PortaCo SR-10-26-O, SR-10-26-1 Original Operation Manual

ORIGINAL OPERATION MANUAL

RAIL SAW

SR-10-26-O & SR-10-26-1

2

RAIL SAW SR-10-26-O & SR-10-26-1 ORIGINAL OPERATION MANUAL

Change overview

Auditing

Date

Comment, including chapter

changed by

01

11-26-2018

Creation

Jesse Bunn

3

RAIL SAW SR-10-26-O & SR-10-26-1 ORIGINAL OPERATION MANUAL

1 About this manual ................................................................................................................................................. 5

2 General ................................................................................................................................................................. 6

2.1 General information............................................................................................................................................................... 6

2.2 Designated use ....................................................................................................................................................................... 6

2.3 Unintended use ...................................................................................................................................................................... 7

2.4 Environment requirements .................................................................................................................................................... 7

2.4.1 Operating requirements ........................................................................................................................................... 7

2.4.2 Emissions .................................................................................................................................................................. 7

3 Safety .................................................................................................................................................................... 8

3.1 Basics ..................................................................................................................................................................................... 8

3.2 Important safety information ................................................................................................................................................ 9

3.3 Qualification of the operating and maintenance personnel ................................................................................................ 12

3.4 Emergency information / safety devices .............................................................................................................................. 13

3.5 Safety signs .......................................................................................................................................................................... 13

4 Design and function .............................................................................................................................................14

4.1 Design .................................................................................................................................................................................. 14

4.2 Accessories and kits descriptions ......................................................................................................................................... 15

4.3 Specification ......................................................................................................................................................................... 15

4.3.1 Hydraulic fluid ........................................................................................................................................................ 16

4.3.2 Supply, interfaces and connections ........................................................................................................................ 16

4.4 Function ............................................................................................................................................................................... 16

4.5 Boundaries and interfaces ................................................................................................................................................... 16

5 Transport, assembly and dismantling ...................................................................................................................17

6 Commissioning and operation ..............................................................................................................................17

6.1 General information for start-up ......................................................................................................................................... 17

6.1.1 Tool preparation ..................................................................................................................................................... 18

6.1.2 Testing .................................................................................................................................................................... 20

6.1.3 Specification of the hydraulic system ..................................................................................................................... 20

6.2 Tool connecting procedures ................................................................................................................................................ 22

6.3 Cut off blade installation ...................................................................................................................................................... 22

6.4 Rail clamp installation .......................................................................................................................................................... 23

6.5 Saw Mounting ...................................................................................................................................................................... 24

6.6 Connecting hoses ................................................................................................................................................................. 24

6.7 Operation ............................................................................................................................................................................. 25

6.8 Disconnecting Hoses ............................................................................................................................................................ 26

4

RAIL SAW SR-10-26-O & SR-10-26-1 ORIGINAL OPERATION MANUAL

6.9 Cold Weather Operation ...................................................................................................................................................... 26

7 Maintenance ........................................................................................................................................................27

7.1 Change of hydraulic fluid ..................................................................................................................................................... 27

8 Troubleshooting ...................................................................................................................................................28

8.1 General information for maintenance and repairs .............................................................................................................. 28

8.2 Troubleshooting and repairs ................................................................................................................................................ 28

9 Shutdown and re-commissioning .........................................................................................................................29

10 Storage .................................................................................................................................................................29

11 Dismantling and disposal .....................................................................................................................................29

Publisher: PortaCo Inc.

1805 2nd Ave N, Moorhead, MN 56560

Phone +1 (218) 336 0223, Fax +1 (218) 233 5281

info@portaco.com, www.portaco.com/

Date of publication: 12-01-2018

Documentation version: 1.0

Document / order number: 6559-OOP

5

RAIL SAW SR-10-26-O & SR-10-26-1 ORIGINAL OPERATION MANUAL

1 About this manual

This document is the original operation manual for the Rail Saw SR-10-26-O & SR-10-26-1-O of PortaCo Inc., 1805 2nd Ave N,

Moorhead, MN 56560.

The Rail Saws are designed to cut rail which is mounted to ties from a standing position.

The operation manual is intended to enable the operator to safely operate the system as intended and warn them of foreseeable

misuse. The manual is intended for the operating company´s specialized staff. In addition to the operation manual, the spare parts

catalogue and the maintenance manual of the manufacturers of the individual components are to be observed.

WARNING

Operating errors using the device, e.g. by instruction errors, may lead to personal injury or damage to the

device.

- The instruction for use must be accessible to operators and maintenance personnel at all times!

- A copy of the technical documentation including the instruction for use must be kept in a suitable and

accessible place.

The explanation of the hazard pictograms is contained in chapter safety.

This document is to be treated as confidential. No portion of the document may be disseminated to another party or reproduced

without written permission from PortaCo Inc. All rights reserved.

6

RAIL SAW SR-10-26-O & SR-10-26-1 ORIGINAL OPERATION MANUAL

2 General

This chapter contains basic information about the machine and is intended to provide an initial overview.

2.1 General information

The rail saw is designed to cut rail which is mounted to ties from a standing position. This tool will help eliminate the use of other

methods that increase the likely hood of injury. When properly used this tool will help reduce back strain and also reduce operator

fatigue.

The tool is hydraulically powered. The hydraulic energy is provided by a hydraulic unit. The hydraulic unit is not part of the scope of

delivery. We recommend the Hydraulic Power Units D-23, E-15, G-18, G-21, G-23 or G-31.

Further design information is shown and described in chapter 4.

Regarding ergonomics, the stresses and strains resulting from the device are typical for a device in the construction industry.

Figure 1. Identification plate (type plate)

2.2 Designated use

The Rail Saws are designed to cut rail which is mounted to ties from a standing position.

To use the tool as intended, all persons who use the device must adhere to the guidelines in this operation manual.

7

RAIL SAW SR-10-26-O & SR-10-26-1 ORIGINAL OPERATION MANUAL

2.3 Unintended use

- Do not allow others to be near the tool when starting it or while operating. Keep bystanders and animals out of the work area.

- Do not operate the tool near energized transmission lines.

- Do not overreach. Maintain proper footing and balance at all times.

- Connecting to power source which exceeds the required flow and pressure rating

- Always connect hydraulic hoses to the tool before activating the hydraulic circuit on your power unit. Check that hydraulic

couplers are secure before activating the circuit.

- Never operate a tool that is damaged, improperly adjusted, or not completely and securely assembled.

- Never carry or pick this tool up by the hydraulic hose.

- Be sure to keep hands and other parts clear and free from all moving parts.

- During startup of the tool, do not rest the tool on any surface.

- Make sure the tool’s wheel has stopped turning before setting down tool.

- At the work site, never carry the tool with the wheel rotating.

- Always use sockets that meet the minimum requirements of the tool.

- Atmosphere temperature below -10°C/14°F or above 40°C/104F

- Hydraulic oil temperature below 10°C/50°F or above 80°C/180°F

2.4 Environment requirements

2.4.1 Operating requirements

The machine is designed for use on construction sites outdoors. It can be used at temperatures between

-10 °C to 40 °C (14°F to 104°F). The temperature of the hydraulic fluid should be at least 10 °C (50°F).

When working in tunnels, the country-specific safety regulations must be observed.

2.4.2 Emissions

In technically perfect condition, the A-weighted emission sound level at the work place is lower than 70 dB(A). Hearing protectors is

not required.

Other emissions do not occur during regular device operation.

In the event of damage, hydraulic fluid may leak. Should this be the case, eliminate the leak and remove any fluid which has leaked

with the intended binders.

8

RAIL SAW SR-10-26-O & SR-10-26-1 ORIGINAL OPERATION MANUAL

3 Safety

3.1 Basics

The machine corresponds to the generally recognized standards of technology and practice. Nevertheless, knowledge of the

residual risks as well as general knowledge of the device is required to ensure safe and accident-free work.

The safety information is understood to be in addition to the existing accident prevention regulations and laws. The information is

intended to warn operating personnel about foreseeable misuse. Existing safety prevention measures and laws must be followed at

all costs!

The operation manual must be read and understood by all persons who work on the device. Introduction to the device is to be

documented in writing.

CAUTION

Hazards from the operational environment of the device can lead to injuries of persons.

- No alterations to the device may be made which lead to a change in function.

- All hazards from the environment or from unforeseeable operating conditions of the device cannot be

captured and depicted within this manual.

Modifications to the machine must be made by the distributing company. In this case this manual will also be

adapted.

The chapter on safety regulations serves to:

- explain the depiction of the safety regulations and symbols

- inform users about dangers, residual risks and measures for reducing risks

- specify the minimum requirements of the operating personnel

9

RAIL SAW SR-10-26-O & SR-10-26-1 ORIGINAL OPERATION MANUAL

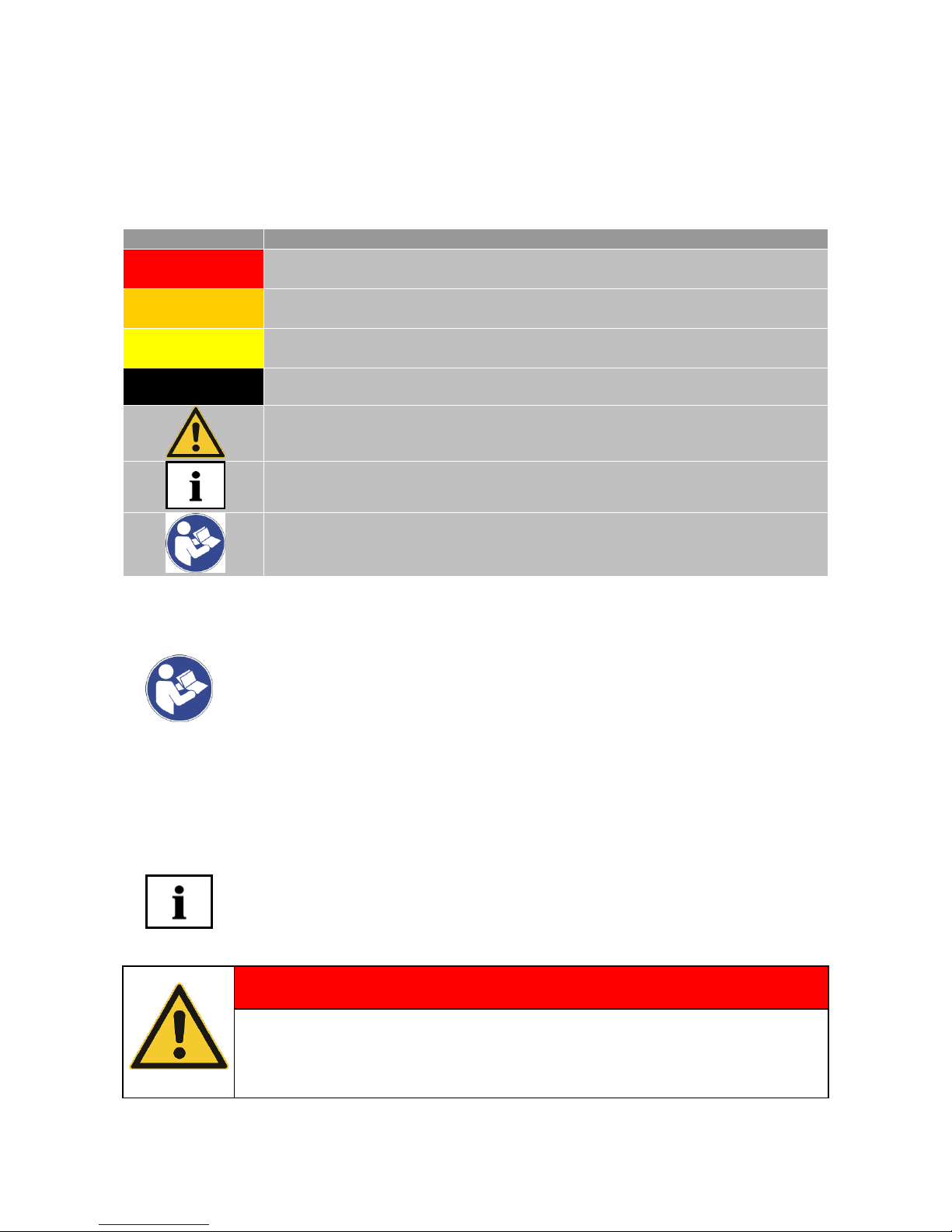

Symbol

Meaning

DANGER

DANGER indicates a hazard with a high degree of risk, which when it is not avoided results in death or

serious injury.

WARNING

WARNING indicates a hazard with a medium degree of risk, which when it is not avoided may result in

death or serious injury.

CAUTION

CAUTION indicates a hazard with a low degree of risk, which when it is not avoided may result in minor

or moderate injury.

NOTICE

NOTE, non-compliance may result in environmental or material damage

Attention risk of injury!

General note for helpful tips and additions.

Read the safety information before using the machine. Non-compliance may result in injuries and

damage to property.

Table 1: Signal words and Symbols

3.2 Important safety information

Read this chapter and observe the safety information before using.

The safety regulations are to be observed by all persons who work on the device. The regulations and instructions for accident

prevention valid at the place of operation are to be observed. Instruction of the operating and maintenance personnel in system

safety is to be documented.

Please pay particular attention to this chapter to avoid accidents!

PortaCo Inc. is not liable for injury to persons or property which results from misuse of the machine.

DANGER

There is a danger of crushing in the area where the tool is working.

- Do not reach or step into the working area of the device when tool is working.

Use personal safety equipment.

Loading...

Loading...