USER’S MANUAL / INSTRUCTIONS

NITRONOX

10115900 Rev. N 04/2018 www.porterinstrument.com/nitronox

Manufacturer:

Parker Hannifin Corporation

Precision Fluidics Division

Porter Instrument

245 Township Line Road

Hatfield, PA 19440 USA

Office 215 723 4000

Fax 215 723 5106

This product complies with the Medical Device Directive (93 / 42 / EEC). A “Declaration of Conformity” in

accordance with the directive has been made and is on file.

European Communities should contact the Authorized Representative listed below regarding any Medical

The Quality System for Porter Instrument is certified to ISO 13485. The scope of our registration is:

“The design, manufacture, distribution and servicing of Nitrous Oxide – Oxygen Sedation Flowmeters, Gas

Scavenging Systems, Gas Distribution Systems and Office Communication Systems for use by a physician,

dentist or licensed healthcare Professional.”

Check our website: www.porterinstrument.com for additional information.

To register your product: www.porterinstrument.com/resources-dental choose Warranty tab.

To download a User’s Manual: www.porterinstrument.com/resources-dental choose Manuals tab

Device Directive (MDD) inquiries.

Contact Name: Parker Hannifin Ltd Instrumentation Products Division

Mailing Address: Riverside Road, Pottington Business Park

Barnstaple, EX 31 1NP, England

Phone: +44 (0) 1271-313131 Fax: +44 (0) 1271-373636

Nitronox® Inhalation Analgesia System - Serial Number:

Table of Contents

Examination ............................................................................................................. 1

Warnings and Precautions ....................................................................................... 2

New or Modified Installations ................................................................................... 3

Side Effects / Contraindications ............................................................................... 4

Development of Nitronox Delivery Protocols ........................................................... 5

Self-Administration vs. Assist to Self-Administration ............................................... 6

Demand Valve Instructions ...................................................................................... 7

Installations: Preparation of Mobile E-Stand ............................................................ 9

Installations: Preparation of Nitronox Scavenger Parts ........................................... 11

Installations: Attachment of Cylinders ...................................................................... 12

Description ............................................................................................................... 13

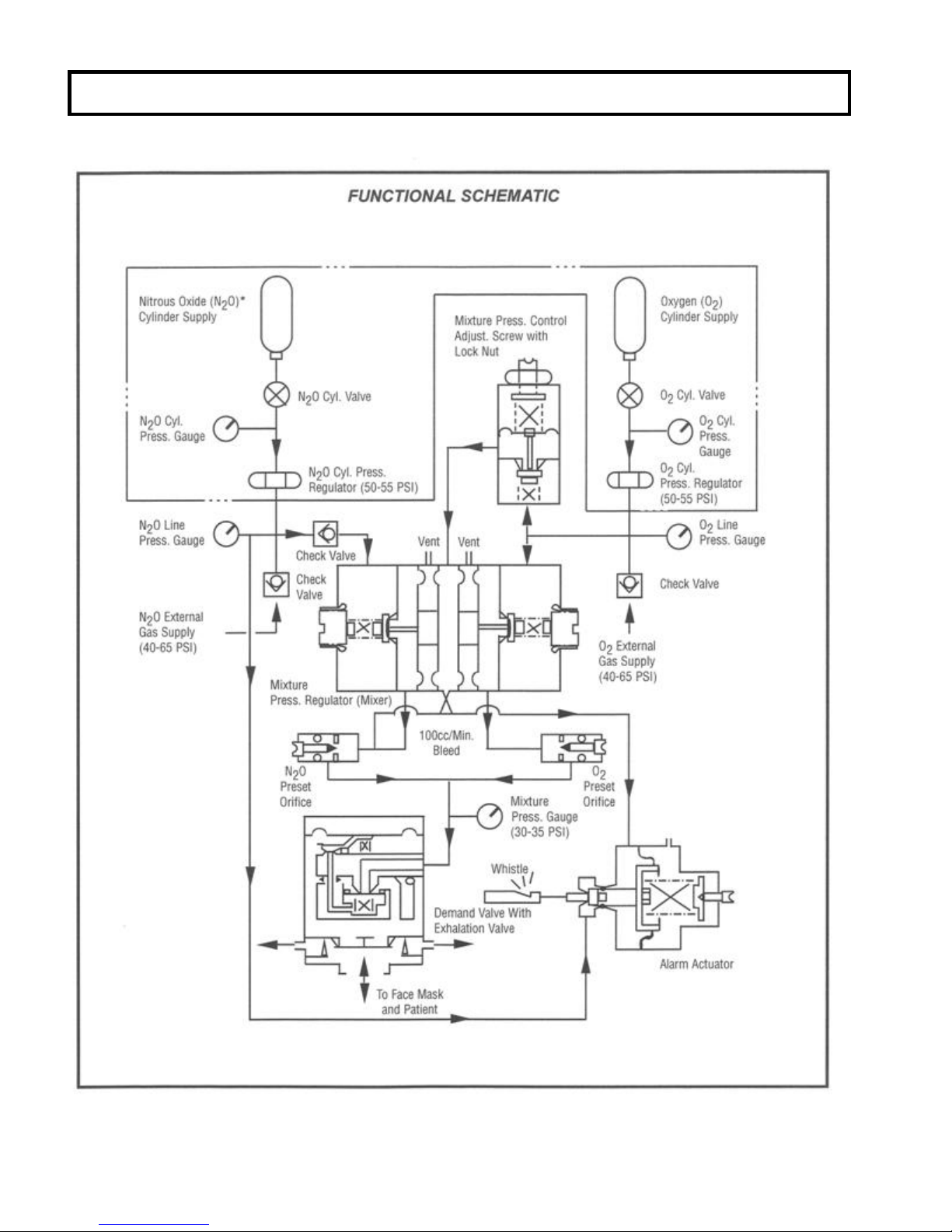

Functional Schematic .............................................................................................. 14

Specifications / Functional Features ........................................................................ 15

Functional Warnings and Cautions .......................................................................... 15

Functional Tests ...................................................................................................... 15

Operation / Maintenance ......................................................................................... 16

Troubleshooting ....................................................................................................... 20

Warranty .................................................................................................................. 21

Examination

Examine shipping carton for signs of external damage.

Remove contents from carton and inspect for visible damage or missing parts.

If damage is discovered or suspected and/or parts are missing, notify Porter or authorized

distributor immediately.

1

IMPORTANT:

READ MANUAL COMPLETELY BEF OR E OP ER ATI NG T HI S DE VI CE

Basic delivery technique is described. Also, this manual contains instructions on periodically required

checks to be performed by the user. These checks are necessary to insure the proper performance of

this device and its safety features. Retain this manual for future reference.

WARNINGS AND PRECAUTIONS

These warnings and precautions are to help

you to understand how to safely operate the

Nitronox device. A WARNING alerts you to a

possible hazard to people. A CAUTION alerts

you to the possibility of equipment damage.

WARNING: New or modified installations properly connected gas pipelines are

absolutely essential to patient safety. The

ultimate responsibility of assuring that lines

are not crossed rests with the user. See

next page for details.

WARNING: Porter equipment utilizes the

cross+protection system. The flexible hose

and connectors that connect to the housing are

diameter indexed; 3/8” O.D. for Nitrous Oxide

and ½” O.D. for Oxygen. The

cross+protection system is designed to

prevent misconnection of Oxygen and Nitrous

Oxide hoses. DO NOT ATTEMPT TO

CHANGE THE DIAMETERS OR

CONNECTORS OF THE DEVICE! Tampering

with the cross+protection system constitutes

acceptance of liability by the installer.

WARNING: Nitronox® Inhalation Analgesia

systems are intended to be used by medical

personnel trained in its use and the use of

nitrous oxide and oxygen for medical

applications.

WARNING: Do not use this device for the

administration of general anesthesia or as a

part of, or in conjunction with, a general

anesthesia administration system.

WARNING: Use Scavenging

Monitor for N2O in the patient treatment area

to insure that controls are effective in achieving

low levels of ppm (parts per million) exposure.

Contact Porter or Authorized Distributor for

details on monitors and testing.

Inspect and maintain the analgesia delivery

system to prevent N2O leaks in all hoses,

connections and fittings. Have all leaks

repaired immediately.

WARNING: Medical workers are exposed to

O during administration of N2O/O2 conscious

N

2

sedation analgesia. NIOSH has recommended

that exposures should be minimized. Contact

NIOSH (1-800-35-NIOSH) to receive NIOSH

Publications on Control of Nitrous Oxide in

Dental Operatories. Exposure can be

minimized by effective controls. National

Institute for Occupational Safety and Health

(NIOSH) publications state that controls,

including System Maintenance, Ventilation and

Work Practices can effectively reduce N

O

2

concentrations in patient procedures. Your

accessory Porter Nitronox Scavenger System

is an important part of the system of controls in

medical settings.

WARNING: When using a single use

full face mask, not supplied sterile.

Dispose of mask after use to prevent

patient cross-contamination. When

using multiple use mask, follow

manufacturer’s sterilization

instructions.

CAUTION: Always use clean, dry medical

grade gases. Introduction of moisture or other

contaminants into this device may result in

defective operation.

CAUTION: Do not attempt to repair, alter or

calibrate this device. Unauthorized repair,

alteration or misuse of this device is likely to

adversely affect the performance and will void

the warranty.

CAUTION: Never oil or grease any part of this

system (minimize fire or explosion potential).

2

NEW OR MODIFIED INSTALLATIONS

WARNING:

ALWAYS ASSURE THAT LINES ARE NOT CROSSED!

WARNING: New or modified central supply installations - properly connected gas pipelines are

absolutely essential to patient safety. The authorized distributor or contractor should provide written

documentation that all gas pipelines are connected properly and that the system has been pressure tested

prior to use. While this is a good business practice, it is important that the user verify by their own test,

independent of the authorized distributor or contractor, that all gas pipelines are connected correctly prior to

using the system. The ultimate responsibility of assuring that lines are not crossed rests with the

user.

Do not allow crossed lines to defeat the safety features of the Nitronox and/or central

gas supply manifold systems. Crossed lines will create a dangerous and hazardous condition

where, under a loss of oxygen supply, 100% nitrous oxide will be delivered through the oxygen

delivery path and subsequently to the patient.

Maintain patient observation during procedures. Prevent over sedation. If a patient becomes over

sedated when being delivered 100% oxygen [during an apparent loss of nitrous oxide supply], it is a

definite indication of crossed lines. If crossed lines are suspected, remove the mask immediately

and encourage mouth breathing. Deliver pure oxygen from an oxygen demand valve only if the

oxygen source is independent from the suspected crossed lines area.

INPUT PRESSURE DIFFERENCES

WARNING: Oxygen input pressure more than 15 psi (1 bar) higher than Nitrous Oxide input

pressure will cause low oxygen percentage mixture delivery. DO NOT use Nitronox if O2 input

exceeds N2O input by 15 psi or higher.

3

SIDE EFFECTS & CONTRAINDICATIONS

Note: This is not an exhaustive list. The list was prepared from published articles.

Possible Side Effects of Nitrous Oxide – Oxygen Conscious Sedation: May experience

nausea, vomiting, excessive sweating, euphoria, excitement, deep sedation, drowsiness, sleep,

dizziness, lightheadedness, dysphoria, amnesia, and headaches.

Precautions and Contraindications for Nitrous Oxide Use

Precautions/Relative Contraindications

Discontinue the Nitrous Oxide delivery if observed: prolonged inspirations,

irregular breathing, involuntary eye movements, swallowing or gagging, dilated

pupils and rigid muscles.”

Side effects (e.g., nausea, vomiting, dizziness, dysphoria, etc.) are not tolerable

Current vitamin B

deficiency

12

Bronchoconstrictive disease (asthma) – (at determination of medical professional)

The use with pediatric patients, especially age 1 to 4 years, requires caution and

specific protocols developed by the medical professional; upper age limit at

determination of medical professional. Weight limitations at the determination of

medical professional.

Contraindications

Inability to hold own face mask, impaired oxygenation, or hemodynamic instability

Acute drug or alcohol intoxication or impaired consciousness (head injury,

endocrine or metabolic disease, patients taking antidepressant or psychotropic

drugs), psychologic impairment, patient who has taken medication to induce sleep.

Decompression injuries, increased intracranial pressure, increased intraocular

pressure, intraocular surgery, bowel obstruction, middle ear surgery, emphysema,

pulmonary hypertension and others

Current upper respiratory tract infection, chronic obstructive pulmonary disease

(COPD), cystic fibrosis, shock, acute pulmonary edema (APE), pneumothorax, and

major chest or maxillofacial trauma, bleomycin therapy, recent

pneumoencephalography

Pregnancy (first trimester) – patient may wish to contact OBGYN / medical

professional.

4

Development of Nitronox Delivery Protocols

It is the responsibility of the medical establishment and the medical professional to develop and

establish specific delivery protocols.

The Nitronox® Inhalation Analgesia System is designed to deliver a fixed concentration of 50%

nitrous oxide and 50% oxygen on the demand flow [self-administration] principle. The medical

professional will turn on and observe the operating indicators of the device. In order to receive the

analgesic, the patient will self-administer by holding the face mask firmly in place during the

procedure. With the face mask sealed every time the patient takes a breath, the patient inhalation

will open the demand valve and deliver the mixed gas through the face mask.

Common procedures conducted with Nitrous Oxide – Oxygen Sedation include:

General Pain Management, Labor and Delivery, Wound Debridement, Fracture Reduction,

Catheter Insertion, Foreign Object Removal, Setting Broken Bones / Lacerations, Botulinium

Injection, Barium Enema, Joint Injections, Gastrostomy, Sutures, IV Starts, CT Scans.

The Nitronox Inhalation Analgesia System is considered transient (less than 60 minutes) in terms

of continuous use when providing Analgesia (pain management), Minimal Sedation or Moderate

Sedation. However, a procedure or medical condition that occurs over the course of many hours,

also is considered to be using transient delivery, in that, given self-administration techniques, the

patient will be unlikely to hold the face mask to the face continuously for over 60 minutes. For

example, a woman in labor may safely use Nitronox in a transient self-administration mode over

the course of several hours as secondary labor and end labor stages are experienced. The upper

limit of the number of hours of this described transient delivery is at the determination of the

medical professional.

Patient Population (Adult and Pediatric): Used to deliver a gas mixture to a conscious

spontaneously breathing patient who is awake, alert and cooperative and requires relief

from moderate to severe pain and is under the continuous supervision of a healthcare

professional. Age/Weight limitations: see Relative Contraindications (at the determination

of medical professional).

Note: Porter recommends the use of a disposable full face mask (DEHP-free and Latex-free) that

is biocompatible for medical use. Follow manufacturer’s instructions. The disposable mask

materials have been chosen by the medical device manufacturers of the masks intended for

medical usage. Many establishment protocols also call for the use of a bacterial filter. Follow

manufacturer’s instructions.

Continuous flow vs. demand flow devices

Equipment to deliver nitrous oxide and oxygen sedation are often categorized as demand

flow or continuous flow devices. The Nitronox is a demand flow device. Different specific

delivery protocols will be established for the two categories of equipment. The differences

center around self-administration for demand flow devices vs. direct administration by

medical professionals for continuous flow devices. Also, continuous flow devices typically

allow the administration of variable concentrations of nitrous oxide and variable flow rates

of delivered mixture. However, some establishments have developed specific protocols

for delivery with continuous flow devices, where the medical professional is able to adjust

to deliver various percentage mixes, where, with supervision, the delivery could be

described as “self-administration,” in that the patient will hold the full face mask to the

face.

5

SELF-ADMINISTRATION VS. ASSIST TO SELF-ADMINISTRATION

WARNING: Encourage patient to self-administer. Self-administration is a safety feature of the

demand flow Nitronox in that, if for any reason the patient becomes over sedated, the patient will

be unable to successfully hold the mask in a tight seal position on the face. The result will be that

the mask falls away from the face and the demand flow will cease, allowing the patient to breathe

room air in through the mouth or nose.

WARNING: If a patient is unable to fully self-administer, and the medical professional provides

an assist to placement of the mask in a sealing position on the face, maintain patient observation

to prevent over sedation under any conditions. Discontinue the assistance in mask placement

immediately upon any observation of over sedation; remove the mask from the face entirely.

Never use a mask strap to hold the mask to the face. Never force the mask on the face; the

patient must always be spontaneously breathing.

At the determination of a medical professional, as an added precaution for procedures where an

assist to self-administration is used, the medical establishment may elect to continuously sample

the mixture delivery downstream from the demand valve by installation of an oxygen analyzer.

Self-administration for pediatric patients

Some establishments have developed specific protocols instructing the provider to

administer (“assisted-mask application” of Nitronox) nitrous oxide to pediatric patients,

typically ages 1 to 4. The concept that, for certain circumstances, the use of the Nitronox,

or the use of other demand valve delivery systems, should have a protocol where the

provider administers the nitrous oxide, as opposed to complete self-administration, is in

potential conflict with protocols for labor analgesia, where there is an emphasis on selfadministration. It is the responsibility of the medical establishment and the medical

professional to develop and establish specific delivery protocols.

Self-administration for laboring women

Establishments that have developed specific protocols for laboring women often include a

particular emphasis on self-administration and education for the laboring woman and for

her support persons on the techniques of self-administration. In these specific protocols,

the establishments have concluded that nitrous oxide can only safely be self-administered

by the laboring woman; with support persons needing to be educated that they absolutely

cannot assist in the delivery of nitrous oxide by holding the mask up to the laboring

woman’s face, since an integral safety feature of nitrous oxide use is that when the woman

has physiologically reached her limit of nitrous oxide intake, she will no longer be able to

hold the mask up to her face for more, thus self-regulating the intake. The establishments

have concluded that when someone else is allowed to hold the mask up to her face, the

potential risk of losing consciousness increases dramatically. Thus, there is an initial and

repetitive education for the laboring women and support persons.

6

DEMAND VALVE INSTRUCTIONS

Description: The demand valve of the Nitronox Inhalation Analgesia System is designed to be

used with a full face mask (Porter recommends a standard, single use, disposable mask, not

supplied sterile, DEHP-free, Latex-free, with materials chosen by the manufacturer for

biocompatibility in a medical setting) for administration of nitrous oxide to a breathing patient. It

contains no buttons or levers to force the gas into the patient and is for self-administration.

Do not strap mask on patient. Allow the patient to hold the mask over the nose and mouth to selfadminister. Upon inhalation, the demand valve opens and the nitrous oxide / oxygen mixture will

start to flow. Ceasing to inhale or if the patient stops breathing, the valve automatically closes to

stop the flow of the nitrous oxide / oxygen mixture.

Specifications:

Flow: The demand valve (through the Nitronox housing) is to be connected to a nitrous oxide

supply capable of delivering a minimum of 100 LPM @ 40-90 psig (2.8–6.2 bar). The valve itself:

160 LPM set flow: As required in demand mode 0-160 LPM at 40 psig.

Inlet fitting: Standard male DISS.

Filter: 2 micron sintered stainless steel.

Outlet: 22 mm outside diameter x 15 mm inside diameter (fits standard medical masks).

Materials: Housing and plastic parts: “Noryl”, polyester, polysulfone. Moving and adjusting parts:

Stainless steel. Fasteners: Steel, brass and aluminum all plated for corrosion resistance. Rubber

parts (except hose): Silicone

Maintenance: Cleaning (specific to the demand valve)

WARNING: Do not use near open flame or in an unventilated area. Can accelerate

burning and be toxic.

WARNING: Since the described cleaning procedures for the demand valve call

for disassembly of components, the procedures must be performed in a

hydrocarbon residue free area because of the danger of spontaneous combustion

when the residues are exposed to nitrous oxide.

Standard Cleaning and Disinfecting After Use

1. Remove (unscrew) the outlet adapter housing (mask connection outlet) and remove

(lift) the exhalation valve assembly (with attached flapper valve) from the main demand

valve subassembly. Do not remove the hose assembly.

2. Clean all foreign matter from the adapter housing, exhalation valve assembly, and

outside surfaces of main demand valve subassembly with mild soap solution, being

careful not to get any liquid inside the demand valve subassembly. Rinse the parts

thoroughly in clean water.

3. Carefully examine the three assemblies of the demand valve. Discard and replace any

cracked or damaged parts. Contact Porter for replacement assemblies.

4. Disinfect the demand valve (and collection manifold).

7

Cold Disinfecting

1. Remove the outlet adapter and the exhalation valve assembly from the demand valve

assembly as described above. Clean the outlet adapter and the exhalation valve

assembly using a disinfecting solution approved by your facility. (Refer to

Manufacturer’s Recommendations). Do not allow any solution inside the demand valve

subassembly.

2. Remove the outlet adapter and the exhalation valve assembly from the solution and

rinse thoroughly with sterile water. Rinse repeatedly to be sure that all of the solution is

removed from the parts.

3. Check the exhalation valve assembly to be sure the flapper valve is not twisted.

WARNING: If the flapper is twisted or not properly positioned, the demand valve will not

function properly. Make sure that the flapper valve lies flat against its seat.

4. Reassemble the parts

Maintenance:

Replacement Parts: Outlet Adapter Housing, Exhalation Valve Assembly, Sintered Stainless

Steel Filter

Recommended Overhaul Period:

The demand valve should be overhauled annually. Contact Porter for details.

WARNING: Do not disassemble or tamper with the main demand valve subassembly.

This will void the warranty. Improper disassembly or improper assembly procedures

may alter the performance of the valve which could cause serious injury to the patient.

In case of malfunction, return the demand valve to Porter immediately.

8

Installations

Nitronox Main Housing, Mobile E-Stand (Fig. 1.1), Mobile Stand, Wall Mount (Fig. 1.2),

Demand Valve, Corrugated Hose, Scavenger Interface

Preparation of Mobile E-Stand Fig. 1.1

Also see FM-916 E-Stand User’s Instructions

1. Slide Center Column with Cylinder

Restraint and Cylinder Yoke Block into 5Star Base (Fig. 2.1). Push down firmly until

snug. Align Cylinder Restraint as shown.

Base of cylinders will fit in between wheels

(Fig. 2.2).

Fig. 2.1

Fig. 2.2

2. Adjust the Recessed Mounting Post to

highest height by loosening and tightening

the small black handle (Fig. 3.1) on the

Yoke Block – and raising the Mounting Post

(Fig. 3.2).

Fig. 3.1 Fig. 3.2

3. The Nitronox Main Housing will mount on

the Mounting Post of the E-Stand [or Mobile

Stand] by sitting the bottom of the Housing

(Fig. 4.1) on top of the Mounting Post

(larger threads Fig. 4.2). Hold the Mounting

Post in one hand and position the Housing

with the other.

Fig. 4.1

Fig. 4.2

4. Secure the Housing on the Mounting Post

(Fig. 5.1) by twisting the Post

(counterclockwise) with one hand and

holding the Housing steady with the other

hand. Twist until the Post is snug (Fig. 5.2).

9

E-Stand with Nitronox Wall Mount

Fig. 1.1

Fig. 5.1

Fig. 1.2

Fig. 5.2

Preparation of Mobile E-Stand (continued)

5. Attach the Handle (Fig. 6.1) to the Mounting

Post – just under the Retaining Ring / Oring (Fig. 6.2). Firmly tighten both screws so

that the Handle cannot be twisted. The

back of the Handle should be positioned

over the back two cylinders (Fig. 6.3).

Fig. 6.1

Fig. 6.3

Fig. 6.2

6. Carefully clip the [shipping accessory]

plastic fasteners off of the green Oxygen

Hose and blue Nitrous Oxide Hose – under

the E-Stand Block (Fig. 7). Be careful – do

not cut the Hoses.

Fig. 7

10

7. Connect the Diameter Indexed Safety

System (DISS) color-coded green [white]

Oxygen and blue Nitrous Oxide Hoses to

the appropriate connections (Fig. 8.1) on

the bottom of the Nitronox Main Housing.

Slide the Hoses through the opening in the

Handle (Fig. 8.2) before connecting. Firmly

tighten the Hoses using a wrench.

Fig. 8.3 (shown with white hose)

Fig. 8.1

Fig. 8.2

Preparation of Nitronox Scavenger Parts

For further details, refer to Nitronox Scavenger

System User’s Manual 10152100

8. Connect the Demand Valve (Fig. 9.1) to the

black Gas Delivery Hose (connected

through underside of Nitronox Main

Housing Fig. 9.2). This is a quick connect

attachment. Push the two ends together

until click sound is heard (Fig. 9.3). To

remove – push the metal clip in – and pull

apart.

Fig. 9.1

Fig. 9.3

9. The bracket and clip on the side of the

Housing (Fig. 10.1) may be used to hold

the Demand Valve assembly and Hoses

when not in use (Fig. 10.2).

Fig. 10.1

Fig. 10.2

Fig. 9.2

11

10. Follow instructions FM-1236 included with

19mm Magenta Hose: Part number

92120041 – 19mm Corrugated Scavenger

Hose Assembly Instructions. (Figs. 11.1,

11.2, Fig. 12)

Nitronox Scavenger on Housing

Fig. 11.1

Fig. 11.2

Fig. 12

11. Attach the Nitronox Scavenger Interface to

the Center Column (Figs. 13.1, 13.2).

Fig. 13.1

Fig. 13.2

Attachment of Cylinders

Caution:

take care not to catch or pinch fingers.

12. Loosen the Tee Handle (Fig. 14.1) until

point is even with the inside of the Swivel

Arm. Push Tee Handle inwards to flip to

open position. Align Tee Handle vertically

(Fig. 14.2).

Fig. 14.1

13. Undo the Hook & Loop straps on the

Cylinder Restraint (Fig. 15)

14. Cylinder Preparation: Remove any plastic

wrap from the top of cylinder, including the

cylinder plastic washer. Verify that the

rubber washer (Fig. 16.2) provided with the

E-Stand is still in place. Use the E-Stand

washer.

15. Mount the “E” cylinders of Oxygen and

Nitrous Oxide (not included) to the E-Stand

Block. Insert cylinders correctly on indexing

pins and as marked on Block (N

16.1, 16.2; O

mounting in appropriate position.

N

Washer

When operating the swivel yoke,

Figs. 16.3, 16.4). Pins assure

2

O Pins Rubber

2

Fig. 16.1

Fig. 16.2

Fig. 14.2

Fig. 15

O Figs.

2

Fig. 16.4

Fig. 16.3

Do not remove or alter

gas indexing pins

O2 Pins

Warning

16. Slide the cylinder into place by lining up the

pins and pin holes on the cylinder. Push

into place. Properly placed, the cylinder

should hang on the pins (Fig. 17).

17. Cylinders should hang freely between

wheel base. If the wheel base interferes,

loosen and rotate cylinder restraint.

18. Rotate swivel clockwise to close (Fig. 18.1).

Swivel will move into the locked position

when Tee Handle is tightened. Secure the

Hook & Loop straps to hold cylinder in

place (Fig. 18.2).

Fig. 17

Fig. 18.2

Fig. 18.1

Fig. 19

19. The Cylinder Valve Wrench (hanging from

black Knob) is used to open/close Cylinder

Valves (Fig. 19). See FM-916 User’s

Instructions.

12

Description of Unit

The Nitronox® is an inhalation analgesia

system designed to deliver a fixed

concentration of 50% nitrous oxide and 50%

oxygen on the demand flow principle.

Nitronox operates either on pipeline gas

supply using a Mobile Stand or Wall Mount,

or medical “E” or “D” size cylinder supply by

means of a small cylinder yoke block with

regulators (Mobile “E” Stand).

The Nitronox

configurations offering three mounting styles.

1. Nitronox with Mobile Stand only (for use

with pipeline gas supply only).

2. Nitronox with Mobile “E” Stand (Fig. 20)

and cylinder mount- (2) nitrous oxide and

(2) oxygen – “E” or ”D” size. Refer to FM916 for Installation and User Instructions.

3. Nitronox with wall mount (for use with

pipeline gas supply)

Use Nitronox in conjunction with Nitronox

Scavenger System; Refer to User’s Manual /

Instructions 10152100.

Fig. 21 – Nitronox Front Cover with Mixture

Pressure and N

®

is available in various

Fig. 21

O and O2 Line Pressure Gauges

2

Fig. 20

Fig. 20 - Nitronox with Mobile E- Stand

13

Nitronox® Inhalation Analgesia System

9

14

Specifications / Functional Features

Gas Supply Duration Flow Capability Mixture Concentration

“E” Size Cylinders At Normal

Breathing Rates:

N

O Approximately 6 – 6.5 Hrs.

2

O

Approximately 2 – 2.5 Hrs.

2

Oxygen Fail Safe:

If apparatus oxygen line

pressure is depleted or disconnected, nitrous oxide

flow and demand valve flow stops automatically. If

apparatus nitrous oxide line pressure is depleted or

disconnected, demand valve will continue to

function providing 100% oxygen at reduced flow

capacity of about 55 LPM. If patient takes abnormal

shallow breaths (100 to 200 cc tidal volume),

oxygen concentration automatically increases.

Mixer Pressure Alarm: A whistle will sound

when a gas mixture regulator seat malfunction

affecting mixture concentration has occurred.

114 LPM, Maximum Mixture Concentration

(Factory Adjusted)

50% N

O and 50% O2

2

+/- 5 Percentage Points O

Warnings

If WHISTLE ALARM sounds, discontinue

patient use immediately and shut off gas

supply.

WARNING: DO NOT use Nitronox if O2 input

exceeds N2O input by 15 psi (1 bar) or

higher [see Warnings page 3]

2

Warning: Nitronox® Inhalation Analgesia

systems are intended to be used by medical

personnel trained in its use and the use of

nitrous oxide and oxygen for medical

applications.

Warnings

DO NOT use Nitronox if either line or

mixture pressure is out of green band (see

“Maintenance”). Figs. 22.1, 22.2

Encourage patient to self administer at all

times [see Warnings page 3 for details].

Fig. 22.1 Fig. 22.2

Functional Tests

Prior to first use and periodically thereafter (monthly

is suggested), perform the following tests:

Whistle Alarm Actuation:

1. Increase mixture pressure per Page 7, Step 2,

“Maintenance”, until gauge reading is in RED

“Do Not Use” area, per gauge illustration.

2. WHISTLE should sound in this range.

3. If WHISTLE sounds before or after this range,

WHISTLE ALARM ACTUATOR must be

adjusted (see “Maintenance”).

Fail Safe Check-Out Test:

1. With unit in operation (one each O2&N2O gas

supplies on), turn off or disconnect oxygen at

supply source.

2. As oxygen pressure falls to zero (as read on

oxygen line pressure gauge), demand valve

flow must stop completely.

15

Operation / Maintenance

Cylinder Pressure Readings:

compressed gas, while in the cylinder, thus the

cylinder pressure gauge can be used to determine

the amount of gas remaining in the cylinder. For

example, 2000 psi indicates full, 1000 psi indicates

half full, etc. Nitrous Oxide is a liquefied

compressed gas that vaporizes in the cylinder, thus

the cylinder pressure gauge cannot be used to

determine the amount of gas remaining in the

cylinder until all liquid in the cylinder vaporizes.

While liquid remains in the cylinder, the cylinder

pressure gauge indicates the vapor pressure which

depends on and varies with the temperature of the

liquid. For example, at 68ºF (20ºC), the vapor

pressure is about 750 psi (50 bar); at 20ºF (-7ºC), it

drops to about 400 psi (30 bar); while at 90ºF

(32ºC), it increases to about 1000 psi (70 bar). After

all the liquid vaporizes, the pressure will decrease

normally as the gas is withdrawn, and the cylinder

pressure gauge can then be us ed to determine the

amount of gas remaining in the cylinder

Oxygen is a true

.

Cautions

Always turn on CYLINDER VALVES slowly

and fully (“E” cylinder yoke models).

Hex hole in cylinder valve wrench to be

used only to tighten cylinder valve packing

nut in event of a leak.

NEVER ATTEMPT TO LOOSEN cylinder

valve packing nut. If valve stem is tight,

return cylinder to supplier.

Warning: Do not remove or alter gas

indexing pins

Good practices: Cylinders with E- Stand

1. Two cylinders of O

are typically connected at all times. Exception:

When using external gas supply of oxygen, the

E- Stand may be populated with N

and O

cylinders are not placed on “E” Stand.

2

2. Minimize leak risks: Confirm Yoke Washers are

in place before replacing/mounting cylinders.

Use Porter #A-3399-000 replacement washers

(once/yr.). Have spare washers.

and two cylinders of N2O

2

O cylinders

2

16

3. Minimize leak risks: With cylinder in position,

rotate swivel arm and move into secure locked

position when Tee Handle is tightened. To

prevent movement and potential damage to

yoke pins, always fasten the Hook & Loop strap

restraints around cylinders.

4. Assure E- Stand is populated with at least one

full cylinder of O

and N2O before starting any

2

procedure.

5. Label each cylinder with a tag or sticker

indicating “In-Use” and “Full” (“Full” is reserve

cylinder.)

6. Use Cylinder Valve Wrench to open the “InUse” cylinders of O

and N2O. Verify wrench is

2

attached to Block.

7. Cylinder pressure gauges on Block provide a

visual indication of cylinder status (see details

on Cylinder Pressure Readings)

8.

Caution: If all four cylinders (or both cylinders

of one gas) are open, the two cylinders of O2

and N

O will deplete in tandem. The “Full”

2

cylinder will empty with the “In-Use” cylinder

and will not be available as a future spare.

9. When “In-Use” cylinder is depleted, open the

spare “Full” cylinder (Close valve on empty

cylinder).

10. When “In-Use” O

Oxygen Fail Safe will stop N

cylinder is depleted, the

2

O flow and

2

demand valve flow automatically.

11. When “In-Use” N

Nitronox will deliver 100% O

O cylinder is depleted, the

2

through the

2

Demand Valve.

12. After use, turn off cylinder valves.

Caution:

With O2 cylinder turned on, the Nitronox will

have an intentional small O

tend to deplete the O

O

cylinder valve is left on.

2

cylinder if, after use, the

2

bleed, which will

2

Models With “E” Cylinder Yoke (Simple

Operation Procedure)

1. Open one each O2 and N2O Cylinder Valves

with wrench provided.

2. Observe cylinder pressures. Replace cylinder

when less than 300 psi (20 bar), at room

temperature (21.1 ºC, 70ºF). During

replacement, close all Cylinder Valves.

3. Observe line pressures (Figs. 23.1, 23.2).

Normal is 50-55 psi [3.4–3.8 bar] (green band)

for static no-flow condition. Pressure will

decrease slightly during each inspiration (see

“Maintenance”).

4. Observe mixture pressure (Fig. 23.3). Normal is

30-35 psi [2.0–2.4 bar] (green band) for static

no-flow condition. Pressure will decrease

slightly during each inspiration (see

“Maintenance”).

5. If all pressures are normal, Nitronox is ready to

use. Remove Demand Valve with Mask from

storage bracket. Instruct patient to hold Mask

lightly on face covering nose and mouth.

Instruct to breathe normally, preferably through

nose.

Encourage patient to self administer at all

times [see Warnings page 3 for details].

6. After use, turn off Cylinder Valves; store

Demand Valve with Hose. Dispose of single

use mask (not supplied sterile).

Models Using Pipeline or External Gas

Supply (Mobile Stand or Wall Mt.)

1. Connect external gas supply hoses to DISS

(Diameter Indexed Safety System) fittings.

External pressure must be 40-65 psi (2.8–4.5

bar), preferably 50-55 psi (3.4–3.8 bar).

Observe external pressures on apparatus LINE

PRESSURE GAUGES. WARNING: DO NOT

use Nitronox if O2 input exceeds N2O input

by 15 psi (1 bar) or higher.

2. Observe mixture pressure as in step 4 above.

3. Follow step 5 procedure above.

4. After use, disconnect external gas supply.

17

Fig. 23.2

Fig. 23.3

Fig. 23.1

Maintenance

1. Line Pressure Adjustment: (Green Band

for Model Using Mobile “E” Stand): Locate

appropriate PRESSURE REGULATOR (blue

lettering – nitrous oxide; green lettering –

oxygen); remove 9/16” acorn nut; insert 5/32”

hex socket key and adjust pressure to within

green band.

2.

Mixture Pressure Control Adjustment:

(Green Band): Remove LOWER CHROME

PLUG from case back. With wrench, loosen

7/16 inch hex nut (counterclockwise)

approximately one quarter turn. Insert

screwdriver through access hole, in bottom of

case, into slot of adjusting screw. While holding

nut with wrench, adjust counterclockwise to

increase pressure – clockwise to decrease.

After adjustment, tighten nut while holding

screw in position with screwdriver (see

illustration Fig. 24).

3. Leak Test System – Monthly Check of

working pressure leaks. Verify hoses are

attached from E-Stand to Nitronox Housing.

Turn one O

Stand pressure gauges read cylinder

pressures. Verify Nitronox line pressure gauges

read within green band. Note: fail safe is open

and pressure reaches Demand Valve. Turn off

N

O cylinder valve. Verify that N2O E-Stand

2

gauge reads about 750 psi (50 bar). Note exact

needle position. Verify that there is little or no

movement [up to ½ increment] of the exact

needle position in 15 minutes. Nitronox N

line pressure gauge needle will stay in green

band with no movement. Turn off O

valve. It is normal that needle of O

gauge will drop. Nitronox O

gauge needle will stay in green band with no

movement (will eventually drop after E-Stand

gauge pressure naturally depletes).

4. Whistle Alarm Actuator Adjustment:

Remove UPPER CHROME PLUG from case

back (Fig. 25). With mixture pressure

temporarily adjusted (per Step 2,

“Maintenance”) in middle of range shown (Fig.

26), insert 1/8” hex key (not provided) into

adjustment screw at end of ALARM

ACTUATOR. Adjust screw either clockwise or

counterclockwise until whistle sounds clearly.

DO NOT over adjust. Return mixture pressure

to middle of green band. Whistle sound must

stop with pressure in green band and whistle

must sound with pressure in range shown in

Fig. 26 (about 40 psi [2.8 bar]). If this cannot be

achieved, discontinue use of apparatus and

notify authorized distributor immediately.

and one N2O cylinder on. Verify E-

2

cylinder

2

E-Stand

2

line pressure

2

O

2

Fig. 24

Alarm

Actuator

Fig. 25 Back of Case; Upper adjustment access

Temporary

mixture pressure

Fig. 26

adjust range

18

Maintenance

5. Cleaning Methods

We recommend the use of an approved disinfectant for the dental / medical environment for cleaning the

outside of the Nitronox, demand valve, and accessories. Do not spray disinfectant directly onto housing.

Spray disinfectant into disposable towel and wipe unit thoroughly removing excess disinfectant to eliminate

buildup. Follow the manufacturer’s directions for use.

Introduction of moisture or other contaminants into this device may result in defective operation.

grease any part of this system (minimize fire or explosion potential).

See special demand valve cleaning instructions.

Never oil or

6. Replacing the E-Stand Check Valve

See FM-916 E-Stand for illustrations and instructions for replacement of the Check Valve Assembly.

Field repair of the Nitronox is limited to maintenance adjustments and replacement parts obtained

through Porter. All other repairs should be performed by an authorized Porter service representative.

Although the materials contained in the Nitronox Inhalation Analgesia System do not have a specified shelf life,

Porter advises a factory performance check and repair procedure every 2 years. It is Porter practice to

recommend a complete factory elastomer change out after every 10 years of product operation in the field.

Following this schedule of maintenance and repair will assure a useful product operation field life of 15 years or

more.

Also, to assure a long useful product operation field life, perform the periodic field performance tests and

adjustments, including the Line Pressure Adjustment, the Mixture Pressure Control Adjustment, the Leak Testing

of the System, and the Whistle Alarm Actuator Adjustment.

Perform the specific cleaning procedures for the Demand Valve. It is advisable to overhaul the Demand Valve

annually.

Note: In the Nitronox Scavenger System User’s Manual / Instructions 10152100, the maintenance is to replace

the foam resistor every 6 months.

19

Troubleshooting

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

1. Leakage at YOKE

CYLINDER VALVE

connection.

2. Low or no reading on

CYLINDER GAUGE with

CYLINDER VALVES open.

3. O2 cylinder (or external

supply) used too quickly

4. Line pressure out of green

band.

5. Mixture pressures out of

green band.

6. WHISTLE ALARM failure

during functional test.

7. WHISTLE ALARM sound

Note: a momentary “chirp”

sound is acceptable upon

initial application of pressure if

whistle then stops [reseats]

Missing or defective yoke seal

washer (models with “E”

cylinder yoke); damaged pins.

Cylinder pressure too low or

cylinders empty (models with

“E” cylinder yoke).

O2 cylinder valve (or external

supply) left on after use and

natural bleed depletes cylinder

(or external supply).

O

cylinder contains up to 2.5

2

hrs. breathing supply; N

O

2

cylinder contains up to 6.5 hrs.

Apparatus exposed to

temperature below 32ºF / 0ºC.

PRESSURE REGULATOR out

of adjustment (models with “E”

cylinder yoke).

PRESSURE REGULATOR

defective (models with “E”

cylinder yoke).

CONTROLLED PRESSURE

REGULATOR section of

mixture requires adjustment

REGULATOR malfunction

(models with “E” cylinder

yoke).

ALARM ACTUATOR out of

adjustment.

ACTUATOR DEFECTIVE

Leak at N2O pressure control

seat causing low O

2

concentration.

ACTUATOR DEFECTIVE.

Replace with Porter part No.

A-3399-000 (4 per Unit).

Replace cylinder with full

cylinder of appropriate gas.

Use practice of turning off

cylinder (or external supply)

after use.

Expect higher usage of O

2

cylinders

Allow apparatus to return to

room temperature before

making adjustment.

See “Maintenance” adjustment,

Step 1.

Discontinue use and notify

authorized distributor.

See “Maintenance” adjustment,

Step 2.

Discontinue use and notify

authorized distributor.

See “Maintenance” adjustment,

Step 3.

Discontinue use and notify

authorized distributor.

Discontinue use and notify

authorized distributor.

20

CERTIFICATE OF WARRANTY

THIS WARRANTY IS GIVEN IN PLACE OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR

OTHERWISE.

Under no circumstances shall Parker Hannifin Corporation be liable for incidental or consequential damages as

those terms are defined in the uniform commercial code.

Parker Hannifin Corporation, Porter Instrument warrants that each product or part shall be free from defects in

workmanship and materials, under normal use and with appropriate maintenance, for one (1) year from the date

of delivery to customer unless otherwise specified in writing. All rubber and plastic parts and accessories are

warranted under the same conditions for a period of ninety (90) days from date of purchase.

No statement or claim about the product by any employee, agent, representative, or dealer of Parker Hannifin

Corporation shall constitute a warranty by Parker Hannifin Corporation or give to rise to any liability or obligation

of Parker Hannifin Corporation.

Parker Hannifin Corporation shall not be liable for any damage, injury or loss arising out of the use of the product,

whether as a result of a defect in the product or otherwise, if, prior to such damage, injury or loss, the product was

(1) damaged or misused; (2) repaired, altered or modified by persons other than Parker Hannifin Corporation; (3)

not installed in strict compliance with applicable codes and ordinances; or (4) not installed by an authorized

Parker Hannifin Corporation dealer. Parker Hannifin Corporation's obligation for breach of this warranty, or for

negligence or otherwise, shall be strictly and exclusively limited to the repair or replacement of the product or part.

This warranty shall be void on any product on which the serial number has been a ltered, defaced or removed.

ORDERS All orders are to be made through authorized Parker Hannifin Corporation distributors. All billing will be

done through said distributors. Direct orders will be handled through the authorized local dealer as determined by

Parker Hannifin Corporation.

RETURNS All returned merchandise will be handled through the local Parker Hannifin Corporation distributor. No

returns will be accepted unless authorized in writing by Parker Hannifin Corporation and accompanied by the

original shipping invoice. All returns are subject to restocking charge.

Policies subject to change without notice.

The Quality System for Porter is certified to ISO 13485. The scope of our registration is:

The design, manufacture, distribution and servicing of Nitrous Oxide - Oxygen Sedation

Flow Meters, Gas Scavenging Systems, Steam Sterilizers, Gas Distribution and Office

Communication Systems for use by a physician , dentist or licensed healthcare professional.

21

Loading...

Loading...