Porter-Cable N020227 User Manual

Instruction

®

FRANÇAISE : PAGE 17

ESPAÑOL: PÁGINA 35

manual

Drywall Sander

MODEL 7800

MODEL 7801

To learn more about PORTER-CABLE

visit our website at:

http://www.deltaportercable.com

Copyright © 2001, 2002, 2005, 2006

2007, 2008 PORTER-CABLE

IMPORTANT!

Please make certain that the person who is

to use this equipment carefully reads and

understands these instructions before starting

operations.

The Model and Serial No. plate is located on the

main housing of the tool. Record these numbers in

the spaces below and retain for future reference.

Model No. _________________________________

Type ______________________________________

Serial No. _________________________________

Part No. N020227 12-02-08 _Rev.A

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ..............................2

SAFETY GUIDELINES............................................3

GENERAL SAFETY RULES .......................................4

ADDITIONAL SPECIFIC SAFETY RULES ............................6

CARTON CONTENTS ............................................8

FUNCTIONAL DESCRIPTION .....................................9

ASSEMBLY ...................................................10

OPERATION ..................................................10

TROUBLESHOOTING ..........................................14

MAINTENANCE................................................14

SERVICE .....................................................15

ACCESSORIES ................................................15

WARRANTY...................................................16

FRANÇAIS ....................................................17

ESPAÑOL.....................................................35

IMPORTANT SAFETY INSTRUCTIONS

equipment. When using tools or equipment, basic safety precautions should always

be followed to reduce the risk of personal injury. Improper operation, maintenance or

modification of tools or equipment could result in serious injury and property damage.

There are certain applications for which tools and equipment are designed. PORTERCABLE strongly recommends that this product NOT be modified and/or used for any

application other than for which it was designed.

If you have any questions relative to its application, DO NOT use the product until

you have written PORTER-CABLE and we have advised you.

INFORMATION REGARDING SAFE AND PROPER OPERATION IS AVAILABLE FROM:

Read all warnings and operating instructions before using any tool or

Online, contact us at: www.deltaportercable.com

By mail, contact us at:

The Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive

Itasca, IL 60143-3201

American National Standards Institute

25 West 43rd Street, 4 floor

New York, NY 10036 www.ansi.org

ANSI 01.1Safety Requirements for Woodworking Machines

The U.S. Department of Labor regulations

Technical Service Manager

PORTER-CABLE

4825 Highway 45 North

Jackson, TN 38305

www.osha.gov

2

It is important for you to read and understand this manual. The

SAFETY GUIDELINES - DEFINITIONS

information it contains relates to protecting YOUR SAFETY and

PREVENTING PROBLEMS. The symbols below are used to help you

recognize this information.

indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

indicates a potentially haz ard ous situation which, if not avoided,

may result in minor or mod er ate injury.

used without the safety alert symbol indicates potentially hazardous

situation which, if not avoided, may result in property damage.

3

GENERAL SAFETY RULES

To reduce the risk of injury, read the instruction manual.

GENERAL POWER TOOL SAFETY WARNINGS

Read all safety warnings and instructions Failure to follow

the warnings and instructions may result in electric shock,

fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite acci-

dents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords increase the risk of electric

shock.

e) When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is unavoidable, use a ground

fault circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of inatten-

tion while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position

before connecting to power source and/or battery pack, picking up or

4

GENERAL SAFETY RULES

carrying the tool. Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result

in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collec-

tion facilities, ensure these are connected and properly used. Use of dust

collection can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your appli-

cation. The correct power tool will do the job better and safer at the rate for

which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source and/or the battery pack from

the power tool before making any adjustments, changing accessories,

or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow per-

sons unfamiliar with the power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired before

use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc., in accordance with

these instructions taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

5) SERVICE

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

continued

5

ADDITIONAL SPECIFIC SAFETY RULES

SAFETY WARNINGS COMMON FOR GRINDING, SANDING, WIRE BRUSHING,

POLISHING OR ABRASIVE CUTTING-OFF OPERATIONS:

a) This power tool is intended to function as a sander. Read all safety warnings,

instructions, illustrations and specifications provided with this power tool. Failure to

follow all instructions listed below may result in electric shock, fire and/or serious

injury.

b) Operations such as polishing, grinding, wire brushing or cutting-off are not

recommended to be performed with this power tool. Operations for which the

power tool was not designed may create a hazard and cause personal injury.

c) Do not use accessories which are not specifically designed and recommend-

ed by the tool manufacturer. Just because the accessory can be attached to your

power tool, it does not assure safe operation.

d) The rated speed of the accessory must be at least equal to the maximum

speed marked on the power tool. Accessories running faster than their RATED

SPEED can break and fly apart.

e) The outside diameter and the thickness of your accessory must be within

the capacity rating of your power tool. Incorrectly sized accessories cannot be

adequately guarded or controlled.

f) The arbor size of wheels, flanges, backing pads or any other accessory must

properly fit the spindle of the power tool. Accessories with arbor holes that do

not match the mounting hardware of the power tool will run out of balance, vibrate

excessively and may cause loss of control.

g) Do not use a damaged accessory. Before each use inspect the accessory such

as abrasive wheels for chips and cracks, backing pad for cracks, tear or excess

wear, wire brush for loose or cracked wires. If power tool or accessory is dropped,

inspect for damage or install an undamaged accessory. After inspecting and

installing an accessory, position yourself and bystanders away from the plane of

the rotating accessory and run the power tool at maximum no-load speed for one

minute. Damaged accessories will normally break apart during this test time.

h) Wear personal protective equipment. Depending on application, use face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron capable of stopping small abrasive or workpiece

fragments. The eye protection must be capable of stopping flying debris generated

by various operations. The dust mask or respirator must be capable of filtrating

particles generated by your operation. Prolonged exposure to high intensity noise

may cause hearing loss.

i) Keep bystanders a safe distance away from work area. Anyone entering the

work area must wear personal protective equipment. Fragments of workpiece or

of a broken accessory may fly away and cause injury beyond immediate area of

operation.

j) Hold power tool by insulated gripping surfaces only, when performing an opera-

tion where the cutting accessory may contact hidden wiring or its own cord.

Cutting accessory contacting a "live" wire may make exposed metal parts of the

power tool "live" and shock the operator.

k) Position the cord clear of the spinning accessory. If you lose control, the cord

may be cut or snagged and your hand or arm may be pulled into the spinning

accessory.

l) Never lay the power tool down until the accessory has come to a complete

stop. The spinning accessory may grab the surface and pull the power tool out of

your control.

m) Do not run the power tool while carrying it at your side. Accidental contact with

the spinning accessory could snag your clothing, pulling the accessory into your

body.

n) Regularly clean the power tool’s air vents. The motor’s fan will draw the dust

inside the housing and excessive accumulation of powdered metal may cause

electrical hazards.

o) Do not operate the power tool near flammable materials. Sparks could ignite

these materials.

6

p) Do not use accessories that require liquid coolants. Using water or other liquid

coolants may result in electrocution or shock.

KICKBACK AND RELATED WARNINGS

Kickback is a sudden reaction to a pinched or snagged rotating wheel, backing pad,

brush or any other accessory. Pinching or snagging causes rapid stalling of the rotating

accessory which in turn causes the uncontrolled power tool to be forced in the direction

opposite of the accessory’s rotation at the point of the binding.

For example, if a backing pad is snagged or pinched by the workpiece, the edge of the

pad that is entering into the pinch point can dig into the surface of the material causing

the wheel to climb out or kick out. The wheel may either jump toward or away from the

operator, depending on direction of the wheel’s movement at the point of pinching.

Kickback is the result of power tool misuse and/or incorrect operating procedures or

conditions and can be avoided by taking proper precautions as given below.

a) Maintain a firm grip on the power tool and position your body and arm to allow

you to resist kickback forces. Always use auxiliary handle, if provided, for maximum

control over kickback or torque reaction during start-up. The operator can control

torque reactions or kickback forces, if proper precautions are taken.

b) Never place your hand near the rotating accessory. Accessory may kickback over

your hand.

c) Do not position your body in the area where power tool will move if kickback

occurs. Kickback will propel the tool in direction opposite to the wheel’s movement at

the point of snagging.

d) Use special care when working corners, sharp edges etc. Avoid bouncing and

snagging the accessory. Corners, sharp edges or bouncing have a tendency to

snag the rotating accessory and cause loss of control or kickback.

e) Do not attach a saw chain woodcarving blade or toothed saw blade. Such

blades create frequent kickback and loss of control.

SAFETY WARNINGS SPECIFIC FOR SANDING OPERATIONS:

a) Do not use excessively oversized sanding disc paper. Follow manufacturer’s

recommendations when selecting sanding paper. Larger sanding paper extending

beyond the sanding pad presents a laceration hazard and may cause snagging,

tearing of the disc or kickback.

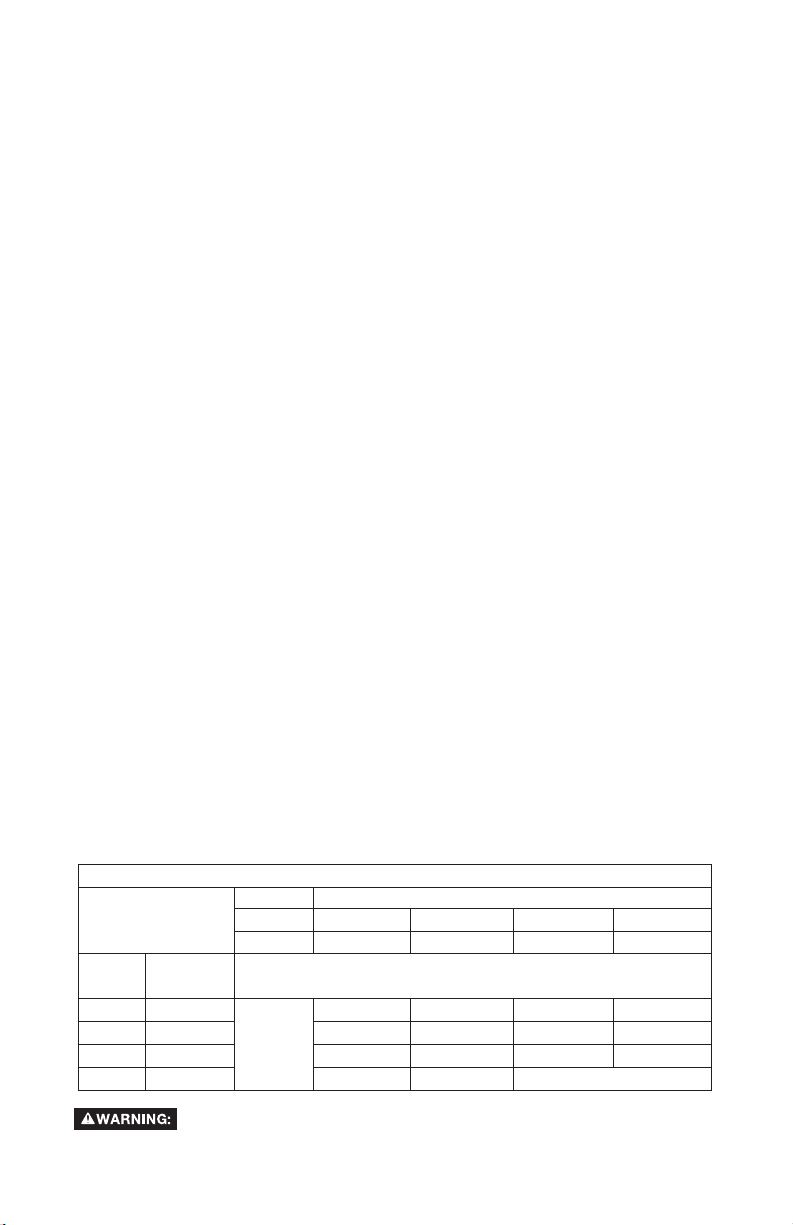

EXTENSION CORD

An extension cord must have adequate wire size (AWG or American Wire

Gauge) for safety. The smaller the gauge number of the wire, the greater the

capacity of the cable, that is 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. When using more than one extension to make up the total length, be sure each

individual extension contains at least the minimum wire size. The following table

shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the

heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

Not More

Than

120V

240V

25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 Not Recommended

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

7

• leadfromlead-basedpaint.

• crystallinesilicafrombricksandcementandothermasonryproducts.

• arsenicandchromiumfromchemically-treatedlumber(CCA).

Your risk from exposure to these chemicals varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well ventilated area

with approved safety equipment, such as dust masks that are specially designed to filter

out microscopic particles.

Avoid prolonged contact with dust from power sanding, sawing,

grinding, drilling, and other construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes,

or lay on the skin may promote absorption of harmful chemicals.

Use of this tool can generate and/or disburse dust, which may cause

serious and permanent respiratory damage or other injury. Always use NIOSH/OSHA/

MSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and body.

ALWAYS wear proper personal hearing protection that conforms to

ANSI S12.6 (S3.19) during use. Under some conditions and duration of use, noise from

this product may contribute to hearing loss.

ALWAYS USE SAFETY GLASSES. (ANSI Z87.1) and (CAN/CSA Z94.3)

Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting

operation is dusty. ALWAYS WEAR CERTIFIED SAFETY EQUIPMENT:

• ANSIZ87.1eyeprotection(CAN/CSAZ94.3)

• ANSIS12.6(S3.19)hearingprotection

• NIOSH/OSHA/MSHArespiratoryprotection

SYMBOLS

The label on your tool may include the following symbols.

The symbols and their

definitions are as follows:

V ....................... volts A ................. amperes

Hz .................... hertz W ................ watts

min ................... minutes

................ direct current .............. alternating or direct current

..................... Class I Construction

......................... (grounded)

.................... Class II Construction ............... safety alert symbol

......................... (double insulated) BPM ........... beats per minute

…/min .............. per minute RPM ........... revolutions per minute

OPM ................ orbits per minute

.............. alternating current

n

o ............... no load speed

............... earthing terminal

MOTOR

Be sure your power supply agrees with nameplate marking. 120 Volts AC means your

tool will operate on alternating current. As little as 10% lower voltage can cause loss of

power and can result in overheating. All PORTER-CABLE tools are factory-tested; if this

tool does not operate, check the power supply.

Accessories must be rated for at least the speed recommended on the

tool warning label. Accessories running over rated speed can fly apart and cause injury.

Accessory ratings must always be above tool speed as shown on tool nameplate.

To reduce the risk of injury, turn unit off and disconnect it from

power source before installing and removing accessories, before adjusting or

when making repairs.

An accidental start-up can cause injury.

Save theSe inStructionS

8

ADDITIONAL SAFETY RULES FOR PAINT REMOVAL

1. Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of control-

ling the contaminated dust. The greatest danger of lead poisoning is to children and

pregnant women.

2. Since it is difficult to identify whether or not a paint contains lead without a chemical

analysis, we recommend the following precautions when sanding any paint:

PERSONAL SAFETY

1. No children or pregnant women should enter the work area where the paint sanding

is being done until all clean up is completed.

2. A dust mask or respirator should be worn by all persons entering the work area.

The filter should be replaced daily or whenever the wearer has difficulty breathing.

See your local hardware store for the proper NIOSH approved dust mask.

3. NO EATING, DRINKING or SMOKING should be done in the work area to pre-

vent ingesting contaminated paint particles. Workers should wash and clean up

BEFORE eating, drinking or smoking. Articles of food, drink, or smoking should not

be left in the work area where dust would settle on them.

ENVIRONMENTAL SAFETY

1. Paint should be removed in such a manner as to minimize the amount of dust gen-

erated.

2. Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mil

thickness.

3. Sanding should be done in a manner to reduce tracking of paint dust outside the

work area.

CLEANING AND DISPOSAL

1. All surfaces in the work area should be vacuumed and thoroughly cleaned daily

for the duration of the sanding project. Vacuum filter bags should be changed frequently.

2. Plastic drop cloths should be gathered up and disposed of along with any dust

chips or other removal debris. They should be placed in sealed refuse receptacles

and disposed of through regular trash pick-up procedures. During clean up, children and pregnant women should be kept away from the immediate work area.

3. All toys, washable furniture and utensils used by children should be washed thor-

oughly before being used again.

SAVE THESE INSTRUCTIONS!

CARTON CONTENTS

Drywall Sander

Instruction Manual

FUNCTIONAL DESCRIPTION

FOREWORD

The PORTER-CABLE Drywall Sander is designed for sanding walls and ceilings

made of drywall or plaster. The Sander provides a superior finish, and is faster

than conventional finishing methods for both new construction and renovation

work. Clean-up time for Model 7800 is minimized by the use of an external

vacuum cleaner attached to the sander.

9

ASSEMBLY

NOTE: This tool is shipped completely assembled. No assembly time or tools

are required.

ABRASIVE DISC SELECTION

An abrasive disc is already included with the Drywall Sander. For details on

the type of grit, refer to the packaging. Higher grit number corresponds to a

smoother finish.

recommended by PORTER-CABLE.

Do not attempt to use any abrasives other than those

OPERATION

disconnect tool from power source before installing and removing accessories, before adjusting or changing set-ups or when making repairs. An

accidental start-up can cause injury.

HOW TO HOLD A DRYWALL SANDER

Hold the sander with both hands on the

main tube (A) Fig. 1. Position your hands

anywhere along the main tube to provide the

best combination of reach and leverage.

To reduce the risk of serious personal injury, turn tool off and

A

personal injury, keep your hands on the

main tube (A) Fig. 1. Keep away from the

sanding head area. The sanding head

swivels in multiple directions and can pinch

your hand.

CONNECTING THE SANDER TO YOUR SHOP VAC

Furnished with the Drywall Sander are:

•A 13' (396 cm) long vacuum hose. This hose has a standard 1-1/4" (3.2 cm)

vacuum cleaner connector on one end and a special swivel connector on

the other end. It has a static dissipating feature to dissipate static electrical

charges.

•

An adapter [1-1/4" (3.2 cm) to 2-1/2" (6.4 cm)] to allow the connection of the

sander to a 2-1/2" (6.4 cm) vacuum cleaner.

To reduce th e ris k of

Fig. 1

10

INSTALLATION

1. Install the special drywall dust bag into your vacuum cleaner, following the

instructions supplied with the vacuum cleaner. If this dust bag does not fit

your vacuum cleaner correctly, purchase and install a suitable filter bag that

is rated for drywall dust.

drywall dust. Failure to do so will increase the level of airborne dust particles

in the work area. Continued and prolonged exposure to high concentrations

of airborne dust may affect your respiratory system function.

2. Connect the vacuum hose to the Drywall Sander. Open the hose connector

by turning the large nut (A) Fig. 2 counterclockwise a few turns. Push the

vacuum hose swivel connector (B) Fig. 2 into the connector and seat firmly.

Turn the large nut clockwise to tighten the connector.

To reduce the risk of personal injury, use a dust bag rated for

B

A

Fig. 2

3. Connect the vacuum hose to your vacuum cleaner. Use the 1-1/4" (3.2 cm)

to 2-1/2" (6.4 cm) adapter if necessary. If your vacuum cleaner requires a

special connector (something other than the standard 1-1/4" (3.2 cm) to

2-1/2" (6.4 cm) connectors supplied with the Drywall Sander), contact your

vacuum cleaner supplier for the proper adapter.

TO START AND STOP THE DRYWALL

SANDER

Be certain that the power circuit voltage is

the same as that shown on the specification

plate of the tool, and that the switch is OFF

(O). Connect the tool to the power circuit.

The Drywall Sander is equipped with a

“rocker” type switch (A) Fig. 4. The top

end of the switch button is labeled "O"

(OFF), and the bottom end of the button is

labeled "I" (ON). To start the sander, press

the bottom end of the "I" switch. To stop

the sander, press the top end of the "O"

switch.

11

A

B

Fig. 4

SPEED CONTROL

The 7800 Sander is equipped with a variable speed control. Adjust the speed by

turning the control knob (B) Fig. 4. The control knob is numbered “1” through “5”.

The setting “1” is the slowest speed (approximately 1000 RPM) and “5” is the

fastest speed (approximately 2,000 RPM).

Use the higher speed settings for fast stock removal. Use the lower speed setting

to reduce removal rate for more precise control. The Model 7801 Drywall Sander

has a constant speed of 2,000 RPM.

BRUSH-TYPE SKIRT

A brush-type skirt (A) Fig. 5 surrounds the

abrasive pad on the Model 7800. This

skirt serves two purposes:

It extends below the surface of the

•

abrasive pad to prevent the abrasive

from “gouging” the work.

•

It helps contain the drywall dust until

the vacuum cleaner pulls it away.

Replace the skirt if it is damaged or if it

is worn excessively. Replacement skirts

are available from any PORTER-CABLE

Service Center.

Since the Model 7801 requires no

vacuum cleaner, the skirt is shorter, but

still prevents "gouging".

A

B

Fig. 5

TO REPLACE A SKIRT

connect tool from power source before installing and removing accessories,

before adjusting or changing set-ups or when making repairs. An accidental

start-up can cause injury.

1. Remove abrasive pad (see Abrasive Pad Replacement).

2. Use phillips screwdriver to remove the six retaining screws (B) Fig. 5.

3. Lift the skirt out of housing.

4. Position the new skirt to the housing and install the six retaining screws.

5. Replace the abrasive pad.

SANDING DRYWALL

The Drywall Sander has an articulating sanding head. The head can swivel in

multiple directions, allowing the abrasive pad to conform to the work surface

(Figs. 6, 7, and 8). This action enables you to sand the top, middle, and bottom

of a wall or ceiling joint without changing position.

1. Turn the vacuum cleaner switch ON (I). (Model 7800 only).

respirator approved by NIOSH for “Dust and Mist”.

2. Turn Drywall Sander switch ON (I).

3. Position the Drywall Sander lightly against the work surface. Apply just

enough pressure to align the sanding head with the work surface.

4. Apply additional pressure to engage the abrasive pad on the work surface.

Move the sander in an overlapping pattern to smooth the drywall compound

down to a “featheredge”.

To reduce the risk of serious personal injury, turn tool off and dis-

To reduce the risk of personal injury, ALWAYS wear a

12

Fig. 7

Fig. 6

Apply ONLY enough pressure to keep the

abrasive pad flat against the work.

Keep the sander in constant motion while

the abrasive pad is in contact with the

work surface. Use a steady, sweeping

motion. Excessive pressure, stopping

the sander on the work, or moving the

sander erratically can cause unacceptable

swirl marks and unevenness in the work

surface.

NOTE: Do not allow rotating abrasive pad to contact sharp protrusions. Contact

with protruding objects (nails, screws, electrical boxes, etc.), can severely

damage the abrasive pad.

ABRASIVE PAD REPLACEMENT

To reduce the risk of serious personal injury, turn tool off and

disconnect tool from power source before installing and removing accessories, before adjusting or changing set-ups or when making repairs. An acci-

dental start-up can cause injury.

1. Grasp the abrasive pad and the sander housing to prevent pad rotation.

2. Rotate the pad retaining nut (A) Fig. 9 counterclockwise and remove.

3. Lift off the large metal washer (B) Fig. 9, and the abrasive pad (C) Fig. 9.

NOTE: When the abrasive pad (C) Fig. 9 is lifted from the sander, the abrasive

back-up disc (A) Fig. 10 is exposed. Note that this back-up disc is also covered

with an abrasive material, and is used ONLY to prevent “slippage” between the

back-up disc and the foam-backed abrasive pad. It is NOT suitable for use as a

sanding abrasive. DO NOT USE THE SANDER WITHOUT A PROPER ABRASIVE

PAD.

13

Fig. 8

4. Position the new abrasive pad to the back-up disc, and center the hole of the

disc on the hub (B) Fig. 10 of the back-up disc.

5. Position the large metal washer (B) Fig. 9, and the retaining nut (A) Fig. 9, to

the sander.

6. Rotate the retaining nut clockwise to hand tighten (while holding the abrasive

pad as described in step 1).

A

A

C

B

B

Fig. 9 Fig. 10

TRANSPORTATION AND STORAGE

Keep the sander dry during transport and storage. Protect the abrasive pad.

Contact with another object may deform the pad, causing it to sand unevenly.

If you cannot protect the pad during transport or storage, remove and store it

separately.

TROUBLESHOOTING

For assistance with your tool, visit our website at www.deltaportercable.com

for a list of service centers, or call the PORTER-CABLE Customer Care Center at

(888)-848-5175.

MAINTENANCE

To reduce the risk of injury, turn unit off and disconnect it from

power source before installing and removing accessories, before adjusting or

when making repairs. An accidental start-up can cause injury.

glasses. Also use face or dust mask if cutting operation is dusty. ALWAYS wear certified

safety equipment:

• ANSIZ87.1eyeprotection(CAN/CSAZ94.3)

• ANSIS12.6(S3.19)hearingprotection

• NIOSH/OSHA/MSHArespiratoryprotection.

REPAIRS

For assistance with your tool, visit our website at www.deltaportercable.com for a list of

service centers, or call the PORTER-CABLE Customer Care Center at (888) 848-5175.

CLEANING

dry compressed air is a suggested maintenance procedure. To reduce the risk of serious personal injury, ALWAYS wear ANSI Z87.1 safety glasses while using compressed

air.

ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety

Periodically blowing dust and chips out of the motor housing using clean,

14

When cleaning, use only mild soap and a damp cloth on plastic parts.

Many household cleaners contain chemicals which could seriously damage plastic.

Also, do not use gasoline, turpentine, lacquer, paint thinner, dry cleaning fluids or similar products which may seriously damage plastic parts. NEVER let any liquid get inside

the tool; NEVER immerse any part of the tool into a liquid.

FAILURE TO START

Should your tool fail to start, check to make sure the prongs on the cord plug are making

good contact in the outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION

This tool has been lubricated with a sufficient amount of high grade lubricant for the life

of the unit under normal operating conditions. No further lubrication is necessary.

BRUSH INSPECTION

For your continued safety and electrical protection, brush inspection and replacement

on this tool should ONLY be performed by a PORTER-CABLE FACTORY SERVICE

CENTER OR PORTER-CABLE AUTHORIZED WARRANTY SERVICE CENTER.

At approximately 100 hours of use, take or send your tool to your nearest PORTERCABLE Factory Service center or PORTER-CABLE Authorized Warranty Service Center

to be thoroughly cleaned and inspected. Have worn parts replaced and lubricated with

fresh lubricant. Have new brushes installed, and test the tool for performance.

Any loss of power before the above maintenance check may indicate the need for

immediate servicing of your tool. DO NOT CONTINUE TO OPERATE TOOL UNDER

THIS CONDITION. If proper operating voltage is present, return your tool to the service

station for immediate service.

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our service

website at www.deltaportercableservicenet.com. You can also order parts from your

nearest PORTER-CABLE Factory Service Center or PORTER-CABLE Authorized

Warranty Service Center. Or, you can call our Customer Care Center at (888) 848-

5175.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about PORTER-CABLE, its factory service centers or authorized warranty service centers, visit our website at www.deltaportercable.com or call our Customer Care

Center at (888) 848-5175. All repairs made by our service centers are fully guaranteed

against defective material and workmanship. We cannot guarantee repairs made or

attempted by others.

You can also write to us for information at PORTER-CABLE, 4825 Highway 45 North,

Jackson, Tennessee 38305 - Attention: Product Service. Be sure to include all of the

information shown on the nameplate of your tool (model number, type, serial number,

etc.).

ACCESSORIES

Since accessories, other than those offered by PORTER-CABLE, have

not been tested with this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury, only PORTER-CABLE recommended accessories

should be used with this product.

A complete line of accessories is available from your PORTER-CABLE Factory Service

Center or a PORTER-CABLE Authorized Warranty Service Center. Please visit our Web

Site www.deltaportercable.com for a catalog or for the name of your nearest supplier.

15

WARRANTY

AVERTISSEMENT

DO NOT REMOVE

GROUND PIN FROM

PLUG

DO NOT REMOVE

GROUND PIN FROM

PLUG

NO QUITE EL TERMINAL

DE CONEXIÓN A TIERRA

DEL ENCHUFE

NE RETIREZ PAS LA

BROCHE DE MISE À LA

TERRE DE LA FICHE

WARNINGWARNING

ADVERTENCIA

PORTER-CABLE will repair, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase. This warranty does not cover

part failure due to normal wear or tool abuse. For further detail of warranty coverage and

warranty repair information, visit www.deltaportercable.com or call (888) 848-5175. This

warranty does not apply to accessories or damage caused where repairs have been

made or attempted by others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, PORTER-CABLE tools are covered by our:

1 YEAR FREE SERVICE: PORTER-CABLE will maintain the tool and replace worn

parts caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE: If you are not completely satisfied with the

performance of your PORTER-CABLE Power Tool, Laser, or Nailer for any reason, you

can return it within 90 days from the date of purchase with a receipt for a full refund – no

questions asked.

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For

products sold in Latin America, see country specific warranty information contained in

the packaging, call the local company or see website for warranty information.

To register your tool for warranty service visit our website at www.deltaportercable.

com.

WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call (888) 848-5175 for a free

replacement.

16

Loading...

Loading...