Porta-King G_HW810300 User Manual

BEFORE BEGINNING INSTALLATION, PLEASE READ THROUGH ALL INSTRUCTIONS.

Uncrate shipment and check against packing list to insure all materials are included before beginning installation. If any

discrepencies are noted, please notify the factory immediately at (800) 456-5464.

Note: All building dimensions are outside (O.D.)., unless shown or noted otherwise on drawing.

RECOMMENDED TOOLS FOR INSTALLATION:

Tape measure Chalk line Carpenter's level

Hammer Hacksaw Broom

Combination square Pliers Utility knife

Rubber mallet Screwdriver Extension cord

Circular saw Drill bits (metal and masonry) Power drill

Step ladder

Fasteners and supplies are required for tying into existing floor and walls.

Note: Porta-King will supply one nutrunner attachment for installation of #12-3/4" slotted hex head screw.

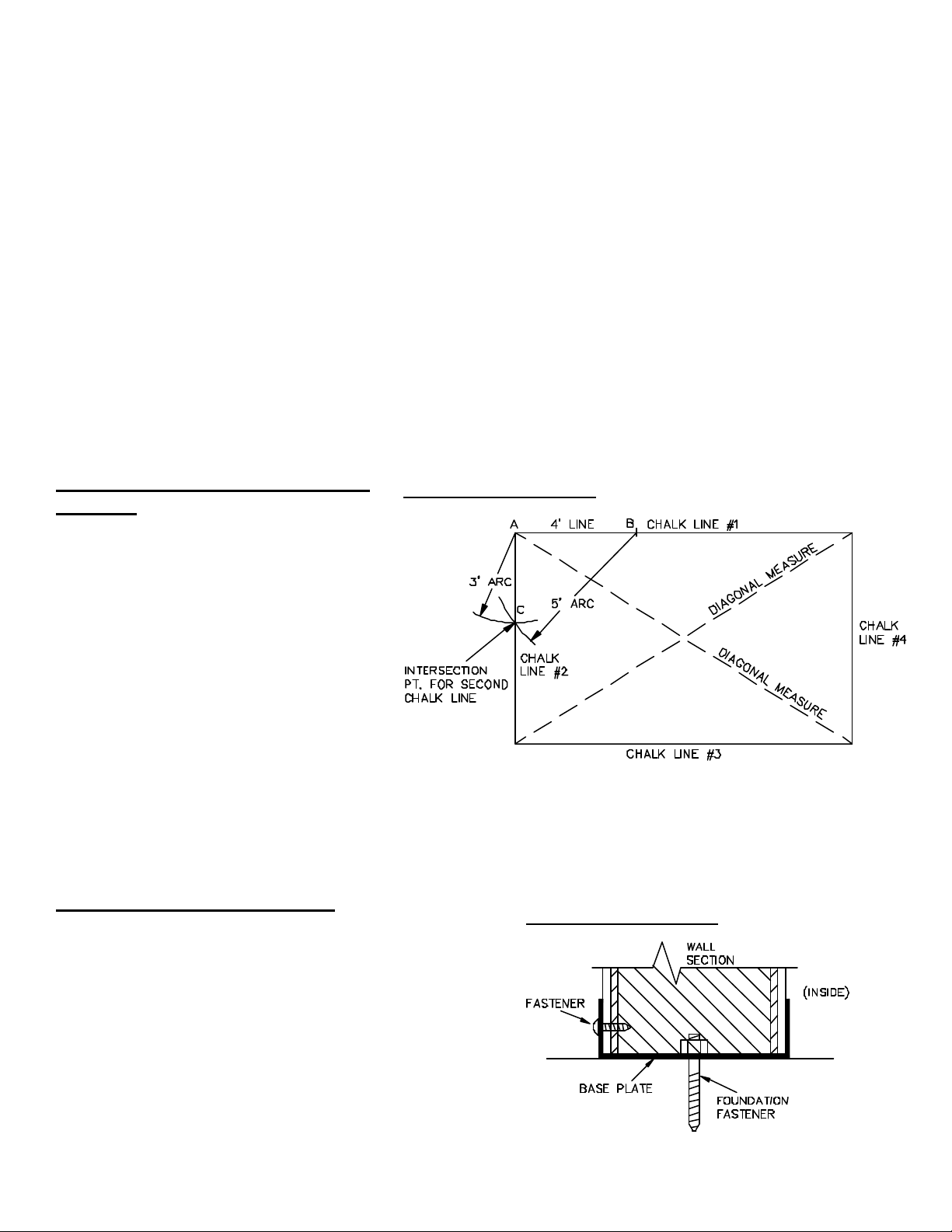

1. CONSTRUCTING A CHALK LINE

LAYOUT:

DETAIL INSTRUCTION No. 1

Strike a chalk line (#1) on the floor to

establish location of the first wall. This line

will represent the outside edge of the base

plate. Using the 3,4,5 triangle method,

construct the first corner of your building.

Measure 4' from point A on line #1, and

mark this point B. Strike a 5' arc from point

B and a 3' arc from point A, the intersection

of the two arcs is point C. Strike chalk line

#2 through point A and C to form a 90

degree corner. Continue with this procedure

to establish the remaining chalk lines. Once

layout is complete, take diagonal

measurements from corner to corner. Diagonal measurement should be within 1/8" of each other to ensure the building

is in square.

2. BASE PLATE INSTALLATION:

The base plate will be mitered and sized to fit the

required layout. Attach the base plate to the foundation

DETAIL INSTRUCTION No. 2

using appropriate fasteners, install the fasteners starting

from one corner and proceeding on 24" centers.

Appropriate fasteners for attachment of the base plate

to the foundation to be furnished by others, depending

on site conditions.

Note: Be sure that the base plate is installed level and

in square.

1

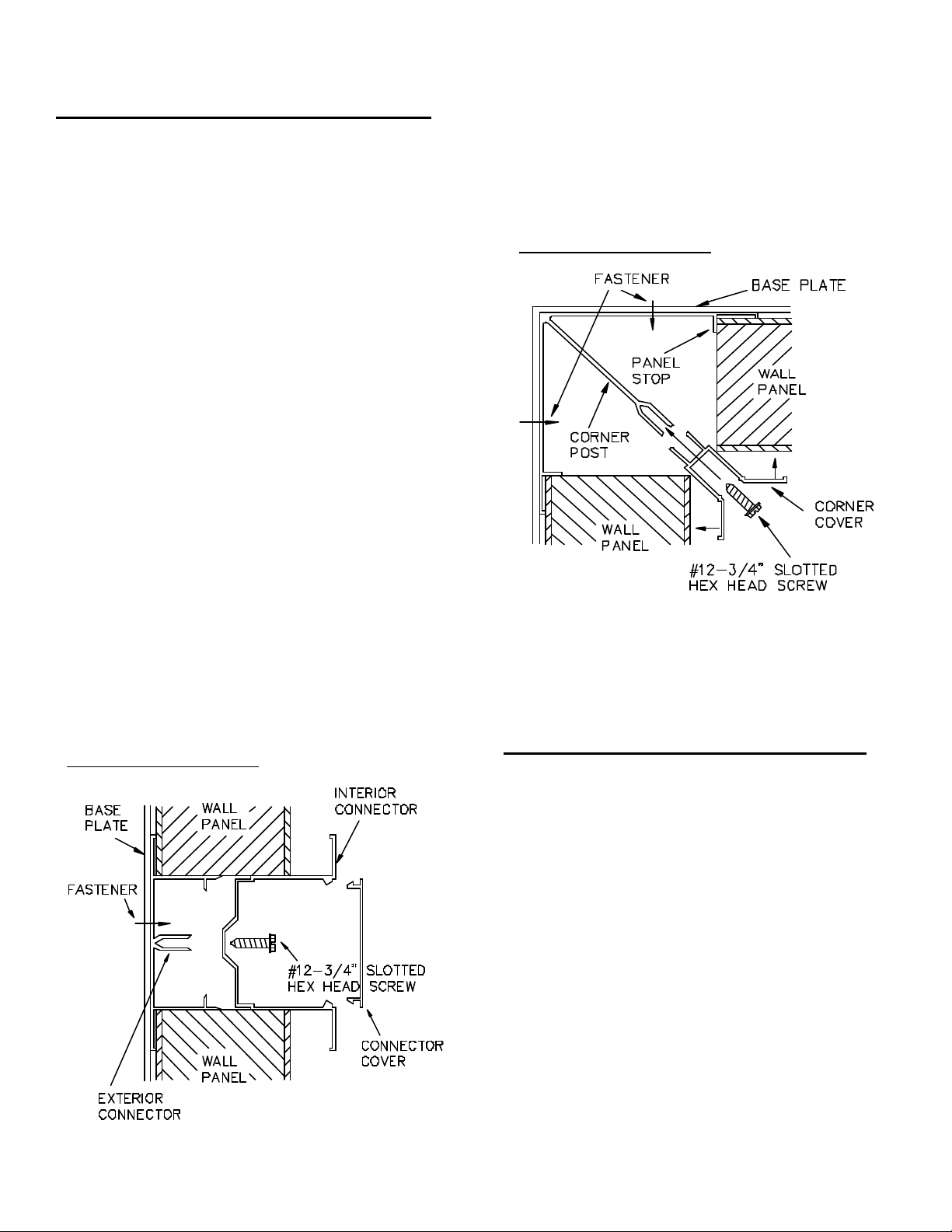

3. CORNER POST - PANEL INSTALLATION:

(If the building is a Two or Three Wall type which is attached to existing walls, refer to Instruction #9.)

Start with one corner post. Insert corner post into base plate at any corner (support corner until panels are installed on

each side). Insert panel into base plate and corner post, sliding panel firmly into place, proceed with panel on opposite

side of corner post. Screw corner cover to corner post with #12 x 3/4” slotted hex head screws to secure panels.

DETAIL INSTRUCTION No. 3

Notes: Check layout for appropriate colors for interior

and exterior of building.

Check layout for any critical dimensions. Refer

to Installation Drawings for proper location of sized

components.

Visually inspect to ensure panels fit properly at

all connections. Panel should fit flush with panel stop of

corner or connector. As each wall is installed, be sure

the length of wall is the same dimension at the top and

bottom, to keep wall square.

Buildings with overheight wall pane ls will have a

splice. Shim splice as required to keep level.

Helpful hint: Start the #12 x 3/4” slotted hexhead screws into covers before putting the covers into

place.

DETAIL INSTRUCTION No. 4

4. CONNECTOR - PANEL INSTALLATION:

Insert exterior connector into base plate and slide firmly

against panel. Insert the next panel on the other side of

the exterior connector. Attach interior connector to

exterior connector with #12 x 3/4” slotted hex head

screws to secure panel connection. Plumb every panel

connection. Once panel connection is secured, install

#8 x 5/8" self drilling screw through 1 1/4" lip of base

plate and into connector.

Install connector cover by snapping into interior

connector. If electric is required in connector, wait to

install connector cover until electric is installed.

Note: Do not over tighten connector fasteners as this

can squeeze the shoulders of the extrusion making it

difficult to install the connector covers.

2

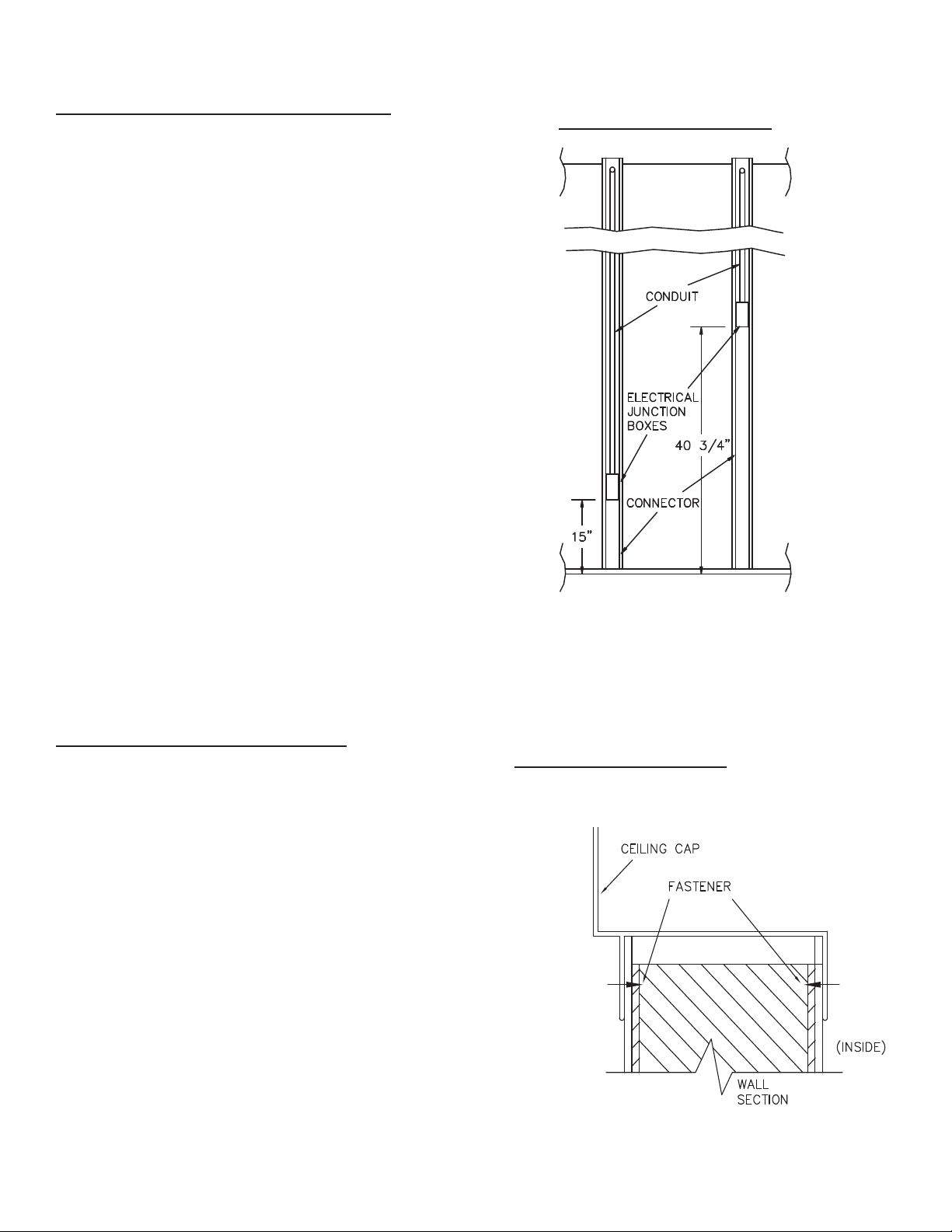

5. ELECTRICAL BOX INSTALLATION:

The light switches and electrical outlets are shipped

from the factory knocked down and are to be

installed on site. The electrical junction boxes are to

be installed on site, using the #8 x 5/8" self drilling

screws supplied. Screw through the back of the

junction box and into the connector. After junction

box is attached, measure and cut the connector cover

to fit above and below junction box.

Note: You may also want to cut the connector cover

just above or even with the ceiling line to facilitate

later access without removal of the ceiling.

DETAIL INSTRUCTION No. 5

6. CEILING CAP INSTALLATION:

The ceiling cap will be mitered and sized to fit the

required layout. It is important to install the ceiling

cap in conjunction with the wall panels to ensure the

dimensional stability of the building. Ceiling cap are

sections are spliced at vertical connectors. Secure

ceiling cap to the vertical extrusion (corner post and

connector) by fastening through the ceiling cap legs

and into the vertical extrusions with a #8 x 5/8" self

drilling screw. Do this at every panel connection, on

both the interior and exterior around entire perimeter

of building.

DETAIL INSTRUCTION No. 6

3

Loading...

Loading...