Page 1

Part No. D23269-049-2

Single Stage Oillube

Compressor

Instruction

manual

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

The Model and Serial No. plate is located on the

frame. Record these numbers in the spaces below

and retain for future reference.

Model No.

Type

Serial No.

ESPAÑOL: PÁGINA 25

FRANÇAIS: PAGE 49

IMPORTANT

Please make certain that the person who is to use this

equipment carefully reads and understands these

instructions before starting operations.

PROFESSIONAL POWER TOOLS

Copyright © 2004 PORTER-CABLE Corporation

MODEL

CPLC7060V

®

Page 2

2 - ENGD23269

indicates a

potentially hazardous situation which,

if not avoided, may result in minor or

moderate injury.

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help

you recognize this information, we use the symbols below. Please read the manual and pay attention to these sections.

indicates an

imminently hazardous situation

which, if not avoided, will result in

death or serious injury.

used without

the safety alert symbol indicates a

potentially hazardous situation which,

if not avoided, may result in property

damage.

indicates a

potentially hazardous situation which,

if not avoided, could result in death

or serious injury.

Call our Toll Free Number 1-888-559-8550, to obtain the location of the nearest Authorized

Service Center for ordering repair parts and for warranty repairs.

When ordering repair parts from your local Authorized Service Center, always give the following information:

• Model number of your compressor

• Part number and description of the item you wish to purchase

Retain Original Sales Receipt as Proof of Purchase for Warranty Repair Work.

SAFETY GUIDELINES - DEFINITIONS

IMPORTANT SAFETY INSTRUCTIONS

When using electric tools, basic safety precautions

should always be followed to reduce the risk of

fire, electric shock and personal injury, including the following:

READ AND FOLLOW ALL INSTRUCTIONS.

This tool was designed for certain applications. Porter-Cable strongly recommends

that this tool NOT be modified and/or used for any application other than for which it

was designed. If you have any questions relative to its application, DO NOT use the

tool until you have written Porter-Cable and we have advised you.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North

P.O. Box 2468

Jackson, TN 38302-2468

Page 3

3 - ENG D23269

RISK OF BURSTING

SA

VE THESE INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS INJURY

AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

RISK OF EXPLOSION OR FIRE

AIR TANK: THE FOLLOWING CONDITIONS COULD LEAD TO A WEAKENING OF THE TANK, AND RESULT

IN A VIOLENT TANK EXPLOSION AND COULD CAUSE PROPERTY DAMAGE OR SERIOUS INJURY.

HAZARD

WHAT CAN HAPPEN

HOW TO PREVENT IT

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

WHAT CAN HAPPEN

HOW TO PREVENT IT

IT IS NORMAL FOR ELECTRICAL CONTACTS

WITHIN THE MOTOR AND PRESSURE SWITCH TO

SPARK.

IF ELECTRICAL SPARKS FROM COMPRESSOR

COME INTO CONTACT WITH FLAMMABLE

VAPORS, THEY MAY IGNITE, CAUSING FIRE OR

EXPLOSION.

RESTRICTING ANY OF THE COMPRESSOR

VENTILATION OPENINGS WILL CAUSE SERIOUS

OVERHEATING AND COULD CAUSE FIRE.

UNATTENDED OPERATION OF THIS PRODUCT

COULD RESULT IN PERSONAL INJURY OR

PROPERTY DAMAGE. TO REDUCE THE RISK

OF FIRE, DO NOT ALLOW THE COMPRESSOR

TO OPERATE UNATTENDED.

ALWAYS OPERATE THE COMPRESSOR IN A

WELL VENTILATED AREA FREE OF COM-

BUSTIBLE MATERIALS, GASOLINE OR SOLVENT VAPORS.

IF SPRAYING FLAMMABLE MATERIALS, LOCATE

COMPRESSOR AT LEAST 20 FEET AWAY FROM

SPRAY AREA. AN ADDITIONAL LENGTH OF

HOSE MAY BE REQUIRED.

STORE FLAMMABLE MATERIALS IN A SECURE

LOCATION AWAY FROM COMPRESSOR.

NEVER PLACE OBJECTS AGAINST OR ON TOP

OF COMPRESSOR. OPERATE COMPRESSOR

IN AN OPEN AREA AT LEAST 12 INCHES AWAY

FROM ANY WALL OR OBSTRUCTION THAT

WOULD RESTRICT THE FLOW OF FRESH AIR TO

THE VENTILATION OPENINGS.

OPERATE COMPRESSOR IN A CLEAN, DRY, WELL

VENTILATED AREA. DO NOT OPERATE UNIT

INDOORS OR IN ANY CONFINED AREA.

ALWAYS REMAIN IN ATTENDANCE WITH THE

PRODUCT WHEN IT IS OPERATING.

ALWAYS DISCONNECT ELECTRICAL POWER

BY MOVING PRESSURE SWITCH LEVER TO

THE OFF POSITION AND DRAIN TANK DAILY

OR AFTER EACH USE.

1. FAILURE TO PROPERLY DRAIN CONDENSED

WATER FROM THE TANK, CAUSING RUST

AND THINNING OF THE STEEL TANK.

2. MODIFICATIONS OR ATTEMPTED REPAIRS

TO THE TANK.

3. UNAUTHORIZED MODIFICATIONS TO THE

UNLOADER VALVE, SAFETY VALVE, OR ANY

OTHER COMPONENTS WHICH CONTROL

TANK PRESSURE.

4. EXCESSIVE VIBRATION CAN WEAKEN THE

AIR TANK AND CAUSE RUPTURE OR

EXPLOSION.

A

TTACHMENTS & ACCESSORIES:

EXCEEDING THE PRESSURE RATING OF AIR

TOOLS, SPRAY GUNS, AIR OPERATED ACCESSO-

RIES, TIRES AND OTHER INFLATABLES CAN

CAUSE THEM TO EXPLODE OR FLY APART, AND

COULD RESULT IN SERIOUS INJURY.

DRAIN TANK DAILY OR AFTER EACH USE. IF

TANK DEVELOPS A LEAK, REPLACE IT IMMEDIATELY WITH A NEW TANK OR REPLACE THE

ENTIRE COMPRESSOR.

NEVER DRILL INTO, WELD, OR MAKE ANY MODIFICATIONS TO THE TANK OR ITS ATTACH-

MENTS.

THE TANK IS DESIGNED TO WITHSTAND SPECIF-

IC OPERATING PRESSURES. NEVER MAKE

ADJUSTMENTS OR PARTS SUBSTITUTIONS TO

ALTER THE FACTORY SET OPERATING PRESSURES.

FOR ESSENTIAL CONTROL OF AIR PRESSURE,

YOU MUST INSTALL A PRESSURE REGULATOR

AND PRESSURE GAUGE TO THE AIR OUTLET OF

YOUR COMPRESSOR. FOLLOW THE EQUIPMENT

MANUFACTURERS RECOMMENDATION AND NEVER EXCEED THE MAXIMUM ALLOWABLE PRESSURE RATING OF ATTACHMENTS. NEVER USE

COMPRESSOR TO INFLATE SMALL LOW-PRESSURE OBJECTS SUCH AS CHILDREN’S TOYS,

FOOTBALLS, BASKETBALLS. ETC.

Page 4

4 - ENGD23269

RISK FROM FLYING OBJECTS

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

WHAT CAN HAPPEN

HOW TO PREVENT IT

AIR OBTAINED DIRECTLY FROM THE COMPRES-

SOR SHOULD NEVER BE USED TO SUPPLY AIR

FOR HUMAN CONSUMPTION. IN ORDER TO USE

AIR PRODUCED BY THIS COMPRESSOR FOR

BREATHING, SUITABLE FILTERS AND IN-LINE

SAFETY EQUIPMENT MUST BE PROPERLY

INSTALLED. IN-LINE FILTERS AND SAFETY

EQUIPMENT USED IN CONJUNCTION WITH THE

COMPRESSOR MUST BE CAPABLE OF TREATING AIR TO ALL APPLICABLE LOCAL AND FEDERAL CODES PRIOR TO HUMAN CONSUMPTION.

RISK TO BREATHING

WHAT CAN HAPPEN

HOW TO PREVENT IT

YOUR AIR COMPRESSOR IS POWERED BY ELECTRICITY. LIKE ANY OTHER ELECTRICALLY POWERED DEVICE, IF IT IS NOT USED PROPERLY IT

MAY CAUSE ELECTRIC SHOCK.

NEVER OPERATE THE COMPRESSOR OUTDOORS

WHEN IT IS RAINING OR IN WET CONDITIONS.

NEVER OPERATE COMPRESSOR WITH PROTECTIVCOVERS REMOVED OR DAMAGED. a

RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN

HOW TO PREVENT IT

THE COMPRESSED AIR STREAM CAN CAUSE

SOFT TISSUE DAMAGE TO EXPOSED SKIN AND

CAN PROPEL DIRT, CHIPS, LOOSE PARTICLES

AND SMALL OBJECTS AT HIGH SPEED, RESULTING IN PROPERTY DAMAGE OR PERSONAL

INJURY.

ALWAYS WEAR ANSI Z87.1 APPROVED SAFETY

GLASSES WITH SIDE SHIELDS WHEN USING

THE COMPRESSOR.

NEVER POINT ANY NOZZLE OR SPRAYER

TOWARD ANY PART OF THE BODY OR AT

OTHER PEOPLE OR ANIMALS.

ALWAYS TURN THE COMPRESSOR OFF AND

BLEED PRESSURE FROM THE AIR HOSE AND

TANK BEFORE ATTEMPTING MAINTENANCE,

ATTACHING TOOLS OR ACCESSORIES.

WORK IN AN AREA WITH GOOD CROSS-VENTILATION. READ AND FOLLOW THE SAFETY

INSTRUCTIONS PROVIDED ON THE LABEL OR

SAFETY DATA SHEETS FOR THE MATERIAL YOU

ARE SPRAYING. USE A NIOSH/MSHA

APPROVED RESPIRATOR DESIGNED FOR USE

WITH YOUR SPECIFIC APPLICATION.

THE COMPRESSED AIR DIRECTLY FROM YOUR

COMPRESSOR IS NOT SAFE FOR BREATHING.

THE AIR STREAM MAY CONTAIN CARBON

MONOXIDE, TOXIC VAPORS, OR SOLID PARTICLES FROM THE TANK. BREATHING THESE

CONTAMINANTS CAN CAUSE SERIOUS INJURY

OR DEATH.

SPRAYED MATERIALS SUCH AS PAINT, PAINT

SOLVENTS, PAINT REMOVER, INSECTICIDES,

WEED KILLERS, CONTAIN HARMFUL VAPORS

AND POISONS.

REPAIRS ATTEMPTED BY UNQUALIFIED PERSONNEL CAN RESULT IN SERIOUS INJURY OR DEATH

BY ELECTROCUTION.

ANY ELECTRICAL WIRING OR REPAIRS

REQUIRED ON THIS PRODUCT SHOULD BE PER-

FORMED BY AUTHORIZED SERVICE CENTER

PERSONNEL IN ACCORDANCE WITH NATIONAL

AND LOCAL ELECTRICAL CODES.

ELECTRICAL GROUNDING: FAILURE TO PROVIDE

ADEQUATE GROUNDING TO THIS PRODUCT

COULD RESULT IN SERIOUS INJURY OR DEATH

FROM ELECTROCUTION. SEE GROUNDING

INSTRUCTIONS.

MAKE CERTAIN THAT THE ELECTRICAL CIRCUIT

TO WHICH THE COMPRESSOR IS CONNECTED

PROVIDES PROPER ELECTRICAL GROUNDING,

CORRECT VOLTAGE AND ADEQUATE FUSE

PROTECTION.

Page 5

5 - ENG D23269

RISK FROM MOVING PARTS

RISK OF BURNS

RISK OF FALLING

IMPORTANT SAFETY INSTRUCTIONS (cont’d)

WHAT CAN HAPPEN

HOW TO PREVENT IT

WHAT CAN HAPPEN

HOW TO PREVENT IT

WHAT CAN HAPPEN

HOW TO PREVENT IT

MOVING PARTS SUCH AS THE PULLEY, FLY-

WHEEL AND BELT CAN CAUSE SERIOUS

INJURY IF THEY COME INTO CONTACT WITH

YOU OR YOUR CLOTHING.

TOUCHING EXPOSED METAL SUCH AS THE

COMPRESSOR HEAD OR OUTLET TUBES, CAN

RESULT IN SERIOUS BURNS.

NEVER OPERATE THE COMPRESSOR WITH

GUARDS OR COVERS WHICH ARE DAMAGED OR

REMOVED.

NEVER TOUCH ANY EXPOSED METAL PARTS

ON COMPRESSOR DURING OR IMMEDIATELY

AFTER OPERATION. COMPRESSOR WILL

REMAIN HOT FOR SEVERAL MINUTES AFTER

OPERATION.

DO NOT REACH AROUND PROTECTIVE

SHROUDS OR ATTEMPT MAINTENANCE UNTIL

UNIT HAS BEEN ALLOWED TO COOL.

A PORTABLE COMPRESSOR CAN FALL FROM A

TABLE, WORKBENCH OR ROOF CAUSING DAM-

AGE TO THE COMPRESSOR AND COULD

RESULT IN SERIOUS INJURY OR DEATH TO THE

OPERATOR.

ALWAYS OPERATE COMPRESSOR IN A STABLE

SECURE POSITION TO PREVENT ACCIDENTAL

MOVEMENT OF THE UNIT. NEVER OPERATE

COMPRESSOR ON A ROOF OR OTHER ELEVATED POSITION. USE ADDITIONAL AIR HOSE TO

REACH HIGH LOCATIONS.

WHAT CAN HAPPEN

HOW TO PREVENT IT

RISK OF PROPERTY DAMAGE WHEN

TRANSPORTING COMPRESSOR

(Fire, Inhalation, Damage

to Vehicle Surfaces)

OIL CAN LEAK OR SPILL AND COULD RESULT

IN FIRE OR BREATHING HAZARD, SERIOUS

INJURY OR DEATH CAN RESULT. OIL LEAKS

WILL DAMAGE CARPET, PAINT OR OTHER SURFACES IN VEHICLES OR TRAILERS.

ALWAYS PLACE COMPRESSOR ON A PROTEC-

TIVE MAT WHEN TRANSPORTING TO PROTECT

AGAINST DAMAGE TO VEHICLE FROM LEAKS.

REMOVE COMPRESSOR FROM VEHICLE IMMEDIATELY UPON ARRIVAL AT YOUR DESTINATION.

ATTEMPTING TO OPERATE COMPRESSOR WITH

DAMAGED OR MISSING PARTS OR ATTEMPT-

ING TO REPAIR COMPRESSOR WITH PROTECTIVE SHROUDS REMOVED CAN EXPOSE YOU TO

MOVING PARTS AND CAN RESULT IN SERIOUS

INJURY.

ANY REPAIRS REQUIRED ON THIS PRODUCT

SHOULD BE PERFORMED BY AUTHORIZED

SERVICE CENTER PERSONNEL.

Page 6

6 - ENGD23269

GLOSSARY

SPECIFICATIONS

Model No. CPLC7060V

Horsepower Peak 7.0

Voltage/Hertz/Phase 240V/60/1

Minimum Branch Circuit Requirement 15 Amp

* Fuse Type Time Delay

Air Tank Capacity (Gallon) 60 ASME, Vertical

Approximate Cut-in Pressure 110 PSIG

Approximate Cut-out Pressure 135 PSIG

SCFM @ 40 PSIG 12.1

SCFM @ 90 PSIG 9.7

Become familiar with these terms before operating the unit.

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of air delivery.

PSIG: Pounds per square inch gauge; a unit of measure of pressure.

ASME: American Society of Mechanical Engineers; made, tested, inspected and

registered to meet the standards of the ASME.

Code Certification: Products that bear one or more of the following marks: UL,

CUL, ETL, CETL, have been evaluated by OSHA certified independent safety laboratories and meet the applicable Underwriters Laboratories Standards for Safety.

Cut-In Pressure: While the motor is off, air tank pressure drops as you continue to

use your accessory. When the tank pressure drops to the factory set low pressure

the motor will restart automatically. The low pressure at which the motor automatically restarts is called “cut-in” pressure.

Cut-Out Pressure: When an air compressor is turned on and begins to run, air

pressure in the air tank begins to build. It builds to a factory set high pressure

before the motor automatically shuts off - protecting your air tank from pressure

higher than its capacity. The high pressure at which the motor shuts off is called

“cut-out” pressure.

Branch Circuit: Circuit carrying electricity from electrical panel to outlet.

ACCESSORIES

Accessories for this unit are available at the store the unit was purchased.

* This air compressor can be operated on a 15 amp circuit if:

1. Voltage supply to circuit is normal.

2. Circuit is not used to supply any other electrical needs (lights, appliances, etc.)

3. Extension cords comply with specifications in owners manual.

4. Circuit is equipped with 15 amp circuit breaker or 15 amp time delay fuse

marked Type D.

If any of the above conditions cannot be met, or if operation of the air compressor

repeatedly causes interruption of the power it may be necessary to operate it from

a 20 amp circuit. It is not necessary to change the cord set.

* A circuit breaker is preferred. Use only a fuse or circuit breaker that is the same

rating as the branch circuit on which the air compressor is operated. If the air compressor is connected to a circuit protected by fuses, use dual element time delay

fuses.

Page 7

7 - ENG D23269

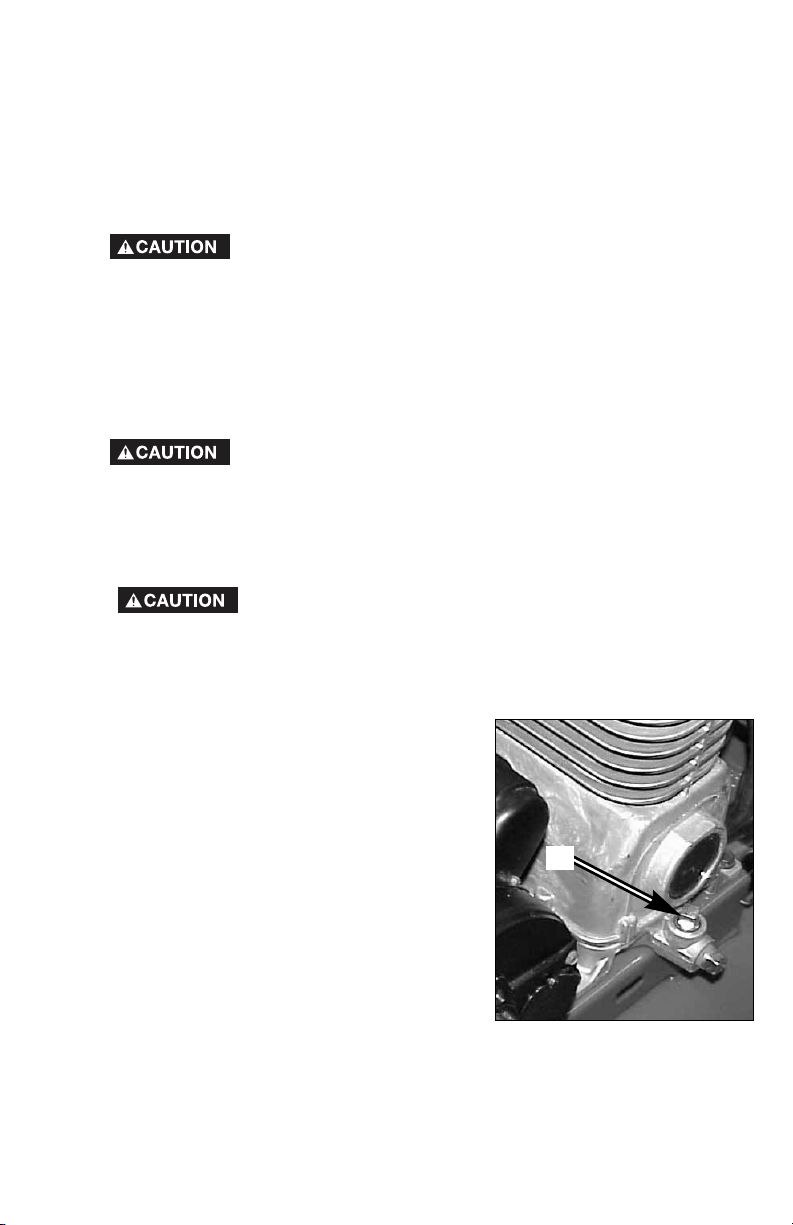

To Add Oil To Pump

Compressors are shipped without oil. A small amount

of oil may be present in the pump upon receipt of the

air compressor. This is due to plant testing and does not mean the

pump contains oil. Do not attempt to operate this air compressor

without first adding oil to the crankcase. Serious damage can result

from even limited operation unless filled with oil and broken in correctly. Make sure to closely follow initial start-up procedures.

Multi-Viscosity motor oils, like 10W 30, should not be

used in an air compressor. They leave carbon

deposits on critical components, thus reducing performance and

compressor life. Use air compressor oil only.

NOTE: Use an air compressor oil such as SAE-20 API CG/CD heavy duty motor oil.

Under extreme winter conditions use SAE-10 weight oil.

1. Place unit on a level surface.

2. Remove oil fill plug (A) and slowly add a compressor oil until it is even with the top of the

oil fill hole. NOTE: Do not allow oil to be lower

than 3/8" (6 threads) from the top at any time.

When filling the crankcase, the oil flows very

slowly into the pump. If the oil is added too

quickly, it will overflow and appear to be full.

NOTE: Crankcase oil capacity is approximately 16 fluid ounces.

3. Replace oil fill plug.

A

Tools Required for Assembly

1 - 9/16” socket or open end wrench

Electric drill

Unpacking

1. Remove all packaging.

It may be necessary to brace or support one side of

the outfit when removing the pallet because the air

compressor will have a tendency to tip.

2. Remove and discard the (4) screws and washers holding the compressor to the

pallet.

3. With the help of another person carefully remove air compressor from pallet

and place on a level surface.

ASSEMBLY

Page 8

8 - ENGD23269

INSTALLATION

Location of the Air Compressor

• Locate the air compressor in a clean, dry, and well ventilated area.

• Located the air compressor at least 12" away from the wall or other obstructions that will interfere with the flow of air.

• Locate the air compressor as close to the main power supply as possible to

avoid using long lengths of electrical wiring. Long lengths of electrical wiring

could cause power loss to the motor.

• The air filter must be kept clear of obstructions which could reduce air flow to

the air compressor.

Anchoring of the Air Compressor

Excessive Vibration can weaken the air tank and

cause an explosion. The compressor must be properly

mounted.

The air compressor MUST be bolted to a solid, level surface.

Hardware needed:

4 - Concrete anchors (not supplied)

4 - 3/8” Lag screw to fit concrete anchors

(not supplied)

4 - 5/8” Washer (found in parts bag)

- shims (if needed)

1. Place the air compressor

on on a solid, level surface.

2. Mark the surface using

the holes in the air compressor feet as a template.

3. Drill holes in the surface

for the concrete anchors.

Install concrete anchors.

4. Line-up holes in surface

with holes in air compressor feet.

5. Place the (4) washers (supplied) between the floor and air compressor feet. If

needed, solid shims may be placed between the washers and floor to evenly

distribute weight on all four feet. See next figure.

6. Place the (4) 3/8” lag screws through the air compressor feet, washers, shims,

and into the anchors.

7. Torque 3/8” lag screws to 7-10 ft.-lbs.

3/8” Lag

Screw

(not supplied)

5/8” Washer

(supplied)

Shim Under

Washer

(not supplied)

Concrete Anchor

(not supplied)

Surface Line

Page 9

9 - ENG D23269

Wiring Instructions

Improper electrical installation of this product may

void its warranty and your fire insurance. Have circuit

wiring performed by qualified personnel such as a licensed electricians who is familiar with the current national electrical code and any

prevailing local electrical codes.

RISK OF ELECTRICAL SHOCK. Improper electrical

grounding can result in electrical shock. The wiring

should be done by a qualified electrician

A qualified electrician needs to knows the following before wiring:

1. The amperage rating of the electrical box should be adequate. Refer to the

Specification Chart, in the parts manual, for this information.

2. The supply line should have the same electrical characteristics (voltage, cycle,

phase) as the motor. Refer to the motor nameplate, on side of motor, for this

information.

NOTE: The wiring must be the same as the motor nameplate voltage plus or minus

10%. Refer to local codes for recommended wire sizes, correct wire size, and maximum wire run; undersize wire causes high amp draw and overheating to the motor.

Electrical wiring must be located away from hot surfaces such as manifold assembly, compressor outlet

tubes, heads, or cylinders.

GROUNDING INSTRUCTIONS

This product should be connected to a metallic, permanent wiring system, of an

equipment-grounding terminal or lead on the product.

Voltage and Circuit Protection

Refer to the Parts Manual for the voltage and minimum branch circuit requirements.

Certain air compressors can be operated on a 15 amp circuit if the following condi-

tions are met.

1. Voltage supply through branch circuit is 15 amps.

2. Circuit is not used to supply any other electrical needs (lights, appliances, etc.).

3. Circuit is equipped with a 15 amp circuit breaker or 15 amp time delay fuse.

NOTE: If compressor is connected to a circuit protected by fuses, use only time

delay fuses marked “D”.

If any of the above conditions cannot be met, or if operation of the compressor

repeatedly causes interruption of the power, it may be necessary to operate it from

a 20 amp circuit.

Page 10

10 - ENGD23269

Air Distribution System

Plastic or PVC pipe is not designed for use with

compressed air. Regardless of its indicated pressure rating, plastic pipe can burst from air pressure. Use only metal

pipe for air distribution lines.

The next figure represents a typical air distribution system. The following are tips to

remember when setting up the air compressor’s air distribution system.

● Use pipe that is the same size as the air tank outlet. Piping that is too small will

restrict the flow of air.

● If piping is over 100 feet long, use the next larger size.

● Bury underground lines below the frost line and avoid pockets where conden-

sation can gather and freeze. Apply pressure before underground lines are covered to make sure all pipe joints are free of leaks.

● A flexible coupling is recommended to be installed between the air discharge

outlet and main air distribution line to allow for vibration.

● A separate regulator is recommended to control the air pressure. Air pressure

from the tank is usually to high for individual air driven tools.

MAIN DISTRIBUTION AIR LINES

Slope pipe in direction of air flow.

Water condensate flows along

bottom of pipe to drain legs,

preventing it from entering feeder

lines.

AIR USAGE

LINES

DRAIN

LEGS

REGULATOR

LUBRICATOR

DRAIN

TRAP

MOISTURE

SEPARATOR

AND TRAP

DIRT

LEG

TYPICAL COMPRESSED

AIR DISTRIBUTION SYSTEM

DIRT

LEG

FILTER

FLEXIBLE

COUPLING

AIR DISCHARGE

VALVE

DRAIN COCK

VALVE

DRAIN

TRAPS

REGULATOR

COMPRESSOR

LUBRICATOR

AIR

Page 11

11 - ENG D23269

OPERATION

Know Your Air Compressor

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT. Compare the illustrations with your unit to familiarize yourself with the location of various controls and adjustments. Save this manual for future reference.

Description of Operation

Become familiar with these controls before operating the unit.

On/Auto/Off Switch: Turn this switch ON to provide

automatic power to the pressure switch and OFF to

remove power at the end of each use.

Pressure Switch: The pressure switch automatically

starts the motor when the air tank pressure drops

below the factory set “cut-in” pressure. It stops the

motor when the air tank pressure reaches the factory set “cut-out” pressure.

Safety Valve: If the pressure switch does not shut

off the air compressor at its “cut-out” pressure setting, the safety valve will protect against high pressure by “popping out” at its factory set pressure

(slightly higher than the pressure switch “cut-out”

setting).

Tank Pressure Gauge: The tank pressure gauge

indicates the reserve air pressure in the tank.

Globe Valve (sold separately): Opens and closes air discharge valve. Turn knob

counter-clockwise to open and clockwise to close.

Drain Valve: The drain valve is located at the base of the

air tank and is used to drain condensation at the end of

each use.

Cooling System (not shown): This compressor contains

an advanced design cooling system. At the heart of this

cooling system is an engineered fan. It is perfectly normal

for this fan to blow air through the vent holes in large

amounts. You know that the cooling system is working when air is being expelled.

Air Compressor Pump (not shown): Compresses air into the air tank. Working air

is not available until the compressor has raised the air tank pressure above that

required at the air outlet.

Check Valve: When the air compressor is operating, the

check valve is “open”, allowing compressed air to enter the air

tank. When the air compressor reaches “cut-out” pressure,

the check valve “closes”, allowing air pressure to remain inside

the air tank.

Pressure Release Valve: The pressure release valve, located

on the side of the pressure switch, is designed to automatically

release compressed air from the compressor head and the

outlet tube when the air compressor reaches “cut-out” pressure or is shut off. The pressure release valve allows the motor

to restart freely. When the motor stops running, air will be heard escaping from this

valve for a few seconds. No air should be heard leaking when the motor is running,

or continuous leaking after unit reaches “cut-out” pressure.

Pressure

Release

Valve

Check Valve

Pressure

Switch

On/Auto/Off

Switch

Safety

Valve

Tank

Pressure

Gauge

Globe Valve

Drain Valve

Page 12

12 - ENGD23269

Air Intake Filter (not shown) This filter is designed to clean air coming into the

pump. This filter must always be clean and ventilation openings free from obstructions. See "Maintenance".

How to Use Your Unit

How to Stop:

1. Set the On/Auto/Off lever to “OFF”.

Before Starting

Break-in Procedure

Serious damage may result if the following break-in

instructions are not closely followed.

This procedure is required before the air compressor is put into service and when

the check valve or a complete compressor pump has been replaced.

1. Make sure the On/Auto/Off lever is in the "OFF" position.

2.

Recheck all wiring. Make sure wires are secure at all terminals connections.

Make sure all contacts move freely and are not obstructed.

3. Open the globe valve fully to permit air to escape and prevent air pressure

build up in the air tank during the break-in period.

4. Move the On/Auto/Off lever to "ON/AUTO" position. The compressor will start.

5. Run the compressor for 30 minutes. Make sure the globe valve is open and

there is minimal air pressure build-up in tank.

6. Check all air line fittings and connections/piping for air leaks by applying a

soap solution. Correct if necessary. NOTE: Minor leaks can cause the air compressor to overwork, resulting in premature breakdown or inadequate performance.

7. Check for excessive vibration. Readjust or shim air compressor feet, if necessary.

8. After 30 minutes, move the On/Auto/Off lever to "OFF" position and close the

globe valve.

9. Move the On/Auto/Off lever to "ON/AUTO" position. The air receiver will fill to

“cut-out” pressure and the motor will stop.

Before Each Start-Up:

1. Place On/Auto/Off lever to “OFF”.

2. Close the globe valve.

3. Attach hose and accessories. NOTE: A regulator MUST be installed when

using accessories rated at less than 110 PSI.

Too much air pressure causes a hazardous risk of

bursting. Check the manufacturer’s maximum pressure rating for air tools and accessories. The regulator outlet pressure

must never exceed the maximum pressure rating.

How to Start

1. Turn the On/Auto/Off lever to “AUTO” and allow tank pressure to build. Motor

will stop when tank pressure reaches “cut-out” pressure.

2. When the tank pressure reaches “cut-out” pressure open the globe valve.

IMPORTANT: When using regulator and other accessories refer to the manufacturer-s instructions.

NOTE: Always operate the air compressor in well-ventilated areas free of gasoline

or other combustible vapors. If the compressor is being used to operate a sprayer,

DO NOT place compressor near the spray area.

Page 13

13 - ENG D23269

MAINTENANCE

Customer Responsibilities

Daily or

after each

use

Before

each

use

Check Safety Valve

Drain Tank

Oil Leaks

Check Oil

Change Oil

Unusual Noise and/or

Vibration

Air Filter

Drive Belt

Condition

Motor Pulley/Flywheel

alignment

Air compressor pump

intake and exhaust

valves

Inspect air lines and fittings for leaks

●

●

●

Unit cycles automatically when power is on.

When performing maintenance, you may be

exposed to voltage sources, compressed air, or moving parts.

Personal injuries can occur. Before performing any maintenance or

repair, disconnect power source from the compressor and bleed off all

air pressure.

●

Every

8

hours

Every

40

hours

Every

100

hours

Yearly

Every

160

hours

●

●

●

1

●

●

●

1- more frequent in dusty or humid conditions

●

To ensure efficient operation and longer life of the air compressor outfit, a routine

maintenance schedule should be prepared and followed. The following routine

maintenance schedule is geared to an outfit in a normal working environment operating on a daily basis. If necessary, the schedule should be modified to suit the

conditions under which your compressor is used. The modifications will depend

upon the hours of operation and the working environment. Compressor outfits in an

extremely dirty and/or hostile environment will require a greater frequency of all

maintenance checks.

NOTE: See “Operation” section for the location of controls.

To Check Safety Valve

If the safety valve does not work properly, over-

pressurization may occur, causing air tank rupture or an explosion.

1. Before starting compressor, pull the ring on the safety valve to make sure that

the safety valve operates freely. If the valve is stuck or does not operate

smoothly, it must be replaced with the same type of valve.

Page 14

14 - ENGD23269

To Drain Tank

1. Set the On/Auto/Off lever to “OFF”.

2. Close the globe valve.

3. Remove the air tool or accessory.

4. Open the globe valve and allow the air to slowly bleed from the air tank until

tank pressure is approximately 20 psi.

5. Close the globe valve.

6. Drain water from air tank by opening drain valve (counter-clockwise) on bottom

of tank.

Water will condense in the air tank. If not drained,

water will corrode and weaken the air tank causing a

risk of air tank rupture.

7. After the water has been drained, close the drain valve (clockwise). The air

compressor can now be stored.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be

removed, cleaned, then reinstalled.

Oil

Checking

1. Remove the oil fill plug (A). The oil level should be

even with the top of the fill hole and no lower than 6

threads from the top of fill hole.

2. If needed, slowly add oil until it reaches the top of fill

hole.

NOTE: Use a air compressor oil such as SAE-20 (API

CG/CD heavy duty motor oil. Under extreme winter conditions use SAE-10 weight oil.

Changing

1. Remove the oil fill plug (A).

2. Remove the oil drain plug (B) and drain oil into a

suitable container.

3. Replace the oil drain plug (B) and tighten securely

NOTE: Use a air compressor oil such as SAE-20 (API CG/CD heavy duty motor oil.

Under extreme winter conditions use SAE-10 weight oil.

4. Slowly fill crankcase to the top of the fill hole. Crankcase capacity is 16 fluid

ounces (473.2 ml).

Overfilling with oil will cause premature compressor

failure. Do not overfill.

5. Replace oil fill plug (A) and tighten securely.

A

B

Air Filter - Inspection and Replacement

Hot surfaces. Risk of burn. Compressor heads are

exposed when filter cover is removed. Allow com-

pressor to cool prior to servicing.

Keep the air filter clean at all times. Do not operate

the air compressor with the air filter removed.

Page 15

15 - ENG D23269

Motor Pulley/Flywheel Alignment

NOTE: Once the motor pulley has been moved from its factory set location, the

grooves of the flywheel and pulley must be aligned to within 1/16" to prevent

excessive belt wear.

The air compressor flywheel and motor pulley must be in-line (in the same plane)

within 1/16" to assure belt retention within flywheel belt grooves. To check alignment, perform the following steps:

1. Unplug air compressor from power source.

2. Remove belt guard

3. Place a straightedge against the outside

of the flywheel and the motor drive pulley.

4. Measure the distance between the edge

of the belt and the straightedge at points

A1 and A2 in figure. The difference

between measurements should be no

more than 1/16".

5. If the difference is greater or less than 1/16" loosen the set screw holding the

motor drive pulley to the shaft and adjust the pulley’s position on the shaft until

the A1 and A2 measurements are within 1/16" of each other.

6. Tighten the motor drive pulley set screw to 70-80 in.-lbs.

7. Visually inspect the motor drive pulley to verify that it is perpendicular to the

drive motor shaft. Points B1 and B2 of Figure should appear to be equal. If

they are not, loosen the setscrew of the motor drive pulley and equalize B1 and

B2, using care not to disturb the belt alignment performed in step 2.

8. Retighten the motor drive pulley setscrew to 70-80 in.-lbs.

9. Reinstall belt guard.

A dirty air filter will not allow the compressor pump to operate at full capacity.

Before you use the compressor pump, check the air filter to be sure it is clean and

in place.

If it is dirty, replace it with a new filter. On some models,the filter may be removed

by using a pair of needle nose pliers or a screwdriver. Pull or pry out the old filter

and carefully clean the filter area. Push in the new air filter.

Air Compressor Pump Intake and Exhaust Valves

Once a year have a Trained Service Technician check the air compressor

pump intake and exhaust valves.

Inspect Air Lines and Fittings for Leaks

1. Turn the air compressor on to inspect for air leaks.

2. Apply a soap solution to all air line fittings and connections/piping.

3. Correct any leaks found.

IMPORTANT: Even minor leaks can cause the air compressor to overwork, resulting

in premature breakdown or inadequate performance.

Page 16

16 - ENGD23269

SERVICE AND ADJUSTMENTS

Unit cycles automatically when power is on. When doing

Maintenance, you may be exposed to voltage sources, com-

pressed air or moving parts. Personal injuries can occur.

Before performing any Maintenance or repair, unplug the compressor and bleed off

all air pressure.

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST

BE PERFORMED BY TRAINED SERVICE TECHNICIAN.

Before servicing:

●

Unplug or disconnect electrical supply to the air compressor.

●

Bleed tank of pressure.

●

Allow the air compressor to cool.

To Replace or Clean Check Valve

1. Release all air pressure from air tank. See “To Drain Tank” in the Maintenance

section.

2. Unplug unit.

3. Using an adjustable wrench loosen

outlet tube nut at air tank and pump.

Carefully move outlet tube away from

check valve.

4. Using an adjustable wrench loosen

pressure relief tube nut at air tank and

pressure switch. Carefully move pressure relief tube away from check valve.

5. Unscrew the check valve (turn coun-

terclockwise) using a 7/8” open end

wrench. Note the orientation for

reassembly.

6. Using a screwdriver, carefully push the

valve disc up and down. NOTE: The

valve disc should move freely up and

down on a spring which holds the

valve disc in the closed position, if not

the check valve needs to be cleaned or replaced.

7. Clean or replace the check valve. A solvent, such

as paint or varnish remover can be used to clean

the check valve.

8. Apply sealant to the check valve threads.

Reinstall the check valve (turn clockwise).

9. Replace the pressure release tube. Tighten nuts.

10. Replace the outlet tube and tighten nuts.

11. Perform the Break-in Procedure. See “Break-in

Procedure” in the Operation section.

In closed position disc is visible.

In open position nothing is visible.

Screwdriver

Outlet Tube

Nuts

Nut

Pressure

Relief Tube

Check

Valve

Nut

Page 17

17 - ENG D23269

To Replace Belt

Serious injury or damage may occur if parts of the

body or loose items get caught in moving parts.

Never operate the unit with the belt guard removed. The belt guard should

be removed only when the compresor is unplugged.

1. Unplug compressor.

2. Remove the front of the belt guard by

disengaging the snaps. Insert a flat

bladed screwdriver at each snap location and pry the beltguard apart.

3. Loosen the wing nut on hold down

plate and tilt motor to allow for easy

removal or installation of the belt.

4. Remove belt.

5. Replace belt. NOTE: The belt must be

centered over the grooves on the flywheel and motor pulley.

6. Turn the wing nut on the hold down

plate until it makes contact with the

washer, plus one additional turn.

7. Replace the belt guard.

Belt Guard

Wing Nut

Motor

This motor has a manual thermal overload protector. If the motor overheats for any

reason, the overload protector will shut off the motor. The motor must be allowed

to cool down before restarting. To restart:

1. Place the On/Auto/Off lever in the Off position.

2. Allow the motor to cool.

3. Depress the red reset button on the motor.

4. Place the On/Auto/Off lever in the On/Auto postion

to restart the motor.

IMPORTANT: If the overload protector shuts the motor

off frequently, check for a possible voltage problem.

Low voltage can also be suspected when:

1. The motor does not get up to full power or speed.

2. Fuses blow out when starting the motor; lights dim

and remain dim when motor is started and is running.

Page 18

18 - ENGD23269

STORAGE

Before you store the air compressor, make sure you do the following:

1. Review the "Maintenance" section on the preceding pages and perform scheduled maintenance as necessary.

2. Set the On/Auto/Off lever to “OFF”.

3. Close the globe valve.

4. Remove the air tool or accessory.

5. Open the globe valve and allow the air to slowly bleed from the air tank until

tank pressure is approximately 20 psi.

6. Drain water from air tank by opening drain valve (counter-clockwise) on bottom

of tank.

Water will condense in the air tank. If not drained,

water will corrode and weaken the air tank causing a

risk of air tank rupture.

7. After the water has been drained, close the drain or drain valve.

NOTE:

If drain valve is plugged, release all air pressure. The valve can then

be removed, cleaned, then reinstalled.

8. Protect the air hose from damage (such as being stepped on or run over).

Page 19

19 - ENG D23269

TROUBLESHOOTING

Performing repairs may expose voltage sources, moving parts

or compressed air sources, moving parts or compressed air

sources. Personal injury may occur. Prior to attempting any repairs, unplug the air

compressor and bleed off all air tank air pressure.

PROBLEM

CAUSE

CORRECTION

Pressure switch does

not shut off motor when

compressor reaches

“cut-out” pressure.

Pressure switch “cutout” too high.

Move On/Auto/Off lever to the

“OFF” position, if the outfit does

not shut off contact a Trained

Service Technician.

Contact a Trained Service

Technician.

Excessive tank pressure - safety valve

pops off.

Tube fittings are not tight

enough.

Tighten fittings where air can be

heard escaping. Check fittings

with soapy water solution. DO

NOT OVERTIGHTEN.

Air leaks at fittings.

Air leaks at pressure

switch release valve.

Defective pressure

switch release valve.

Contact a Trained Service

Technician.

Air leaks in air tank

or at air tank welds.

Defective air tank.

Air tank must be replaced. Do

not repair the leak.

Do not drill into, weld or otherwise modify air tank or it will

weaken. The tank can rupture or

explode.

Air leaks between

head and valve

plate.

Leaking seal.

Contact a Trained Service

Technician.

Air leaks at or inside

check valve

Check valve seat damaged.

A defective check valve results in

a constant air leak at the pressure

release valve when there is pressure in the tank and the compressor is shut off. Replace check

valve. Refer the “To Replace or

Clean Check Valve” in the

“Operation” section.

Page 20

20 - ENGD23269

PROBLEM

CAUSE

CORRECTION

Possible defect in safety valve.

Operate safety valve manually by

pulling on ring. If valve still leaks,

it should be replaced.

Defective check valve. Remove and clean, or replace.

Knocking Noise.

Compressor is not

supplying enough

air to operate

accessories.

Prolonged excessive use

of air.

Compressor is not large

enough for air requirement.

Hole in hose.

Check valve restricted.

Air leaks.

Restricted air intake filter

Decrease amount of air usage.

Check the accessory air requirement. If it is higher than the

SCFM or pressure supplied by

your air compressor, you need a

larger compressor.

Check and replace if required.

Remove and clean, or replace.

Tighten fittings.

Clean or replace air intake filter.

Do not operate the air compressor

with the filter removed. Refer to

the “Air Filter” paragraph in the

“Maintenance “ section

Loose pulley Tighten pulley set screw,

70-80 in.-lbs.

Compressor mounting

screws loose

Tighten mounting screws,

15-20 ft.-lbs.

Loose flywheel Tighten flywheel screw,

15-20 ft.-lbs.

Loose belt

Loosen wingnut and then tighten

wingnut until it contacts the washer, plus one turn.

Carbon build-up in

pump

Have checked by a Trained

Service Technician.

Belt to tight Loosen wingnut and then tighten

wingnut until it contacts the washer, plus one turn.

Loose belt.

Loosen wingnut and then tighten

wingnut until it contacts the washer, plus one turn.

Page 21

21 - ENG D23269

PROBLEM

CAUSE

CORRECTION

Motor will not run.

Fuse blown, circuit

breaker tripped.

1. Check fuse box for blown

fuse and replace as necessary. Reset circuit breaker.

Do not use a fuse or circuit

breaker with higher rating

than that specified for your

particular branch circuit.

2. Check for proper fuse. You

should use a time delay fuse.

3. Check for low voltage conditions and/or proper extension

cord.

4. Disconnect the other electrical appliances from circuit or

operate the compressor on

its own branch circuit.

Motor overload protection switch has tripped

Let motor cool off and overload

switch will automatically reset.

Tank pressure exceeds

pressure switch “cut-in”

pressure.

Motor will start automatically

when tank pressure drops below

“cut-in” pressure of pressure

switch.

Extension cord is wrong

length or gauge.

Check for proper gauge wire and

cord length.

Loose electrical connections.

Check wiring connection inside

pressure switch and terminal box

area.

Have checked by a Trained

Service Technician.

Check valve stuck

open.

Remove and clean, or replace.

Possible defective

motor or starting capacitor.

Have checked by a Trained

Service Technician. Do not operate the compressor in the paint

spray area. See flammable vapor

warning.

Paint spray on internal

motor parts.

Bleed the line by pushing the

lever on the pressure switch to

the “off” position; if the valve

does not open, replace switch.

Pressure release valve

on pressure switch has

not unloaded head

pressure.

Page 22

22 - ENGD23269

PROBLEM

CAUSE

CORRECTION

Clean or replace. See Air Filter

paragraph in the Maintenance

section.

Dirty air filter.

Restricted air intake

Excessive belt

wear

Loose belt.

Loosen wingnut and then tighten

wingnut until it contacts the

washer, plus one turn.

Tight belt.

Loosen wingnut and then tighten

wingnut until it contacts the

washer, plus one turn.

Loose pulley.

Have checked by a Trained

Service Technician.

Pulley misalignment.

See Motor Pulley/Flywheel

Alignment paragraph in the

Maintenace section.

Squealing sound.

Loose belt.

Loosen wingnut and then tighten

wingnut until it contacts the

washer, plus one turn.

Compressor pump has

no oil.

See Oil-Checking paragraph in

the Maintenace section.

Page 23

23 - ENG D23269

NOTES

Page 24

24 - ENGD23269

LIMITED WARRANTY

PORTER-CABLE CORPORATION warrants to the original purchaser that each new air

compressor and service part is free from defects in material and workmanship and agrees to

repair or replace under this warranty any defective product or part as follows from the original

date of purchase.

5 YEARS – Limited warranty on 2-stage oil-free air compressor pumps that operate at

1725 RPM and 1 year limited warranty on all other parts.

3 YEARS – Limited warranty on oil-lubricated air compressor pumps and 1 year limited

warranty on all other parts.

1 YEAR – Limited warranty on all other air compressor products.

90 Day – Service parts

Engine warranties are the responsibility of the engine manufacturer. Warranties of merchandise

sold by Porter-Cable which has been manufactured by and identified as the product of another

company are the responsibility of the manufacturer of that product.

THIS WARRANTY IS NOT TRANSFERABLE AND DOES NOT COVER

G

Products sold damaged or incomplete, sold “as is”, sold reconditioned or used as rental

equipment.

G

Delivery, installation or normal adjustments explained in the owner’s manual.

G

Damage or liability caused by shipping, improper handling, improper installation, incorrect

voltage or improper wiring, improper maintenance, improper modification, or the use of

accessories and/or attachments not specifically recommended by PORTER-CABLE for the

tool.

G

Repairs necessary because of operator abuse or negligence, or the failure to install, operate,

maintain and store the product according to the instructions in the owner’s manual.

G

Damage caused by cold, heat, rain, excessive humidity, corrosive environments and materials, or other contaminants.

G

Expendable items that become worn during normal use such as drain valves, fuses, filters,

belts, air cleaners, spark plugs, engine oil and pump oil.

G

Cosmetic defects that do not interfere with tool functionality.

G

Freight costs from customer to Porter-Cable.

G

Repair and transportation costs of products or parts determined not to be defective.

G

ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE

THAT MAY RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT. Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

G

IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF

ORIGINAL PURCHASE. Some states do not allow limitations on how long an implied war-

ranty lasts, so the above limitations may not apply to you.

WARRANTY SERVICE is available by delivering or shipping the defective product or part to

any Porter-Cable authorized warranty service location. To determine the nearest authorized warranty service location, call the toll free number, 1-888-559-8550, 24 hours a day, 7 days a week.

Specific instructions regarding servicing arrangements and scheduling may vary depending on

the type and size of the product and the availability of repair parts.

G

DO NOT return the defective product to the retailer.

G

Retain the original cash register sales receipt as proof of purchase for warranty work.

G

Only Air compressors with 60 and 80 gallon tanks will be inspected at the site of installation.

G

The customer should contact Porter-Cable directly if the purchaser does not receive satisfactory results from the authorized warranty service center.

Porter-Cable Corporation

4825 Highway 45 North

P.O. Box 2468

Jackson, TN 38302-2468

1-888-559-8550

®

Loading...

Loading...