Page 1

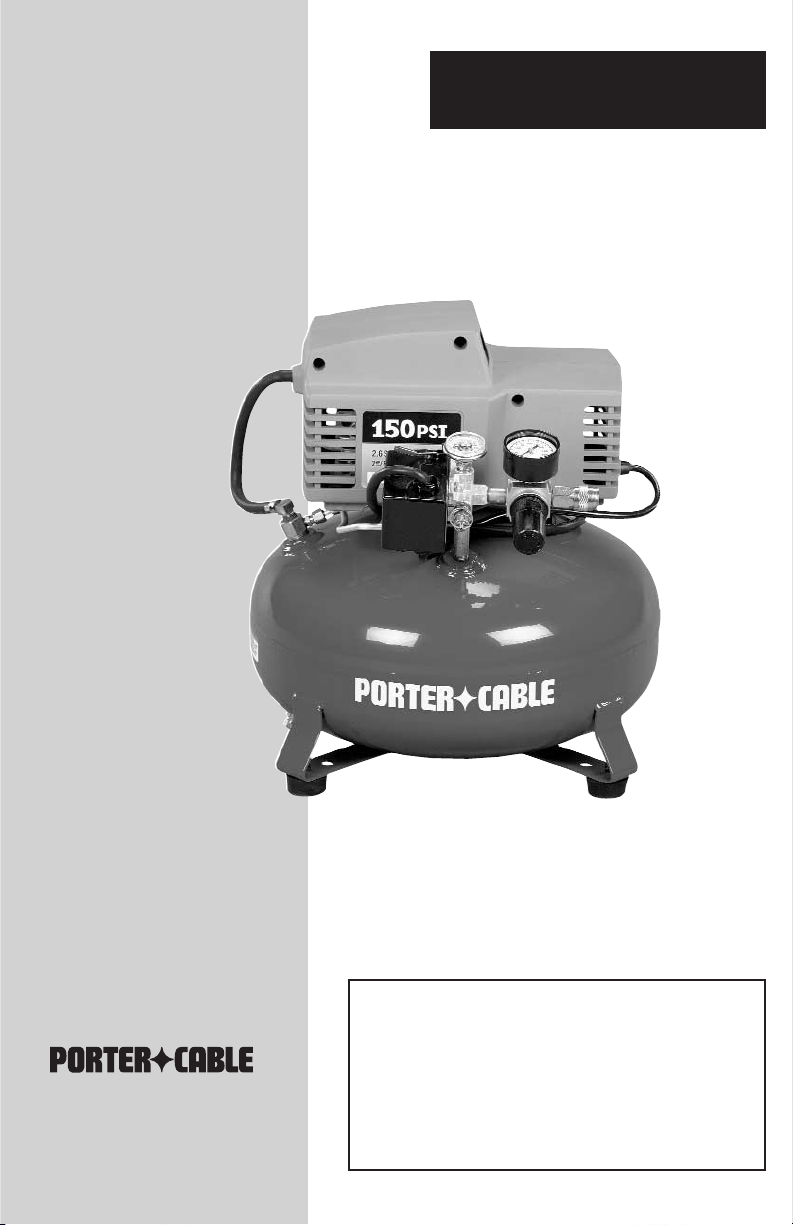

Pancake Compressor

Instruction

manual

The Model and Serial No. plate is located on the main

housing of the tool. Record these numbers in the

spaces below and retain for future reference.

Model No. ______________________________________

Type ___________________________________________

Serial No. _______________________________________

IMPORTANT

Please make certain that the person who is

to use this equipment carefully reads and

understands these instructions before

starting operations.

Part No. D27856-0210-0

ESPAÑOL: PÁGINA 19

FRANÇAISE : PAGE 37

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

MODEL

CPFAC2600P

Copyright © 2002 Porter-Cable Corporation

PROFESSIONAL POWER TOOLS

Page 2

2 - ENG

D27856

SAFETY GUIDELINES - DEFINITIONS

Indicates an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, could

result in

death or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, may

result in

minor or moderate injury.

Used without the

safety alert symbol

indicates a potentially hazardous

situation which, if not avoided, may

result in property damage

.

This manual contains information that is important for you to know and understand. This information

relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you

recognize this information, we use the symbols below. Please read the manual and pay attention to

these sections.

IMPORTANT SAFETY INSTRUCTIONS

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known (to the State of California) to

cause cancer, birth defects or other reproductive harm. Some example of these chemicals are:

●

lead from lead-based paints

●

crystalline silica from bricks and cement and other masonry products

●

arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, always wear MSHA/NIOSH approved, properly fitting face mask or respirator when using

such tools.

When using air tools, basic safety precautions should always be followed to reduce the risk of of

personal injury.

READ AND FOLLOW ALL INSTRUCTIONS.

This tool was designed for certain applications. Porter-Cable strongly recommends that this tool NOT

be modified and/or used for any application other than for which it was designed. If you have any

questions relative to its application DO NOT use the tool until you have written Porter-Cable and we

have advised you.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North

P.O. Box 2468

Jackson, TN 38302-2468

Page 3

3 - ENG

D27856

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD RESULT IN

SERIOUS INJURY AND PROPERTY DAMAGE. READ AND UNDERSTAND ALL

WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT.

RISK OF EXPLOSION OR FIRE

ALWAYS OPERATE THE COMPRESSOR IN A

WELL VENTILATED AREA FREE OF

COMBUSTIBLE MATERIALS, GASOLINE OR

SOLVENT VAPORS.

IF SPRAYING FLAMMABLE MATERIALS,

LOCATE COMPRESSOR AT LEAST 20 FEET

AWAY FROM SPRAY AREA. AN ADDITIONAL

LENGTH OF HOSE MAY BE REQUIRED.

STORE FLAMMABLE MATERIALS IN A

SECURE LOCATION AWAY FROM

COMPRESSOR.

NEVER PLACE OBJECTS AGAINST OR ON

TOP OF COMPRESSOR. OPERATE

COMPRESSOR IN AN OPEN AREA AT LEAST

12 INCHES AWAY FROM ANY WALL OR

OBSTRUCTION THAT WOULD RESTRICT THE

FLOW OF FRESH AIR TO THE VENTILATION

OPENINGS.

OPERATE COMPRESSOR IN A CLEAN, DRY,

WELL VENTILATED AREA. DO NOT OPERATE

UNIT INDOORS OR IN ANY CONFINED AREA.

ALWAYS REMAIN IN ATTENDANCE WITH THE

PRODUCT WHEN IT IS OPERATING.

ALWAYS DISCONNECT ELECTRICAL POWER

BY MOVING PRESSURE SWITCH LEVER TO

THE OFF POSITION AND DRAIN TANK DAILY

OR AFTER EACH USE.

HOW TO PREVENT IT

IT IS NORMAL FOR ELECTRICAL CONTACTS

WITHIN THE MOTOR AND PRESSURE SWITCH

TO SPARK.

IF ELECTRICAL SPARKS FROM

COMPRESSOR COME INTO CONTACT WITH

FLAMMABLE VAPORS, THEY MAY IGNITE,

CAUSING FIRE OR EXPLOSION.

RESTRICTING ANY OF THE COMPRESSOR

VENTILATION OPENINGS WILL CAUSE

SERIOUS OVERHEATING AND COULD CAUSE

FIRE.

UNATTENDED OPERATION OF THIS

PRODUCT COULD RESULT IN PERSONAL

INJURY OR PROPERTY DAMAGE. TO

REDUCE THE RISK OF FIRE, DO NOT ALLOW

THE COMPRESSOR TO OPERATE

UNATTENDED.

WHAT CAN HAPPEN

HAZARD

Page 4

4 - ENG

D27856

HAZARD

RISK OF BURSTING

AIR TANK: THE FOLLOWING CONDITIONS COULD LEAD TO A WEAKENING OF

THE TANK, AND RESULT IN A VIOLENT TANK EXPLOSION AND COULD CAUSE

PROPERTY DAMAGE OR SERIOUS INJURY.

HOW TO PREVENT IT

WHAT CAN HAPPEN

DRAIN TANK DAILY OR AFTER EACH USE. IF

TANK DEVELOPS A LEAK, REPLACE IT

IMMEDIATELY WITH A NEW TANK OR REPLACE

THE ENTIRE COMPRESSOR.

NEVER DRILL INTO, WELD, OR MAKE ANY

MODIFICATIONS TO THE TANK OR ITS

ATTACHMENTS.

THE TANK IS DESIGNED TO WITHSTAND

SPECIFIC OPERATING PRESSURES. NEVER

MAKE ADJUSTMENTS OR PARTS

SUBSTITUTIONS TO ALTER THE FACTORY

SET OPERATING PRESSURES.

FOR ESSENTIAL CONTROL OF AIR

PRESSURE,YOU MUST INSTALL A PRESSURE

REGULATOR AND PRESSURE GAUGE TO THE

AIR OUTLET (IF NOT EQUIPPED) OF YOUR

COMPRESSOR. FOLLOW THE EQUIPMENT

MANUFACTURERS RECOMMENDATION AND

NEVER EXCEED THE MAXIMUM ALLOWABLE

PRESSURE RATING OF ATTACHMENTS.

NEVER USE COMPRESSOR TO INFLATE

SMALL LOW-PRESSURE OBJECTS SUCH AS

CHILDREN’S TOYS, FOOTBALLS,

BASKETBALLS, ETC.

1. FAILURE TO PROPERLY DRAIN

CONDENSED WATER FROM THE

TANK, CAUSING RUST AND THINNING

OF THE STEEL TANK.

2. MODIFICATIONS OR ATTEMPTED

REPAIRS TO THE TANK.

3. UNAUTHORIZED MODIFICATIONS TO

THE UNLOADER VALVE, SAFETY

VALVE, OR ANY OTHER COMPONENTS

WHICH CONTROL TANK PRESSURE.

4. EXCESSIVE VIBRATION CAN WEAKEN

THE AIR TANK AND CAUSE RUPTURE

OR EXPLOSION.

ATTACHMENTS & ACCESSORIES:

EXCEEDING THE PRESSURE RATING OF AIR

TOOLS, SPRAY GUNS, AIR OPERATED

ACCESSORIES, TIRES AND OTHER

INFLATABLES CAN CAUSE THEM TO

EXPLODE OR FLY APART, AND COULD

RESULT IN SERIOUS INJURY.

HAZARD

RISK FROM FLYING OBJECTS

HOW TO PREVENT IT

WHAT CAN HAPPEN

THE COMPRESSED AIR STREAM CAN

CAUSE SOFT TISSUE DAMAGE TO EXPOSED

SKIN AND CAN PROPEL DIRT, CHIPS, LOOSE

PARTICLES AND SMALL OBJECTS AT HIGH

SPEED, RESULTING IN PROPERTY DAMAGE

OR PERSONAL INJURY.

ALWAYS WEAR ANSI Z87.1 APPROVED

SAFETY GLASSES WITH SIDE SHIELDS WHEN

USING THE COMPRESSOR.

NEVER POINT ANY NOZZLE OR SPRAYER

TOWARD ANY PART OF THE BODY OR AT

OTHER PEOPLE OR ANIMALS.

ALWAYS TURN THE COMPRESSOR OFF AND

BLEED PRESSURE FROM THE AIR HOSE AND

TANK BEFORE ATTEMPTING MAINTENANCE,

ATTACHING TOOLS OR ACCESSORIES.

Page 5

5 - ENG

D27856

HAZARD

HAZARD

HOW TO PREVENT IT

WHAT CAN HAPPEN

RISK TO BREATHING

AIR OBTAINED DIRECTLY FROM THE

COMPRESSOR SHOULD NEVER BE USED TO

SUPPLY AIR FOR HUMAN CONSUMPTION. IN

ORDER TO USE AIR PRODUCED BY THIS

COMPRESSOR FOR BREATHING, SUITABLE

FILTERS AND IN-LINE SAFETY EQUIPMENT

MUST BE PROPERLY INSTALLED. IN-LINE

FILTERS AND SAFETY EQUIPMENT USED IN

CONJUNCTION WITH THE COMPRESSOR

MUST BE CAPABLE OF TREATING AIR TO

ALL APPLICABLE LOCAL AND FEDERAL

CODES PRIOR TO HUMAN CONSUMPTION.

WORK IN AN AREA WITH GOOD CROSSVENTILATION. READ AND FOLLOW THE

SAFETY INSTRUCTIONS PROVIDED ON THE

LABEL OR SAFETY DATA SHEETS FOR THE

MATERIAL YOU ARE SPRAYING. USE A

NIOSH/MSHA APPROVED RESPIRATOR

DESIGNED FOR USE WITH YOUR SPECIFIC

APPLICATION.

THE COMPRESSED AIR DIRECTLY FROM

YOUR COMPRESSOR IS NOT SAFE FOR

BREATHING. THE AIR STREAM MAY

CONTAIN CARBON MONOXIDE, TOXIC

VAPORS, OR SOLID PARTICLES FROM THE

TANK. BREATHING THESE CONTAMINANTS

CAN CAUSE SERIOUS INJURY OR DEATH.

SPRAYED MATERIALS SUCH AS PAINT,

PAINT SOLVENTS, PAINT REMOVER,

INSECTICIDES, WEED KILLERS, MAY

CONTAIN HARMFUL VAPORS AND POISONS.

RISK OF ELECTRICAL SHOCK

HOW TO PREVENT IT

WHAT CAN HAPPEN

YOUR AIR COMPRESSOR IS POWERED BY

ELECTRICITY. LIKE ANY OTHER

ELECTRICALLY POWERED DEVICE, IF IT IS

NOT USED PROPERLY IT MAY CAUSE

ELECTRIC SHOCK.

REPAIRS ATTEMPTED BY UNQUALIFIED

PERSONNEL CAN RESULT IN SERIOUS

INJURY OR DEATH BY ELECTROCUTION.

ELECTRICAL GROUNDING: FAILURE TO

PROVIDE ADEQUATE GROUNDING TO THIS

PRODUCT COULD RESULT IN SERIOUS

INJURY OR DEATH FROM ELECTROCUTION.

SEE GROUNDING INSTRUCTIONS.

NEVER OPERATE THE COMPRESSOR

OUTDOORS WHEN IT IS RAINING OR IN WET

CONDITIONS.

NEVER OPERATE COMPRESSOR WITH

PROTECTIVE COVERS REMOVED OR

DAMAGED.

ANY ELECTRICAL WIRING OR REPAIRS

REQUIRED ON THIS PRODUCT SHOULD BE

PERFORMED BY AUTHORIZED SERVICE

CENTER PERSONNEL IN ACCORDANCE WITH

NATIONAL AND LOCAL ELECTRICAL CODES.

MAKE CERTAIN THAT THE ELECTRICAL

CIRCUIT TO WHICH THE COMPRESSOR IS

CONNECTED PROVIDES PROPER

ELECTRICAL GROUNDING, CORRECT

VOLTAGE AND ADEQUATE FUSE

PROTECTION.

Page 6

6 - ENG

D27856

HAZARD

HOW TO PREVENT IT

WHAT CAN HAPPEN

RISK OF BURNS

TOUCHING EXPOSED METAL SUCH AS THE

COMPRESSOR HEAD OR OUTLET TUBES,

CAN RESULT IN SERIOUS BURNS.

NEVER TOUCH ANY EXPOSED METAL

PARTS ON COMPRESSOR DURING OR

IMMEDIATELY AFTER OPERATION.

COMPRESSOR WILL REMAIN HOT FOR

SEVERAL MINUTES AFTER OPERATION.

DO NOT REACH AROUND PROTECTIVE

SHROUDS OR ATTEMPT MAINTENANCE

UNTIL UNIT HAS BEEN ALLOWED TO COOL.

HAZARD

HOW TO PREVENT IT

WHAT CAN HAPPEN

RISK FROM MOVING PARTS

NEVER OPERATE THE COMPRESSOR WITH

GUARDS OR COVERS WHICH ARE DAMAGED

OR REMOVED.

ANY REPAIRS REQUIRED ON THIS PRODUCT

SHOULD BE PERFORMED BY AUTHORIZED

SERVICE CENTER PERSONNEL.

MOVING PARTS SUCH AS THE PULLEY,

FLYWHEEL AND BELT CAN CAUSE SERIOUS

INJURY IF THEY COME INTO CONTACT WITH

YOU OR YOUR CLOTHING.

ATTEMPTING TO OPERATE COMPRESSOR

WITH DAMAGED OR MISSING PARTS OR

ATTEMPTING TO REPAIR COMPRESSOR

WITH PROTECTIVE SHROUDS REMOVED CAN

EXPOSE YOU TO MOVING PARTS AND CAN

RESULT IN SERIOUS INJURY.

HAZARD

HOW TO PREVENT IT

WHAT CAN HAPPEN

HAZARD

HOW TO PREVENT IT

WHAT CAN HAPPEN

RISK OF FALLING

A PORTABLE COMPRESSOR CAN FALL

FROM A TABLE, WORKBENCH OR ROOF

CAUSING DAMAGE TO THE COMPRESSOR

AND COULD RESULT IN SERIOUS INJURY

OR DEATH TO THE OPERATOR.

ALWAYS OPERATE COMPRESSOR IN A

STABLE SECURE POSITION TO PREVENT

ACCIDENTAL MOVEMENT OF THE UNIT.

NEVER OPERATE COMPRESSOR ON A ROOF

OR OTHER ELEVATED POSITION. USE

ADDITIONAL AIR HOSE TO REACH HIGH

LOCATIONS.

RISK OF PROPERTY DAMAGE WHEN TRANSPORTING COMPRESSOR

OIL CAN LEAK OR SPILL AND COULD

RESULT IN FIRE OR BREATHING HAZARD,

SERIOUS INJURY OR DEATH CAN RESULT.

OIL LEAKS WILL DAMAGE CARPET, PAINT OR

OTHER SURFACES IN VEHICLES OR

TRAILERS.

ALWAYS PLACE COMPRESSOR ON A

PROTECTIVE MAT WHEN TRANSPORTING TO

PROTECT AGAINST DAMAGE TO VEHICLE

FROM LEAKS. REMOVE COMPRESSOR FROM

VEHICLE IMMEDIATELY UPON ARRIVAL AT

YOUR DESTINATION.

(Fire, Inhalation, Damage to Vehicle Surfaces)

Page 7

7 - ENG

D27856

HAZARD

HOW TO PREVENT IT

WHAT CAN HAPPEN

RISK OF UNSAFE OPERATION

REVIEW AND UNDERSTAND ALL

INSTRUCTIONS AND WARNINGS IN THIS

MANUAL.

BECOME FAMILIAR WITH THE OPERATION

AND CONTROLS OF THE AIR COMPRESSOR.

KEEP OPERATING AREA CLEAR OF ALL

PERSONS, PETS, AND OBSTACLES.

KEEP CHILDREN AWAY FROM THE AIR

COMPRESSOR AT ALL TIMES.

DO NOT OPERATE THE PRODUCT WHEN

FATIGUED OR UNDER THE INFLUENCE OF

ALCOHOL OR DRUGS. STAY ALERT AT ALL

TIMES.

NEVER DEFEAT THE SAFETY FEATURES OF

THIS PRODUCT.

EQUIP AREA OF OPERATION WITH A FIRE

EXTINGUISHER.

DO NOT OPERATE MACHINE WITH MISSING,

BROKEN, OR UNAUTHORIZED PARTS.

UNSAFE OPERATION OF YOUR AIR

COMPRESSOR COULD LEAD TO SERIOUS INJURY OR DEATH TO YOU OR OTHERS.

Page 8

8 - ENG

D27856

GLOSSARY

SCFM or CFM: Standard Cubic Feet per Minute; a unit of measurement of air

delivery.

PSIG or PSI: Pounds per square inch gauge.

CUT-IN PRESSURE: While the motor is off, air tank pressure drops as you

continue to use your accessory or air tool. When the tank pressure drops to a

certain low level the motor will restart automatically. The low pressure at which

the motor automatically restarts is called “cut-in pressure.”

CUT-OUT PRESSURE: When you turn on your air compressor and it begins to

run, air pressure in the air tank begins to build. It builds to a certain high pressure

before the motor automatically shuts off - protecting your air tank from pressure

higher than its capacity. The high pressure at which the motor shuts off is called

“cut-out pressure.”

CODE CERTIFICATION: Products that bear one or more of the following marks:

UL, CUL, ETL, CETL, have been evaluated by OSHA certified indepenent safety

laboratories and meet the applicable Underwriters Laboratories Standards for

Safety.

DUTY CYCLE

Porter-Cable air compressors should be operated on not more than a 50% duty

cycle. This means an air compressor that pumps air more than 50% of one hour

is considered misused, because the air compressor is undersized for the required

air demand. Maximum compressor pumping time per hour is 30 minutes.

SPECIFICATIONS

MODEL NO. CPFAC2600P

Horsepower-Peak 2.0

SCFM @ 40 psig 3.7

SCFM @ 90 psig 2.6

Cut-In 120 PSI

Cut-Out 150 PSI

Bore 1.875"

Stroke 1.250"

Voltage/Hertz/Phase 120/60/1

Minimum Branch Circuit 15 Amp

* Fuse Type Time Delay

Amperage at Max. Load 10 Amps

Tank Size 6 Gallon

* A circuit breaker is preferred. Use only a fuse or circuit breaker that is the same

rating as the branch circuit on which the air compressor is operated. If

compressor is connected to a circuit protected by fuses, use only time delay

fuses. Time delay fuses should be marked “D” in Canada and “T” in the US.

Page 9

9 - ENG

D27856

HOW TO SET UP YOUR UNIT

Location of the Air Compressor

Locate the air compressor in a clean, dry and well ventilated area. The air

compressor should be located at least 12" away from the wall or other

obstructions that will interfere with the flow of air. The air compressor pump and

shroud are designed to allow for proper cooling. The ventilation openings on the

compressor are necessary to maintain proper operating temperature. Do not

place rags or other containers on or near these openings.

GROUNDING INSTRUCTIONS

RISK OF ELECTRICAL SHOCK. In the event of a short

circuit, grounding reduces the risk of shock by providing an

escape wire for the electric current. This air compressor must be properly

grounded.

The portable air compressor is equipped with a cord having a grounding wire

with an appropriate grounding plug (see following illustrations). The plug must

be used with an outlet that has been installed and grounded in accordance with

all local codes and ordinances.

1. The cord set and plug with this unit contains a grounding pin. This plug

MUST be used with a grounded outlet.

IMPORTANT: The outlet being used must

be installed and grounded in accordance

with all local codes and ordinances.

2. Make sure the outlet being used has

the same configuration as the

grounded plug. DO NOT USE AN

ADAPTER. See illustration.

3. Inspect the plug and cord before each use. Do not use if there are signs of

damage.

4. If these grounding instructions are not completely understood, or if in doubt

as to whether the compressor is properly grounded, have the installation

checked by a qualified electrician.

IMPROPER GROUNDING CAN RESULT IN ELECTRICAL

SHOCK. Do not modify the plug provided. If it does not fit

the available outlet, a correct outlet should be installed by a qualified

electrician. Repairs to the cord set or plug MUST be made by a qualified

electrician.

Grounding Pin

Grounded

Outlets

Plug

INSTALLATION

Page 10

10 - ENG

D27856

Extension Cords

Using extension cords is not recommended. The use of extension cords will

cause voltage to drop resulting in power loss to the motor and overheating.

Attach extra air hoses at the air outlet instead of using extension cords.

If an extension cord must be used, be sure it is:

• a 3-wire extension cord that has a 3-blade grounding plug, and a 3-slot

receptacle that will accept the plug on the product

• in good condition

• no longer than 50 feet

• 12 gauge (AWG) or larger. (Wire size increases as gauge number

decreases. 10 AWG and 8 AWG may also be used. DO NOT USE 14 OR

16 AWG.)

Voltage and Circuit Protection

Refer to the Specification Chart for the voltage and minimum branch circuit

requirements.

Certain air compressors can be operated on a 15 amp circuit if the following

conditions are met.

1. Voltage supply through branch circuit is 15 amps.

2. Circuit is not used to supply any other electrical needs (lights, appliances,

etc.).

3. Extension cords comply with specifications.

4. Circuit is equipped with a 15 amp circuit breaker or 15 amp time delay

fuse. NOTE: If compressor is connected to a circuit protected by fuses,

use only time delay fuses. Time delay fuses should be marked "D" in

Canada and "T" in the US.

If any of the above conditions cannot be met, or if operation of the compressor

repeatedly causes interruption of the power, it may be necessary to operate it

from a 20 amp circuit. It is not necessary to change the cord set.

Page 11

11 - ENG

D27856

DESCRIPTION OF OPERATION

Description of Operation

Become familiar with these controls before operating the unit.

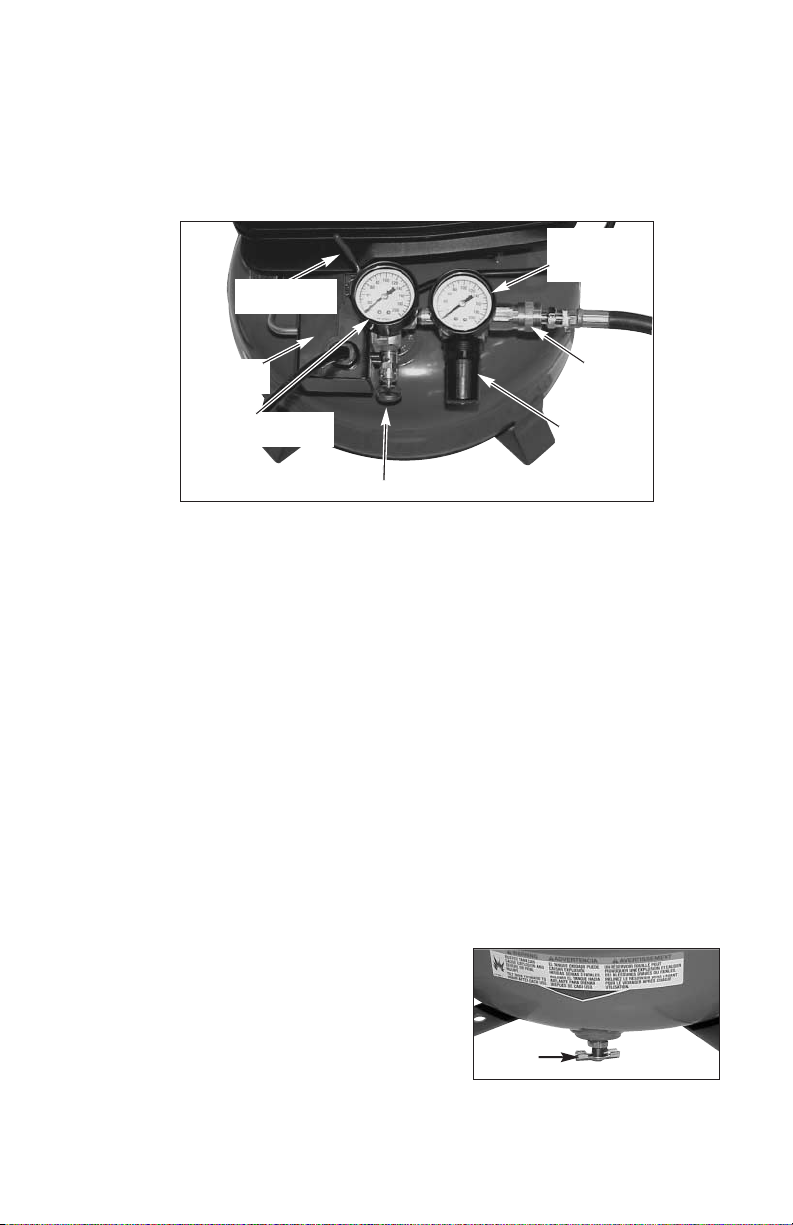

On/Auto/Off Switch: Turn this switch ON to provide automatic power to the

pressure switch and OFF to remove power at the end of each use.

Pressure Switch: The pressure switch automatically starts the motor when the

air tank pressure drops below the factory set "cut-in” pressure. It stops the

motor when the air tank pressure reaches the factory set "cut-out” pressure.

Safety Valve: If the pressure switch does not shut off the air compressor at its

"cut-out” pressure setting, the safety valve will protect against high pressure by

"popping out” at its factory set pressure (slightly higher than the pressure

switch "cut-out” setting).

Outlet Pressure Gauge: The outlet pressure gauge indicates the air pressure

available at the outlet side of the regulator. This pressure is controlled by the

regulator and is always less than or equal to the tank pressure.

Tank Pressure Gauge: The tank pressure gauge indicates the reserve air

pressure in the tank.

Regulator: Controls the air pressure shown on the outlet pressure gauge. Pull

the knob out and turn clockwise to increase pressure and counter-clockwise to

decrease pressure. When the desired pressure is reached push knob in to lock

in place.

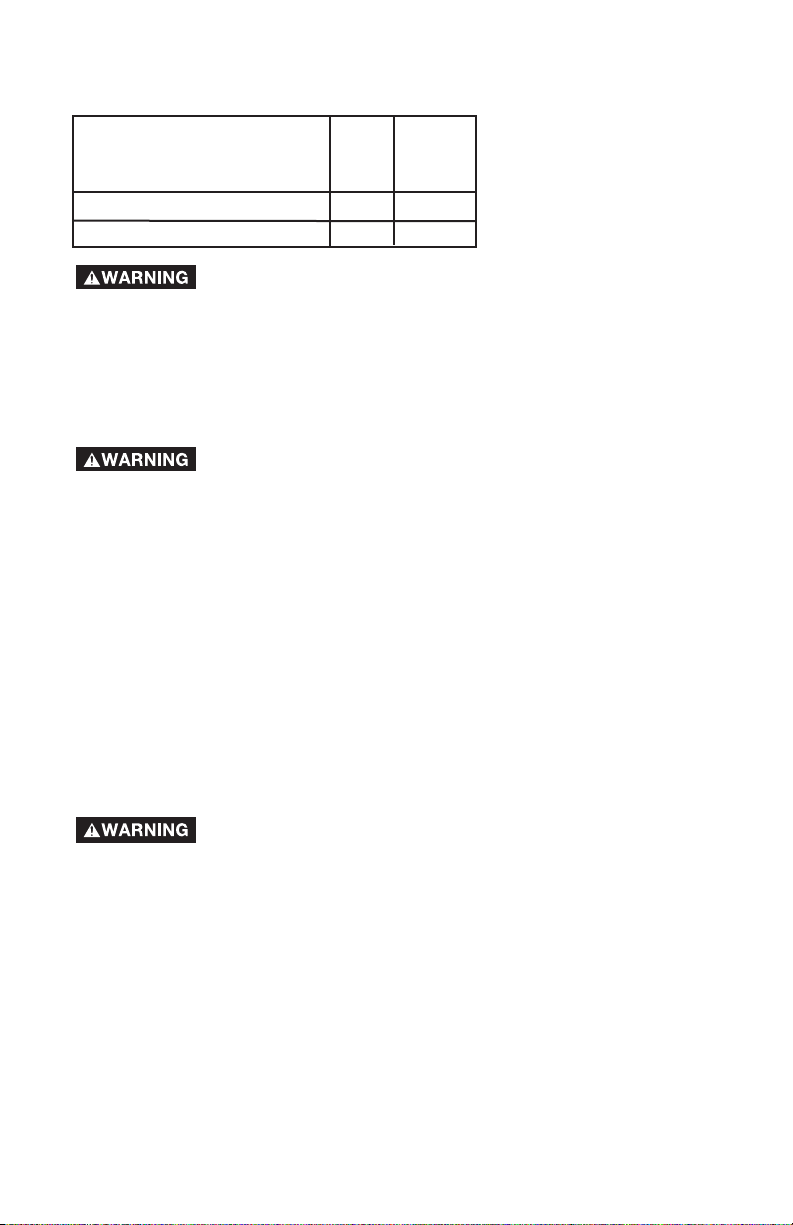

Drain Valve: The drain valve is located at the

base of the air tank and is used to drain

condensation at the end of each use.

Cooling System (not shown): This compressor

contains an advanced design cooling system. At

the heart of this cooling system is an engineered

fan. It is perfectly normal for this fan to blow air

through the vent holes in large amounts. You know that the cooling system is

working when air is being expelled.

Know Your Air Compressor

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with

the location of various controls and adjustments. Save this manual for future

reference.

Drain

Valve

Outlet

Pressure

Gauge

Safety Valve

Pressure

Switch

Regulator

Tank

Pressure Gauge

On/Auto/Off

Switch

Quick

Connect

Page 12

Air Compressor Pump (not shown): Compresses air into the air tank.

Working air is not available until the compressor has raised the air tank pressure

above that required at the air outlet.

Check Valve: When the air compressor is

operating, the check valve is "open”, allowing

compressed air to enter the air tank. When the

air compressor reaches "cut-out” pressure, the

check valve "closes”, allowing air pressure to

remain inside the air tank.

How to Use Your Unit

How to Stop:

1. Set the On/Auto/Off lever to "OFF".

Before First Start-up

Break-in Procedure

Serious damage may result if the following break-in

instructions are not closely followed.

This procedure is required before the air compressor is put into service and

when the check valve or a complete compressor pump has been replaced.

1. Make sure the On/Auto/Off lever is in the "OFF" position.

NOTE: Pull coupler back until it clicks to

prevent air from escaping through the

quick connect.

2.

Plug the power cord into the correct

branch circuit receptacle.

(Refer to

Voltage and Circuit Protection

paragraph in the Installation section

of this manual.)

3. Open the drain valve fully

(counterclockwise) to permit air to

escape and prevent air pressure

build up in the air tank during the break-in period.

4. Move the On/Auto/Off lever to "ON/AUTO" position. The compressor will

start.

5. Run the compressor for 15 minutes. Make sure the drain valve is open and

there is minimal air pressure build-up in tank.

6. After 15 minutes, close the drain valve (clockwise). The air receiver will fill to

"cut-out" pressure and the motor will stop.

The compressor is now ready for use.

12 - ENG

D27856

Regulator

On/Auto/

Off Lever

Quick

Connect

Check Valve

Page 13

13 - ENG

D27856

Before Each Start-Up:

1. Place On/Auto/Off lever to "OFF" and close air regulator.

2. Pull regulator knob out, turn counterclockwise until it stops. Push knob in

to lock in place.

3. Attach hose and accessories. NOTE: The hose or accessory will require a

quick connect plug if the air outlet is equipped with a quick connect

socket.

Too much air pressure causes a hazardous risk of bursting.

Check the manufacturer’s maximum pressure rating for air

tools and accessories. The regulator outlet pressure must never exceed

the maximum pressure rating.

How to Start:

1. Turn the On/Auto/Off lever to "AUTO" and allow tank pressure to build.

Motor will stop when tank pressure reaches "cut-out" pressure.

2. Pull the regulator knob out and turn clockwise to increase pressure. When

the desired pressure is reached push knob in to lock in place. The

compressor is ready for use.

NOTE: Always operate the air compressor in well-ventilated areas free of

gasoline or other combustible vapors. If the compressor is being used to

operate a sprayer DO NOT place near the spray area.

Page 14

14 - ENG

D27856

Customer Responsibilities

Daily or

after

each

use

Before

each

use

●

●

Check Safety Valve

Drain Tank

NOTE: See "Operation" section for the location of controls.

Unit cycles automatically when power is on. When

performing maintenance, you may be exposed to voltage

sources, compressed air, or moving parts. Personal injuries can occur.

Before performing any maintenance or repair, disconnect power source

from the compressor and bleed off all air pressure.

To Check Safety Valve

If the safety valve does not work properly, over-

pressurization may occur, causing air tank rupture or an

explosion.

1. Before starting compressor, pull the ring on the safety valve to make sure

that the safety valve operates freely. If the valve is stuck or does not

operate smoothly, it must be replaced with the same type of valve.

To Drain Tank

1. Set the On/Auto/Off lever to "OFF".

2. Pull the regulator knob out and turn counterclockwise to set the outlet

pressure to zero.

3. Remove the air tool or accessory.

4. Pull ring on safety valve allowing air to bleed from the tank until tank

pressure is approximately 20 psi. Release safety valve ring.

5. Drain water from air tank by opening drain valve (counter-clockwise) on

bottom of tank.

Water will condense in the air tank. If not drained, water

will corrode and weaken the air tank causing a risk of air

tank rupture.

6. After the water has been drained, close the drain valve (clockwise). The air

compressor can now be stored.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be

removed, cleaned, the reinstalled.

MAINTENANCE

Page 15

15 - ENG

D27856

Unit cycles automatically when power is on. When doing

Maintenance, you may be exposed to voltage sources,

compressed air or moving parts. Personal injuries can occur. Before

performing any Maintenance or repair, unplug the compressor and bleed

off all air pressure.

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE

PERFORMED BY A TRAINED SERVICE TECHNICIAN.

Before servicing:

Unplug or disconnect electrical supply to the air compressor.

Bleed tank of pressure

Allow the air compressor to cool

To Replace or Clean Check Valve

1. Release all air pressure from air tank. See “To Drain Tank" in the

Maintenance section.

2. Unplug unit.

3. Remove the hose by removing the

hose clamp.

NOTE: The hose clamp is not reusable.

You must purchase a new hose clamp,

see the Parts List Manual or purchase a

standard hose clamp at a local hardware

store.

4. Unscrew the check valve (turn

counter-clockwise) using a socket wrench.

5. Make sure the valve disc moves freely inside the check valve and the

spring holds the disc in the upper, closed position. The check valve may be

cleaned with a solvent, such as paint and varnish remover.

6. Apply sealant to the check valve threads. Reinstall the check valve (turn

clockwise).

7. Replace hose and new hose clamp.

8. Perform the Break-in Procedure. See "Break-in Procedure" in the

Operation section.

Check

Valve

Hose Clamp

SERVICE AND ADJUSTMENTS

Page 16

To Replace Regulator

1. Release all air pressure from air tank. See "To Drain Tank" in the

Maintenance section.

2. Unplug unit.

3. Using an adjustable wrench remove the

outlet pressure gauge and quick connect

from the regulator.

4. Remove the regulator.

5. Apply pipe sealant tape to the nipple on the

standpipe.

6. Assemble the regulator and orient as shown.

NOTE: Arrow indicates flow of air. Make sure it is

pointing in the direction of air flow.

7. Reapply pipe sealant to outlet pressure gauge

and quick connect.

8. Reassemble outlet pressure gauge and quick

connect. Orient outlet pressure gauge to read

correctly. Tighten connect with wrench.

Nipple

Outlet

Pressure

Gauge

Quick

Connect

Regulator

Regulator

Regulator

Arrow

16 - ENG

D27856

Page 17

17 - ENG

D27856

Before you store the air compressor, make sure you do the following:

1. Review the "Maintenance" section on the preceding pages and perform

scheduled maintenance as necessary.

2. Set the On/Auto/Off lever to “OFF”.

3. Turn the regulator counterclockwise and set the outlet pressure to zero.

4. Remove the air tool or accessory.

5. Pull ring on safety valve allowing air to bleed from the tank until tank

pressure is approximately 20 psi. Release safety valve ring.

6. Drain water from air tank by opening drain valve on bottom of tank.

Water will condense in the air tank. If not drained, water

will corrode and weaken the air tank causing a risk of air

tank rupture.

7. After the water has been drained, close the drain or drain valve.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be

removed, cleaned, then reinstalled.

8. Protect the electrical cord and air hose from damage (such as being

stepped on or run over). Wind them loosely around the compressor

handle. (If so equipped)

Store the air compressor in a clean and dry location.

STORAGE

Page 18

LIMITED WARRANTY

Porter-Cable Corporation

Jackson, TN USA

1-888-559-8550

PORTER-CABLE CORPORATION warrants to the original purchaser that all products covered under this

warranty are free from defects in material and workmanship. Products covered under this warranty include air

compressors, air tools, service parts, pressure washers, and generators, which have the following warranty

periods:

3 YEARS - Limited warranty on 2-stage oil-free air compressor pumps that operate at 1725 RPM.

2 YEARS - Limited warranty on oil-lubricated air compressor pumps.

1 YEAR - Limited warranty on all other air compressor components.

2 YEARS - Limited warranty on electric generator alternators.

1 YEAR - Limited warranty on other generator components.

2 YEARS - Limited warranty on pneumatic air tools as described in Porter-Cable general catalog.

1 YEAR - Limited warranty on pressure washers used in consumer applications (i.e. personal residential

household usage only).

90 DAY - Pressure washers used for commercial applications (income producing) and service parts.

1 YEAR - Limited warranty on all accessories.

Porter-Cable will repair or replace, at Porter-Cable's option, products or components which have failed

within the warranty period.

Service will be scheduled according to the normal work flow and business

hours at the service center location, and the availability of replacement parts.

All decisions of Porter-

Cable Corporation with regard to this limited warranty shall be final.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

RESPONSIBILITY OF ORIGINAL PURCHASER (initial User):

• To process a warranty claim on this product, DO NOT return it to the retailer. The product must be

evaluated by an Porter-Cable Authorized Warranty Service Center. For the location of the nearest Porter-

Cable Authorized Warranty Service Center call 1-888-559-8550, 24 hours a day, 7 days a week.

• Retain original cash register sales receipt as proof of purchase for warranty work.

• Use reasonable care in the operation and maintenance of the product as described in the Owners

Manual(s).

• Deliver or ship the product to the nearest Porter-Cable Authorized Warranty Service Center. Freight costs,

if any, must be paid by the purchaser.

• Air compressors with 60 and 80 gallon tanks will be inspected at the site of installation. Contact the nearest

Porter-Cable Authorized Warranty Service Center that provides on-site service calls, for service call

arrangements.

• If the purchaser does not receive satisfactory results from the Porter-Cable Authorized Warranty Service

Center, the purchaser should contact Porter-Cable.

THIS WARRANTY DOES NOT COVER:

• Merchandise sold as reconditioned, used as rental equipment, and floor or display models.

• Merchandise that has become damaged or inoperative because of ordinary wear, misuse*, cold, heat, rain,

excessive humidity, freeze damage, use of improper chemicals, negligence, accident, failure to operate the

product in accordance with the instructions provided in the Owners Manual(s) supplied with the product,

improper maintenance, the use of accessories or attachments not recommended by Porter-Cable, or

unauthorized repair or alterations.

* An air compressor that pumps air more than 50% during a one hour period is considered misuse

because the air compressor is undersized for the required air demand.

• Repair and transportation costs of merchandise determined not to be defective.

• Costs associated with assembly, required oil, adjustments or other installation and start-up costs.

• Expendable parts or accessories supplied with the product which are expected to become inoperative or

unuseable after a reasonable period of use, including but not limited to sanding disks or pads, saw and

shear blades, grinding stones, springs, chisels, nozzles, o-rings, air jets, washers and similar accessories.

• Merchandise sold by Porter-Cable which has been manufactured by and identified as the product of

another company, such as gasoline engines. The product manufacturer's warranty, if any, will apply.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY

RESULT FROM ANY DEFECT, FAILURE OR MALFUNCTION OF THE PRODUCT IS NOT COVERED BY

THIS WARRANTY. Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation or exclusion may not apply to you.

• IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE.

Some states do not allow limitations on how long an implied warranty lasts, so the above limitations may

not apply to you.

Page 19

Compresores

de tipo plano

Manual de

Instrucciones

La placa de Modelo y de Número de Serie está

localizada en la caja principal de la herramienta. Anote

estos números en las líneas de abajo y guárdelos para

su referencia en el futuro.

Número de modelo _______________________________

Tipo ____________________________________________

Número de serie _________________________________

IMPORTANTE

Asegúrese de que la persona que va a usar

esta herramienta lea cuidadosamente y

comprenda estas instrucciones antes de

empezar a operarla.

Número de parte D27856-0210-0

ENGLISH: PAGE 1

FRANÇAISE : PAGE 37

Para obtener más información

sobre Porter-Cable,

visite nuestro sitio web en:

http://www.porter-cable.com

MODELO

CPFAC2600P

PROFESSIONAL POWER TOOLS

Copyright © 2002 Porter-Cable Corporation

Page 20

20 - SP

D27856

DEFINICIONES DE NORMAS DE SEGURIDAD

Indica una situación de

inminente riesgo, la

cual, si no es evitada, causará la

muerte o lesiones serias.

Indica una

situación

potencialmente riesgosa, que si no es

evitada, podría resultar en la muerte o

lesiones serias.

Indica una situación

potencialmente

peligrosa, la cual, si no es evitada, podría

resultar en lesiones menores o

moderadas.

Usado sin el

símbolo de

seguridad de alerta indica una situación

potencialmente riesgosa la que, si no es

evitada, podría causar daños en la

propiedad.a

SEGURIDAD Y PREVENCIÓN DE PROBLEMAS DEL EQUIPO: Para ayudar al

reconocimiento de esta información, hemos utilizado los símbolos mostrados abajo.

Sírvase leer el manual y prestar atención a dichas secciones.

IMPORTANTES INSTRUCCIONES DE SEGURIDAD

Algunos tipos de aserrín creados por máquinas eléctricas de lijado, aserrado,

amolado, perforado u otras actividades de la construcción, contienen materiales

químicos conocidos (en el Estado de California) como causantes de cáncer, defectos de nacimiento u otros

daños del aparato reproductivo. Algunos ejemplos de dichos productos químicos son:

●

El plomo contenido en algunas pinturas con base de plomo

●

Sílice cristalizado proveniente de los ladrillos, el cemento y otros productos de albañilería

●

Arsénico y cromo provenientes del tratamiento químico dado a la madera

Su riesgo a dichas exposiciones variará dependiendo de la frecuencia con la que usted realice

diferentes tipos de trabajo. Para reducir su exposición a la acción de dichos agentes químicos:

trabaje en zonas bien ventiladas, y hágalo con equipo de seguridad aprobado,

use siempre protección

facial o respirador MSHA / NIOSH aprobados cuando deba utilizar dichas herramientas.

Al utilizar herramientas neumáticas también deben tomarse precauciones básicas de seguridad, a fin

de reducir la posibilidad de riesgo de lesiones personales.

LEA Y SIGA TODAS LAS INSTRUCCIONES

Esta herramienta ha sido diseñada para ciertos usos. Porter-Cable recomienda enfáticamente que la

misma NO sea modificada y/o utilizada para cualquier otra aplicación más que para la que fuera

diseñada. En caso de tener dudas relacionadas con su aplicación, NO utilice la herramienta hasta

haber escrito a Porter-Cable y recibir nuestra respuesta aconsejándolo.

Gerente de Servicio Técnico

Porter-Cable Corporation

4825 Highway 45 North

P.O. Box 2468

Jackson, TN 38302-2468

Page 21

21 - SP

D27856

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

GUARDE ESTAS INSTRUCCIONES

LA OPERACIÓN O EL MANTENIMIENTO INADECUADOS DE ESTE PRODUCTO

PODRÍAN OCASIONAR SERIAS LESIONES Y DAÑOS A LA PROPIEDAD. LEA Y

COMPRENDA TODAS LAS ADVERTENCIAS E INSTRUCCIONES DE

FUNCIONAMIENTO ANTES DE UTILIZAR ESTE EQUIPO.

RIESGO DE EXPLOSIÓN O INCENDIO

OPERE SIEMPRE EL COMPRESOR EN UN

SECTOR BIEN VENTILADO Y LIBRE DE

MATERIALES COMBUSTIBLES, GASOLINA O

EMANACIONES DE SOLVENTE.

EN UN ÁREA DE ROCIADO DE MATERIALES

INFLAMABLES, UBIQUE AL COMPRESOR

POR LO MENOS A 6,1M (20 PIES) DE

DISTANCIA DEL ÁREA DE ROCIADO. PODRÍA

REQUERIRSE UNA EXTENSIÓN DE LA

MANGUERA.

ALMACENE LOS MATERIALES

INFLAMABLES EN UNA

UBICACIÓN SEGURA, ALEJADOS DEL

COMPRESOR.

JAMÁS COLOQUE OBJETOS APOYADOS O

SOBRE EL COMPRESOR. OPERE EL

COMPRESOR EN UN SECTOR ABIERTO, POR

LO MENOS A 30 CM (12 PULGADAS)

ALEJADO DE CUALQUIER PARED U

OBSTRUCCIÓN QUE RESTRINJA EL FLUJO DE

AIRE FRESCO A LAS ABERTURAS DE

VENTILACIÓN.

OPERE EL COMPRESOR EN UN SECTOR

LIMPIO, SECO, Y BIEN VENTILADO. NO OPERE

LA UNIDAD EN ESPACIOS CERRADOS O

CUALQUIER ÁREA CONFINADA.

MANTÉNGASE SIEMPRE ALERTA CADA VEZ

QUE EL PRODUCTO ESTE FUNCIONANDO.

DESCONECTE SIEMPRE EL SUMINISTRO

ELÉCTRICO MOVIENDO LA PALANCA

CONMUTADORA DE PRESIÓN A LA

POSICIÓN DE APAGADO (OFF)

¿CÓMO PREVENIRLO?

PARA LOS CONTACTOS ELÉCTRICOS ES

NORMAL LA EXISTENCIA DE CHISPAS

ENTRE EL MOTOR Y EL INTERRUPTOR A

PRESIÓN.

SI LAS CHISPAS ELÉCTRICAS PROVENIENTES

DEL COMPRESOR TOMARAN CONTACTO

CON EMANACIONES DE MATERIALES

INFLAMABLES, ELLOS PODRÍAN ARDER

ORIGINANDO INCENDIO O EXPLOSIÓN.

RESTRINGIR CUALQUIERA DE LAS

ABERTURAS DE VENTILACIÓN CAUSARÁ UN

SERIO RECALENTAMIENTO Y PODRÍA

PRODUCIR UN INCENDIO.

DEJAR DESATENDIDO ESTE PRODUCTO

MIENTRAS EL MISMO ESTÁ EN

FUNCIONAMIENTO PUEDE RESULTAR EN

LESIONES PERSONALES O DAÑOS A LA

PROPIEDAD. PARA REDUCIR EL RIESGO DE

INCENDIO, NO PERMITA QUE EL

COMPRESOR OPERE DESATENDIDO.

¿QUÉ PUEDE OCURRIR?

PELIGRO

Page 22

22 - SP

D27856

PELIGRO

RIESGO DE EXPLOSIÓN

AIR TANK: THE FOLLOWING CONDITIONS COULD LEAD TO A WEAKENING OF

THE TANK, AND RESULT IN A VIOLENT TANK EXPLOSION AND COULD CAUSE

PROPERTY DAMAGE OR SERIOUS INJURY.

DRENE EL TANQUE DIARIAMENTE O

DESPUÉS DE CADA USO. SI EL TANQUE

GENERA UNA PÉRDIDA, REEMPLÁCELO

INMEDIATAMENTE CON UN NUEVO TANQUE O

REEMPLACE EL COMPRESOR COMPLETO.

JAMÁS PERFORE, SUELDE, O EFECTÚE

MODIFICACIÓN ALGUNA AL TANQUE O SUS

ACCESORIOS.

EL TANQUE ESTÁ DISEÑADO PARA RESISTIR

PRESIONES OPERATIVAS ESPECÍFICAS.

JAMÁS EFECTÚE AJUSTES O SUSTITUYA

PARTES QUE ALTEREN LAS REGULACIONES

DE PRESIÓN ORIGINALES DE FÁBRICA.

PARA UN CONTROL ESENCIAL DE LA

PRESIÓN, DEBE USTED INSTALAR UN

REGULADOR Y UN MEDIDOR DE PRESIÓN A

LA SALIDA DEL AIRE DE SU COMPRESOR. (SI

NO ESTUNIER EQUIPADO) SIGA LAS

RECOMENDACIONES DE LOS FABRICANTES

DE SU EQUIPO Y JAMÁS EXCEDA LOS

VALORES MÁXIMOS DE PRESIÓN PERMITIDOS

PARA LOS ACCESORIOS. JAMÁS USE EL

COMPRESOR PARA INFLAR OBJETOS QUE

REQUIEREN POCA O BAJA PRESIÓN, TALES

COMO JUGUETES PARA LOS NIÑOS,

PELOTAS DE FÚTBOL, PELOTAS DE

BASQUET, ETC.

1. Drenaje inadecuado del agua condensada

en el tanque, siendo la causa del óxido

que reduce el espesor del tanque de

acero.

2. Modificaciones o intento de reparaciones

al tanque.

3. Modificaciones no autorizadas a la válvula

de descarga, válvula de seguridad o

cualquier otro componente que controle la

presión del tanque.

4. La vibración excesiva puede debilitar el

tanque de aire y causar su ruptura o

explosión.

AGREGADOS Y ACCESORIOS

EL EXCESO A LOS VALORES DE PRESIÓN

ESTABLECIDOS PARA LAS HERRAMIENTAS

NEUMÁTICAS, PISTOLAS ROCIADORAS,

ACCESORIOS ACTIVADOS POR AIRE,

CUBIERTAS Y OTROS OBJETOS INFLABLES,

PUEDE CAUSAR SU EXPLOSIÓN O SER

ARROJADOS, PUDIENDO OCASIONAR SERIAS

LESIONES.

PELIGRO

RIESGO DE OBJETOS ARROJADOS POR EL AIRE.

EL CHORRO DE AIRE COMPRIMIDO PUEDE

CAUSAR DAÑOS SOBRE LOS TEJIDOS

BLANDOS DE LA PIEL EXPUESTA, Y PUEDE

PROPULSAR SUCIEDAD, ASTILLAS,

PARTÍCULAS

SUELTAS Y PEQUEÑOS OBJETOS

A ALTA VELOCIDAD, OCASIONANDO

DAÑOS A

LA PROPIEDAD O LESIONES PERSONALES.

AL UTILIZAR EL COMPRESOR, USE SIEMPRE

ANTEOJOS DE SEGURIDAD ANSI Z87.1

APROBADOS, CON PROTECCIÓN LATERAL.

JAMÁS APUNTE NINGUNA BOQUILLA O

PULVERIZADOR HACIA PARTES DEL

CUERPO, A OTRAS PERSONAS O

ANIMALES.

APAGUE SIEMPRE EL COMPRESOR Y

PURGUE LA PRESIÓN DE LA MANGUERA DEL

AIRE Y DEL TANQUE, ANTES DE INTENTAR EL

MANTENIMIENTO, EL ACOPLE DE

HERRAMIENTAS O

ACCESORIOS.

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

Page 23

23 - SP

D27856

PELIGRO

PELIGRO

RIESGO DE INHALACIÓN

EL AIRE OBTENIDO DIRECTAMENTE DEL

COMPRESOR JAMÁS

DEBERÁ SER UTILIZADO PARA PROVEER AIRE

PARA CONSUMO HUMANO. PARA PODER

UTILIZAR EL AIRE PRODUCIDO POR ESTE

COMPRESOR Y HACERLO RESPIRABLE,

DEBERÁN

INSTALARSE UN FILTRO ADECUADO Y UN

EQUIPO DE SEGURIDAD INTERCALADO. LOS

FILTROS INTERCALADOS TANTO COMO EL

EQUIPO DE SEGURIDAD UTILIZADO EN

CONJUNTO CON EL COMPRESOR, DEBERÁN

SER CAPACES DE PROCESAR EL

TRATAMIENTO DEL AIRE DE ACUERDO A

TODOS LOS CÓDIGOS LOCALES Y

FEDERALES, PREVIO AL CONSUMO

HUMANO.

EL AIRE COMPRIMIDO PROVENIENTE DEL

COMPRESOR NO ES SANO PARA RESPIRAR.

EL CHORRO DE AIRE PUEDE CONTENER

MONÓXIDO DE CARBONO, VAPORES

TÓXICOS O PARTÍCULAS SÓLIDAS

PROVENIENTES DEL TANQUE. LA

INHALACIÓN DE DICHOS CONTAMINANTES

PUEDE LLEGAR A CAUSAR SERIAS

LESIONES O LA MUERTE.

RIESGO DE DESCARGA ELÉCTRICA

SU COMPRESOR DE AIRE ESTÁ ACCIONADO

POR ELECTRICIDAD. COMO CUALQUIER OTRO

DISPOSITIVO ELÉCTRICO IMPULSADO

ELÉCTRICAMENTE, SI NO SE LO UTILIZA

ADECUADAMENTE, PODRÍA CAUSARLE

UNA DESCARGA ELÉCTRICA.

LAS REPARACIONES INTENTADAS POR

PERSONAL NO CALIFICADO PODRÍAN

OCASIONAR SERIAS LESIONES O LA

MUERTE POR ELECTROCUCIÓN.

CONEXIÓN A TIERRA: DEJAR DE PROVEER

UNA ADECUADA CONEXIÓN A TIERRA A

ESTE PRODUCTO PODRÍA OCASIONAR

LESIONES SERIAS O LA MUERTE POR

ELECTROCUCIÓN. VER INSTRUCCIONES

PARA LA PUESTA A TIERRA.

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

EL ROCIADO DE MATERIALES TALES COMO

PINTURA, SOLVENTES, REMOVEDORES DE

PINTURA, INSECTICIDAS, MATA HIERBAS,

CONTIENEN EMANACIONES DAÑINAS Y

VENENOSAS.

TRABAJE EN UN ÁREA CON BUENA

VENTILACIÓN CRUZADA. LEA Y SIGA LAS

INSTRUCCIONES DE SEGURIDAD

PROVISTAS EN EL RÓTULO O EN LOS DATOS

DE LAS HOJAS DE SEGURIDAD DEL

MATERIAL QUE ESTÁ PULVERIZANDO. USE

EL RESPIRADOR APROBADO NIOSH/MSHA

DESIGNADO PARA UTILIZARSE CON SU

APLICACIÓN ESPECÍFICA.

JAMÁS OPERE EL COMPRESOR A LA

INTEMPERIE CUANDO ESTÁ LLOVIENDO O EN

CONDICIONES DE HUMEDAD.

NUNCA OPERE EL COMPRESOR SIN SUS

DEFENSAS O SUS CUBIERTAS REMOVIDAS

O DAÑADAS.

CUALQUIER CONEXIÓN ELÉCTRICA O

REPARACIÓN REQUERIDA POR ESTE

PRODUCTO DEBE SER EFECTUADA POR

PERSONAL AUTORIZADO DE LOS

SERVICENTROS DE ACUERDO A LOS

CÓDIGOS ELÉCTRICOS NACIONALES Y

LOCALES.

ASEGÚRESE QUE EL CIRCUITO ELÉCTRICO

AL CUAL ESTÁ CONECTADO EL COMPRESOR,

SUMINISTRA APROPIADA CONEXIÓN A

TIERRA, TENSIÓN CORRECTA Y UNA

ADECUADA PROTECCIÓN DE FUSIBLES.

Page 24

24 - SP

D27856

PELIGRO

RIESGO DE QUEMADURAS

TOCAR EL METAL EXPUESTO TAL COMO EL

CABEZAL DEL COMPRESOR O LOS TUBOS

DE SALIDA DEL ESCAPE, PUEDE

OCASIONARLE SERIAS QUEMADURAS.

JAMÁS TOQUE PARTES DE METAL

EXPUESTAS EN EL COMPRESOR DURANTE

O INMEDIATAMENTE DESPUÉS DE LA

OPERACIÓN. EL COMPRESOR

PERMANECERÁ CALIENTE POR VARIOS

MINUTOS LUEGO DE LA OPERACIÓN.

NO LO CUBRA CON FUNDAS PROTECTORAS

O INTENTE EL MANTENIMIENTO HASTA QUE

LA UNIDAD HAYA ALCANZADO SU

ENFRIAMIENTO.

PELIGRO

RIESGO DE PARTES MÓVILES

NUNCA OPERE EL COMPRESOR SIN SUS

DEFENSAS O SUS CUBIERTAS REMOVIDAS O

DAÑADAS.

CUALQUIER REPARACIÓN REQUERIDA POR

ESTE PRODUCTO DEBE SER EFECTUADA

POR PERSONAL AUTORIZADO DE LOS

SERVICENTROS.

PARTES MOVIBLES TALES COMO LA POLEA,

EL VOLANTE Y LA CORREA PODRÍAN SER LA

CAUSA DE SERIAS LESIONES SI ELLAS

ENTRARAN EN CONTACTO CON USTED O

SUS ROPAS.

INTENTAR OPERAR EL COMPRESOR CON

SUS PARTES DAÑADAS O FALTANTES, O LA

REPARACIÓN DEL COMPRESOR CON SUS

PROTECCIONES REMOVIDAS, PUEDE

EXPONERLO A USTED A PARTES

MOVIBLES, QUE PODRÍAN RESULTAR EN

LESIONES SERIAS.

PELIGRO

PELIGRO

RIESGO DE CAIDA

UN COMPRESOR PORTÁTIL PUEDE CAERSE

DE LA MESA, EL BANCO DE TRABAJO O DEL

TECHO DAÑANDO AL COMPRESOR Y

PUDIENDO RESULTAR EN SERIAS

LESIONES O LA MUERTE DEL OPERADOR.

OPERE SIEMPRE EL COMPRESOR EN UNA

POSICIÓN ESTABLE Y SEGURA A FIN DE

PREVENIR EL MOVIMIENTO ACCIDENTAL DE

LA UNIDAD. JAMÁS OPERE EL COMPRESOR

SOBRE UN TECHO U OTRA POSICIÓN

ELEVADA. UTILICE MANGUERAS

ADICIONALES DE AIRE PARA ALCANZAR

POSICIONES ALTAS.

RIESGO DE DAÑOS A LA PROPIEDAD AL TRANSPORTAR EL COMPRESOR

EL ACEITE PUEDE DERRAMARSE Y ELLO

PODRÍA RESULTAR EN SERIAS LESIONES O

LA MUERTE DEBIDO AL RIESGO DE

INCENDIO O INHALACIÓN. EL DERRAME DE

ACEITE DAÑA ALFOMBRAS, PINTURAS U

OTRAS SUPERFICIES DE VEHÍCULOS O

REMOLQUES.

DEPOSITE EL COMPRESOR SOBRE UNA

ALFOMBRILLA PROTECTORA CUANDO LO

TRANSPORTE. A FIN DE PROTEGER AL

VEHÍCULO DE PÉRDIDAS POR GOTEO, RETIRE

EL COMPRESOR DEL VEHÍCULO

INMEDIATAMENTE DESPUÉS DE SU ARRIBO AL

DESTINO.

(Fuego, inhalación, daño a la superficie de vehículos)

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

Page 25

25 - SP

D27856

RIESGO DE OPERACIÓN INSEGURA

REVISE Y COMPRENDA TODAS LAS

INSTRUCCIONES Y ADVERTENCIAS

CONTENIDAS EN ESTE MANUAL.

FAMILIARÍCESE CON LOS MÉTODOS DE

OPERACIÓN Y CONTROL DEL COMPRESOR

DE AIRE.

MANTENGA LIBRE LA ZONA DE

OPERACIONES DE PERSONA ALGUNA,

ANIMALES DOMÉSTICOS Y OBSTÁCULOS.

MANTENGA ALEJADOS A LOS NIÑOS DEL

COMPRESOR DE AIRE EN TODO MOMENTO.

NO OPERE EL PRODUCTO CUANDO SE

ENCUENTRE FATIGADO O BAJO LA

INFLUENCIA DEL ALCOHOL O DROGAS.

ESTÉ ALERTA EN TODO MOMENTO.

JAMÁS ALTERE LOS ELEMENTOS DE

SEGURIDAD DE ESTE PRODUCTO.

EQUIPE LA ZONA DE OPERACIONES CON UN

EXTINGUIDOR DE FUEGO.

NO OPERE LA MAQUINA SI ÉSTA TIENE

PARTES FALTANTES, ROTAS O NO

AUTORIZADAS.

LA OPERACIÓN INSEGURA DE SU

COMPRESOR DE AIRE PODRÍA

OCASIONARLE SERIAS LESIONES O LA

MUERTE A USTED U OTROS.

PELIGRO

¿CÓMO PREVENIRLO?

¿QUÉ PUEDE OCURRIR?

Page 26

26 - SP

D27856

GLOSARIO

SCFM o CFM: Pies cúbicos estándar por minuto, una unidad de medida de

suministro de aire.

PSIG o PSI: Libras manométricas por pulgada cuadrada.

PRESIÓN DE CONEXIÓN: Mientras el motor está apagado, la presión del

tanque de aire baja a medida que se continúa utilizando el accesorio. Cuando

la presión del tanque baje a aproximadamente 120 PSI, el motor volverá a

ponerse en marcha automáticamente. La presión baja a la que el motor vuelve

a ponerse en marcha se conoce como “presión de conexión”.

PRESIÓN DE DESCONEXIÓN: Cuando se enciende el compresor de aire y

éste comienza a funcionar, la presión de aire del tanque de aire empieza a

aumentar y lo hace hasta aproximadamente 150 PSI antes de que el motor se

apague automáticamente. La presión alta a la que el motor se apaga se

conoce como “presión de desconexión”.

Código de certificación: los productos que ostentan uno o más de las marcas

siguientes: UL, CUL, ETL, CETL, han sido evaluados por Laboratorios

certificados independientes de seguridad OSHA, y alcanzado los estándares de

seguridad requeridos.

CICLO DE SERVICIO

Los compresores de aire de Porter-Cable deben utilizarse a no más de un

ciclo de servicio del 50%. Esto significa que si un compresor de aire bombea

aire más del 50% de una hora, se considera que se está utilizando

incorrectamente, porque el compresor es demasiado pequeño para la

demanda de aire requerida. El tiempo máximo de bombeo del compresor por

hora es de 30 minutos.

ESPECIFICACIONES

NO. DE MODELO CPFAC2600P

Potencia en caballos -Pico 2,0

SCFM a 40 psig 3,7

SCFM a 90 psig 2,6

Presión de conexión 120 PSI

Presión de desconexión 150 PSI

Diámetro interior 1,875"

Carrera 1,250"

Tensión/Hz/Fase 120/60/1

Circuito de derivación mínimo 15 A

*Tipo de fusible Retardo

Amperaje a carga máx. 10 A

Tamaño del tanque 6 galones

*Se prefiere un cortacircuitos. Use únicamente un fusible o interruptor automático de

circuito que esté especificado para el ramal en el cual esta operando el compresor de

aire. Si el compresor está conectado a un circuito protegido por fusibles, use sólo

fusibles de acción retardada. Los fusibles de acción retardada deben estar marcados

con la letra "D" en Canadá y "T" en EE.UU.

Page 27

27 - SP

D27856

INSTALLATION

CÓMO PREPARAR LA UNIDAD

Ubicación del compresor de aire

Ubique al compresor de aire en una zona limpia, seca y bien ventilada. La bomba del

compresor de aire y su carcasa han sido diseñadas para permitir un enfriamiento

adecuado. Las aberturas de ventilación del compresor resultan - entonces - necesarias

para el mantenimiento de una adecuada temperatura de funcionamiento. No coloque

géneros o contenedores, encima, ni en las proximidades de dichas aberturas. E l filtro de

aire debe mantenerse libre de obstrucciones que podrían reducir el flujo de aire al

compresor.

INSTRUCCIONES PARA CONECTAR A TIERRA

RIESGO DE DESCARGA ELÉCTRICA Ante la eventualidad de

un cortocircuito, la conexión a tierra reduce el riesgo de

electrocución proveyendo un conductor de escape para la corriente eléctrica. Este

compresor de aire debe estar adecuadamente conectado a tierra.

El compresor portátil de aire está equipado con un cable que tiene un conductor

destinado a tierra, con una espiga apropiada para su conexión (ver las siguientes

ilustraciones). El enchufe debe ser utilizado con un toma corriente que haya sido

instalado y conectado a tierra de acuerdo a todos los códigos y ordenanzas locales.

1. El cable que acompaña a esta unidad tiene una espiga para conexión a tierra. Esta

DEBE ser utilizada con un tomacorriente conectado a tierra.

IMPORTANTE: El tomacorriente que será utilizado deberá haber sido conectado a tierra

conforme a todos los códigos locales y ordenanzas.

2. Asegúrese de que el tomacorriente que

será utilizado tenga la misma

configuración que el enchufe de

conexión a tierra. NO UTILICE UN

ADAPTADOR. Ver figura.

3. Inspeccione el enchufe y su cordón antes

de cada uso. No use si existieran signos de

daños.

4. Si las instrucciones de conexión a tierra no fueran completamente comprendidas, o si se

estuviera ante la duda acerca de que el compresor estuviese adecuadamente conectado

a tierra, haga verificar la instalación por un electricista competente.

LA CONEXIÓN INADECUADA A TIERRA PUEDE DETERMINAR UNA

DESCARGA ELÉCTRICA.

No modifique el enchufe provisto. Si el mismo no penetrara el tomacorriente

disponible, un electricista competente deberá instalar uno apropiado.

La reparación del cable o del enchufe DEBERÁ ser efectuada por un electricista

competente.

Espiga de conexión a tierra

Tomacorrientes

conectados

a tierra

Enchufe

Page 28

28 - SP

D27856

Cables de extensión eléctrica

No se recomienda la utilización de cables de extensión eléctrica. El uso de cables de

extensión eléctrica originará una caída de tensión, lo que determinará una pérdida de

potencia del motor así como su recalentamiento. En lugar de utilizar un cable de

extensión eléctrica, incremente el alcance de la manguera de aire dentro de la zona de

trabajo, añadiéndole otro largo de manguera a su extremo. Conecte los largos

adicionales de manguera de acuerdo a su necesidad.

Si - no obstante - debe utilizarse una extensión de cable, asegúrese de que:

• La extensión eléctrica de 3 conductores, tenga un enchufe de conexión a tierra de 3

hojas, y que exista un receptáculo que acepte el enchufe del producto.

• Esté en buenas condiciones.

• No más largo que 15,2 m (50 pies).

• Calibre 12 (AWG) o mayor. (La medida de los cables se incrementa a medida que su

número ordinal decrece. 10 y 8 AWG pueden ser usados también. NO USE 14 NI 16

AWG).

Protección del voltaje y del circuito

Acerca del voltaje y la mínima cantidad de circuitos requeridos, refiérase al Manual de

piezas.

Ciertos compresores de aire pueden ser operados en un circuito de 15 A, siempre que

se cumplan las siguientes condiciones:

1. Que el voltaje suministrado a través de los ramales del circuito sea de 15 A.

2. Que el circuito no sea utilizado para alimentar ninguna otra necesidad eléctrica

(iluminación, artefactos, etc.)

3. Que los cables de extensión cumplan con las especificaciones.

4. El circuito cuenta con un disyuntor de 15 amperios o un fusible de acción retardada

de 15 amperios. NOTA: Si el compresor está conectado a un circuito protegido

por fusibles, use sólo fusibles de acción retardada. Los fusibles de acción

retardada deben estar marcados con la letra "D" en Canadá y "T" en EE.UU.

Si cualquiera de las condiciones enumeradas no pudiese ser cumplida, o si el

funcionamiento del compresor causara reiteradas interrupciones de la energía con la que

se lo alimenta, podría ser necesario operar al mismo desde un circuito de 20 A. Para ello

no será necesario cambiar su cable de limentación.

Page 29

29 - SP

D27856

Descripción de operaciones

Familiarícese con estos controles antes de operar la unidad.

Interruptor On/Auto/Off: Mueva este interruptor a la posición ON para dar contacto

automático al interruptor de presión, y OFF para interrumpir la energía eléctrica al

término del uso.

Interruptor de presión: El interruptor de presión permite el arranque automático del

motor cuando la presión del tanque disminuye por debajo del valor de la presión de

conexión regulada en fábrica. El motor se detendrá cuando la presión del tanque alcance

los valores de presión de corte, regulado en fábrica para su desconexión.

Válvula de seguridad: Si el interruptor de presión dejara de cortar el suministro de

presión del compresor conforme a los valores prefijados para la presión de corte, la

válvula de seguridad protegerá contra la presión elevada, "saltando" de acuerdo a los

valores prefijados en fábrica (ligeramente superiores a los de presión de corte de la llave

interruptora.)

Manómetro para controlar la presión de salida. Este manómetro indicará la presión de

aire disponible a la salida del regulador. Esta presión está controlada por el regulador y

es siempre menor o igual que la presión del tanque

Manómetro de la presión del tanque: El manómetro que controla la presión del tanque

indica la reserva de presión del tanque de aire.

Regulador: Controla la presión de aire mostrada en el manómetro de salida. Tire de la

perilla y gírela en sentido horario para incrementar la presión, y hágalo en sentido inverso

para disminuirla. Cuando se logre la presión deseada, presione la perilla para bloquearla.

Válvula de drenaje: La válvula de drenaje se

encuentra ubicada sobre la base del tanque de aire y

se usa para drenar la condensación al fin de cada uso

Sistema de enfriamiento (no mostrado): Este

compresor contiene un sistema de avanzada para el

control de enfriamiento. En el núcleo de este sistema

de enfriamiento hay un ventilador especialmente

diseñado. Resulta perfectamente normal - para este

ventilador - soplar aire en grandes cantidades a través de los orificios de ventilación. De

tal manera se podrá saber que el sistema de enfriamiento trabaja cuando el aire esta

siendo expelido.

OPERACIÓN

Conozca su compresor de aire

LEA ESTE MANUAL DEL PROPIETARIO Y SUS NORMAS DE SEGURIDAD ANTES DE

OPERAR LA UNIDAD. Compare las ilustraciones contra su unidad a fin de familiarizarse

con la ubicación de los distintos controles y regulaciones. Conserve este manual para

referencias futuras.

Conexión

rápida

Válvula

de

drenaje

Manómetro

de presión

de salida

Válvula de seguridad

Interruptor

de presión

Regulador

Manómetro

de presión

del tanque

Interruptor

On/Auto/Off

Switch

Page 30

30 - SP

D27856

Bomba de compresión del aire (no mostrada): Comprime el aire dentro del tanque. El

aire de trabajo no se encuentra disponible hasta que el compresor haya alcanzado a

llenar el tanque hasta un nivel de presión por encima del requerido para la salida del aire.

Válvula reguladora: Cuando el compresor de aire se

encuentra funcionando, la válvula reguladora esta

"abierta", permitiendo la entrada del aire comprimido al

tanque de aire. Cuando el nivel de presión del tanque

alcanza el punto de "corte", la válvula reguladora "se

cierra", reteniendo la presión del aire dentro del tanque.

Antes de poner en marcha

Procedimiento para el asentamiento

Si las siguientes instrucciones no fuesen seguidas estrictamente,

podrán ocurrir serios daños.

Este procedimiento es necesario antes de poner en servicio al compresor de aire, y cuando la

válvula reguladora o la bomba completa del compresor haya sido reemplazada

1. Asegúrese que la palanca On/Auto/Off esté en la posición "OFF".

NOTA: Tire del acoplamiento hacia atrás hasta

percibir el "clic" que impide el escape del aire de

la conexión rápida.

2. Enchufe el cable de alimentación en el

receptáculo del ramal del circuito correcto.

(Referirse al párrafo "Protección del voltaje y

del circuito" en la sección "Instalación" de

este manual).

3. Abra completamente la válvula de drenaje

(sentido antihorario) a fin de permitir la salida

del aire e impedir el aumento de la presión

dentro del tanque de aire durante el periodo

de asentamiento.

4. Mueva la palanca On/Auto/Off a la posición "ON/AUTO". El compresor se pondrá en marcha.

5. Haga funcionar el compresor durante 15 minutos. Asegúrese de que la válvula de drenaje

esté abierta y que la presión de aire acumulado en el tanque sea mínima.

6. Luego de 15 minutos, cierre la válvula de drenaje (sentido horario). El aire recibido irá

llenando hasta el punto de "corte" de presión, y el motor se detendrá.

El compresor estará ahora listo para ser usado.

Válvula

reguladora

Conexión

rápida

Regulador

Interruptor

On/Auto/Off

Switch

Cómo utilizar su unidad

Cómo detenerla:

1. Coloque la posición de la llave interruptora On/Auto/Off en la posición "OFF".

Page 31

31 - SP

D27856

Antes de cada puesta en marcha:

1. Coloque el interruptor On/Auto/Off en la posición "OFF" y cierre el regulador de aire.

2. Tire de la perilla del regulador, gire en sentido antihorario hasta el límite. Empuje la perilla

hasta su posición blocante.

3. Conecte la manguera y accesorios. NOTA: Tanto la manguera como los accesorios

requerirán un enchufe de conexión rápida si la salida del aire está equipada con un zócalo de

conexión rápida.

Demasiada presión de aire podrá ser la causa de riesgo de

explosión. Verifique los valores de máxima presión dados por el

fabricante de las herramientas neumáticas y los accesorios. La presión de salida del

regulador jamás debe exceder los valores de máxima presión especificados.

Cómo poner en marcha:

1. Mueva la palanca On/Auto/Off a la posición "AUTO" y deje que se incremente la presión del

tanque. El motor se detendrá una vez alcanzado el valor de presión "de corte" del tanque.

2. Tire de la perilla del regulador y gire en sentido horario para incrementar la presión. Cuando

el valor deseado de presión sea logrado, presione la perilla hasta su posición blocante. El

compresor estará listo para ser usado.

NOTA: Opere siempre el compresor de aire en áreas bien ventiladas, libres de gasolina u otras

emanaciones combustibles. Si el compresor será utilizado para utilizar un rociador, NO lo coloque

en las cercanías de la zona de rociado.

Page 32

32 - SP

D27856

MANTENIMIENTO

Responsabilidades del cliente

●

●

Verifique la válvula de seguridad

Drenaje del tanque

Cuando se realizan trabajos de mantenimiento, usted

puede estar expuesto a fuentes de voltaje, aire comprimido o

piezas en movimiento. Pueden ocurrir lesiones personales. Antes de realizar

cualquier trabajo de mantenimiento o reparación, desconecte la fuente de energía

del compresor y purgue toda la presión de aire.

NOTA: Vea en la sección "Operación" la ubicación de los controles.

Cómo verificar la válvula de seguridad

Si la válvula de seguridad no trabaja adecuadamente, ello

podrá determinar la sobrepresión del tanque, creando el

riesgo de su ruptura o explosión.

1. Antes de poner en marcha el motor, tire del anillo de la válvula de seguridad para

confirmar la seguridad de que la misma opera libremente, si la válvula quedase

trabada o no trabajara cómodamente, deberá ser reemplazada por el mismo tipo de

válvula.

Cómo drenar el tanque

1. Coloque la palanca On/Auto/Off en la posición "OFF".

2. Tire de la perilla del regulador y gire en sentido contrario a las agujas de reloj para

establecer la salida de presión en cero.

3. Remueva la herramienta neumática o el accesorio.

4. Tire del aro de la válvula de seguridad dejando purgar el aire del tanque hasta que

este reduzca su presión aproximadamente a 20 PSI. Suelte el aro de la válvula de

seguridad.

5. Drene el agua contenida en el tanque de aire, abriendo la válvula de drenaje

ubicada en la base del tanque (en sentido contrario a las agujas de reloj).

Dentro del tanque se producirá condensación de agua. Si no

drena, el agua lo corroerá y debilitará causando un riesgo de

ruptura del tanque de aire.

6. Una vez drenada el agua, cierre la válvula de drenaje (girando en sentido horario).

Ahora el compresor de aire podrá ser guardado.

NOTA: Si la válvula de drenaje fuera del tipo enchufe, elimine toda la presión de aire. La

válvula podrá entonces ser extraída, limpiada y finalmente reinstalada.

Diariamente

o luego de

cada uso

Antes

de

cada

uso

Page 33

33 - SP

D27856

SERVICIO Y AJUSTES

La unidad cicla automáticamente en cuanto la energía

eléctrica es conectada. Al efectuar el mantenimiento, usted

quedará expuesto a tensión viva, aire comprimido o partes en movimiento. Debido

a tales circunstancias, podrían ocurrirle lesiones personales. Antes de efectuar

mantenimiento o reparación alguna, desenchufe el compresor y purgue cualquier

presión de aire.

TODO TIPO DE MANTENIMIENTO Y OPERACIONES DE REPARACIÓN NO

MENCIONADOS, DEBERÁN SER EFECTUADOS POR PERSONAL TÉCNICO

ESPECIALIZADO.

Antes de dar servicio:

· Desenchufe o desconecte el suministro eléctrico al compresor de aire.

· Purgue la presión del tanque.

· Deje enfriar al compresor de aire.

Para reemplazar o limpiar la válvula reguladora

1. Libere toda presión de aire del tanque. Vea "Drenaje del tanque" en la sección mantenimiento.

2. Desenchufe el equipo.

3. Extraiga la manguera removiendo la abrazadera que la

sujeta.

NOTA: La abrazadera de la manguera no es reutilizable.

Deberá comprarse una nueva abrazadera, ver la lista de

partes del manual o compre una abrazadera estándar en

cualquier comercio de ferretería.

4. Desenrosque la válvula reguladora (gire en sentido

antihorario) utilizando una llave tubular.

5. Asegúrese que el disco de la válvula se mueva

libremente dentro de la válvula reguladora y que el

resorte sujete al disco en posición erguida y cerrada. La válvula reguladora puede ser limpiada con

solvente, tal como los utilizados para pinturas y removedores de barniz.

6. Aplique sellador a los filamentos roscados de la válvula reguladora. Reinstale la válvula reguladora

(girando en sentido horario).

7. Reponga la manguera y coloque la nueva abrazadera.

8. Ejecute el proceso de "asentamiento". Vea "Proceso de asentamiento" en la sección "Operación".

Válvula

reguladora

Abrazadera de manguera

Page 34

34 - SP

D27856

Para reemplazar el regulador

1. Libere toda la presión del aire del tanque. Vea "Drenaje del tanque" en la sección

"Mantenimiento".

2. Desenchufe el equipo.

3. Utilizando una llave regulable, extraiga el manómetro

de presión externa y la conexión rápida del

regulador.

4. Extraiga el regulador.

5. Aplique cinta selladora de cañerías sobre el niple del

tubo vertical.

6. Ensamble el regulador y oriéntelo de acuerdo a lo mostrado.

NOTA: La flecha indica el sentido del flujo del aire. Asegúrese que esté apuntando a la dirección

en la que fluye el aire.

7. Reaplique sellador de cañerías al manómetro de presión

externa y a la conexión rápida.

8. Rearme el manómetro de presión de salida y el conector

rápido. Oriente el manómetro de salida para permitir su

lectura correctamente. Ajuste las conexiones con la

llave.

Niple

Medidor

de salida

de presión

Conector

rápido

Regulador

Regulador

Regulador

Flecha

Page 35

35 - SP

D27856

ALMACENAJE

Antes de guardar su compresor de aire, asegúrese de hacer lo siguiente:

1. Revise la sección "Mantenimiento" de las páginas precedentes y ejecute el

mantenimiento programado de acuerdo a la necesidad.

2. Coloque la palanca On/Auto/Off en la posición "OFF".

3. Gire el regulador en sentido antihorario y fije la presión de salida en cero.

4. Extraiga la herramienta neumática o el accesorio.

5. Tire del anillo de la válvula de seguridad permitiendo el purgado del aire del tanque

hasta que la presión del mismo llegue aproximadamente a 20 PSI. Suelte el anillo

de la válvula de seguridad.

6. Drene el agua del tanque de aire abriendo la válvula de drenaje ubicada en el fondo

del tanque.

El agua se condensa dentro del tanque de aire. Si no se

drena, ella corroerá debilitando la paredes del tanque de

aire, originando un riesgo de ruptura de sus paredes.

7. Una vez que el agua haya sido drenada, cierre la válvula de drenaje.

NOTA: Si la válvula de drenaje estuviese enchufada, libere toda la presión de aire. La

válvula podrá ser extraída, limpiada y luego reinstalada.

8. Proteja el cable eléctrico y las mangueras de aire de daños (tales como ser

pisoteados o pasados por encima). Enróllelos en forma floja, alrededor de la manija

del compresor. (Si así estuviese equipado).

Almacene el compresor de aire en un sitio limpio y seco.

Page 36

GARANTÍA LIMITADA

PORTER-CABLE CORPORATION garantiza al comprador original de todos los productos cubiertos bajo

esta garantía, que los mismos se encuentran libres de defectos en materiales y mano de obra. Los productos

cubiertos bajo esta garantía incluyen todos los compresoresde aire, herramientas neumáticas, piezas de

servicio, lavadoras a presión y generadores, los cuales tienen los siguientes periodos de garantía:

3 AÑOS - Garantía limitada en las bombas compresoras de 2 tiempos sin aceite, que operan a 1725 RPM.

2 AÑOS - Garantía limitada en las bombas compresoras de aire, lubricadas con aceite.

1 AÑO - Garantía limitada en todos los componentes de los otros compresoras de aire.

2 AÑOS - Garantía limitada en los generadores de corriente alterna.

2 AÑOS - Garantía limitada en las herramientas.

1 AÑO - Garantía limitada en lavadoras a presión usadas en aplicaciones domesticas (por ej. Uso

residencial y personal exclusivo).

90 DÍAS - Lavadoras a presión utilizadas para usos comerciales (que producen ingresos) y piezas de servicio.

1 AÑO - Garantía limitada sobre todos los servicios.

Porter-Cable reparará o reemplazará, a opción de Porter-Cable, productos o componentes con fallas, que

se encuentren comprendidos dentro del periodo de garantía. El servicio será programado de acuerdo al flujo

normal de trabajo y el horario normal de atención a clientes en el domicilio del servicentro, y conforme a la

disponibilidad de piezas de reemplazo. Todas las decisiones de Porter-Cable Corporation relacionadas con

esta garantía limitada, serán definitivas.

Esta garantía le otorga derechos legales específicos, aunque también usted podría tener otros derechos que

podrán variar entre estados.

RESPONSABILIDAD DEL COMPRADOR ORIGINAL (Usuario inicial):

• Para procesar un reclamo de garantía sobre este producto, NO lo devuelva al comercio vendedor. El producto

deberá ser evaluado por un servicentro autorizado de Porter Cable para la atención de garantías. Para

informarse de la ubicación más cercana del servicentro autorizado para atención de garantías de Porter-Cable,

llame al 1-888-559-8550 que atiende 24 horas diarias, los 7 días de la semana.

• Retenga el recibido de venta original, como comprobante de su compra, para obtener la atención de su garantía.

• Mantenga un cuidado razonable en la operación y mantenimiento del producto, de acuerdo a lo descripto en

el(los) Manual(es) del propietario.

• Entregue o envíe el producto al servicentro autorizado para atención de garantías de Porter-Cable más cercano.

Los costos de flete, si hubiese alguno, deberán ser abonados por el comprador.

• Únicamente los compresores de aire con tanques de 60 y 80 galones serán inspeccionados en el sitio de

instalación. Contacte el servicentro autorizado para atención de garantías de Porter-Cable más cercano que

provea atención domiciliaria de solicitudes de servicio, para efectuar los arreglos para la prestación de dicho

servicio.

• Si el comprador no obtuviese un resultado satisfactorio de parte del servicentro autorizado para atención de

garantías de Porter-Cable, deberá contactar a Porter-Cable.

ESTA GARANTÍA NO CUBRE:

• Mercadería vendida como reacondicionada, usada como equipo en alquiler y modelos de piso para

exhibición.

• La mercadería que se encuentre dañada o inoperante debido al uso ordinario, inadecuado, frío, calor,

lluvia, humedad excesiva, dañada por congelamiento, uso de productos químicos inapropiados,

negligencia, accidente, fallas en la operación del producto relacionado con las instrucciones contenidas

en el(los) Manual(es) del propietario provistos con el producto, mantenimiento inadecuado, uso de

accesorios o agregados no recomendados por Porter-Cable, reparaciones no autorizadas o

modificaciones.

* Un compresor de aire que bombea aire durante más del 50% durante una hora, está considerado como

de uso inadecuado, dado que el compresor está subdimensionado para la demanda de aire requerida

• Los costos de reparación y transporte de la mercadería determinada no defectuosa.

• Los costos asociados con el armado, aceite requerido, regulaciones u otros costos de instalación y

puesta en marcha.

• Las partes consumibles o accesorios provistos con el producto cuya expectativa de desgaste e

inoperatividad luego de un periodo razonable de uso, incluido pero no limitado a discos de lijado o

almohadillas, sierras y hojas cortantes, piedras de amolar, resortes, cortantes, picos, o-rings, picos de

aire, lavadoras y accesorios similares.

• La mercadería vendida por Porter-Cable que haya sido fabricada e identificada como producto de otra

empresa. En dicho caso tendrá validez la garantía extendida por su fabricante.

• CUALQUIER PÉRDIDA INCIDENTAL, CONSECUENTE, DAÑO O GASTO QUE PUDIESE RESULTAR

DE CUALQUIER DEFECTO, FALLA O MAL FUNCIONAMIENTO DEL PRODUCTO, NO QUEDA

CUBIERTO EN LOS ALCANCES DE ESTA GARANTÍA. Algunos estados no permiten la exclusión ni

limitación de daños incidentales o consecuentes, en dicho caso la limitación antes mencionada no será de

aplicación en su caso.

• LAS GARANTÍAS IMPLÍCITAS, INCLUYENDO AQUELLAS RELACIONADAS CON LA

COMERCIALIZACIÓN Y CALIFICACIÓN PARA UN PROPÓSITO EN PARTICULAR, QUEDAN

LIMITADAS A UN AÑO A PARTIR DE LA FECHA ORIGINAL DE SU COMPRAAlgunos estados no