Hydraulic Power Unit

Pioneer Series

G-09, G-11, G-13

1805 2ndAVENUE NORTH * MOORHEAD, MN, USA 56560-2310

E-MAIL ADDRESS; info@portaco.com * INTERNET ADDRESS: www.portaco.com

OPERATION,

MAINTENANCE,

AND REPAIR MANUAL

PHONE (218) 236-0223 * FAX (218) 233-5281

2

TABLE OF CONTENTS

1.0 Introduction

1.1 General Information

1.2 Features

1.3 Options

1.4 Safety Summary

1.5 General Safety Precautions

1.6 Warning and Caution Statements

1.7 Training Requirements

2.0 Installation Instructions

2.1 Unpacking Instructions

2.2 Engine Preparation

2.3 Hydraulic Power Unit Preparation

2.4 Testing

2.5 Adjustments

2.6 Hose Requirements

2.7 Tool Connecting Procedures

2.8 Work Area Safety Precautions

3.0 Operating Instructions

3.1 Description of Power Unit

3.2 Controls and Graphics

3.3 Before Start Up

3.4 Positioning the Power Unit

3.5 Startup

3.6 Shutdown

3.7 Cold Weather Operation

3.8 Storage Preparation

4.0 Maintenance Instructions

4.1 Routine Servicing and Inspection

Schedule

4.2 Assembly View and Parts List

4.3 Hydraulic Fluids and engine

maintenance

4.4 Trouble Shooting

4.5 Technical Specifications

3

1.0 INTRODUCTION

1.1 General Information

CAUTION: DO NOT USE CLOSEDCENTER TOOLS WITH THIS

POWER UNIT

This manual presents installation,

operation, and maintenance information

for the Pioneer G-09, G-11, G-13 series

PortaCo Hydraulic Power Units. Model

G-09S06-52-W, G-11S07-52-W,

G-13S08-52-W.

PortaCo, Inc. reserves the right to make

changes at anytime without notice and

without incurring any obligation.

The Pioneer Power Unit is designed to

provide hydraulic flow and pressure for

operation of H.T.M.A. type I, II,

hydraulic tools.

The G-09506-52-W provides 5.9 gpm

(22.4 Liters) at 1800 psi (125 BAR) to

operate type I hydraulic tools. The

G-11507-52-W provides 7gpm

(26 Liters) at 2000 psi (148 BAR) to

operate type I hydraulic tools. The

G-13508-52-W provides 8 gpm (30.3

Liters) at 2000 psi (148 BAR) to operate

type II hydraulic tools.

For the G-11, and G-13 PortaCo power

units produce a maximum pressure of

148 BAR (2150 PSI). The G-09 power

unit produces a maximum pressure of

135 BAR (1950 PSI).

1.2 Features

The main features of the PortaCo

Pioneer G-09, G-11, and G-13 pioneer

series are as follows:

Standard unit is a wheeled style frame:

Length 67.3 cm (26.5 in.)

Width 50.8 cm (20 in.)

Height 69.8 cm (27.5 in.)

Weight 64.9 kg (143 lbs.)

Upper ambient operating

Temperature 43 C (110° F)

Lower ambient operating

Temperature -28°C (-20 F)

The Pioneer series comes with either a

Briggs & Stratton or a Honda Engine.

See the engine manual supplied with the

power unit for recommended fuel and

fuel restrictions.

The standard wheeled Pioneer series

power unit is equipped with collapsible

handle, which locks in place with a

latch, (see fig. 1.2A) and a lifting point

for a crane hook. (Fig. 1.2B)

The power units are all equipped with

air-to-oil coolers with suction fan

mounted to the power shaft on the

engine.

The fuel and hydraulic systems are selfcontained with the required reservoir,

filtration and level indicators.

(Fig. 1.2A)

4

LIFT HERE

1.3 Options

manual. Read and understand this

manual and any stickers attached to the

power unit before operating. Failure to

do so could result in personal injury or

equipment damage.

Check the rules and regulations at your

location. The rules may include

employer’s work safety program.

Regulations may identify hazards such

as working around utility supply lines or

hazardous slopes.

Read and understand any manuals for

additional or optional equipment, which

maybe shipped with the Pioneer power

unit.

Consult PortaCo. For special options that

may be available

1.4 Safety Summary

Tool operators and maintenance

personnel must always comply with the

safety precautions given in this manual

and on the stickers and tags attached to

the tool and hoses.

These safety precautions are given for

your safety. Review them carefully

before operating the power unit and

before performing maintenance or

repairs.

Supervising personnel should develop

additional precautions relating to the

specific work area and local safety

regulations.

1.5 General Safety Precautions

The PortaCo Inc. Pioneer G-09, G-11,

and G-13 Series Hydraulic Power Units

are designed to provide safe and

dependable service ifoperated according

to the instructions provided in this

1.6 Warning and Caution Precautions

Warning and Caution statements have

been strategically placed throughout the

text, prior to operating or maintenance

procedures, practices, or conditions,

considered essential to protection of

personnel or equipment and property.

WARNING: HIGHLIGHTS AN

ESSENTIAL OPERATING OR

MAINTENANCE PROCEDURE,

PRACTICE, CONDITION

STATEMENT, ETC. WHICH IF

NOT STRICTLY OBSERVED,

COULD RESULT IN INJURY TO,

OR DEATH OF, PERSONNEL OR

LONG TERM HEALTH HAZARDS.

CAUTION: HIGHLIGHTS AN

ESSENTIAL OPERATING OR

MAINTENANCE PROCEDURE,

PRACTICE, CONDITION

STATEMENT, ETC. WHICH IF

NOT STRICTLY OBSERVED,

COULD RESULT IN DAMAGE TO,

OR DESTRUCTION OF,

5

EQUIPMENT OR LOSS OF

MISSION EFFECTIVENESS.

See engine manual for recommended oil

and checking procedures.

1.7 Training Requirements

Operator training should consist of

information found in this manual for the

hydraulic power unit. In addition the

operator must receive instructions both

through demonstrations and verbally

with the tools or applications in which

the power unit is going to be used. The

new operator must start in an area

without bystanders and use all controls

until able to fully operate the power unit

under the conditions for the work area.

2.0 INSTALLATION

INSTRUCTIONS

2.1 Unpacking Instructions

Upon receiving your Pioneer hydraulic

power unit, promptly remove it from the

shipping container. Always keep top

side of container up. Inspect unit for

damage which may have incurred during

shipping and report it to carrier for

claim.

NOTE: clean up oil and fuel spills

immediately. Do not over fill fluids.

2.3 Hydraulic Power Unit Preparation

CAUTION: DO NOT OPERATE

POWER UNIT WITH BELOW

RECOMMENDED HYDRAULIC

OIL LEVEL. PUMP DAMAMAGE

MAY ACURE.

Check hydraulic fluid level by looking at

sight pipe located on top of the oil

reservoir. Proper oil level is indicated

when the center section of the sight pipe

is dark. To add hydraulic fluid remove

filter cap on top of reservoir, replace

when finished. Reservoir capacity is

18.9 LTR (5.0 gal) do not overfill fluids,

clean up oil spills immediately. Only

hydraulic fluids meeting the

specifications located below are

recommended for use with PortaCo

hydraulic power units.

(Fig. 2.3A)

2.2 Engine Preparation

CAUTION: READ AND

UNDERSTAND ENGINE MANUAL

WHICH IS PROVIDED IN

ADDITION TO THE PORTACO

MANUAL BEFORE STARTING

THE POWER UNIT.

CAUTION: ALWAYS CHECK

ENGINE OIL BEFORE STARTING

POWER UNIT.

Make sure engine oil is at the “FULL”

mark on the dipstick.

Viscosity (Fluid Thickness)

METRIC U.S.A.

10 C 95 Centistokes 50 F 450 SSU Max

38 C 27-42 C.S. 100 F 130-200 SSU

60 C 16.5 C.S, Min. 140 F 85 SSU Min.

Pour Point -10 F/23 C Minimum (for cold startup)

Viscosity Index(ASTM D 2220) 140 Minimum

Demulsibility(ASTM D-1401) 30 Minutes Maximum

Flash Point (ASTM D-92) 340 F/171 C Minimum

Rust Inhibition (ASTM D-665 A & B) Pass

Oxidation (ASTM D943) 1000 Hours Minimum

Pump Wear Test (ASTM D2882) 60 mg Maximum

6

The following fluids work well over a

Type

Hydraulic fluid

Chevron

“Clarity” AW 15032

Exxon

“Univis” J 32

Mobil

D.T.E. 13

M

Gulf

“Harmony” AW

-

HVI-150-32

Shell

“Tellus T” 32

Texaco

“Rando” HDZ 32

Union

“Unax” AW

-WR-32Amsoil

AWH 15032

Sunvis

Low Pour H/032

-

product code 19300

wide temperature range at startup, allow

moisture to settle out, and resist

biological growth likely in cool

operating hydraulic circuits. These

fluids are recommended by PortaCo, Inc.

Other fluids that meet or exceed the

specifications of these fluids may also be

used.

Fill the fuel reservoir to a level just

below the bottom of the filter tube.

Always use clean gasoline as

recommended in the engine manual. Do

not overfill fluids, clean up oil and fuel

spills immediately.

2.4 Testing

All power units are tested at the factory

and their flows and pressures are

recorded on the test report, which is

shipped with the power unit. Testing of

the power unit is not required unless it is

damaged during shipping.

of the hoses. Make sure flow

direction is correct.

c. Start the engine and allow the

hydraulic fluid to warm to about

100° F/38 C°.

d. Open the tester restrictor valve (fully

open.) This represents minimum

load.

e. Set the flow control to “ON” and set

engine throttle for maximum speed.

f. Check the flow rate and pressure on

the tester gauges. The back pressure

reading should be under 17.3 bar

(250 PSI). The flow readings should

match those listed in section 1.1

General Information of this manual.

g. With engine throttle set at maximum

speed slowly close the restrictor

valve on the tester while observing

the flow pressure gauges.

h. As the hydraulic system relief valve

begins to crack (open) and bypass

fluid through the valve, the flow rate

will begin to drop. At this time, the

pressure in the system should be

between 145-155 BAR (2100-2250

PSI).

i. If the pressure is not as specified, the

hydraulic circuit relief valve must be

adjusted or replaced. (See section

4.2 for procedure.)

- If the flow rate drops below the

specified range, the pump or

control valve may be worn.

Always perform “before startup

procedures” found in section 3.3 before

testing. PortaCo Hydraulic Tester, Part

Number T-00016-XX-0 is recommended

for all tests.

a. Set the hydraulic circuit to “OFF.”

b. Connect hydraulic hoses to the

power unit. Connect the PortaCo

Hydraulic Tester to the opposite end

- If the flow remains constant, but

pressure does not increase, the

relief valve may be defective.

2.5 Adjustments

The engine RPM’s and the hydraulic

system flow and pressure relief are set at

the factory and must not be readjusted.

7

DO NOT change governor setting or

tamper with governor components,

which may increase the governed engine

speed.

WARNING: OPERATING THE

POWER UNIT AT EXCESSIVE

SPEEDS INCREASE THE DANGER

OF PERSONAL INJURY.

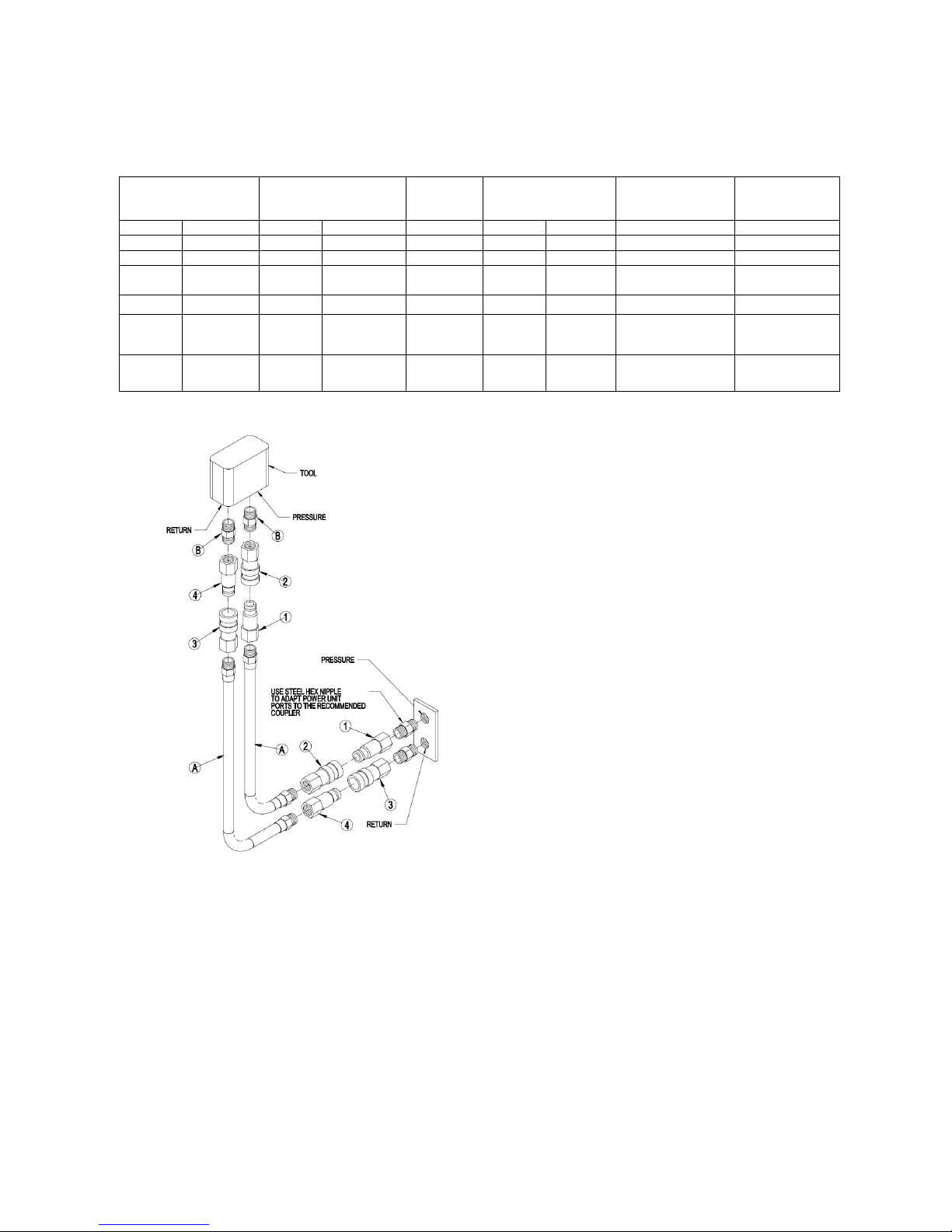

Two hoses are required to complete the

circuit, each hose should have a male

coupler on one end and a female coupler

on the opposite. See diagram on page 8

for hose routing.

*Important – Oil should always flow

from the male coupler through the

female coupler.

2.6 Hose Requirements

The Pioneer series are easily moved

close to the job site. It is not often

necessary or advisable to use long hoses.

All hoses must have an oil resistant inner

surface and an abrasion resistant outer

surface. Each hose must have male pipe

ends for most application. Longer hoses

can be used when necessary, but can

affect the operation of the tool due to

resistance in the hose.

If small diameter or long hoses are used,

or if restrictive fittings are connected to

the supply and return ports, the pressure

required, to push the fluid through the

system and back to the tank will be

higher. This will reduce tool power.

The pressure and return hose are

connected to the control block. A

½-inch male pipe hose end can be

connected, to H.T.M.A. flat-nosed

quick-disconnect couplings (available

through PortaCo, Inc).

The right port is the return port. A

female H.T.M.A. quick-disconnect

coupling should be connected to this

port.

NOTE: The pressure increase in

uncoupled hoses left in the sun may

make them difficult to connect. When

possible after use, connect the free ends

of the operating hoses together.

HOSE TYPES

Hydraulic hose types authorized for use

by PortaCo, Inc. are as follows:

1. Labeled and certified non-conductive

2. Wire braided (conductive)

3. Fabric braided (not certified or labeled non-

conductive)

Hose 1: Listed above is the only hose authorized

for use near electrical conductors.

Hoses 2 and 3: Listed above are conductive and

must never be used near electrical conductors.

HOSE PRESSURE RATING

The left port of the control block is the

pressure (oil out) fitting. A male

H.T.M.A. quick-disconnect coupling

(without lock ring) must be connected to

this port.

The rated working pressure of the

hydraulic hose must be at least 175 bar

(2500 PSI.)

8

HYDRAULIC HOSE RECOMMENDATIONS

Table 2.6A

FLOW PER CIRCUIT LENGTH EACH HOSE USE INSIDE DIAMETER SAE SPEC HOSE

GPM LPM FEET METERS INCH MM

5 to 8 19 to 30 To 50 To 15 Both 1/2 13 SAE 100R1-8 100R7-8

5 to 8 19 to 30 51-100 15 to 30 Both 5/8 16 SAE 100R2-10 SAE 100R8-10

5 to 8 19 to 30 100-300 30 to 90 Pressure

Return

9 to 12 34 to 45 To 50 To 15 Both 5/8 16 SAE 100R2-10 SAE 100R8-10

9 to 12 34 to 45 51-100 15 to 30 Pressure

Return

9 to 12 34 to 45 100-200 30 to 60 Pressure

Return

5/8

3/4

5/8

3/4

3/4

1

16

19

16

19

19

25.4

(WIRE BRAID)

SAE 100R2-10

SAE 100R1-12

SAE 100R2-10

SAE 100R3-12

SAE 100R2-12

SAE 100R1-16

SAE SPEC

HOSE (FIBER

BRAID)

SAE 100R8-10

SAE 100R7-12

SAE 100R8-10

SAE 100R7-12

SAE 100R8-12

SAE 100R7-16

FOR SINGLE CIRCUIT FLOWS UP TO

10 GPM plumb hose and tool as illustrated

in fig. 1. Numbers are represented below as

paragraph numbers.

1. H.T.M.A. 3/8-inch Male Quick Acting

Coupler with ½-inch NPT thread.

2. H.T.M.A. 3/8-inch Female Quick

Acting Coupler with ½-inch NPT

thread.

At the tool this may be H.T.M.A.

3/8-inch Female Quick Acting

Coupler with 3/8-inch NPT

thread.

3. H.T.M.A. 3/8-INCH Female

Quick Acting Coupler with ½-inch

NPT thread.

4. H.T.M.A. 3/8-inch Male Quick

Acting Coupler with ½-inch NPT

thread.

At the tool this may be 3/8-inch

Male Quick Acting Coupler with

3/8-inch NPT thread.

A. Refer to Table 2.6A for hose

recommendations

B. Use adapters with threads that

match tool port.

9

2.7 Tool Connecting Procedures.

Inspect hose for cuts, crushing, leaks, or

abrasion which maybe a safety hazard or

reduce fluid flows.

WARNING: DO NOT

ATTEMPT TO LOCATE

HYDRAULIC LEAKS BY FEELING

AROUND HOSES AND FITTING

WITH HANDS. “PIN-HOLE” LEAKS

CAN PENETRATE THE SKIN.

Stop the engine before connecting the

tool and, or hoses to the off power unit,

and when switching hoses or tools. Turn

the hydraulic on/off valve to the off

position before starting the engine.

Make sure all hoses are connected for

correct flow direction to and from the

tool being used. When routing hose in

the work area, position them where

personnel will not be at risk of tripping

over them or where vehicles can run

over the hoses. Do not lay hose over

sharp projects.

WARNING: PRESSURIZED FLUID

ESCAPING FROM A DAMAGED

HOSE CAN PENETRATE THE

SKIN AND BE INJECTED IN THE

BODY CAUSING INJURY OR

DEATH.

CAUTION: DO NOT PULL ON HOSES

TO DRAG POWER UNIT.

2.8 Work Area Safety Precautions

engine exhaust can be fatal.

- Keep clear of hot exhaust.

- Do not use PortaCo hydraulic

power units in potentially explosive

atmospheres such as near

wastewater drains or landfill sites.

- Do not operate if flammable gases

or vapors are present.

- Keep the power unit at least 1meter

(3.3 ft) away from buildings, obstructions,

and flammable objects. Do not aim engine

exhaust at materials that could catch fire.

- Allow the engine to cool before

storing the power unit in an

enclosed space.

- PortaCo hydraulic power units must

not be located below overhead

gantries, power lines, or walkways

where there might be a risk of

falling objects.

- Provide ambient light intensity of

200 Lux for working indoors or

outdoors particularly if working at

night.

- Always wear appropriate safety

equipment such as goggles, ear

protection, and foot protections.

- Operate only tools which fit into

the specifications prescribed in

section 1.1 of this manual.

- Never operate the power unit in a

closed space. Inhalation of

- Do not stand on power unit.

10

3.0 OPERATING INSTRUCTIONS

3.1 Description of Power Unit

The PortaCo Pioneer series

Hydraulic Power Unit has been designed

for the purpose of supplying hydraulic

fluid under pressure to power hydraulic

hand tools. The standard engine is a

Honda 9 hp, 11 hp, or 13 hp. depending

on the model of power unit purchased.

See section 1.2 features of this manual

for specifications. See the technical

manuals supplied by the engine

manufacture included with this power

unit for detailed technical specifications.

PortaCo Hydraulic Power Units have

been designed for use indoors and

outdoors. PortaCo power units should

not be operated under wet conditions, or

at ambient operating temperatures,

outside the recommended temperature

range of -28° C to 43° C. (-20° F to

110° F).

CAUTION: DO NOT USE CLOSEDCENTER TOOLS WITH THIS

POWER UNIT.

During operation, the engine may bog,

run at lower rpm, when under load. As

the tool being used is loaded, meets with

increase resistance, the pressure required

to operate the tool increases. The

increased pressure adds load to the pump

which loads the engine, there by

reducing the RPMS. As a result, the

flow will drop as pressure increases.

The hydraulic system has a pressure

limiter set at 148 BAR (2150 PSI) which

diverts the flow back to the tank until the

pressure drops below 148 BAR (2150

PSI.)

Tools with higher flow and, or pressure

requirements will not operate at their full

potential if used with the PortaCo

Hydraulic Power Unit. Tools with lower

flow and or pressure requirements may

be damaged if used with this power unit.

The engine throttle and the hydraulic

system relief value are preset at the

factory and must not be altered for any

reason without consulting PortaCo Inc.

Any alterations approved by PortaCo

Inc., can only be preformed by personnel

qualified to maintain hydraulic systems.

Tools which are commonly used with

PortaCo’s Pioneer series Hydraulic

power unit are as follows:

Impact Wrenches

Impact Drills

Picks

Handheld grinders

Breakers

Tampers

Hand Held Saws

Hand Held Pruners

Do not use the Pioneer series power unit

with close-center tools, tools which do

not allow the oil to return to the power

unit when not activated. Do not use in

jacking operations. Do not use to

activate cylinders without an inline

open-center control system. Do not

operate without a return oil hose.

If there are any doubts weather your tool

can be used with the Pioneer series unit

please contact the service department at

PortaCo Inc. (218-236-0223) for advice.

PortaCo Inc. accepts NO responsibility

for machines that are used for any

purpose other than the intended purpose

as specified in the operating instructions

or approved directly by PortaCo Inc.

11

3.2 Controls and Graphics

WARNING: FAILURE TO

FOLLOW THE PROCEDURES

LISTED IN THE ENGINE’S

OWNER’S MANUAL COULD

RESULT IN PERSONAL INJURY

OR EQUIPMENT DAMAGE.

Refer to the engine owner’s manual for

explanation of controls and symbols

located on the engine.

The following decals are placed on the

power unit to aid in its operation and

maintenance. The operator should locate

and understand them before using this

power unit.

(Fig. 3.2B)

A caution fan decal advises operators of

an area, which contains a potential

hazard if guards are not properly in

position. (Fig. 3.2A)

(Fig. 3.2A)

The hydraulic oil reservoir is marked

with a hydraulic oil decal (Fig. 3.2B)

and there is a hydraulic oil drain decal

indicating the tank’s drain plug (Fig.

3.2C)

(Fig 3.2C)

The hydraulic work ports are labeled

respectively as to their function with a

decal (Fig. 3.2D). The left port is

pressure and is equipped with a male

quick coupler. The right port is return

and is equipped with a female quick

coupler.

(Fig. 3.2D)

The hydraulic circuit on the pioneer

series power unit is controlled with a

rotary on-off knob. The rotation

12

directions for the on and off positions

are indicated by the decal on the knob

(Fig. 3.2E).

(Fig. 3.2 E)

A PortaCo serial number decal is

attached to the power unit on the back

side of the fuel tank. The serial number

tag displays PortaCo’s address and

phone number in addition to the units

model number, serial number, and other

technical specifications (Fig 3.2F).

(Fig. 3.2 G)

The caution do not touch hot surface

decal is located on the top of the hood

next to the engine (Fig 3.2 H).

(Fig. 3.2F)

The hydraulic fluid reservoir decal (Fig

3.2 G) is located on the hydraulic tank

next to the filter. The hydraulic fluid

reservoir decal tells when fluid should be

added by looking in the sight tube when

the engine is at idle.

(FIG. 3.2 H)

3.3 Before Start Up

Check engine oil level, and engine air

filter. Refer to the engine manual for

proper procedures when checking, filing,

cleaning, or replace any engine

components and fluids.

Check the hydraulic oil reservoir level.

Add oils as required to raise level to full

mark. Use only hydraulic fluids

recommended in section 2.3 of this

manual. Drain reservoir and change the

filter every 300 hrs. or yearly which ever

is more frequent. Hydraulic reservoir

holds 18.9 liters (5 gallons) and is

13

drained by removing a plug under the

tank. See section 4.3 for procedures.

Check that the fuel level is at an

adequate level before starting engine.

Before using the Pioneer power unit,

inspect the oil cooler grill for blocking

or contamination. The power units must

be free of leaves, dirt, oil, and other

contaminants, which may inhibit cooling

or create a fire hazard. Use compressed

air or a pressure washer to keep unit

clean.

Check that the battery terminals are

clean and free from any objects, which

could cause the battery to short out

which, could lead to fire or explosion.

Replace worn or damaged straps.

The Pioneer power unit can be pushed

around the work sight and be positioned

close to the work being done. To lock

the handle in position lift handle until

latches automatically catch on stops at

each end of handle. (Fig. 1.2A) To lower

the handle lift up on both latches at the

same time and let the handle drop down.

The Pioneer unit can also be position by

using a crane. The power unit has a

lifting point so it can be loaded easily or

positioned at the work sight with a crane.

(Fig 1.2B)

Place the PortaCo hydraulic Power Unit

on a level surface with no greater than a

20 degree slope to prevent fuel spillage

and power unit movement.

Check that fasteners and fittings are

tight, and tighten any fittings, which may

develop a leak or fasteners that may

become loose immediately. Hydraulic

hoses and couples should be inspected

for wear, cracking, or fatigue prior to

starting the engine.

WARNING: NEVER INSPECT

PRESSUREIZED HOSES,

COUPLERS, OR FITTINGS WITH

HANDS OR AT CLOSE

DISTANCES. PRESSURIZE FLUID

CAN PUNCTURE THE SKIN AND

INJECT OIL INTO THE BODY

RESULTING IN DEATH.

Do not use hoses, couples, or fittings

which are damaged, replace

immediately.

See section 2.8 of this manual for

additional safety procedures.

3.4 Positioning the Power Unit

WARNING: PLACING THE

PORTACO HYDRAULIC POWER

UNIT ON EXCESSIVE SLOPES OR

UNSTABLE GROUND COULD

CAUSE THE UNIT TO ROLL OR

TIP DAMAGING THE POWER

UNIT OR ENDANGERING

WORKERS.

Locate hydraulic power unit in well lit

area with a minimum ambient light

intensity of 200 lux weather indoors or

outdoors, particularly at night. Keep the

power unit at least 1 meter (3.3ft) away

from buildings, obstructions, and

flammable objects. Do not aim engine

exhaust at materials that could catch fire.

3.5 Start Up

(A)Observe all safety precautions found

through out this manual and the

included engine manual.

(B) Connect the hoses to the tool and

then to the power unit.

14

NOTE: Clean ends of couplers before

connecting to prevent system

contamination.

(C) For Pioneer series power units turn

the control value fully

counterclockwise (OFF). (See Fig.

3.5A)

(Fig. 3.5A)

(D)To start engine slide throttle knob

left slightly (Fig 3.5 B), then turn the

ignition key to start the engine (Fig

3.5 C). Allow the engine to run at

low speed until the engine and

hydraulic circuits are warm. Use

short starting cycles (15 secs. per

min.) to prolong starter life.

Extended cranking can damage

starter motor.

(Fig. 3.5 B)

(Fig. 3.5 C)

(E) Rotate the hydraulic control valve to

the “ON” position or on some

models select the flow required.

*Important – Make sure the control

value is in the OFF position before

connecting or disconnecting hoses to

the tool.

Tools used with the Pioneer power

unit must be designed for operation

with open-center systems.

3.6 Shutdown

A. NORMAL SHUTDOWN

1) Observe all safety precautions

2) Rotate hydraulic control valves to

the “OFF” position.

3) Slide the throttle lever to the idle

position.

4) Allow engine to idle for 2 to 3

minutes; then turn ignition “OFF”,

rotate counter clockwise.

5) Disconnect the hoses from the

power unit pressure hose first.

Then disconnect hoses from the

tool. When possible after use,

connect the free ends of the

operating hoses together. The

15

pressure increase in uncoupled

hoses left in the sun may make

them difficult to connect.

6) Allow the hydraulic power unit to

cool down before enclosing in a

small area for transportation or

storage.

B. EMERGENCY SHUTDOWN

In the event of an emergency,

immediately set the ignition switch to

“OFF”.

3.7. Cold Weather Operation

Hydraulic fluids are thicker in cold

weather; therefore, run the engine at low

idle long enough to bring the fluid

temperature up to minimum of 10°C/50°

F or until the hydraulic tank feels warm.

In cold weather, a cover over the cooler

will allow faster warm-up.

To prepare the engine for transportation

or storage refer to the engine owner's

manual. Remove the ground cable from

the battery.

To prepare the hydraulic system for

storage fill the hydraulic oil reservoir to

the full mark, and check that the fill cap

and filter are tight. When removing

from storage during a 3 month or longer

period, drain the water from the

hydraulic oil reservoir, if any

condensation has occurred, and replace

the hydraulic oil filter. (See section 4)

This will remove any water which may

have condensed in the hydraulic oil

reservoir during storage.

Store the PortaCo Pioneer hydraulic

power unit on a smooth level surface.

The power unit should be stored in a

cool, dry environment which is not

subjected to rapid temperature changes.

3.8 Storage Preparation

16

4.0 MAINTENANCE INSTRUCTIONS

Item

Action

Each use

First

Every 3

Every 6

Every year

Engine

Oil

Check

O

Change

OOAir Cleaner

Check

O

Change

O (1)

O *(1)

Replace

O**

Spark Plug

Check

O

Replace

O

Sediment

Clean

O

Spark

Clean

O

Idle speed

Adjust

O(2)

Fuel tank

Check

O (2)

Fuel

tube

Check

Every 2 years (

2)Valve

Check

O (2)

Combustion

Clean

After every

50

0 hours (

2

)

4.1 Routine Servicing and Inspections Schedule

Maintenance Schedule (Preformed at every indicated month or operating interval,

whichever comes first.)

cup

arrester

and filter

clearance

chamber

NOTE:

or 5 hrs.

month or

20 hrs.

months or

50 hrs.

months or

100 hrs.

or 300 hrs.

(1): Service more frequently when used in dusty areas

(2): These items should be serviced by your Honda servicing dealer, unless you

have the proper tools and are mechanically proficient. Refer to the Honda

shop manual for service procedures.

(3): For commercial use, log hours of operation to determine proper maintenance

intervals.

* Internal vent carburetor with dual element type only.

Cyclone type every 6 months or 150 hours

**Replace paper element type only

Cyclone type every 2 years or 600 hours

Lube Data

Engine Lube:

Capacity: 1 ¾ qts with filter Type: SAE 30……40 F & above

1 ½ qts without filter 5W-30……0 -40 F

SYNTHETIC

5W-20/5W-30……40 F & Below

17

Hydraulic System:

Capacity: 17 qts reservoir Type: viscosity grade 32

20 qts total system with filter

Service Replacements Parts

Description Part Number Source

Filter Hydraulic Oil

10 micron twist on

1083-OOP PortaCo Inc.

SPE-15-10 LHA

18

CAUTION: USE ONLY GENUINE PORTACO INC PARTS OR EQUIVALENT.

THE USE OF REPLACEMENT PARTS WHICH ARE NOT OF EQUIVALENT

QUALITY MAY DAMAGE THE HYDRAULIC POWER UNIT.

WARNING: UNAUTHORIZED MODIFICATIONS TO THE POWER UNIT

MAY IMPAIR THE FUNCTION AND/OR SAFETY AND IMPAIR MACHINE

LIFE. USE ONLY APPROVED SERVICE PARTS OR ACCESSORIES.

4.2 Assembly View and Parts List

G-09/G11/G13 SERIES

ITEM P/N DESCRIPTION QTY

1 1013-OOP FILTER 1

2 1041-OOP NUT JAM 17

3 1042-OOP BOLT 3/8 8

4 1044-OOP BOLT ¼ 21

5 1048-OOP PLUG MAGNET 1

6 1061-OOP NUT 3/8 6

7 1062-OOP NUT ¼ 11

8 1063-OOP WASHER LOCK 3/8 6

9 1064-OOP WASHER LOCK 1/4 31

10 1068-OOP FITTING 2

12 1080-OOP PIN COTTER 1/8 2

13 1085-OOP CLAMP 2

14 1093-OOP WASHER FLAT 3/8 6

15 1132-OOP FITTING 2

16 1146-OOP VALVE RELIEF 1

17 1285-OOP GAUGE HOUR METER 1

18 2057-OOP BOLT 1/4 2

19 1416-OOP CLAMP HOSE 4

20 1423-OOP STRAP 1

21 1444-OOP FITTING 3

22 1457-OOP TIE 8” 8

23 1505-OOP FITTING 1

24 1631-OOP NUT 3/8 4

25 1768-OOD GAUGE SIGHT 1

26 1871-OOP BOLT 3/8 2

27 1895-OOD LATCH HANDLE 2

28 1926-OOP CLAMP HOSE 2

29 1930-OOP CABLE POS. RED 1

30 1931-OOP CABLE NEG. BLACK 1

31 1940-OOP VALVE 1

32 1960-OOD SPACER HANDLE 2

33 2531-OOP FITTING 1

37 2187-OOP CAP 1

38 2368-OOD AXLE 1

39 2443-OOP WHEEL 2

40 2466-OOD CONTAINER 1

41 4366-OOP HOSE PRESSURE 1

42 2476-OOP FITTING 1

43 2490-OOP FITTING 1

44 2498-OOP TRIM 1

45 2651-OOP BUMPER HOOD 1

19

46 2701-OOP COUPLER HYD 1

47 2702-OOP COUPLER HYD 1

48 2780-OOP HANDLE 1

49 2781-OOD GRAPHIC SET 1

50 2782-OOD COUPLER PUMP DRIVE 1

51 2783-OOP HOSE SUCTION 1

52 2784-OOW TANK HYDRAULIC 1

53 2785-OOD SPACER AXLE 2

54 2786-OOW GRILL 1

55 2787-OOP GUARD FAN 1

56 2788-OOP COOLER HYDRAULIC 1

57 2789-OOP PUMP 9HP & 11 HP HONDA 1

2414-OOP PUMP 13 HP HONDA

58 2790-OOP HOSE HYDRAULIC RETURN 2

59 2791-OOP FAN 1

60 2792-OOD MANIFOLD HYDRAULIC 1

61 2793-OOP ENGINE HONDA 9 HP 1

2886-OOP ENGINE HONDA 11 HP

2890-OOP ENGINE HONDA 13 HP

62 2794-OOW HOOD 1

64 2796-OOP FITTING BUSHING 1

65 1929-OOP BATTERY 1

66 1083-OOP ELEMENT HYDRAULIC FILTER 1

67 KEY ENGINE/FAN 1

68 WIRE HOUR METER 1

69 2445-OOD SPACER 2

70 3496-OOP GROMMET 1

71 1733-OOP BOLT 3

72 2304-OOP BOLT 2

73 1099-OOP WASHER FLAT ¼ 2

74 2752-OOP SET SCREW 2

76 1221-OOP BOLT ¼ 3

77 3012-OOP CAP / PLUG 1

78 1544-OOP SHIM AS REQUIRED

79 1656-OOP WASHER FLAT 3/16 5

3612-OOD FAN GUARD 1

3613-OOW LIFTING EYE 1

20

21

4.3 HYDRAULIC FLUID AND

Temperature Range

Oil

5

° C (40° F) and above

S

AE 30

¯18° C

-

(0° F)

-

5° C (40° F)

5W-30

5

° C (40° F) and below

Synthetic 5W

-

20

ENGINE MAINTENANCE

replace it. Slightly lubricate the filter

seal before installation.

WARNING: SHUT OFF ENGINE

BEFORE DOING ANY

MAINTENANCE. TO PREVENT

ACCIDENTAL START-UP, TURN

THE IGNITION SWITCH OFF AND

DISCONNECT THE NEGATIVE

CABLE FROM THE BATTERY

TERMINAL.

Engine Lubrication Servicing

Check the engine oil level and change

oil and filter as required in the

maintenance table section 4.1 of this

manual.

The oil level should be between the

“full” and “add” marks of the dipstick.

Also illustrated in the engine manual.

To add oil to the engine, remove the

filler cap. Engine oil capacity is 1.8

liters (1.9 quarts) when changing oil

filter.

The following oils are recommended by

the engine manufacturer:

NOTE: See engine manual for

additional service requirements.

NOTE: Dispose of all consumable items

(filters, oils….etc.) in a manner that is

compatible with the environment.

PortaCo, Inc. suggests you take such

items in a sealed container to your local

service station for reclamation. DO

NOT throw these items in the trash or

pour them on the ground.

Hydraulic Fluid Servicing

Removing Condensation

Once a week (Less often in hot dry

weather) take a small sample from the

bottom of the hydraulic tank by

removing the ½” N.P.T. drain plug. If

clear water appears, drain the tank until

clean oil starts to show. Always drain

tank into a suitable container. If fluid is

milky, allow unit to settle for 48 hours

before draining.

When draining oil place a suitable

container under the drain plug and

remove plug. Drain engine completely

and replace plug.

Engine Fuel Servicing

Replace the fuel filter every 100 hrs. or

yearly. Remove the filter cartridge and

10W-30

5W-30

NOTE: Water in the fluid reduces

lubrication and causes premature wear.

1% water in a 140 BAR (2000 PSI)

system can cause a 25% increases in

wear rate.

Replace Filter and Fluid

CAUTION: ALWAYS FOLLOW

ANY HANDLING PRECAUTIONS

PUBLISHED BY THE

MANUFACTURES OF THE

LUBRICANTS OR HYDRAULIC

FLUIDS USED.

22

- Remove the drain plug on the

underside of the hydraulic tank and

drain oil into a suitable container.

Let reservoir completely drain and

reinstall the plug.

- Place the drain pan under the

hydraulic oil filter and remove filter.

(Fig. 4.3C)

- Apply a film of clean oil to the

gasket surface of a new hydraulic oil

filter. PortaCo Inc. number 1083OOP (LHA# SPE-15-10).

- Install new filter element and tighten

one-half turn after initial gasket

contact.

- Fill hydraulic oil reservoir with a

fluid recommended in section 3.2 of

this manual. Fill tank until oil level is

just below filler tube. Reservoir

capacity is 18.9 liters (5.0 gal.)

- Dispose of oil and filters in a

responsible manor, see previous

note.

- Shut engine off, check oil level and

add fluid if required. Do not overfill

or fluid may be forced out of

hydraulic fill cap when operating

unit. To maximize life of the

PortaCo Inc. Hydraulic Power Unit

all maintenance must be preformed

in accordance with the manual and

the engine manual provided.

CAUTION: ALWAYS CLEAN UP

ANY FLUID SPILLS

IMMEDIATELY.

CAUTION: ALWAYS FOLLOW

ANY HANDLING PRECAUTIONS

PUBLISHED BY THE

MANUFACTURES OF THE

LUBRICANTS OR HYDRAULIC

FLUIDS USED.

(Fig. 4.3C)

- Start engine and allow to run at idle

for 3 minutes

23

4.4 Trouble Shooting

Problem Cause Remedy

Engine will not start Engine Switch “OFF” Turn engine switch “ON.”

Engine oil low Add engine oil if required

Fuel valve “OFF” Turn fuel valve “ON”

Fuel level low Add fuel

Fuel not reaching

carburetor

Refer to engine manual for proper

procedure

No spark at spark plug Refer to engine manual for proper

procedure

None of the above Take the engine to an authorized

dealer that represents the

manufacturer of the engine your

power unit is equipped with.

Engine runs but

hydraulic circuit will

not drive tools.

ON-OFF valve “OFF” Turn valve “ON”

Tool not connected to

power unit

Hydraulic fluid reservoir

Turn valve “OFF,” connect tool,

turn valve “ON”

Check and fill as required

low

Damaged couplers or

hoses

Check that couplers and hoses are

in good condition, replace as

required

Tool hoses incorrectly

connected to circuit

Check that hoses connect

“pressure” from power unit to

pressure inlet of tool, and “Return”

at power unit connects to return

outlet of tool.

Relief valve stuck open.

Clear blockage (see section 4.2)

replace if required.

Engine runs but

Tool is defective Repair as necessary

hydraulic circuit will

not drive tool

Tool runs too hot Relief value set too low Adjust cracking pressure to 123.2

bar (1800 psi)

Hoses too small Size hose as require in section 2.6

Cooler blocked Clean hydraulic oil cooler

Tool Doesn’t meet

system specifications

See section 1.1 for system

specifications

Closed-center tool in use Use only open-center tools

24

Hydraulic Fluid Requirements

Type

Hydraulic fluid

Chevron

“Clarity” AW ISO 32

Exxon

“Univis” J 32

Mobil

D.T.

E. 13 M

Gulf

“Harmony” AW

-

HVI-150-32

Shell

“Tellus T” 32

Texaco

“Rando” HDZ 32

Union

“Unax” AW

-WR-32Amsoil

AWH ISO 32

Sunvis

Low Pour H/032

-

product code 193000

Viscosity (Fluid Thickness)

METRIC U.S.A.

10 C 95 Centistokes 50 F 450 SSU Max

38 C 27-42 C.S. 100 F 130-200 SSU

60 C 16.5 C.S., Min. 140 F 85 SSU Min.

Pour Point – 10 F/-23 C Minimum (for cold startup)

Viscosity Index (ASTM D 2220) 140 Minimum

Demulsibility (ASTM D-1401) 30 Minutes Maximum

Flash Point (ASTM D-92) 340 F/171 C Minimum

Rust Inhibition (ASTM D-665 A & B) Pass

Oxidation (ASTM D943) 1000 Hours Minimum

Pump West Test (ASTM D2882) 60 mg Maximum

Recommend Hydraulic Fluids

Hose Requirements; (2) 3/8-inch diameter hose 5-8 meter (15 to 25 feet) long with 175

Bar (2500 psi) minimum rated working pressure.

Coupler recommendation: ½ inch FLAT FACE HTMA couplers rated at 2500 psi

working pressure. Threads are to match fittings used of on hoses or fittings used as

adapters.

Operate PortaCo Hydraulic Power Unit in well-ventilated areas only. DO NOT operate

hydraulic power unit in combustible atmospheres. Remove flammable materials from

work area. Operate only within temperature range of –20°C to 40°C (-4°F to 104°F)

Bolt Tightening Torque

Bolt Size Torque

#10-32

¼-20

5/16-18

3/8-16

38 in. lbs.

76 in. lbs.

13 ft. lbs.

23 ft. lbs.

25

SERVICE AND REPAIR NOTES

Loading...

Loading...