Porter-Cable 314 User guide

Trim SawInstruction

manual

The Model and Serial No. plate is located on the main

housing of the tool. Record these numbers in the

spaces below and retain for future reference.

Model No. ______________________________________

Type ___________________________________________

Serial No. _______________________________________

IMPORTANT

Please make certain that the person who is

to use this equipment carefully reads and

understands these instructions before

starting operations.

Part No. 900315-0010

ESPAÑOL: PÁGINA 17

FRANÇAISE : PAGE 35

MODEL 314

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

Copyright © 2000 Porter-Cable Corporation

900315 - 10-31-00.qxd 2/25/02 9:45 AM Page 1

2

SAFETY INSTRUCTIONS

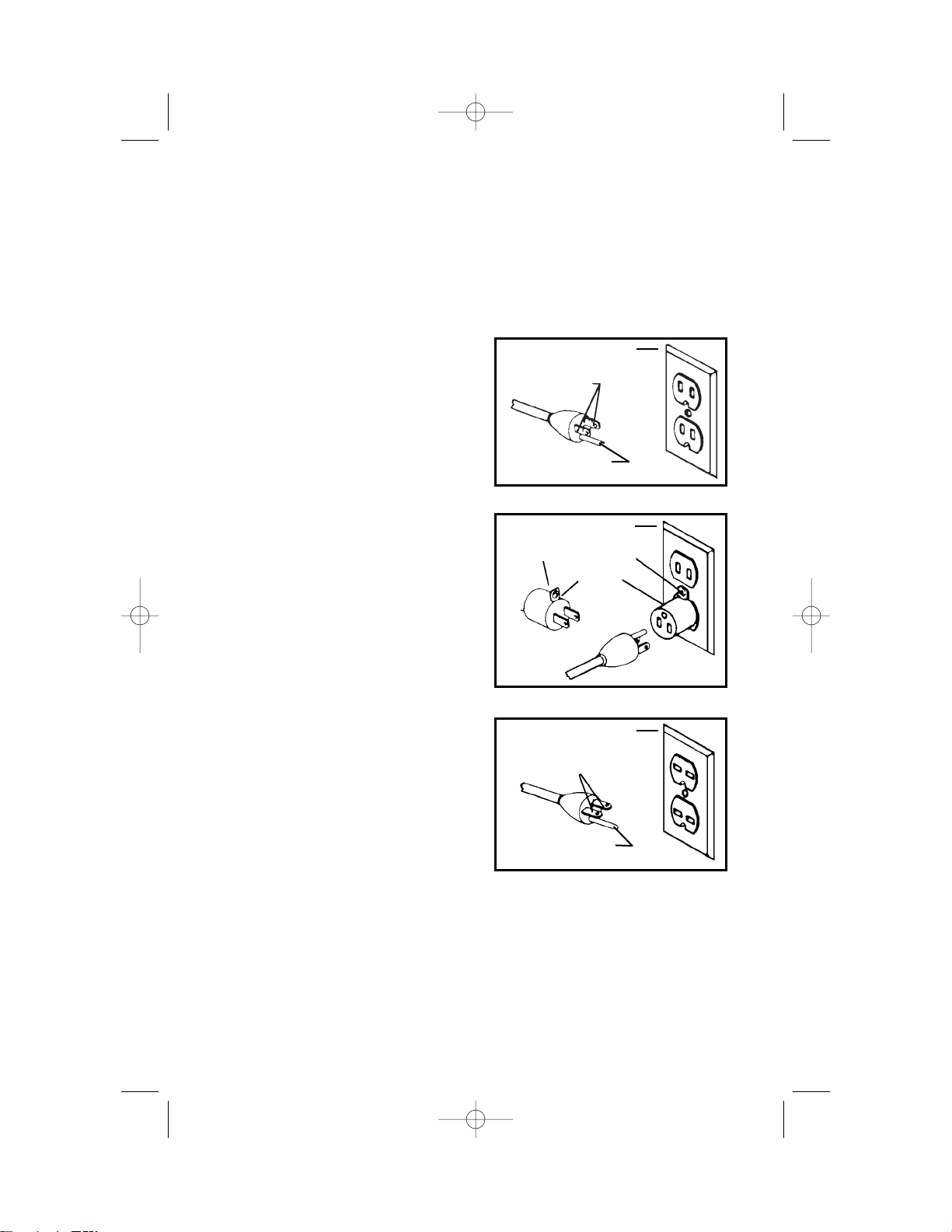

GROUNDING INSTRUCTIONS

This tool should be grounded while in use to protect the operator from electric

shock. The tool is equipped with an approved three-conductor cord and

three-prong grounding type plug to fit the proper grounding type receptacle.

The green (or green and yellow) conductor in the cord is the grounding wire.

Never connect the green (or green and yellow) wire to a live terminal.

If your unit is for use on less than 150

Volts, the power cord is equipped with

a plug that has two flat, parallel

current-carrying prongs and one

longer, round or “U”-shaped, ground

prong which requires a mating 3conductor grounded type receptacle,

as shown in Fig. 1.

An adapter, shown in Fig. 2, is

available for connecting 3-prong

grounding type plugs that are used on

units less than 150 Volts to 2-prong

receptacles. THIS ADAPTER IS NOT

ALLOWED IN CANADA. The green

colored rigid ear, lug, etc., must be

connected to a permanent ground

such as a properly grounded outlet

box, as shown in Fig. 2.

If your unit is for use on 150 to 250

Volts, the power cord is equipped with

a plug that has two flat current

carrying prongs in tandem, and one

round or “U”-shaped, longer ground

prong, as shown in Fig. 3. This plug is

used only with the proper mating 3conductor grounding type receptacle,

as shown in Fig. 3. No adapter is

available for this type plug.

IN ALL CASES, MAKE SURE THE

RECEPTACLE IN QUESTION IS

PROPERLY GROUNDED.

NEVER REMOVE GROUNDING PRONG FROM POWER PLUG.

EXTENSION CORDS

Use only three-wire extension cords which have three-prong grounding-type

plugs and three-pole receptacle which accept the tool’s plug. Replace

damaged or worn cord immediately. DO NOT ATTEMPT TO REPAIR POWER

CORD.

GROUNDED OUTLET BOX

Fig. 1

Fig. 2

Fig. 3

CURRENT

CARRYING

PRONGS

GROUNDING PRONG

IS LONGEST OF THE 3 PRONGS

GROUNDED OUTLET BOX

GROUNDED OUTLET BOX

GROUNDING MEANS

ADAPTER

CURRENT

CARRYING

PRONGS

GROUNDING PRONG

IS LONGEST OF THE 3 PRONGS

900315 - 10-31-00.qxd 2/25/02 9:45 AM Page 2

3

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, basic safety precautions should always

be followed to reduce the risk of fire, electric shock and personal injury,

including the following:

WARNING: SOME DUST CREATED BY POWER SANDING, SAWING,

GRINDING, DRILLING, AND OTHER CONSTRUCTION ACTIVITIES

contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

· lead from lead-based paints,

· crystalline silica from bricks and cement and other masonry products, and

· arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, such as those

dust masks that are specially designed to filter out microscopic particles.

READ AND FOLLOW ALL INSTRUCTIONS.

There are certain applications for which this tool was designed. Porter-Cable

strongly recommends that this tool NOT be modified and/or used for any

application other than for which it was designed. If you have any questions

relative to its application DO NOT use the tool until you have written PorterCable and we have advised you.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North

Jackson, TN 38305

1. KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

2. AVOID DANGEROUS ENVIRONMENT. Don’t expose power tools to

rain. Don’t use power tools in damp or wet locations. Keep area well lit. Avoid

chemical or corrosive environment. Do not use tool in presence of flammable

liquids or gases.

3. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with grounded

surfaces. For example: pipes, radiators, ranges, refrigerator enclosures.

4. KEEP CHILDREN AWAY. Do not let visitors contact tool or extension

cord. All visitors should be kept away from work area.

5. STORE IDLE TOOLS. When not in use, tools should be stored in dry, and

high or locked-up place – out of reach of children.

6. DON’T FORCE TOOL. It will do the job better and safer at the rate for

which it was intended.

7. USE RIGHT TOOL. Don’t force small tool or attachment to do the job of

a heavy duty tool. Don’t use tool for purpose not intended – for example – do

not use a circular saw for cutting tree limbs or logs.

8. DRESS PROPERLY. Do not wear loose clothing or jewelry. Loose

clothing, draw strings and jewelry can be caught in moving parts. Rubber

gloves and non-skid footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

9. USE SAFETY GLASSES. Wear safety glasses or goggles while operating

power tools. Also face or dust mask if operation creates dust. All persons in

the area where power tools are being operated should also wear safety

glasses and face or dust mask.

900315 - 10-31-00.qxd 2/25/02 9:45 AM Page 3

4

10. DON’T ABUSE CORD. Never carry tool by cord or yank it to disconnect

from receptacle. Keep cord from heat, oil, and sharp edges. Have damaged or

worn power cord and strain reliever replaced immediately. DO NOT ATTEMPT

TO REPAIR POWER CORD.

11. SECURE WORK. Use clamps or a vise to hold work. It’s safer than using

your hand and it frees both hands to operate tool.

12. DON’T OVERREACH. Keep proper footing and balance at all times.

13. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better and

safer performance. Follow instructions for lubricating and changing accessories.

Inspect tool cords periodically and if damaged, have repaired by authorized

service facility. Inspect extension cords periodically and replace if damaged.

Have all worn, broken or lost parts replaced immediately. Keep handles dry,

clean and free from oil and grease.

14. DISCONNECT TOOLS when not in use, before servicing, and when

changing accessories such as blades, bits, cutters, etc.

15. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking

to see that keys and adjusting wrenches are removed from the tool before

turning it on.

16. AVOID UNINTENTIONAL STARTING. Do not carry a plugged-in tool with

finger on switch. Be sure switch is off when plugging in. Keep hands, body and

clothing clear of blades, bits, cutters, etc. when plugging in the tool.

17. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use

only extension cords marked “Suitable for use with outdoor appliances – store

indoors when not in use.”

18. STAY ALERT. Watch what you are doing. Use common sense. Do not

operate tool when you are tired or while under the influence of medication,

alcohol or drugs.

19. CHECK DAMAGED PARTS. Before further use of the tool, a guard or

other part that is damaged should be carefully checked to determine that it will

operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any

other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced by an authorized service

center unless otherwise indicated elsewhere in this instruction manual. Have

defective switches replaced by authorized service center. Do not use tool if

switch does not turn it on and off.

20. WEAR EAR PROTECTION to safeguard against possible hearing loss.

SAVE THESE INSTRUCTIONS

ADDITIONAL SAFETY RULES FOR CIRCULAR SAWS

1. KEEP GUARDS IN PLACE AND IN WORKING ORDER. Never wedge or

tie lower guard open. Check operation of lower guard before each use. Do not

use if lower guarddoes not close briskly over saw blade. CAUTION: If saw is

dropped, lower guard may be bent, restricting full return.

2. KEEP BLADES CLEAN AND SHARP. Sharp blades minimize stalling and

kickback.

3. DANGER: KEEP HANDS AWAY FROM CUTTING AREA. Keep hands

away from blades. Do not reach underneath work while blade is rotating. Do

not attempt to remove cut material when blade is moving. CAUTION: Blades

coast after turned off.

900315 - 10-31-00.qxd 2/25/02 9:45 AM Page 4

5

4. SUPPORT LARGE PANELS. Large panels must be supported, as shown

in Fig. 10, to minimize the risk of blade pinching and kickback. When cutting

operation requires the resting of the saw on the workpiece, the saw shall be

rested on the larger portion and the smaller portion cut off.

5. USE RIP FENCE. Always use a fence or straight edge guide when

ripping.

6. GUARD AGAINST KICKBACK. Kickback occurs when the blade is

pinched and the saw is driven back towards the operator. Keep body to side

of blade. Stay alert and maintain firm grip on saw for control. Release switch

immediately if blade binds or saw stalls. Keep blades sharp. Support panels

as shown in Fig. 10. Use fence or straight edge guide when ripping. DO NOT

force tool. DO NOT remove saw from work during a cut while blade is moving.

7. LOWER GUARD. Raise lower guard with the retracting handle when

pocket cutting.

8. ADJUSTMENTS. Before cutting be sure depth and bevel adjustments

are tight.

9. USE ONLY CORRECT BLADES IN MOUNTING. Do not use blades with

incorrect size holes. Never use defective or incorrect blades, washers or bolts.

10. AVOlD CUTTlNG NAlLS AND KNOTS. Inspect for and remove all nails

from lumber before cutting. Try to layout cuts between knots.

11. SOME WOOD CONTAINS PRESERVATIVES WHICH CAN BE TOXIC.

Take extra care to prevent inhalation and skin contact when working with

these materials. Request, and follow, any safety information available from

your material supplier.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

MOTOR

Many Porter-Cable tools will operate on either D.C., or single phase 25 to 60

cycle A.C. current and voltage within plus or minus 5 percent of that shown

on the specification plate on the tool. Several models, however, are designed

for A.C. current only. Refer to the specification plate on your tool for proper

voltage and current rating.

CAUTION: Do not operate your tool on a current on which the

voltage is not within correct limits. Do not operate tools rated A.C.

only on D.C. current. To do so may seriously damage the tool.

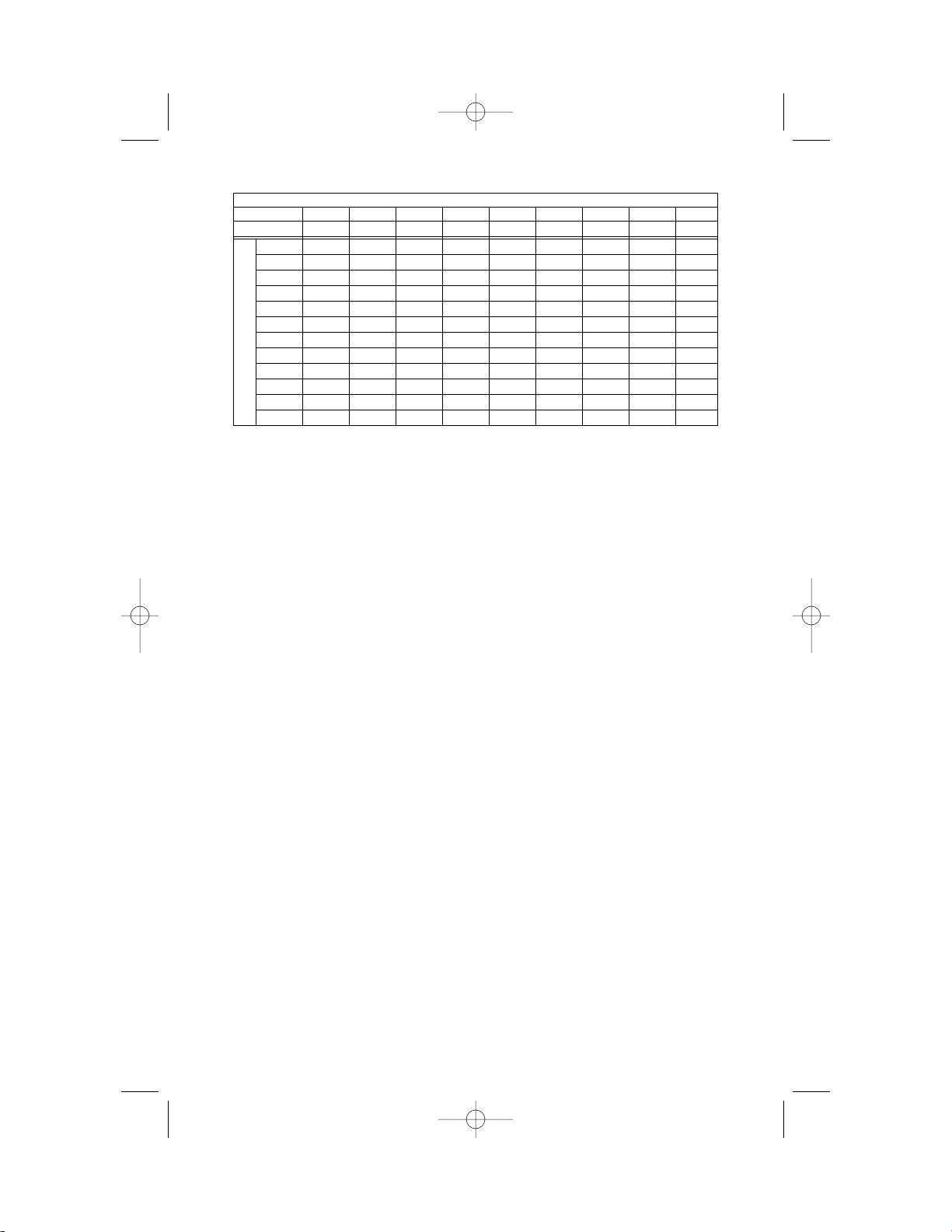

EXTENSION CORD SELECTION

If an extension cord is used, make sure the conductor size is large enough to

prevent excessive voltage drop which will cause loss of power andpossible

motor damage. A table of recommended extension cord sizes will be found in

this section. This table is based on limiting line voltage drop to 5 volts (10 volts

for 230 volts) at 150% of rated amperes. If an extension cord is to be used

outdoors it must be marked with the suffix W-A following the cord type

designation. For example – SJTW-A to indicate it is acceptable for outdoor use.

900315 - 10-31-00.qxd 2/25/02 9:45 AM Page 5

6

RECOMMENDED EXTENSION CORD SIZES FOR USE WITH PORTABLE ELECTRIC TOOLS

OPERATING INSTRUCTIONS

FOREWORD

Your Porter-Cable Trim Saw is designed for cutting trim, composition board,

plywood, plastics, plexiglas and other problem materials. Maximum depth of

cut is 1

5

/16

" at 90° and 1

1

/16

" at 45° with 4

1

/2

" diameter blade.

SELECTING THE BLADE

A Combination Blade is furnished with your saw and is an excellent blade for

all general ripping and crosscutting operations. When crosscutting and

smoothness of cut is an important factor, a thin rim blade is recommended.

Also, a fine tooth blade should be used when cutting plywood and masonite.

Special blades are available for cutting plexiglas and “problem materials”

such as metal laminates and gauge size sheet steel. Recommended blades

for use with your saw are listed under ACCESSORIES in the back of this

manual.

TO CHANGE SAW BLADES

CAUTION: DISCONNECT SAW FROM POWER SOURCE.

To remove the blade, place the teeth of the blade against the edge of a board

and loosen the blade retaining screw by turning it counterclockwise with

wrench provided. Remove blade retaining screw and outer flange washer.

Hold telescoping guard open and remove blade. Before installing a new

blade, remove inner flange washer and wipe it clean. Also remove any

sawdust that may have accumulated within the guards, around the saw

arbor, and from the telescoping guard spring. Check the telescoping guard

to insure it is in working order.

CAUTION: If telescoping guard movement is sluggish or binding

exists, return the saw to your nearest AUTHORIZED PORTER-CABLE

SERVICE STATION or PORTER-CABLE SERVICE CENTER for repair.

NEVER use your saw if the telescoping guard is not in working order.

Install the inner flange washer and place the new blade on the arbor making

sure the teeth point UP at the front of the saw, (EXCEPT for the special blade

for cutting plexiglas – see below).

Clean and replace the outer flange washer making certain the square hole

mates with the squared end of the saw arbor. Install and firmly tighten the

blade retaining screw.

Length of Cord in Feet

115V 25 Ft. 50 Ft. 100 Ft. 150 Ft. 200 Ft. 250 Ft. 300 Ft. 400 Ft. 500 Ft.

230V 50 Ft. 100 Ft. 200 Ft. 300 Ft. 400 Ft. 500 Ft. 600 Ft. 800 Ft. 1000 Ft.

0-2 18 18 18 16 16 14 14 12 12

2-3 18 18 16 14 14 12 12 10 10

3-4 18 18 16 14 12 12 10 10 8

4-5 18 18 14 12 12 10 10 8 8

5-6 18 16 14 12 10 10 8 8 6

6-8 18 16 12 10 10 8 6 6 6

8-10 18 14 12 10 8 8 6 6 4

10-12 16 14 10 8 8 6 6 4 4

12-14 16 12 10 8 6 6 6 4 2

14-16 16 12 10 8 6 6 4 4 2

16-18 14 12 8 8 6 4 4 2 2

18-20 14 12 8 6 6 4 4 2 2

Nameplate Ampere Rating

900315 - 10-31-00.qxd 2/25/02 9:45 AM Page 6

Loading...

Loading...