Porter-Cable 1500, 895736 User Manual

Instruction

manual

The Model and Serial No. plate is located on the main

housing of the tool. Record these numbers in the

spaces below and retain for future reference.

Model No. ______________________________________

Type ___________________________________________

Serial No. _______________________________________

IMPORTANT

Please make certain that the person who is

to use this equipment carefully reads and

understands these instructions before

starting operations.

ESPAÑOL: PÁGINA 17

FRANÇAISE : PAGE 33

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

Copyright © 2004 Porter-Cable Corporation

Part No. 895736 - 04-28-04

MODEL 1500

Tile Saw

2

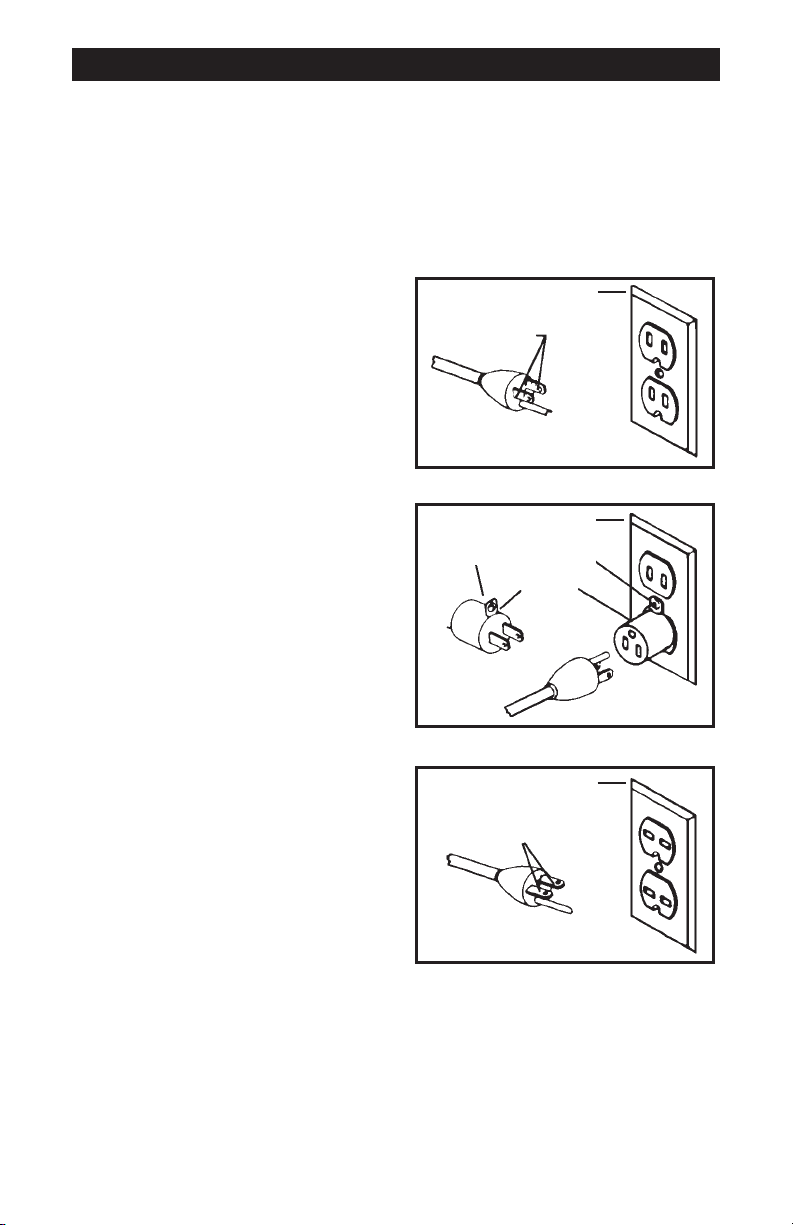

GROUNDING INSTRUCTIONS

1. All grounded, cord-connected tools:

In the event of a malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the risk of electric shock.

This tool is equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug must be plugged

into a matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

Do not modify the plug provided - if

it will not fit the outlet, have the

proper outlet installed by a qualified

electrician.

Improper connection of the

equipment-grounding conductor

can result in risk of electric shock.

The conductor with insulation

having an outer surface that is

green with or without yellow stripes

is the equipment-grounding

conductor. If repair or replacement

of the electric cord or plug is

necessary, do not connect the

equipment-grounding conductor to

a live terminal.

Check with a qualified electrician or

service personnel if the grounding

instructions are not completely

understood, or if in doubt as to

whether the tool is properly

grounded.

Use only 3-wire extension cords

that have 3-prong grounding type

plugs and matching 3-conductor

receptacles that accept the tool’s

plug, as shown in Fig. A.

Repair or replace damaged or worn

cord immediately.

2. Grounded, cord-connected tools

intended for use on a supply circuit

having a nominal rating less than

150 volts:

If the tool is intended for use on a

circuit that has an outlet that looks

like the one illustrated in Fig. A, the tool will have a grounding plug that

looks like the plug illustrated in Fig. A.

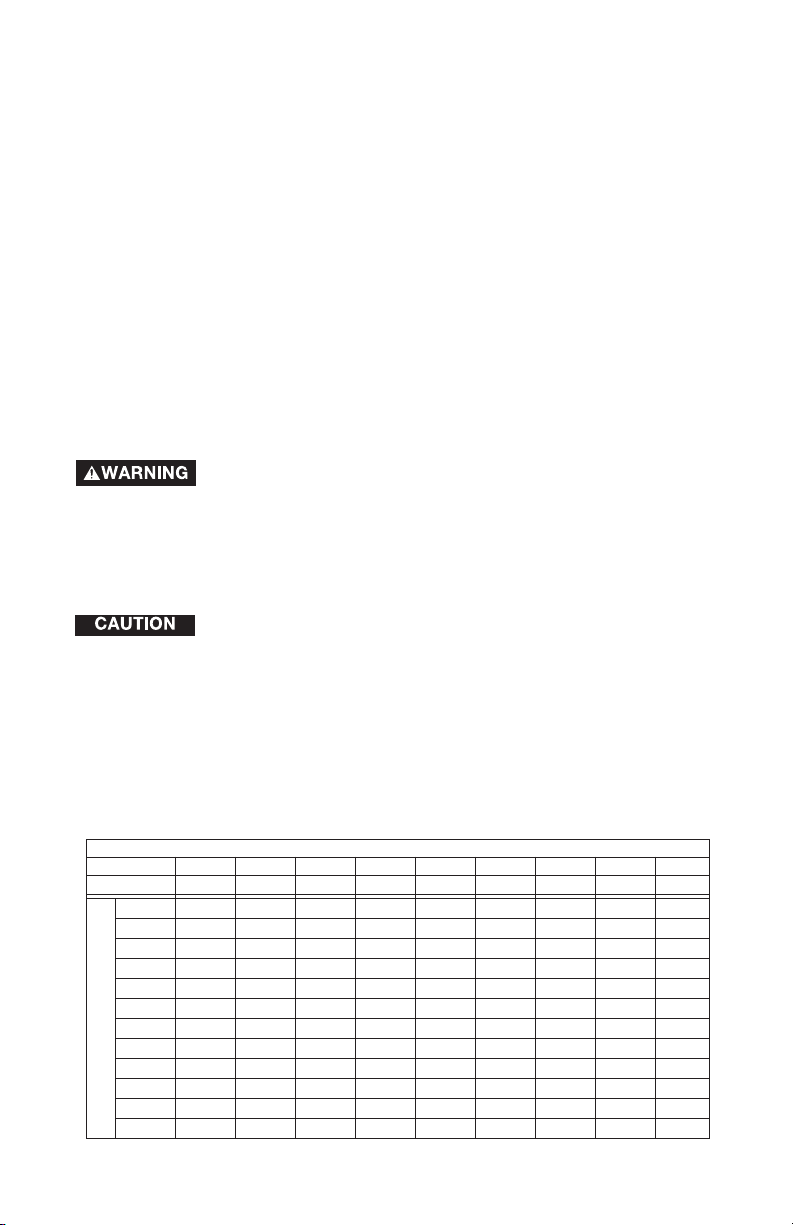

A temporary adapter, which looks like the adapter illustrated in Fig. B,

may be used to connect this plug to a matching 2-conductor receptacle

as shown in Fig. B if a properly grounded outlet is not available. The

temporary adapter should be used only until a properly grounded outlet

can be installed by a qualified electrician. The green-colored rigid ear,

GROUNDED OUTLET BOX

Fig. A

Fig. B

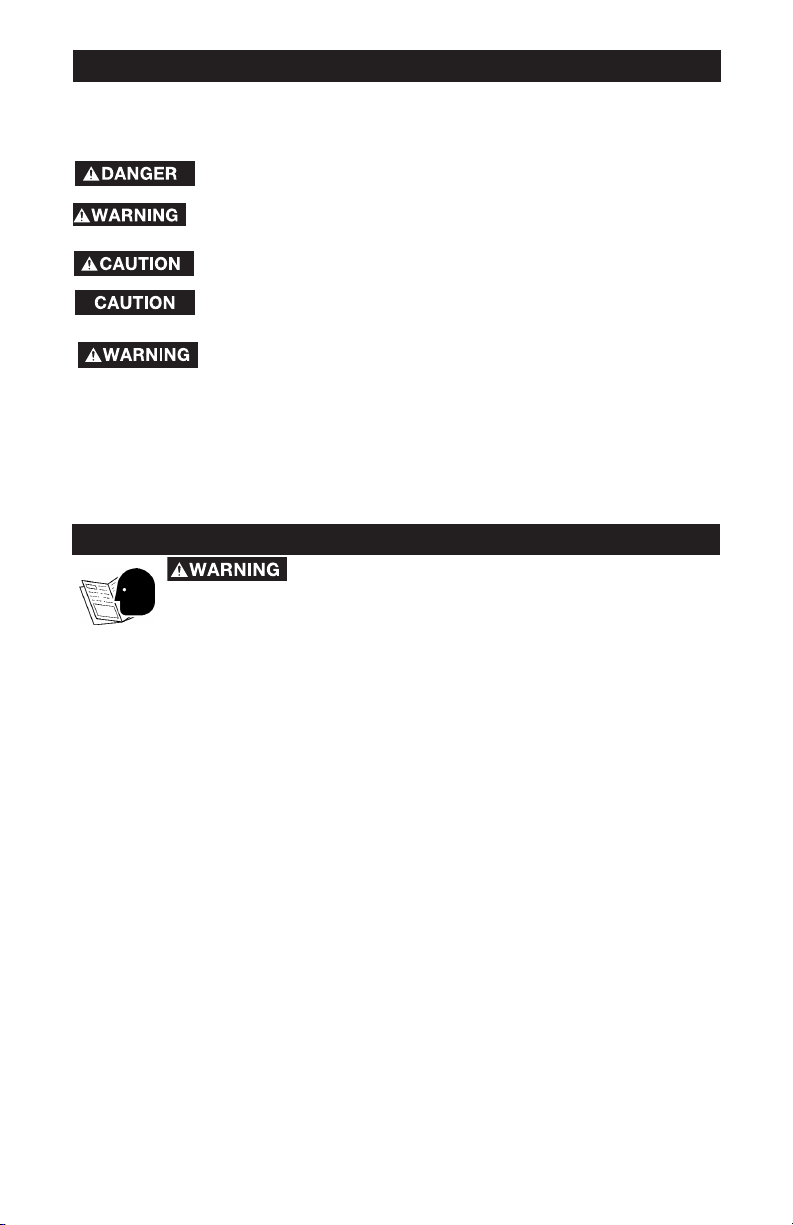

Fig. C

CURRENT

CARRYING

PRONGS

GROUNDING PRONG

IS LONGEST OF THE 3 PRONGS

GROUNDED OUTLET BOX

GROUNDED OUTLET BOX

GROUNDING MEANS

ADAPTER

CURRENT

CARRYING

PRONGS

GROUNDING PRONG

IS LONGEST OF THE 3 PRONGS

SAFETY INSTRUCTIONS

3

lug, and the like, extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box. Whenever

the adapter is used, it must be held in place with a metal screw.

NOTE: In Canada, the use of a temporary adapter is not permitted by

the Canadian Electric Code.

3. Grounded, cord-connected tools intended for use on a supply circuit

having a nominal rating between 150 - 250 volts, inclusive:

If the tool is intended for use on a circuit that has an outlet that looks

like the one illustrated in Fig. C, the tool will have a grounding plug that

looks like the plug illustrated in Fig. C. Make sure the tool is connected

to an outlet having the same configuration as the plug. No adapter is

available or should be used with this tool. If the tool must be reconnected for use on a different type of electric circuit, the reconnection should be made by qualified service personnel; and after

re-connection, the tool should comply with all local codes and

ordinances.

IN ALL CASES, MAKE CERTAIN THE RECEPTACLE IN

QUESTION IS PROPERLY GROUNDED. IF YOU ARE NOT SURE

HAVE A QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

NEVER REMOVE GROUNDING PRONG FROM POWER PLUG.

EXTENSION CORDS

Use proper extension cords. Make sure your extension

cord is in good condition and is a 3-wire extension cord which has a 3prong grounding type plug and matching receptacle which will accept

the tool’s plug. When using an extension cord, be sure to use one

heavy enough to carry the current of the tool. An undersized cord will

cause a drop in line voltage, resulting in loss of power and overheating.

Fig. D, shows the correct gauge to use depending on the cord length.

If in doubt, use the next heavier gauge. The smaller the gauge number,

the heavier the cord.

Length of Cord in Feet

115V 25 Ft. 50 Ft. 100 Ft. 150 Ft. 200 Ft. 250 Ft. 300 Ft. 400 Ft. 500 Ft.

230V 50 Ft. 100 Ft. 200 Ft. 300 Ft. 400 Ft. 500 Ft. 600 Ft. 800 Ft. 1000 Ft.

0-2181818161614141212

2-3181816141412121010

3-418181614121210108

4-5 18 18 14 12 12 10 10 8 8

5-6 18 16 14 12 10 10 8 8 6

6-8 18 16 12 10 10 8 6 6 6

8-10 18 14 12 10 8 8 6 6 4

10-12 16 14 10 8 8 6 6 4 4

12-14 16 12 10 8 6 6 6 4 2

14-16 16 12 10 8 6 6 4 4 2

16-18 14 12 8 8 6 4 4 2 2

18-20 14 12 8 6 6 4 4 2 2

Nameplate Ampere Rating

Fig. D

Read and understand all instructions. Failure to

follow all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS.

1. For your own safety, read the instruction manual before operating

the tool. Learn the tool’s application and limitations as well as the specific

hazards peculiar to it.

2. Keep guards in place and in working order.

3. Always wear eye protection.

Wear safety glasses. Everyday

eyeglasses only have impact resistant lenses; they are not safety

glasses. Also use face or dust mask if cutting operation is dusty. These

safety glasses must conform to ANSI Z87.1 requirements. NOTE:

Approved glasses have Z87 printed or stamped on them.

4. Remove adjusting keys and wrenches. Form habit of checking to see

that keys and adjusting wrenches are removed from tool before turning it

“on”.

5. Keep work area clean. Cluttered areas and benches invite accidents.

6. Don’t use in dangerous environment. Don’t use power tools in damp

or wet locations, or expose them to rain. Keep work area well-lighted.

7. Keep children and visitors away. All children and visitors should be

kept a safe distance from work area.

8. Make workshop childproof – with padlocks, master switches, or by

removing starter keys.

9. Don’t force tool. It will do the job better and be safer at the rate for

which it was designed.

10. Use the right tool. Don’t force tool or attachment to do a job for which

it was not designed.

4

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known (to the State of California) to

cause cancer, birth defects or other reproductive harm. Some example of these chemicals are:

●●

lead from lead-based paints

●●

crystalline silica from bricks and cement and other masonry products

●●

arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well ventilated area, and work with

approved safety equipment, always wear MSHA/NIOSH approved, properly fitting face mask or

respirator when using such tools.

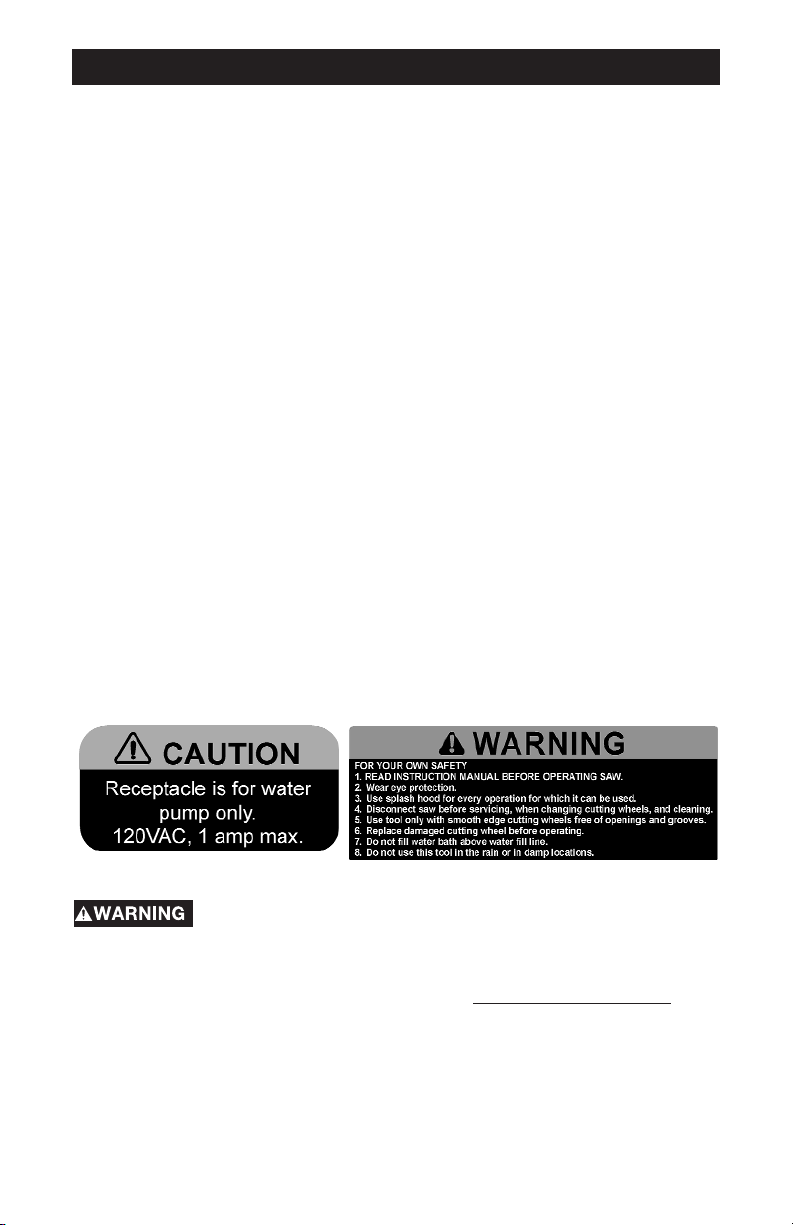

SAFETY GUIDELINES - DEFINITIONS

indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

indicates a potentially hazardous situation which, if not avoided,may result in

minor or moderate injury.

used without the safety alert symbol indicates potentially hazardous situation

which, if not avoided, may result in property damage.

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize

this information, we use the symbols below. Please read the manual and pay attention to these

sections.

IMPORTANT SAFETY INSTRUCTIONS

5

11. Wear proper apparel. No loose clothing, gloves, neckties, rings,

bracelets, or other jewelry to get caught in moving parts. Nonslip footwear

is recommended. Wear protective hair covering to contain long hair.

12. Secure work. Use clamps or a vise to hold work when practical. It’s

safer than using your hand and frees both hands to operate tool.

13. Don’t overreach. Keep proper footing and balance at all times.

14. Maintain tools in top condition. Keep tools sharp and clean for best

and safest performance. Follow instructions for lubricating and changing

accessories.

15. Disconnect tools before servicing and when changing accessories

such as blades, bits, cutters, etc.

16. Use recommended accessories. The use of accessories and

attachments not recommended by Delta may cause hazards or risk of injury

to persons.

17. Reduce the risk of unintentional starting. Make sure switch is in “OFF”

position before plugging in power cord.

In the event of a power failure,

move switch to the “OFF” position.

18. Never stand on tool. Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted.

19. Check damaged parts. Before further use of the tool, a guard or other

part that is damaged should be carefully checked to ensure that it will

operate properly and perform its intended function – check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced.

20. Direction of feed. Feed work into a blade or cutter against the direction

of rotation of the blade or cutter only.

21. Never leave tool running unattended. Turn power off. Don’t leave

tool until it comes to a complete stop.

22.

Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or under

the influence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious personal

injury.

23. Make sure tool is disconnected from power supply while motor is

being mounted, connected or reconnected.

24. The dust generated by certain woods and wood products can be

injurious to your health. Always operate machinery in well ventilated areas

and provide for proper dust removal. Use wood dust collection systems

whenever possible.

25. Wear ear protection to safeguard against possible hearing loss.

6

ADDITIONAL SPECIFIC SAFETY RULES

1. Disconnect saw before servicing, when changing cutting wheels,

and cleaning.

2. Use splash hood for every operation for which it can be used.

3. To avoid the possibility of the appliance plug or receptacle getting

wet, position tile saw to one side of a wall mounted receptacle to prevent

water from dripping onto the receptacle or plug. The user should arrange a

“drip loop” in the cord connecting the saw to a receptacle. The “drip loop”

is that part of the cord below the level of the receptacle, or the connector if

an extension cord is used, to prevent water traveling along the cord and

coming in contact with the receptacle.

4. If the plug or receptacle does get wet, DON’T unplug the cord.

Disconnect the fuse or circuit breaker that supplies power to the tool.

Then unplug and examine for presence of water in the receptacle.

5. When the tool is not in use, the switch should be locked in the

OFF position to prevent unauthorized use of the tool.

6. Make sure your fingers and hands are not in the cutting line of

the blade.

7. Use only continuous wet cut diamond blades rated at 6000

RPMs or greater. Use tool only with smooth edge cutting wheels free of

openings and grooves.

8. Check water level and operation of pump before each use.

9. Replace damaged cutting wheel before operating tile saw.

10. Do not fill water bath above water fill line.

11. Only plug water pump cord into motor receptacle.

12. Ground Fault Circuit Interrupter (GFCI) protection should be

provided on the circuit(s) or outlet(s) to be used for the tile saw.

Improper operation or maintenance of this product could result

in serious injury and property damage. Read and understand all warnings and

operating instructions before using this tool. When using power tools, basic

safety precautions should always be followed to reduce the risk of personal

injury. For additional information visit our website www.porter-cable.com

.

Additional Information regarding the safe and proper operation of power tools

(i.e. a safety video) is available from the Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851 (www.powertoolinstitute.com). Additional

Information is also available from the National Safety Council, 1121 Spring Lake

Drive, Itasca, IL 60143-3201, the American National Standards Institute ANSI

01.1Safety Requirements for Woodworking Machines, and the U.S. Department

of Labor regulations.

Loading...

Loading...