MODEL

WS-10-64-3

WELD SHEAR

1805 2ndAVENUE NORTH * MOORHEAD, MN, USA 56560-2310

E-MAIL ADDRESS; info@portaco.com * INTERNET ADDRESS: www.portaco.com

OPERATION,

MAINTENANCE,

AND REPAIR

MANUAL

PHONE (218) 236-0223 * FAX (218) 233-5281

1

TABLE OF CONTENTS

1.0 Introduction

1.1 General Information

1.2 Features

1.3 Safety Summary

1.4 General Safety Precautions

1.5 Warning and Caution Statements

1.6 Training Requirements

2.0 Installation Instructions

2.1 Unpacking Instructions

2.2 Tool Preparations

2.3 Testing

2.4 Hose Requirements

2.5 Hydraulic Fluid Recommendations

2.6 Tool Connecting Procedures

2.7 Work Area Safety Precautions

3.0 Operating Instructions

3.1 Description of Power Unit

3.2 Controls and Graphics

3.3 Before Operating

3.4 Positioning on Rail

3.5 Connecting Hoses

3.6 Operating Instructions

3.7 Disconnecting Hoses

3.8 Cold Weather Operation

3.9 Storage Preparation

4.0 Maintenance Instructions

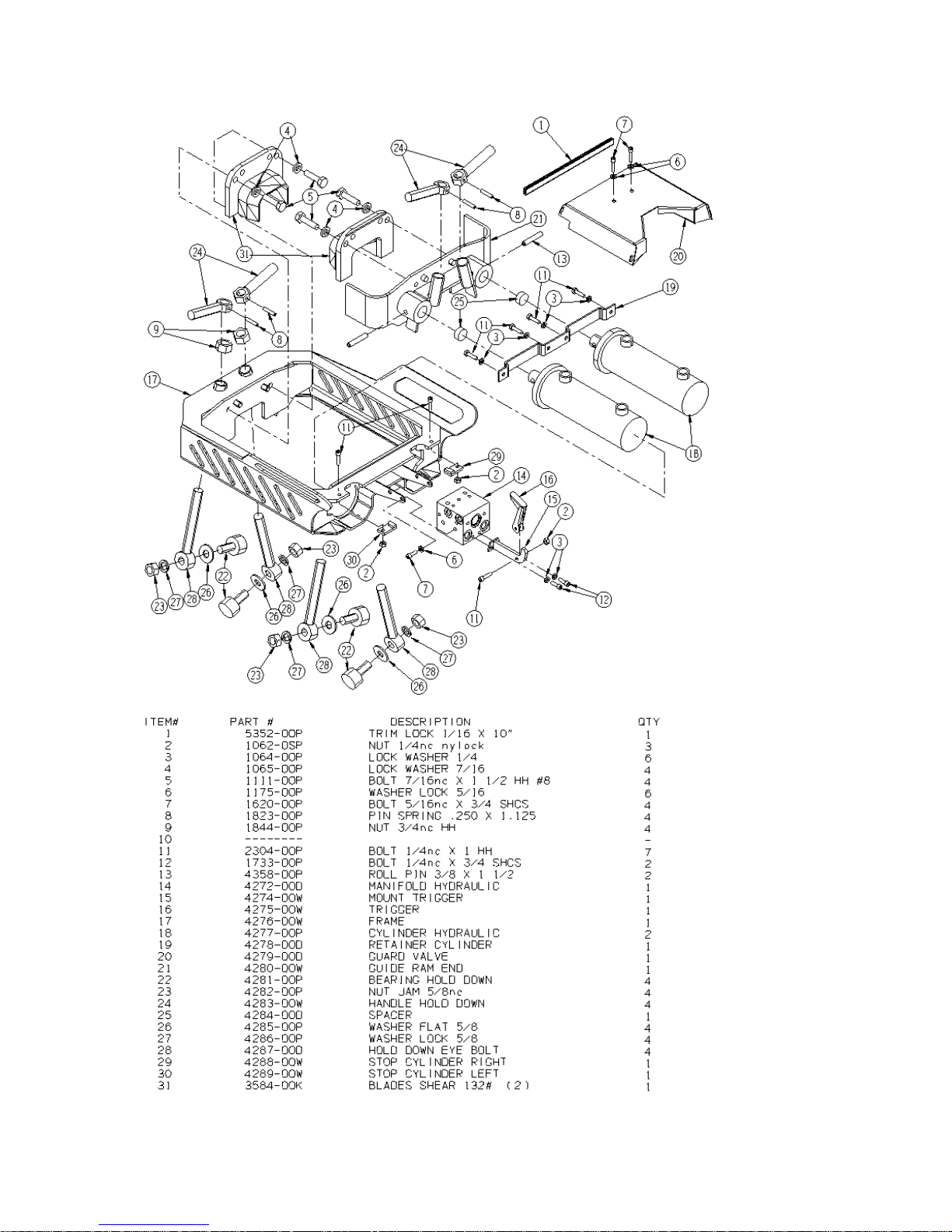

4.1 Assembly View and Parts List

4.2 Graphic Set Complete

4.3 Tool Maintenance

4.4 Trouble Shooting

4.5 Technical Specification

2

1.0 INTRODUCTION

C

1.1 General Information

This manual presents removal,

operation, and maintenance

information for PortaCo’s model

WS-10-64-3 Weld Shear. The tool is

designed to remove the excess

material when performing Thermit

and Buta type welds. It's light weight

compact size allows for use inside

rail pulling equipment. All hydraulic

plumbing is protected by a one piece

guard to prevent damage and to

contain any leaks if any damage

occurs. When properly used this tool

will help reduce back strain and also

reduce operator fatigue.

shearing blades to the full open

position when the valve control lever

is released. (See figure 1.2A arrow

A) This reduces total shearing time

and reduces the operator's exposure

to the heat produced during the

welding procedure.

B

A

Figure 1.2A

PortaCo, Inc. reserves the right to

make changes at anytime without

notice and without incurring any

obligation.

1.2 Features

The main features of the PortaCo

Weld Shear Model WS-00-64-3 are

as follows.

Standard unit:

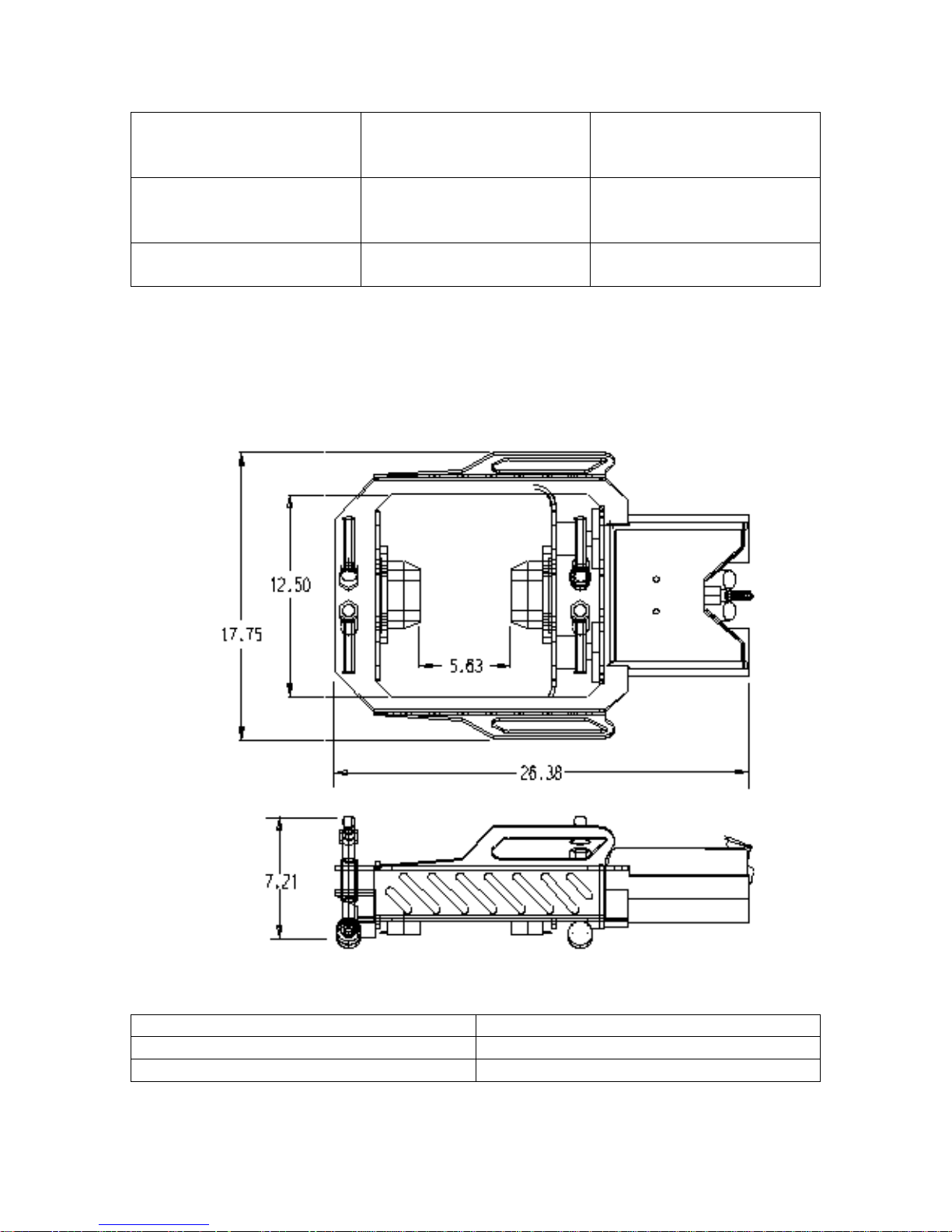

Length 26.38 in/ 67.0 cm

Width 17.75 in/ 45.1 cm

Height 7.21 in/ 18.3 cm

Weight 84-lbs/ 38.1 kg

(includes blades)

Upper ambient operating

temperature 110°F (43° C), lower

ambient operating temperature -20°F

(-28° C).

PortaCo, Inc.'s weld shear features

an auto cycle valve which returns the

The control valve also limits the

speed for shearing and provides a

rapid retract for easy operation.

The hydraulic plumbing is protected

by a one-piece guard to prevent

damage and to contain any leaks if

any damage occures. (figure 1.2A

arrow B)

The hydraulic quick connect couplers

are located at the rear of the shear

and directs the hoses along the rail

out of the work area. (figure 1.2A

arrow C) The path of the hose's

along the rail reduces the potential

for a worker to trip on them.

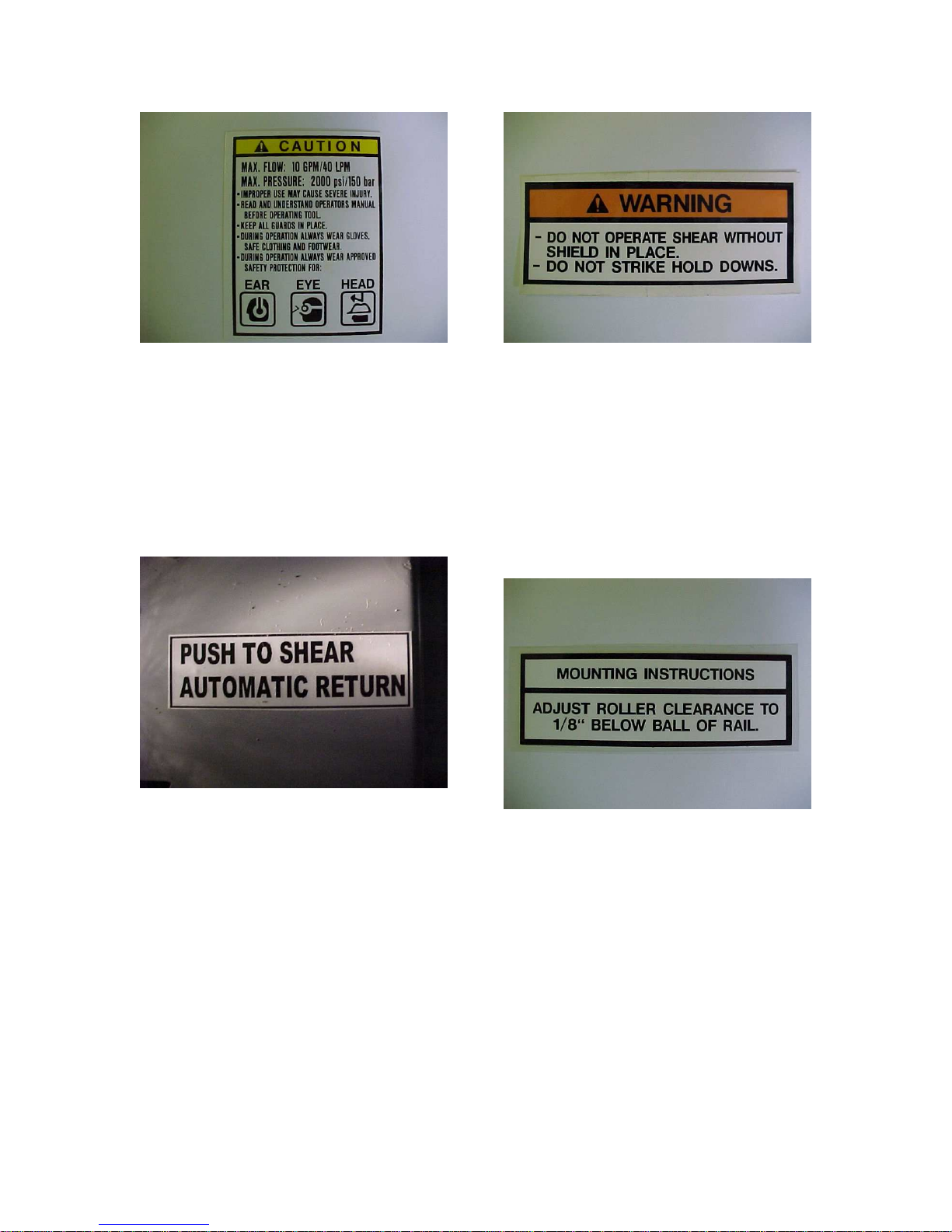

Roller hold-downs, provide a secure

mount to the rail and allows smooth

operation during the shearing

process. The roller height is set with

a jam nut providing a snug fit on any

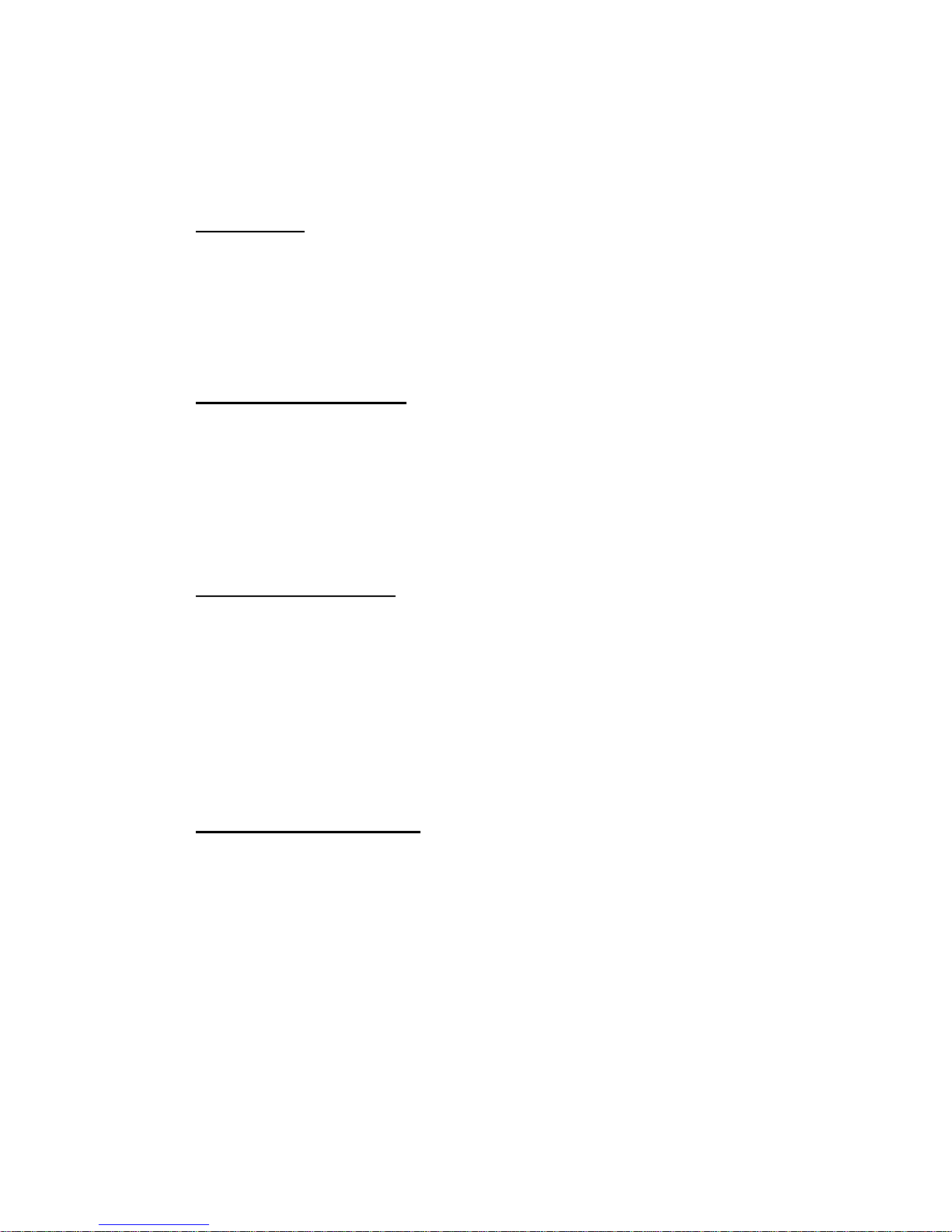

size rail. (figure 1.2B arrow A)

3

The roller assembly is easily

A

B

removed for replacement of any

component of the hold-down

assembly. (figure 1.2B arrow B)

Figure 1.2B

Handles incorporated into the frame

allow for even balance and level

transportation for quick positioning

on the rail. Figure 1.3

and before performing maintenance

or repairs. Supervising personnel

should develop additional

precautions relating to the specific

work area and local safety

regulations.

1.4 General Safety Precautions

The PortaCo Inc. tools are designed

to provide safe and dependable

service if operated according to the

instructions provided in this manual.

Read and understand this manual

and any stickers attached to the

power unit before operating. Failure

to do so could result in personal

injury or equipment damage.

Check the rules and regulations at

your location. The rules may include

an employer’s work safety program.

Regulations may identify hazards

such as working around utility supply

lines or hazardous slopes.

1.3 Safety Summary

Tool operators and maintenance

personnel must always comply with

the safety precautions given in this

manual and on the stickers and tags

attached to the tool and hoses.

These safety precautions are given

for your safety. Review them

carefully before operating the tool

Read and understand any manuals

for additional or optional equipment,

which maybe shipped with the tool.

1.5 Warning and Caution

Statements

Warning and Caution statements

have been strategically placed

throughout the text prior to operating

or maintenance procedures,

practices, or conditions considered

essential for the protection of

personnel, equipment, and property.

WARNING: HIGHLIGHTS A,

ESSENTIAL OPERATING, OR

MAINTENANCE PROCEDURE,

PRACTICE, CONDITION

STATEMENT, ETC… WHICH IF

NOT STRICTLY OBSERVED,

4

COULD RESULT IN INJURY TO,

OR DEATH OF, PERSONNEL OR

LONG TERM HEALTH HAZARDS.

CAUTION: HIGHLIGHTS AN

ESSENTIAL OPERATING OR

MAINTENANCE PROCEDURE,

PRACTICE, CONDITION

STATEMENT, ETC. WHICH IF NOT

STRICTLY OBSERVED, COULD

RESULT IN DAMAGE TO, OR

DESTRUCTION OF, EQUIPMENT

OR LOSS OF MISSION

EFFECTIVENESS.

1.6 Training Requirements

Operator training for the weld shear

should consist of information found

in this manual. In addition the

operator must receive instructions,

both verbally and through

demonstrations for applications in

which the tool is going to be used.

The new operator must start in an

area without bystanders and use the

tool until able to fully operate the tool

under the conditions for the work

area.

2.0 INSTALLATION INSTRUCTIONS

2.1 Unpacking Instructions

Upon receiving your weld shear

promptly remove it from the shipping

container. Always keep top side of

container up. Inspect unit for

damage which may have incurred

during shipping and report it to

carrier for claim.

2.2 Tool Preparations

The PortaCo G-18D55-53-W power

unit is recommended for hydraulic

supply. This unit is equipped with

two 5-gpm/20 lpm circuits that can

be combined for on 10 gpm/40 lpm

circuits.

If the tool is used in cold weather,

preheat the hydraulic fluid by running

power source at low engine speed.

Fluid temperature should be at or

above 50° F/10° C (400-ssu/82

centistroke) before use, when using

recommended fluids. Using too thick

of fluid may result in tool damage.

2.3 Testing

WARNING: NEVER STICK

FOREIGN OBJECTS, FINGERS,

OR OTHER EXTRMITIES INTO

MOVING MECHANISMS. FAILURE

TO FOLLOW THESE

INSTRUCTIONS MAY LEAD TO

SEVERE PERSONAL INJURY OR

TOOL DAMAGE.

Before operating the weld shear it is

important to inspect the shear blades

for excessive wear or damage.

Replace the shear blades if required

before operating the shear. Follow all

safety precautions and procedures

when inspecting tool.

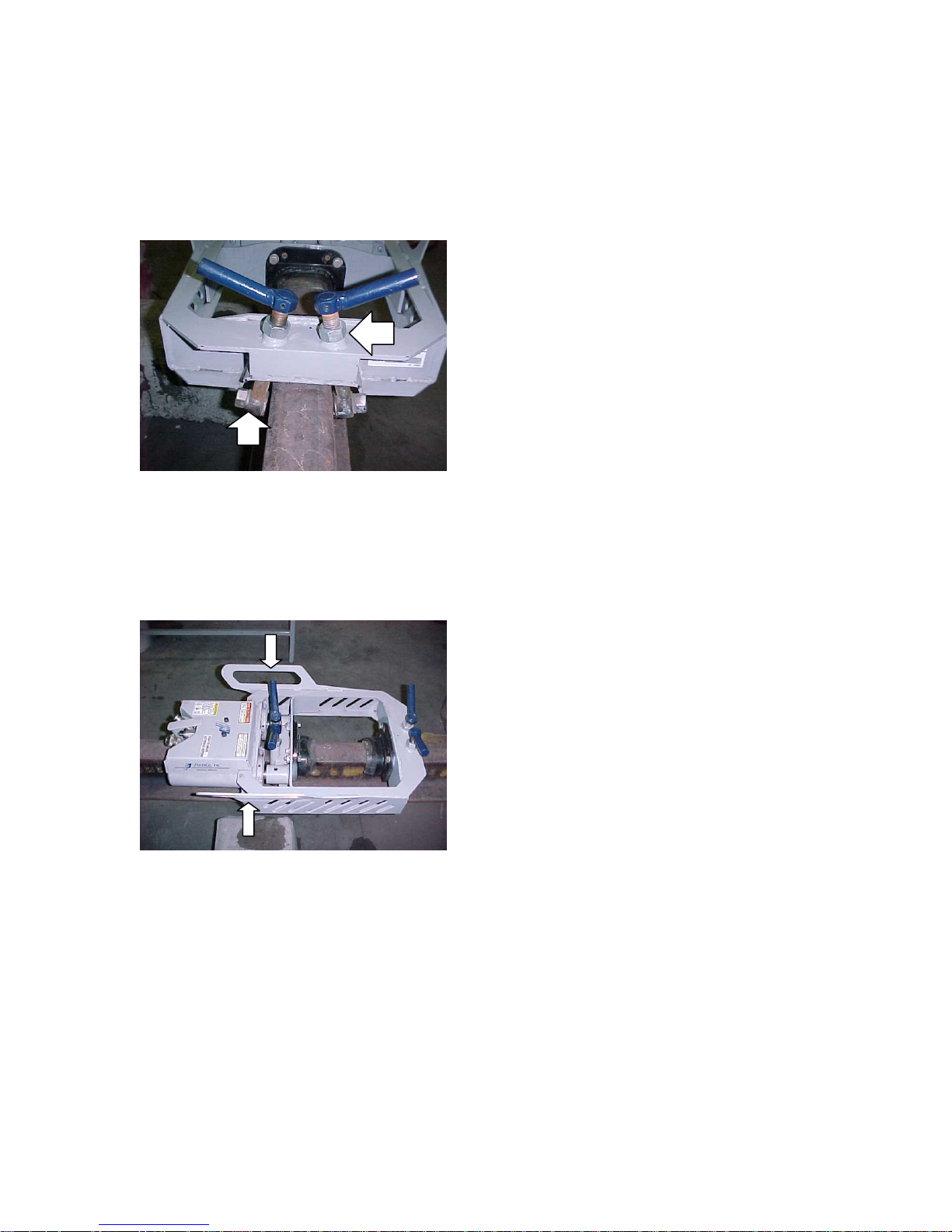

To test the function of the shear,

connect the hydraulic hoses to the

tool see section 2.6 of this manual

for proper procedure. With the flow

from the power source "on" press the

control lever down and hold it there.

(See figure 2.3A) The shear blades

should close at a slow rate of speed.

Allow the blades to contact each

other. Release the lever and the

shear blades should move to full

open without touching the lever or

any form of assistance.

5

If the shear fails to complete any of

these functions see the trouble

shooting section of this manual.

Figure 2.3A

CAUTION: THE PRESSURE

TESTING PROCEDURE MUST BE

CONDUCTED BY A QUALIFIED

HYDRAULIC TECHNICIAN.

To test the pressure exerted at the

shear blades, disconnect the shear

from the power source. Remove the

shear blades from the frame.

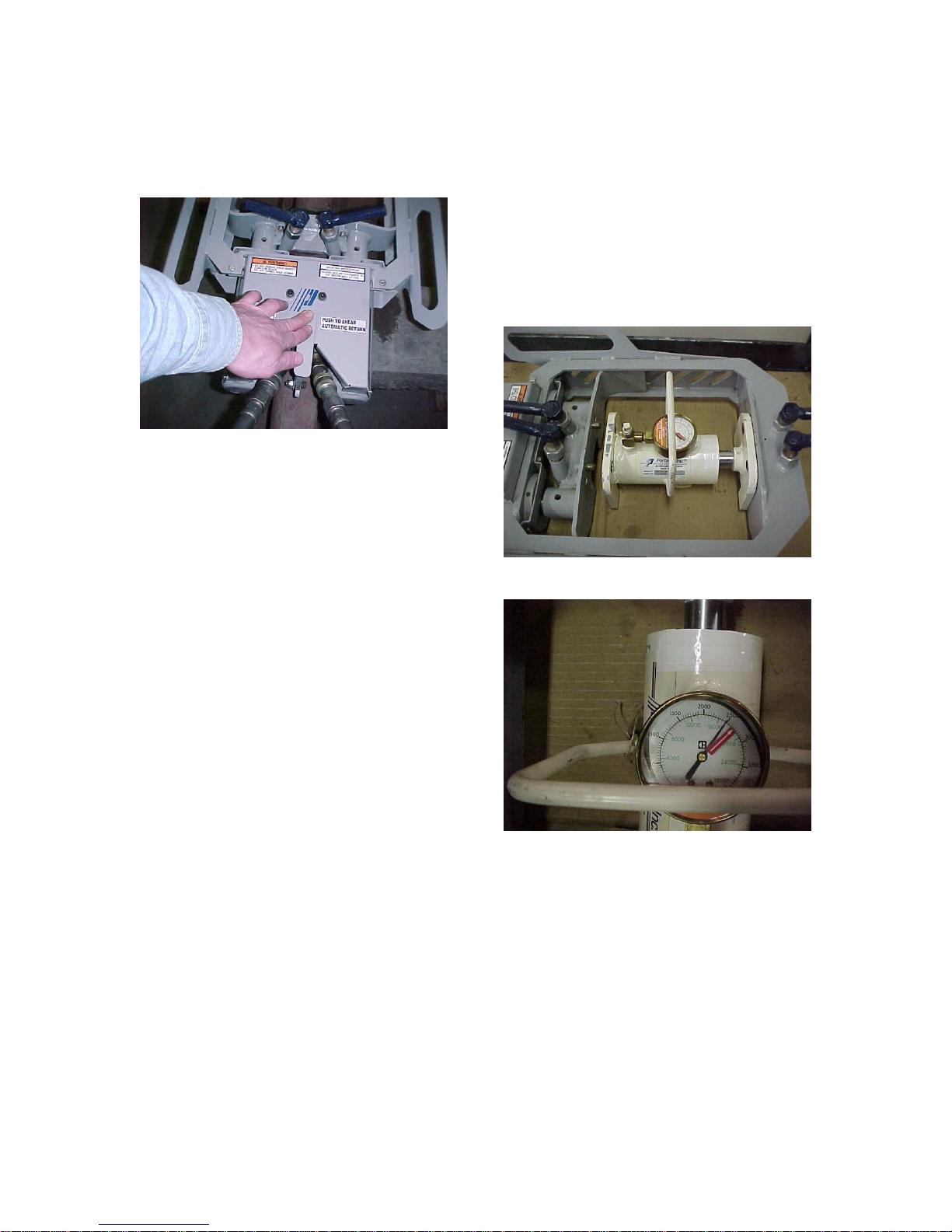

The needle should be within 500 psi

of the red arrow. (figure 2.3C) When

testing follow the instructions

provided with the test equipment.

Testers other than PortaCo. Inc.'s

model TS-00-XX-O may instruct the

technician to perform the test in a

manor slightly different than the

procedure just described.

Figure 2.3B

Insert a pressure testing system

between the frame and the ram end

frame of the shear. PortaCo's Model

TS-00-X-O Tester Shear, is

recommended for this procedure.

(see figure 2.3B)

The model TS-00-X-O tester is

capable of testing most shears. It

features a pressure gauge with and

arrow indicating the optimum force

applied.

Position tester while closing the

shearing mechanism, aligning the

pins in the frames with the holes in

the tester. Hold the control lever

down till the needle, on the pressure

gauge, of the tester stops climbing.

Figure 2.3C

CAUTION: WHEN TESTING THE

RAIL SHEAR, BE SURE TO

FOLLOW ALL SAFETY

GUIDELINES.

2.4 Hose Requirements

It is not often necessary or advisable

to use long hoses. All hoses must

have an oil resistant inner surface

and an abrasion resistant outer

6

surface. Each hose must have male

FLOW PER CIRCUIT

SAE SPEC HOSE

pipe ends for most application.

Longer hoses can be used when

necessary, but can affect the

operation of the engine due to

resistance in the hose.

If small diameter or long hoses are

used, or if restrictive fittings are

connected to the supply and return

ports, the pressure required to push

the fluid through the system and

back to the tank will be higher. This

will reduce tool power.

HOSE TYPES

Hydraulic hose types authorized for

use by PortaCo, Inc. is as follows:

1. Labeled and certified nonconductive

2. Wire braided (conductive)

3. Fabric braided (not certified or

labeled non-conductive)

Hose 1: Listed above is the only

hose authorized for use near

electrical conductors.

*Important – Oil should always

flow from the male coupler

through the female coupler.

NOTE: The pressure increase in

uncoupled hoses left in the sun may

make them difficult to connect.

When possible after use, connect the

free ends of the operating hoses

Hoses 2 and 3: Listed above are

conductive and must never be used

near electrical conductors.

HOSE PRESSURE RATING

The rated working pressure of the

hydraulic hose must be at least 175

bar (2500 psi).

together.

HYDRAULIC HOSE RECOMMENDATION

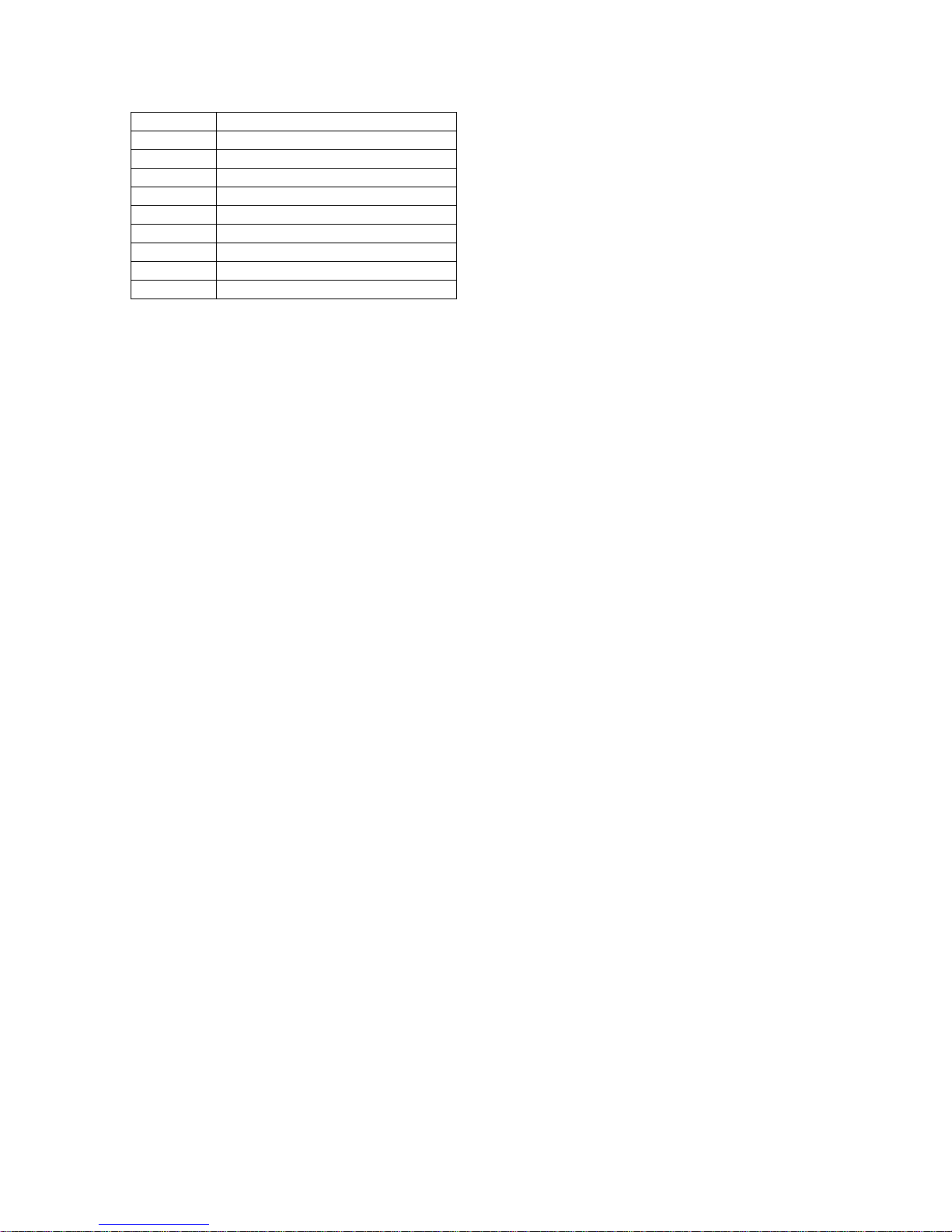

Table 2.4

LENGTH EACH HOSE USE INSIDE DIAMETER

GPM LPM FEET METERS INCH MM

5 to 8 19 to 30 To 50 To 15 Both ½ 13 SAE 100R1-8 100R7-8

5 to 8 19 to 30 51-100 15 to 30 Both 5/8 16 SAE 100R2-10 SAE 100R8-10

5 to 8 19 to 30 100-300 30 to 90 Pressure

Return

9 to 12 34 to 45 To 50 To 15 Both 5/8 16 SAE 100R2-10 SAE 100R8-10

9 to 12 34 to 45 51-100 15 to 30 Pressure

Return

9 to 12 24 to 45 100-200 30 to 60 Pressure

Return¾1

5/8

¾

5/8

¾

16

19

16

19

19

25.4

(WIRE DRAID)

SAE 100R2-10

SAE 100R1-12

SAE 100R2-10

SAE 100R3-12

SAE 100R2-12

SAE 100R1-16

SAE SPEC

HOSE (FIBER

BRAID)

SAE 100R8-10

SAE 100R7-12

SAE 100R8-10

SAE 100R7-12

SAE 100R8-12

SAE 100R7-16

2.5 Hydraulic Fluid Recommendation

Inspect hose for cuts, crushing, leaks,

or abrasion which maybe a safety

hazard or reduce fluid flows.

The following fluids work well over a

Wide temperature range at startup,

Allow moisture to settle out, and resist

Biological growth likely in cool operating

Hydraulic circuits. These fluids are

Recommended by PortaCo inc. Other

That meets or exceeds the specifications

of these fluids may also be used.

7

Type Hydraulic fluid

Chevron “Clarity” AW 15032

Exxon “Univis” J 32

Mobil D.T.E. 13 M

Gulf “Harmony” AW-HVI-150-32

Shell “Tellus T” 32

Texaco “Rando” HDZ 32

Union “Unax” AW-WR-32

Amsoil AWH 15032

Sunvis

Low Pour H/032-product code 19300

Hydraulic fluid requirements:

WARNING: PRESSURIZED FLUID

ESCAPING FROM A DAMAGED

HOSE CAN PENETRATE THE

SKIN AND BE INJECTED IN THE

BODY CAUSING INJURY OR

DEATH.

CAUTION: DO NOT PULL ON

HOSES TO DRAG POWER UNIT.

a) Viscosity (fluid Thickness)

USA METRIC

50 F 4450 SSU Max 10 C 95 Centistokes

100 F 130-200 SSU 38 C 27-42 C.S.

140 F 85 SSU Min. 60 C 16.5 C.S, Min.

Pour Point- 10 F/-23 C Minimum (for cold startup)

Viscosity Index (ASTM D 2220) 140Minimum

Demulsibility(ASTM D-1401) 30 Minutes

Maximum

Flash Point (ASTM D-92) 340 F/171 C Minimum

Rust Inhibition (ASTM D-665 A & B) Pass

Oxidation(ASTM D943) 1000 Hours Minimum

Pump Wear Test (ASTM D2882) 60 mg

Maximum

2.6 Tool Connecting Procedures

Stop the engine before connecting

the tool and, or hoses to the power

unit, and when switching hoses or

tools. Turn the hydraulic on/off valve

to the off position before starting the

engine. Make sure all hose are

connected for correct flow direction

to and from the tool being used.

When routing hose in the work area,

position them where personnel will

not be at risk of tripping over them or

where vehicles can run over the

hoses. Do not lay hose over sharp

objects.

2.7 Work Area Safety Precautions

- Never operate the tool when you

are tired, angry, emotionally

disturbed, or under the influence

of alcohol, drugs, medications, or

anything that could affect your

vision, alertness, coordination or

judgement.

- Establish a training program for all

operators to ensure safe

operation.

- Do no operate the tool unless

thoroughly trained or under the

supervision of an instructor.

- Do not allow others to be near the

tool when starting it or while

operating. Keep bystanders and

animals out of the work area.

- Always wear safety goggles, ear,

leg, and head protection devices,

safety footwear, and snug fitting

clothes.

- Do not operate the tool near

energized transmission lines.

- Do not overreach. Maintain

proper footing and balance at all

times.

8

- Be sure to keep hands and other

parts clear and free from all

moving parts.

- Keep all body parts away from

moving jaws.

- Always connect hydraulic hoses to

the tool before activating the

hydraulic circuit on your power

unit. Check that hydraulic

couplers are secure before

activating the circuit.

- Only a properly trained person

should perform any maintenance,

service, and or repairs to a tool.

- Never operate a tool that is

damaged, improperly adjusted, or

not completely and securely

assembled.

- Do not operate the tool until you

have a clear work area and a

secure balance.

- Keep handles clean and dry.

- Never carry or pick this tool up by

the hydraulic hose

- Disconnect tool from hydraulic

source before inspection or

cleaning.

SAFETY REGULATION

Enter below any local or other safety regulations required for the operator to

follow. Make sure the operator and maintenance personnel have knowledge of

these regulations.

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

9

3.0 Operating Instructions

3.1 Description of Power Tool

PortaCo’s model WS-10-64-3 Weld

Shear is intended to be used to

shear Thermit and Buta type welds.

It's light-weight construction and

auto cycle valve reduces operator

fatigue.

PSI). The maximum pressure of the

hydraulic system is limited to 148.3

BAR (2150 PSI). The power source

provided the required flow and

pressure to operated HTMA type I

15-23 LPM (4-6 GPM) and type RR

34-40 LPM (9-10.5) tools. All which,

are OPEN-CENTER tools required

an operating pressure of 138 BAR

(2000 PSI).

The closing rate of the shear

blades, are limited to the industries

standard and cannot be altered.

When the control lever is release

the blades automatically retract at a

more rapid rate to reduce shearing

time.

The PortaCo Weld Shear secures to

the rail at four points. Adjustable

roller hold downs provide a smooth

shearing operation and guide the

shear on worn rail. Hold down

assemblies have been designed to

be easily serviced in the field.

Hydraulic quick connect couplers

are located at the rear of the tool to

allow more convenient routing of the

supply hoses.

Fully guarded hydraulic plumbing

protects the operator from

accidental leakage of oil onto the

welded area, reducing the potential

for a fire.

The G-18D55-53-W is a versatile

power unit that can meet the needs

for most hydraulic tools used by the

rail road industry. This power unit is

capable of powering two tools

simultaneously at 5 GPM (20 LPM)

or one tool a 10 GPM (40 LPM) all

the flows are at 138 BAR (2000

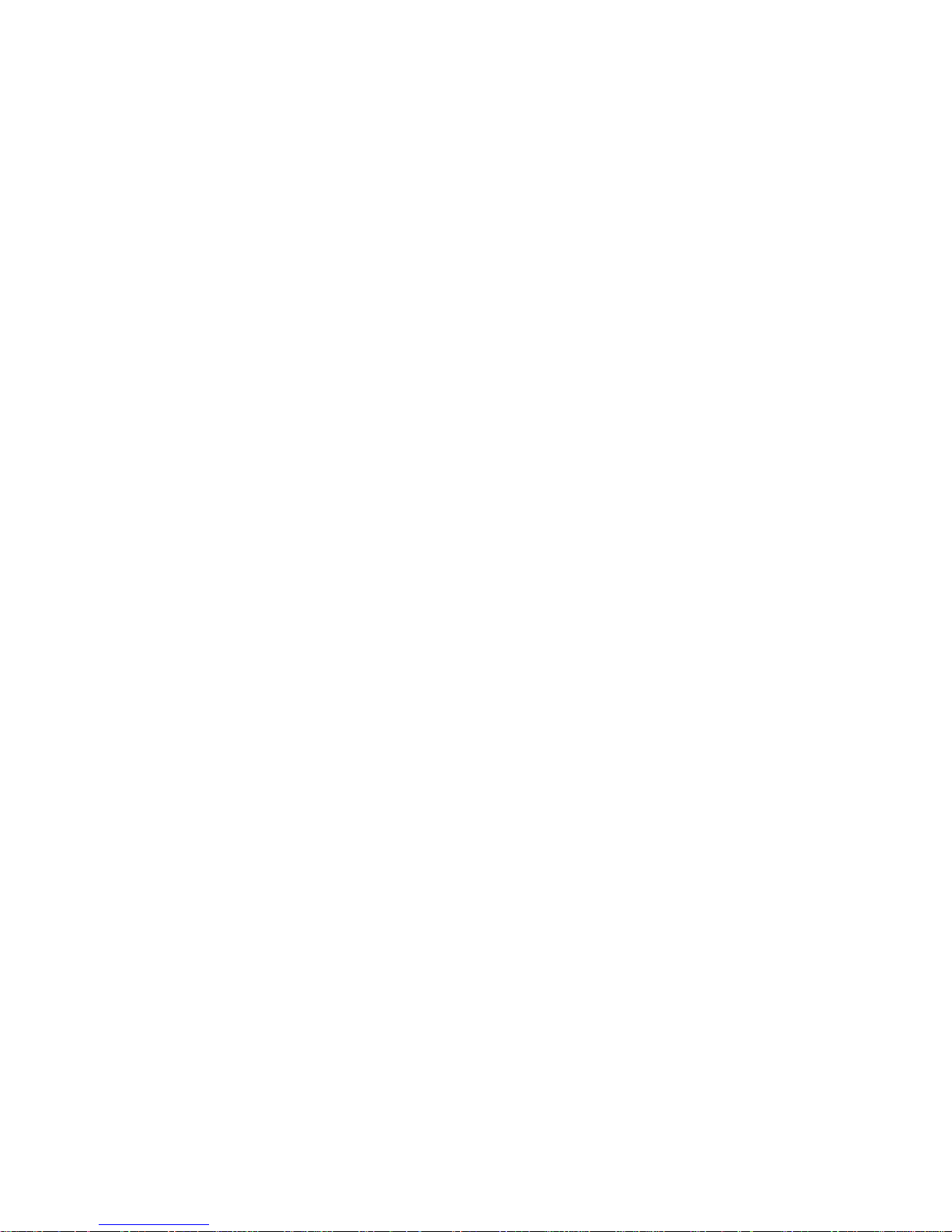

3.2 Controls and Graphics

The following decals are placed on

the tool to aid in its operation and

maintenance. The operator should

locate and understand them before

using this power tool.

The weld shear has five instructional

decals located on the tool.

On the hydraulic system guard cover

there is a CAUTION decal that

specifies that the weld shear is rated

for a flow of 10 GPM/40 LPM and

pressure of 2000 PSI/150 BAR do

not exceed these flow / pressure

ratings. Also on the decal is a few

written warnings “improper use may

cause severe injury, read and

understand operators manual before

operating tool, keep all guards in

place, during operation always wear

gloves, safe clothing and footwear,

and during operation always wear

approved safety protection for ears,

eyes, and head.” (figure 3.2A) (figure

3.2F arrow A)

10

Figure 3.2A

Figure 3.2C

The valve lever operating instruction

decal is located to the right of the

control and instructs the operator to

"PUSH TO SHEAR, AUTOMATIC

RETURN".(figure 3.2B)(figure 3.2F

arrow B)

Figure 3.2B

The "WARNING' decal indicates a

practice which if conducted could

result in injury to the operator or

bystander, or damage to the tool.

Follow the instructions "DO NOT

OPERATE SHEAR WITHOUT

SHIELD IN PLACE" and "DO NOT

STRIKE HOLD DOWNS" printed on

this decal. (figure 3.2C) (figure 3.2F

arrow C).

The mounting instructions decal is

also located on the guard cover. It

states the correct procedure for

adjusting the hold down rollers.

It tells the operator to "ADJUST

ROLLER CLEARANCE TO 1/8"

BELOW BALL OF RAIL". (figure

3.2D)(figure 3.2F arrow D)

Figure 3.2D

On the inside of the far side of the

frame, is a serial # decal. This decal

has the serial number as well as the

model number of the unit. Each unit

has it’s own unique serial number. It

is important to keep this decal

protected and kept legible. The

serial number is needed when

ordering replacement parts.

(figure 3.2E)(figure 3.2G arrow E)

11

ABC

D

a leak is present, hydraulic oil on the

weld area is flammable.

Inspect the hold down assemblies,

make sure they all operate properly.

Replace any damaged or severely

worn components before operation.

Hold downs which aren't operating

correctly may result in an inferior

sheared weld.

Figure 3.2E

Figure 3.2F

Inspect the shear blades and replace

if severely worn or damaged.

BAD "REPLACE"

Figure 3.2G

3.3 Before Operating

Check that the guard is in position

and securely fastened, and in good

condition. Inspect the weld shear for

any hydraulic oil leaks and repair as

required, Do Not operate the shear if

E

GOOD

Inspect hoses, which connect weld

shear to power source for wear,

cracking, fatigue, or leaks before

using. Also check that couplers are

in good condition.

12

WARNING: NEVER INSPECT

PRESSURIZED HOSES,

COUPLERS, OR FITTINGS WITH

HANDS OR AT CLOSE

DISTANCES. PRESSURIZED

FLUID CAN PUNCTURE THE SKIN

AND INJECT OIL INTO THE BODY

RESULTING IN DEATH.

Do not use hoses, couplers, or

fittings which are damaged, replace

immediately.

3.4 Positioning on Rail

Place the shear over the weld,

centering the weld between the

shearing blades.

Turn the handle on all four rollers to

position each roller under the rail.

ADJUSTMENT

NUT

1/8"

CLEARANCE

Adjust the roller clearance to 1/8"

below the ball of the rail using the

nut to maintain the clearance.

3.5 Connecting Hoses

WARNING: ALWAYS STOP THE

HYDRAULIC POWER SOURCE

FLOW AND DEPRESSURIZE THE

SYSTEM BEFORE CONNECTING

A TOOL. FAILURE TO COMPLY

COULD RESULT IN

PRESSURIZED FLUID

PENETRATING THE SKIN AND

INJECTED INTO THE BODY

CAUSING INJURY OR DEATH.

Wipe quick couplers with a clean lint

free cloth before connecting them.

1. Stop the hydraulic power source.

2. Depressurize the system.

3. Allow system and hydraulic fluid

to cool if too hot to handle.

13

4. Securely connect the return (tank

R

"R") hose from the power source

to the tool.

5. Securely connect the supply

(pressure "P") hose from the

power source to the tool.

P

When connecting hoses from power

source to the tool. It is

recommended that you connect the

return hoses first and disconnect last

to minimize or avoid trapping

pressure within the tool.

When connecting the quick couplers,

the flow should run from male

coupler to the female coupler. The

female coupler on the tool is the

inlet. Quick couplers are marked

with a flow direction arrow.

CAUTION: DO NOT PULL ON

HOSES TO DRAG POWER TOOL.

and only requires the operator to

close the jaws. Once the weld has

been sheared the operator releases

the lever and the jaws automatically

return to full open.

1. Press the control lever down and

hold until the jaws have

completely closed.

2. Release the handle and the jaws

will automatically return to full

open.

3. Disconnect the hoses, see

section 3.7 in this manual for

proper procedure.

4. Turn the hold downs to release

the rail and lift the puller off.

3.7 Disconnecting Hoses:

1. Stop the hydraulic power source.

2. Depressurize the system

NOTE: When possible, connect the

free ends of uncoupled hoses to

prevent build up in the hoses. The

sun can also increase pressure in

the hoses and make connecting

them difficult.

3.6 Operating Instructions

PortaCo, Inc.'s weld shear is

equipped with an auto cycle valve,

3. Disconnect the supply (pressure

"P") hose to the power source

(pressure port) than from the tool

(“IN” port).

4. Disconnect the return (tank) hose

to the hydraulic power source

(return port) than from the tool

(“OUT” port).

14

5. To prevent contamination, always

install dust caps over the

hydraulic ports of the tool when

disconnected.

WARNING: IF INJURY RESULTS

FROM ESCAPING HYDRAULIC

FLUID, SEEK IMMEDIATE

MEDICAL ATTENTION. SERIOUS

BODILY INJURY MAY OCCUR IF

PROPER MEDICAL ATTENTION IS

NOT ADMINISTERED

IMMEDIATELY.

WARNING: DO NOT ATTEMPT TO

LOCATE HYDRAULIC LEAKS BY

FEELING AROUND HOSES AND

FITTING WITH HANDS. ”PIN

HOLE” LEAKS CAN PENETRATE

THE SKIN.

3.8 Cold Weather Operation

Hydraulic fluids are thicker in cold

weather; therefore, run the engine at

low idle lone enough to bring the

fluid temperature up to minimum of

10°C/50 F or until the top of the

hydraulic tank feels warm, before

operating tool.

3.9 Storage Preparation

Store the weld shear on a smooth

level surface.

The tool should be stored in a cool,

dry environment which is not

subjected to rapid temperature

changes.

15

CAUTION: USE ONLY GENUINE PORTACO INC PARTS OR EQUIVALENT.

THE USE OF REPLACEMENT PARTS WHICH ARE NOT OF EQUIVALENT

QUALITY MAY DAMAGE THE HYDRAULIC POWER UNIT.

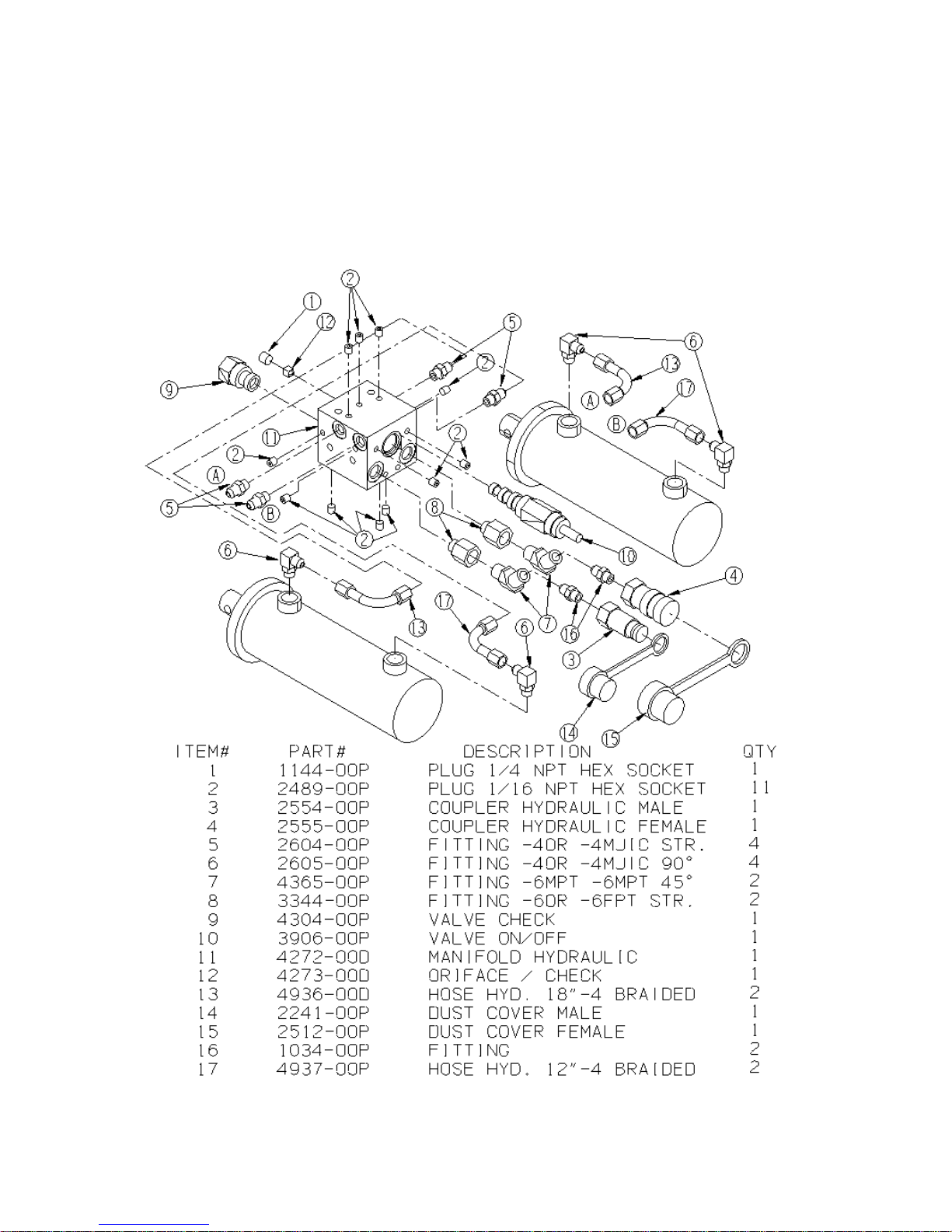

4.0 Maintenance Instruction

4.1 Assembly View and Parts List

16

17

4.2 Graphic Set Complete

(3494-00D)

2158-08D

2158-00D

2906-00D

3492-01D

3494-03D

3494-04D

3463-00D

18

4.3 Care Requirements

Monthly:

Maintenance

CLEANING AND MAINTENANCE

RECOMMENDATIONS Wipe all

external surfaces after each use with

a clean, lint free cloth to remove

surface contaminants from the tool.

Daily:

1. Wipe all tool surfaces, fittings,

and coupling free of grease, dirt,

and foreign materials.

WARNING: DO NOT ATTEMPT TO

LOCATE HYDRAULIC LEAKS BY

FEELING AROUND HOSES AND

FITTINGS WITH HANDS. “PINHOLE” LEAKS CAN PENETRATE

THE SKIN.

2. Inspect the tool signs of leaks

and worn, and/or damage

couplers. Replace if necessary.

3. To prevent contamination, always

install dust caps over the

hydraulic ports when

disconnected.

Inspect the hold down assemblies for

wear or damage and replace any

components as necessary to

maintain a good working condition.

Hold down service kits:

64-4294-OOK Roller bearing

replacement kit

64-4295-OOK Hold down bolt

replacement kit

Annually:

Remove the hydraulic system guard

and inspect fittings and tubing for

damage and replace as required.

Check linkage between valve and

lever for excessive wear and replace

as required.

NOTE: Do not attempt to repair this

product. Only properly trained

person should perform any

maintenance, service, and or repair

to a tool.

4. Inspect shear blades every day.

Replace as required.

COMPLETE DIASSEMBLY OF

THE TOOL IS NOT

RECOMMENDED. RETURN TO

PORTACO, INC. FOR REPAIRS.

19

4.4 Trouble Shooting

The following chart can be used as a guide to correct any problem you may

experience with the tool.

To determine the problem in operation of the weld shear always check that the

hydraulic power source is supplying the correct hydraulic flow and pressure to

the tool as listed in the table. Be sure you are using an accurate flow meter.

Check the flow with the hydraulic fluid temperature at least 80° F/27° C.

NOTE: Stop and depressurize the hydraulic system before connecting or

disconnecting a tool. Failure to follow these instructions can lead to severe

personal injury. Read and follow the instructions in this manual for the proper

way to connect and disconnect tools from the hydraulic systems.

PROBLEM CAUSE REMEDY

Shear binds or travels

jerky.

Hold downs are too tight. Adjust hold downs so

rollers are 1/8" below the

ball of the rail.

Hold downs are damaged Check for damage to the

hold down bolts or rollers.

Replace if required.

Air in system Run shear to full close

and hold for 10 seconds

to purge air.

If blades move but not

enough power to shear

weld.

Inspect shear blades for

wear or damage.

Hydraulic system leak. Check system for leaks

Replace shear blades if

required.

and repair as required.

Relief valve set to low on

power source.

Test power source and

repair or replace as

required.

Check lever linkage for

wear.

If lever bottoms before

full travel, replace or

repair control lever.

Leaky cylinder seal Perform test in section

2.3 of this manual.

Blades don't retract or

retract slowly

Control valve not

returning fully

Check that lever or valve

is returning completely.

Repair/ replace as

needed.

Hydraulic system leak. Check system for leaks

and repair as required.

20

Blades don't retract or

retract slowly.

Check valve malfunction. Remove check valve and

inspect for contamination.

Replace if required.

Shear blades close

completely but fails to

Damaged or worn shear

blades.

Replace shear blades.

shear weld.

Shear runs opposite to

control

Hoses hooked up to

wrong ports.

Check that hoses are

connect correctly.

NOTE: After reviewing trouble shooting chart and still unable to determine

problem call the service department at PortaCo Inc. (218-236-0223) for

assistance.

4.5 Technical Specifications

Weld Shear with blades 84-lbs/38.1 kg

Max Pressure 2000 psi/150 bar

Max Flow 10 gpm/40 lpm

21

Consumable Items List

Description Part Number Source

Coupler HYD FF-372-6FP M 2554-00P PortaCo Inc.

Coupler HYD FF-371-6FP F 2555-00P PortaCo Inc.

Cover Coupler # NR-37 BRUNNING 2241-00P PortaCo Inc.

Cover Coupler # NR-50 2512-00P PortaCo Inc.

Shear Blade Kit 3584-OOK PortaCo Inc.

Hydraulic Fluid Requirements

Viscosity (Fluid Thickness)

METRIC U.S.A.

10 C 95 Centistokes 50 F 450 SSU Max

38 C 27-42 C.S. 100 F 130-200 SSU

60 C 16.5 C.S., Min. 140 F 85 SSU Min.

Pour Point – 10 F/-23 C Minimum (for cold startup)

Viscosity Index (ASTM D 2220) 140 Minimum

Demulsibility (ASTM D-1401) 30 Minutes Maximum

Flash Point (ASTM D-92) 340 F/171 C Minimum

Rust Inhibition (ASTM D-665 A & B) Pass

Oxidation (ASTM D943) 1000 Hours Minimum

Pump West Test (ASTM D2882) 60 mg Maximum

Recommend Hydraulic Fluids

Type Hydraulic fluid

Chevron “Clarity” AW ISO 32

Exxon “Univis” J 32

Mobil D.T.E. 13 M

Gulf “Harmony” AW-HVI-150-32

Shell “Tellus T” 32

Texaco “Rando” HDZ 32

Union “Unax” AW-WR-32

Amsoil AWH ISO 32

Sunvis Low Pour H/032-product code 193000

Coupler recommendation: 3/8 inch FLAT FACE HTMA couplers rated at 2500 psi

working pressure. Threads are to match fittings used on hoses or fittings used

as adapters.

Bolt Size Torque

#10-32

¼-20

5/16-18

3/8-16

38 in. lbs.

76 in. lbs.

13 ft. lbs.

23 ft. lbs

22

SERVICE AND REPAIR NOTES

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

23

MODEL

WS-10-64-3

WELD SHEAR

1805 2ndAVENUE NORTH * MOORHEAD, MN, USA 56560-2310

E-MAIL ADDRESS; info@portaco.com * INTERNET ADDRESS: www.portaco.com

OPERATION,

MAINTENANCE,

AND REPAIR

MANUAL

PHONE (218) 236-0223 * FAX (218) 233-5281

1

TABLE OF CONTENTS

1.0 Introduction

1.1 General Information

1.2 Features

1.3 Safety Summary

1.4 General Safety Precautions

1.5 Warning and Caution Statements

1.6 Training Requirements

2.0 Installation Instructions

2.1 Unpacking Instructions

2.2 Tool Preparations

2.3 Testing

2.4 Hose Requirements

2.5 Hydraulic Fluid Recommendations

2.6 Tool Connecting Procedures

2.7 Work Area Safety Precautions

3.0 Operating Instructions

3.1 Description of Power Unit

3.2 Controls and Graphics

3.3 Before Operating

3.4 Positioning on Rail

3.5 Connecting Hoses

3.6 Operating Instructions

3.7 Disconnecting Hoses

3.8 Cold Weather Operation

3.9 Storage Preparation

4.0 Maintenance Instructions

4.1 Assembly View and Parts List

4.2 Graphic Set Complete

4.3 Tool Maintenance

4.4 Trouble Shooting

4.5 Technical Specification

2

1.0 INTRODUCTION

C

1.1 General Information

This manual presents removal,

operation, and maintenance

information for PortaCo’s model

WS-10-64-3 Weld Shear. The tool is

designed to remove the excess

material when performing Thermit

and Buta type welds. It's light weight

compact size allows for use inside

rail pulling equipment. All hydraulic

plumbing is protected by a one piece

guard to prevent damage and to

contain any leaks if any damage

occurs. When properly used this tool

will help reduce back strain and also

reduce operator fatigue.

shearing blades to the full open

position when the valve control lever

is released. (See figure 1.2A arrow

A) This reduces total shearing time

and reduces the operator's exposure

to the heat produced during the

welding procedure.

B

A

Figure 1.2A

PortaCo, Inc. reserves the right to

make changes at anytime without

notice and without incurring any

obligation.

1.2 Features

The main features of the PortaCo

Weld Shear Model WS-00-64-3 are

as follows.

Standard unit:

Length 26.38 in/ 67.0 cm

Width 17.75 in/ 45.1 cm

Height 7.21 in/ 18.3 cm

Weight 84-lbs/ 38.1 kg

(includes blades)

Upper ambient operating

temperature 110°F (43° C), lower

ambient operating temperature -20°F

(-28° C).

PortaCo, Inc.'s weld shear features

an auto cycle valve which returns the

The control valve also limits the

speed for shearing and provides a

rapid retract for easy operation.

The hydraulic plumbing is protected

by a one-piece guard to prevent

damage and to contain any leaks if

any damage occures. (figure 1.2A

arrow B)

The hydraulic quick connect couplers

are located at the rear of the shear

and directs the hoses along the rail

out of the work area. (figure 1.2A

arrow C) The path of the hose's

along the rail reduces the potential

for a worker to trip on them.

Roller hold-downs, provide a secure

mount to the rail and allows smooth

operation during the shearing

process. The roller height is set with

a jam nut providing a snug fit on any

size rail. (figure 1.2B arrow A)

3

The roller assembly is easily

A

B

removed for replacement of any

component of the hold-down

assembly. (figure 1.2B arrow B)

Figure 1.2B

Handles incorporated into the frame

allow for even balance and level

transportation for quick positioning

on the rail. Figure 1.3

and before performing maintenance

or repairs. Supervising personnel

should develop additional

precautions relating to the specific

work area and local safety

regulations.

1.4 General Safety Precautions

The PortaCo Inc. tools are designed

to provide safe and dependable

service if operated according to the

instructions provided in this manual.

Read and understand this manual

and any stickers attached to the

power unit before operating. Failure

to do so could result in personal

injury or equipment damage.

Check the rules and regulations at

your location. The rules may include

an employer’s work safety program.

Regulations may identify hazards

such as working around utility supply

lines or hazardous slopes.

1.3 Safety Summary

Tool operators and maintenance

personnel must always comply with

the safety precautions given in this

manual and on the stickers and tags

attached to the tool and hoses.

These safety precautions are given

for your safety. Review them

carefully before operating the tool

Read and understand any manuals

for additional or optional equipment,

which maybe shipped with the tool.

1.5 Warning and Caution

Statements

Warning and Caution statements

have been strategically placed

throughout the text prior to operating

or maintenance procedures,

practices, or conditions considered

essential for the protection of

personnel, equipment, and property.

WARNING: HIGHLIGHTS A,

ESSENTIAL OPERATING, OR

MAINTENANCE PROCEDURE,

PRACTICE, CONDITION

STATEMENT, ETC… WHICH IF

NOT STRICTLY OBSERVED,

4

COULD RESULT IN INJURY TO,

OR DEATH OF, PERSONNEL OR

LONG TERM HEALTH HAZARDS.

CAUTION: HIGHLIGHTS AN

ESSENTIAL OPERATING OR

MAINTENANCE PROCEDURE,

PRACTICE, CONDITION

STATEMENT, ETC. WHICH IF NOT

STRICTLY OBSERVED, COULD

RESULT IN DAMAGE TO, OR

DESTRUCTION OF, EQUIPMENT

OR LOSS OF MISSION

EFFECTIVENESS.

1.6 Training Requirements

Operator training for the weld shear

should consist of information found

in this manual. In addition the

operator must receive instructions,

both verbally and through

demonstrations for applications in

which the tool is going to be used.

The new operator must start in an

area without bystanders and use the

tool until able to fully operate the tool

under the conditions for the work

area.

2.0 INSTALLATION INSTRUCTIONS

2.1 Unpacking Instructions

Upon receiving your weld shear

promptly remove it from the shipping

container. Always keep top side of

container up. Inspect unit for

damage which may have incurred

during shipping and report it to

carrier for claim.

2.2 Tool Preparations

The PortaCo G-18D55-53-W power

unit is recommended for hydraulic

supply. This unit is equipped with

two 5-gpm/20 lpm circuits that can

be combined for on 10 gpm/40 lpm

circuits.

If the tool is used in cold weather,

preheat the hydraulic fluid by running

power source at low engine speed.

Fluid temperature should be at or

above 50° F/10° C (400-ssu/82

centistroke) before use, when using

recommended fluids. Using too thick

of fluid may result in tool damage.

2.3 Testing

WARNING: NEVER STICK

FOREIGN OBJECTS, FINGERS,

OR OTHER EXTRMITIES INTO

MOVING MECHANISMS. FAILURE

TO FOLLOW THESE

INSTRUCTIONS MAY LEAD TO

SEVERE PERSONAL INJURY OR

TOOL DAMAGE.

Before operating the weld shear it is

important to inspect the shear blades

for excessive wear or damage.

Replace the shear blades if required

before operating the shear. Follow all

safety precautions and procedures

when inspecting tool.

To test the function of the shear,

connect the hydraulic hoses to the

tool see section 2.6 of this manual

for proper procedure. With the flow

from the power source "on" press the

control lever down and hold it there.

(See figure 2.3A) The shear blades

should close at a slow rate of speed.

Allow the blades to contact each

other. Release the lever and the

shear blades should move to full

open without touching the lever or

any form of assistance.

5

If the shear fails to complete any of

these functions see the trouble

shooting section of this manual.

Figure 2.3A

CAUTION: THE PRESSURE

TESTING PROCEDURE MUST BE

CONDUCTED BY A QUALIFIED

HYDRAULIC TECHNICIAN.

To test the pressure exerted at the

shear blades, disconnect the shear

from the power source. Remove the

shear blades from the frame.

The needle should be within 500 psi

of the red arrow. (figure 2.3C) When

testing follow the instructions

provided with the test equipment.

Testers other than PortaCo. Inc.'s

model TS-00-XX-O may instruct the

technician to perform the test in a

manor slightly different than the

procedure just described.

Figure 2.3B

Insert a pressure testing system

between the frame and the ram end

frame of the shear. PortaCo's Model

TS-00-X-O Tester Shear, is

recommended for this procedure.

(see figure 2.3B)

The model TS-00-X-O tester is

capable of testing most shears. It

features a pressure gauge with and

arrow indicating the optimum force

applied.

Position tester while closing the

shearing mechanism, aligning the

pins in the frames with the holes in

the tester. Hold the control lever

down till the needle, on the pressure

gauge, of the tester stops climbing.

Figure 2.3C

CAUTION: WHEN TESTING THE

RAIL SHEAR, BE SURE TO

FOLLOW ALL SAFETY

GUIDELINES.

2.4 Hose Requirements

It is not often necessary or advisable

to use long hoses. All hoses must

have an oil resistant inner surface

and an abrasion resistant outer

6

surface. Each hose must have male

FLOW PER CIRCUIT

SAE SPEC HOSE

pipe ends for most application.

Longer hoses can be used when

necessary, but can affect the

operation of the engine due to

resistance in the hose.

If small diameter or long hoses are

used, or if restrictive fittings are

connected to the supply and return

ports, the pressure required to push

the fluid through the system and

back to the tank will be higher. This

will reduce tool power.

HOSE TYPES

Hydraulic hose types authorized for

use by PortaCo, Inc. is as follows:

1. Labeled and certified nonconductive

2. Wire braided (conductive)

3. Fabric braided (not certified or

labeled non-conductive)

Hose 1: Listed above is the only

hose authorized for use near

electrical conductors.

*Important – Oil should always

flow from the male coupler

through the female coupler.

NOTE: The pressure increase in

uncoupled hoses left in the sun may

make them difficult to connect.

When possible after use, connect the

free ends of the operating hoses

Hoses 2 and 3: Listed above are

conductive and must never be used

near electrical conductors.

HOSE PRESSURE RATING

The rated working pressure of the

hydraulic hose must be at least 175

bar (2500 psi).

together.

HYDRAULIC HOSE RECOMMENDATION

Table 2.4

LENGTH EACH HOSE USE INSIDE DIAMETER

GPM LPM FEET METERS INCH MM

5 to 8 19 to 30 To 50 To 15 Both ½ 13 SAE 100R1-8 100R7-8

5 to 8 19 to 30 51-100 15 to 30 Both 5/8 16 SAE 100R2-10 SAE 100R8-10

5 to 8 19 to 30 100-300 30 to 90 Pressure

Return

9 to 12 34 to 45 To 50 To 15 Both 5/8 16 SAE 100R2-10 SAE 100R8-10

9 to 12 34 to 45 51-100 15 to 30 Pressure

Return

9 to 12 24 to 45 100-200 30 to 60 Pressure

Return¾1

5/8

¾

5/8

¾

16

19

16

19

19

25.4

(WIRE DRAID)

SAE 100R2-10

SAE 100R1-12

SAE 100R2-10

SAE 100R3-12

SAE 100R2-12

SAE 100R1-16

SAE SPEC

HOSE (FIBER

BRAID)

SAE 100R8-10

SAE 100R7-12

SAE 100R8-10

SAE 100R7-12

SAE 100R8-12

SAE 100R7-16

2.5 Hydraulic Fluid Recommendation

Inspect hose for cuts, crushing, leaks,

or abrasion which maybe a safety

hazard or reduce fluid flows.

The following fluids work well over a

Wide temperature range at startup,

Allow moisture to settle out, and resist

Biological growth likely in cool operating

Hydraulic circuits. These fluids are

Recommended by PortaCo inc. Other

That meets or exceeds the specifications

of these fluids may also be used.

7

Type Hydraulic fluid

Chevron “Clarity” AW 15032

Exxon “Univis” J 32

Mobil D.T.E. 13 M

Gulf “Harmony” AW-HVI-150-32

Shell “Tellus T” 32

Texaco “Rando” HDZ 32

Union “Unax” AW-WR-32

Amsoil AWH 15032

Sunvis

Low Pour H/032-product code 19300

Hydraulic fluid requirements:

WARNING: PRESSURIZED FLUID

ESCAPING FROM A DAMAGED

HOSE CAN PENETRATE THE

SKIN AND BE INJECTED IN THE

BODY CAUSING INJURY OR

DEATH.

CAUTION: DO NOT PULL ON

HOSES TO DRAG POWER UNIT.

a) Viscosity (fluid Thickness)

USA METRIC

50 F 4450 SSU Max 10 C 95 Centistokes

100 F 130-200 SSU 38 C 27-42 C.S.

140 F 85 SSU Min. 60 C 16.5 C.S, Min.

Pour Point- 10 F/-23 C Minimum (for cold startup)

Viscosity Index (ASTM D 2220) 140Minimum

Demulsibility(ASTM D-1401) 30 Minutes

Maximum

Flash Point (ASTM D-92) 340 F/171 C Minimum

Rust Inhibition (ASTM D-665 A & B) Pass

Oxidation(ASTM D943) 1000 Hours Minimum

Pump Wear Test (ASTM D2882) 60 mg

Maximum

2.6 Tool Connecting Procedures

Stop the engine before connecting

the tool and, or hoses to the power

unit, and when switching hoses or

tools. Turn the hydraulic on/off valve

to the off position before starting the

engine. Make sure all hose are

connected for correct flow direction

to and from the tool being used.

When routing hose in the work area,

position them where personnel will

not be at risk of tripping over them or

where vehicles can run over the

hoses. Do not lay hose over sharp

objects.

2.7 Work Area Safety Precautions

- Never operate the tool when you

are tired, angry, emotionally

disturbed, or under the influence

of alcohol, drugs, medications, or

anything that could affect your

vision, alertness, coordination or

judgement.

- Establish a training program for all

operators to ensure safe

operation.

- Do no operate the tool unless

thoroughly trained or under the

supervision of an instructor.

- Do not allow others to be near the

tool when starting it or while

operating. Keep bystanders and

animals out of the work area.

- Always wear safety goggles, ear,

leg, and head protection devices,

safety footwear, and snug fitting

clothes.

- Do not operate the tool near

energized transmission lines.

- Do not overreach. Maintain

proper footing and balance at all

times.

8

- Be sure to keep hands and other

parts clear and free from all

moving parts.

- Keep all body parts away from

moving jaws.

- Always connect hydraulic hoses to

the tool before activating the

hydraulic circuit on your power

unit. Check that hydraulic

couplers are secure before

activating the circuit.

- Only a properly trained person

should perform any maintenance,

service, and or repairs to a tool.

- Never operate a tool that is

damaged, improperly adjusted, or

not completely and securely

assembled.

- Do not operate the tool until you

have a clear work area and a

secure balance.

- Keep handles clean and dry.

- Never carry or pick this tool up by

the hydraulic hose

- Disconnect tool from hydraulic

source before inspection or

cleaning.

SAFETY REGULATION

Enter below any local or other safety regulations required for the operator to

follow. Make sure the operator and maintenance personnel have knowledge of

these regulations.

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

9

3.0 Operating Instructions

3.1 Description of Power Tool

PortaCo’s model WS-10-64-3 Weld

Shear is intended to be used to

shear Thermit and Buta type welds.

It's light-weight construction and

auto cycle valve reduces operator

fatigue.

PSI). The maximum pressure of the

hydraulic system is limited to 148.3

BAR (2150 PSI). The power source

provided the required flow and

pressure to operated HTMA type I

15-23 LPM (4-6 GPM) and type RR

34-40 LPM (9-10.5) tools. All which,

are OPEN-CENTER tools required

an operating pressure of 138 BAR

(2000 PSI).

The closing rate of the shear

blades, are limited to the industries

standard and cannot be altered.

When the control lever is release

the blades automatically retract at a

more rapid rate to reduce shearing

time.

The PortaCo Weld Shear secures to

the rail at four points. Adjustable

roller hold downs provide a smooth

shearing operation and guide the

shear on worn rail. Hold down

assemblies have been designed to

be easily serviced in the field.

Hydraulic quick connect couplers

are located at the rear of the tool to

allow more convenient routing of the

supply hoses.

Fully guarded hydraulic plumbing

protects the operator from

accidental leakage of oil onto the

welded area, reducing the potential

for a fire.

The G-18D55-53-W is a versatile

power unit that can meet the needs

for most hydraulic tools used by the

rail road industry. This power unit is

capable of powering two tools

simultaneously at 5 GPM (20 LPM)

or one tool a 10 GPM (40 LPM) all

the flows are at 138 BAR (2000

3.2 Controls and Graphics

The following decals are placed on

the tool to aid in its operation and

maintenance. The operator should

locate and understand them before

using this power tool.

The weld shear has five instructional

decals located on the tool.

On the hydraulic system guard cover

there is a CAUTION decal that

specifies that the weld shear is rated

for a flow of 10 GPM/40 LPM and

pressure of 2000 PSI/150 BAR do

not exceed these flow / pressure

ratings. Also on the decal is a few

written warnings “improper use may

cause severe injury, read and

understand operators manual before

operating tool, keep all guards in

place, during operation always wear

gloves, safe clothing and footwear,

and during operation always wear

approved safety protection for ears,

eyes, and head.” (figure 3.2A) (figure

3.2F arrow A)

10

Figure 3.2A

Figure 3.2C

The valve lever operating instruction

decal is located to the right of the

control and instructs the operator to

"PUSH TO SHEAR, AUTOMATIC

RETURN".(figure 3.2B)(figure 3.2F

arrow B)

Figure 3.2B

The "WARNING' decal indicates a

practice which if conducted could

result in injury to the operator or

bystander, or damage to the tool.

Follow the instructions "DO NOT

OPERATE SHEAR WITHOUT

SHIELD IN PLACE" and "DO NOT

STRIKE HOLD DOWNS" printed on

this decal. (figure 3.2C) (figure 3.2F

arrow C).

The mounting instructions decal is

also located on the guard cover. It

states the correct procedure for

adjusting the hold down rollers.

It tells the operator to "ADJUST

ROLLER CLEARANCE TO 1/8"

BELOW BALL OF RAIL". (figure

3.2D)(figure 3.2F arrow D)

Figure 3.2D

On the inside of the far side of the

frame, is a serial # decal. This decal

has the serial number as well as the

model number of the unit. Each unit

has it’s own unique serial number. It

is important to keep this decal

protected and kept legible. The

serial number is needed when

ordering replacement parts.

(figure 3.2E)(figure 3.2G arrow E)

11

ABC

D

a leak is present, hydraulic oil on the

weld area is flammable.

Inspect the hold down assemblies,

make sure they all operate properly.

Replace any damaged or severely

worn components before operation.

Hold downs which aren't operating

correctly may result in an inferior

sheared weld.

Figure 3.2E

Figure 3.2F

Inspect the shear blades and replace

if severely worn or damaged.

BAD "REPLACE"

Figure 3.2G

3.3 Before Operating

Check that the guard is in position

and securely fastened, and in good

condition. Inspect the weld shear for

any hydraulic oil leaks and repair as

required, Do Not operate the shear if

E

GOOD

Inspect hoses, which connect weld

shear to power source for wear,

cracking, fatigue, or leaks before

using. Also check that couplers are

in good condition.

12

WARNING: NEVER INSPECT

PRESSURIZED HOSES,

COUPLERS, OR FITTINGS WITH

HANDS OR AT CLOSE

DISTANCES. PRESSURIZED

FLUID CAN PUNCTURE THE SKIN

AND INJECT OIL INTO THE BODY

RESULTING IN DEATH.

Do not use hoses, couplers, or

fittings which are damaged, replace

immediately.

3.4 Positioning on Rail

Place the shear over the weld,

centering the weld between the

shearing blades.

Turn the handle on all four rollers to

position each roller under the rail.

ADJUSTMENT

NUT

1/8"

CLEARANCE

Adjust the roller clearance to 1/8"

below the ball of the rail using the

nut to maintain the clearance.

3.5 Connecting Hoses

WARNING: ALWAYS STOP THE

HYDRAULIC POWER SOURCE

FLOW AND DEPRESSURIZE THE

SYSTEM BEFORE CONNECTING

A TOOL. FAILURE TO COMPLY

COULD RESULT IN

PRESSURIZED FLUID

PENETRATING THE SKIN AND

INJECTED INTO THE BODY

CAUSING INJURY OR DEATH.

Wipe quick couplers with a clean lint

free cloth before connecting them.

1. Stop the hydraulic power source.

2. Depressurize the system.

3. Allow system and hydraulic fluid

to cool if too hot to handle.

13

4. Securely connect the return (tank

R

"R") hose from the power source

to the tool.

5. Securely connect the supply

(pressure "P") hose from the

power source to the tool.

P

When connecting hoses from power

source to the tool. It is

recommended that you connect the

return hoses first and disconnect last

to minimize or avoid trapping

pressure within the tool.

When connecting the quick couplers,

the flow should run from male

coupler to the female coupler. The

female coupler on the tool is the

inlet. Quick couplers are marked

with a flow direction arrow.

CAUTION: DO NOT PULL ON

HOSES TO DRAG POWER TOOL.

and only requires the operator to

close the jaws. Once the weld has

been sheared the operator releases

the lever and the jaws automatically

return to full open.

1. Press the control lever down and

hold until the jaws have

completely closed.

2. Release the handle and the jaws

will automatically return to full

open.

3. Disconnect the hoses, see

section 3.7 in this manual for

proper procedure.

4. Turn the hold downs to release

the rail and lift the puller off.

3.7 Disconnecting Hoses:

1. Stop the hydraulic power source.

2. Depressurize the system

NOTE: When possible, connect the

free ends of uncoupled hoses to

prevent build up in the hoses. The

sun can also increase pressure in

the hoses and make connecting

them difficult.

3.6 Operating Instructions

PortaCo, Inc.'s weld shear is

equipped with an auto cycle valve,

3. Disconnect the supply (pressure

"P") hose to the power source

(pressure port) than from the tool

(“IN” port).

4. Disconnect the return (tank) hose

to the hydraulic power source

(return port) than from the tool

(“OUT” port).

14

5. To prevent contamination, always

install dust caps over the

hydraulic ports of the tool when

disconnected.

WARNING: IF INJURY RESULTS

FROM ESCAPING HYDRAULIC

FLUID, SEEK IMMEDIATE

MEDICAL ATTENTION. SERIOUS

BODILY INJURY MAY OCCUR IF

PROPER MEDICAL ATTENTION IS

NOT ADMINISTERED

IMMEDIATELY.

WARNING: DO NOT ATTEMPT TO

LOCATE HYDRAULIC LEAKS BY

FEELING AROUND HOSES AND

FITTING WITH HANDS. ”PIN

HOLE” LEAKS CAN PENETRATE

THE SKIN.

3.8 Cold Weather Operation

Hydraulic fluids are thicker in cold

weather; therefore, run the engine at

low idle lone enough to bring the

fluid temperature up to minimum of

10°C/50 F or until the top of the

hydraulic tank feels warm, before

operating tool.

3.9 Storage Preparation

Store the weld shear on a smooth

level surface.

The tool should be stored in a cool,

dry environment which is not

subjected to rapid temperature

changes.

15

CAUTION: USE ONLY GENUINE PORTACO INC PARTS OR EQUIVALENT.

THE USE OF REPLACEMENT PARTS WHICH ARE NOT OF EQUIVALENT

QUALITY MAY DAMAGE THE HYDRAULIC POWER UNIT.

4.0 Maintenance Instruction

4.1 Assembly View and Parts List

16

17

4.2 Graphic Set Complete

(3494-00D)

2158-08D

2158-00D

2906-00D

3492-01D

3494-03D

3494-04D

3463-00D

18

4.3 Care Requirements

Monthly:

Maintenance

CLEANING AND MAINTENANCE

RECOMMENDATIONS Wipe all

external surfaces after each use with

a clean, lint free cloth to remove

surface contaminants from the tool.

Daily:

1. Wipe all tool surfaces, fittings,

and coupling free of grease, dirt,

and foreign materials.

WARNING: DO NOT ATTEMPT TO

LOCATE HYDRAULIC LEAKS BY

FEELING AROUND HOSES AND

FITTINGS WITH HANDS. “PINHOLE” LEAKS CAN PENETRATE

THE SKIN.

2. Inspect the tool signs of leaks

and worn, and/or damage

couplers. Replace if necessary.

3. To prevent contamination, always

install dust caps over the

hydraulic ports when

disconnected.

Inspect the hold down assemblies for

wear or damage and replace any

components as necessary to

maintain a good working condition.

Hold down service kits:

64-4294-OOK Roller bearing

replacement kit

64-4295-OOK Hold down bolt

replacement kit

Annually:

Remove the hydraulic system guard

and inspect fittings and tubing for

damage and replace as required.

Check linkage between valve and

lever for excessive wear and replace

as required.

NOTE: Do not attempt to repair this

product. Only properly trained

person should perform any

maintenance, service, and or repair

to a tool.

4. Inspect shear blades every day.

Replace as required.

COMPLETE DIASSEMBLY OF

THE TOOL IS NOT

RECOMMENDED. RETURN TO

PORTACO, INC. FOR REPAIRS.

19

4.4 Trouble Shooting

The following chart can be used as a guide to correct any problem you may

experience with the tool.

To determine the problem in operation of the weld shear always check that the

hydraulic power source is supplying the correct hydraulic flow and pressure to

the tool as listed in the table. Be sure you are using an accurate flow meter.

Check the flow with the hydraulic fluid temperature at least 80° F/27° C.

NOTE: Stop and depressurize the hydraulic system before connecting or

disconnecting a tool. Failure to follow these instructions can lead to severe

personal injury. Read and follow the instructions in this manual for the proper

way to connect and disconnect tools from the hydraulic systems.

PROBLEM CAUSE REMEDY

Shear binds or travels

jerky.

Hold downs are too tight. Adjust hold downs so

rollers are 1/8" below the

ball of the rail.

Hold downs are damaged Check for damage to the

hold down bolts or rollers.

Replace if required.

Air in system Run shear to full close

and hold for 10 seconds

to purge air.

If blades move but not

enough power to shear

weld.

Inspect shear blades for

wear or damage.

Hydraulic system leak. Check system for leaks

Replace shear blades if

required.

and repair as required.

Relief valve set to low on

power source.

Test power source and

repair or replace as

required.

Check lever linkage for

wear.

If lever bottoms before

full travel, replace or

repair control lever.

Leaky cylinder seal Perform test in section

2.3 of this manual.

Blades don't retract or

retract slowly

Control valve not

returning fully

Check that lever or valve

is returning completely.

Repair/ replace as

needed.

Hydraulic system leak. Check system for leaks

and repair as required.

20

Blades don't retract or

retract slowly.

Check valve malfunction. Remove check valve and

inspect for contamination.

Replace if required.

Shear blades close

completely but fails to

Damaged or worn shear

blades.

Replace shear blades.

shear weld.

Shear runs opposite to

control

Hoses hooked up to

wrong ports.

Check that hoses are

connect correctly.

NOTE: After reviewing trouble shooting chart and still unable to determine

problem call the service department at PortaCo Inc. (218-236-0223) for

assistance.

4.5 Technical Specifications

Weld Shear with blades 84-lbs/38.1 kg

Max Pressure 2000 psi/150 bar

Max Flow 10 gpm/40 lpm

21

Consumable Items List

Description Part Number Source

Coupler HYD FF-372-6FP M 2554-00P PortaCo Inc.

Coupler HYD FF-371-6FP F 2555-00P PortaCo Inc.

Cover Coupler # NR-37 BRUNNING 2241-00P PortaCo Inc.

Cover Coupler # NR-50 2512-00P PortaCo Inc.

Shear Blade Kit 3584-OOK PortaCo Inc.

Hydraulic Fluid Requirements

Viscosity (Fluid Thickness)

METRIC U.S.A.

10 C 95 Centistokes 50 F 450 SSU Max

38 C 27-42 C.S. 100 F 130-200 SSU

60 C 16.5 C.S., Min. 140 F 85 SSU Min.

Pour Point – 10 F/-23 C Minimum (for cold startup)

Viscosity Index (ASTM D 2220) 140 Minimum

Demulsibility (ASTM D-1401) 30 Minutes Maximum

Flash Point (ASTM D-92) 340 F/171 C Minimum

Rust Inhibition (ASTM D-665 A & B) Pass

Oxidation (ASTM D943) 1000 Hours Minimum

Pump West Test (ASTM D2882) 60 mg Maximum

Recommend Hydraulic Fluids

Type Hydraulic fluid

Chevron “Clarity” AW ISO 32

Exxon “Univis” J 32

Mobil D.T.E. 13 M

Gulf “Harmony” AW-HVI-150-32

Shell “Tellus T” 32

Texaco “Rando” HDZ 32

Union “Unax” AW-WR-32

Amsoil AWH ISO 32

Sunvis Low Pour H/032-product code 193000

Coupler recommendation: 3/8 inch FLAT FACE HTMA couplers rated at 2500 psi

working pressure. Threads are to match fittings used on hoses or fittings used

as adapters.

Bolt Size Torque

#10-32

¼-20

5/16-18

3/8-16

38 in. lbs.

76 in. lbs.

13 ft. lbs.

23 ft. lbs

22

SERVICE AND REPAIR NOTES

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

________________________________________________________________

23

MODEL

WS-10-64-3

WELD SHEAR

1805 2ndAVENUE NORTH * MOORHEAD, MN, USA 56560-2310

E-MAIL ADDRESS; info@portaco.com * INTERNET ADDRESS: www.portaco.com

OPERATION,

MAINTENANCE,

AND REPAIR

MANUAL

PHONE (218) 236-0223 * FAX (218) 233-5281

1

TABLE OF CONTENTS

1.0 Introduction

1.1 General Information

1.2 Features

1.3 Safety Summary

1.4 General Safety Precautions

1.5 Warning and Caution Statements

1.6 Training Requirements

2.0 Installation Instructions

2.1 Unpacking Instructions

2.2 Tool Preparations

2.3 Testing

2.4 Hose Requirements

2.5 Hydraulic Fluid Recommendations

2.6 Tool Connecting Procedures

2.7 Work Area Safety Precautions

3.0 Operating Instructions

3.1 Description of Power Unit

3.2 Controls and Graphics

3.3 Before Operating

3.4 Positioning on Rail

3.5 Connecting Hoses

3.6 Operating Instructions

3.7 Disconnecting Hoses

3.8 Cold Weather Operation

3.9 Storage Preparation

4.0 Maintenance Instructions

4.1 Assembly View and Parts List

4.2 Graphic Set Complete

4.3 Tool Maintenance

4.4 Trouble Shooting

4.5 Technical Specification

2

1.0 INTRODUCTION

C

1.1 General Information

This manual presents removal,

operation, and maintenance

information for PortaCo’s model

WS-10-64-3 Weld Shear. The tool is

designed to remove the excess

material when performing Thermit

and Buta type welds. It's light weight

compact size allows for use inside

rail pulling equipment. All hydraulic

plumbing is protected by a one piece

guard to prevent damage and to

contain any leaks if any damage

occurs. When properly used this tool

will help reduce back strain and also

reduce operator fatigue.

shearing blades to the full open

position when the valve control lever

is released. (See figure 1.2A arrow

A) This reduces total shearing time

and reduces the operator's exposure

to the heat produced during the

welding procedure.

B

A

Figure 1.2A

PortaCo, Inc. reserves the right to

make changes at anytime without

notice and without incurring any

obligation.

1.2 Features

The main features of the PortaCo

Weld Shear Model WS-00-64-3 are

as follows.

Standard unit:

Length 26.38 in/ 67.0 cm

Width 17.75 in/ 45.1 cm

Height 7.21 in/ 18.3 cm

Weight 84-lbs/ 38.1 kg

(includes blades)

Upper ambient operating

temperature 110°F (43° C), lower

ambient operating temperature -20°F

(-28° C).

PortaCo, Inc.'s weld shear features

an auto cycle valve which returns the

The control valve also limits the

speed for shearing and provides a

rapid retract for easy operation.

The hydraulic plumbing is protected

by a one-piece guard to prevent

damage and to contain any leaks if

any damage occures. (figure 1.2A

arrow B)

The hydraulic quick connect couplers

are located at the rear of the shear

and directs the hoses along the rail

out of the work area. (figure 1.2A

arrow C) The path of the hose's

along the rail reduces the potential

for a worker to trip on them.

Roller hold-downs, provide a secure

mount to the rail and allows smooth

operation during the shearing

process. The roller height is set with

a jam nut providing a snug fit on any

size rail. (figure 1.2B arrow A)

3

The roller assembly is easily

A

B

removed for replacement of any

component of the hold-down

assembly. (figure 1.2B arrow B)

Figure 1.2B

Handles incorporated into the frame

allow for even balance and level

transportation for quick positioning

on the rail. Figure 1.3

and before performing maintenance

or repairs. Supervising personnel

should develop additional

precautions relating to the specific

work area and local safety

regulations.

1.4 General Safety Precautions

The PortaCo Inc. tools are designed

to provide safe and dependable

service if operated according to the

instructions provided in this manual.

Read and understand this manual

and any stickers attached to the

power unit before operating. Failure

to do so could result in personal

injury or equipment damage.

Check the rules and regulations at

your location. The rules may include

an employer’s work safety program.

Regulations may identify hazards

such as working around utility supply

lines or hazardous slopes.

1.3 Safety Summary

Tool operators and maintenance

personnel must always comply with

the safety precautions given in this

manual and on the stickers and tags

attached to the tool and hoses.

These safety precautions are given

for your safety. Review them

carefully before operating the tool

Read and understand any manuals

for additional or optional equipment,

which maybe shipped with the tool.

1.5 Warning and Caution

Statements

Warning and Caution statements

have been strategically placed

throughout the text prior to operating

or maintenance procedures,

practices, or conditions considered

essential for the protection of

personnel, equipment, and property.

WARNING: HIGHLIGHTS A,

ESSENTIAL OPERATING, OR

MAINTENANCE PROCEDURE,

PRACTICE, CONDITION

STATEMENT, ETC… WHICH IF

NOT STRICTLY OBSERVED,

4

COULD RESULT IN INJURY TO,

OR DEATH OF, PERSONNEL OR

LONG TERM HEALTH HAZARDS.

CAUTION: HIGHLIGHTS AN

ESSENTIAL OPERATING OR

MAINTENANCE PROCEDURE,

PRACTICE, CONDITION

STATEMENT, ETC. WHICH IF NOT

STRICTLY OBSERVED, COULD

RESULT IN DAMAGE TO, OR

DESTRUCTION OF, EQUIPMENT

OR LOSS OF MISSION

EFFECTIVENESS.

1.6 Training Requirements

Operator training for the weld shear

should consist of information found

in this manual. In addition the