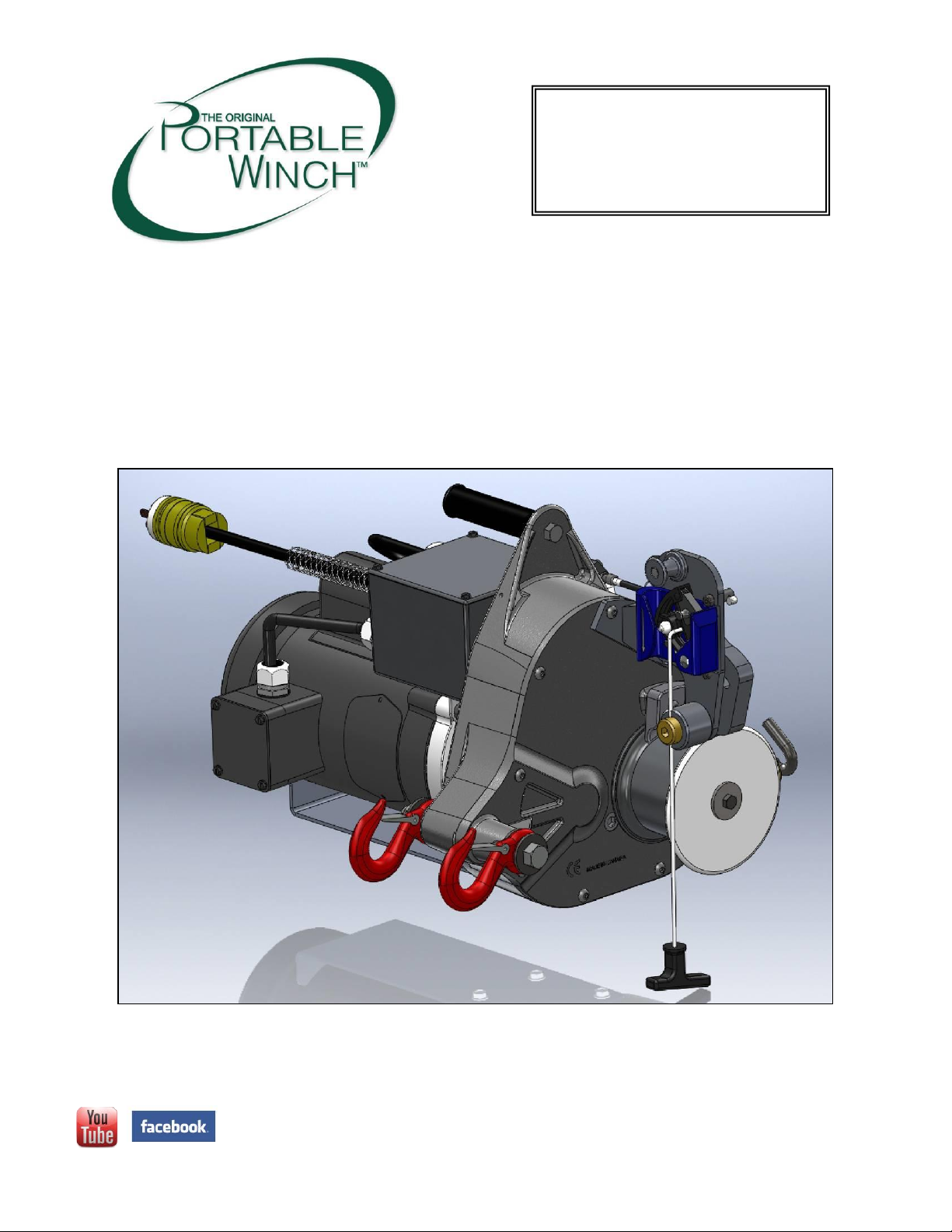

Portable Winch PCT1800 User Manual

READ

CAREFULLY

BEFORE USE

Portable Winch Co.

PORTABLE CAPSTAN AC ELECTRIC PULLING/LIFTING WINCHTM

PCT1800-50Hz-P & PCT1800-60Hz-P

USER MANUAL

Maximum pulling force (single line): 820 kg (1800 lb)

Rated lifting capacity (single line): 250 kg (550 lb)

www.portablewinch.com English version

© 2013 Portable Winch Co. - All Rights Reserved

2

Summary

Introduction – p. 3

1.0 Safety guidelines – p. 3

1.1 Safety messages – p. 3

1.2 Labels – p. 4

1.2.1 Serial number and warning label – p. 4

1.2.2 Rope ‘DANGER’ label – p. 4

1.3 Safety information – p. 4

2.0 Before first use – p. 6

2.1 Upon receiving the winch – p. 6

2.2 Capstan drum – p. 6

3.0 Winch usage – p. 7

3.1 Working cycle – p. 8

3.2 Rope – p. 8

3.2.1 Rope type – p. 8

3.2.2 Rope maintenance – p. 8

3.2.3 At the end of the rope – p. 9

3.2.3.1 Recommendations – p. 9

3.2.3.1.1 When pulling – p. 9

3.2.3.1.2 When lifting – Rope with buried eyed splice – p. 9

3.3 Winch anchors – p. 10

3.3.1 Using the polyester sling – p. 10

3.3.2 Using the hitch plate winch anchor for tow balls – p. 11

3.3.3 Using the winch support plate with square tubing – p. 11

3.3.4 Using the winch support plate with Heck-Pack system for European balls – p. 12

3.3.5 Using the tree/pole mount with anchor strap – p. 13

3.3.5.1 With the winch support plate – p. 13

3.3.5.2 With the vertical pull winch support – p. 14

3.3.6 Using the vertical pull winch support with square tubing – p. 16

3.4 Moving a load – p. 17

3.4.1 Installing the rope on the PCT1800 Winch – p. 18

3.4.2 Lifting – p. 19

3.4.2.1 Load lifting chart – p. 19

3.4.2.2 Lifting operation – p. 20

3.4.2.3 Lowering a load – p. 20

3.4.2.4 Sending the rope back down – p. 22

3.4.3 Pulling – p. 22

3.4.3.1 Releasing the tension – p. 23

3.4.3.1.1 When pulling with the rope grabbing system engaged – p. 23

3.4.3.1.2 When pulling with the rope grabbing system disengaged – p. 23

3.5 If the PCT1800 AC Electric Portable Capstan Pulling/Lifting Winch doesn’t work – p. 23

4.0 Maintenance – p. 23

4.1 Cleaning – p. 23

4.2 Lubrication – p. 24

4.3 AC Electric motor – p. 24

4.4 Storage – p. 24

5.0 Complementary information – p. 24

5.1 Accessories – p. 24

5.2 Serial number localization – p. 24

5.3 Warranty – p. 25

5.4 CE Declaration of conformity – p. 26

5.5 Exploded view and parts list – p. 27

5.6 Electrical diagrams – p. 29

5.7 Technical data – p. 30

5.8 Periodical tests – p. 31

5.9 Manufacturer – p. 31

Schedule 1. Examining the rope – p. 32

3

Introduction

Portable Winch Co. wishes to thank you for purchasing a PCT1800 AC Electric Portable

Capstan Pulling/Lifting WinchTM. This manual was written to help you make the best use of your

new winch and to use it in the most secure way. READ IT CAREFULLY BEFORE USING THE

WINCH. For any problems or questions please refer to an authorized Portable Winch Co. dealer

or contact us directly.

1.0 Safety guidelines

The PCT1800 AC Electric Portable Capstan Pulling/Lifting WinchTM is designed for lifting objects

at angles up to vertical. It is fitted with a rope grabbing system that can maintain the load in

position and provide stop and go operation. THE ROPE GRABBING SYSTEM IS NOT

DESIGNED TO STOP A FAST MOVING LOAD OR TO LIFT PEOPLE. The use of a lifting

device implies serious risks of injuries, property damage or even death. DO NOT

UNDERESTIMATE ITS POTENTIAL DANGER.

WHEN LIFTING, NEVER GO OVER THE RATED LIFTING CAPACITY (250 kg

(550 lb)) SINGLE LINE.

WHEN LIFTING, NEVER BYPASS THE ROPE GRABBING SYSTEM.

NEVER SHOCKLOAD THE SYSTEM.

NEVER OPERATE THE WINCH WITHOUT PROPER TRAINING AND

SUPERVISION. REMEMBER THE FIRST CAUSE OF ACCIDENT IS HUMAN ERROR. MAKE

SURE EVERY PERSON HAS RECEIVED THE APPROPRIATE TRAINING FOR THE JOB.

THE MANUFACTURER IS NOT RESPONSIBLE FOR DAMAGE CAUSED BY

NEGLECTING TO FOLLOW THE GUIDELINES AND BY NEGLECTING TO FOLLOW SAFETY

REGULATIONS.

In particular, the USER has the obligation to verify:

a) If the electrical receptacle is equipped with a ground compatible with the connector;

b) If the electrical system is adequate;

c) The implementation of safety measures to prevent loads from falling.

1.1 Safety messages

Your safety and the safety of others are very important. You will find important safety messages

in this manual. READ THEM CAREFULLY.

These security messages are warning you of potential injuries to either you or others. Every

safety message is preceded by a warning symbol and one of the following terms:

DANGER, WARNING or CAUTION.

4

These indicator words mean:

You WILL be MORTALLY or SEVERELY INJURED if you do not follow these

instructions.

You COULD be MORTALLY or SEVERELY INJURED if you do not follow

these instructions.

You COULD be INJURED if you do not follow these instructions.

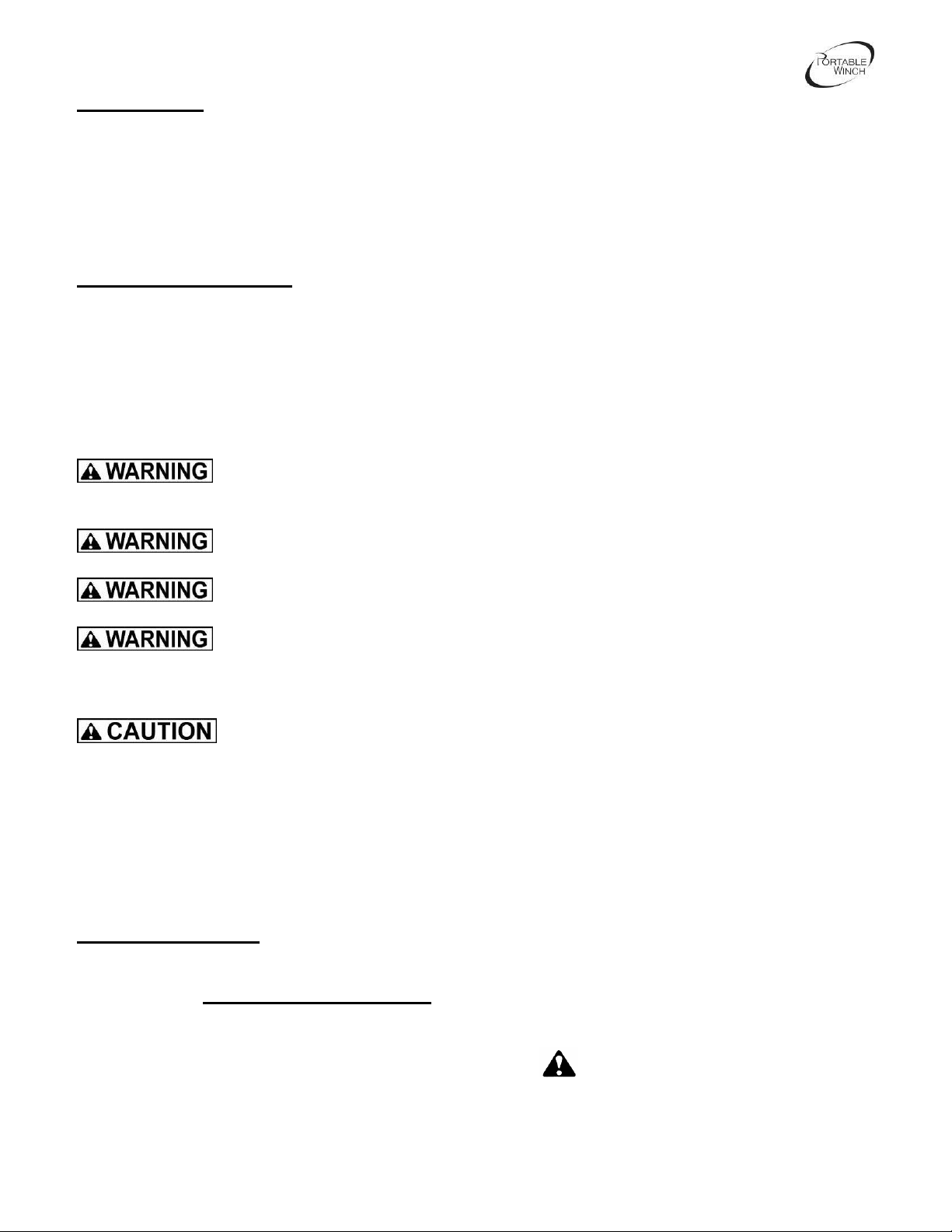

1.2 Labels

1.2.1 Serial number and warning label

The serial number and warning label is positioned on the right

side of the winch housing. Read the meaning of all four icons

(figure 1 to the right):

1. Read this instruction manual and Baldor engine user’s

manual prior to using the winch.

2. Only use low-stretch rope. Minimum diameter: 12 mm

(1/2’’). Maximum diameter: 13 mm (1/2’’).

3. Never place your hands near the moving parts while the

engine is running.

4. Never use the winch for lifting people.

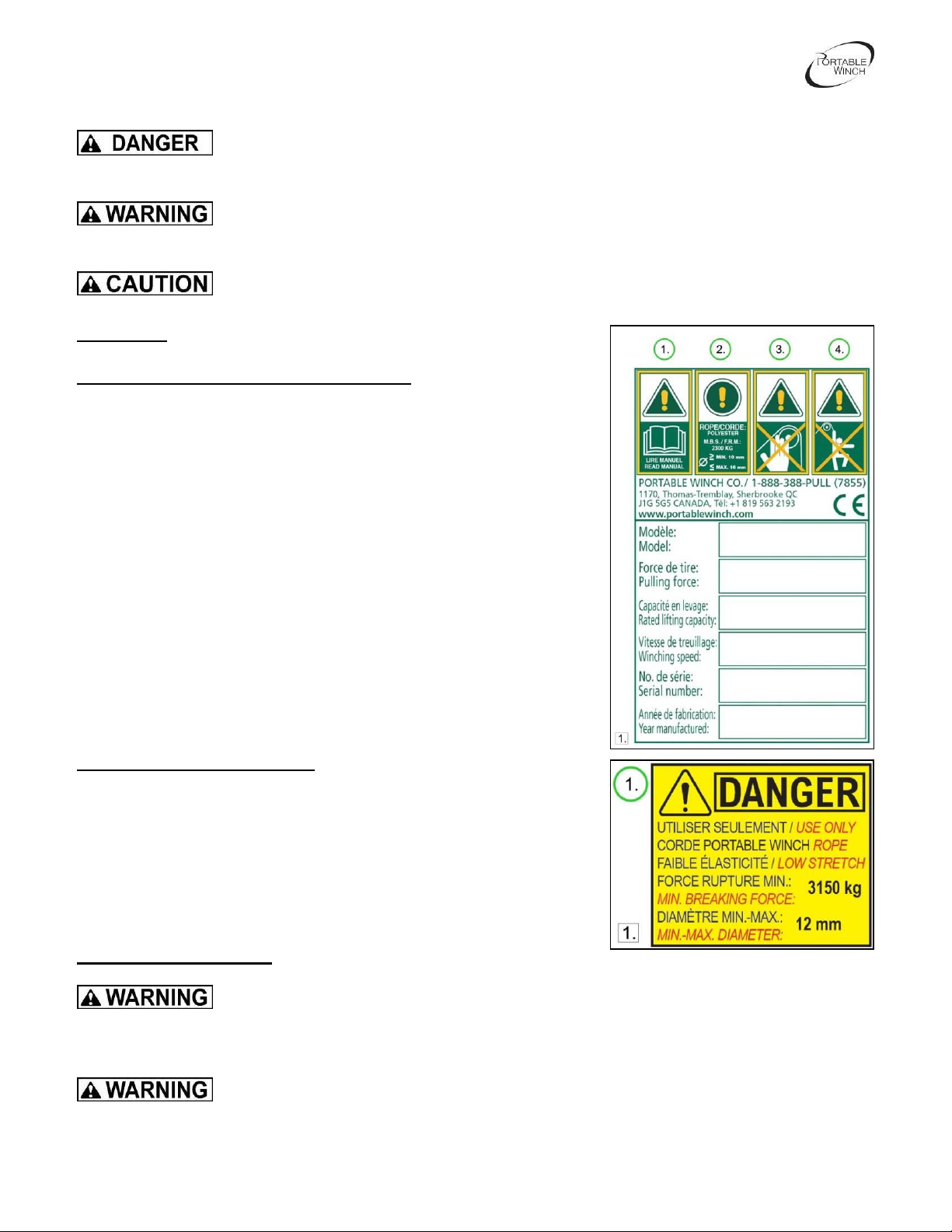

1.2.2 Rope ‘DANGER’ label

The rope ‘DANGER’ label is positioned on the top of the winch

housing. The meaning of the icon in figure 1 to the right is:

1. It is IMPERATIVE to use ONLY Portable Winch Co.

double braided polyester rope 12-13 mm (1/2’’) with

buried eyed splice and a minimal breaking strength of

3150 kg (6945 lb).

1.3 Safety information

DO NOT LET CHILDREN USE THE PCT1800 AC ELECTRIC PORTABLE

CAPSTAN PULLING/LIFTING WINCHTM. KEEP CHILDREN AND ANIMALS AWAY FROM THE

WORK AREA.

NEVER LET SOMEONE WITHOUT TRAINING USE THE PCT1800 AC

ELECTRIC PORTABLE CAPSTAN PULLING/LIFTING WINCHTM. MAKE SURE THE USER

KNOWS ABOUT THE SAFETY AND USAGE PROCEDURES AND HAS READ THIS MANUAL

5

AND THE BALDOR MOTOR LEAFLET. THE OPERATOR SHOULD BE ABLE TO OPERATE A

LIFTING DEVICE AND BE AWARE OF ALL ASPECTS OF SUCH OPERATIONS. HE SHOULD

ALSO BE AWARE OF LOCAL REGULATION.

INFORM ALL USERS OF THE SAFETY GUIDELINES AND USAGE

PROCEDURES.

FAMILIARIZE YOURSELF WITH THE PRODUCT AND THE SAFETY

GUIDELINES BEFORE WORKING WITH THIS WINCH.

MAKE SURE THAT YOUR CLOTHES ARE NOT GOING TO GET CAUGHT

INTO THE WINCH MOBILE PARTS.

USE ONLY 12 MM TO 13 MM (1/2’’) DIAMETER DOUBLE BRAID PORTABLE

WINCH CO. POLYESTER ROPE WITH THIS WINCH.

ALWAYS USE THE PCT1800 AC ELECTRIC PORTABLE CAPSTAN

PULLING/LIFTING WINCHTM HORIZONTALLY, USING A PULLEY OR THE VERTICAL PULL

WINCH SUPPORT TO REDIRECT THE ROPE VERTICALLY.

REPLACE ANY SAFETY LABELS THAT ARE DAMAGED, ILLEGIBLE OR

MISSING.

NEVER PUT YOUR HANDS ON THE CAPSTAN DRUM, THE ROPE

GRABBING SYSTEM, THE ROPE ENTRY PULLEY OR NEAR THE ROPE GUIDE WHEN THE

MOTOR IS CONNECTED TO POWER SOURCE.

ALWAYS KEEP BYSTANDERS OUTSIDE THE WORKING AREA.

NEVER PULL ROLLING OBJECTS THAT MIGHT ROLL OUT OF YOUR

CONTROL.

NEVER TRY TO MOVE FIXED OR OBSTRUCTED LOADS.

AVOID EXCESSIVE INCHING (E.G. GIVING SHORT PULSES TO THE

MOTOR).

ALWAYS INITIATE MOVEMENTS OF THE LOAD WITH THE LOWEST

AVAILABLE SPEED. THE ROPE SHALL BE TIGHTENED AND SHALL NOT BE IN THE

SLACK-CONDITION WHEN THE LOAD MOVEMENT BEGINS.

SIDE-PULL OF LOAD IS NOT ALLOWED WITH THIS WINCH.

KEEP IN MIND THAT YOUR SET-UP IS ONLY AS RESISTANT AS THE

WEAKEST LINK. THIS IS WHY IT IS VERY IMPORTANT TO USE THE ADEQUATE

6

ACCESSORIES IN ACCORDANCE WITH THE JOB TO BE DONE. IN THIS CASE (LIFTING),

IT IS RECOMMENDED TO HAVE A 10 TO 1 SAFETY FACTOR FOR ALL ACCESSORIES.

IT IS STRICTLY FORBIDDEN TO:

LIFT LOADS WITH A WEIGHT GREATER THAN TO THE RATED LIFTING CAPACITY

(250 KG (550 LB);

TO LIFT LOADS THAT IMPAIR THE OPERATOR’S VISIBILITY OR THAT COULD

COLLIDE WITH OTHER MOVING LOADS OR WITH ADJACENT STRUCTURES;

USE THE WINCH TO LIFT PEOPLE;

ALLOW PEOPLE TO PASS UNDER A SUSPENDED LOAD;

LIFT LOADS THAT ARE POORLY SLINGED;

LEAVE SUSPENDED LOADS UNATTENDED;

ALLOW OTHER PEOPLE TO USE THE WINCH.

2.0 Before first use

2.1 Upon receiving the winch

Inspect the box to detect any apparent damage. If there is damage or missing parts, inform the

carrier immediately.

2.2 Capstan drum

Your PCT1800 AC Electric Portable Capstan Pulling/Lifting WinchTM is equipped with the 85 mm

(3-3/8") diameter capstan drum and the 127 mm (5") diameter safety lip.

If you wish to change the drum for the 57 mm (2-1/4") drum (sold separately), you will also need

to purchase and install the 117 mm (4-5/8’’) diameter safety lip. To do so, follow these simple

steps:

The tools required to change the drum are:

A 4 mm (5/32") hex wrench (included

with your winch).

An 11 mm (7/16’’) wrench or adjustable

wrench (not included).

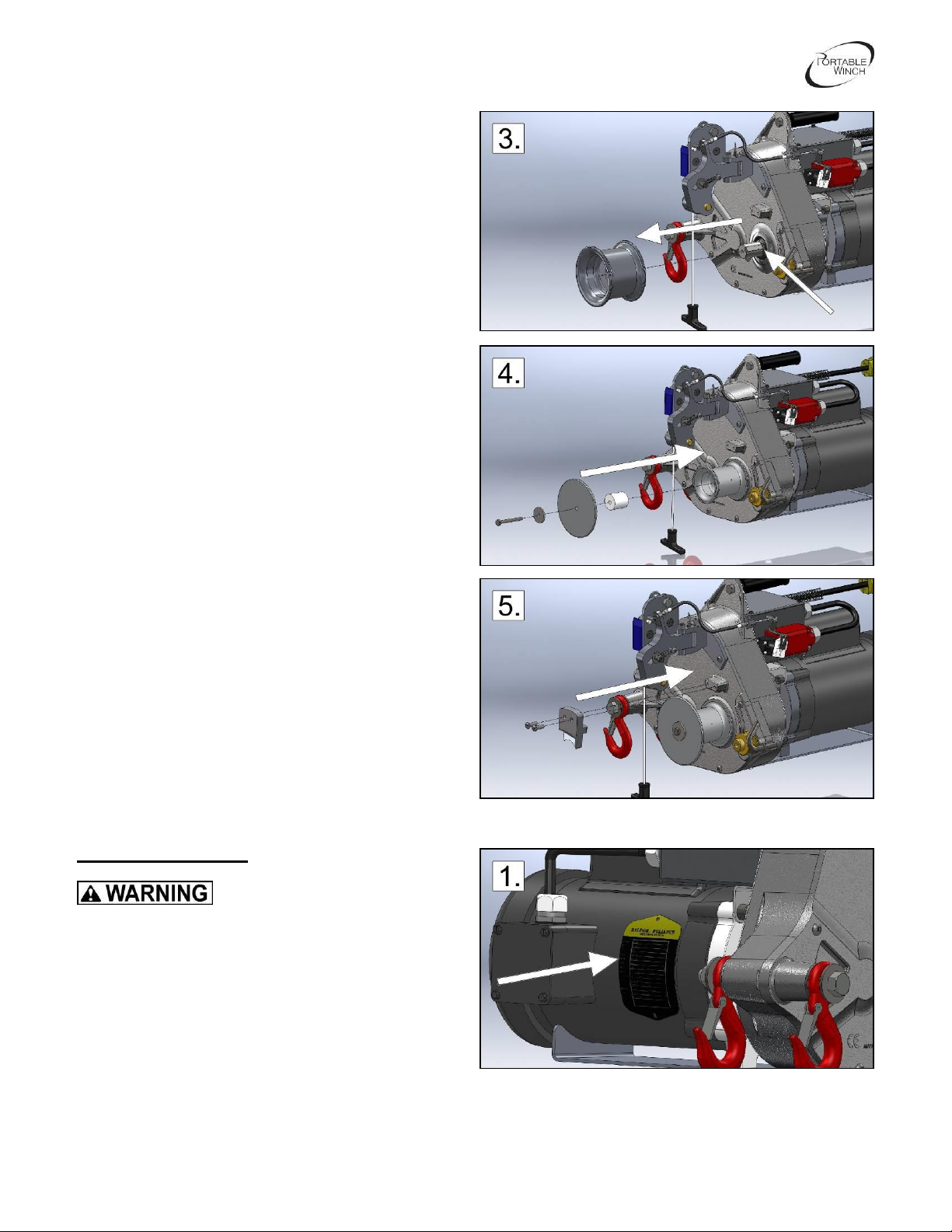

1) Figure 1: Remove the two bolts holding

the rope guide and then, remove the

rope guide;

2) Figure 2: Remove the hex bolt holding

the safety lip and drum using the 11 mm

(7/16’’) wrench. Then, remove the

washer, the safety lip and the spacer

bushing;

7

3) Figure 3: Remove the drum from the

shaft. If necessary, you may push it

forward with two screwdrivers. Make

sure that the shaft key stays in place.

4) Figure 4: Insert the 57 mm (2-1/4’’)

drum on the winch shaft. Insert the

washer, the 117 mm (4-5/8’’) safety lip

and the spacer bushing on the hex bolt

and insert this assembly in the hole of

the shaft. Then, tighten the hex bolt with

the 11 mm (7/16’’) wrench;

5) Figure 5: Insert the new rope guide in

position and tighten it using the two (2)

bolts.

IMPORTANT: Make sure that the rope

guide is not in contact with the capstan

drum.

3.0 Winch usage

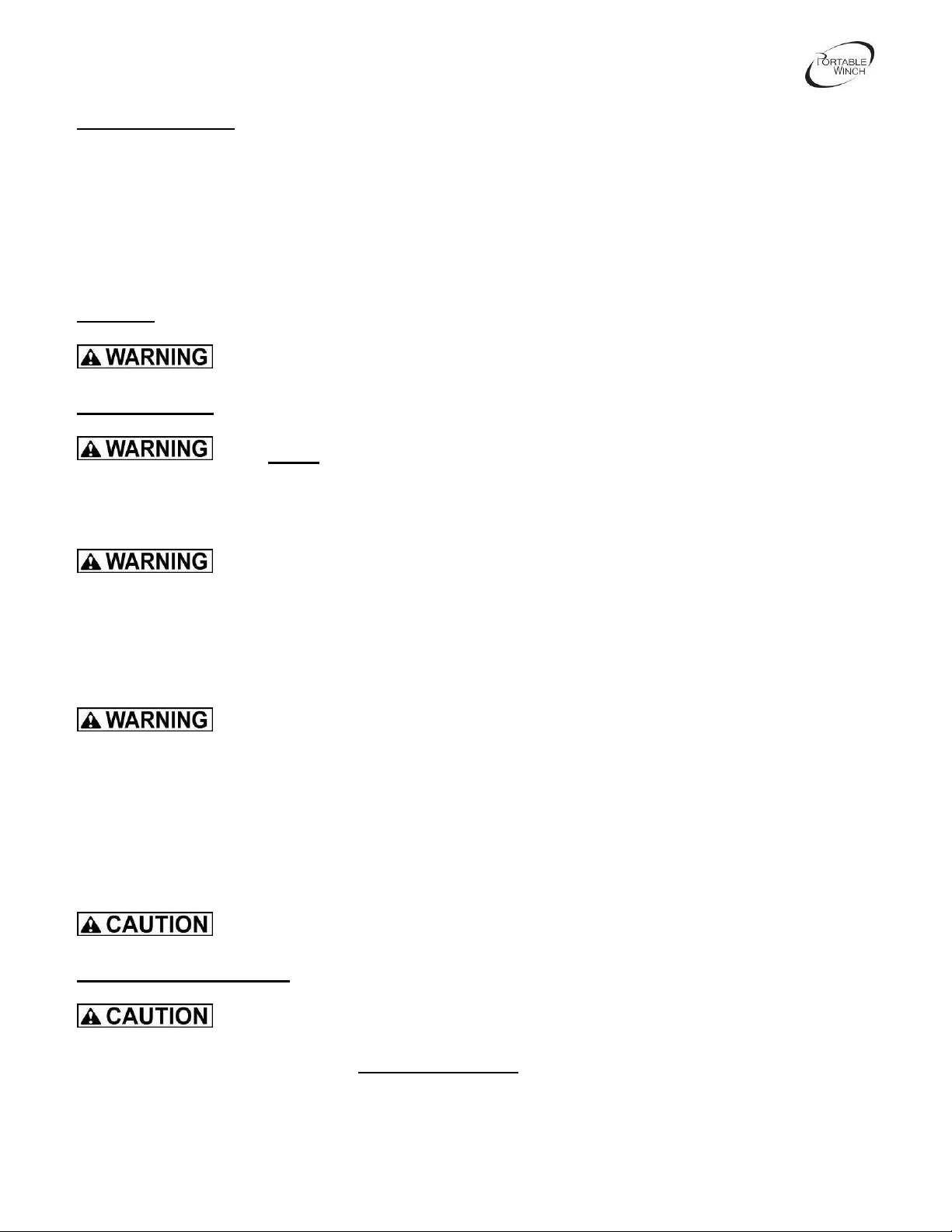

MOST WINCHING

SITUATIONS PRESENT POTENTIAL

DANGERS!

The winch must be plugged into a grounded

plug. The use of an extension cord can cause

a loss of power at full capacity. As listed on the

product label (figure 1), make sure the voltage

and current type are respected. Units

115V-60hz require 20 amps while the units 220V-50hz require 10 amps.

8

3.1 Working cycle

This PCT1800 AC Electric Portable Capstan Pulling/Lifting WinchTM is designed for intermittent

use. The engine manufacturer recommends an engine duty cycle of 25%. So, to get a maximum

lifetime out of the engine, it should only be used for fifteen (15) minutes period every hour. This

data varies depending on the loads pulled or lifted. Light loads can be lifted or pulled

continuously without affecting the life of the engine. Continuous pulls are however less

damageable for the motor than frequents stop and go.

3.2 Rope

STAY OUT OF THE WINCH LINE’S PATH.

3.2.1 Rope type

USE ONLY LOW STRETCH 12 OR 13 MM (1/2’’) DIAMETER PORTABLE

WINCH CO. DOUBLE BRAIDED POLYESTER ROPE WITH A MINIMAL BREAKING POINT OF

3150 KG (6945 LB) WITH THIS WINCH. PLEASE CONTACT US FOR OTHER ROPE TYPE’S

SUITABILITY.

DO NOT USE 3-STRAND POLYPROPYLENE YELLOW ROPE!

Polypropylene and polyethylene ropes are dangerous for winching because of their great

elasticity and low melt point.

Make sure the rope is not damaged and that it offers an adequate resistance to pull the

load.

STRETCH EQUALS DANGER!

A stretched rope can recoil and cause serious burns as the rope leaves your hand.

All ropes stretch: a longer one more than a shorter one. The more you pull, the more it

stretches.

A stretched rope can also move the load in an unpredictable or dangerous way.

A stretched rope can recoil and bring your hand towards the winch causing severe

injuries. NEVER WRAP THE ROPE AROUND YOUR HAND.

ALWAYS WEAR GLOVES.

3.2.2 Rope maintenance

The rope and its ends should be inspected regularly to detect wear. Please

refer to CI 2001 Document - FIBER ROPE INSPECTION AND RETIREMENT CRITERIA from

the Cordage Institute available at www.ropecord.com for the procedure and criteria of scrapping

the rope.

You will find a chart located at the end of this manual to better help you register your

observations.

9

IF YOUR ROPE IS DIRTY, WASH IT. DIRTY ROPES DETERIORATE

FASTER AND CAUSE PREMATURE WEAR OF THE PARTS IN CONTACT WITH THE ROPE

SUCH AS THE CAPSTAN DRUM AND ROPE GUIDE.

3.2.3 At the end of the rope

3.2.3.1 Recommendations

Since the PCT1800 AC Electric Portable Capstan Pulling/Lifting WinchTM can be used for pulling

and lifting, there are some guidelines to follow:

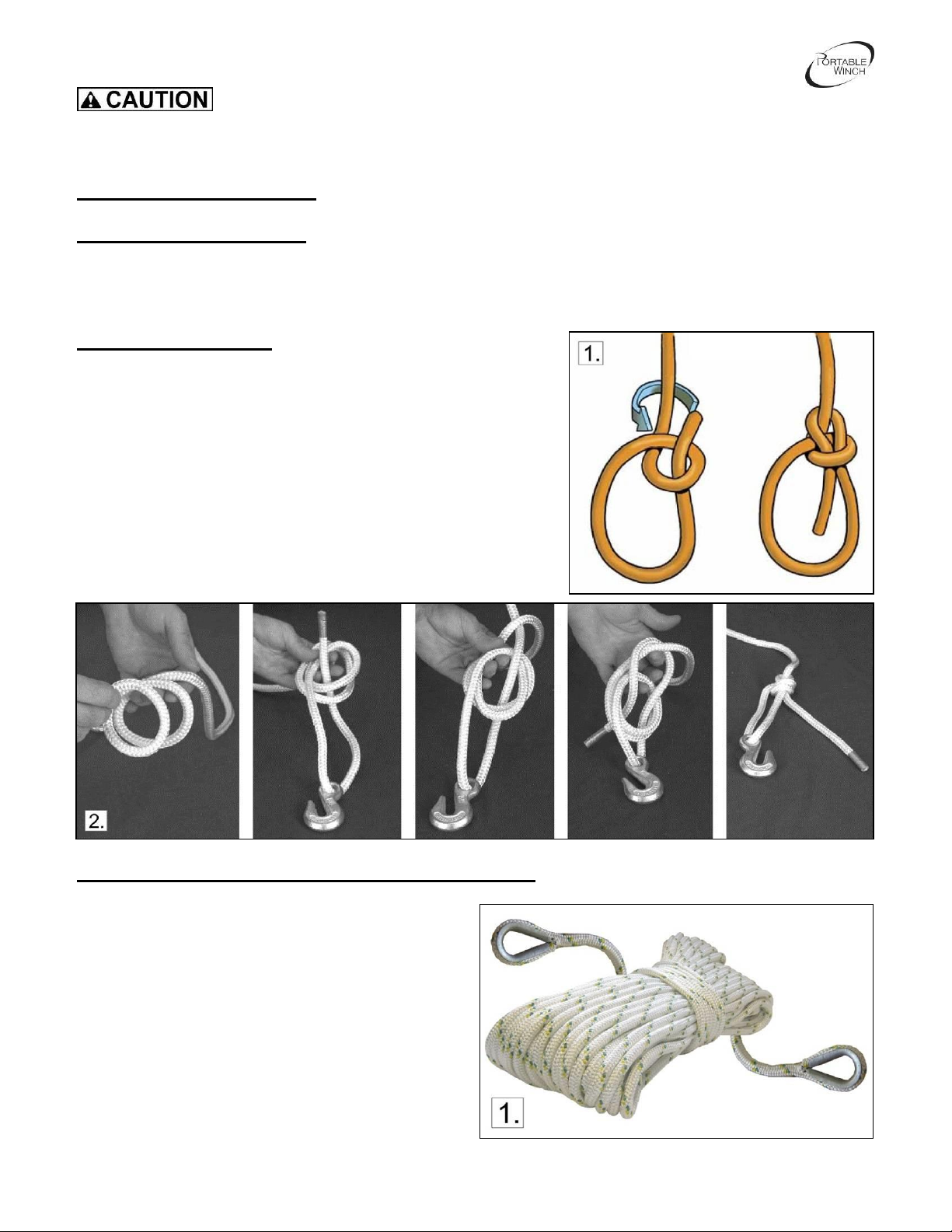

3.2.3.2.1 When pulling

For pulling loads, you have to attach the load to the end

of the rope. Even if a simple knot can do the job, we

recommend the installation of a hook with the bowline

knot (figure 1 on the right) because it can be easily

undone if you need to change the hook. Moreover, it

retains about 70% of the rope’s capacity while most knots

will reduce it by more than 50%.

Even better, the double bowline knot (figure 2 below) will

keep about 75% of your rope’s capacity.

3.2.3.1.2 When lifting - Rope with buried eyed splice

For lifting, again, you have to attach the load to

the end of the rope. Even if you believe that a

bowline knot could do the job, it is STRONGLY

RECOMMENDED to use the Portable Winch

Co. rope with buried eyed splice. The

installation of a hook with a strong enough

safety factor carabiner or shackle to the rope

will help prevent any problems that might occur

in case of knot failure.

NOTE: Please, check with local authority for

safety regulation in your area.

10

3.3 Winch anchors

The winch is anchored to a fixed point using the included polyester sling or with optional

anchoring devices and the rope end is tied to the object you want to move. The load is moving

towards the winch when you pull the rope.

3.3.1 Using the polyester sling (included with the winch)

Go around the anchor point with the sling. Insert each end of the sling in one of the safety hooks

located on the winch (figure 1 below).

Position the winch in line with the load. When the winch is under tension, it will try to align itself

with the load. The friction of the sling against the anchor point could prevent correct alignment. If

that is the case, release the tension on the rope and position the sling on the anchor point so

that the tension is equally distributed on both winch anchor hooks.

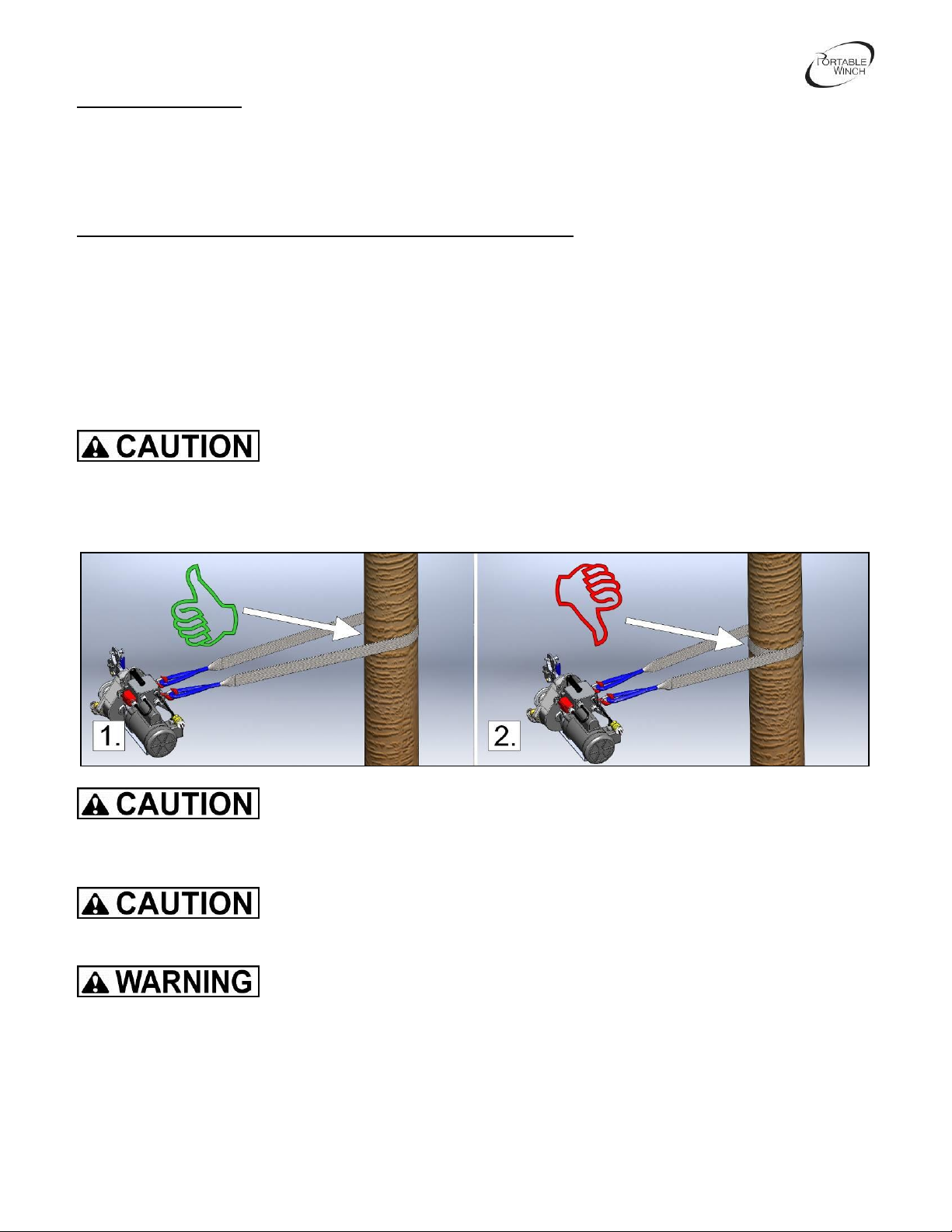

DON’T DO THIS! WHEN YOU ANCHOR THE WINCH, MAKE SURE

THAT YOU DO NOT DO A COMPLETE WRAP AROUND THE ANCHOR POINT (FIGURE 2

BELOW). THIS SET-UP WILL PREVENT PROPER ALIGNMENT OF THE WINCH WITH THE

LOAD AND WILL PUT UNEVEN TENSION ON THE WINCH ANCHOR HOOKS.

AVOID INSTALLING THE SLING ON SHARP EDGES THAT MIGHT

DAMAGE IT. WHETHER YOU ARE USING A POST, A TREE OR A STUMP, ALWAYS

INSTALL THE SLING NEAR THE ANCHOR’S BASE.

USING A STUMP AS AN ANCHOR POINT MEANS PAYING SPECIAL

ATTENTION IN ORDER TO PREVENT THE SLING FROM SLIPPING OVER IT.

MAKE SURE THE ANCHOR POINT IS STRONG ENOUGH TO RESIST

THE PULL WITHOUT BREAKING OR BEING DAMAGED.

Loading...

Loading...