ESPAÑOL: PAGINA 11

FRANÇAISE : PAGE 23

14" “Dry-Cut” Metal

Cutting Saw

Instruction

Manual

Part No. 896182-009

The Model and Serial No. plate is located on the main

housing of the tool. Record these numbers in the

spaces below and retain for future reference.

Model No. _____________________________________

Type __________________________________________

Serial No.______________________________________

IMPORTANT

Please make certain that the person who is to

use this equipment carefully reads and

understands these instructions before starting

operations.

MODEL 1410

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

Copyright © 2000 Porter-Cable Corporation

SAFETY INSTRUCTIONS

GROUNDING INSTRUCTIONS

WARNING: THIS TOOL SHOULD BE

GROUNDED WHILE IN USE TO PROTECT THE

OPERATOR FROM ELECTRIC SHOCK. The tool

is equipped with an approved three-conductor

cord and three-prong grounding type plug to fit

the proper grounding type receptacle. The green

(or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green

and yellow) wire to a live terminal.

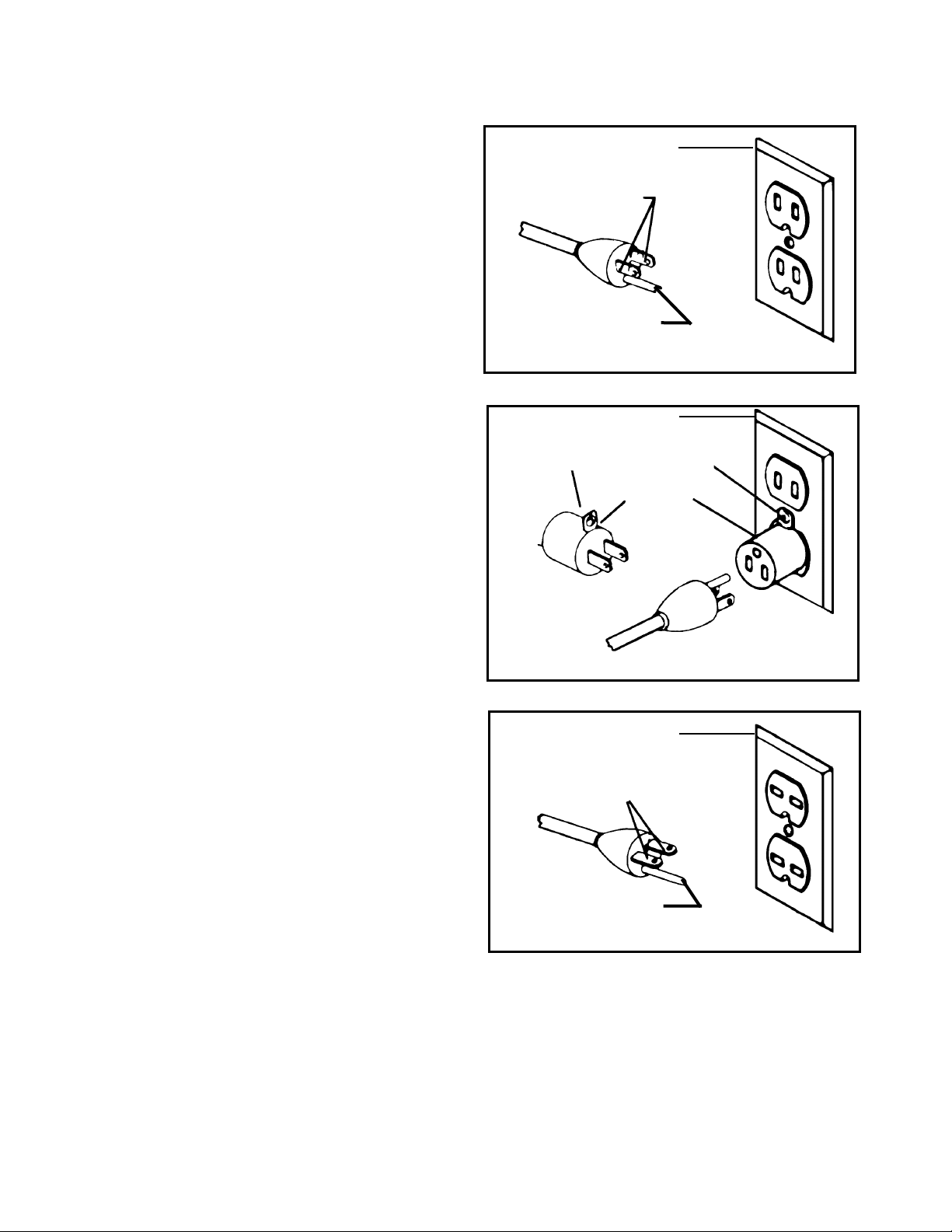

If your unit is for use on less than 150 Volts, the

power cord is equipped with a plug that has two

flat, parallel current-carrying prongs and one

longer, round or “U”-shaped, ground prong which

requires a mating 3-conductor grounded type

receptacle, as shown in Fig. 1.

An adapter, shown in Fig. 2, is available for

connecting 3-prong grounding type plugs that are

used on units less than 150 Volts to 2-prong

receptacles. THIS ADAPTER IS NOT ALLOWED

IN CANADA. The green colored rigid ear, lug, etc.,

must be connected to a permanent ground such

as a properly grounded outlet box, as shown in

Fig. 2.

If your unit is for use on 150 to 250 Volts, the

power cord is equipped with a plug that has two

flat current carrying prongs in tandem, and one

round or “U”-shaped, longer ground prong, as

shown in Fig. 3. This plug is used only with the

proper mating 3-conductor grounding type

receptacle, as shown in Fig. 3. No adapter is

available for this type plug.

WARNING: IN ALL CASES, MAKE SURE THE

RECEPTACLE IN QUESTION IS PROPERLY

GROUNDED.

NEVER REMOVE GROUNDING PRONG FROM

POWER PLUG.

EXTENSION CORDS

Use only three-wire extension cords which have three-prong grounding type plugs and three-pole receptacle

which accept the tool’s plug. Replace damaged or worn cord immediately. DO NOT ATTEMPT TO REPAIR

POWER CORD.

2

Fig. 1

Fig. 2

Fig. 3

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING PRONG IS

LONGEST OF THE 3 PRONGS

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING PRONG IS

LONGEST OF THE 3 PRONGS

GROUNDED OUTLET BOX

GROUNDING MEANS

ADAPTER

3

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electric tools, basic safety precautions should always be followed to reduce

the risk of fire, electric shock and personal injury, including the following:

READ AND FOLLOW ALL INSTRUCTIONS.

There are certain applications for which this tool was designed. Porter-Cable strongly recommends that this tool

NOT be modified and/or used for any application other than for which it was designed. If you have any questions

relative to its application DO NOT use the tool until you have written Porter-Cable and we have advised you.

Technical Service Manager

Porter-Cable Corporation

4825 Highway 45 North,

Jackson, TN 38305

1. FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING THE TOOL. Learn the

tool’s application and limitations as well as the specific hazards peculiar to it.

2. KEEP GUARDS IN PLACE and in working order.

3. GROUND ALL TOOLS. If tool is equipped with three-prong plug, it should be plugged into a three-hole

electrical receptacle. If an adapter is used to accommodate a two-prong receptacle, the adapter plug must be

attached to a known ground. Never remove the third prong.

4. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting

wrenches are removed from tool before turning it “ON”.

5. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

6. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations, or expose

them to rain. Keep work area well-lighted.

7. KEEP CHILDREN AND VISITORS AWAY. All children and visitors should be kept a safe distance from work

area.

8. MAKE WORKSHOP CHILDPROOF – with padlocks, master switches, or by removing starter keys.

9. DON’T FORCE TOOL. It will do the job better and be safer at the rate for which it was designed.

10. USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed.

11. WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or other jewelry to get

caught in moving parts. Nonslip footwear is recommended. Wear protective hair covering to contain long hair.

12. ALWAYS USE SAFETY GLASSES. Wear safety glasses (must comply with ANSI Z87.1). Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses. Also use face or dust mask if cutting

operation is dusty.

13. SECURE WORK. Use clamps or a vise to hold work when practical. It’s safer than using your hand and

frees both hands to operate tool.

14. DON’T OVERREACH. Keep proper footing and balance at all times.

15. MAINTAIN TOOLS IN TOP CONDITION. Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

16. DISCONNECT TOOLS before servicing and when changing accessories such as blades, bits, cutters, etc.

17. USE RECOMMENDED ACCESSORIES. The use of improper accessories may cause hazards.

18. AVOID ACCIDENTAL STARTING. Make sure switch is in “OFF” position before plugging in power cord.

19. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is accidentally

contacted.

20. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should

be carefully checked to ensure that it will operate properly and perform its intended function - check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged should be properly repaired or replaced.

21. DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation of the blade or

cutter only.

22. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don’t leave tool until it comes to a

complete stop.

23. DRUGS, ALCOHOL, MEDICATION. Do not operate tool while under the influence of drugs, alcohol or any

medication.

24. MAKE SURE TOOL IS DISCONNECTED FROM POWER SUPPLY while motor is being mounted,

connected or reconnected.

4

25. WARNING: SOME DUST CREATED BY POWER SANDING, SAWING, GRINDING, DRILLING, AND OTHER

CONSTRUCTION ACTIVITIES contains chemicals known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

•lead from lead-based paints,

•crystalline silica from bricks and cement and other masonry products, and

•arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

SAVE THESE INSTRUCTIONS

ADDITIONAL SAFETY RULES FOR “DRY-CUT” SAWS

1. WARNING: Do not operate your dry-cut saw until it is completely assembled and installed according to the

instructions.

2. IF YOU ARE NOT thoroughly familiar with the operation of “dry-cut” metal cutting machines, obtain advice

from your supervisor, instructor or other qualified person.

3. WEAR SAFETY GOGGLES, HEARING PROTECTION, face shield, respirator, body apron, head covering,

safety shoes, and long tight-fitting sleeves.

4. USE ONLY RECOMMENDED carbide tipped metal cutting blades, rated at 1500 RPM or higher.

5. TIGHTEN ARBOR SCREW and all clamps before operating.

6. MAKE SURE spindle lock is disengaged before operating.

7. KEEP HANDS OUT of the path of saw blade.

8. SECURE WORK PIECE PROPERLY. Work should be straight and firmly clamped to avoid possible

movement and pinching as the cut nears completion.

9. PROVIDE ADEQUATE SUPPORT to the sides of the saw table for long workpiece.

10. NEVER CUT ANYTHING FREEHAND.

11. NEVER REACH behind or beneath the blade.

12. MAKE SURE the blade has come to a complete stop before removing or securing workpiece, or changing

workpiece angle.

13. MAKE SURE the inside surfaces of the blade flanges as well as the sides of the blade are free from any

foreign matter.

14. ALWAYS CHECK THE BLADE for cracks or other damage before operation. Replace cracked or damaged

blade immediately.

15. MAKE SURE blade is not contacting workpiece before switch is turned on.

16. ALLOW THE MOTOR to come up to full speed before starting cut.

17. AFTER TURNING MACHINE ON, gently lower the blade to engage workpiece, then slowly increase

pressure as required to produce the least amount of “sparking”.

18. IMPORTANT: After completing the cut, release power switch and wait for coasting blade to stop

completely, before returning saw to the raised position.

19. NEVER OPERATE the machine in an area with flammable solids, liquids or gases. Sparks or hot fragments

could cause a fire or explosion.

20. THIS TOOL is designed for ferrous metals only. DO NOT attempt to cut wood, masonry, aluminum or

magnesium with this tool.

21. SHOULD ANY PART of your machine be missing, damaged or fail in any way, or any electrical component

fail to perform properly, shut-off switch and remove plug from power supply outlet. Replace missing, damaged

or failed parts before resuming operation.

22. NEVER CONFINE THE PIECE BEING CUT OFF. Never hold it, clamp it, touch it, or use length stops

against it while the blade is turning. It must be free to move sideways. If confined, it could wedge against the

blade and be thrown violently.

23. ADDITIONAL INFORMATION regarding the safe and proper operation of this product is available from

the National Safety Council, 444 N. Michigan Avenue, Chicago, IL 60611, in the Accident Prevention Manual

for Industrial Operation and also in the Safety Data Sheets provided by the NSC. Please also refer to the

American National Standard Institute ANSI B11.10 Safety Requirements for the Construction, Care and Use of

Metal Sawing Machines and the U.S. Department of Labor OSHA 1910 Regulations.

REPLACEMENT PARTS

When servicing use only identical replacement parts.

Loading...

Loading...