Porter-Cable 1000003754 User Manual

AIR COMPRESSOR

Maintenance-free pump

Compresor de aire

La pompe sans entretien

Compresseur d’air

La bomba sin mantenimiento

Instruction manual

Manuel d'instructions

Manual de'instrucciones

Française : Page 21

Español: Página 42

www.deltaportercable.com

TO REDUCE THE RISK OF INJURY,

MANUAL BEFORE OPERATING PRODUCT.

DEBE LEER EL MANUAL DE INSTRUCCIONES ANTES

DE OPERAR EL PRODUCTO

BLESSURES, L’UTILISATEUR DOIT LIRE LE MODE

D’EMPLOI AVANT D’UTILISER LE PRODUIT.

USER MUST READ INSTRUCTION

PARA REDUCIR EL RIESGO

DE LESIONES, EL USUARIO

AFIN DE RÉDUIRE LE

RISQUE DE

C2005

SAFETY GUIDELINES - DEFINITIONS

This manual contains information that is important for you to know and understand. This information relates to protecting YOUR SAFETY and PREVENTING

EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these symbols.

Indicates an

imminently hazardous

situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially

hazardous situation

which, if not avoided, could result in

death or serious injury.

which, if not avoided,

minor or moderate injury.

indicates a potentially hazardous

situation which, if not avoided, may

result in property damage.

Indicates a potentially

hazardous situation

may result in

Used without the

safety alert symbol

IMPORTANT SAFETY INSTRUCTIONS

Some dust created by power sanding, sawing, grinding,

known to the State of California to cause cancer, birth defects or other

reproductive harm. Some example of these chemicals are:

• lead from lead-based paints

• crystalline silica from bricks and cement and other masonry products

• arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, al ways wear

OSHA/MSHA/NIOSH approved, properly fit ting face mask or res pi ra tor when

us ing such tools.

When using air tools, basic safety precautions should always be followed to

reduce the risk of personal injury.

other reproductive harm. Wash hands after handling.

operation and maintenance instructions.

drilling, and other construction activities contains chemicals

This product contains chemicals, including lead, known to

the State of California to cause cancer, and birth defects or

Do not operate this unit until you read and

understand this instruction manual for safety,

SAVE THESE INSTRUCTIONS

HAZARD

RISK OF EXPLOSION OR FIRE

WHAT CAN HAPPEN HOW TO PREVENT IT

• It is normal for electrical contacts within the motor and

pressure switch to spark.

• Always operate the compressor in a well ventilated area

free of combustible materials,

gasoline, or solvent vapors.

2 - ENG1000003754

• If electrical sparks from compressor come into contact with

flammable vapors, they may

ignite, causing fire or explosion.

• Restricting any of the compressor ventilation openings

will cause serious overheating and could cause fire.

• Unattended operation of this product could result in personal injury

or property damage. To reduce the

risk of fire, do not allow the compressor to operate unattended.

• If spraying flammable materials, locate compressor at least

20 feet (6.1 m) away from spray

area. An additional length of

air hose may be required.

• Store flammable materials in a secure location

away from compressor.

• Never place objects against

or on top of compressor.

• Operate compressor in an open

area at least 12" (30.5 cm) away

from any wall or obstruction that

would restrict the flow of fresh

air to the ventilation openings.

• Operate compressor in a

clean, dry well ventilated area.

Do not operate unit indoors

or in any confined area.

• Always remain in attendance with

the product when it is operating.

• Always turn off and unplug

unit when not in use.

HAZARD

RISK TO BREATHING (ASPHYXIATION)

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air directly from

your compressor is not safe

for breathing. The air stream

may contain carbon monoxide,

toxic vapors, or solid particles

from the air tank. Breathing

these contaminant's can cause

serious injury or death.

• Sprayed materials such as

paint, paint solvents, paint

remover, insecticides, weed

killers, may contain harmful vapors and poisons.

• Air obtained directly from the

compressor should never be

used to supply air for human

consumption. In order to use air

produced by this compressor

for breathing, suitable filters and

in-line safety equipment must be

properly installed. In-line filters and

safety equipment used in conjunction with the compressor must

be capable of treating air to all

applicable local and federal codes

prior to human consumption.

• Work in an area with good cross

ventilation. Read and follow the

safety instructions provided on

the label or safety data sheets

for the materials you are spraying. Always use certified safety

equipment: OSHA/MSHA/NIOSH

respiratory protection designed for

use with your specific application.

3 - ENG 1000003754

HAZARD

RISK OF BURSTING

Air Tank: The air tank on your Air Compressor is designed and may be UM

coded [for units with air tanks greater than 6" (152 mm)] according to ASME

Section VIII, Div. 1 rules. All pressure vessels should be inspected once

every two years. To find your state pressure vessels inspector, look under the

Division of Labor and Industries in the government section of a phone book .

The following conditions could lead to a weakening of the

air tank, and result in a violent air tank explosion:

WHAT CAN HAPPEN HOW TO PREVENT IT

• Failure to properly drain

condensed water from air

tank, causing rust and thinning of the steel air tank.

• Modifications or attempted

repairs to the air tank.

• Unauthorized modifications to the safety valve or

any other components which

control air tank pressure.

Attachments & accessories:

• Exceeding the pressure rating of air tools, spray guns, air

operated accessories, tires,

and other inflatables can cause

them to explode or fly apart, and

could result in serious injury.

Tires

• Over inflation of tires could result in

serious injury and property damage.

• Drain air tank daily or after

each use. If air tank develops

a leak, replace it immediately

with a new air tank or replace

the entire compressor.

• Never drill into, weld, or make any

modifications to the air tank or its

attachments. Never attempt to

repair a damaged or leaking air

tank. Replace with a new air tank.

• The air tank is designed to withstand specific operating pressures. Never make adjustments

or parts substitutions to alter the

factory set operating pressures.

• Follow the equipment manufacturers recommendation and never

exceed the maximum allowable pressure rating of attachments. Never use compressor

to inflate small low pressure

objects such as children’s toys,

footballs, basketballs, etc.

• Use a tire pressure gauge to check

the tires pressure before each use

and while inflating tires; see the tire

sidewall for the correct tire pressure.

NOTE: Air tanks, compressors and

similar equipment used to inflate tires

can fill small tires similar to these very

rapidly. Adjust pressure regulator on

air supply to no more than the rating

of the tire pressure. Add air in small

increments and frequently use the

tire gauge to prevent over inflation.

4 - ENG1000003754

HAZARD

RISK OF ELECTRICAL SHOCK

WHAT CAN HAPPEN HOW TO PREVENT IT

• Your air compressor is powered by electricity. Like any

other electrically powered

device, If it is not used properly

it may cause electric shock.

• Repairs attempted by unqualified

personnel can result in serious

injury or death by electrocution.

• Electrical Grounding: Failure

to provide adequate grounding

to this product could result in

serious injury or death from

electrocution. Refer to "Grounding

Instructions" paragraph in

the "Installation" section.

• Never operate the compressor outdoors when it is raining or in wet conditions.

• Never operate compressor with protective covers

removed or damaged.

• Any electrical wiring or repairs

required on this product should be

performed by authorized service

center personnel in accordance with

national and local electrical codes.

• Make certain that the electrical

circuit to which the compressor

is connected provides proper

electrical grounding, correct voltage

and adequate fuse protection.

HAZARD

RISK FROM FLYING OBJECTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• The compressed air stream can

cause soft tissue damage to

exposed skin and can propel dirt,

chips, loose particles, and small

objects at high speed, resulting in

property damage or personal injury.

• Always wear certified safety equipment: ANSI Z87.1 eye protection

(CAN/CSA Z94.3) with side shields

when using the compressor.

• Never point any nozzle or sprayer

toward any part of the body or

at other people or animals.

• Always turn the compressor

off and bleed pressure from

the air hose and air tank before

attempting maintenance, attaching tools or accessories.

5 - ENG 1000003754

HAZARD

RISK OF HOT SURFACES

WHAT CAN HAPPEN HOW TO PREVENT IT

• Touching exposed metal such

as the compressor head, engine

head, engine exhaust or outlet

tubes, can result in serious burns.

• Never touch any exposed metal

parts on compressor during or

immediately after operation.

Compressor will remain hot for

several minutes after operation.

• Do not reach around protective

shrouds or attempt maintenance

until unit has been allowed to cool.

HAZARD

RISK FROM MOVING PARTS

WHAT CAN HAPPEN HOW TO PREVENT IT

• Moving parts such as the pulley,

flywheel, and belt can cause

serious injury if they come into

contact with you or your clothing.

• Attempting to operate compressor

with damaged or missing parts or

attempting to repair compressor

with protective shrouds removed

can expose you to moving parts

and can result in serious injury.

• Never operate the compressor

with guards or covers which

are damaged or removed.

• Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

• Air vents may cover moving parts

and should be avoided as well.

• Any repairs required on this product

should be performed by authorized

service center personnel.

6 - ENG1000003754

HAZARD

RISK OF UNSAFE OPERATION

WHAT CAN HAPPEN HOW TO PREVENT IT

• Unsafe op er a tion of your air

compressor could lead to se ri ous

in ju ry or death to you or others.

• Review and understand all

instructions and warnings

in this manual.

• Be come fa mil iar with the op eration

and con trols of the air compressor.

• Keep operating area clear of all

persons, pets, and obstacles.

• Keep chil dren away from the

air compressor at all times.

• Do not operate the product

when fatigued or under the

influence of alcohol or drugs.

Stay alert at all times.

• Never defeat the safety features of this prod uct.

• Equip area of operation

with a fire extinguisher.

• Do not op er ate machine

with missing, broken, or

un au tho rized parts.

HAZARD

RISK OF FALLING

WHAT CAN HAPPEN HOW TO PREVENT IT

• A portable compressor can

fall from a table, workbench,

or roof causing damage to

the compressor and could

result in serious injury or

death to the operator.

RISK FROM NOISE

WHAT CAN HAPPEN HOW TO PREVENT IT

• Under some conditions

and duration of use, noise

from this product may

contribute to hearing loss.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

• Always operate compressor in a

stable secure position to prevent

accidental movement of the

unit. Never operate compressor

on a roof or other elevated

position. Use additional air

hose to reach high locations.

HAZARD

• Always wear certified safety

equipment: ANSI S12.6

(S3.19) hearing protection.

7 - ENG 1000003754

SPECIFICATIONS

Model No. C2005

Bore 1.875"

Stroke 1.250"

Voltage/Hz-Single Phase 120/60

Minimum Branch Circuit Requirement 15 amps

Fuse Type Time Delay

Air Tank Capacity (Gallon) 6

Approximate Cut-in Pressure 120 PSIG

Approximate Cut-out Pressure 150 PSIG

SCFM @ 40 PSIG *3.7

SCFM @ 90 PSIG *2.6

*Tested per ISO 1217

Refer to Glossary for abbreviations.

GLOSSARY

Become familiar with these terms before operating the unit.

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure of air delivery.

PSIG: Pounds per square inch gauge; a unit of measure of pressure.

Code Certification: Products that bear one or more of the following marks: UL,

CUL, ETL, CETL, have been evaluated by OSHA certified independent safety laboratories and meet the applicable Standards for Safety.

Cut-In Pressure: While the motor is off, air tank pressure drops as you continue

to use your accessory. When the tank pressure drops to a certain lower level the

motor will restart automatically. The low pressure at which the motor automatically

restarts is called "cut-in" pressure.

Cut-Out Pressure: When an air compressor is turned on and begins to run, air

pressure in the air tank begins to build. It builds to a certain high pressure before

the motor automatically shuts off, protecting your air tank from pressure higher

than its capacity. The high pressure at which the motor shuts off is called "cutout" pressure.

Branch Circuit: Circuit carrying electricity from electrical panel to outlet.

DUTY CYCLE

This air compressor pump is capable of running continuously. However, to

prolong the life of your air compressor, it is recommended that a 50%-75%

average duty cycle be maintained; that is, the air compressor pump should not

run more than 30-45 minutes in any given hour.

ACCESSORIES

Accessories for this unit are available at the store the unit was purchased.

8 - ENG1000003754

ASSEMBLY

Unpacking

1. Remove unit from carton and discard all packaging.

INSTALLATION

HOW TO SET UP YOUR UNIT

Location of the Air Compressor

• Locate the air compressor in a clean, dry and well ventilated area.

• The air compressor should be located at least 12" (30.5 cm) away from the

wall or other obstructions that will interfere with the flow of air.

• The air compressor pump and shroud are designed to allow for proper cooling.

The ventilation openings on the compressor are necessary to maintain proper

operating temperature. Do not place rags or other containers on or near these

openings.

GROUNDING INSTRUCTIONS

ing reduces the risk of shock by providing an escape wire for the electric current. This air compressor must be properly grounded.

The portable air compressor is equipped with a cord having a grounding wire with

an appropriate grounding plug (see following illustrations).

1. The cord set and plug with this unit contains a grounding pin. This plug

MUST be used with a grounded outlet.

IMPORTANT: The outlet being used must

be installed and grounded in accordance

with all local codes and ordinances.

2. Make sure the outlet being used has

the same configuration as the grounded plug. DO NOT USE AN ADAPTER.

See illustration.

3. Inspect the plug and cord before each

use. Do not use if there are signs of damage.

4. If these grounding instructions are not completely understood, or if in doubt as

to whether the compressor is properly grounded, have the installation checked

by a qualified electrician.

RESULT IN ELECTRICAL SHOCK.

Do not modify the plug provided. If it does not fit the available outlet, a correct

outlet should be installed by a qualified electrician.

Repairs to the cord set or plug MUST be made by a qualified electrician.

Risk of Electrical Shock. In the event of a short circuit, ground-

Plug

Grounded

Outlets

Grounding Pin

Risk of Electrical Shock. IMPROPER GROUNDING CAN

9 - ENG 1000003754

EXTENSION CORDS

If an extension cord must be used, be sure it is:

• a 3-wire extension cord that has a 3-blade grounding plug, and a 3-slot receptacle that will accept the plug on the product

• in good condition

• no longer than 50 feet

• 14 gauge (AWG) or larger. (Wire size increases as gauge number decreases.

12 AWG and 10 AWG may also be used. DO NOT USE 16 OR 18 AWG.)

drop resulting in power loss to the motor and overheating. Instead of using

an extension cord, increase the working reach of the air hose by attaching another length of hose to its end. Attach additional lengths of hose as

needed.

The use of an undersized extension cord will cause voltage to

VOLTAGE AND CIRCUIT PROTECTION

Refer to the specification chart for the voltage and minimum branch circuit requirements.

a 15 amp circuit if the following conditions are met.

1. Voltage supply to circuit must comply with the National Electrical Code.

2. Circuit is not used to supply any other electrical needs.

3. Extension cords comply with specifications.

4. Circuit is equipped with a 15 amp circuit breaker or 15 amp time delay fuse.

NOTE: If compressor is connected to a circuit protected by fuses, use only

time delay fuses. Time delay fuses should be marked "D" in Canada and "T"

in the US.

If any of the above conditions cannot be met, or if operation of the compressor

repeatedly causes interruption of the power, it may be necessary to operate it from

a 20 amp circuit. It is not necessary to change the cord set.

Risk of Opertion.Certain air compressors can be operated on

10 - ENG1000003754

OPERATION

KNOW YOUR AIR COMPRESSOR

READ THIS OWNER’S MANUAL AND SAFETY RULES BEFORE OPERATING

YOUR UNIT. Compare the illustrations with your unit to familiarize yourself with

the location of various controls and adjustments. Save this manual for future

reference.

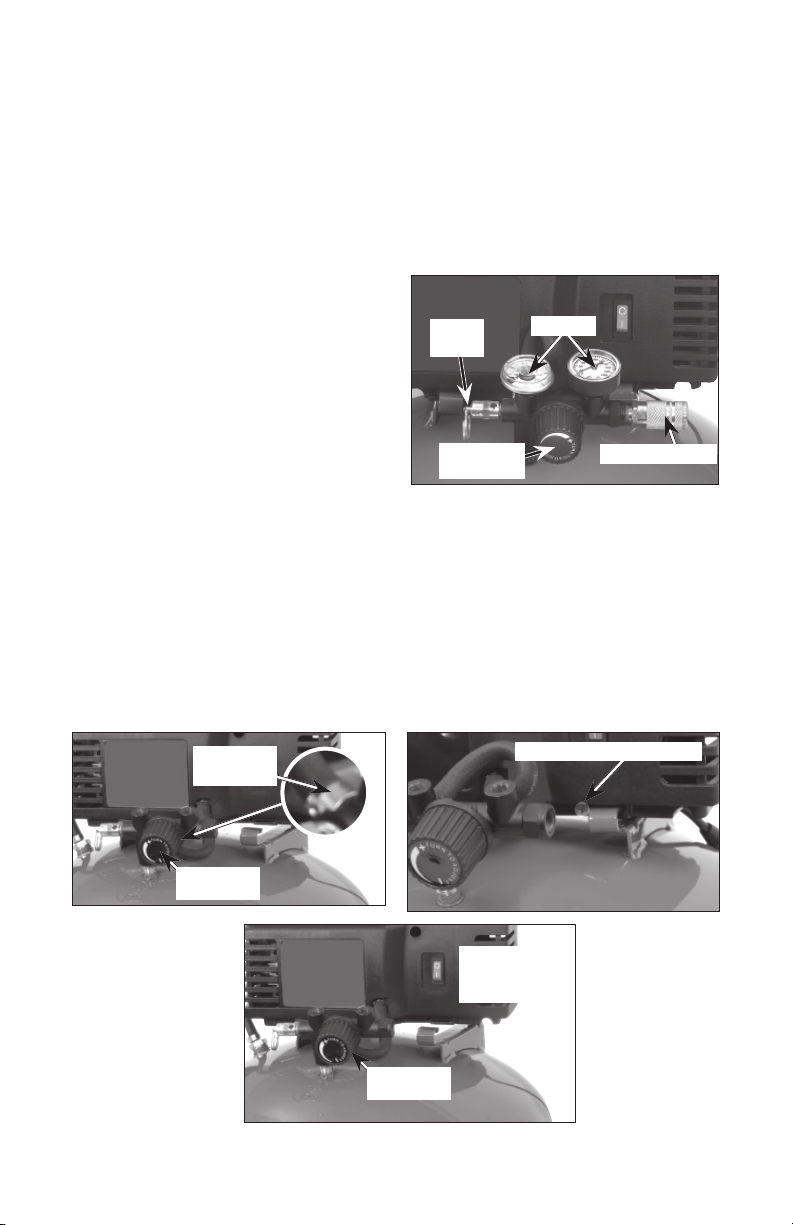

On(I)/Off(O) Switch

Tank

Pressure

Gauge

Safety

Valve

Regulator

Outlet

Pressure

Gauge

Quick

Connect

DESCRIPTION OF OPERATION

Become familiar with these controls before operating the unit.

On(I)/Off(O) Switch: Place this switch in the On (I) position to provide automatic

power to the pressure switch and Off (O) to remove power at the end of each

use.

Pressure Switch (not shown): The pressure switch automatically starts the

motor when the air tank pressure drops below the factory set "cut-in" pressure.

It stops the motor when the air tank pressure reaches the factory set "cut-out"

pressure.

Safety Valve: If the pressure switch does not shut off the air compressor at its

"cut-out" pressure setting, the safety valve will protect against high pressure by

"popping out" at its factory set pressure (slightly higher than the pressure switch

"cut-out" setting).

Tank Pressure Gauge: The tank pressure gauge indicates the reserve air pressure in the tank.

Outlet Pressure Gauge: The outlet pressure gauge indicates the air pressure

available at the outlet side of the regulator. This pressure is controlled by the

regulator and is always less than or equal to the tank pressure.

Regulator: Controls the air pressure shown on the outlet pressure gauge. Turn

regulator knob clockwise to increase pressure and counterclockwise to decrease

pressure.

Cooling System (not shown): This compressor contains an advanced design

cooling system. At the heart of this cooling system is an engineered fan. It is

perfectly normal for this fan to blow air through the vent holes in large amounts.

11 - ENG 1000003754

You know that the cooling system is working when air is being expelled.

Air Compressor Pump (not shown): Compresses air into the air tank. Working

air is not available until the compressor has raised the air tank pressure above that

required at the air outlet.

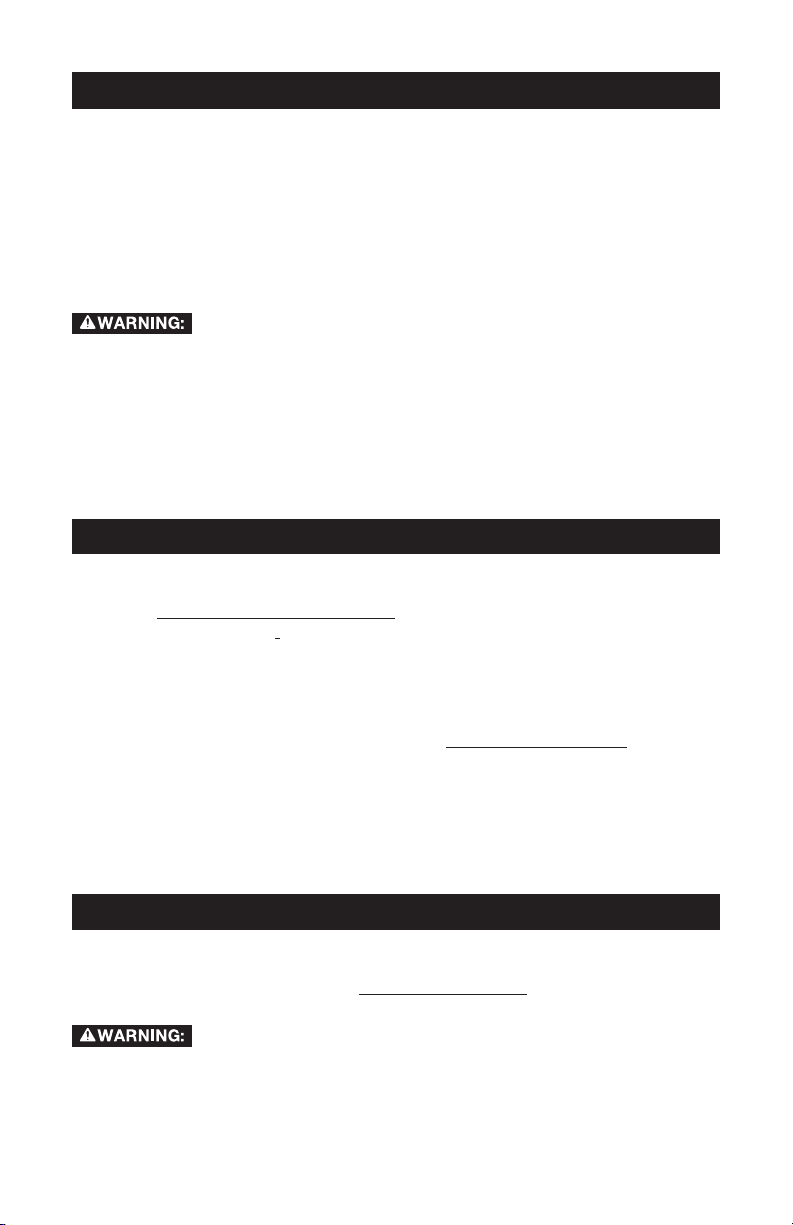

Drain Valve: The drain valve is located at the base of the

air tank and is used to drain condensation at the end of

each use.

Check Valve: When the air compressor is operating, the

check valve is "open", allowing compressed air to enter

Drain

Valve

the air tank. When the air compressor reaches "cut-out"

pressure, the check valve "closes", allowing air

pressure to remain inside the air tank.

Motor Overload Protector (not shown): The

motor has an automatic reset thermal overload

Check Valve

protector. If the motor overheats for any reason,

the overload protector will shut off the motor.

The motor must be allowed to cool down before

restarting. The compressor will automatically

restart after the motor cools.

HOW TO USE YOUR UNIT

How to Stop

1. Set the On/Off switch to "Off".

Before Starting

instruction manual for safety, operation and maintenance instructions.

Break-in Procedure

following break-in instructions are not closely followed.

This procedure is required before the air compressor is put into service and when

the check valve or a complete compressor pump has been replaced.

1. Make sure the On/Off switch is in the "Off" position.

Plug the power cord into the correct branch circuit receptacle.

2.

and Circuit Protection paragraph in the Installation section of this manual.)

3. Open the drain valve (counter-clockwise) fully to permit air to escape and prevent air pressure build up in the air tank during the break-in period.

4. Move the On/Off switch to "On" position. The compressor will start.

5. Run the compressor for 15 minutes. Make sure the drain valve is open and

there is minimal air pressure build-up in tank.

6. After 15 minutes, close the drain valve by turning clockwise. The air receiver

will fill to "cut-out" pressure and the motor will stop.

The compressor is now ready for use.

Before Each Start-Up

1. Set the On/Off switch to "Off".

2. Turn the regulator knob counter-clockwise to set the outlet pressure to zero.

3. Attach hose and accessories.

installing or disconnecting to prevent hose whip.

Do not operate this unit until you read and understand this

Risk of Unsafe Operation. Serious damage may result if the

(Refer to Voltage

Risk of unsafe operation. Firmly grasp air hose in hand when

Risk of unsafe operation. Do not use damaged or worn

12 - ENG1000003754

accessories.

NOTE: The hose or accessory will require a quick connect plug if the air outlet is

equipped with a quick connect socket.

risk of bursting. Check the manufacturer’s maximum pressure rating for air

tools and accessories. The regulator outlet pressure must never exceed the

maximum pressure rating.

Risk of Bursting. Too much air pressure causes a hazardous

contain wa ter condensation and oil mist. Do not spray un fil tered air at an

item that could be damaged by moisture. Some air tools and accessories may

require filtered air. Read the in struc tions for the air tools and accessories.

How to Start

1.

Set the On/Off switch to "On" and allow tank pressure to build. Motor will stop

when tank pressure reaches "cut-out" pressure.

2. Turn regulator knob clockwise to increase pressure and stop when desired

pressure is reached.

immediately and have it checked by a trained service technician.

The compressor is ready for use.

Risk of unsafe operation. Compressed air from the unit may

If any unusual noise or vibration is noticed, stop the compressor

MAINTENANCE

CUSTOMER RESPONSIBILITIES

Before

each use

Check Safety Valve

Drain Tank

Unit cycles automatically when power is on. When performing

maintenance, you may be exposed to voltage sources, compressed air, or

moving parts. Personal injuries can occur. Before performing any maintenance

or repair, disconnect power source from the compressor and bleed off all air

pressure.

NOTE: See Operation section for the location of controls.

X

TO CHECK SAFETY VALVE

over-pressurization may occur, causing air tank rupture or an explosion.

equipment: ANSI Z87.1 eye protection (CAN/CSA Z94.3) with side shields.

1. Before starting compressor, pull the ring on the safety valve to make sure

that the safety valve operates freely. If the valve is stuck or does not operate

smoothly, it must be replaced with the same type of valve.

Risk of Bursting. If the safety valve does not work properly,

Risk from Flying Objects. Always wear certified safety

Daily

or after

each

use

X

13 - ENG 1000003754

NOTE: See Operation section for the location of controls.

TO DRAIN TANK

high pressure air. Keep face and other body parts away from outlet of drain.

Use ANSI Z87.1 eye protection (CAN/CSA Z94.3) when draining as debris

can be kicked up into face. Use ear protection [(ANSI S12.6 (S3.19) hearing

protection] as air flow noise is loud when draining.

1. Set the On/Off switch to "Off".

2. Turn the regulator knob counter-clockwise to set the outlet pressure to zero.

3. Remove the air tool or accessory.

4. Pull ring on safety valve allowing air to bleed from the tank until tank pressure

is approximately 20 PSI. Release safety valve ring.

5. Drain water from air tank by opening drain valve on bottom of tank.

drained, water will corrode and weaken the air tank causing a risk of air tank

rupture.

tain oil and rust which can cause stains.

6. After the water has been drained, close the drain valve. The air compressor

can now be stored.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be

removed, cleaned, the reinstalled.

Risk of Unsafe Operation. Risk from noise. Air tanks contain

Risk of Bursting. Water will condense in the air tank. If not

Risk of Property Damage. Drain water from air tank may con-

SERVICE AND ADJUSTMENTS

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE

PERFORMED BY TRAINED SERVICE TECHNICIAN.

power is on. When servicing, you may be exposed to voltage sources,

compressed air, or moving parts. Before servicing unit unplug or disconnect

electrical supply to the air compressor, bleed tank of pressure, and allow the

air compressor to cool.

TO REPLACE OR CLEAN CHECK VALVE

1. Release all air pressure from air tank. See "To Drain Tank" in the Maintenance

section.

2. Unplug unit.

3. Remove the hose by removing the

hose clamp. NOTE: The hose clamp

is not reusable. You must purchase a

new hose clamp, see the Parts List or

purchase a standard hose clamp at a

local hardware store.

4. Unscrew the check valve (turn coun-

ter-clockwise) using a socket wrench.

5. Make sure the valve disc moves freely

inside the check valve and the spring

holds the disc in the upper, closed

position. The check valve may be

cleaned with a solvent, such as paint and varnish remover.

6. Apply sealant to the check valve threads. Reinstall the check valve (turn clock-

Risk of Unsafe Operation. Unit cycles automatically when

Hose Clamp

Check Valve

14 - ENG1000003754

wise).

7. Replace hose and new hose clamp.

8. Perform the Break-in Procedure. See "Break-in Procedure" in the Operation

section.

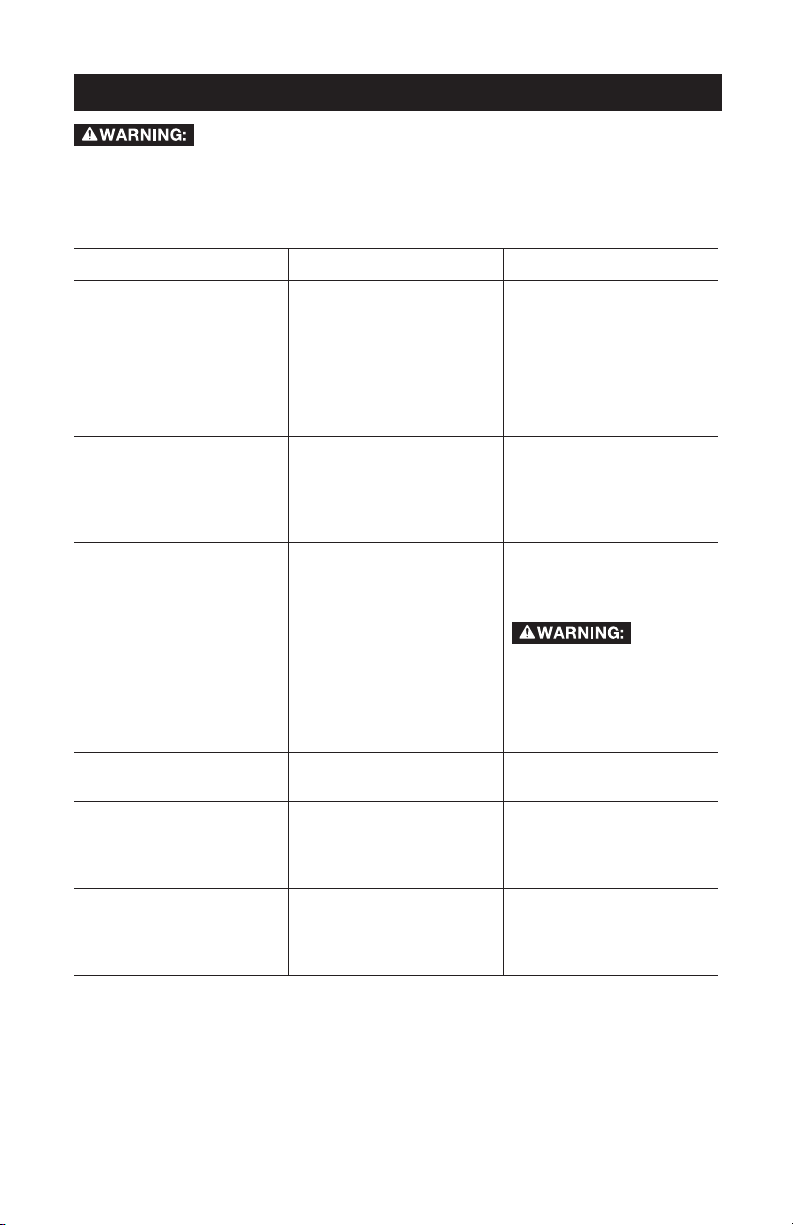

TO REPLACE REGULATOR

1. Release all air pressure from air tank. See "To Drain Tank" in the Maintenance

section.

2. Unplug unit.

3. Using an adjustable wrench remove

the gauges, quick connect, and

safety valve from the regulator

manifold.

Safety

Valve

4. Remove the hose by removing the

hose clamp. NOTE: The hose clamp

is not reusable. You must purchase a

new hose clamp, see the Parts List

Manual or purchase a standard hose

clamp at a local hardware store.

Regulator

Manifold

5. Remove pump mounting screws securing pump (one on each side).

6. Carefully slide pump from brackets and out of the way.

7. Using an adjustable wrench remove the regulator manifold.

8. Apply pipe sealant to new regulator manifold and assemble, tighten with

wrench.

9. Reapply pipe sealant to gauges, quick connect, and safety valve.

10. Reassemble all components in reverse order of removal. Make sure to orient

gauges to read correctly and use wrenches to tighten all components.

Gauges

Quick Connect

Hose

Clamp

Regulator

Manifold

Pump Mounting Screw

Pump shown

moved out of

the way

Regulator

Manifold

15 - ENG 1000003754

STORAGE

Before you store the air compressor, make sure you do the following:

1. Review the Maintenance section on the preceding pages and perform sched-

uled maintenance as necessary.

2. Set the On/Off switch to "Off" and unplug unit.

3. Turn the regulator counterclockwise and set the outlet pressure to zero.

4. Remove the air tool or accessory.

5. Pull ring on safety valve allowing air to bleed from the tank until tank pressure

is approximately 20 PSI. Release safety valve ring.

6. Drain water from air tank by opening drain valve on bottom of tank.

drained, water will corrode and weaken the air tank causing a risk of air tank

rupture.

7. After the water has been drained, close drain valve by turning clockwise.

If drain valve is plugged, release all air pressure. The valve can then be

NOTE:

removed, cleaned, then reinstalled.

Protect the electrical cord and air hose from damage (such as being stepped

8.

on or run over). Wind them loosely around the compressor handle.

9. Store the air compressor in a clean and dry location.

Risk of Bursting. Water will condense in the air tank. If not

SERVICE

REPLACEMENT PARTS

Use only identical replacement parts. For a parts list or to order parts, visit our

website at servicenet.porter-cable.com. You can also order parts from your nearest factory-owned branch, or by calling our Customer Care Center at 1-888-8485175 to receive personalized support from highly-trained technicians.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For

information about Porter-Cable, its factory-owned branches, or an Authorized

Warranty Service Center, visit our website at deltaportercable.com or call our

Customer Care Center at (888)-848-5175. All repairs made by our service centers are fully guaranteed against defective material and workmanship. We cannot

guarantee repairs made or attempted by others.

You can also write to us for information at PORTER-CABLE, 4825 Highway 45

North, Jackson, Tennessee 38305 - Attention: Product Service. Be sure to include

all of the information shown on the nameplate of your tool (model number, type,

serial number, etc.).

ACCESSORIES

A complete line of accessories is available from your Porter-Cable•Delta Supplier,

Porter-Cable•Delta Factory Service Centers, and Porter-Cable Authorized Service

Stations. Please visit our Web Site deltaportercable.com for a catalog or for the

name of your nearest supplier.

have not been tested with this product, use of such accessories could be hazardous.

For safest operation, only Porter-Cable•Delta recommended accessories should be

used with this product.

Since accessories other than those offered by Porter-Cable•Delta

16 - ENG1000003754

TROUBLESHOOTING

power is on. When servicing, you may be exposed to voltage sources, compressed air, or moving parts. Before servicing unit unplug or disconnect

electrical supply to the air compressor, bleed tank of pressure, and allow the

air compressor to cool.

Risk of Unsafe Operation. Unit cycles automatically when

PROBLEM CAUSE CORRECTION

Excessive tank pressure

- safety valve pops off.

Air leaks at fittings. Tube fittings are not

Air leaks in air tank or at

air tank welds.

Air leaks between head

and valve plate.

Air leak from safety

valve.

Knocking Noise. Possible defect in

Pressure switch does

not shut off motor when

compressor reaches

"cut-out" pressure.

Pressure switch "cutout" too high.

tight enough.

Defective air tank. Air tank must be

Leaking seal. Contact a Trained

Possible defect in

safety valve.

safety valve.

Move On/Off lever to

the "Off" position, if

the outfit does not shut

off contact a Trained

Service Technician.

Contact a Trained

Service Technician.

Tighten fittings where air

can be heard escaping.

Check fittings with

soapy water solution.

Do Not Overtighten.

replaced. Do not repair

the leak.

Risk

bursting. Do not drill

into, weld or otherwise

modify air tank or it will

weaken. The tank can

rupture or explode.

Service Technician.

Operate safety valve

manually by pulling on

ring. If valve still leaks,

it should be replaced.

Operate safety valve

manually by pulling on

ring. If valve still leaks,

it should be replaced.

17 - ENG 1000003754

PROBLEM CAUSE CORRECTION

Pressure reading on

the regulated pressure

gauge drops when an

accessory is used.

Compressor is not

supplying enough air to

operate accessories.

Regulator knob has

continuous air leak.

Regulator will not

shut off air outlet.

It is normal for "some"

pressure drop to occur.

If there is an excessive

amount of pressure drop

when the accessory

is used, adjust the

regulator following

the instructions in

the "Description of

Operation" paragraph in

the Operation Section.

NOTE: Adjust the

regulated pressure

under flow conditions

(while accessory

is being used).

Prolonged excessive

use of air.

Compressor is not

large enough for

air requirement.

Decrease amount

of air usage.

Check the accessory

air requirement. If

it is higher than the

SCFM or pressure

supplied by your air

compressor, you need

a larger compressor.

Hole in hose. Check and replace

if required.

Check valve restricted. Remove and clean,

or replace.

Air leaks. Tighten fittings.

Damaged regulator. Replace.

Damaged regulator. Replace.

18 - ENG1000003754

PROBLEM CAUSE CORRECTION

Motor will not run. Fuse blown, circuit

breaker tripped.

Extension cord is wrong

length or gauge.

Loose electrical

connections.

Faulty motor. Have checked by

Motor overload protection

switch has tripped

Check fuse box

for blown fuse and

replace as necessary.

Reset circuit breaker.

Do not use a fuse or

circuit breaker with

higher rating than

that specified for your

particular branch circuit.

Check for proper

fuse. You should use

a time delay fuse.

Check for low

voltage problem.

Check the

extension cord.

Disconnect the other

electrical appliances

from circuit or operate

the compressor on its

own branch circuit.

Check the

extension cord.

Check wiring connection

inside terminal box.

a Trained Service

Technician.

Refer to "Motor Overload

Protection" under

Operation. If motor

overload protection

trips frequently,

contact a Trained

Service Technician

19 - ENG 1000003754

FULL ONE YEAR WARRANTY

H

PORTER-CABLE industrial tools are warranted for one year from date of purchase.

We will repair, without charge, any defects due to faulty materials or workmanship.

For warranty repair information, call (888)-848-5175. This warranty does not apply

to accessories or damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may have other rights

which vary in certain states or provinces.

LATIN AMERICA: This warranty does not apply to products sold in Latin America.

For products sold in Latin America, see country specific warranty information

contained either in the packaging, call the local company or see website for

warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible

or are missing, call (888)-848-5175 for a free replacement.

INCORRECT USE CAN CAUSE HAZARDS. FOLLOW THESE INSTRUCTIONS:

RISK OF BURSTING. MAKE SURE THE COMPRESSOR OUTLET PRES-

SURE IS SET LOWER THAN THE MAXIMUM OPERATING PRESSURE OF

THE SPRAY GUN OR TOOL. BEFORE STARTING THE COMPRESSOR,

PULL THE RING ON THE SAFETY VALVE TO MAKE SURE THE VALVE

MOVES FREELY. DRAIN WATER FROM TANK AFTER EACH USE.

RISK OF FIRE OR EXPLOSION. DO NOT SPRAY A FLAMMABLE OR

COMBUSTIBLE LIQUID OR PAINT NEAR SPARKS, FLAMES, PILOT LIGHTS, OR IN

A CONFINED AREA. THE SPRAY AREA MUST BE WELL VENTILATED. KEEP

COMPRESSOR AT LEAST 20 FEET AWAY FROM SPRAY AREA. DO NOT CARRY

AND OPERATE THE COMPRESSOR, OR ANY OTHER ELECTRICAL DEVICE NEAR

THE SPRAY AREA. NEVER SMOKE WHEN SPRAYING. USE A MINIMUM OF 25

FEET OF HOSE TO CONNECT A SPRAY GUN TO THE COMPRES SOR.

RISK OF PERSONAL INJURY. NEVER SPRAY COMPRESSED AIR OR

MATERIAL AT THE BODY.

RISK OF ELECTRICAL SHOCK. DO NOT EXPOSE TO RAIN. STORE INDOORS.

READ OWNER'S MANUAL FOR COMPLETE SAFETY, OPERATION, AND

REPAIR INSTRUCTIONS.

WARNI NG

WARNING

HOT SURFACE. RISK OF

BURNS. DO NOT TOUCH.

ADVERTENCIA

SUPERFICIE CALIENTE.

RIESGO DE QUEMADURAS.

NO TOCAR.

AVERTISSEMENT

SURFACE TRÈS CHAUDE.

RISQUES DE BRÛLURES.

NE PAS TOUCHER.

LA-2921

LA-2828

EL USO INDEBIDO PUEDE GENERAR RIESGOS.

SEGUIR ESTAS INSTRUCCIONES:

RIESGO DE ESTALLIDO. ASEGÚRESE QUE LA VÁLVULA

DE SALIDA DEL COMPRESOR ESTE REGULADA POR

DEBAJO DEL MÁXIMO DE LA PRESIÓN DE OPERACIÓN

DE LA PISTOLA ROCIADORA O HERRAMIENTA. ANTES

DE ARRANCAR EL COMPRESOR, TIRAR DEL ANILLO EN

LA VÁLBULA DE SEGURIDAD PARA ASEGURARSE QUE

LA VÁLVULA SE MUEVE LIBREMENTE. DRENAR EL AGUA

DEL TANQUE DESPUÉS DE CADA USO.

RIESGO DE FUEGO O EXPLOSIÓN. NO ROCIAR

LÍQUIDO NI PINTURAS INFLAMABLES O

COMBUSTIBLES CERCA DE CHISPAS, LLAMAS, LLAMAS

DE PILOTO O EN ÁREAS CERRADAS. EL ÂREA DE

TRABAJO DEBE ESTAR BIEN VENTILADA. MANTENER EL

COMPRESOR ALEJADO POR LO MENOS 20 PIES DEL

AREA DE PINTURA. NO LLEVAR NI OPERAR EL

COMPRESOR NI DISPOSITIVO ELÉCTRICO ALGUNO

CERCA DEL AREA DEL ROCIADO. NUNCA FUME EN EL

ÁREA DEL ROCIADO. USAR UNA MANGUERE DE UN

MÍNIMO DE 25" PARA CONECTAR LA PISTOLA AL

COMPRESOR.

RIESGO DE DAÑOS PERSONALES. NUNCA DISPARE

AIRE COMPRIMIDO MI MATERIAL AL CUERPO.

RIESGO DE CHOQUE ELÉCTRICO. NO EXPONER A

LLUVIA. ALMACENAR EN INTERIORES.

PARA SEGURIDAD COMPLETA, OPERACIÓN E

INSTRUCCIONES PARA REPARAR, LEER EL MANUAL

DEL OPERADOR.

WARNING ADVERTENCIA AVERTISSEMENT

RUSTED TANK CAN

CAUSE EXPLOSION AND

SEVERE OR FATAL

INJURY.

TILT TANK FORWARD TO

LA-3092-1

DRAIN AFTER EACH USE.

D21248

EL TANQUE OXIDADO PUEDE

CAUSAR EXPLOSIî N

HERIDAS SERIAS O FATALES.

INCLINAR EL TANQUE HACIA

ADELANTE PARA DRENAR

DESPUƒS DE CADA USO.

UNE UTILISATION INCORRECTE PEUT ÊTRE DANGEREUSE.

SUIVEZ LES INSTRUCTIONS CI-DESSOUS:

RISQUE D'ECLATEMENT. ASSUREZ-VOUS QUE LA PRESSION

DE SORTIE DU COMPRESSEUR EST RÉGLÉE À UN NIVEAU

INFÉRIEUR À LA PRESSION D'UTILISATION MAXIMUM DU

PISTOLET VAPORISATEUR OU DE L'ACCESSOIRE. AVANT DE

DÉMARRER LE COMPRESSEUR, TIREZ SUR L'ANNEAU DE LA

SOUPAPE DE SÛRETÉ POUR VOUS ASSURER QU'ELLE

FONCTIONNE LIBREMENT. VIDANGEZ L'EAU DU RÉSERVOIR À

AIR APRÈS CHAQUE UTILISATION.

RISQUE D'INCENDIE OU D'EXPLOSION. NE PAS VAPORISER

UN LIQUIDE OU UN PEINTURE INFLAMMABLE OU COMBUSTIBLE

PRÈS D'ÉTINCELLES, DE FLAMMES, DE VEILLEUSES NI DANS UN

ENDROIT RESTREINT OU RENFERMÉ. L'AIRE DE VAPORISATION

DOIT ÊTRE BIEN AÉRÉE. GARDEZ LE COMPRESSEUR À UNE

DISTANCE D'AU MOINS 20 PIEDS DE LA SURFACE À VAPORISER.

NE PORTEZ PAS LE COMPRESSEUR ET NE L'UTILISEZ PAS NI

AUCUN AUTRE APPAREIL ÉLECTRIQUE À PROXIMITÉ DE L'AIRE

DE VAPORISATION. NE FUMEZ JAMAIS QUAND VOUS

VAPORISEZ. UTILISEZ UN FLEXIBLE D'AIR D'UNE LONGUEUR

MINIMUM DE 25 PIEDS POUR RELIER LE PISTOLET

VAPORISATEUR AU COMPRESSEUR.

RISQUE DE DANGER CORPOREL. NE DIRIGEZ JAMAIS UN JET

D'AIR COMPRIMÉ OU DE LIQUIDE VERS VOTRE CORPS.

RISQUE DE CHOC ÉLECTRIQUE. N'EXPOSEZ PAS LE

COMPRESSEUR À LA PLUIE. REMISEZ-LE À L'INTÉRIEUR.

LISEZ LE MANUEL DE L'UTILISATEUR POUR DES

INSTRUCTIONS COMPLÈTES CONCERNANT LA SÉCURITÉ,

L'UTILISATION ET LES RÉPARATIONS.

UN RƒSERVOIR ROUILLƒ PEUT

PROVOQUER UNE EXPLOSION ET CAUSER

DES BLESSURES GRAVES OU FATALES.

INCLINEZ LE RƒSERVOIR VERS L'AVANT

POUR LE VIDANDER APRéS CHAQUE

UTILISATION.

D21249FBJ

20 - ENG1000003754

Loading...

Loading...