Page 1

1

Read and fully understand the

instructions before operating

the Portek Flexisharp

portek.co.uk

Li-ion Battery Powered

Chainsaw Sharpener

Operators Handbook

Page 2

2

Before you start

READ AND UNDERSTAND THIS MANUAL

FULLY BEFORE OPERATING THE FLEXISHARP

This user manual accompanies this chainsaw Sharpener and contains important information

on setup and handling.

Before using the equipment, read the user manual carefully. This particularly applies to the

safety notes. Failure to do so may result in personal injury or damage to the equipment.

Store the user manual for further use.

This graphic accompanied by the words WARNING and DANGER

highlights an act or a condition which can lead to SERIOUS INJURY

ALWAYS WEAR EYE PROTECTION.

Residual risks

This machine is only designed for sharpening chainsaws. Before commissioning, the device

must be fixed to a workbench or another similar surface. Use the chain - saw sharpener only

if you fully understand all the functions and can perform without restrictions or have received

appropriate instructions. Respect technical data and safety precautions.

!

Do not use this product in any other way as stated for normal use. Not observing general

regulations in force and instructions from this manual does not make the manufacturer liable

for damages.

Please note that our equipment has not been designed for commercial, trade or industrial

use. If the equipment is used in commercial, trade or industrial operation or for similar

activities, we cannot assume any liability.

Specifications, descriptions and illustrative material in this manual are as accurate as known

at the time of publication, but are subject to change without notice. Illustrations may include

optional equipment and accessories, and may not include all standard equipment.

ALWAYS WEAR SAFETY CLOTHING IN CONJUNCTION WITH HAND, EYE, HEARING

AND FOOT PROTECTION TO HSE/EN SPECIFICATIONS

Page 3

Important safety information

Residual risks

Even when the device is used properly and all safety regulations are complied with, there still

may be some residual risks.

3

• Noise emissions

• Dust emissions

• Vibrations to hand and arms

• Danger of burns

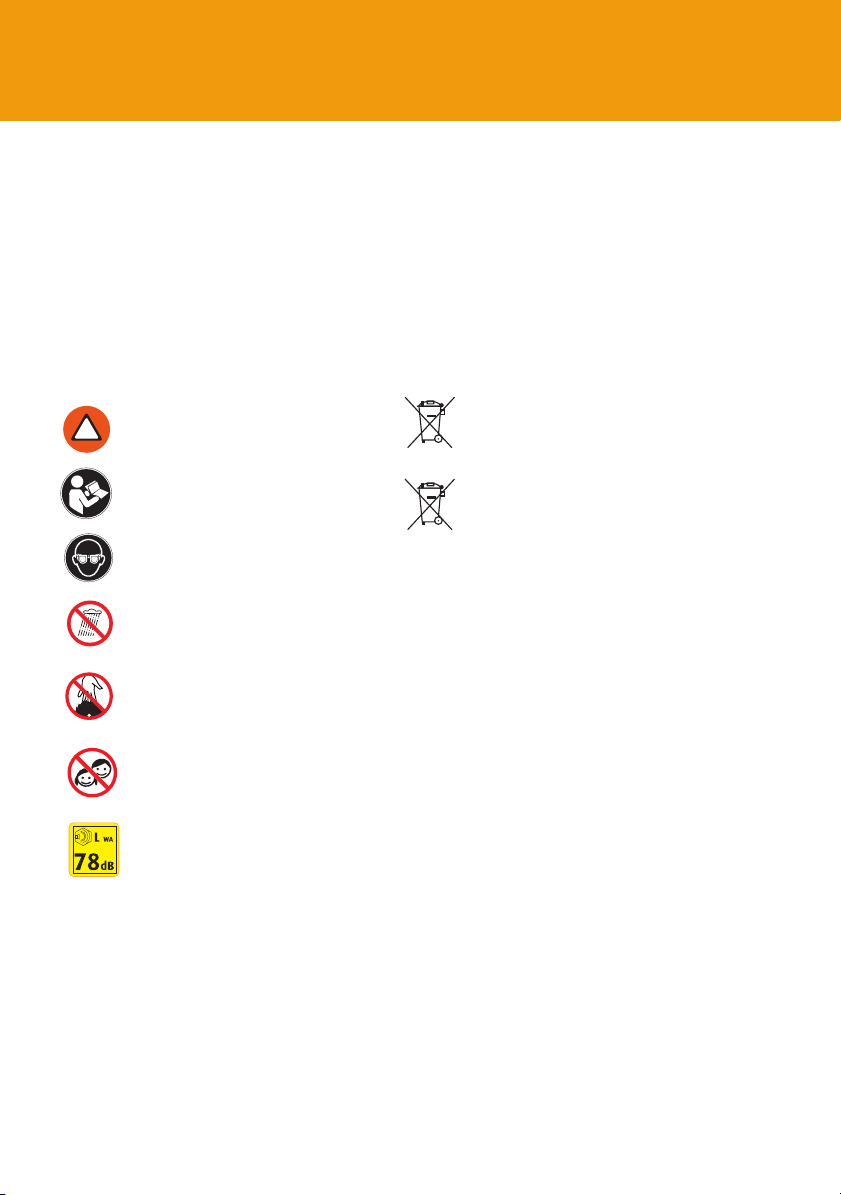

Symbols

Denotes risk of personal injury or

!

damage to the tool.

Read instruction manual before use.

Wear eye protection.

Do not use the appliance in the rain

or in wet places.

Danger! Do not touch the

grinding wheel

Children shall not play with

the appliance.

• Tool and workpiece heat up during operation.

• Risk of injury

• Sharp tools and workpiece edges

Dispose appliances according to the regulation

and requirement of local council.

Do not dispose of batteries in household

waste, fire (risk of explosion) or water.

Damaged batteries may damage the

environment and your health if toxic fumes or

liquids leak out.

Li-ion

Dispose of batteries in discharged condition.

Dispose of batteries in accordance with the

local regulations. Take batteries to an old

battery collection point where they will

be recycled in an environmentally friendly

manner.

Information of the acoustic

power level.

Page 4

4

Flexisharp

14

2

10

8

1

5

9

13

7

3

4

6

Page 5

1. Chain stopper

2. Chain stopper setting screw

3. Scale for setting grinding angle

4. Locking screw for grinding angle setting

5. Chain carrier

6. Chain setting wheel

7. Setting screw for limiting depth

8. Grinding wheel

9. On/Off switch

10. LED working light

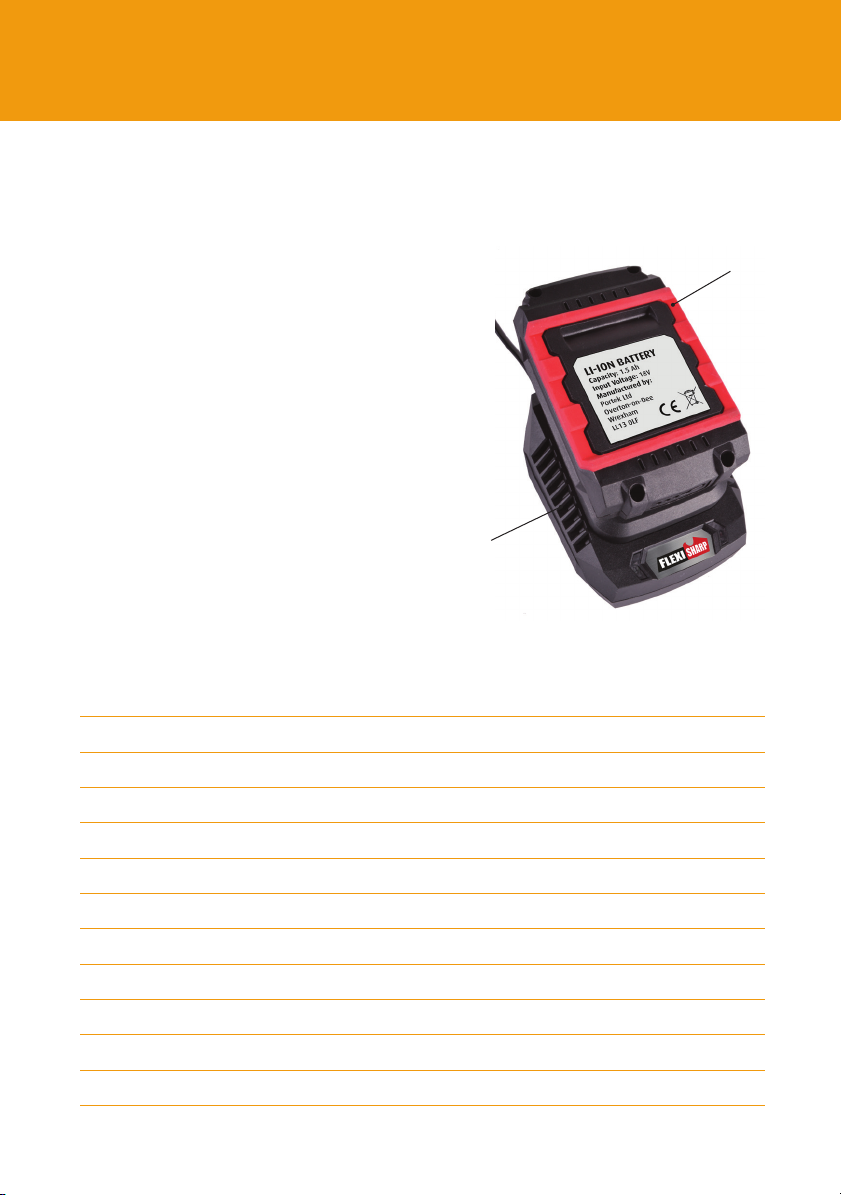

11. Battery

12. Charger

13. Grinding wheel cover

14. Grinding wheel shield

5

Contents

11

12

CONTENTS

Before you start 2

Safety introduction 3

Flexisharp main features 4 - 5

General safety information 6 - 7

Sharpener, battery and charging safety 8 - 11

Charging the battery 12

Assembly 13

Operation 14 - 15

Parts listing 16 - 17

Technical data and disposal 18

Troubleshooting 19

Declaration of Conformity 20

Page 6

6

General Safety Information

Read all safety warnings. Failure to follow the warnings may result in serious

!

injury or even death.

1. Keep children and bystanders away while operating a power tool. Distractions cause a

loss of control.

2. Check for signs of wear or damage, before using the tool and after any impact, and

repair as necessary.

3. The tool is designed for use by adults. Young people over 16 years may use the tool

under supervision only.

4. The manufacturer is not liable for damage which is caused through inappropriate use or

incorrect operation.

1. Work area safety

• Keep work area clean and well lit. Cluttered or dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust

or fumes.

2. Electrical safety

• Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

• Do not abuse the charger cord. Keep cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of electric shock.

• The use of a RCD (residual current device) with a rated residual current of 30 mA or less

is advised for additional safety when using the charging unit.

Page 7

General Safety Information

3. Personal Safety

!

• Stay alert, watch what you are doing and use common sense when operating a

power tool. Do not use a power tool while you are tired or under the influence of

drugs, alcohol or medication. A moment of inattention while operating power tools

may result in serious personal injury.

WARNING! Wear ear protectors. Exposure to noise can cause hearing loss.

!

WARNING! Use protective equipment. Always wear safety glasses when

working with the machine.

• The use of protective clothing is recommended, such as dust mask, protective

gloves, sturdy non-slip footwear, helmet and ear defenders. Wear a hairnet if you

have long hair. It is recommended to wear gloves, sturdy non slipping shoes and

apron.

• Prevent unintentional starting. Ensure the switch is in the off- before connecting to

battery pack, picking up, adjusting or carrying the tool. Carrying power tools with

your finger on the switch or energising power tools that have the switch on invites

accidents.

7

• Never reach into the danger area of the machine when it is running. Chips and

splinters must not be removed while the machine is running.

• WARNING! Always allow the cut-off wheel to come to a stop

!

4. Service

• Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Page 8

8

Sharpener Unit Safety

!

Safety Warnings for Chainsaw Sharpener

• Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power

tool that cannot be controlled with the switch is dangerous and must

be repaired.

• Disconnect the plug from the power source and/or the battery pack from the power

tool before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

• WARNING! The adjusting nut must be tightened before starting to work with the

machine.

• Maintain power tools. Check for misalignment or binding of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly

maintained power tools.

• WARNING! Always use the protective shields on the machine. Do not remove the

transparent front guard. If the transparent front guard is damaged or missing, re-turn

tool to authorized service station for replacement.

• Do not use a damaged grinding wheel. Before each use inspect the wheel for chips

and cracks or excess wear. The grinding wheel must be properly mounted and turn

freely. Perform a test run for at least 30 seconds without load. Do not use damaged,

out of round or vibrating grinding wheels.

• Immediately switch off the machine in case of considerable vibrations or if other

malfunctions occur. Check the machine in order to find out the cause.

• The outside diameter and the thickness of your accessory must be within the capacity

rating of your power tool.

Page 9

Battery Safety

!

Safety Warnings for Battery

• Charge a rechargeable battery unit using only the charger supplied by the

manufacturer. There is the danger of fire if other types of rechargeable battery

units are used.

• When they are not being used, store rechargeable battery units away from paperclips,

coins, keys, nails, screws or other small metal objects that could cause the contacts to

be bridged. Short circuiting the contacts of a rechargeable battery unit may result in

heat damage or fire.

Fluids may leak out of rechargeable battery units if they are misused. If this

happens, avoid contact with the fluid. If contact occurs, flush the affected area

with water. Seek additional medical help if any of the fluid gets into your

eyes. Escaping battery fluid may cause skin irritation or burns.

• The battery pack supplied with your cordless tool is not charged. The battery pack has

to be charged before you use the tool for the first time.

• For optimum battery performance avoid low discharge cycles. Charge the battery pack

frequently.

• Store the battery pack in a cool place, ideally at 15°C. The battery must be charged for

storage until the second led is lit. Charging needs to be done when the light gets down

to 1 led.

9

Store battery with at least 2 leds lit

Page 10

10

Battery Safety

Safety Warnings for Battery

!

• Lithium-ion batteries are subject to a natural ageing process. The battery pack must

be replaced at the latest when its capacity falls to just 80% of its capacity when new.

Weakened cells in an aged battery pack are no longer capable of meeting the high

power requirements and therefore pose a safety risk.

• Do not throw battery packs into an open fire. There is a risk of explosion!

• Do not ignite the battery pack or expose it to fire.

• Do not exhaustively discharge batteries. Exhaustive discharge will damage the battery

cells. The most common cause of exhaustive discharge is lengthy storage or non-use

of partly discharged batteries. Stop working as soon as the performance of the battery

falls noticeably or the electronic protection system triggers. Place the battery pack in

storage only after it has been fully charged.

• Protect batteries and the tool from overloads. Overloads will quickly result in overheating and cell damage inside the battery housing without this overheating actually

being apparent externally.• Avoid damage and shocks. Replace batteries which have

been dropped from a height of more than one metre or which have been exposed to

violent shocks without delay, even if the housing of the battery pack appears to be

undamaged. The battery cells inside the battery may have suffered serious damage. In

this respect, please also read the waste disposal information.

• If the battery pack suffers overloading and overheating, the integrated protective cutoff will switch off the equipment for safety reasons.

Important. Do not press the ON/OFF switch any more if the protective cut-off has

actuated. This may damage the battery pack.

• Use only original battery packs. The use of other batteries may result in injuries,

explosion and a fire risk.

Page 11

Charging Safety

Safety instructions for charge and charging process

!

• Please check the data marked on the rating plate of the battery charger. Be sure to

connect the battery charger to a power supply with the voltage marked on the rating

plate. Never connect it to a different mains voltage.

• Protect the battery charger and its cable from damage and sharp edges. Have

damaged cables repaired without delay by a qualified electrician.

• Do not use damaged battery chargers.

• In heavy use the battery pack will become warm. Allow the battery pack to cool to

room temperature before commencing with the charging.

• Do not over-charge batteries. Do not exceed the maximum charging times. These

charging times only apply to discharged batteries. Frequent insertion of a charged or

partly charged battery pack will result in over-charging and cell damage. Do not leave

batteries in the charger for days on end.

• Never use or charge batteries if you suspect that the last time they were charged was

more than 12 months previously. There is a high probability that the battery

pack has already suffered dangerous damage (exhaustive discharge).

• Charging batteries at a temperature below 10°C will cause chemical damage to the cell

and may cause a fire.

• Do not use batteries which have heated during the charging process, as the battery

cells may have suffered dangerous damage.

• Do not use batteries which have suffered curvature or deformation during the charging

process or which show other non-typical symptoms (gassing, hissing, cracking…).

• Never fully discharge the battery pack (recommended depth of discharge max. 80%)

A complete discharge of the battery pack will lead to premature ageing of

the battery cells.

11

Page 12

12

Charging the Battery

Identify all the parts packaged in the carton against the parts list. Remove all protective

materials and place parts on a non-abrasive surface to avoid scratching. Please contact

your dealer if anything is missing. Improper handling or assembly may result in damage

to the chainsaw sharpener or serious injury through faulty assembly.

Assemble the chainsaw sharpener on a stable, non-abrasive surface such as worktable to

avoid damaging the item.

Charging the battery pack

The battery is protected from exhaustive discharge. An integrated protective circuit

automatically switches off the equipment when the battery is flat.

Warning! Do not actuate the On/Off switch any more if the protective circuit has tripped.

This may damage the battery.

1. Remove the battery pack from the equipment, pressing the

pushlock button downwards to do so.

2. Check that your mains voltage is the same as that marked on the

rating plate of the battery charger. To ensure that the battery pack

provides long service you should take care to recharge it promptly.

You must recharge the battery pack when you notice that the power of the chain

sharpener drops. You can additionally see the level of charge by looking at the battery.

Battery release

Press button for battery

charging condition

It has a battery check function activated by pressing as shown in picture below. Three bar

led advises power level. It is advised to recharge the battery when it reaches 1 led only.

Never fully discharge the battery pack. Never fully discharge the battery pack by leaving

a used battery for extended time without a small amount of charging. This may cause

the battery pack to develop a defect. Always store with 1 or 2 led’s worth of charge for

optimum life of battery.

Page 13

Assembly

The Flexisharp is supplied partly assembled, please assemble the machine

as follows:

1. Remove the large locking wheel from the chain guide assembly and place the bolt end

through the hole in the unit base. Replace the locking wheel on to the bolt and adjust to the

required angle before fully tightening. When installing the Flexisharp on to a work bench,

make sure that the locking screw is easily accessible.

Chain clamp

assemby

Locking wheel

Tension nut

13

2. Remove the plastic tension nut from

the end of the tension cable. Pull the cable

through the chain guide clamping piece and

replace the plastic tension nut.

Work Surface Mounting

3. Place the unit base on to a solid, level work surface. Ensure the base extends out far enough

over the edge so that the chain can hang freely and you have easy access to the vice angle

adjustment screw underneath. Mount the base to the work surface through the two 9mm

(1/4") mounting holes (bolts not included).

4. The Flexisharp is assembled and ready for use. The pre-installed grinding wheel is for

universal use. To replace a grinding wheel see “Grinding Wheel Replacement” section

Page 14

14

Operation

WARNING: Before installing the battery, make sure the

!

machine is switched ‘OFF’ to avoid unintended starting.

1. Clean the chain before sharpening. Inspect the chain for

the most worn-out cutter tooth and start sharpening with

this tooth. The most worn-out tooth is important in order

to sharpen all other teeth to the same depth!

2. Lift up the chain stop, position the chain and secure the chain between the clamping piece of the

chain guide assembly. Fold down the chain stop and pull back the first cutter tooth against the

chain stop. Make sure the chain is between both guide boards so that the chain can not tilt

to the side.

3. Check the necessary filing angle according to the specifications for the chain. Adjust the filing

angle on the chain guide assembly to 25° - 30° or to the required angle and tighten the

locking screw.

4. Lower the motor housing so that the grinding

wheel skims the chain tooth. Hold it in this

position while you tighten the screw so that

the grinding wheel will only go down to that

point, fix this position with the locking screw.

5. Switch ‘ON’ the Flexisharp by pressing firmly.

Use the handle to bring the grinding wheel

down towards the chain tooth. As you bring

down the motor housing the tension cable

will automatically clamp the chain between

the metal chain boards.

6. After sharpening one tooth, turn off

the machine. Lift the motor housing,

to release the clamp boards, and move

the chain so that the next link is positioned against the chain

stop. Mark the first cutter tooth with chalk, then sharpen every

second tooth in one direction. Repeat this process until you have

sharpened all of the links set up for this angle.

7. Change the cutting angle to 30° or to the required angle of

the opposite direction of the remaining chain cutter teeth.

ON/OFF switch

Page 15

Changing Grinding Wheels

To avoid malfunction, damage or injury always use a suitable grinding wheel that is in good

condition. Do not use a grinding wheel that is chipped, cracked, or worn. You can check if the

wheel has cracks not visible to the human eye by hanging it up by the central hole and tapping

it with a non-metal object (ie: screwdriver handle). If it is in good condition it will produce a

metallic sound. A dull sound indicates a crack or break. Make sure before carrying out any work

on the Flexisharp that the battery is removed.

Replacement Portek Grinding Wheels are available:

4.5mm thick wheel part number 092/01 and 3.2mm thick wheel part number 092/02

Changing the Grinding Wheel

1. Switch off the machine and remove battery.

2. Remove the grinding wheel protective cover by

unscrewing the 3 retaining screws.

3. Hold the grinding wheel firmly with one hand and

loosen the locking nut.

4. Remove the old grinding wheel and replace with

a new one. Tighten the fixing nut but do not over

tighten - over tightening may cause the wheel

to crack or break. Only use grinding wheels with

an outer diameter of 108mm and inner diameter

of 23mm. The grinding speed of replacement

grinding wheel must meet or exceed the RPM

rating of the machine.

5. Remount the grinding wheel protective cover

onto the machine. Never operate the Flexisharp

without the grinding wheel cover in place. Keep

away from the wheel when it is turning, and

make sure no one is standing close, in the line

of the wheel rotation trajectory. If the grinding

wheel vibrates on start up, turn off the machine

immediately and check that the grinding wheel is

mounted securely!

6 Never try to stop the grinding wheel with your

hands, even if you are wearing safety gloves. The

grinding wheel will cut through gloves and your

hand, causing serious injury. Replace the grinding

wheel when it grinds down to a diameter

of 95mm.

Remove cover

Release wheel by loosening locking nut

Replace with new wheel and ensure

protective shield is in place.

15

Page 16

16

Parts List

PART NO. DESCRIPTION QTY

1 Screw ST4.2 × 14 10

2 Motor cover 1

3 Motor 1

4 Power cord 2

5 Cord Pressing Plate 2

6 Grinding Wheel Base 1

7 Switch Plate 1

8 Switch 1

9 Screw 1

10 Nut 1

11 Housimg 1

12 LED Light 1

13 LED Cover 1

14 LED Clamp 1

15 Screw ST4.2 × 8 2

16 Grinding Wheel 1

17 Grinding Lock Cap 1

18 Grinding Wheel Cover 1

19 Screw ST4.2 × 14 3

20 PCB 1

21 Nut M8 1

22 Gauge Cover 1

23 Torsion Spring 1

24 Pull Rod 1

25 Cable 1

26 Screw ST4.2 × 12 2

27 Baffle 1

28 Screw ST5.5 × 20 3

29 Wash 1

30 Steel Bushing 1

PART NO. DESCRIPTION QTY

31 Swing Arm 1

32 Chain Stop 1

33 Washer φ4 1

34 Screw M8 x45 1

35 Chain Saw Frame 1

36 Screw ST4.8×10 2

37 Inner Clamping Piece 1

38 Chain Wheel 2

39 Outer Clamping Piece 1

40 Pad 2

41 Transmission Shaft 2

42 Nut M5 1

43 Nut 1

44 Nut M6 1

45 Screw M6 1

46 Nut 1

47 Base 1

48 Washer φ9 2

49 Pivot Pin φ9 1

50 Right Battery Pack Interface 1

51 Contact Stand 1

52 Baffle 1

53 Discharge Protection Plate 1

54 Battery Pack 1

55 Left Battery Pack Interface 1

56 Cable 1

57 Chain Stop 1

58 Spring 1

59 Clamp 1

60 Screw ST4.2 × 12 4

Page 17

Parts List

17

Walking forward,

take slow sweeping

movements to clear long

grass and brush with ease

WEAR SAFETY

PROTECTION AT

ALL TIMES!

Page 18

18

Technical data

Technical data

Battery voltage 20 V

Input power: 50W

No-load speed 6500 min-1

Grinding disk diameter 108 mm

Grinding disk thickness max. 3.2 mm

hole diameter 23 mm

Weight without battery/Charging 1.7 kg

equipment

Sound pressure level LpA 54.1 dB (A)

Sound power level LWA 67.1 dB (A)

Uncertainty K = 3 dB (A)

The sound levels have been determined in accordance with noise measuring process

Li-ion

Main Unit

Do not dispose of electrical appliances as unsorted municipal waste, use

separate collection facilities. Contact your local government for information

regarding the collection systems available. If electrical appliances are disposed of in

landfills or dumps, hazardous substances can leak into the groundwater and get into

the food chain, damaging your health and well-being.

Li-ion Battery

Do not dispose of batteries in household waste, fire (risk of explosion) or

water. Damaged batteries may damage the environment and your health

if toxic fumes or liquids leak out. Dispose of batteries in discharged condition.

Dispose of batteries in accordance with the local regulations. Take batteries to an

old battery collection point where they will be recycled in an environmentally

friendly manner.

Page 19

Troubleshooting

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTIONS

LED light isn’t bright, 1.Battery not charged 1.Charge the battery

machine cannot work 2.Battery pack not 2.Remove and insert

installed properly the battery pack again

3.Switch damaged 3.Replace with new

switch

LED light is bright, 1.Connection terminal 1.Replace the

machine cannot work loose connection terminal

2.Motor damaged 2.Replace a new motor

LED light isn’t brightφ 1.Connection terminal 1.Replace the terminal

machine is working loose connection

2.Motor damaged 2.Replace a new motor

Machine shaking 1.Wheel shaking or 1.Replace the wheel

damaged

2.Wheel nut loose or 2.Replace the nut

slipping

19

Page 20

20

Declaration of Conformity

EC Declaration of Conformity

Portek Ltd, Bryn Hall, Knolton Bryn, Overton on Dee,Wrexham, LL13 0LF

declare that the machinery named below conforms to the requirements of

EC Council Machinery Directive, Annex II

Designation of Machinery: Portek Chainsaw Sharpener

Relevant EC Council Directives:

2006/42/EC (Machinery Directive)

2014/30/EU (Electromagnetic Compatibility Directive)

Applied Harmonised Standards:

BS EN ISO 12100:2010

BS EN 62841-3-4:2016

The unit complies with all applicable Essential Requirements of the Directives.

Signature of Manufacturer's Representative:

Portek Ltd.

Bryn Hall, Knolton Bryn

Overton-on-Dee

Wrexham, LL13 0LF

Tel: 01234 889 454

Fax: 01234 889 464

General enquiries

Email: info@portek.co.uk

Declaration made by Steve Morris

Design Engineer on 02/07/2018.

0718 ©2018 Portek Ltd

Loading...

Loading...