Porter Cable CPL55GH8W Owner’s Manual

Instruction

Oillube

manual

MODEL

CPL55GH8W

Compressor

IMPORTANT

o learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

PORTER+CRBLEo

PROFESSIONAL POWER TOOLS

3opyright © 2000 PORTER CABLE Corporation P;trt N¢_ D:": 2Z 008

Please make certain that the person who is to use

this equipment carefully reads and understands

these instructions before starting operations.

The Model and Serial No plate is located on the

frame Record these numbers in the spaces below

and retain for future reference

Model No

Type

Serial No

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This infor

mation relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To

help you recognize this information, we use the symbols below Please read the manual and

pay attention to these sections

DANGER indicates an imminently

hazardous situation which, if not

avoided, will result in death or

serious injury,

CAUTION indicates a potentially

hazardous situation which, if not

avoided, _ result in minor or

rnodera'_e i_.

[R.'_li=i [,]_r

WARNING indicates a potentially

hazardous situation which, if not

avoided, could result in death or

S@J'io_ injury

Call our Toll Free Number 1-888-559-8550, to obtain the location of the nearest Autho-

rized Service Center for ordering repair parts and for warranty repairs.

When ordering repair parts from your Iocat Authorized Service Center. always gwe the

following information:

• Model number of your compressor

• Part number and description of the item you wish to purchase

Retain Original Sales Receipt as Proof of Purchase for Warranty Repair Work.

CAUTION used without the safety

alert symbol indicates a potentially

hazardous situation which, if not

avoided, may result in I_r_erty

damage.

IMPORTANT SAFETY INSTRUCTIONS

This product is not equipped with a spark arresting muffler. If the

product will be used around flammable materials, or on land covered with

materials such as agricultural crops, forest, brush, grass, or other similar items,

then an approved spark attester must be installed and is legally required in the

state of California. It is a violation of California statutes section 130050 and/or

sections 4442 and 4443 of the California Public Resources Code, unless the

engine is equipped with a spark arrestor, as defined in section 4442, and

maintained in effective working order. Spark arresters are also required on some

U. S. Forest service land and may also be legally required under other statutes

and ordinances.

This product may contain chemicals known to the state of California to cause

cancer, birth defects, or other reproductive harm. This warning is given in

compliance with California Proposition 65, as detectable amounts of chemicals

subject to proposition 65 may be contained in this product.

READ AND FOLLOW ALL INSTRUCTIONS.

This tool was designed for certain applications PortepCable strongly recommends

that this tool NOT be modified and/or used for any application other than for which

it was designed. If you have any questions relative to its application DO NOT use

the tool until you have wrJtten Porter-Cable and we have advised you.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North

RO. Box 2468

Jackson, TN 38302 2468

2 _ NC,

IMPORTANT SAFETY INSTRUCTIONS (cont'd)

SAVE THESE INSTRUCTIONS _\ I

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN SERIOUS INJURY

AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL WARNINGS AND OPERATING

INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

HAZARD

RISK OF EXPLOSION OR FIRE i_ I

i

WHAT CAN HAPPEN

GASOLINE AND GASOLINE VAPORS CAN BECOME

IGNITED BY COMING INTO CONTACT WITH HOT

COMPONENTS SUCH AS THE MUFFLER, FROM

ENGINE EXHAUST GASES, OR FROM AN

ELECTRICAL SPARK,

COMBUSTIBLE .MATERIALS WH]CH COME INTO

CONTACT WITFI HOT ENGIN E PARTS CAN BECOME

IGNITED

UNATTENDED OPERATION OF THIS PRODUCT

COULD RESULT IN PERSONAL INJURY OR

PROPERTY DAMAGE.

RISK OF BURSTING

AIR TANK: THE FOLLOWING CONDITIONS COULD LEAD TO A WEAKENING OF THE TANK, AND RESULT

IN A VIOLENT TANK EXPLOSION AND COULD CAUSE PROPERTY DAMAGE OR SERIOUS INJURY.

WHAT CAN HAPPEN

1 FAILURE TO PROPERLY DRAIN CONDENSED

WATER FROM THE TANK, CAUSING RUST AND

THINNING OF THE STEEL TANK

2 MODIFICATIONS OR A_IEMPTED REPAIRS

TO THE TANK.

3 UNAUTHORIZED MODIFICATIONS TO THE

UNLOADER VANE, SAFETY VALVE, OR ANY

OTHER COMPONENTS WHICH CONTROL

TANK PRESSURE.

4 EXCESSIVE VIBRATION CAN WEAKEN THE AIR

TANK AND CAUSE RUPTURE OR EXPLOSION.

EXCESSIVE VIBRATION WILL OCCUR iF THE

COMPRESSOR IS NOT

PROPERLY MOUNTED OR IF THE ENGINE

OPERATES ABOVE RECOMMENDED RPM

ATTACHMENTS & ACCESSORIES;

EXCEEDING THE PRESSURE RATING OF AIR

TOOLS, SPRAY GUNS, AIR OPERATED

ACCESSORIES TIRES AND OTHER INFLATABLES

CAN CAUSE THEM TO EXPLODE OR FLY APART

AND COULD RESULT IN SERIOUS INJURY

TURN ENGINE OFF AND ALLOW IT TO COOL

BEFORE ADDING FUEL TO THE TANK EQUIP

AREA OF OPERATION WITH A FIRE EXTINGUISHER

CERBEIED TO HANDLE GASOLINE OR FUEL FIRES

ADD FUEL OUTDOORS IN A WELL VENTILATED

AREA MAKE SURE THERE ARE NO SOURCES OF

IGNITION, SUCH AS CIGARETTES NEAR

REFUELING LOCATION

OPERATE COMPRESSOR IN A CLEAN DRY, WELL

VENTILATED AREA A MINIMUM QF FORTY EIGH]

INCHES FROM ANY BUILDING. OBJECT OR WALL

DO NOT OPERATE UNIT INDOORS OR IN ANY

CONFINED AREA.

STORE FUEL IN A SECURE LOCATION AWAY FROM

COMPRESSOR

ALWAYS REMAIN IN ATTENDANCE WITH THE

PRODUCT WHEN IT IS OPERATING.

r

DRAIN TANK DAILY OR AFTER EACH USE. iF TANK

DEVELOPS A [ EAK REPL_,CE IT IMMEDIATELY WITH

A NEW TANK OR REPLACE THE ENTIRE

COMPRESSOR

NEVER DRILL INTO, WELD, OR MAKE ANY

MODIFICATIONS TO THE TANK OR ITS

AI_ACH MENTS

THE TANK IS DESIGNED TO WITHSTAND SPECIFIC

OPERATING PRESSURES NEVER MAKE

ADJUSTMENTS OR PARTS SUBSTITUTIONS TO

ALTER THE FACTORY SET OPERATING

PRESSURES.

DO NOT REMOVE THE STIFFENER BAR

CONNECTING THE COMPRESSOR PUMP ]O THE

ENGINE EXCEPT TO ADJUST BELT TENSION THEN

SECURELY TIGHTEN THE STIFFENER BAR NUTS

THIS BAR CONTROLS OUTFIT VIBRATION.

FOR ESSEN]IAL CONTROL OF AIR PRESSURE YOU

MUST INSTALL A PRESSURE REGULATOR AND

PRESSURE GAUGE TO THE AIR OUTLET OF YOUR

COMPRESSOR FOLLOW THE EQUIPMENT

MANUFACTURERS RECOMMENDATION AND

NEVER EXCEED THE MAXIMUM ALLOWABLE

PRESSURE RATINGOFAI_ACHMENTS NEVERUSE

COMPRESSOR TO INFLATE SMALL LOW-

PRESSURE OBJECTS SUCH AS CHILDREN'S

TOYS, FOOTBALLS, BASKETBALLS. ETC.

3 FNG

I

HOW TO PREVENT IT

HOW TO PREVENT IT

IMPORTANT SAFETY INSTRUCTIONS (cont'd)

RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

THE COMPRESSED AIR STREAM CAN CAUSE

SOFT TISSUE DAMAGE TO EXPOSED SKIN AND

CAN PROPEL DIRT¸ CHIPS¸ LOOSE PARTICLES

AND SMALL OBJECTS A1 HIGH SPEED¸

RESULTING IN PROPERTY DAMAGE QR PERSONAL

INJURY¸

RISK TO BREATHING

WHAT CAN HAPPEN HOW TO PREVENT IT

BREATHING EXHAUST FUMES FROM ENGINE

WILL CAUSE SERIOUS INJURY OR DEATH.

THE COMPRESSED AIR FROM YOUR

COMPRESSOR IS NOT SAFE FOR BREATHING!

THE AIR STREAM MAY CONTAIN CARBON

MONOXIDE, TOXIC VAPORS OR SOLID PARTICLES

FROM THE TANK

SPRAYED MATERIALS SUCH AS PAINT PAINT

SOLVENTS, PAINT REMOVER, INSECTICIDES,

WEED KILLERS. CONTAIN HARMFUL VAPORS AND

POISONS

>a

ALWAYS WEAR ANSI Z87 1 APPROVED SAFETY

GLASSES WITH SIDE SHIELDS WHEN USING THE

COMPRESSOR

NEVER POINT ANY NOZZLE OR SPRAYER TOWARD

ANY PART OF THE BODY OR AT OTHER PEOPLE

OR ANIMALS

ALWAYS TURN THE COMPRESSOR OFF AND

BLEED PRESSURE FROM THE AIR HOSE AND

TANK BEFORE ATTEMPTING MAINTENANCE,

ATTACHING TOOLS OR ACCESSORIES

ALWAYS OPERATE AIR COMPRESSOR OUTSIDE

IN A CLEAN, WELL VENTILATED AREA. AVOID

ENCLOSED AREAS SLiCH ,\S GARAGES

BASEMENTS STORAGE SHEDS WHICH LACK A

STEADY EXCHANGE Of AIR KEEP CHILDREN

PETS AND OTHERS A_,AY FROM AREA OF

OPERATION

NEVER INHALE AIR PROM THE COMPRESSOR

EITHER DIRECTLY OR FROM A BREATHING DEVICE

CONNECTED TO THE COMPRESSOR

WORK IN AN AREA WITH GOOD CROSS-

VENTILATION. READ AND FOLLOW THE SAFETY

INSTRUCTIONS PROVIDED ON THE LABEL OR

SAFETY DATA SHEETS FOR THE MATERIAL YOU

ARE SPRAYING. USE A NIOSH/MSRA APPROVED

RESPIRATOR DESIGNED FOR USE WITH YOUR

SPECIFIC APPLICATION

RISK FROM MOVING PARTS r_

WHAT CAN HAPPEN HOW TO PREVENT IT

THE ENGINE CAN START ACCIDENTALLY IF THE ALWAYS DISCONNECT THE SPARK PLUG AND

FLYWHEEL IS TURNED BY HAND OR MOVED BY BLEED PRESSURE FROM THE TANK BEFORE

PULLING ON THE STARTER ROPE PERFORMING MAINTENANCE.

MOVING PARTS SUCH AS THE PULLEY FLYWHEEL

ANDBE[, CAN CAUSE SERIOUS INJURY, IFTHEY

COME INTO CONTACT WI]H YOU DR YOUR

CLOTHING

ATTEMPTING TO OPERATE COMPRESSOR WITH

DAMAGED OR MISSING PARTS OR ATTEMPTING

TO REPAIR COMPRESSOR WITH PROTECTIVE

SHROUDS REMOVED CAN EXPOSE YOU TO

MOVING PARTS AND (;AN RESULT IN SERIOUS

INJURY.

NEVER OPERATE THE COMPRESSOR WITH

GUARDS OR COVERS WHICH ARE DAMAGED OR

REMQVED

ANY REPAIRS REQUIRED ON IHIS PRODUCT

SHOULD BE PERFORMED BY AUTHORIZED

SERVICE CENTER PERSONNEL.

4 ENG

IMPORTANT SAFETY INSTRUCTIONS (cont'd)

RISK OF BURNS

WHAT CAN HAPPEN

TOUCHING EXPOSED METAL SUCH AS THE

COMPRESSOR HEAD OR OUTLET TUBES OR

CONTACT WITH HOT ENGINE PARTS, SUCH AS

TBE MUFFLER, CAN RESU_IN SERIOUSBURNS.

THE GASOLINE ENGINE, THE ENGINE MUFFLER,

THE COMPRESSOR HEAD AND TUBING BECOME

VERY HOT DURING OPERATION

RISK OF FALLING

WHAT CAN HAPPEN

A PORTABLE COMPRESSOR CAN FALL FROM A

TABLE, WORKBENCH OR ROOF CAUSING

DAMAGE TO THE COMPRESSOR AND COULD

RESULT IN SERIOUS INJURY OR DEATH TO THE

OPERATOR OR BYSTANDERS.

RISK OF PROPERTY DAMAGE WHEN

TRANSPORTING COMPRESSOR

(Fire, Inhalation, Damage

to Vehicle Surfaces)

WHAT CAN HAPPEN

FUEL OR OIL CAN LEAK OR SPILL AND COULD

RESULT IN FIRE OR BREATHING HAZARD,

SERIOUS INJURY OR DEATH CAN RESULT. FUEL

OR OIL LEAKS WILL DAMAGE CARPET, PAINT OR

OTHER SURFACES IN VEHICLES OR TRAILERS

Gsw*g9 -- 9/22/99

HOW TO PREVENT IT

NEVER TOUCH ANY EXPOSED METAL PARTS ON

ENGINE OR COMPRESSOR DURING OR

IMMEDIATELY AFTER OPERATION ENGINE AND

COMPRESSOR WILL REMAIN NOT FOR SEVERAL

MINUTES AFTER OPERATION

DO NOT REACH AROUND PROTECTIVE SHROUDS

OR ATTEMPT MAINTENANCE UNTIL UNIT HAS

BEEN ALLOWED TO COOL

HOW TO PREVENT IT

ALWAYS OPERATE COMPRESSOR IN A STABLE

SECURE POSITION TO PREVENT ACCIDENTAL

MOVEMENT OF THE UNIT NEVER OPERATE

COMPRESSOR ON A ROOF OR OTHER ELEVATED

POSITION. USE ADDITIONAL AIR HOSE TO

REACH HIGH LOCATIONS.

HOW TO PREVENT IT

IF COMPRESSOR IS EQUIPPED WITH A FUEL SHUT-

OFF VALVE, TURN THE VALVE TO THE OFF

POSITION BEFORE TRANSPORTING TO AVOID

FUEL LEAKS. iF COMPRESSOR IS NOT EQUIPPED

WITH A FUEL SHUT-OFF VALVE, DRAIN THE FUEL

FROM TANK BEFORE TRANSPORTING

TRANSPORT FUEL ONLY IN AN OSHA APPROVED

CONTAINER ALWAYS PLACE COMPRESSOR ON A

PROTECTIVE MAT WHEN TRANSPORTING TO

PROTECT AGAINST DAMAGE TO VEHICLE FROM

LEAKS. REMOVE COMPRESSOR FROM VEHICLE

IMMEDIATELY UPON ARRIVAL AT YOUR

DESTINATION.

5 ENG

GLOSSARY

CFM: Cubic feet per minut_

SCFM: Standard cubic feet per rninute;a unit of measure of air delivery

PSlG: Pounds per square Jncl_gauge; a unit of measure of pressure

ASME: American Society of Mechanical Engineers; made, tested, inspected and

registered to meet the standards of ASME.

California Code: Unit may comply with California Code 462 (¢)(2)/(M) (2).

Specification/mode/ label is on the side of the tank on units that comply with

California Code.

Unloader Blow-Off Pressure: When the maximum tank pressure is obtained, the

unloader valve will blow off This will cause the conqpressor to exhaust the air to

the atmosphere and not into the tank. This decreases the load on the engine and

allows it to run at a near no load condition.

Unloader Reset Pressure: When the tank pressure drops to a pre determined

point, the unloader valve closes The tank pressure will now increase until it

reaches the unloader blow-oft pressure.

Code Certification: Products that bear one or more of the following marks: UL,

CUL, ETL, CETL, have been evaluated by OSHA certified independent safety

laboratories and meet the applicable Underwriters Laboratories Standards for

Safety.

DUTY CYCLE

Porter-Cable air compressors should be operated eta not more than a 50% duty

cycle This means an air compressor that pumps air more than 50% of one hour is

considered misuse, because the air compressor is undersized for the required air

demand. Maximum compressor pumping time per hour is 30 minutes.

SPECIFICATIONS

Model No.

Engine Horsepower 5.5

Bore 2.875"

Stroke 2.0"

Air Tank Capacity (Gallon) 8

Approximate Unloader Reset Pressure 110 PStG

Approximate Unloader Blow-off Pressure 135 PSIG

SCFM @ 40 PSIG 12.0

SCFM @ 90 PSIG

IMPORTANT: See engine operator's manual for engine information.

6 _NG

CPL55GH8W

101

DESCRIPTION OF OPERATION

Air Compressor Pump (not shown): D

Compresses air into the air tank. E C

Unloader Valve (not shown): When the

maximum tank pressure is obtained, the

unloader valve will exhaust the

compressed air to the atmosphere

(blow-off). When the tank pressure drops

to a pre determined point, the unloader

valve closes and causes the tank

pressure to increase.

Safety Valve (C} Fig. 1: If the unloader Fig. 1

valve does not retease pressure when tank reaches "blow-off" pressure, the safety

valve will protect against high pressure by "popping off" at its factory set pressure

(slightly higher than the pressure switch blow off setting).

Outlet Pressure Gauge (D) Fig. 1: The outlet pressure gauge indicates theail

pressure available at the outlet side of the regulator This pressure is controlled by

the regulator and is always less than or equal to the tank pressure.

Tank Pressure Gauge (El Fig. 1: The tank pressure gauge indicates the reserve a_r

pressure in the tank.

Regulator (F} Fig. 1: Controls the air pressure shown on the outlet pressure gauge

Puff the knob out and turn clockwise to increase pressure and counterclockwise to

decrease pressure, When the desired pressure is reached push knob in to lock in

place.

Drain Valve (not shown}: A drain valve is located at the base of each air tank and

is used to drain condensation at the end of each use

Air Intake Filter (not shown}: This filter is designed to clean air coming into the

pump. This filter n3_ust,always be clean and ventilation openings free from

obstructions. See "Maintenance".

Throttle Control (not shown): A throttle control has been rncorporated as an extra

feature. When maximum tank pressure is reached and the unloader valve vents air.

it also activates a throttle control on the engine. This gas saving feature holds the

engine at a factory-set idling speed until air pressure in the air tank drops to reset

pressure. It then reactivates the throttle control and accelerates the engine to full

throttle.

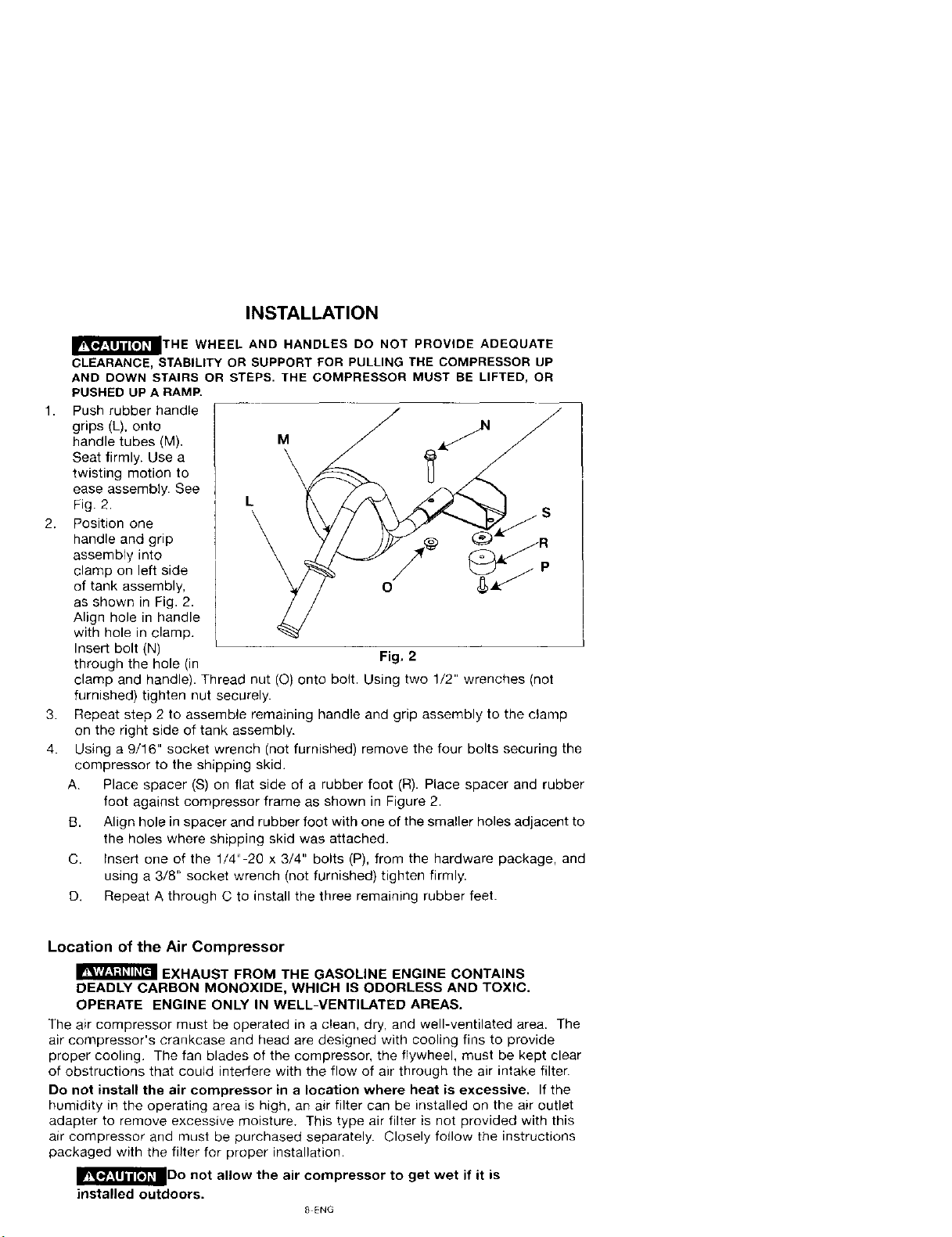

INSTALLATION

_THE WHEEL AND HANDLES DO NOT PROVIDE ADEQUATE

CLEARANCE, STABILITY OR SUPPORT FOR PULLING THE COMPRESSOR UP

AND DOWN STAIRS OR STEPS. THE COMPRESSOR MUST BE LIFTED, OR

PUSHED UP A RAMP.

1. Push rubber handle

grips (L), onto

handle tubes (M).

Seat firmly. Use a

twisting motion to

ease assembly. See

Fig. 2.

2. Position one

handle and grip

assembly into

clamp on left side

of tank assembly,

as shown in Fig. 2.

Align hole in handle

with hole in clamp.

Inser_ bolt (N)

through the hole (in Fig. 2

clamp and handle). Thread nut (O) onto bolt. Using two 1/2" wrenches (not

furnished) tighten nut securely.

3.

Repeat step 2 to assemble remaining handle and grip assembly to the clamp

on the right side of tank assembly.

4.

Using a 9/16" socket wrench (not furnished) remove the four bolts securing the

compressor to the shipping skid.

A. Place spacer (S) on flat side of a rubber foot (R). Place spacer and rubber

foot against compressor frame as shown in Figure 2.

B. Align hole in spacer and rubber foot with one of the smaller holes adjacent to

the holes where shipping skid was attached.

C. Insert one of the 1/4"-20 x 3/4" bolts (P), from the hardware package, and

using a 3/8" socket wrench (not furnished) tighten firmly.

D. Repeat A through C to install the three remain=ng rubber feet.

L

O

S

Location of the Air Compressor

EXHAUST FROM THE GASOLINE ENGINE CONTAINS

DEADLY CARBON MONOXIDE, WHICH IS ODORLESS AND TOXIC.

OPERATE ENGINE ONLY IN WELL-VENTILATED AREAS.

The air compressor must be operated in a clean, dry, and well-ventilated area. The

air compressor's crankcase and head are designed with cooling fins to provide

proper cooling. The fan blades of the compressor, the flywheel, must be kept clear

of obstructions that could interfere with the flow of air through the air intake filter.

Do not install the air compressor in a location where heat is excessive. If the

humidity in the operating area is high, an air filter can be installed on the air outlet

adapter 1o remove excessive moisture. This type air filter is not provided with this

air compressor and must be purchased separately. Closely follow the instructions

packaged with the filter for proper installation.

_Do not allow the air compressor to get wet if it is

installed outdoors.

8 ENG

Loading...

Loading...