DES

IG N

ERS AND

M A

NU

FACTURERS

OF SPECIALIZED

MATTRESS

S EW I

CA

TAL

NG

EQ

OG

#9700 12/94

UIP

ME

N T

PBS

Blind

St

itch

700

Ma

chi

ne

0U\{]

~1J~~©u0CQ)O\D~D

®

~@

r

lgj

~O©!:§

~&~u~

U\'lU&O\D~&[S

97

Rantoul

(508)922-2611 • (800)343-8138 • F

©&u&[SCQ)@

Street,

Beverly,

AX

MA

[617)5

01915

99-7081

Ordering Information

TO

ORDER

TO

ORDER

(Fax & Message Service available 24 hours per day.)

TO

ORDER

Porter

HAVE

1. Customer

2.

Bill

To

3. Fax

4. Person placing

5. Machine Model

6.

Part

Number

Number

PRICES

All prices are F.O.B. Beverly,

at

the

time

Al

l prices are list, unless otherwise

Open

account

lished credit.

Overseas orders

unless otherwise noted.

BY

BY

BY

Sewing

97

Beverly,

THIS

INFORMATION READY:

Number

and Shi

AND

of shipment.

terms

PHONE:

FAX:

(800)343-8138

(617)599-7081

MAIL:

Machines,

Rantoul

MA

p To address

order

Number

or

complete

Street

01915

es

part

Inc.

USA

description

TERMS:

MA,

and

are valid

noted

extended to firms with estab-

must

be

paid before

shipment

.

SHIPPING:

Please state how

when

ordering

Federa

l Express;

Freight charges

If a customer

costs

are

included

the

parts

air

freight; 3

are

included

is

on

C.O.D. status,

in

shipme

(UPS Red/ Blue/Ground;

the C.O.D. amount.

nt

day

in

is

the

to

be

serv

invoice.

then

made

ice).

shipping

TAXES:

Where

taxes

1\UNIMUM

Due

have established a

RETURNED

Porter

must

1.

2. All parts to

3. Credit for

4. A restocking charge

the

law requires,

must

be

charged.

ORDERS:

to the rising costs

GOODS:

Sewing

be

All

customers

(Ret

urned

Parts

returned

returned

Porter

the

Porter

by

Porter

Cred

parts

has

strictly

returned

it

ordered

adhered

must ca11

Material Authorization)

to

costomer. We will not

60

days after rece

be

prepaid

Parts

parts

and

credited aga

memos

incorrectly

state

of

handling

minimum

a policy

with

returned

unless

Department.

will

are

on

to

Porter

out a RMA

must

otherwise

be

issued

not sent.

of

15%

sales

order

returned

to

number

ipt

.

be

upon

inst

the

will

by t

he

and/or

orders,

of

shipped

ins

be iss

costomer.

CLAIMS:

If

a parcel post s

condition, advise

can be filed. All parcel post packages

by

Porter.

arri

ves

damaged, request

nota

tion

on

concealed at the

for

an

inspection

This is necessary

case

of

truck lines,

will give

responsible for

any

hip

ment

us immediately

If

a truck, UPS

the

freight bill.

time

and

in

you

needed

the

safe arrival

reaches

or

the

of

delivery, call the carrier

obtain a

order

to file a claim. In the

must

assistance,

you

so

express

driver to

If

tl1e

damage was

DAMAGE

file the claim. We

but

the carrier is

of

goods.

use

we

$25.00.

parts

obtain a

number.

will

accept

to

truc

ted

inspe

ction

accoun.

ued

in

damaged

that

a claim

are

insured

shipment

make

REPORT

that

RMA

be

parts

by

on

a

L

PBS

700

Blind

Stitch Machine

Contents

OPERATING

Handwheel Rotation

Oiling

Threading Machine ................................................................ ...................................... 5

Adjusting

Replacing Needle ..............................

Needle Recommendation ....... ................................................ ............ ............................ 7

r

ADJUSTMENTS

PARTS DIAGRAMS

Regulating Stitch Length ................................ .............................................. ................. 7

Proper Setting

Cam Shaft Off-Set Specs ................................................................... ............................. 9

Setting

Adjusting Needle Stroke to Presser Foot .............................. ..........................................

Adjusting Feed Dog ..................................................................................................... 1 0

Adjusting Looper ............................ ....................... ...................................................... 11

Adjusting Looper to Needle

Troubleshooting .................................................................... .......................................

Main

Main

Needle

Feed Drive Group ................................... ........................ ............................................

Looper Drive Group ........................................................... ......................................... 17

Feed Frame Group 1 ......................................................................................... ..........

Feed Frame Group 2 ...................................................................................................

Regulating Group ........................................................................................................

Presser Foot Group ........................................................... ...........................................

Covers

Alternate Cover ............. .............................. ..... .

Puller Assembly ...........................................................................................................

Drive Assembly (Front} ............................................................... ................................

Drive Assembly (Rear} ................................. ............................... .................................

Upper Puller ........................ ....................................... ................................................

Puller Shaft ...............................

Gearbox (Front) ..........................................................................................................

Gearbox (Rear} ......................................................................................... ..................

Lower Puller .................................................... ...........................................................

Lower Drive Assembly .................................................................................................

Under Table .................................................................................. ............................

INSTRUCTIONS

and

Speed ............................................................................... ...... 4

and

Maintenance .......... ................................................................. .......... .......... 4

Cam to Needle ......................................... ...................................................... 6

..

........... ................................................................ 7

for

Cam Connection ....................................................... ........................ 8

Cam

Shaft

Stroke .............................................................................................. 9

and

Presser Foot ................................................................

Frame Group .................................................................................................. .

Shaft Group ............................................................................................

Drive

Group ........ ................................................... .........................................

................................... ........ ..............................................................................

..

............. ................. ......... .................

..

................................................. ...............................

..

~:-::

...

..

10

11

12

13

14

15

16

18

19

20

21

22

23

24

26

27

28

29

30

31

32

33

34

INDEX

MEASUREMENT

.................................................................................................................................. .

CONVERSION

CHART

©1994

........................................................................

Porter Sewing Machines, Inc.

..

36

38

4

PBS

700

Blind

Stitch Machine

OPERATING INSTRUCTIONS

Handwheel Rotation

Turn handwheel only in direction away from operator for clockwise rotation.

up to obtain the same clockwise rotation.

1,800

to

2,000 stitches per minute.

become skilled in the operation

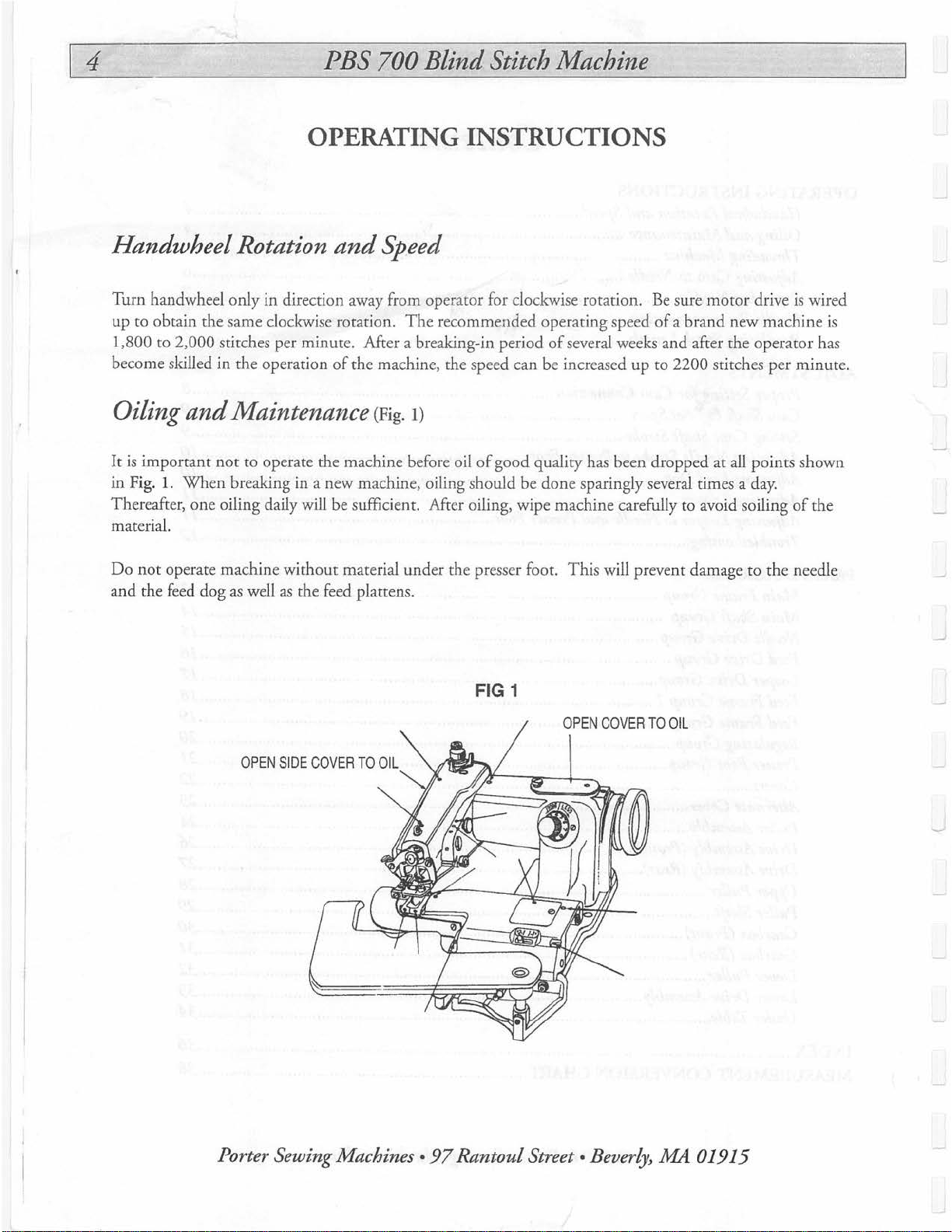

Oiling

It

is

in Fig.

Thereafter, one oiling daily will be sufficient.

material.

Do

not

and the feed dog

and

Maintenance (Fig. 1)

important

1.

operate machine without material under the presse

not

When

to operate the machine before oil

breaking in a new machine, oiling should be done sparingly several times a

as

well

as

and

of

the feed

Speed

The

recommended operating speed

Mter a breaking-in period

the machine, the speed can be increased up

of

good quality has been dropped at all points shown

Mter

oiling, wipe machine carefully to avoid soiling

plattens.

FIG 1

r foot.

of

several weeks and after the operator has

This

will prevent damage to the needle

Be

sure motor drive is wired

of

a brand new machine is

to

2200 stitches per minute.

day.

of

the

OPEN

SIDE COVER

TO

OIL

Porter Sewing Machines •

97

Rantoul

OPEN

COV

ER

Street • Beverly,

TO OIL

MA

01915

PBS

700

Blind

Stitch Machine

Threading Machine

Turn handwheel

thest left hand position.

Draw thread from spool

between two tension dis

0 , then down through needle

thread

To thread needle at

lifter, then hold thread between index finger

about 5 em

of

machine

(2

inch

point@,

cs

(F

ig.

2)

in

clockwise direction away from operator until needle lever reaches its fur -

on

thread stand

@, and pass it over rear thread guide

cl

amp hole 0 and pass it from

es)

past needle hole.

swing front plate

and

pass

out

and

it

through eyelet

of

way

thumb.

FIG2

of

@}

, through eyelet

the und

and

depress cylinder

End

of

thre

rear thread guide

of

erside

of

needle hole

out

of

ad

must be stub

0,

then slide

front thread guide

CD.

way with knee

not

feather edge.

it

Leave

Right

"''"'

~

Notlik•~

Wr

ong

Telephone

800-343-8138

or

508-922-2611 •

Fax

617-599-7081

6

PBS

700

Blind

Stitch Machine

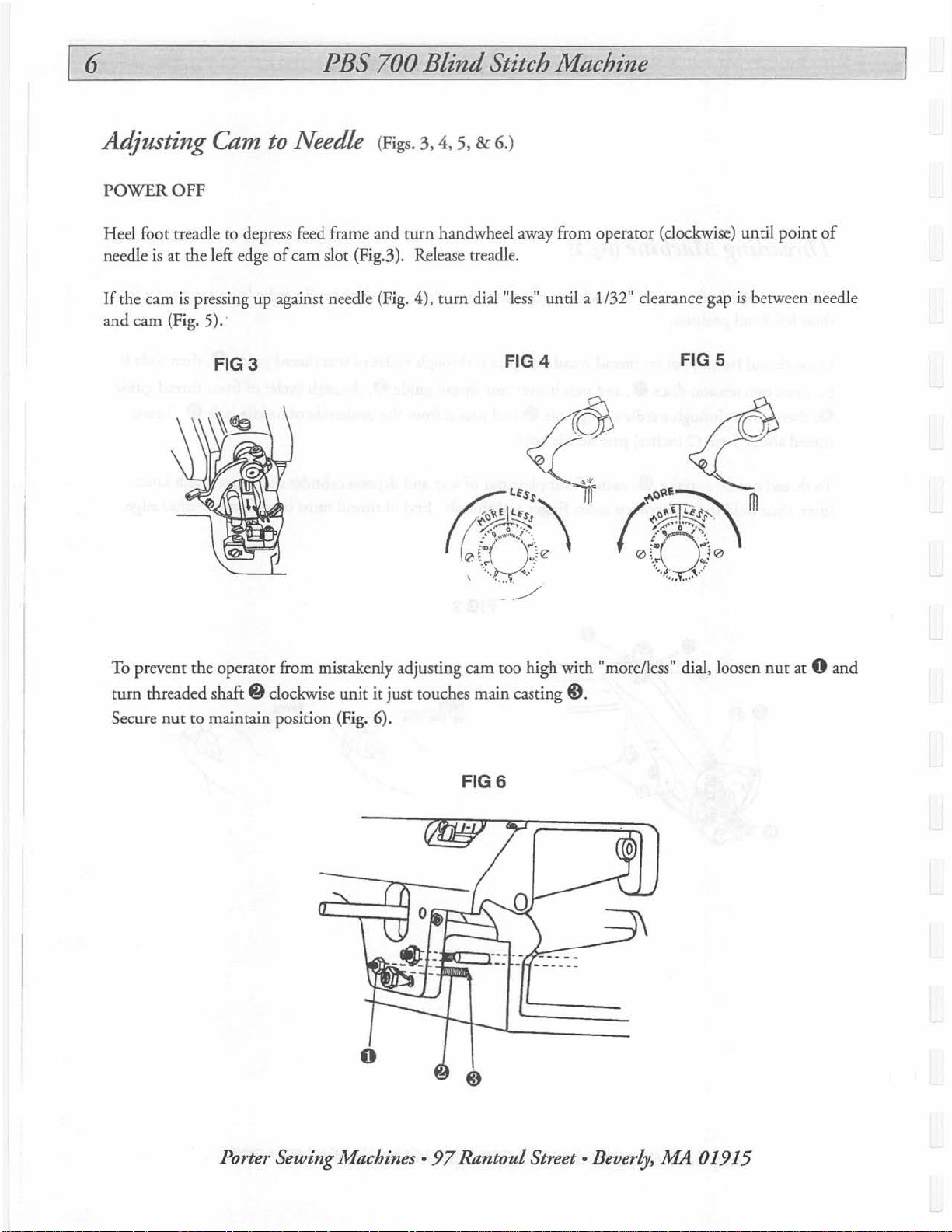

Adjusting

POWER

Heel foot treadle

needle

If

the cam

and cam (Fig. 5).

OFF

is

at the left edge

is

pressing up against needle (Fig. 4), turn dial"less" until a 1/32" clearance gap

Cam

FIG3

to

Needle (Figs.

to

depress feed frame and

of

cam slot (Fig.3). Release treadle.

·

3,

4, 5, & 6.)

turn

handwheel away from operator (clockwise) until

FIG4

FIG 5

point

of

is

between needle

To prevent the operator from mistakenly adjusting cam too high with "more/less" dial, loosen

turn threaded

Secure

nut

shaft@

to maintain position (Fig. 6).

clockwise

unit

it

just touches main casting@).

FIGS

nut

at 0

and

Porter Sewing Machines •

97

Rantoul

Street • Beverly,

.MA

01915

PBS

700

Blind

Stitch Machine

7

Replacing Needle

Turn handwheel away from operator (clockwise) until needle

of

reaches the end

Remove old or defective needle by loosening needle clamp screw

0.

Insert new needle into seat in needle clamp @ and needle

lever@)

(0.04") on the left end

screw

Turn handwheel slowly away from operator

ment

slightly on the needle guide groove

presser foot.

Always replace bent or bl

operation

as

far

0.

of

needle. The curved portion

of

its return stroke (extreme left hand position).

as

it will

machine.

(Fig.?)

go.

Make sure hole

of

presser foot 0 and tighten needle

of

needle

and

observe move-

of

the needle should bear

0 in the left hand

unt

needles.

They

affect the satisfactory

is

part

0-1.0

of

m/m

cl

amp

FlG7

0

Needle Recommendation

S

ize

#5-1/2

Regulating Stitch Length (Fig. 8)

Loosen sc

until desired numb er

larger the number

the

securely.

Number

Stitch Length (

NOTE:

area,

rews

0 in stitch regulating collar @

is

reached by indicator notch

by

the notch, the longer the stitch. The smaller @

num

ber by the notch, the shorter

on

Collar

SPI)

Due

to the changing thicknesses

an

end result

of

6-8 SPI will be satisfactory.

5

5

th

e stitch. Tighten screws 0

6

4.2 3.6

and

turn collar @

of

7

of

FIGS

eccentric.

The

9

3

0

material passing between the cam

and

shoe

Telephone 800-343-8138 or 508-922-2611

• Fax

617

-599-

708

1

8

PBS

700

Blind

Stitch Machine

ADJUSTMENTS

Proper Setting

Turn handwh

the right ha

passes over cam to other side

If

cam moves, make the foll

<D

. Bring the point

ing

sc

rewdriver in pla

needle in position with handwheel while pe

If

still

not

backward

& 0 before putting machine into operation.

eel

nd

edge

correct, readjust by loosening screw 0 again, change angle

as nee

for

Cam Connection

away from operator (clockwise) until needle

of

needle guide

owing adjustments: first open top cover plate and loosen screw 0

of

needle back to the rig

ce.

Move eccentric @ forward

ded and retighten screw

0,

Cam

of

presser foot opening@}.

0.

(Fig. 9)

is

on the down stroke.

@ should stop

ht

hand edge

to

rf

orming this operation. Tighten screw

When adju

FIG9

and

should not move until the point

of

needle guide 0 .

backward until cam is at the stop position, hold ing

of

sted satisfactorily, be sure to tighten both screws 0

Then

eccentric 0

When

loosen screw 0 , keep-

needle reaches

of

needle

on

eccentnc

0.

sl

ightly forward

or

0

Porter Sewing Machines •

97

Rantoul Street • Beverly,

A1A

01915

PBS

700

Blind

Stitch Machine

9

Setting

Remove cover

collar

position collar

(F

ig. 9A).

9B

Fig.

a clearance slot for the travel stroke

no interference contact after performing the off-set adjustment.

FIG9B

Cam Shaft Offset (Figs. 9, 9A, & 9B)

(F

ig.

9)

and

loosen screw @ on cam shaft drive

and

L.H. positioning collar (not shown). Loosen R.H.

@ and slide cam shaft

Then

secure both L.H. and R.H. collars.

shows the pivot shaft for the feed plattens.

to

dimension shown in

of

the cam. Be sure there in

The

shaft h

as

l

FIG9A

r

1/8"

OFFSET

DIMENSION

CAM

SHOE

0

Setting Cam Shaft Stroke (Fig. 9 & 9C)

When

adjust cam to

rib's forward movem

the point

be 5 m/m

of

needle

(13/64") between the center

ent

as

Telephone

is

at the cam, open window plat

shown

in

Fig. 9C.

800-343-8138 or 508-922-2611 • Fax 617-599-7081

........_

_____

e,

loosen screw @ and

of

needle and the end position

1--

of

GUIDE

FIG9C

ALIGNMENT

10

PBS

700

Blind

Stitch Machine

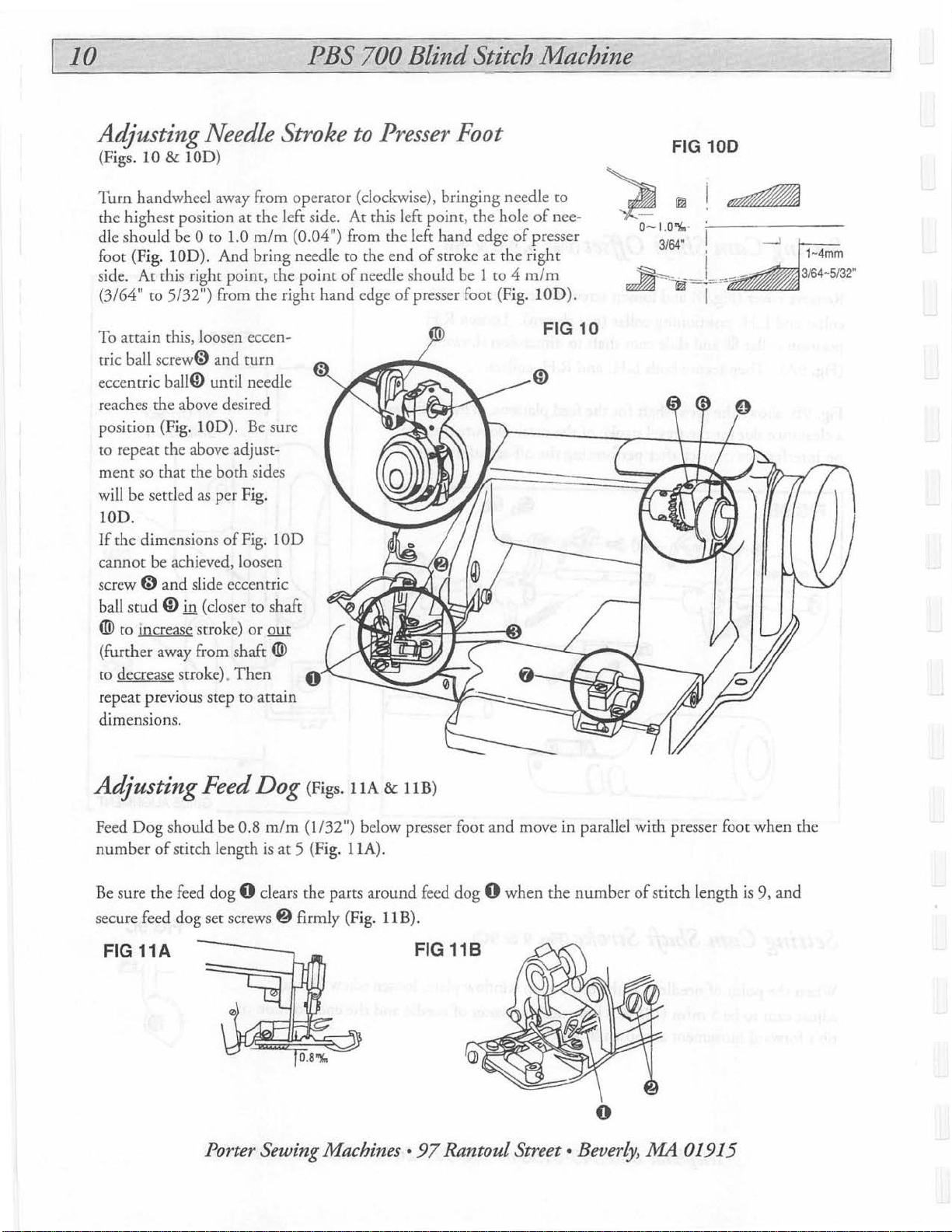

Adjusting Needle Stroke

(Figs. 10 & lOD)

Turn

handwheel away from

th

e highest position

dle should be

foot (Fig.

side.

(3/64"

To attain this, loosen eccentr

ic ball screw(;) and

ecce

reaches the above desired

position (Fig.

to

repeat the above adjustment

will be settled

lOD.

If

the dimensions

cannot

screw

ball

lOD).

At

this rig

to

5/32") from the right

ntric

ball@ until needle

so

that

the

be achieved, loosen

G)

and

stud

ID

in (closer to shaft

at

0

to

1.0

And

ht

point,

turn

lOD

).

both

as

per Fig.

of

Fig. 1

slide eccentric

® to mcrease stroke)

(further away from shaft ®

to

decrease stroke).

repeat previous step

dimensions.

Then

to

ope

rator (clockwise), bringing needle

the left side.

m/m

(0.04") from the left hand edge

bring needle

the

point

hand

Be

sure

sides

OD

or

out

0

attain

to

Presser Foot

At

this left point, the hole

to

the end

of

needle should be 1

edge

of

stroke

of

presser foot (Fig.

of

at

the right

to

4

ro

of

nee-

presser

m/m

lOD

FIG 10

~@

0- I.

).

O"l(.

3/

FIG

64"

100

·

Adjusting Feed Dog (Figs.

Feed

Dog

should be 0.8 m

number

Be sure the feed dog 0 clears the

secure feed

of

stit

dog

ch

length is

set

screws@

FIG 11A

Porter Sewing Machines •

/m

at

5 (Fig.

firmly (Fig.

IIA

&

liB)

(1/32") below presser foot and move

llA).

pans

around

liB).

feed

dog 0 whe

FIG

118

97

Rantoul Street • Beverly, .MA

n the

in

parallel with presser foot

number

of stitch length is 9, and

0

01915

when

the

PBS

700

Blind

Stitch Machine

11

Adjusting

Replaceme

Replacing Looper (Fig. 12A)

Loosen

looper in, the shoulder

der

sc

ofloop

Adjusting

and

Looper must clear the chaining finger 0 a

being

of

Make sure the distance between right hand side

rod folk pin

mally 104

The long prong

from the left

prong

12B).

Presser

ju

st above the needle abo

paper at point

of

Looper (Fig. 12A)

nt part

rew 0 to take

er rod

#2200B. [Generic Polished]

out

of

looper should

@)

at

pomt

Looper to Needle

Foot(Figs.

<D.

fi

and rear

m/m

(4-3/32") (Fig. 12A).

of

hand

the looper

face

the looper should

edge

of

needle hole when the long

is

on

the center

loope

r@.

Wh

en putting new

cou

ch the shoul-

0.

12A, 12B & 12C)

nd

clear needle,

ut

the thickn

of

looper rod ball @ is nor-

be 3 m/m

of

ess

the needle (Fig.

FIG 12A

of a sheet FIG

of

looper

(1/8")

128

If

looper touches needle

crews

s

by screwdriver.

stud

• and needle touches short prong

loosen

@)

point

Be

By

wise,

NOTE:

both

side and lower the other side.

Looper should clear chaining finger

point

loosening screws

In

eccentric stud

and does not have any play left or right. Secure by retightening screw

0 and turn the screwdriver slot in eccentric stud @

If

looper

@ clockwise.

nut

G) by wrench.

downward, which will clear short prong

4D

and raise looper at

certain to tighten

turning eccentric

it will raise

With

sides.

4@

case

of

the above adjustment, be sure that looper rod

or

eccentric stud ®, raise or lower looper

and

Move eccentric

0.

4D

is

0 (Figs. 12B & 12C).

or

presser foot at point

is

hitting needle, turn eccentric

If

looper touches presser foot

of

looper at

Then

turn looper rod

point.

all

screws after adjustments are made.

stud@

lower looper at points • and e .

4D.

This will get the desired clearance.

flush against looper and rod carrier

clockwise

Turning looper rod@), raise one

stud@

(Figs. 12A & 12C).

or

• and presser foot at

from left to right by

@,

at

point

point

at

point

of

looper

counterclock-

loosen

C8,

at

on

~

FIG 12C

Telephone 800-343-8138 or 508-922-2611 • Fax

617

-599-7081

12

PBS

700

Blind

Stitch Machine

Troubleshooting

G

Thread

break

Stitches

skip

Cause

Inspection

L

I

Poor-quaHty

Too

Needle insta.ll

Needle, l

foot,

have defective replace

Thread

or weak

Wrong threading

Needlt

Needle point defective

Looper

thread

thin

needle

ed

incorrectly

ooper,

presser

thre

ad passage

tensi

on

too

strong

installed incorrectly

defective

Thread

Thr

ead tension

Looper

quality

blunt

control

or

broken

Use thread

quality

Replace with a thicker

needle

Smooth

•nd

Adjust to

tension

Replace

needle

Smooth

and

repla.ce looper

·~~·

of

good

with

sandpa

polish

with

buff,

correct

with •

good

with

sandpaper

polish with

huff,

per

or

thread

or

1

··

~1

Relative

of

ooper

c.am

or

and

thin nee

cop

dog

needle

clearance betWeen

looper

dle

hit nee dle

bt:tween

roo

great

tension t

installed

or

worn

Needle

Uneven

Stitches

or

loose

Improper

break

stitch

too

feeding

tight

l

needle

Too

Needle inStalled incorrectly

Looper

Clearance

and

Thread

orwuk

Feed

incorrectly

Porter Sewing Machines •

and

are wrong looper

needle

~int

oo strong

out

97

Rantoul

Timing

between

Direction

needl•

Clearance

and

looper

Thread

or

clearance

need

le

and

Rep

lace with a

needle

and

position

of

between

needle

ten

sion

contro

l

Adjust to

tension

Street • Beverly, .MA

correct

thic

ker

thread

01915

Ref#

1

2 .

3

4

5

6

7 .

8 .

9

10

11

12

13

Part#

....

.700000 . .Side

.700010.

.700020. . .Screw,

...

700030

.....

700040

..

700050

700060

.700070

.....

700080

.700090 . .Nut,

..

700095 . .Pin,

..

700100

....

700110

Description

.Washer,

. . .

.Screw,

. . . .

Thread

..

Thread

.Disc.

.....

Post, Thr

. . .

.Spring,

.....

Screw,

....

Tube,

Cover

Clamp

Side Cove

Guard

Tens

Guide

Thread

ead

Tension

Tension

Spring

Feed

Oil.

PBS

Assembly

Screw ........

. . . . . . 1

ion

Regulating

. .

Tens

Tension

. .

. . . .

..

Lever

. .

700

r....

......

Assy •....

..................

ion

. . . . . . . . . • • .

. . . . . 1

................

. . . . .

.. ..

. .

Plate

Blind

.......

..

Qty

.....

. 1

. 1

. • . 1

1

1

.2

....

1

1

. 1

. 1

..

1

Stitch Machine

Ref # Part

14

....

15

16

17

. .

18 ....

19 . .700170

20 . .700180

21

22

....

23

. .

24

25 . 700230

#

700120..

..

700130

.700

140 . .Screw,

700150

700160

.700190

700200..

700210

700220 . Thread

Descr

.Wick,

.Screw,

.....

Pin,

.... Screw,

. . .

Plate

. .

.Screw,

.....

Screw,

.Washer,

. .

.Screw,

.....

Screw, Thread

Presser

MAIN FRAME GROUP

ipti

on

Oil

Set

Set

Set

, T

op

Cove

Top

Bridge

Clamp

Clamp . .. . .. . ..

Guide

. . . . ..

. .

.....

.............

. . . . . . . . . . . . . . . . . 1

Foo

t . . . . . .

. . . . • •. .

r . . . . . . . . . . . . . . . . . 1

Cover

. . . . . . . . . . • • • . 1

Mig.

Screw

.. ..

Guide

. .

. . . . . . . . 1

.. ..

..

..

.

. . . . .1

.....

........

. . . 2

........

13

Qty

1

2

.1

1

1

.1

Telephone

800-343-8138 or 508-922-2611 •

Fax

617

-599-7081

14

MAIN SHAFT GROUP

Ref#

1

2 . .

3 .

4

5

6 .

7 . .

8

9

10

Part#

....

700240

.....

.700250

..700260

.....

700270

.....

700280

.700290 . .Needle

.70

.....

700310

.....

700320

..

700330

. .

..

....

....

0300 . .Screw

...

.....

Main

Rib

Screw

Screw

Screw, Clamp

Guard

Screw

.Screw

PBS

Description

Shaft

.. . ..

. . . . .

Connection Lever & Eccentric

Eccentr

ic

. .

For

Stud

. .

. . . . . . . .

Connection

. • . . . . . . .

.. ..

....

Ass'y

. .

..

..

..

. . . . .

................

1-----{6

700

Blind

Ass

.............

.............

............

........

'y

Stitch Machine

Oty

Ref # Part

11

..

12

13

14

15

16

17

18

19

700620

..

700610

....

700360

....

700370

..

700380

..

700390

....

700400

....

700410

.700030

..

.1

1

2

.1

.1

1

2

.1

.2

1

#

....

..... Scr

...

. .

..... Scr

Description

..

Stitch

Collar

..

Set

Screw

Collar

Ass'y

ew

Handwheel

.. Scr

ew

.Pulley

Ass'y

ew

..

Screw .....

. . .

....................

. . . .

. . . . . . .

.. ..

.. .. . ..

.....

. . . • • . • .

.. .. .. . ..

..

..........

. . . . . . .

......................

............

. . . .

.........

.............

. • . . .

Qty

1

2

.1

.1

1

3

.1

.1

1

,-@

I

2

16

Porter Sewing Machines •

97

Rantoul

Street • Beverly, A1A

01915

Ref#

1

2

3 .

4 .

5

6

Part#

.... .700430 .....

....

700440

700450

7004

60 ..... Leve

....

.700470 ..... Screw

....

.700480 . .Screw

Description

Need

.. Clamp

...

Pin

PBS

le

Lever

Ass'y

. .

...................

..

.. .

.. .. .. ..

r . . . . . . . . . . . . . .1

700

.. .. ..

................

Blind

.......

. . . 1 9 .

•.• ......

Qty

1

1 8 .

. 1 11

1

Stitch Machine

Ref # Part

....

7 .

10

....

....

#

700490

.700160

..700510

7005

20

700530

Description

.Collar

.Screw

....

Shaft

..... Scre

..

PSM550

w . . . . . ..

NEEDLE DRIVE GROUP

Qty

Ass'y

. . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . .

.. .. . .. .. ..

. . ..

. . . . 1

...

.....

..........

....

..

@--f

15

.2

1

1

Telephone

800

-343-8138 or 508-922-2611 • Fax 61 7-599-7081

16

FEED DRIVE GROUP

Ref#

1 . .

2 . . .

3

4

5 . .

6 .

Part#

.700540

700550

...

.700560

...

.700570

..700580 . .Set

700100

.....

.....

. .

. .

Description

Feed

Lever & Stitch

Feed

Rocker

Feed

Lever

Screw-Le

.Thrust

Collar

Screw

PBS

Collar

Ass

'y

Plate

. . . . .

verPiate..

Ass'y

700

. .

..

......

. • . •

Blind

Ass'y

........

...........

. . .

............

.......

.....

Stitch Machine

Qty

Ref # Part

...

700590 .Feeder

7

1

.....

700600

8

1

9

...

.1

.1

1

2

700610

10 .700620

11

. .

700630

#

Description

..... Feeder

.....

Set

.Stitch

. .

.Feed

. . . . . . . . .

Screw

Screws

Collar

Leve

r . . . . • . . • .

. . . . . . . .2

. . . . . . . . . . . . . . . . . .

...................

Qty

.....

.

...

.1

2

. 1

.1

Porter Sewing Machines •

97

Rantoul

Street • Beverly,

.MA

01915

Ref#

1

2 . .

3 .

4

5 .

6 . .

7

8

9

Part

#

..... 700640

'Z.00650

..700660 . .Collar

.....

700580

....

700670

.700680

..

700690

.....

7007

00

.....

700710 ... ..

PBS

Description

. . .Looper . . . . . . . 1

-. .

.Stud,

Looper

Adjustment

Ass'y

........................

.....

Set

Screw

.......................

..... Loo

.....

per

. .Fo

rk

. .Pin .

Screw

Nut

Rod Fork,

. . . . . . . . . 1

..

.....................

...........................

. . . . . 1

700

. . . .. . . . 1

Sleeve & Stud

Blind

Qty

Ass'y

Stitch Machine

1

1

. 1

1

1

Ref#

1 0 . .

11

12

13

14

15 . .70075

16

17

Part#

700720

. .

700730

....

700770

....

700780

.7007

40 . ..Looper

....

700760 ..... Looper Rod,

....

70076

. .

. .

....

. .

0 . .

5 ..

...

LOOPER DRIVE GROUP

Description

.Looper

Rod

Sleeve

Ass'y

.Scre

w . . . . . . . . . . . .

Stud . .. . ..

.Nut

.Screw

. . . . . .

Rod & Ca

. .

Screw

. . . . . . .1

. .

.. . ..

............

Fork & Carrier

.. . .. .. . ..

rrier Ass

....•.........

'y

Ass'y

Qty

. . . . 1

. 1

.. . .1

.1

.

.1

..........

. . . . .

1

.1

1

17

©--

---

------

I

'

~

Telephone

800

-343-

8138

or 508-922-2611 • Fax 617-599-7081

.-------------

FEED FRAME GROUP 1

Ref#

2 .

3 . . .

4

5 .

6 .

7

8

9 .

10 . 700830. . .Nut

11 ....

12

13

14 . 700880

.

.....

.....

.....

....

Part#

700740

700750

..

700760

700770

700780

700790

70080

700810

700820

700840

700850

700860

.....

.....

. .

. .

0 .

.....

. .

. .

.....

....

. .

---------------------------

Description

..

Rib

Shaft

Assy

..

Feed

Frame

Collar

Ass'y

Set

Screw

............

.Rib

Shaft

Crank

.Screw

..Plate,

Screw, Plate

.Post,

.Platten,

Screw, Platten

Nut

.Screw, Cylinder

. . . . • . • . • • . 1

Window

Spring

. . .

L.H..

..................

PBS

...............

Ass'y

. . . . 1

Ass'y

..

..

.. . .. .. .. . ..

. . . . . . . . . . . 1

700

. . . . . . . . . . . ... 1

. • . • . . . • . 1

.. .. .. . .. ..

. • . • . • . .

..

..........

.. .

. .

..

. . .

............

Blind

Qty

.

.....

. . 1

.2

..

..

.2

...

. 3

1

1

1

1

1

-

--------------------------------~

Stitch Machine 18

Ref#

Part#

15 ....

700890

16

..

700890

17 . .700900

18 . .700910 . .Stud

19

....

700030

20

....

700920

21 . .700930 . .Spri

22 . .700940

23

....

700950

24

...

.700960

25 . .9009

26 . .700970 . .Cylinder

27

....

70

700980

.....

Nut, Platten

.....

Bkt,

. .

Bkt, R.H.

.....

Set

.....

Spacer ...

. .

Screw, Limit

.....

Post

.....

Platten,

. .

Screw,

.....

Shaft,

Description

L.H. Platten

Screw

ng

..

Lock

....................

...............

Platten

. . . . . . . . . . 1

.............. . .

..............

. . .

..

..

R.H

.....

Frame

. . 1

Rocker

. . . . . . . 1

..

. • • .

..

. . • . . • . .

..

.. ..

. . . . .

....

...

. . . • . • .. . . 1

.

....

.....

..........

. • . .

...........

Qty

. 1

..

..

..1

. 1

2

1

1

4

2

1

I

I

Porter Sewing Machines •

97

Rantoul

Street • Beverly,

..Mil

01915

Ref#

1

2

3 .

4 . . .

Part#

..... 700990

.....

701000

700860 . .Nut, Ret'ng

7

01010

PBS

Description

..... Spring Link Ass'y . 1 5

.. Pin

. . . .

. .

....................

.... Screw,

Link .. . ..

..

.. .. .. . ..

700

..

Blind

..

RE

OF

Stitch Machine

Qty

..

1 6

1 7

. 1

AR WA

MAIN FRAME

Ref# Part

..

701020

...

..

701030

...

..

701040 . .Key

LL

#

~

.....

.....

FEED FRAME GROUP 2

Des

cript

ion

Nut,

Spring

........

Main

Spring

.

.

/\

. . •

..

. • . .

...........

19

Qty

1

.1

1

~

J

I

I

,~

/)

<,

/'

..........

/

·

~

@

'

'-....

'·-

/

/

IJ

MAIN

FRAME

Telep

hone 800-343-8138 or 508-922-2611 • Fax

--

617

-599-7081

20

REGULATING GROUP

Ref#

1

2 .

3 .

4 .

5

6 . .

Part#

..... 701050

..701060

..701070

..701080 . .Spring

.....

.7

701

090

01100

.....

.....

..

..... Regulator

..... Screw,

Regulating Fork

Push

Pin

PBS 700 Bli

Description

Rod

Ass'y

.. ..

..

.

..

............

. . . . . .

Ass'y

. . . .

Regulator....... .. . • . • • .

.. ..

. . • .

.

.........

.......

nd Stitch Machine

Qty

Ref

# Part # Description

.

.1

7 .

.1

.1

.2

1

1

..701110

8 .

.701120

9 . .

.701130 . .Screw

10

....

11

.701150

12

..

701160 . .Pin

701140

.....

. .

.....

.....

Dial & Ratchet

Dial

Plate

Ass'y

Shoe

..

. . .

Screw

...........................

. . . .

Ass'y

.................

..................

................

. .

..

....

..

Qt

y

1

1

.1

1

1

1

Porter Sewing Machines •

97

Rantoul

Street

• Bever

ly,

A1A

01915

Ref#

Part#

Description

PBS

700

Blind

Qty

Stitch Machine

Ref#

Part

#

Description

21

PRESSER FOOT GROUP

Qty

700190

700810

2 .

.....

701170 . ..

3

.....

701180 . .Screw

4

701190 . .S

5 .

6 .

.701200 . .Spring

7

.....

701210

.....

701220

8

9 . . .

701230 . .Shoe

10

..

701240

11

....

701250 .....

12 ....

701260

13

. .

700770

14

. .

701270 . .Nee

.Screw

.Screw ............................

.Screw

.....

.Sp

..

....

.Screw

..

pring

......

Shoe

Pin

ring

. . .

Screw

.. .. . ..

Anchor

Guide

. . . . .

. .

dle

Guide

. . . . ....

..

..

.. .. ..

. . . • . . 1

. . . . . 1

. • . . • . . . ....

......................

..

..

..

.. ..

.. ..

..

..

..

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . • . .

. . .

..

...........

....

....

....

2

15

2

16

17 . 701300.

18 . 701310.

1

19

1

20

.1

21 . 700200.

.1

22 . 701330.

.1

23

1

24

.1

25

.1

26 . 701370

.1

27

1

28

....

701280 ..... Screw

....

....

....

....

....

.701360

....

....

701290

701320

700210.

701340

701350

701380

701390

...

....

.....

.....

...

. .

.....

.....

.. . ..

.. .. ..

Screw

. . . 1

.Bushing

.Screw

.Wedge............

..Screw

..Washer

..Presser

.Screw

..........................

. .

..

Foot

......................

Screw

. ..

.. ..

Screw

Washer

Bridge

Chain

. .

....

..........

. . . . . . . . . . . . . . . . . . . . 1

Off

Pin

. . . . . . 1

...........

. .

..

. .

. . . . . .

.

..

. • .

..

......

..

..

.. ..

. . . .

.......

.....

........

. . . . . . . 1

..

1

1

.1

.1

1

1

.1

1

1

1

r

Te

lephone 800-343-8138 or 508-922-2611 •

Fax

617-599-7081

22

COVERS

Ref#

1

2

3 .

4 .

5

6

7

8 .

Part#

..

. .

BHCS440X1/4

.....

BSC-10

.BSC-11 .......

.BSC

-1 . .

.. .BSC

..... BSC-9

-7 . .

.

BSC-4

.BS

P-20

Description

.Screw

......

Bracket

Rig

Cover, Sh

..

Hand

Wheel Cov

..

Large

Shield

...... Top Right

....

....

Small

Shield

. .

.Gear

Box

PBS

.

ht

aft-Rear

Pulley ...............

Belt

Pulley

Cover

700

.. .. .. ..

. . . . .. 1

. . . . 1

er

. . . . . . . . . . . 1

Guard.

. .

. . . . . . . . . . . . . . 1

Blind

Qty

..

.. 4 9 . . .

. • .1

.3

Stitch Machine

Ref # Part

10

11

12

1

13

14

15

16

....

. .

. .

. .

....

#

BSC-3

BSC-2 ........ Bracket Pulley Cov

BSC-8

BHCS6-32X1

BHCS6-32X3/8 .

BSC-6 .......

..

BSC-5

..

SHCS6-32X

........

....... Left

Description

.Guard-Ma

Left

Shield

/4 .Scr

ew

Screw

Bottom Right Belt

Bel

1/4 .Screw

in

Shaft

er

Belt

.. . ..

. . . 1

........................

. . . .

t Br

acket

.....

....

Guard

..

................

......

. . . . 1

. .

..

. . 1

. 1

...

Qty

1

.4

. 5

2

Porter Sewing Machines •

97

Rantoul Street • Beverly,

.MA

01915

ALTERNATE COVER

PBS

700 Blind Stitch Machine

23

Ref#

1

2

Part#

..... BSC-30

.TS-1" . Taping

Description

..

Bii

ndsti

tch

Cover

Scr

ews

. • ..

Qt

. . 1

......

2

y

Telephone 800-343-8138 or 508-922-2611 • Fax 617-599-7081

24

PULLER ASSEMBLY

Ref#

1 .

2 . .

3 .

4

5

6 .

7

8

9

10

Part#

....

BS-2

09

.........

1611A

.C0-401-DOO . .Air

.....

93191

..... BSP

.....

.....

-17

.........

..PBS7

00-

EGH

..

BSP

-22

BSP-

03 . .

BSP

-04

......... Block

..

SHCS8-32X1

PBS 700 Blind Stitch

Description

Spacer

....... 0-30PSIGuage

. .

.Bracket

Adj.

.... Cloth Guide . .. ..

. .

.Shaft

.Support

/2 ...

Screw

. . . . . . . 1

Regulator

Universal Jo

. .

..................

. . . . .

....................

. . .

.. . ..

.. .. ..

...........

int

. . . 1

.. ..

..

. . 1

......

..

. . .

Qty

...

1

1

2

1

1

.2

.2

Machine

Ref # Part

11

...

3011

12

..

BS-233

13

...

5283

14

....

BS-204

15

..

BS-317

16

.. 3/8-16X2-1

17

..

BSP-2

18

.. .BSP-25

19

.. SHCS8-32X3

20

..

BSP-02

#

...

........

. .

. . .

......

...

.........

/2

..

1 . .

......... Pulley

/4

...

. .

Description

Yoke

.........................

Yoke

Bracket

Shaft

..............

Top

Roller.

Yoke

Support

Cloth

Plate

Stud

.Shaft

Screw

.Housing

. . . . . . 1

. . 1

....................

. .....................

. . . . 1

. . . . 11

. . . . . . . . . . . . . . . . .

......................

Qty

1

1

1

1

.2

1

Porter Sewing Machines •

97

Rantoul

Street • Beverly,

.l\1A

01915

Ref#

21

22 . .BSP-06

23

24

25 .FB68·

26

27

28

29

30 ...

Part#

..

375RPP5

.... BSP-24

.. ..

SC37

3-1/4

..

BSP-05

....

HN3

/8·

. .

.SS1/4·28X3/8

..

BS-206

SHCS10·32X1-1

. . ..

. . . .

....

. . . .

. . .

. .

16

.......

. .

PBS

Descri

lion at

.Belt

. .

Shaf

t . . . . . . . . . . . . . . . . . . . . . . . 1

Pulley

. . . . . . . .

.Collar

. . . . . . . .

Bea

ring

. . . .

...

Universal

Nut

.Screw

.Stiffener

/4

Screw

Joint

. . . . . . . . . . .

. . . . . . .

..............

700

..............

.............

. . . . . . . . . . .

. .

Blind

.....

............

......... 2

Stitch Machine

Ref # Part

1

31

....

32 . .SHCS10-32X1

.. 4 33 . .BSP-10

.2

34

....

6

35 ....

1

36 . .Exp

.3

37

.2

38

....

1

#

BS-216

SHCS1/4·20X1·3/4Screw

FU1/4-Biack

1/8X5

.BS

P-01 . ..

BS207

..

......

/8 .

.. ..

Descri

tion

..

Adapter

/2

..

Screw

Mounting

..

Washer

.Pin

...

Support . .. .. .. ..

..

.Support

Mtg

. .

Bracket

. . . .2

. . . .

..

Bracket.

..................

. . . . . . . . . 1

.................

.. ..

. . . . .1

.

......

•

.......

25

at

1

.4

4

2

.1

Telephone

800-343-8138

or

508-922-2611 • Fax 617-599-7081

26

DRIVE ASSEMBLY (FRONT)

Ref

# Part#

1 . .

.SHCS8-32X3

..

BSP-14

2 .

..... BSP-15

3

.....

BSP-21

4

..BSP-19

5 .

6 . .

.450RPP5 . .Belt

.....

425RPP5 . .Belt

7

8

.....

BS-500

..0231-1

9 .

10

..

BSP-24

........

/8 .

. .

.......

...

.

Desc

Screws

.Base

.Adjustment

Pulley

Shaft

Yoke

.Rod

Clevis

.Pulley

PBS

ript

ion

.............

. . . . .

Plate

. . . . . . . . . . . . . .

.........................

. .

. . . o

.........

......................

. . . . .

700

..........

. . . .1

..

o • • o .1

..

Blind

Qty

.

.4

.. ..

1

.4

1

....

1

.1

1

....

.4

Stitch Machine

Ref#

11 ....

12

13

14 .BSP-13

15

16

17 . .6072K21

18 . .FW1/4-Biack

19

20 ...

Part#

BHCS8-32X3

....

BSP-18

.Y

A-18

-3/8 .

....

FBG8-3-1

....

SHCS8-32X1-1

....

BS-501

BSP-16 .......

/8

....

/4

. 1/4

. . .

Description

.Screws

..

Shaft

.Spur Gear ......................

.Side

.Bearing

/2

Screw

.Washer

Pin

Nut

. . . . . . . . 2

U-Joint

Plate

28 Male

Yoke

Plate

..........

Assy

..................

.. . ..

. . • • . . • . ..2

Ball

Joint

.. ..

...

..

..

........

........ 2

. .. .

. .

. . .

....

. . .2

..

Qty

.4

..

..

1

2

1

1

1

Porter Sewing Machines •

97

Rantoul

Street • Beverly,

..MA

01915

PBS

700

Blind

Stitch Machine

DRIVE ASSEMBLY (REAR)

27

Ref#

1

2 .

3 .

4 . .

5

6 .

7 .

8 .

9

10

11

12

Part#

.....

GR3070037 . .Belt

.3007

..30320 . ..

.BS-244

.....

SHCS8-32X3

..BS-213

.41-V

.BS-304

....

BS-306

.SHCS8-32X3/8

.PC5-4

..

HN10-32

. .

....

........

/4

. .

. .

.......

. . .

.

......

Description

.Rod

Pulley

Drive

.Screw

.Pulley

...

Belt

Ecc. Drive

..

Ecc.

.Screw

..Washer

Nut.....

End

..

..

.. ..

.. . .. ..

..

.. .. . .. ..

Flange

. .

..

..

..

.. .. . ..

Hub

Dri

ve

Retainer

. .

...................

.. .. .. .. ..

. . . . . . . 1

. . . . . 1

.. .. . ..

.. ..

..

. . .

. . . . .

. .

.

Qty

....

.. ..

. . . . 1

......

....

.. ..

..

......

Ref # Part

1

13

. 1

14 . .2993

15 . .K11

16

. 3

17

.1

18 . .1412

.1

19

.1

20

.. 1

21

.4

22 . .38

.1

23 . .BS-306

24

#

. .

.HN1/4

-28

M40740080

....

BHCS10-32X1

....

XCK-22

.

. .

FHCS8-32X

....

BS-256

....

BS-258

KLL

....

HHCS10-32X1

.

. .

. .

1-1

.......

. .

.

........

Description

.Nut

. . . . . . . . . . . . . . . . . .

.Push

Rod..

.Positioner

/4

Screw.

.Synchronizer

.Positioner

/4

Screw

.. ..

Handwheel

.Handwheel

..

Bearing

Bus

hing

..

Screw

. . . . . .

..

....

_ . . . . 1

Holder

. .

........

Positioner..

Adapter

. .

. .

Adapter

.. .. .. . .. ..

..

. . . . 1

.......

. . . . . 1

...........

. . . . . . . . . . .

. . . .

...

......

Qty

.2

..

1

1

. 1

.3

1

.1

.1

1

Telephone 800-343-8138 or 508-922-2611 • Fax 617-599-7081

28

UPPER PULLER

Ref#

1 . .

2 . .

3

4

5 . .

6 . .

7

8

9 . .

10

11 ....

Part#

.BSP-06

.BSP-24

.....

BSP-03 . ..

.....

SHCS8-32X5

.3/8-16X2-1/2

.375RPP5-9

.....

BSP-10..

..

...

HN3

.BSP

..

BSP-25

BS-405

/8-16

-21

Description

. .

. .

. .

/8

. .

......

..

..

..

PBS 700 Blind Stitch Machine

.Shaft

..........................

.Pulley

.Su

pport

. . . . . . .

.Screw

.Stud

.Mounting

. . . . . . . . . . . • . .

. . . . .

Belt

. . . . . . . . . . . . . . . 1

Bracket

Nut........

Pulley

Shaft

Pulley

Spacer

. . . .

. .

.....................

. . . .

...

. . . .

. . . . . . .

.............

. . . . . . . . . . . .

.........

Qty

Ref # Part

1

12

4

13

.1

14

.2

15

1

16

17

.1

18

.3

19

1

20 .BSP-02

.. 4 21

.2

22

#

..

BS-5283

....

BS-233 ....

..

3011

..

BS-204

.BSP-04. . .. Block

....

SHCS8-32X1

....

SHCS8-32X1-1/2Screw

.BSP-05

....

SC37

....

FB683X1

. .

....

..........

. . .

/2

. . . .

. . . .

. . .

/4

.....

Description

.Roller

. . 1

Pin

Yoke

..........................

Yoke

Support

.Screw

Universal

Housing

.Collar

Bearing

...................

. . . • . • . • . • . .2

. • . • . .

................

Joint

. . . . . . . . . . . . . . . . .

. . 1

. . .

. . . . . . . . .

..

. . . .

. 1

.........

......

Qty

1

1

.2

2

.1

.2

2

Porter Sewing Machines •

97

Rantoul

Street • Beverly,

.MA

01915

Ref#

Part#

Description

PBS

700

Blind

Qty

Stitch Machine

Ref # Part

#

Description

29

PULLER SHAFT

Qty

.BSP-16

...

FW1

2

3

.....

BSP

4

....

BSP-22

5 . .

.BSP-15 . .Adj.

.

BSP-17 ...

6 . .

...

..

BSP-18

7

/4

-14

...

....

..

....

.Nut

Plate

Block

Base

Shaft

Plate

U-Joint

Shaft

........................

Spacer

..

..

..

..

. . . .

. . . . . . . .

. .

. .

....................

. . . . . . . . . . . . . . 1

. . . . . . . . . . . 1

........

1 8

.1

.1

1

1

.BSP-

9

.BSP-20

10

...

YA-18-3

11

....

BSP-19 . .Shaft

12

.BSP-24

13 . .BSP-11 . .Side

12

/8

...

. .

..

Side

Plate Left. . ................

.Cover

. . . . . . . . . . . . . . . . . . .

Spur

Gear

. . . . . . .

. . . . .. . • .

Pulley

. . . .

Plate

Right

.. ..

. . . . . .

..

................

..

..

. . 1

....

1

.1

.2

1

4

Telephone 800-343-8

138

or 508-922-2611 •

Fax

617-599-7081

30

PBS

700

Blind

Stitch Machine

GEARBOX

Ref# Part#

1

.. . .450APP5·9

2

.....

GR3070037

3

..

6C32H3712

..

HN1/4X28

4

.RCB061014FS

5 . .

6

.....

BSP-24

..425RPP5

7 .

..BSP-23

8 .

.

CS5·4

9 . .

10

....

CD3·5 . .. . .. .Washer

11

..

SS-2·

..

. . .Collar.

7 4 . . . .

(FRONT)

Description

.Belt

....

Belt

...

Pulley

. .

Nut . .. .. . .. .................

.Clutch

..

..

.Pulley

·9

....

Belt

.

.Shaft

..

Spacer

. .

. . . . . 1

.. .. .. . .. ..

Bearing

.. .. . .. ..

..........................

. . . . . . . .1

. . .

..

. . . ........

. .

.........

. . . . 1

..........

• . . .

Qty

1

1

2

.2

.1

1

2

.2

Ref # Part

12

....

SS1/4·28X1

13

....

BH68

14

..

3006

15

..

CS5-4

16

....

CD3·5

17

....

BS-207

18

.87

·43

19

.BS

-303

20

....

RCB061014FS

21

....

BS-228

22 . .60

72K31

#

.........

.

. . .

. . . . ...

. .

. .

........

Description

/4

..

Screw

Bea

.Clutch

.Co

llar

.Wash

Suppo

.Bearing

.Bushing

.Clutch

Collar

... Female

. .

rin

g . . . . . . . .

Arm

.....................

• • . .

...

er

rt

. . . . . . . . • . • • . . . .1

...........

. . .

Bea

rin

g.

. . . . . .2

..

.. ..

. . . . . . .1

Ball Joi

nt

.......

....

.........

..

...........

.........

. . .

.......

Qty

.2

.1

1

2

.2

2

1

. 1

Porter Sewzng Machines •

97

Rantoul

Street • Beverly,

..MA

01915

Ref#

1

2

3 .

4

5

6

7 .

8

9 . .

10

11 . .BS-306

Part#

...

BS-258

....

FHCS8

.1412

.HN1/4-28

...

2993

. . . .

.....

BHCS10-32X1

..HHCS10-32X1

..

38KLL

.HN1

0-32

....

PC5

-4 . . ..

-32X

1-1/4

.........

.. . .Nut

. . . .

. .

.......

Description

..

Handw

heel

.Screw

Positioner

..

Push

Rod

/4

.Screw

. . . . . . .

... Scr

ew

.B

earing

.Nut

. . . . . .

.Washer

Bus

hing

PBS

Adaptor

. . .

Adaptor... .

.. .. ..

. . . . . . . . . . . . 1

.

. . . . . . .

. . . . . . . . . . 1

..

..

.

.. ..

..

.. .. . .. ..

700

Blind

. . . . . . .

.. ..

..

..

. • . . 1

. . . 1

....

..

...

Stitch Machine

Qty

Ref # Part

.1

12

...

BS-305

.3

13

....

BS-304

1

14

..

BS-213

2

15

..

BS-2

16 . ..SHCS8-32X3/4

17

....

3032U

18

. .

.3007

1

19

..

GR3070037

.1

20

.BS-281

1

21

....

HHCS1

22 . ..SHCS8-32X7/8

#

44

. . . . . . .

Description

..

........

. . . . .

. .

. .

0-32X1 ...

.

Ecc. Dri

. .

Ecc. Dri

Pulley . ..

.Dirve

Flange

.Screw

... Pulley

Rod

End

.. Belt

..

Hand

Wheel Shaft

Screw

..

Screw

GEARBOX (REAR)

ve

Retainer . ..

ve

Hub . .. .. ..

..

..

. . . • . . .

..

..

. . . . . . . . . . .

.

..

.. . .. ..

. . . .

..

..

. . . .

. .

..

.. . ..

..

.. ..

. . . 1

....

..

..

. . . . . . . 1

.

Qty

.1

..

.. 1

. ..4

.1

.1

....

..

31

1

1

1

4

Telephone

800-343-8138 or 508-922-2611 •

Fax

617-599-7081

32

LOWER PULLER

Ref#

1 . .

2 .

3 . .

4

5 .

6 . .

7 . .

8

9

10

11 . .122NR

.....

.....

Part#

.5284

.BS

.S

BS

..BS

SS1

exp1

400

..

BS

.BS

S1/4

316

203

234

/4 28x3

/8x

Rpp 5-9 .

232

238

. . . . . . .

.......

28x3/8

. .

. .. .

/8

5/8

. . .

......

. .

Description

.Gro

oved

Lower

Roller

.Screws

..

..

.Yoke

..

. . . . . . . .

Yoke

Bracket

Yoke Pivot

Screws

Pin

..

.. ..

Tim

ing

Belt.

. . . . . . . . . . . . . . 1

Shaft

Air

Cylinder

PBS 700 Blind Stitch

Oty

Roller

. . . . . . . . . . . . . 1

Stripper

.. . ..

Shaft . ..

. . . •

. ..

. . . . •

.. ..

..

..

. . .

..

............

.....

..

..

. • .

..

..........

.......

. . 1

.. . ..

.. ..

........

1

6

.

.1

.1

6

1

1

1

Machine

Ref # Part

12

...

13

14

15

...

16

.. ..

17

. .

18

19

....

20 . ..

21 . .SHCS

#

BSp25 ....

..

SHCS 1/4x1

.BS

201

.BS

202

BS

233

3011

.BSp

25

BS 239 . . .Sha

BS

405

. .

.

..

.........

. .

..

. .

8·32x3

Description

. Pulley.

...

Screws.

.Mou

nting

.Cylinder

Yoke

Bracket

Yoke

. .

..

Pulley

.. ..

ft

.. . ..

Spacer

/8

Screws

.............

. .

Bracket

Suppo

Shaft

• . . . . . •

..

. . .

rt

. . . . 1

..

..

....

..

..

.

.. . ..

.. .. ..

.

....

........

..

..

. . . . 1

.........

......

..

... .. .

Oty

...

...

.

....

..2

. 2

1

1

4

.1

.2

2

Porter Sewing Machines •

97

Rantoul

Street • Beverly,

.M:A

01915

Ref#

Part#

Description

PBS

700

Blind Stitch Machine

Qty

Ref # Part

33

LOWER DRIVE ASSEMBLY

#

Description

Qty

1 ..

2

..

...

..

3

4

.....

5 ..

6 . .

7

..... B7-

8

.....

9 ..

10

..

11 ....

BS-236

BS-237

BS-235

. . . . . .

BSP-25

. .

CS53

.BS-247

38

. . .

BS-254

........ Shaft

6044K3

1 .

HN3/8X16

BS-249

. .

Universal

. .

Shaft

.Universal

..... Pulley

. .

.Co

. . . .Sh

.Bearing

.Knob

.Nut

. .

.Pulley Plate

Joint

..........

. . . . .

Joint

. . . . . . . . . . . .

llar. . . . . . . . . . . . . . . . . . . . . .

aft

Support

..........................

. .

. . .

. • . . . .

. . . . . . .

..

.. ..

. .. .. ..

. . . . . .

..

......

. .

...........

.. .. ..

1

12

....

BS-246

.1

13

.SHCS8-32X5/8

14

.BS-252

15 . .BS-251

16

....

BS-248

17 . .BS-245

18

.CD1-3

19

.01

20 ....

BS-255

21 .SHCS8-32X3

22 . .EDSS1 0-32X3/8

..

.1

.4

2

.4

.4

1

.1

.1

.1

. .

. .

........

........

. .

-25

........ Adj.

.......

Alignment

.Screw

. . . . . . . . . . . . . . . . . .

.Shaft

. . . . . . . .

. .

/8

.Hinge

.Was

.Screw

.Screw

. . . . . . . . .1

Base .................

Block . .. . .. .. .. .. .. ..

her

Snap

Ring

Screw

. . . . . . . . . . . . . . . . . .

. . . . . . . .

Nut

...................

....

.

......

..

..

.....

. . . . .. . .

. . . . . . .1

. . . . . . . . . . . . . .

.......

......

1

. . 2

.1

. 1

1

.2

1

8

.4

I

I

I~

Telep

hone

800-343-8138

or 508-922-2611 •

Fax

617

-599-7081

34

UNDER TABLE

Ref# Part#

1

..... LTV-

2

.....

T-1

3

TS1

.BS-

4 .

Description

110 .

... AirMani

. . ..... Air T

-1/4 . .Ta

263

. .C

fold ......

ub Fitting

ping Screw

yli

nder Bra

PBS

1/8 .

cket

. . . • . .

700

. . . . . . . . . . . . . . 1

. .

Blind Stitch Machine

Qty

. . 1

. .

.4

.....

Ref#

5 .

6

7 .LKCL2

1

.. ..

Part#

122

.6147

R . .

20

Description

.Cylind

.B

. .Air

elt

Guard

Acc

er

uator

..

...........

.........

Qty

. 1

...

.. ..

1

1

Porter Sewing Machines •

97

Rantoul

Street • Beverly,

.M'A.

01915

•

']'1.·'~

r

I

r

·~

,-.

I

r

I'

!'

I

'r-

36

PBS

700

Blind

Stitch Machine

INDEX

Part#

122NR

122R

1412

1412

1611A

2993

2993

3/8-16X23/8-16X2-1/2 0

3006

3007

3007

3011

3011 0 00 00

3011 00

30320

3032U 0 0

375

375R

38KLL

38KLL

400

41-V

425RPP5

425RPP5

450RPP5 0 .... 0026

450RPP5-9

528

5284

6044K31

6072K21 ........

6072K31

614720

6C32

700000

700010

7

700030

700

700030

700040

700050 0 ••

700060

700070

700080

700090

700095

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0

0 • • 0 0

0 0. 0

0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0

0 0 0

0 0 0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 0 0 0

0 0

0 0 0

0.

0 0 . 0

RPP5

PP5

0 0

0

Rpp

5-9

00

00

3 0 0 0

0 0 0. 0

H3712

0 0 0 0 0 0 0 0 013 . 0 0

00020

0 0 • 0 013 . 0

0 • . • • 0

030 0 ........

0 . 0

0 0 0 0

..

00 ...

. .

0 0

........

Page

032

034

31

027 018

024

031

027

1/2 0

-9

-9

......

0 . • 0

0 0 0

0. 0...

028

024

030

027

0031 0 18

0032 0 17

00

00

024

00.

00

..

28

027 0 03

.31 . 17

0 0 0 0 0

.25

0 0 0

..

28

27 0 022

03

00 ...

32

..

00

00

027

0 0

026

. . 030

00

..

030

024 0 13

032 . 01

0033 ....

26

030 0 022

.34 . 06

.. 0 ..

30 0 03

13 0 02

14 . 019

18

..

013

13

0 . 013 0

00 0 ....

13

.. 0013

.. . .13

.. 0 013 010

013

Ref # Part

0 0

011

0 0 0

05

0 03

0 0 0

02

0 0 0 05

14

05

16

0 0

014

0 0 0 02

00 011

..

014

..

021

0 0 0

06

1 0

08

..

008

....

7

.7

.7

....

6

00

..

1

9

..

017

01

.3

00 019

..

0

.4

. 0

05

06

....

7

....

8

..

9

.. 011

#

700100

700100. 0

700110

700120 . ..

700130

700140

700150

700160

700160

700170

700180

700190

700190

700200

700200

700210

700210

700220

700230

700240

700250

700260

700270 0 .. 0 ....

70

0280

7

00290 0 ..

700300

700310

700320 0 ...

700330 0 ••

700360

70037

700380

700390

700400

70041

700430

700440

700450

70

0460

700470

700

480 0 . •

700490

700510

700

520

700530

700

540

700550 . 00

Page

0 0

..

0 0

• . 0

. . 0

..

00

....

.. 0 .. ..

0 0

0 0

...... 0 ..

........

0 0

0 0 .

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0 . 021 0 0

0 0

....

00

..

0 0 0 0 0 0 013

0

..

00

....

0 . •

.. 0 14 0 05

0 0

.........

........

0 0

0 0

. . • • • 0

0 0 . .

.... 0 014 0 ..

. . ••• .

0 0

•. 0 14 0 16

. 0 • • • 0

0 0 0 0 0 0 0 0 0

0 ••• 0 0

0 • • 0

. • • 0 15 . .3

0 0 0 0 0 0 0 0

....

. 0

0 0.

..

00

.. 0 0015

.... 0 .. 0015

0 •

16

0.

013

13 0 13

0

13 0 14

13 0 15

013

13

015 0 08

013

13

013

021

13

013

021

013 023

..

013

14

14

014

014

14 0 06

14

014

14 0 09

14

14 0 13

14 0 15

14 0 17

.14

015 0 ..

15 0 02

015

...

15

15

15

15 .

16 0 .1

16 . .2

Ref # Part

0

0.

...

..

...

..

0 0 0

..

..

....

..

....

..

. 1 0

0 .

. 0 0

..

....

..

700560

.4

700570 0 ..

012

700580

700580

700590

16

700600

700610

017

700610

700620

018

700620

19

020

700630

700640

0 1

700650

021

22

700660 0 00

700670

021

700680

.20

700690

024