Porter-Cable PC186CS, PC186CSL, PCL186CS Instruction Manual

18V 6

-

1

/

2

inch (165mm)

Circular Saw

Instruction manual

Manuel d'instructions

Manual de'instrucciones

www.portercable.com

INSTRUCTIVO DE OPERACIÓN,

CENTROS DE SERVICIO Y PÓLIZA DE

GARANTÍA.

ADVERTENCIA: LÉASE ESTE

INSTRUCTIVO ANTES DE USAR EL

PRODUCTO.

Batteries and chargers sold separately

CATALOG NUMBERS

PC186CS

PC186CSL

PCL186CS

Scie circulaire de 18V,

165 mm (6 1/2 po)

Sierra circular de 165 mm

(6 1/2 pulg.) y 18V

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 1

2

General Power Tool Safety Warnings

Read all safety warnings and instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions

can cause you to lose control

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do

not use any adapter plugs with earthed (grounded) power tools. Unmodified

plugs and matching outlets will reduce risk of electric shock

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock if

your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging

the power tool. Keep cord away from heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is unavoidable, use a ground fault

circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of

electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating

a power tool. Do not use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A moment of inattention while

operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the

tool. Carrying power tools with your finger on the switch or energizing power tools

that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust collection

can reduce dust-related hazards.

:

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 2

3

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application.

The correct power tool will do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the

power tool before making any adjustments, changing accessories, or storing

power tools. Such preventive safety measures reduce the risk of starting the power

tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons

unfamiliar with the power tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with these

instructions, taking into account the working conditions and the work to be

performed. Use of the power tool for operations different from those intended could

result in a hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger specified by the manufacturer. A charger that

is suitable for one type of battery pack may create a risk of fire when used with

another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any

other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects like

paper clips, coins, keys, nails, screws, or other small metal objects that can

make a connection from one terminal to another. Shorting the battery terminals

together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery, avoid

contact. If contact accidentally occurs, flush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected from the battery may cause

irritation or burns.

6) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool is

maintained.

ADDITIONAL SPECIFIC SAFETY RULES

Safety Instructions for All Saws

a. Keep hands away from cutting area and the blade. Keep your second hand on

auxiliary handle, or motor housing. If both hands are holding the saw, they

cannot be cut by the blade.

b. Do not reach underneath the workpiece. The guard cannot protect you from the

blade below the workpiece.

c. Adjust the cutting depth to the thickness of the workpiece. Less than a full

tooth of the blade teeth should be visible below the workpiece.

d. Never hold piece being cut in your hands or across your leg. Secure the

workpiece to a stable platform. It is important to support the work properly to

minimize body exposure, blade binding, or loss of control.

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 3

:

4

e. Hold power tool by insulated gripping surfaces when performing an operation

where the cutting tool may contact hidden wiring or its own cord. Contact with

a "live" wire will also make exposed metal parts of the power tool "live" and shock

the operator.

f. When ripping always use a rip fence or straight edge guide. This improves the

accuracy of cut and reduces the chance of blade binding.

g. Always use blades with correct size and shape (diamond versus round) of

arbor holes. Blades that do not match the mounting hardware of the saw will run

eccentrically, causing loss of control.

h. Never use damaged or incorrect blade washers or bolt. The blade washers and

bolt were specially designed for your saw, for optimum performance and safety of

operation.

CAUSES AND OPERATOR PREVENTION OF KICKBACK:

• Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, causing

an uncontrolled saw to lift up and out of the workpiece toward the operator.

• When the blade is pinched or bound tightly by the kerf closing down, the blade stalls

and the motor reaction drives the unit rapidly back toward the operator.

• If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the

blade can dig into the top surface of the wood causing the blade to climb out of the kerf

and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below:

a. Maintain a firm grip with both hands on the saw and position your arms to

resist kickback forces. Position your body to either side of the blade, but not

in line with the blade. Kickback could cause the saw to jump backwards, but

kickback forces can be controlled by the operator, if proper precautions are taken.

b. When blade is binding, or when interrupting a cut for any reason, release the

trigger and hold the saw motionless in the material until the blade comes to a

complete stop. Never attempt to remove the saw from the work or pull the

saw backward while the blade is in motion or kickback may occur. Investigate

and take corrective actions to eliminate the cause of blade binding.

c. When restarting a saw in the workpiece, center the saw blade in the kerf and

check that saw teeth are not engaged into the material. If saw blade is binding,

it may walk up or kickback from the workpiece as the saw is restarted.

d. Support large panels to minimize the risk of blade pinching and kickback.

Large panels tend to sag under their own weight. Supports must be placed under

the panel on both sides, near the line of cut and near the edge of the panel.

e. Do not use dull or damaged blades. Unsharpened or improperly set blades

produce narrow kerf causing excessive friction, blade binding and kickback.

f. Blade depth and bevel adjusting locking levers must be tight and secure

before making cut. If blade adjustment shifts while cutting, it may cause binding

and kickback.

g. Use extra caution when making a "plunge cut" into existing walls or other

blind areas. The protruding blade may cut objects that can cause kickback.

LOWER GUARD SAFETY INSTRUCTIONS

a. Check lower guard for proper closing before each use. Do not operate the

saw if lower guard does not move freely and close instantly. Never clamp or

tie the lower guard into the open position. If saw is accidentally dropped, lower

guard may be bent. Raise the lower guard with the retracting handle and make sure

it moves freely and does not touch the blade or any other part, in all angles and

depths of cut.

b. Check the operation of the lower guard spring. If the guard and the spring are

not operating properly, they must be serviced before use. Lower guard may

operate sluggishly due to damaged parts, gummy deposits, or a build-up of debris.

c. Lower guard should be retracted manually only for special cuts such as

"plunge cuts" and "compound cuts." raise lower guard by retracting handle

and as soon as blade enters the material, the lower guard must be released.

For all other sawing, the lower guard should operate automatically.

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 4

5

d. Always observe that the lower guard is covering the blade before placing saw

down on bench or floor. An unprotected, coasting blade will cause the saw to

walk backwards, cutting whatever is in its path. Be aware of the time it takes for the

blade to stop after switch is released.

SAFETY INSTRUCTIONS - LASERS (APPLIES TO PC186CSL)

Laser radiation, avoid direct eye exposure, serious eye injury can

result.

• Do not use optical tools such as a telescope or transit to view the laser beam.

• Position the laser so unintentional eye contact will be avoided.

• Do not operate the laser around children or allow children to operate the laser / power

tool.

• Do not disassemble. Modifying the product in any way can increase the risk of laser

radiation.

Use of controls or adjustments or performance of procedures other

than those specified in this manual may result in hazardous laser radiation exposure.

• Do not adjust the laser, when the battery is inserted in the circular saw.

• Do not operate in explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust.

• Store idle product out of reach of children and other untrained persons. Lasers / power

tools are dangerous in the hands of untrained users.

• Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one laser / power tool, may create a risk of injury

when used on another laser / power tool.

• Repairs and servicing MUST be performed by a qualified repair facility. Repairs

performed by unqualified personnel could result in serious injury.

• Do not remove or deface warning labels. Removing labels increases the risk of

exposure to radiation.

• For indoor use only.

• This product is intended for use in a temperature range of 41°F(5°C) - 104°F(40°C).

Some dust created by power sanding, sawing, grinding, drilling,

and other construction activities contains chemicals known to the state of

California to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling,

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

Use of this tool can generate and/or disperse dust, which may

cause serious and permanent respiratory or other injury. Always use

NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct

particles away from face and body.

Always wear proper personal hearing protection that conforms to

ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise

from this product may contribute to hearing loss.

ALWAYS use safety glasses. Everyday eyeglasses are NOT safety

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR

CERTIFIED SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSAZ94.3),

• ANSI S12.6 (S3.19) hearing protection,

• NIOSH/OSHA/MSHA respiratory protection.

:::

:

:

:

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 5

6

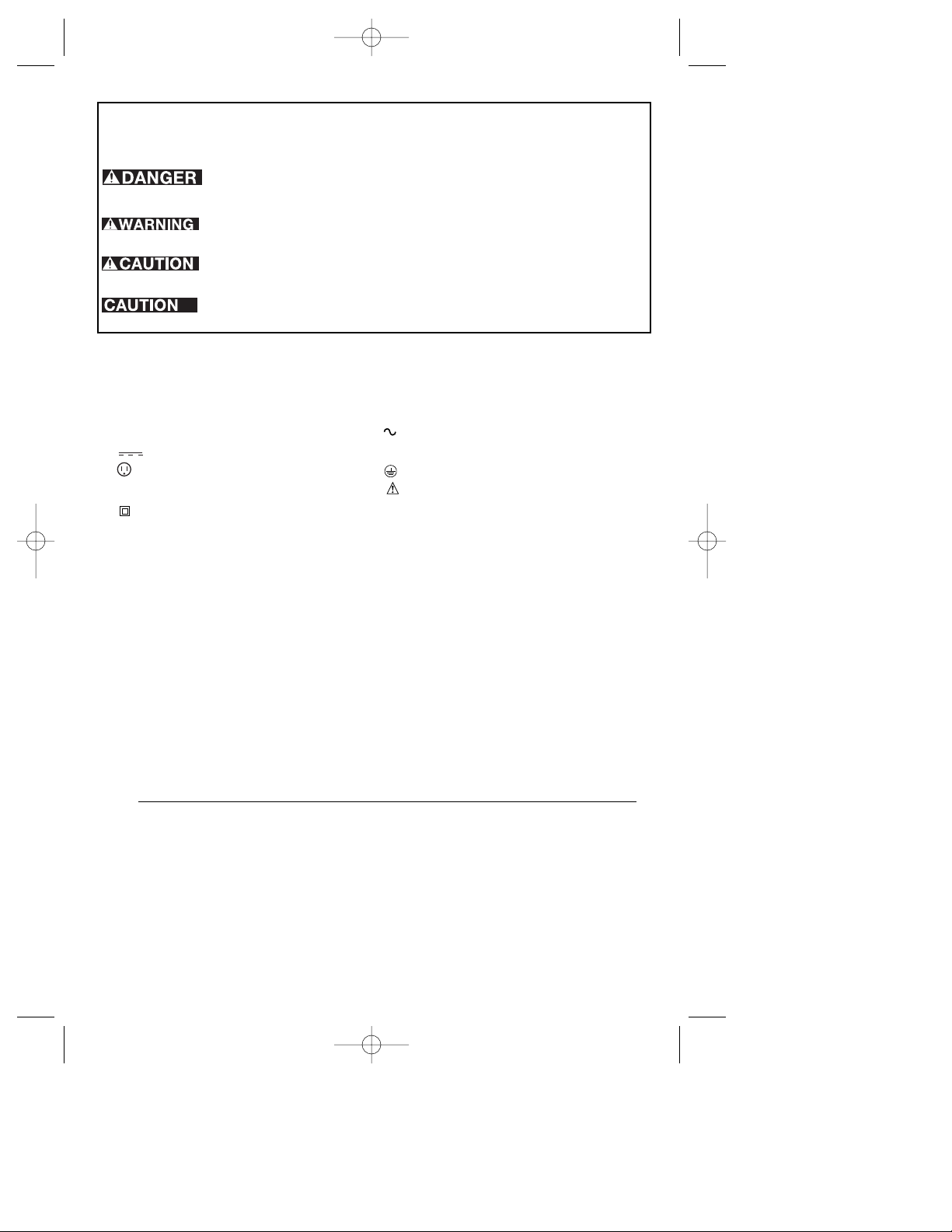

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains

relates to protecting YOUR SAFETY and PREVENTING PROBLEMS. The symbols

below are used to help you recognize this information.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

SYMBOLS

The label on your tool may include the following symbols. The symbols and their definitions

are as follows:

V..................volts A ..................amperes

Hz................hertz W..................watts

min ..............minutes ................alternating current

............direct current

n

o ................no load speed

................Class I Construction ..................earthing terminal

(grounded) ................safety alert symbol

................Class II Construction .../min or rpm..revolutions or reciprocation

(double insulated) per minute

The label on your laser may include the following symbols.

V ................................volts mW......................milliwatts

nm..............................wavelength in

nanometers

IIIa..............................Class IIlA Laser

• When using an extension cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line voltage resulting

in loss of power and overheating. The following table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gage. The smaller the gage number, the heavier the cord.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft. 50 ft. 75 ft. 100 ft. 125 ft. 150 ft. 175 ft.

7.6 m 15.2 m 22.9 m 30.5 m 38.1 m 45.7 m 53.3 m

Wire Size AWG

18 18 16 16 14 14 12

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 6

:

:

:

:

7

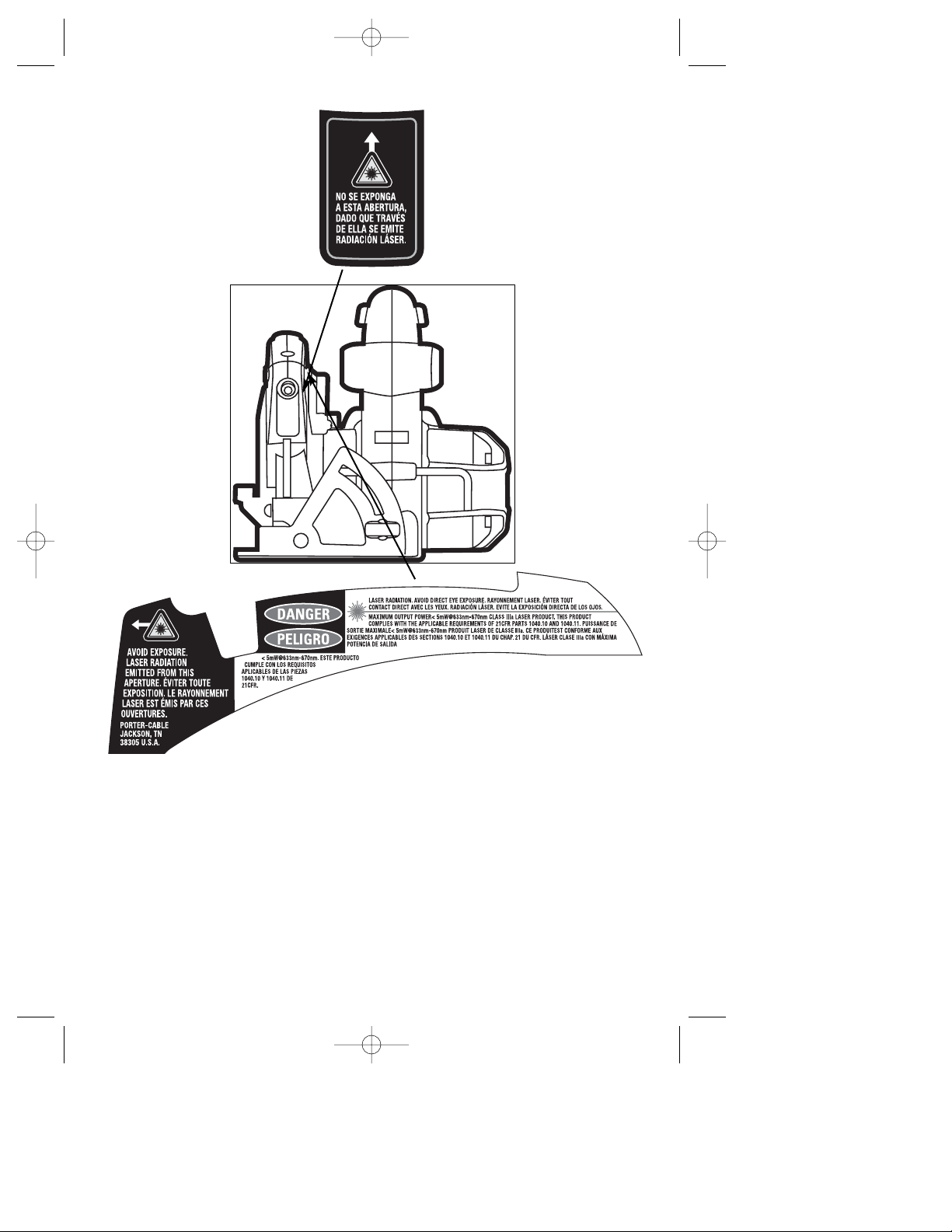

For your convenience and

safety, the following labels are

on your laser.

(APPLIES TO PC186CSL

)

Pour plus de commodité et de

sécurité, les étiquettes

suivantes sont apposées sur

le laser.

(S'APPLIQUE À PC186CSL

)

Para su comodidad y

seguridad, el láser incluye las

siguientes etiquetas.

(SE APLICA A PC186CSL

)

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 7

8

3

1

2

4

5

6

7

8

A

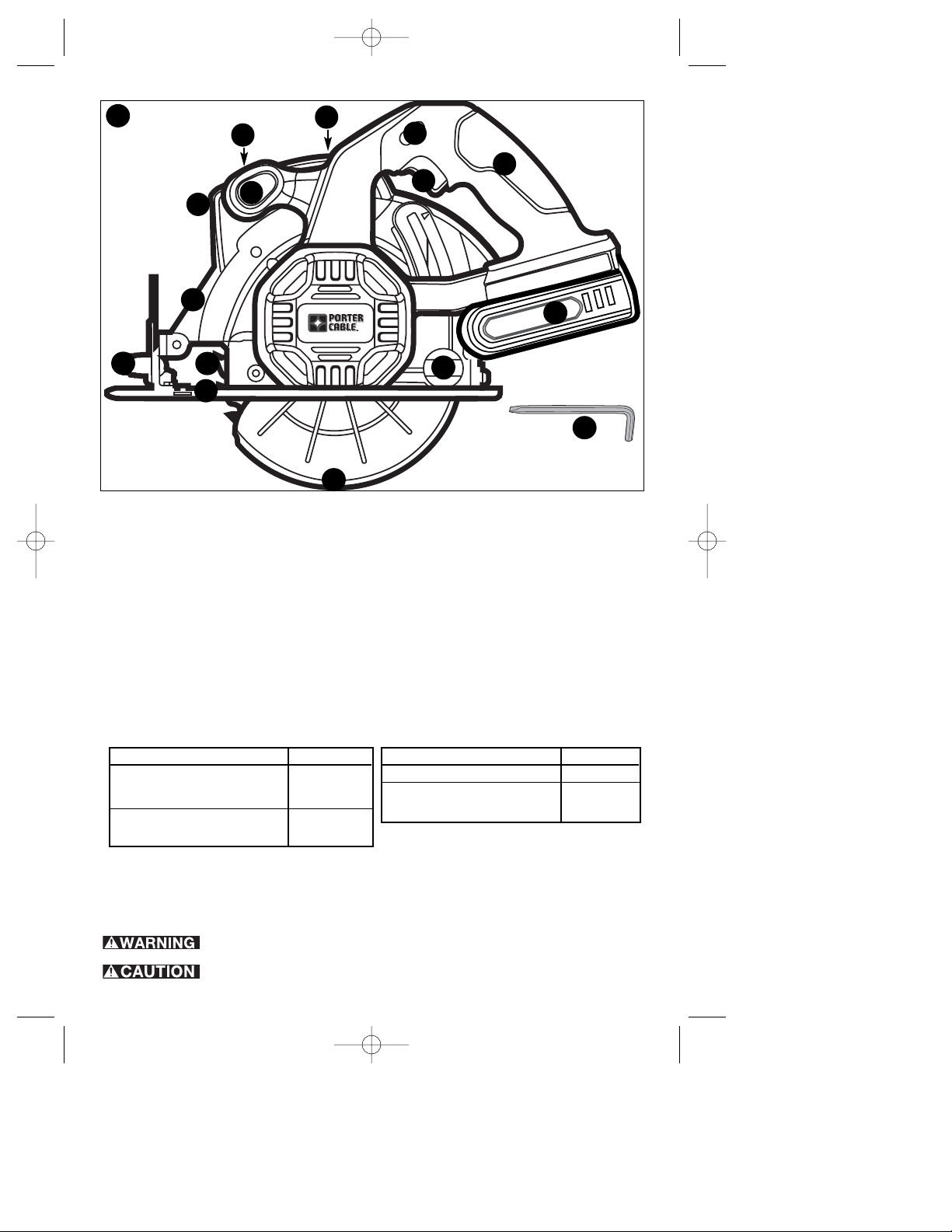

FUNCTIONAL DESCRIPTION

Figure A

1. On/off switch

2. Lock-off button

3. Laser on/off switch (PC186CSL)

4. Laser adjustment tabs (PC186CSL)

5. Laser (PC186CSL)

6. Main handle

7. Secondary handle

8. Shoe

9. Upper guard

10. Saw blade

11. Saw blade guard

12. Wrench

13. Bevel adjustment knob

14. Depth adjustment knob

15. Battery (not included)

16. Spindle lock (not shown)

9

10

11

13

14

15

12

IMPORTANT SAFETY INSTRUCTIONS FOR BATTERY CHARGERS

SAVE THESE INSTRUCTIONS: This manual contains important safety instructions for

battery chargers.

• Before using charger, read all instructions and cautionary markings on charger, battery

pack, and product using battery pack.

Shock hazard. Do not allow any liquid to get inside charger.

Burn hazard. To reduce the risk of injury, charge only designated

:

:

LI-ION Battery Packs and Chargers

Battery: LI-ION 18V

Charger: LI-ION

PC18BL

PC18BLX

PC18BLEX

PCLMVC

PCXMVC

Description Cat. #

NI-CD Battery Packs and Chargers

This product can accept any of the batteries and chargers listed in the chart below.

Battery: NI-CD 18V

Charger: NI-CD

PC18B

PCMVC

PCXMVC

Description Cat. #

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 8

9

PORTER-CABLE batteries. Other types of batteries may burst causing personal

injury and damage.

Under certain conditions, with the charger plugged in to the power

supply, the charger can be shorted by foreign material. Foreign materials of a

conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup

of metallic particles should be kept away from charger cavities. Always unplug the

charger from the power supply when there is no battery pack in the cavity. Unplug

charger before attempting to clean.

• DO NOT attempt to charge the battery pack with any chargers other than the

ones in this manual. The charger and battery pack are specifically designed to

work together.

• These chargers are not intended for any uses other than charging designated

PORTER-CABLE rechargeable batteries. Any other uses may result in risk of fire,

electric shock or electrocution.

• Do not expose charger to rain or snow.

• Pull by plug rather than cord when disconnecting charger. This will reduce risk

of damage to electric plug and cord.

• Make sure that cord is located so that it will not be stepped on, tripped over,

or otherwise subjected to damage or stress.

• Do not use an extension cord unless it is absolutely necessary. Use of

improper extension cord could result in risk of fire, electric shock, or electrocution.

• An extension cord must have adequate wire size (AWG or American Wire

Gauge) for safety. The smaller the gauge number of the wire, the greater the

capacity of the cable, that is 16 gauge has more capacity than 18 gauge. When

using more than one extension to make up the total length, be sure each individual

extension contains at least the minimum wire size.

• Do not place any object on top of charger or place the charger on a soft

surface that might block the ventilation slots and result in excessive internal

heat. Place the charger in a position away from any heat source. The charger

is ventilated through slots in the top and the bottom of the housing.

• Do not mount charger on wall or permanently affix charger to any surface.

The charger is intended to use on a flat, stable surface (i.e., table top, bench top).

• Do not operate charger with damaged cord or plug — have them replaced

immediately.

• Do not operate charger if it has received a sharp blow, been dropped, or

otherwise damaged in any way. Take it to an authorized service center.

• Do not disassemble charger; take it to an authorized service center when service

or repair is required. Incorrect reassembly may result in a risk of electric shock,

electrocution or fire.

• Disconnect the charger from the outlet before attempting any cleaning. This will

reduce the risk of electric shock. Removing the battery pack will not reduce this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard household electrical power

(120 Volts). Do not attempt to use it on any other voltage.

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTION FOR BATTERY PACKS

For safe operation, read this manual and manuals originally supplied

with tool before using the charger.

The battery pack is not fully charged out of the carton. Before using the battery pack

and charger, read the safety instructions below. Then follow charging procedures outlined.

READ ALL INSTRUCTIONS

• Do not incinerate the battery pack even if it is severely damaged or is

completely worn out. The battery pack can explode in a fire. Toxic fumes and

materials are created when LI-ION battery packs are burned.

• Do not charge or use battery in explosive atmospheres, such as in the presence

of flammable liquids, gases or dust. Inserting or removing the battery from the

charger may ignite the dust or fumes.

:

:

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 9

10

• If battery contents come into contact with the skin, immediately wash area with

mild soap and water. If battery liquid gets into the eye, rinse water over the open eye

for 15 minutes or until irritation ceases. If medical attention is needed, the battery

electrolyte for LI-ION batteries is composed of a mixture of liquid organic carbonates

and lithium salts. For NI-Cd batteries it is a 25-35% solution of potassium hydroxide.

• Contents of opened battery cells may cause respiratory irritation. Provide fresh

air. If symptoms persists, seek medical attention.

Burn hazard. Battery liquid may be flammable if exposed to spark or

flame.

• Charge the battery packs only in PORTER-CABLE chargers.

• DO NOT splash or immerse in water or other liquids. This may cause premature

cell failure.

• Do not store or use the tool and battery pack in locations where the

temperature may reach or exceed 105°F (40˚C) (such as outside sheds or metal

buildings in summer).

Never attempt to open the battery pack for any reason. If battery pack

case is cracked or damaged, do not insert into charger. Do not crush, drop or damage

battery pack. Do not use a battery pack or charger that has received a sharp blow, been

dropped, run over or damaged in any way (i.e., pierced with a nail, hit with a hammer,

stepped on). Damaged battery packs should be returned to service center for recycling.

BATTERY CAP INFORMATION

Battery storage and carrying caps are provided for use whenever the

battery is out of the tool or charger. Remove cap before placing battery in

charger or tool.

Fire hazard. Do not store or carry battery so that metal objects can

contact exposed battery terminals. For example, do not place battery in aprons,

pockets, tool boxes, product kit boxes, drawers, etc., with loose nails, screws, keys, etc.

Transporting batteries can possibly cause fires if the battery terminals

inadvertently come in contact with conductive materials such as keys, coins,

hand tools and the like. The US Department of Transportation Hazardous Material

Regulations (HMR) actually prohibit transporting batteries in commerce or on airplanes

(i.e., packed in suitcases and carry-on luggage) UNLESS they are properly protected

from short circuits. So when transporting individual batteries, make sure that the battery

terminals are protected and well insulated from materials that could contact them and

cause a short circuit. NOTE: LI-ION batteries should not be put in checked baggage.

STORAGE RECOMMENDATIONS

1. The best storage place is one that is cool and dry away from direct sunlight and

excess heat or cold.

2. Long storage will not harm the battery pack or charger. Under proper conditions

LI-ION batteries, can be stored for 5 years or more.

CHARGING PROCEDURE

PORTER-CABLE chargers are designed to charge PORTER-CABLE battery packs in

30-60 minutes depending on the pack being charged.

1. Plug the charger into an appropriate outlet before inserting the battery pack.

:::

Battery Cap

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 10

11

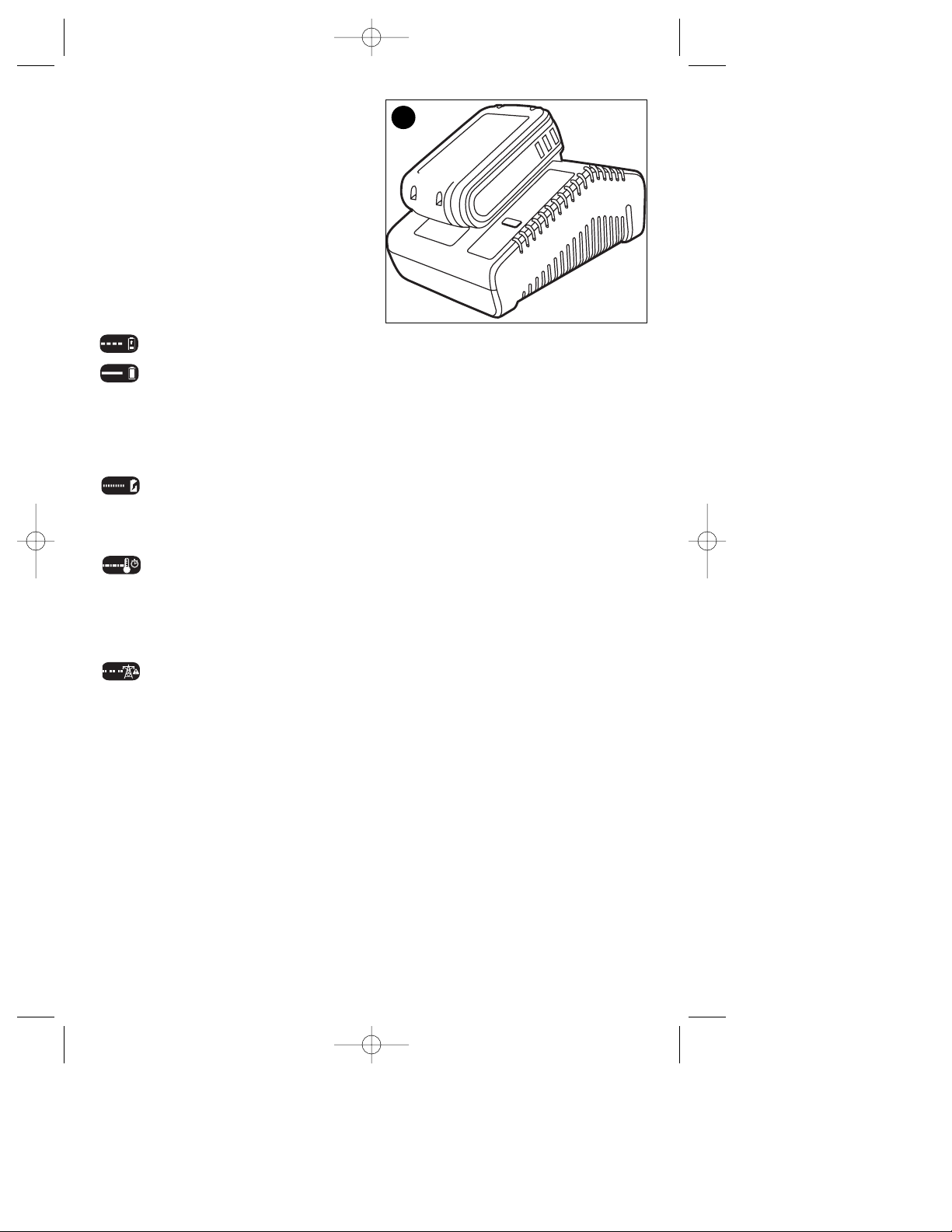

2. Insert the battery pack into the charger

(figure B).

3. The LED will flash indicating that the battery is being charged.

4. The completion of charge is indicated by the LED remaining on continuously.

The pack is fully charged and may be used at this time or left on the charger.

CHARGER DIAGNOSTICS

This charger is designed to detect certain problems that can arise with the battery

packs or the power source. Problems are indicated by one LED flashing in different

patterns.

BAD BATTERY

The charger can detect a weak or damaged battery. The LED flashes in the

pattern indicated on the label. If you see this bad battery blink pattern, do not

continue to charge the battery. Return it to a service center or a collection site for

recycling.

HOT/COLD PACK DELAY

When the charger detects a battery that is excessively hot or excessively cold, it

automatically starts a Hot/Cold Pack Delay, suspending charging until the battery

has normalized. After this happens, the charger automatically switches to the

Pack Charging mode. This feature ensures maximum battery life. The light

flashes in the pattern indicated on the label.

PROBLEM POWER LINE

When the charger is used with some portable power sources such as generators

or sources that convert DC to AC, the charger may temporarily suspend

operation. The LED flashes in the pattern indicated on the label. This indicates

that the power source is out of limits.

LEAVING THE BATTERY IN THE CHARGER

The charger and battery pack can be left connected with the LED glowing indefinitely.

The charger will keep the battery pack fresh and fully charged. This charger features an

automatic tune-up mode which equals or balances the individual cells in the battery pack to

allow it to function at peak capacity. Battery packs should be tuned up weekly or whenever

the battery no longer delivers the same amount of work. To use the automatic tune-up

mode, place the battery pack in the charger and leave it for at least 8 hours.

IMPORTANT CHARGING NOTES

1. Longest life and best performance can be obtained if the battery pack is charged

when the air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the

battery pack in an air temperature below +40°F (+4.5°C), or above +105°F (+40.5°C).

This is important and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while charging. This is a

normal condition, and does not indicate a problem. To facilitate the cooling of the

battery pack after use, avoid placing the charger or battery pack in a warm environment

such as in a metal shed, or an uninsulated trailer.

3. If the battery pack does not charge properly:

B

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 11

12

a. Check current at receptacle by plugging in a lamp or other appliance

b. Check to see if receptacle is connected to a light switch which turns power off

when you turn out the lights.

c. Move charger and battery pack to a location where the surrounding air

temperature is approximately 65°F - 75°F (18°- 24°C).

d. If charging problems persist, take the tool, battery pack and charger to your

local service center.

4. The battery pack should be recharged when it fails to produce sufficient power on

jobs which were easily done previously. DO NOT CONTINUE to use under these

conditions. Follow the charging procedure. You may also charge a partially used pack

whenever you desire with no adverse affect on the battery pack.

5. Foreign materials of a conductive nature such as, but not limited to, steel wool,

aluminum foil, or any buildup of metallic particles should be kept away from charger

cavities. Always unplug the charger from the power supply when there is no battery

pack in the cavity. Unplug charger before attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

Shock hazard. Do not allow any liquid to get inside charger.

Never attempt to open the battery pack for any reason. If the plastic

housing of the battery pack breaks or cracks, return to a service center for recycling.

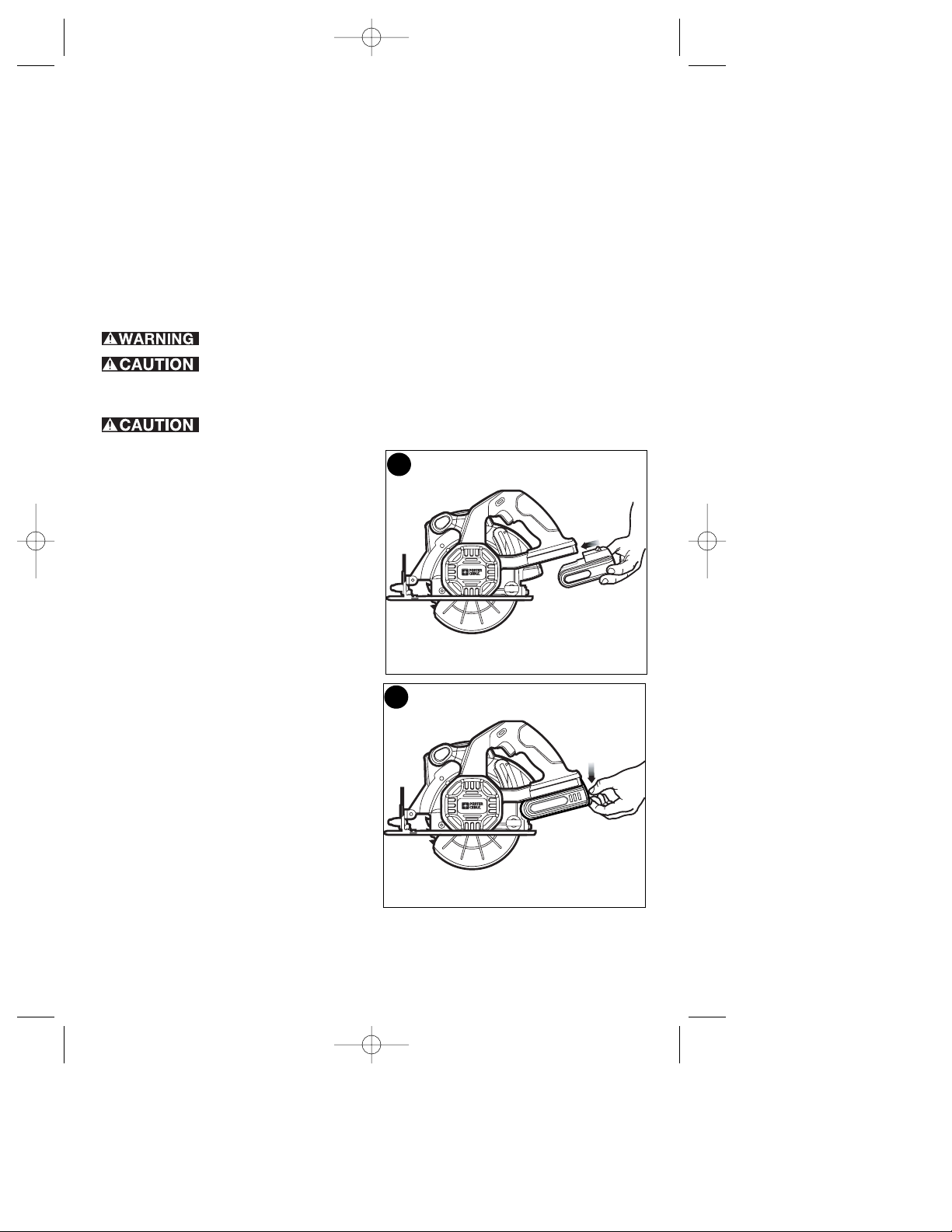

INSTALLING AND REMOVING THE BATTERY PACK FROM THE TOOL

Make certain the lock-off button is engaged to prevent switch actuation

before removing or installing battery.

TO INSTALL BATTERY PACK: Insert battery

pack into tool as shown in figure C.

TO REMOVE BATTERY PACK: Depress the

battery release button as shown in figure D

and pull battery pack out of tool.

:

:

:

C

D

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 12

13

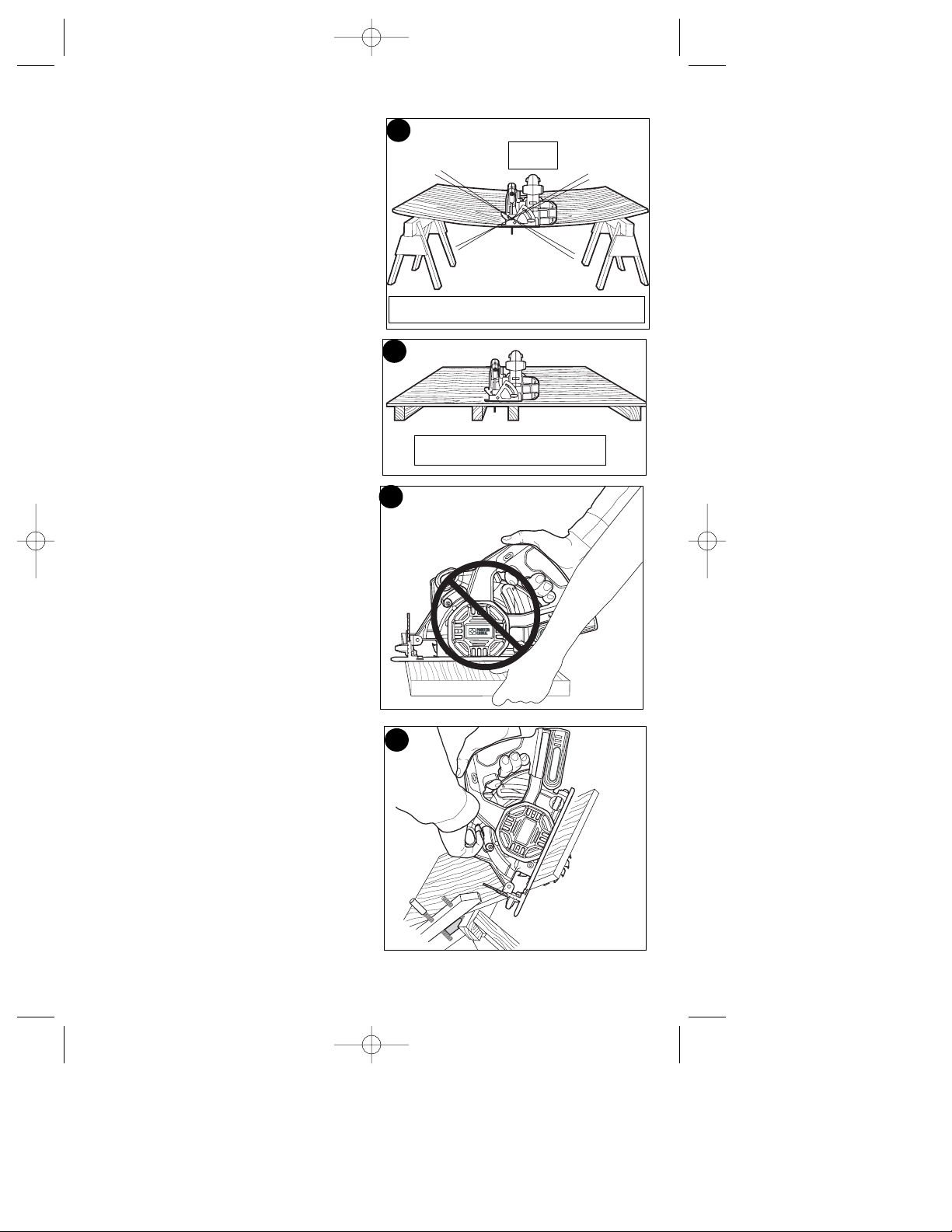

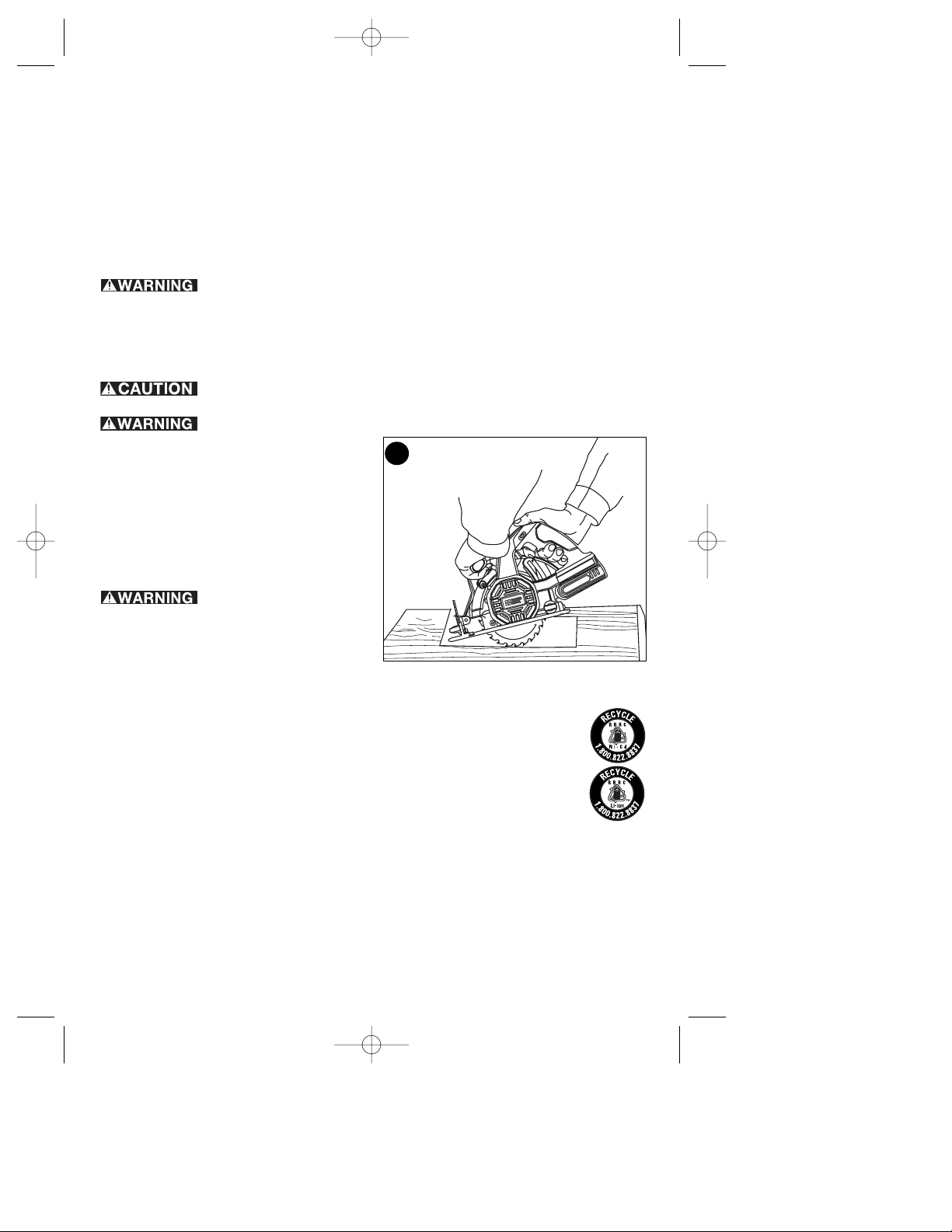

SUPPORTING LARGE PANELS / SECURING WORKPIECE

Support large panels to minimize the risk of

blade pinching and kickback. Large panels

tend to sag under their own weight as shown

in figure E.

Supports must be placed under the panel on

both sides, near the line of cut and near the

edge of the panel (figure F).

Never hold piece being cut in your hands or

across your leg (figure G).

Secure the workpiece to a stable platform as

shown in figure H. It is important to support

the work properly to minimize body

exposure, blade binding, or loss of control.

F

Support work near cut

E

Wrong

Material bends on blade causing heavy loads or kickback

G

H

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 13

14

ASSEMBLY/ADJUSTMENT SET-UP

TO REDUCE THE RISK OF INJURY, ALWAYS REMOVE BATTERY

FROM SAW BEFORE ANY OF THE FOLLOWING ADJUSTMENT OPERATIONS.

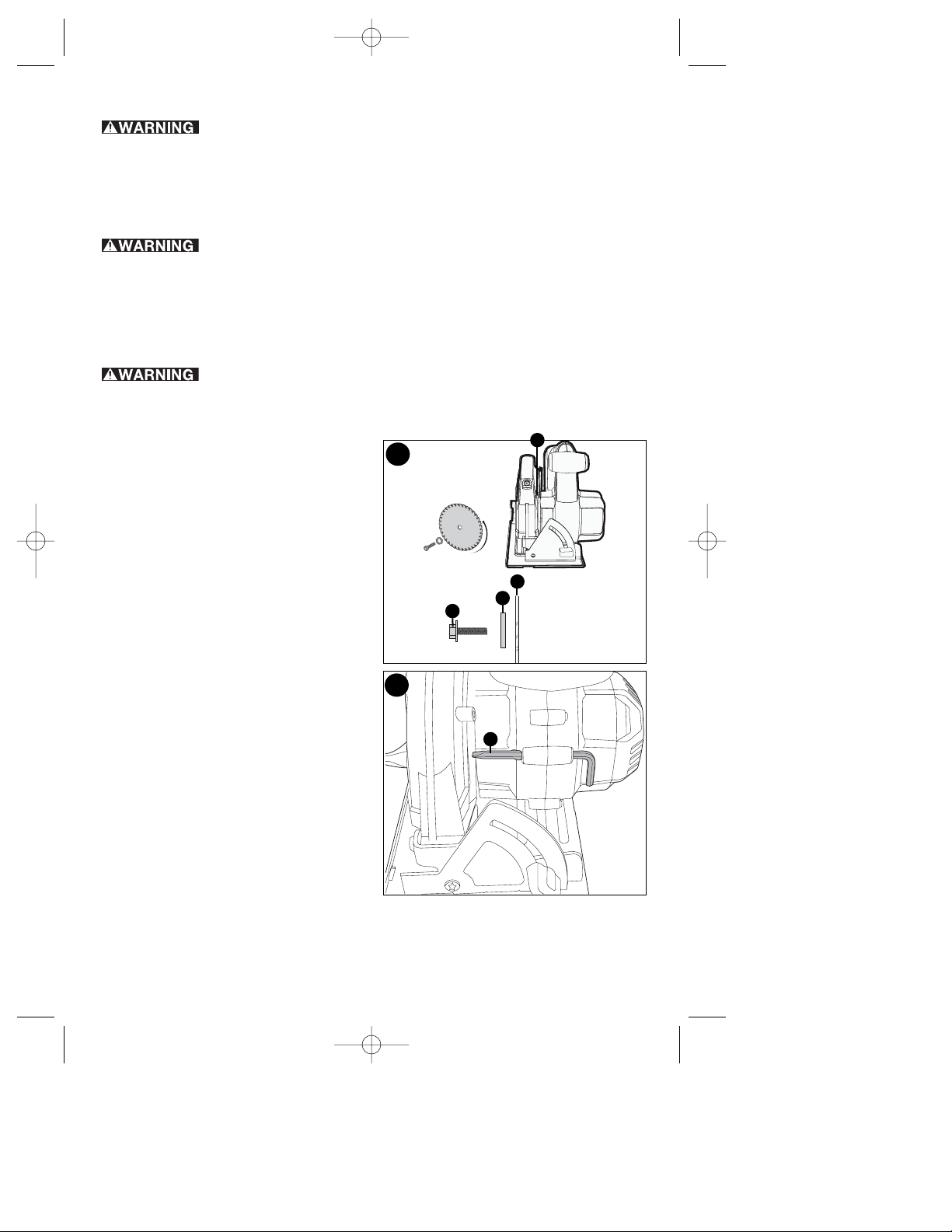

CUTTING DEPTH ADJUSTMENT - FIGURES I & J

The depth of cut should be set according to the thickness of the workpiece.

• Loosen the depth adjustment knob (14) to

unlock the saw shoe (8) as shown in figure I.

• Move the saw shoe into the desired

position. The corresponding depth of cut

can be read from the scale (17).

• Tighten the knob or lever to lock the saw

shoe in place.

• Set depth adjustment of saw such that one

tooth (18) of the blade projects below the

workpiece (19) as shown in figure J.

BEVEL ANGLE ADJUSTMENT - FIGURE K

This tool can be set to bevel angles between

0° and 50°.

• Loosen the bevel adjustment knob (13) to

unlock the saw shoe.

• Move the saw shoe (8) into the desired

position. The corresponding bevel angle can

be read from the scale (20).

• Tighten the bevel adjustment knob (13) to

lock the saw shoe in place.

SHOE ADJUSTMENT FOR 90° CUTS

IF ADDITIONAL ADJUSTMENT IS NEEDED:

• Adjust the saw to 0° bevel.

• Retract blade guard (11).

• Loosen bevel adjustment knob (13). Place a

square against the blade (10) and shoe (8) to adjust the 90° setting.

• Loosen jam nut (13b) and move the adjustment screw (13a) (inset figure K) so that the

shoe will stop at the proper angle. Retighten jam nut.

• Confirm the accuracy of the setting by checking the squareness of an actual cut on a

scrap piece of material.

:

I

17

14

8

K

J

18

19

20

8

13

13 a

13 b

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 14

15

OPERATING INSTRUCTIONS

To reduce the risk of serious personal injury, read, understand and

follow all important safety warnings and instructions prior to using tool.

BLADE SELECTION

Your circular saw is designed for use with 6-1/2 inch (165 mm) diameter blades

that have a 5/8 inch (15.9 mm) diameter bore. Blades must be rated for 6000 RPM

operation (or higher). DO NOT use any abrasive wheels.

GENERAL CUTS

To reduce the risk of injury

, remove the battery, and follow all

assembly, adjustment and set up instructions.

Make sure lower guard operates. Select the proper blade for the material to be cut.

• Measure and mark work for cutting.

• Support and secure work properly (See Safety Rules and Instructions).

• Use appropriate and required safety equipment (See Safety Rules).

• Secure and maintain work area (See Safety Rules).

• With battery inserted, make sure switch turns saw on and off.

To reduce the risk of injury

, It is important to support the work

properly and to hold the saw firmly to prevent loss of control which could cause

personal injury. Figure H illustrates typical hand support.

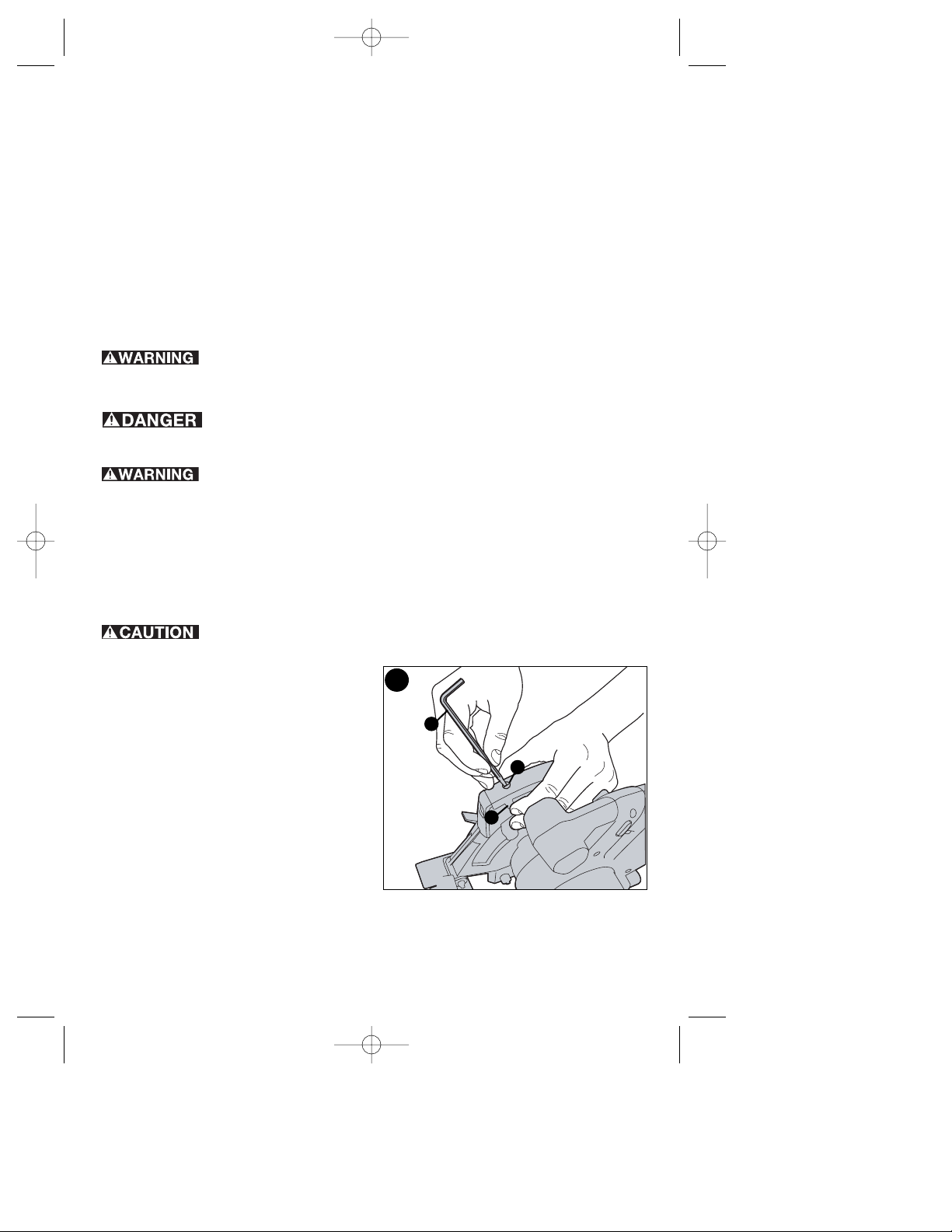

ATTACHING AND REMOVING THE BLADE - FIGURE L

• Retract lower guard and assemble blade (10)

and clamp washer (21) as shown in figure L.

• Depress the spindle lock (16) while turning

the saw spindle with the blade wrench (12)

until the blade lock engages and the blade

stops rotating.

NOTE: Blade wrench is stored on the saw

as shown in figure M.

• Tighten the blade clamping screw (24)

securely with the blade wrench.

NOTE: Never engage the blade lock while

the saw is running, or engage in an effort to

stop the tool. Never turn the tool on while

the blade lock is engaged. Serious damage

to your saw will result.

:::

L

M

24

21

10

16

12

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 15

16

LOWER BLADE GUARD

Laceration Hazard. The lower blade guard is a safety feature which

reduces the risk of serious personal injury. Never use the saw if the lower guard

is missing, damaged, mis-assembled or not working properly. Do not rely on the

lower blade guard to protect you under all circumstances. Your safety depends

on following all warnings and precautions as well as proper operation of the saw.

Check lower guard for proper closing before each use as outlined in Additional

Safety Rules for Circular Saws. If the lower blade guard is missing or not working

properly, have the saw serviced before using. To assure product safety and

reliability, repair, maintenance and adjustment should be performed by an

authorized service center or other qualified service organization, always using

identical replacement parts.

To minimize the risk of eye injury, always use eye protection. Carbide is

a hard but brittle material. Foreign objects in the work piece such as wire or nails can

cause tips to crack or break. Only operate saw when proper saw blade guard is in

place. Mount blade securely in proper rotation before using, and always use a clean,

sharp blade.

Do not cut ferrous metals (steel), masonry, glass or tile with this saw.

A dull blade will cause slow, inefficient cutting overload on the saw motor, excessive

splintering, and could increase the possibility of kickback.

SWITCH

Saw is equipped with a switch lock-off feature to prevent unintentional running.

• To operate the tool, press in on the lock-off button (2) from either side of the saw and

hold it in as you depress the trigger switch (1).

• After you have depressed the trigger and the tool is running, release the lock-off

button. The tool will continue to run as long as the trigger is depressed.

• To turn the tool off, release the trigger switch.

NOTE: This tool has no provision for locking the tool on, and the switch should never

be locked on by any other means.

AUTOMATIC ELECTRIC BRAKE

Your saw is equipped with an electric blade brake which stops the saw blade within 1-1/2

seconds of trigger release. This is automatic and requires no adjustment.

OPERATING THE LASER (CATALOG NUMBER PC186CSL ONLY)

INSTALLING THE BATTERIES - FIGURE N

LASER RADIATION. BE

CERTAIN THE LASER ON/OFF BUTTON

IS IN THE OFF POSITION (SEE SECTION

“SWITCHING THE LASER ON AND OFF)

BEFORE INSTALLING BATTERIES.

Lift the battery door (25) off the laser module

(4) by gently squeezing the front of the door

as shown in figure N. Insert 2 fresh 1.5 volt

AAA batteries making sure to match (+) and

(-) terminals correctly. Reattach the battery

door.

Batteries can explode, or leak, and can cause injury or fire. To

reduce this risk:

• Carefully follow all instructions and warnings on the battery label and package.

• Always insert batteries correctly with regard to polarity (+ and -), marked on the

battery and the equipment.

• Do not short battery terminals.

• Do not charge batteries.

:

:

:

:

:

N

25

5

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 16

17

• Do not mix old and new batteries. Replace all of them at the same time with new

batteries of the same brand and type.

• Remove dead batteries immediately and dispose of per local codes.

• Do not dispose of batteries in fire.

• Keep batteries out of reach of children.

• Remove batteries if the device will not be used for several months.

“Transporting batteries can possibly cause fires if the battery terminals inadvertently

come in contact with conductive materials such as keys, coins, hand tools and the

like. The US Department of Transportation Hazardous Material Regulations (HMR)

actually prohibit transporting batteries in commerce or on airplanes (i.e. packed in

suitcases and carryon luggage) UNLESS they are properly protected from short

circuits. So when transporting individual batteries, make sure that the battery

terminals are protected and well insulated from materials that could contact them

and cause a short circuit.”

ON BOARD LASER

Some saw models are equipped with an on board laser which is turned on and off

separately from the saw.

LASER RADIATION. Never aim the beam at a workpiece with a

reflective surface. Bright shiny reflective sheet steel or similar reflective surfaces are

not recommended for laser use. Reflective surfaces could direct the beam back toward

the operator.

LASER RADIATION. AVOID DIRECT EYE EXPOSURE. Do not stare

into the laser light source. Never aim light at another person or object other than

the workpiece. Laser light can damage your eyes.

DO NOT use tinted glasses to enhance the laser light. Tinted

glasses will reduce overall vision for the application and interfere with the normal operation

of the tool.

SWITCHING THE LASER ON AND OFF

• To turn the laser on, press the laser on/off button (3). To turn the laser off, press the

button a second time.

NOTE: The laser on/off button occupies two different positions, the lower position is

“on” (slightly depressed below flush) and the upper position is “off” (button is flush with

the surface).

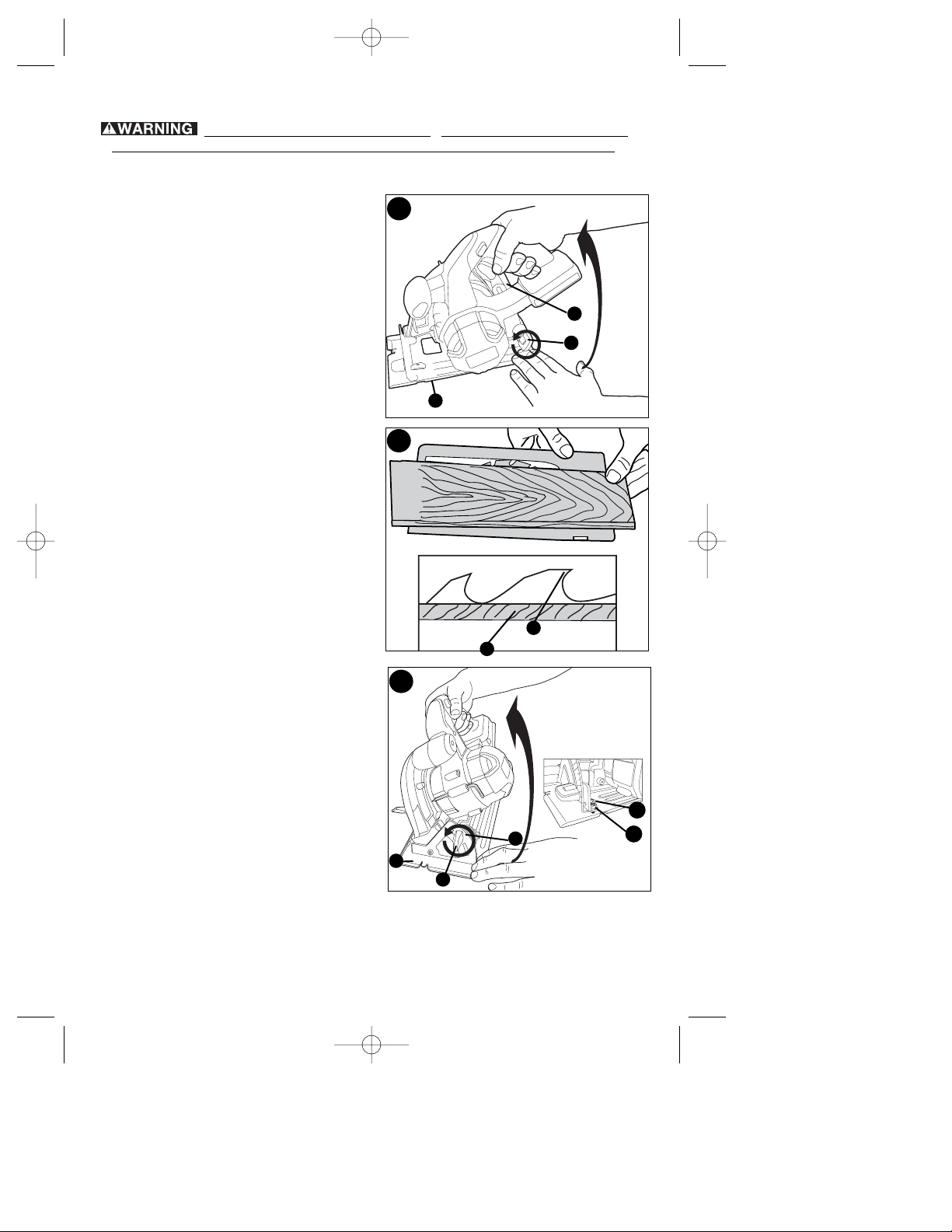

ADJUSTING THE LASER - FIGURE O

TURN OFF TOOL AND REMOVE BATTERY PACK FROM SAW

BEFORE CHANGING ACCESSORIES OR MAKING ANY ADJUSTMENTS.

The laser can be adjusted to remove lateral

and angular error.

• Using a securely mounted scrap piece of

plywood or sheathing make a partial cut

with this saw at least as long as the shoe.

• Turn the saw off, hold the saw motionless

and after the blade stops rotating, remove

the saw from the cut.

• Using a straight edge and pencil, draw a

straight line on the plywood as if extending

the cut from where it ended.

• REMOVE THE SAW BATTERY BEFORE

MAKING LASER ADJUSTMENTS.

• With the saw set at maximum depth of cut,

retract the lower guard and place the saw

blade back in the cut to where it ended (at

the start of the pencil line).

• With the saw shoe sitting solidly on the plywood, turn the laser on, loosen the laser

adjustment screw (26) with the supplied wrench (12) and use the adjustment tabs (27)

on each side of the laser module to align the laser line with the pencil line then

retighten the adjustment screw.

• Turn the laser off and remove the saw from the cut before reinserting the saw battery.

:

:::

O

12

26

27

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 17

18

TO USE THE LASER LINE

• Mark the line that you intend to cut on the workpiece.

• Adjust the depth and angle of cut as required.

• Push the laser on/off switch (3) to the “ON” position and project the laser beam.

• Push in on the lock-off button (2) and depress the saw on/off switch (1) and allow the

blade to reach maximum speed.

• Place the saw shoe on the workpiece. Align the laser line with the mark on the

workpiece and slowly push the saw forward keeping the laser line on the mark.

• Upon completion of the cut, release the trigger and allow the saw blade to come to a

complete stop before switching off the laser.

SAWING

To reduce the risk of serious personal injury, always hold the tool with

both hands.

• Let the blade run freely for a few seconds before starting the cut.

• Apply only a gentle pressure to the tool while performing the cut.

• Work with the shoe pressed against the workpiece.

POCKET CUTTING - FIGURE P

Never move the saw backwards when pocket cutting. This may cause

the unit to raise up off the work surface which could cause injury.

Laceration Hazard. Never tie the blade guard in a raised position.

Pocket cutting is used to cut a hole in a piece of

material without cutting from the side.

• Measure and mark work.

• Tilt saw forward and rest front of the shoe

on material to be cut. Align so that cut will

begin at the back of the drawn rectangle.

• Using the retracting lever, retract blade

guard to an upward position, with the blade

just clearing the material, start motor and

gradually lower the saw into the material.

Laceration Hazard. As

blade starts cutting the material, release the

retracting lever immediately.

• When the shoe rests flat on the material

being cut, complete the cut in forward

direction.

• Allow the blade to come to a complete stop before lifting saw from material.

• When starting each new cut, repeat the above steps.

THE RBRC™ SEAL

The RBRC™ (Rechargeable Battery Recycling Corporation) Seal on the

LI-ION or NI-CD battery (or battery pack) indicates that the costs to recycle the

battery (or battery pack) at the end of its useful life have already been paid by

PORTER-CABLE.

RBRC™ in cooperation with PORTER-CABLE and other battery users, has

established programs in the United States to facilitate the collection of spent LIION or NI-CD batteries. Help protect our environment and conserve natural

resources by returning the spent LI-ION or NI-CD battery to an authorized PORTERCABLE service center or to your local retailer for recycling. You may also contact your

local recycling center for information on where to drop off the spent battery.

RBRC™ is a registered trademark of the Rechargeable Battery Recycling Corporation.

:

:

:

:

P

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 18

19

TROUBLESHOOTING

Problem Possible Cause Possible Solution

• Unit will not start. • Battery pack not installed properly. • Check battery pack

installation.

• Battery pack not charged. • Check battery pack

charging requirements.

• Battery pack will not charge. • Battery pack not inserted into charger. • Insert battery pack into

charger until LED

appears.

• Charger not plugged in. • Plug charger into a

working outlet. Refer to

“Important Charging Notes”

for more details.

• Surrounding air temperature • Move charger and battery

too hot or too cold. pack to a surrounding air

temperature of above 40

degrees F (4,5°C) or below

105 degrees F (+40,5°C).

SPECIAL NOTES FOR USE WITH LITHIUM BATTERIES

• Unit shuts off abruptly. • Battery pack has reached its • Allow battery pack to cool

maximum thermal limit. down.

• Out of charge. ( To • Place on charger and

maximize the life of the allow to charge.

battery pack it is designed

to shutoff abruptly when

the charge is depleted.)

For assistance with your product, visit our website at www.portercable.com for a list of service

centers, or call the PORTER-CABLE Customer Care Center at (888) 848-5175.

MAINTENANCE

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service website at

www.portercable.com. You can also order parts from your nearest PORTER-CABLE Factory

Service Center or PORTER-CABLE Authorized Warranty Service Center. Or, you can call our

Customer Care Center at (888) 848-5175.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about

PORTER-CABLE, its factory service centers or authorized warranty service centers, visit our

website at www.portercable.com or call our Customer Care Center at (888) 848-5175. All repairs

made by our service centers are fully guaranteed against defective material and workmanship. We

cannot guarantee repairs made or attempted by others.

You can also write to us for information at PORTER-CABLE, 4825 Highway 45 North, Jackson,

Tennessee 38305 - Attention: Product Service. Be sure to include all of the information shown on

the nameplate of your tool (model number, type, serial number, etc.).

ACCESSORIES

Always use 6-1/2 inch (165mm) diameter blades. Carbide blades are strongly recommended

for optimum saw performance. Never use abrasive type or metal cutting blades on saw.

Since accessories, other than those offered by PORTER-CABLE, have

not been tested with this product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only PORTER-CABLE recommended

accessories should be used with this product.

A complete line of accessories is available from your PORTER-CABLE Factory Service

Center or a PORTER-CABLE Authorized Warranty Service Center. Please visit our

Web Site www.portercable.comfor a catalog or for the name of your nearest supplier.

:

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 19

20

THREE YEAR LIMITED WARRANTY

PORTER-CABLE will repair, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase. This warranty does not cover

part failure due to normal wear or tool abuse. For further detail of warranty coverage

and warranty repair information, visit www

.portercable.com or call (888) 848-5175. This

warranty does not apply to accessories or damage caused where repairs have been

made or attempted by others. This warranty gives you specific legal rights and you

may have other rights which vary in certain states or provinces.

In addition to the warranty, PORTER-CABLE tools are covered by our:

1 YEAR FREE SERVICE: PORTER-CABLE will maintain the tool and replace worn

parts caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with the

performance of your PORTER-CABLE Power Tool for any reason, you can return it within

90 days from the date of purchase with a receipt for a full refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained in

the packaging, call the local company or see website for warranty information.

To register your tool for warranty service visit our website at www

.portercable.com

.

W

ARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call (888) 848-5175 for a free

replacement.

The following are PORTER-CABLE trademarks for one or more power tools and accessories: a

gray and black color scheme; a “four point star” design; and three contrasting/outlined longitudinal

stripes. The following are also trademarks for one or more PORTER-CABLE and Delta products: 2

BY 4®, 890™, Air America®, AIRBOSS™, Auto-Set®, B.O.S.S.®, Bammer®, Biesemeyer®,

Builders Saw®, Charge Air®, Charge Air Pro®, CONTRACTOR SUPERDUTY®, Contractor's

Saw®, Delta®, DELTA®, Delta Industrial®, DELTA MACHINERY & DESIGN™, Delta Shopmaster

and Design®, Delta X5®, Deltacraft®, DELTAGRAM®, Do It. Feel It.®, DUAL LASERLOC AND

DESIGN®, EASY AIR®, EASYAIR TO GO™, ENDURADIAMOND®, Ex-Cell®, Front Bevel

Lock®, Get Yours While the Sun Shines®, Grip to Fit®, GRIPVAC™, GTF®, HICKORY

WOODWORKING®, Homecraft®, HP FRAMER HIGH PRESSURE®, IMPACT SERIES™,

Innovation That Works®, Jet-Lock®, Job Boss®, Kickstand®, LASERLOC®, LONG-LASTING

WORK LIFE®, MAX FORCE™, MAX LIFE®, Micro-Set®, Midi-Lathe®, Monsoon®, MONSTERCARBIDE™, Network®, OLDHAM®, Omnijig®, PC EDGE®, Performance Crew™, Performance

Gear®, Pocket Cutter®, Porta-Band®, Porta-Plane®, PORTER-CABLE®, PORTER-CABLE

Professional Power Tools®, Powerback®, POZI-STOP™, Pressure Wave®, PRO 4000®,

Proair®, Quicksand and Design®, Quickset II®, QUIET DRIVE TECHNOLOGY™, QUIET DRIVE

TECHNOLOGY AND DESIGN™, Quik-Change®, QUIK-TILT®, RAPID-RELEASE™, RAZOR®,

Redefining Performance®, Riptide®, Safe Guard II®, Sand Trap and Design®, Sanding Center®,

Saw Boss®, Shop Boss®, Sidekick®, Site Boss®, Speed-Bloc®, Speedmatic®, Stair Ease®,

Steel Driver Series®, SUPERDUTY®, T4 & DESIGN®, THE AMERICAN WOODSHOP®, THE

PROFESSIONAL EDGE®, Thin-Line®, Tiger Saw®, TIGERCLAW®, TIGERCLAW AND

DESIGN®, Torq-Buster®, TRU-MATCH®, T-Square®, Twinlaser®, Unifence®, Uniguard®,

UNIRIP®, UNISAW®, UNITED STATES SAW®, Veri-Set®, Versa-Feeder®, VIPER®, VT™, VT

RAZOR™, Water Driver®, WATER VROOM®, Waveform®, Whisper Series®, X5®, YOUR

ACHIEVEMENT. OUR TOOLS.® Trademarks noted with ® are registered in the United States

Patent and Trademark Office and may also be registered in other countries. Other trademarks may

apply.

4825 Highway 45 North, Jackson, Tennessee 38305 (888) 848-5175

www.portercable.coms

90550103 PCL186 Circular Saw 4/7/09 8:23 AM Page 20

Loading...

Loading...