration of use, noise

from this product may contribute to hearing loss.

SYMBOLS

• The label on your tool may include the following symbols. The symbols and their

definitions are as follows:

V..................volts A ..................amperes

Hz................hertz W..................watts

min ..............minutes ................alternating current

............direct current

n

o ................no load speed

................Class I Construction ..................earthing terminal

(grounded) ................safety alert symbol

................Class II Construction …/min ..........revolutions or reciprocation

(double insulated) per minute

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols

below are used to help you recognize this information.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

:

:

:

:

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 4

:

:

:

:

5

EXTENSION CORD

When using an extension cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier the cord.

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC only means

your tool will operate on standard 60 Hz household power. Do not operate AC tools on

DC. A rating of 120 volts AC/DC means that your tool will operate on standard 60 Hz

AC or DC power. This information is printed on the nameplate. Lower voltage will cause

loss of power and can result in over-heating. All Porter Cable tools are factory-tested; if

this tool does not operate, check the power supply.

SAVE THESE INSTRUCTIONS

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

(0-7,6m) (7,6-15,2m) (15,2-30,4m) (30,4-45,7m)

240V 0-50 51-100 101-200 201-300

(0-15,2m) (15,2-30,4m) (30,4-60,9m) (60,9-91,4m)

Ampere Rating

More Not more American Wire Gage

Than Than

0-6 18 16 16 14

6 - 10 18 16 14 12

10 - 12 16 16 14 12

12 - 16 14 12 Not Recommended

Functional Description

A. Trigger Switch E. Secondary Gripping Handle

B. Blade Clamp Release Lever F. Variable Speed Selector Wheel (PC850RSO)

C. Shoe G. Blade Action Selector (PC850RSO)

D. Main Handle H. Adjustable Shoe Button (PC850RSO)

A

E

D

C

B

H

G

F

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 5

6

OPERATION/SET-UP

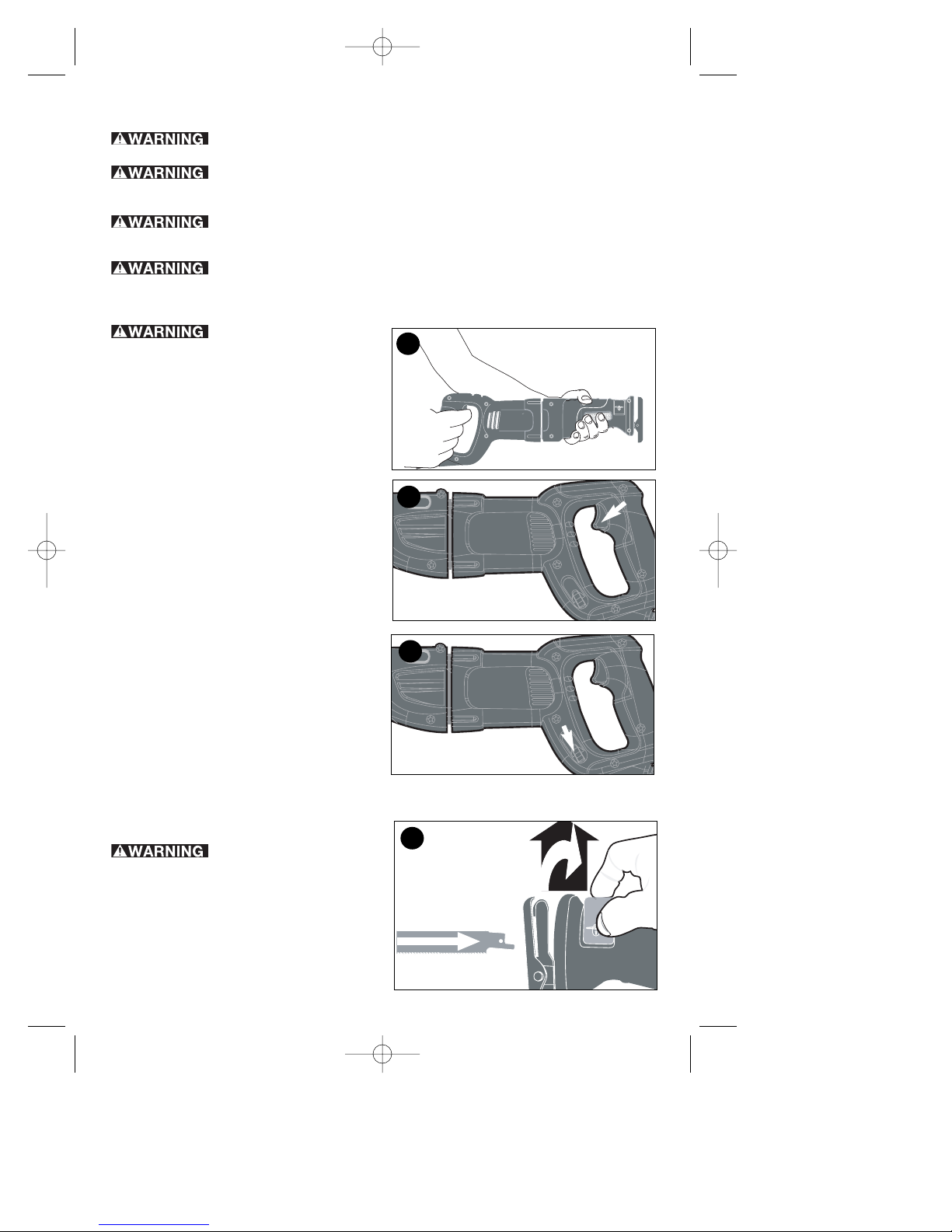

CUT HAZARD.

Turn off and disconnect tool from power source before

making any adjustments or removing or installing attachments or accessories.

CUT HAZARD.

Blade breakage may occur if the blade does not extend

past the shoe and the workpiece during the cut. Increased risk of personal injury, as well

as damage to the shoe and workpiece may result.

ALWAYS use safety glasses.

Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

CUT HAZARD.

Before cutting any type of material, be sure it is firmly

anchored or clamped to prevent slipping.

• Place blade lightly against work to be cut.

• Switch on saw motor before applying pressure.

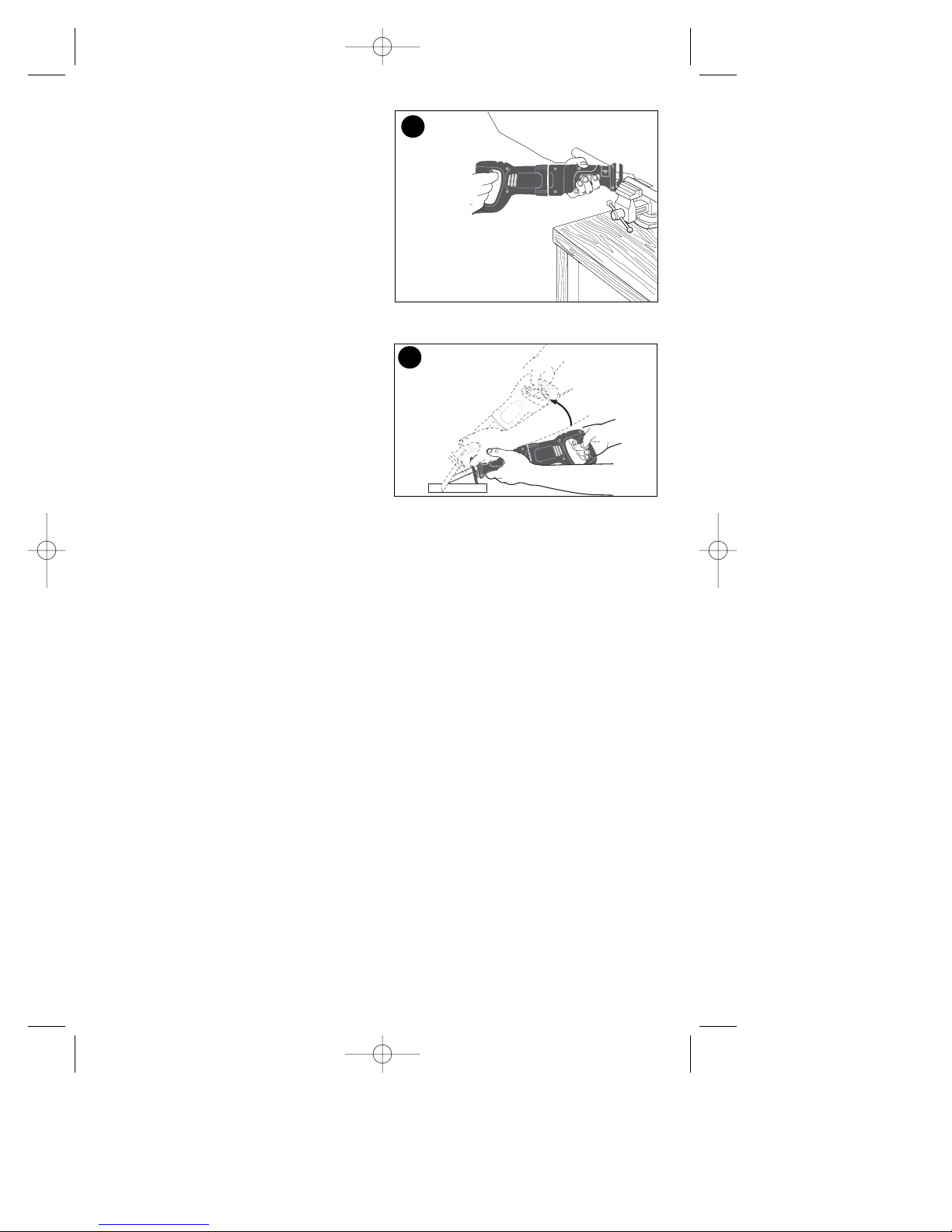

CUT HAZARD. Never hold

and use the product with your fingers

wrapped around shoe adjustment

button.

Always hold saw firmly with both

hands while cutting as shown in Figure 1.

Whenever possible, the saw shoe must be

held firmly against the material being cut.

This will prevent the saw from jumping or

vibrating and minimize blade breakage.

VARIABLE SPEED SWITCH PC750RS

ONLY (FIGURE 2)

The variable speed trigger switch will give

you added versatility. The further the trigger

is depressed the higher the speed of the

saw. To turn the tool “OFF” release the

trigger. NOTE: This tool has no provision to

lock the switch in the ON position, and

should never be locked in the ON position by

any other means.

VARIABLE SPEED SELECTOR WHEELPC850RSO ONLY (FIGURE 3)

The variable speed selector wheel offers a

choice of speeds for greatly improved cutting

rates in various materials. To select a slower

speed for operating the saw, rotate the wheel

to a low number on the dial. To select a higher

speed, rotate the wheel to a higher number.

To turn the tool “OFF” release the trigger.

NOTE: This tool has no provision to lock the

switch in the ON position, and should never be

locked in the ON position by any other means.

BLADE CLAMP RELEASE LEVER

(FIGURE 4)

CUT HAZARD.

Turn off and

disconnect tool from power source before

making any adjustments or removing or

installing attachments or accessories.

To install blade into saw:

1. Lift the blade clamp release lever to its full

open position as shown in Figure 4.

2. Insert blade shank from the front locating

hole in blade over pin on reciprocating

shaft.

:::::

:

4

1

2

3

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 6

1

7

3. Close blade clamp release lever.

4. Check to ensure blade is secure before cutting.

NOTE: Blade can be installed upside-down to assist in flush-to cutting.

To remove blade from saw:

BURN HAZARD.

Do not touch the the blade immediately after use.

Contact with the blade may result in personal injury.

1. Open blade clamp release lever to its full open position.

2. Remove blade.

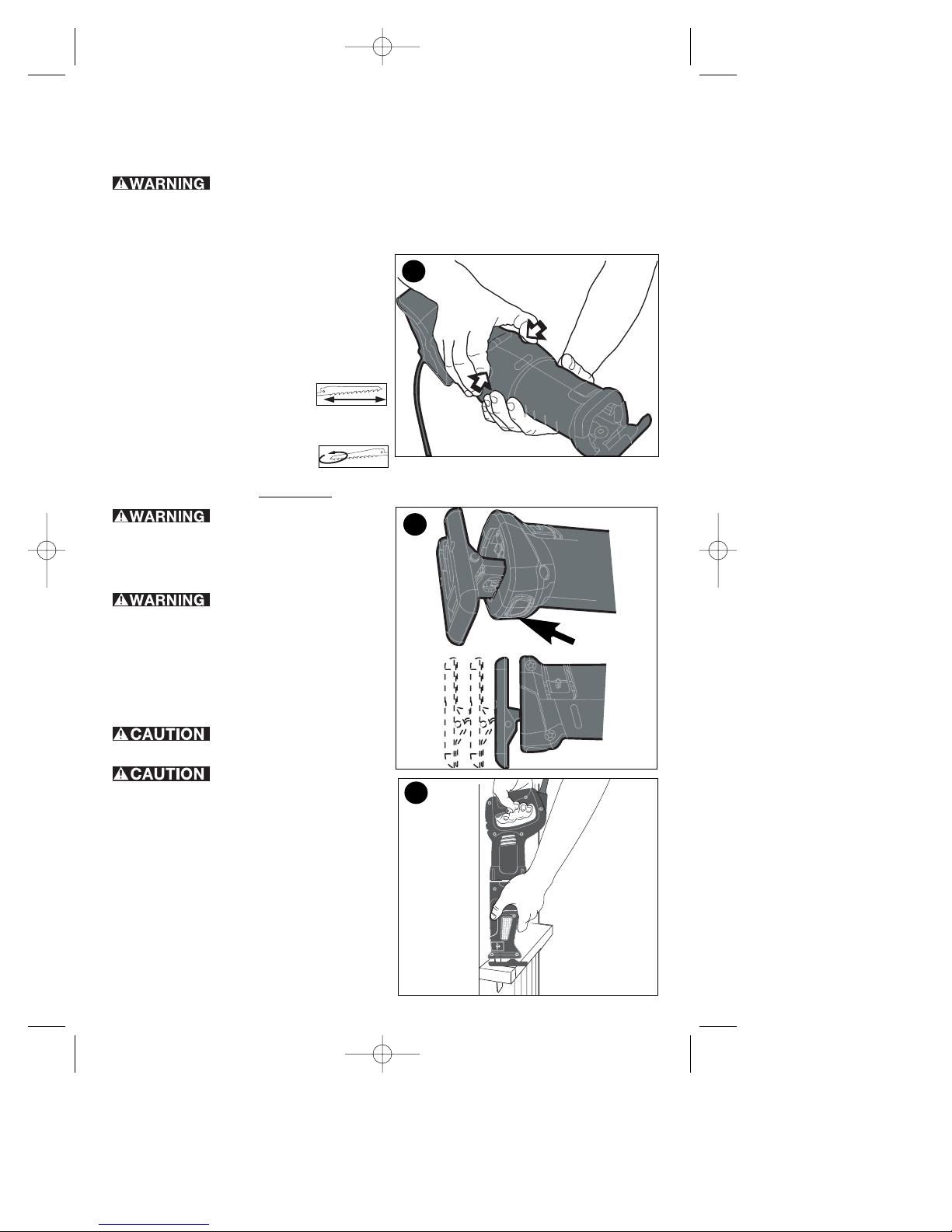

DUAL BLADE MOTION - PC850RSO ONLY

(FIGURE 5)

The PC850RSO has dual blade motion:

straight reciprocating motion or orbital motion.

Straight reciprocating motion is used for all

metal cutting operations and for wood cutting

applications where finish is more important

than speed. To set the saw for straight

reciprocating motion, hold the saw as shown

in figure 5 and slide the button

to the left.

Orbital motion is used for fast cutting of

wood. To set the saw for orbital action, hold

the saw as shown in figure 5 and

slide the button to the right.

ADJUSTABLE SHOE - PC850RSO

ONLY (FIGURE 6)

CUT HAZARD.

Blade

breakage may occur if the blade does not

extend past the shoe and the workpiece

during the cut. Increased risk of personal

injury, as well as damage to the shoe and

workpiece may result.

CUT HAZARD.

Turn off and

disconnect tool from power source before

making any adjustments or removing or

installing attachments or accessories.

The shoe will adjust to limit the depth of cut.

Hold the saw with the underside facing up.

Push the button (shown in Figure 6) on the

hand grip and slide the shoe out to one of

the three settings and release the button.

CUT HAZARD.

To prevent

loss of control, never use tool without shoe.

RISK OF PERSONAL

INJURY AND PROPERTY DAMAGE.

Ensure

the shoe is locked into position before using

tool.

FLUSH CUTTING (FIGURE 7)

• The compact design of the reciprocating

saw motor housing and pivoting shoe

permit close cutting to floors, corners and

other difficult areas.

• To maximize flush cutting capabilities,

insert the blade shaft into the blade clamp

with the teeth of the blade facing up.

• Turn the saw upside down so you are as

close to the work surface as possible.

:

:

:::

5

6

4

7

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 7

8

METAL CUTTING (FIGURE 8)

• Use a finer blade for ferrous metals and a

coarse blade for non-ferrous materials.

• In thin gauge sheet metals it is best to

clamp wood to the underside of the sheet.

This will ensure a clean cut without

excess vibration or tearing of metal.

• Avoid forcing cutting blade as this reduces

blade life and causes costly blade

breakage.

NOTE: Spread a thin film of oil or other

coolant along the line ahead of the saw cut

for easier operation and longer blade life. For

cutting aluminum, kerosene is preferred.

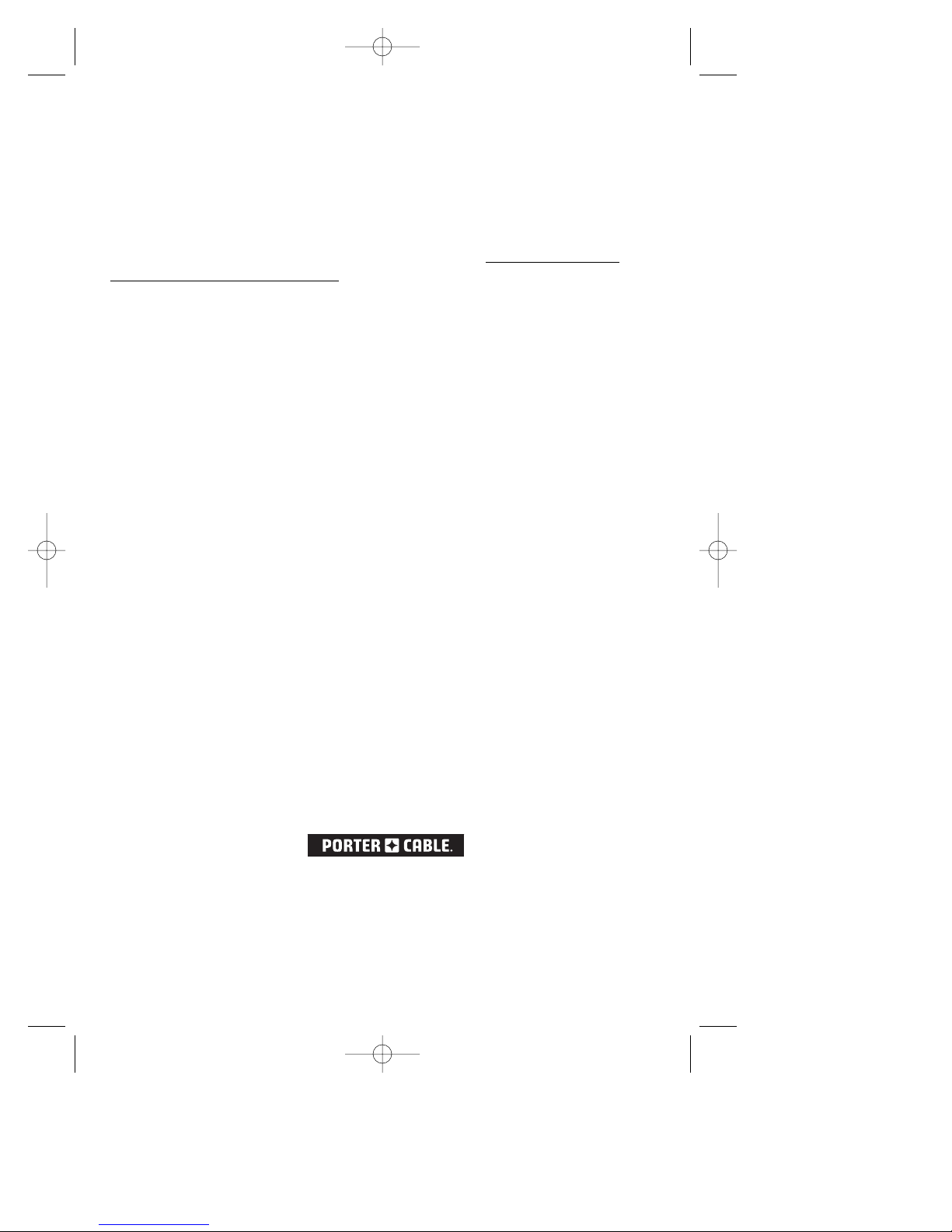

POCKET CUTTING - WOOD ONLY (FIGURE 9)

• Measure the surface area to be cut and

mark clearly with a pencil, chalk or

scriber.

• Insert blade in blade clamp and tighten

blade clamp securely.

• Tip the saw backward until the back edge

of the shoe is resting on the work surface

and the moving blade will clear the

surface.

• Switch motor on, permitting blade to

obtain maximum speed.

• Grip handle steadily and begin a slow,

deliberate upward swing with the handle of the saw.

• The blade will begin to feed into material. Always be sure blade is completely

through material before continuing with pocket cut.

NOTE: In areas where blade visibility is limited, use the edge of the shoe as a guide.

PROJECT TIPS

• Cut only with sharp blades; they cut cleaner, faster and put less strain on the motor

while cutting.

• When cutting, always ensure that the shoe is resting firmly against the workpiece.

This will improve operator control and minimize vibration.

• For longer blade life, use bi-metal blades. These utilize a carbon steel back welded

to high speed steel teeth making the blade more flexible and less prone to breaking.

MAINTENANCE

UNPLUG SAW AND REMOVE ACCESSORY WHEN PERFORMING ANY CLEANING

OR OTHER MAINTENANCE. WHEN SERVICING USE ONLY IDENTICAL

REPLACEMENT PARTS.

Use only mild soap and a damp cloth to clean the tool. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

• Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to

various types of commercial solvents and may be damaged by their use. Use clean

cloths to remove dirt, carbon dust etc.

• When electric tools are used on fiberglass boats, sports cars, drywall etc., they are

subject to accelerated wear and possible premature failure, as the fiberglass chips

and grindings and drywall dust are highly abrasive to bearings, brushes,

commutator, etc. During any use on fiberglass or drywall it is extremely important

that the tool be cleaned frequently by blowing with an air jet.

LUBRICATION

Porter Cable tools are properly lubricated at the factory and are ready for use. Tools

should be lubricated regularly every year depending on usage. (Tools used on heavy

duty jobs and tools exposed to heat may require more frequent lubrication.) This

lubrication should be attempted only by trained power tool repairperson's such as those

at Porter Cable service centers or in other qualified service personnel.

8

9

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 8

®

9

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service website at

www.portercable.com. You can also order parts from your nearest Porter-Cable Factory Service

Center or Porter-Cable Authorized Warranty Service Center. Or, you can call our Customer Care

Center at (888) 848-5175.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about

Porter-Cable, its factory service centers or authorized warranty service centers, visit our website at

www.portercable.com or call our Customer Care Center at (888) 848-5175. All repairs made by our

service centers are fully guaranteed against defective material and workmanship. We cannot

guarantee repairs made or attempted by others.

You can also write to us for information at PORTER-CABLE, 4825 Highway 45 North, Jackson,

Tennessee 38305 - Attention: Product Service. Be sure to include all of the information shown on

the nameplate of your tool (model number, type, serial number, etc.).

ACCESSORIES

This saw will accept up to a 12 inch long blade. Always use the shortest blade suitable

for your project but long enough to keep the blade cutting through the material. Longer

blades are more likely to be bent or damaged during use. During operation some

longer blades may vibrate or shake if the saw is not kept in contact with the workpiece.

Since accessories, other than those offered by Porter-Cable, have not

been tested with this product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only Porter-Cable recommended accessories

should be used with this product.

A complete line of accessories is available from your Porter-Cable Factory Service

Center or a Porter-Cable Authorized Warranty Service Center. Please visit our Web

Site www.portercable.com for a catalog or for the name of your nearest supplier.

THREE YEAR LIMITED WARRANTY

PORTER-CABLE will repair or replace, without charge, any defects due to faulty

materials or workmanship for three years from the date of purchase for tools (two

years for batteries). This warranty does not cover part failure due to normal wear or

tool abuse. For further detail of warranty coverage and warranty repair information,

visit www.portercable.com or call (888) 848-5175. This warranty does not apply to

accessories or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have other rights

which vary in certain states or provinces.

In addition to the warranty, PORTER-CABLE tools are covered by our:

:

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unit will not start. • Cord not plugged in. • Plug tool into a working outlet.

• Circuit fuse is blown. • Replace circuit fuse. (If the

product repeatedly causes the

circuit fuse to blow, discontinue

use immediately and have it

serviced at a Porter Cable

service center or authorized

servicer.)

• Circuit breaker is tripped. • Reset circuit breaker. (If the

product repeatedly causes the

circuit breaker to trip,

discontinue use immediately

and have it serviced at a Porter

Cable service center or

authorized servicer.)

• Cord or switch is damaged. • Have cord or switch replaced

at a Porter Cable Service

Center or Authorized Servicer

For assistance with your product, visit our website at www.portercable.com for a list of service

centers, or call the Porter-Cable Customer Care Center at (888) 848-5175.

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 9

10

1 YEAR FREE SERVICE: PORTER-CABLE will maintain the tool and replace worn

parts caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with the

performance of your PORTER-CABLE Power Tool for any reason, you can return it

within 90 days from the date of purchase with a receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific

warranty information contained in the packaging, call the local company or see website

for warranty information.

To register your tool for warranty service visit our website at www

.portercable.com.

W

ARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call (888) 848-5175 for a free

replacement.

The following are PORTER-CABLE trademarks for one or more power tools and accessories: a

gray and black color scheme; a “four point star” design; and three contrasting/outlined longitudinal

stripes. The following are also trademarks for one or more Porter-Cable and Delta products: Les

éléments ci-dessous sont des marques de commerce des outils et des accessoires de PORTERCABLE : un agencement de couleurs grise et noire; un motif d’ « étoile à quatre pointes » et trois

bandes longitudinales contrastantes/à contours. Les marques suivantes sont également des

marques de commerce se rapportant à un ou plusieurs produits Porter-Cable ou Delta : Las

siguientes son marcas comerciales PORTER-CABLE que distinguen a una o más herramientas y

accesorios: un gráfico de color gris y negro; un diseño de “estrella de cuatro puntas” y tres franjas

longitudinales contrastantes/delineadas. Las siguientes también son marcas comerciales para uno

o más productos de Porter-Cable y Delta: 2 BY 4®, 890™, Air America®, AIRBOSS™, Auto-Set®,

B.O.S.S.®, Bammer®, Biesemeyer®, Builders Saw®, Charge Air®, Charge Air Pro®,

CONTRACTOR SUPERDUTY®, Contractor's Saw®, Delta®, DELTA®, Delta Industrial®, DELTA

MACHINERY & DESIGN™, Delta Shopmaster and Design®, Delta X5®, Deltacraft®,

DELTAGRAM®, Do It. Feel It.®, DUAL LASERLOC AND DESIGN®, EASY AIR®, EASY AIR TO

GO™, ENDURADIAMOND®, Ex-Cell®, Front Bevel Lock®, Get Yours While the Sun Shines®,

Grip to Fit®, GRIPVAC™, GTF®, HICKORY WOODWORKING®, Homecraft®, HP FRAMER

HIGH PRESSURE®, IMPACT SERIES™, Innovation That Works®, Jet-Lock®, Job Boss®,

Kickstand®, LASERLOC®, LONG-LASTING WORK LIFE®, MAX FORCE™, MAX LIFE®, MicroSet®, Midi-Lathe®, Monsoon®, MONSTER-CARBIDE™, Network®, OLDHAM®, Omnijig®, PC

EDGE®, Performance Crew™, Performance Gear®, Pocket Cutter®, Porta-Band®, Porta-Plane®,

Porter Cable®, Porter-Cable Professional Power Tools®, Powerback®, POZI-STOP™, Pressure

Wave®, PRO 4000®, Proair®, Quicksand and Design®, Quickset II®, QUIET DRIVE

TECHNOLOGY™, QUIET DRIVE TECHNOLOGYAND DESIGN™, Quik-Change®, QUIKTILT®, RAPID-RELEASE™, RAZOR®, Redefining Performance®, Riptide®, Safe Guard II®,

Sand Trap and Design®, Sanding Center®, Saw Boss®, Shop Boss®, Sidekick®, Site Boss®,

Speed-Bloc®, Speedmatic®, Stair Ease®, Steel Driver Series®, SUPERDUTY®, T4 & DESIGN®,

THE AMERICAN WOODSHOP®, THE PROFESSIONAL EDGE®, Thin-Line®, Tiger Saw®,

TIGERCLAW®, TIGERCLAW AND DESIGN®, Torq-Buster®, TRU-MATCH®, T-Square®,

Twinlaser®, Unifence®, Uniguard®, UNIRIP®, UNISAW®, UNITED STATES SAW®, Veri-Set®,

Versa-Feeder®, VIPER®, VT™, VT RAZOR™, Water Driver®, WATER VROOM®, Waveform®,

Whisper Series®, X5®, YOUR ACHIEVEMENT. OUR TOOLS.®

Trademarks noted with ® are registered in the United States Patent and Trademark Office and may

also be registered in other countries. Other trademarks may apply. Les marques de commerce

suivies du symbole ® sont enregistrées auprès du United States Patent and Trademark Office et

peuvent être enregistrées dans d’autres pays. D’autres marques de commerce peuvent également

être applicables. Las marcas comerciales con el símbolo ® están registradas en la Oficina de

patentes y marcas comerciales de Estados Unidos (United States Patent and Trademark Office), y

también pueden estar registradas en otros países. Posiblemente se apliquen otras marcas

comerciales registradas.

4825 Highway 45 North Jackson, TN 38305 (888) 848-5175 www.portercable.com

90546363 PC750RS PC850RS 12/9/08 8:54 AM Page 10

Loading...

Loading...