Page 1

Technical Manual

-.8e;~~

Technical Information

Contents:

Group 9

Electrics

WKD 483 521

Page 2

Boxster

Foreword

Foreword

The workshop documentation for the Boxster model has the designation "Boxster" Technical Manual

and contains Technical Information as well as instructions on Repairs.

The integration of the technical information published in the "Boxster" Technical Manual with the

descriptive matter on repairs provides the user with a complex reference work that combines into one

book associated or cross-referenced material of relevance to workshops and originating from various

information media.

The "Boxster" Technical Manual consists of 15 folders, subdivided into the following Groups

0 Entire vehicle -General

0 Diagnosis, part 1 (up to Repair Group 45) *1

0 Diagnosis, part 2 (as of Repair Group 69) *2

1 Engine, part 1 (up to Repair Group 13) *3

1 Engine, part 2 (as of Repair Group 15) *4

2 Fuel, exhaust, engine electronics

3 Transmission, manual transmission

3 Transmission, automatic transmission

4 Running gear

5 Body

6 Body equipment, exterior

7 Body equipment, interior

8 / 9 Air conditioning / Electrics

9 Circuit diagrams, part 1 (up to and including the '99 model) *5

9 Circuit diagrams, part 2 (as of the '00 model) *6

.1

The two folders with Group 0 are to be regarded as one folder; i.e. file the "Technical Information"

notices only in front of the repair descriptions in the folder "Group 0 -Diagnosis, part I"

(up to Repair Group 45).

*2

The second folder "Group 0 -Diagnosis, part 2" (as of Repair Group 69) includes the further

Repair Groups belonging to Group O.

.3

The two folders with Group 1 are to be regarded as one folder; i.e. file the "Technical Information"

notices only in front of the repair descriptions in the folder "Group 1 -Engine, part 1" (up to

Repair Group 13).

*4

The second folder "Group 1 -Engine, part 2" (as of Repair Group 15) includes the further Repair

Groups belonging to Group 1.

Foreword

Printed in Germany -34, October 1999

VORW.CHP

Page 3

Foreword

.!i

The two folders with Group 9 are to be regarded as one folder; i.e. file the "Technical Information"

Boxster

notices only in front of the repair descriptions in the folder "Group 9 -Circuit diagrams, part 1" (up to

the '99 model).

*Ei

The second folder "Group 9 -Circuit diagrams, part 2" (as of the '00 model) includes the further

circuit diagrams belonging to Group 9.

The "Boxster" Technical Manual has the same structure in each folder, with the following breakdown for

all Groups:

Title page, "Boxster" Technical Manual

> Foreword

Title page: "Technical Information"

> Table of Contents, Technical information

> Technical information

Title page: "Repair"

> Repair Groups: overview

> Table of Contents, repairs

> General/technical data

> Instructions on repairs

As can be seen from the breakdown, the published Technical Information is in the front part of each

folder -numbered according to the Groups. The Table of Contents assigned to each Group will be

periodically updated.

Following the Technical Information, separated by a title page, the instructions on repairs -assigned

according to the Groups or broken down into Repair Groups -are included in the folder.

The instructions on repairs will be extended and updated by means of supplements.

Note

Sheets that already exist in the "Boxster" Technical Manual and are updated or revised and thereby

exchanged by a supplement are designated "Replacement sheet". Revisions or technical modifications on

pages of these replacement sheets are identified for the user with a vertical bar at the margin.

VORW.CHP

Foreword

Printed in Germany -34, October 1999

Page 4

Overview of repair groupsBoxster

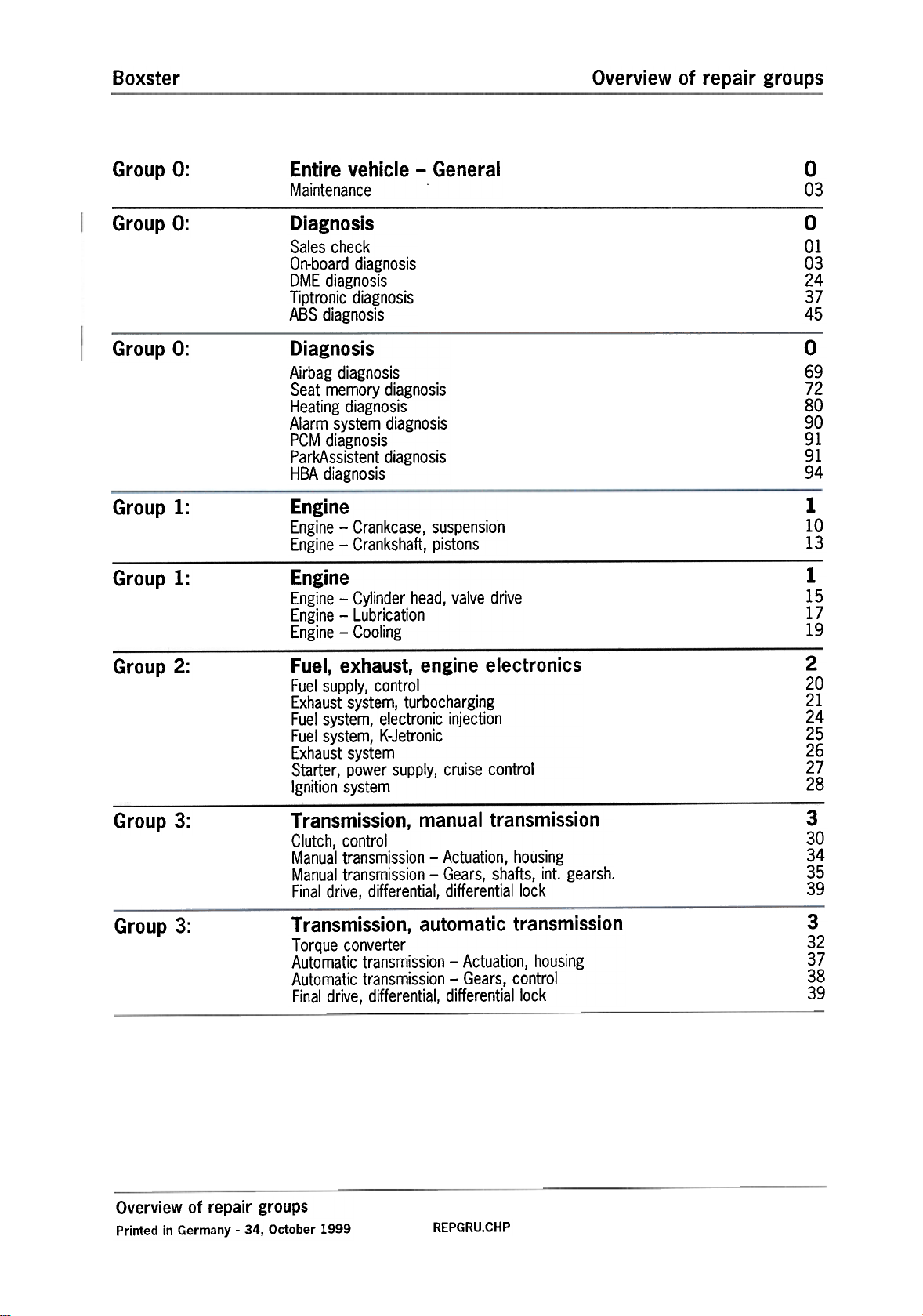

Group 0: Entire vehicle -General

Maintenance

Group 0:

Group 0:

Group 1:

Group 1:

Diagnosis

Sales check

On-board diagnosis

DME diagnosis

Tiptronic diagnosis

ABS diagnosis

Diagnosis

Airbag diagnosis

Seat memory diagnosis

Heating diagnosis

Alarm system diagnosis

PCM diagnosis

ParkAssistent diagnosis

HBA diagnosis

Engine

Engine -Crankcase, suspension

Engine -Crankshaft, pistons

Engine

Engine -Cylinder head, valve drive

Engine -Lubrication

Engine -Cooling

0

03

0

01

03

24

37

45

0

69

72

80

90

91

91

94

1

10

13

1

15

17

19

Group 2:

Group 3:

Group 3:

Fuel, exhaust, engine electronics

Fuel supply, control

Exhaust system, turbocharging

Fuel system, electronic injection

Fuel system, K-Jetronic

Exhaust system

Starter, power supply, cruise control

Ignition system

Transmission, manual transmission

Clutch, control

Manual transmission -Actuation, housing

Manual transmission -Gears, shafts, into gearsh.

Final drive, differential, differential lock

Transmission, automatic transmission

Torque converter

Automatic transmission -Actuation, housing

Automatic transmission -Gears, control

Final drive, differential, differential lock

2

20

21

24

25

26

27

28

3

30

34

35

39

3

32

37

38

39

Overview of repair groups

Printed in Germany -34, October 1999

REPGRU.CHP

Page 5

Overview of repair groups

Boxster

Group 4:

Group 5:

Group 6:

Group 7:

Running gear

Front whee! suspension, drive shafts

Rear wheel suspension, drive shafts

Wheels, tires, suspension alignment

Anti-Lock Brake System (ABS)

Brakes -Brake mechanics

Brakes -Hydraulics, regulator, booster

Steering

Body

Body front

Body center, roof, frame

Body rear

Lids, flaps

Door front, central locking system

Body equipment, exterior

Sliding roof

Convertible top, hardtop

Bumpers

Glazing, window control

Exterior equipment

Interior equipment

Passenger protection

Body equipment, interior

Linings, insulation

Seat frames

Seat upholsteries, covers

4

40

42

44

45

46

47

48

5

50

51

53

55

57

6

60

61

63

64

66

68

69

7

70

72

74

Group 8:

Group 9

Group 9:

Group 9:

Air conditioning

Heating

Ventilation

Air conditioning

Auxiliary air conditioning system

Electrics

Instruments, alarm system

Radio, telephone, on-board computer, navigation

Windshield wiper and washer system

Lights, lamps, switches exterior

Lights, lamps, switches interior, theft protection

Circuit diagrams

Wiring (up to and including the '99 model)

Circuit diagrams

Wiring (from the '00 model)

8

80

85

87

88

9

90

91

92

94

96

9

97

9

97

REPGRU.CHP

Overview of repair groups

Printed in Germany -34, October 1999

Page 6

Boxster

Table of Contents

8

8

8

80

8023 19

85

85

10

19

15

85

85

85

85

85

87

11

30

78

10

19

06

19

19

19

Air conditioning

Air conditioning

Technical data for the air conditioning system

Heating

Removing and installing heat exchanger

Ventilation

Removing and installing mechanical heating / fresh air control. ..

Removing and installing heating / fresh air unit. Installing and adjusting bowden cables of the heating/fresh-air control

Removing and installing heater/fresh-air blower motor. Removing and installing drive motor for fresh-air/recirculation valve.

Removing and installing bulb for rotary blower switch.

Air conditioning

8 -1

80

85- 1

85- 3

85- 7

85-11

85-13

85-15

87

87

87

87

87

87

87

87

87

87

87

87

87

87

87

87

87

87

87

03

0317

8319

5519

3419

7019

0119

5019

2719

2019

2019

5919

8219

5819

7819

5319

6919

0219

Safety regulations when handling refrigerant R 134a Assembly work on air the conditioning system. Nominal values for pressures and temperatures. Removing and installing pressure switch for the air-conditioning system.

Removing and installing fluid tank. Removing and installing the compressor. Removing and installing the expansion valve. Installing and removing the heating /air-conditioning unit. Removing and installing the condenser. Removing and installing the magnetic coupling. Removing and installing drive motors of the heater/air-conditioning unit.

Removing and installing drive motor for fresh-air/recirculation valve. ..

Removing ~nd installing outside temperature sensor. Removing and installing interior temperature sensor. Removing and installing footwell blower outlet sensor. Removing and installing blower driver. Removing and installing fan for condenser. Removing and installing ballast resistor for fan motor. Installing and removing the heatingjair-conditioning unit.

87.

87.

87.

87

87.

87.

87.

87.

87.

87.

87.

87.

87-

87-

87.

87.

87.

87.

87.

-2

-13-15

.17

.19

.23

-25.29

-31.33

-35

37

.39

.41

.43

.45

-47

-49

8 Air conditioning

Printed in Germany -12, 1997

-1

986TOC

1

Page 7

Boxster

Air conditioning

8

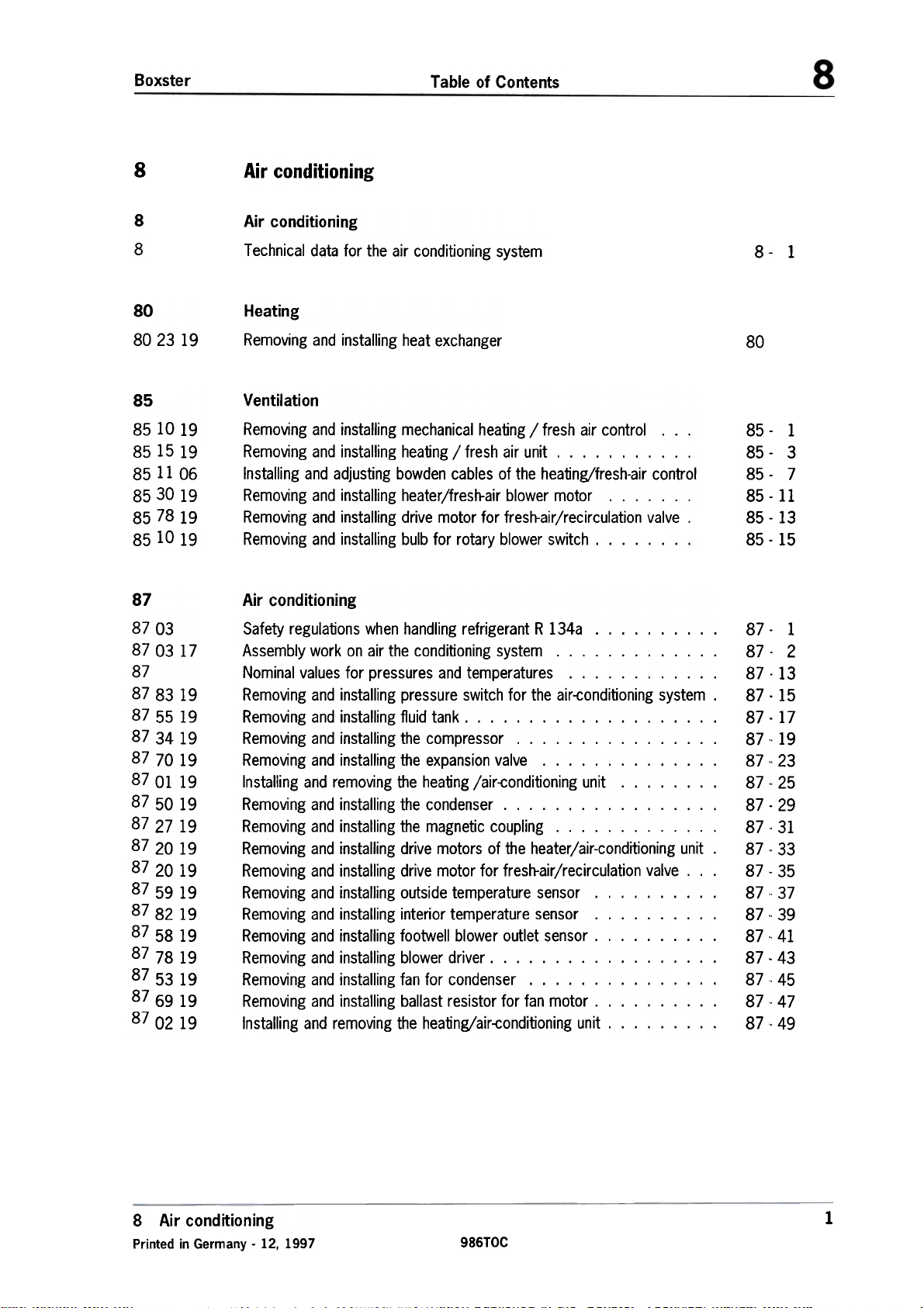

Compressor type 7 S8 16

Refrigerant quantity

Refrigerant oil in the compressor

Hexagon-head bolts on

Expansion valve

Technical data for the air-conditioning system

Compressor

Refrigerant line

Oil filler screw

850 g refrigerant R 134a

195 :f: 15 cm3 NO 8

Thread

M6

M5

M8 23 (17)

M8

M 10

Tightening torque in Nm (ftlb.]

9 (6.5)

6 (4.5)

23 (17)

26...36 (19...27)

Fluid tank

Flange connections of

refrigerant lines

Note

When installing the refrigerant lines, the screw connections and the a-rings must be wetted with

refrigerant oil.

The refrigerant oil must be disposed of as special-category waste.

M6

M8

6 (4.5)

14 (10.5)

8 Technical data for the air-conditioning system

Printed in Germany -12, 1997 9868_1

8 -1

Page 8

Boxster

Heating

80 23 19

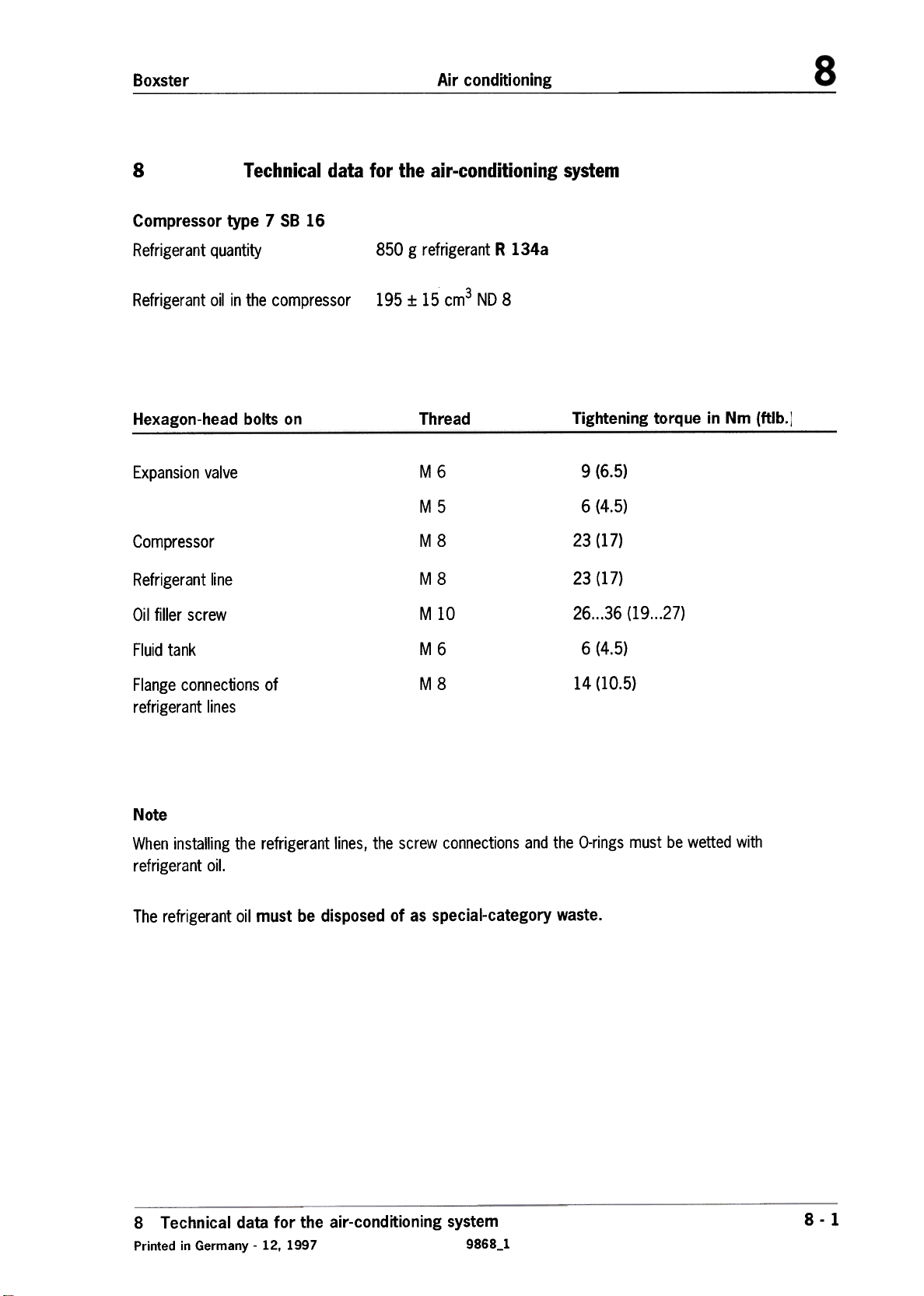

Removal

1. Remove covers from heating and air-conditioning system, battery and fluid reservoir. Disconnect battery and cover terminal or battery.

2. Remove the entire wiper link with wiper motor

(see Repair Group 92).

3. Loosen right dome strut and bracket at the

cowl frame and remove.

\ " '" '"

'/

Removing and installing heat exchanger

\\\

~,~

.~

\ \ -

,.--

~

""

\

6. Release heat exchanger and pull it up and out.

c

~ ~---='

~)

'""-'

,: "'"

t

)

::::::;;;;~!)

u

--=

a:\~

288 -96

Installation

1. Seal cover over the heat exchanger airtight

with butyl adhesive.

I~

4. Clamp shut both heater hoses in front of the

heat exchanger using a commercially available

hose clamp. Loosen heater hoses at the heat

exchanger and pull off.

5. Carefully remove cover over the heat exchanger.

\.

287 -96

2. Replace cover if damaged.

3. The heat exchanger is connected to the engine cooling system, and coolant flows

through it when the engine is running. After removing or installing the heat exchanger I vent

the cooling system (see Repair Group 19).

80 23 19Removing and installing heat exchanger

Printed in Germany. 1996 986801

80 -1

Page 9

Boxster

Ventilation

85 10 19

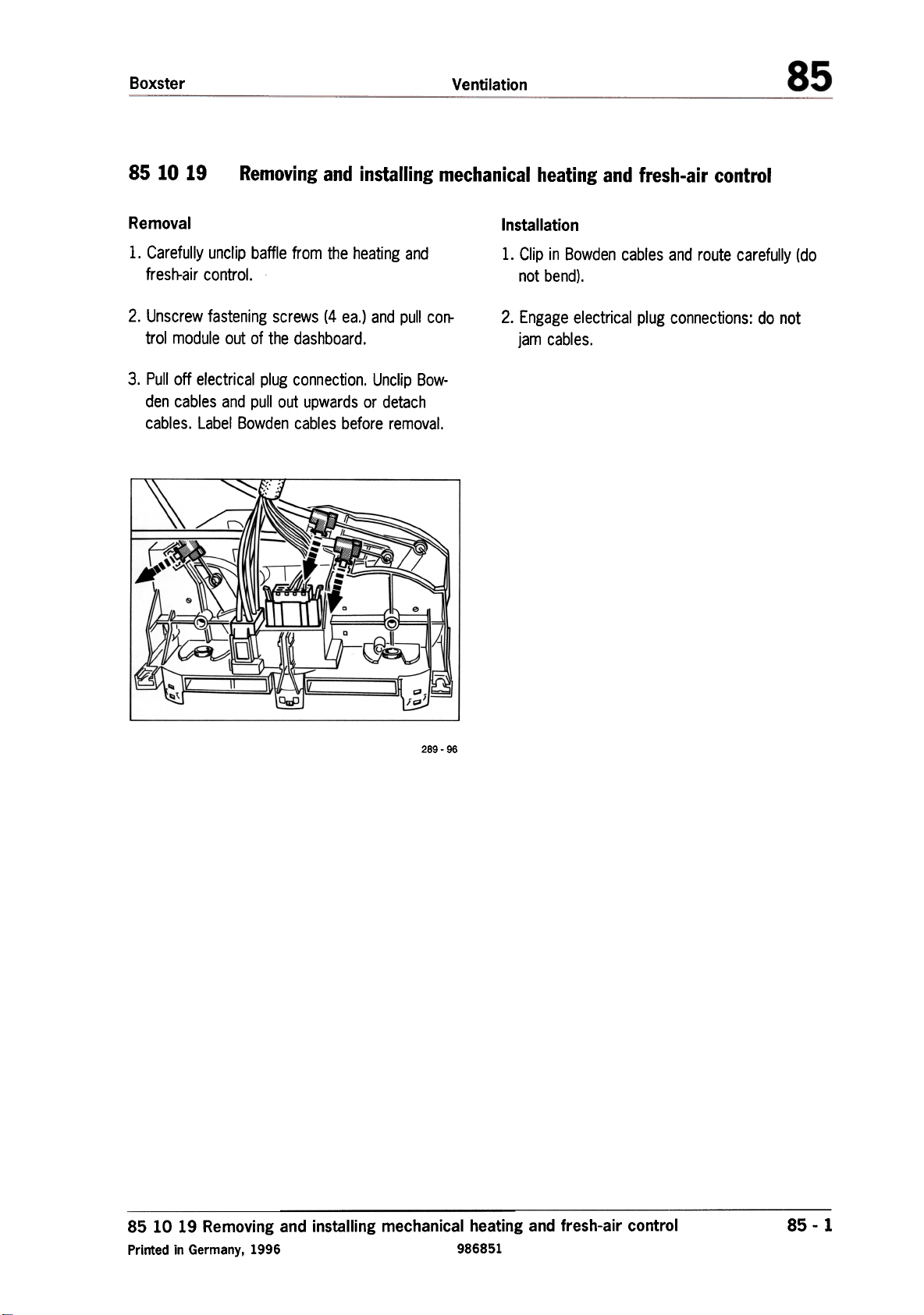

Removal

1. Carefully unclip baffle from the heating and

fresh-air control.

2. Unscrew fastening screws (4 ea.) and pull corr

trol module out of the dashboard.

3. Pull off electrical plug connection. Unclip Bowden cables and pull out upwards or detach

cables. Label Bowden cables before removal.

Removing and installing mechanical heating and fresh-air control

.,..

Installation

1. Clip in Bowden cables and route carefully (do

not bend),

2. Engage electrical plug connections: do not

jam cables.

..U.;

M

~=\ ~-

j~'

289 -96

~

I!!-

85 10 19 Removing and installing mechanical heating and fresh-air control

Printed in Germany, 1996 986851

85 -1

Page 10

Boxster

Ventilation

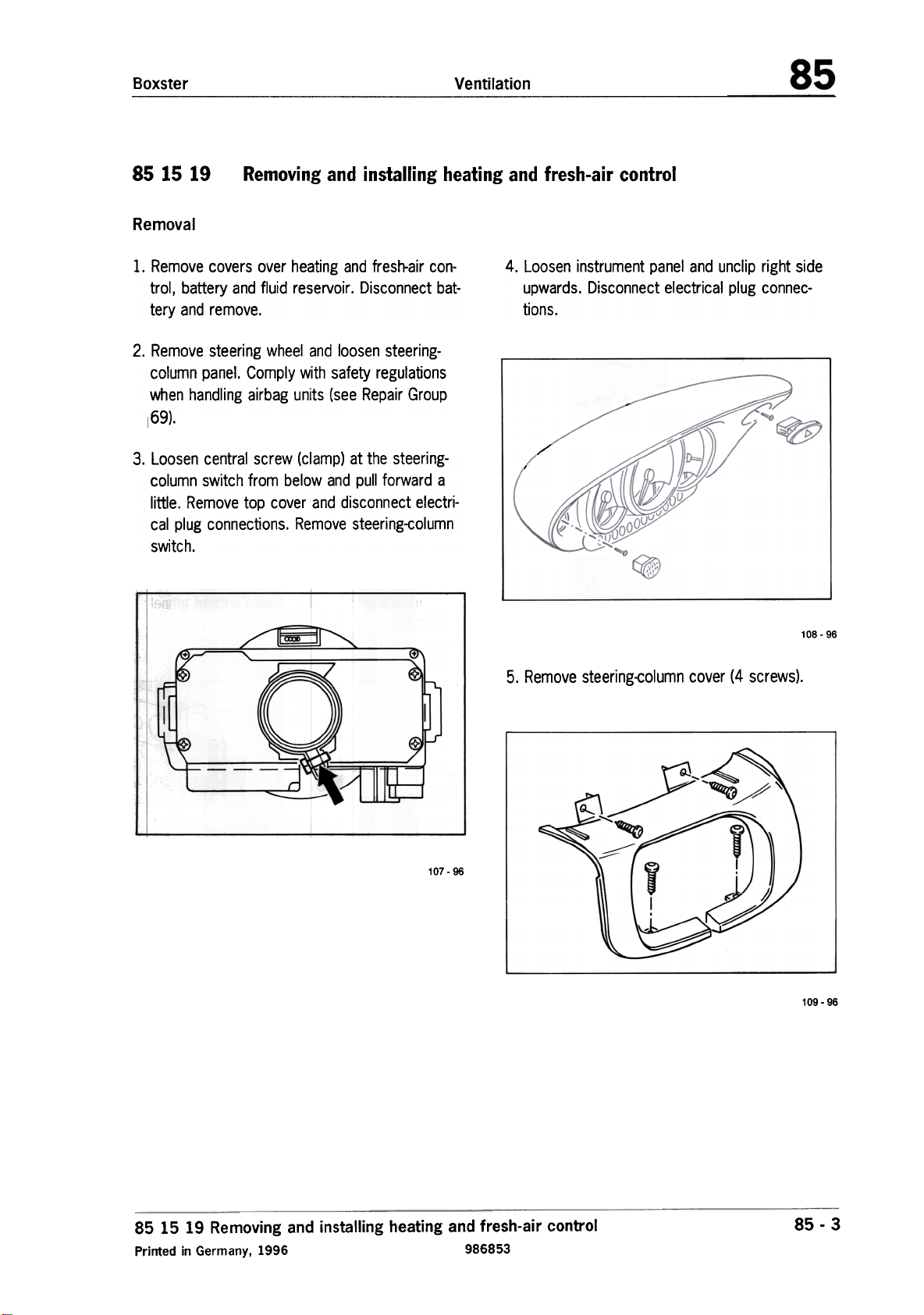

85 15 19 Removing and installing heating and fresh-air control

Removal

1. Remove covers over heating and fresh-air control, battery and fluid reservoir. Disconnect bat-

tery and remove.

2. Remove steering wheel and loosen steeringcolumn panel. Comply with safety regulations

when handling airbag units (see Repair Group

169).

3. Loosen central screw (clamp) at the steeringcolumn switch from below and pull forward a

little. Remove top cover and disconnect electri-

cal plug connections. Remove steering-column

switch.

4. Loosen instrument panel and unclip right side

upwards. Disconnect electrical plug connections.

108- 96

5. Remove steering-column cover (4 screws).

107-96

85 15 19 Removing and installing heating and fresh-air control

Printed in Germany, 1996 986853

109 -96

85 -3

Page 11

Ventilation Boxster

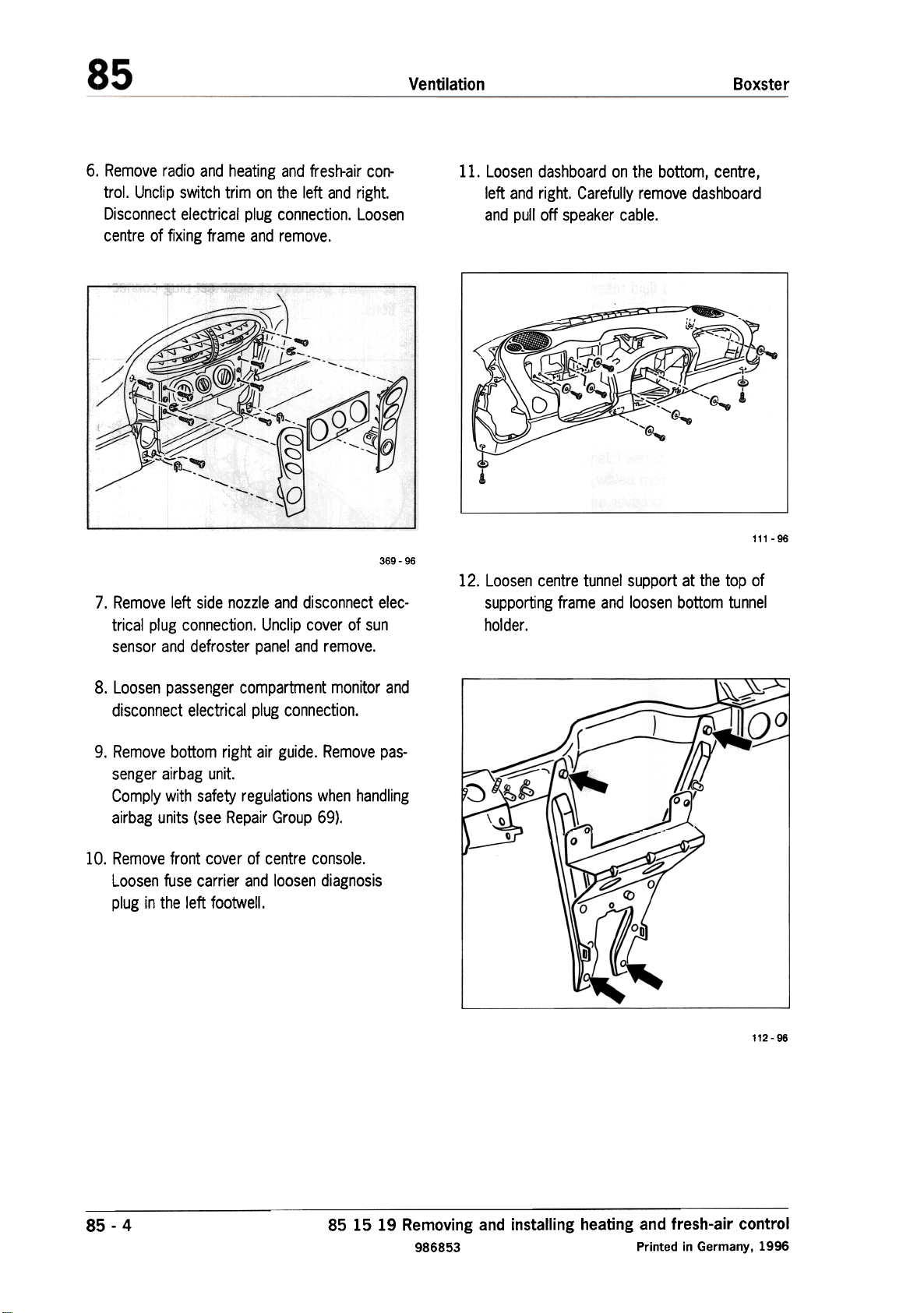

6. Remove radio and heating and fresh-air control. Unclip switch trim on the left and right.

Disconnect electrical plug connection. Loosen

centre of fixing frame and remove.

369-96

7. Remove left side nozzle and disconnect electrical plug connection. Unclip cover of sun

sensor and defroster panel and remove.

11. Loosen dashboard on the bottom, centre,

left and right. Carefully remove dashboard

and pull off speaker cable.

111 -96

12. Loosen centre tunnel support at the top of

supporting frame and loosen bottom tunnel

holder.

8. Loosen passenger compartment monitor and

disconnect electrical plug connection.

9. Remove bottom right air guide. Remove pas-

senger airbag unit.

Comply with safety regulations when handling

airbag units (see Repair Group 69).

10. Remove front cover of centre console.

Loosen fuse carrier and loosen diagnosis

plug in the left footwell.

"'""

l \ \)

--

A1co""'""'-"-"' c

-..co

112 -96

~

85 -4

85 15 19 Removing and installing heating and fresh-air control

986853 Printed in Germany, 1996

Page 12

Boxster

Ventilation

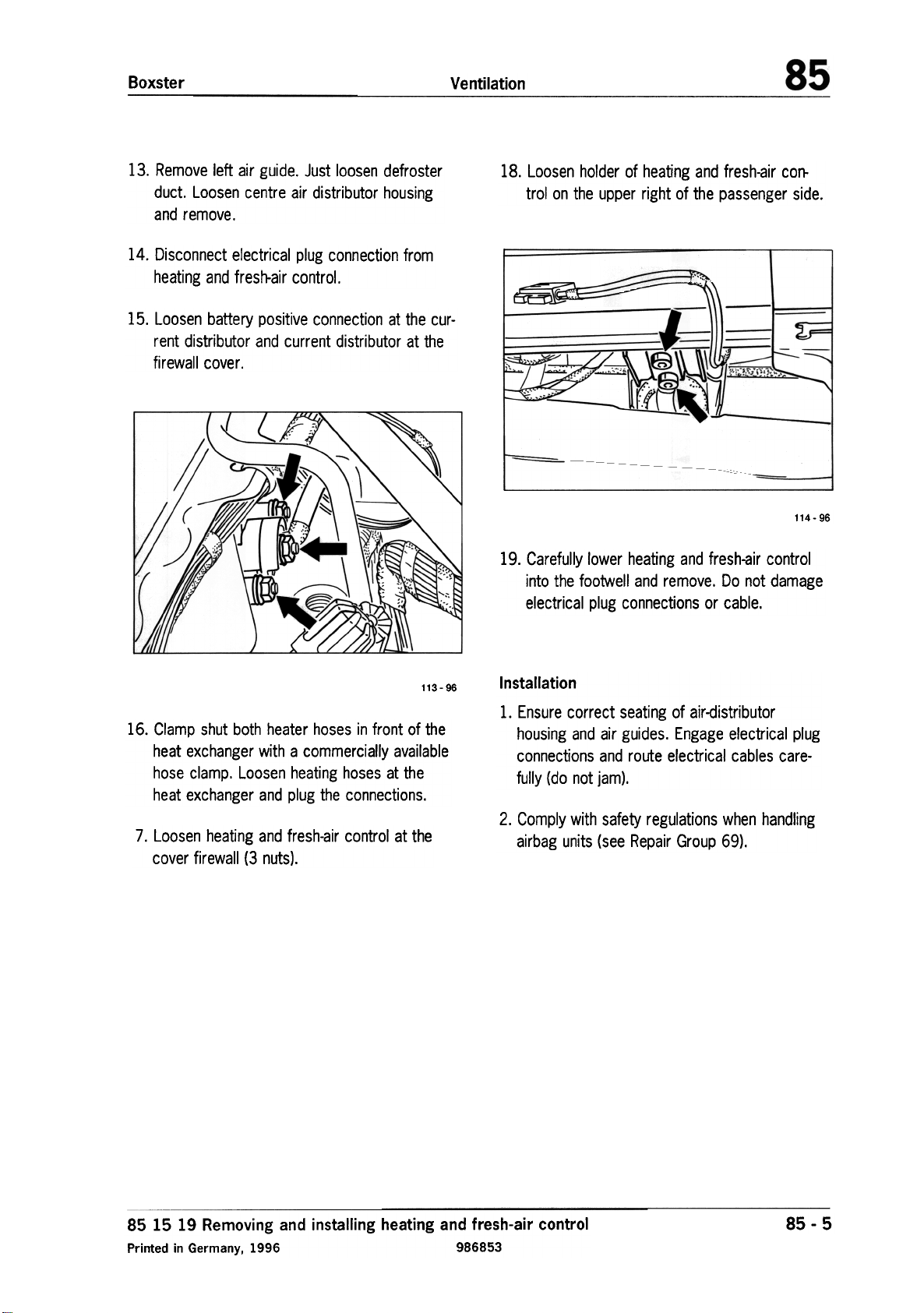

13. Remove left air guide. Just loosen defroster

duct. Loosen centre air distributor housing

and remove.

14. Disconnect electrical plug connection from

heating and fresh-air control.

15. Loosen battery positive connection at the current distributor and current distributor at the

firewall cover.

~

/

~

(

/

\"f;'

18. Loosen holder of heating and fresh-air control on the upper right of the passenger side.

~

--

---

:~"'~;~;;;/

114- 96

19. Carefully lower heating and fresh-air control

into the footwell and remove. Do not damage

electrical plug connections or cable.

/C/

113-96

16. Clamp shut both heater hoses in front of the

heat exchanger with a commercially available

hose clamp. Loosen heating hoses at the

heat exchanger and plug the connections.

7, Loosen heating and fresh-air control at the

cover firewall (3 nuts),

Installation

1. Ensure correct seating of air-distributor

housing and air guides. Engage electrical plug

connections and route electrical cables carefully (do not jam).

2. Comply with safety regulations when handling

airbag units (see Repair Group 69).

85 15 19 Removing and installing heating and fresh-air control

Printed in Germany, 1996 986853

85 -5

Page 13

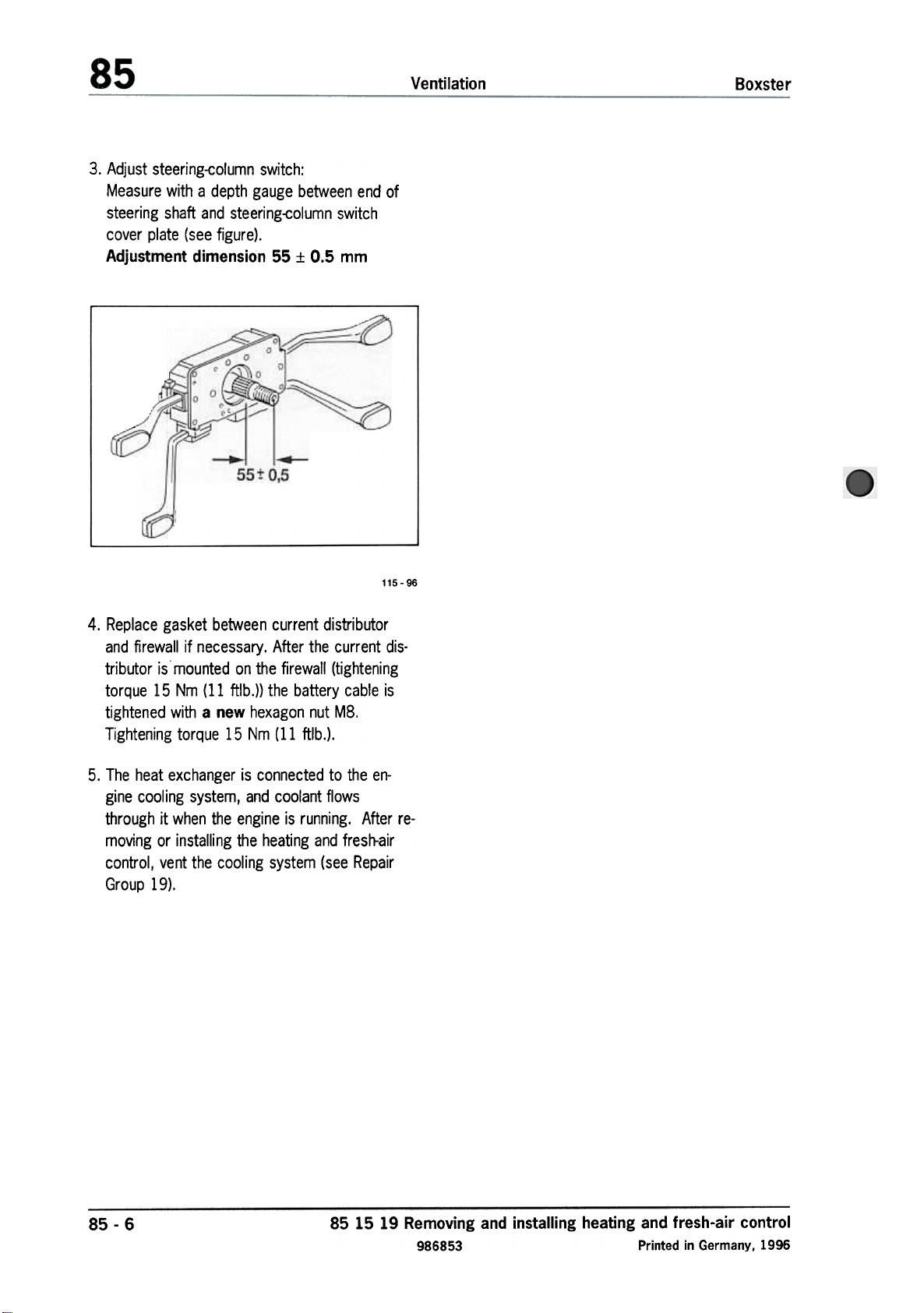

3. Adjust steering-column switch:

Measure with a depth gauge between end of

steering shaft and steering-column switch

cover plate (see figure).

Adjustment dimension 55 :t 0.5 mm

Ventilation

Boxster

4. Replace gasket between current distributor

and firewall if necessary. After the current dis-

tributor is mounted on the firewall (tightening

torque 15 Nm (11 ftlb.)) the battery cable is

tightened with a new hexagon nut M8.

Tightening torque 15 Nm (11 ftlb.).

5. The heat exchanger is connected to the engine cooling system, and coolant flows

through it when the engine is running. After removing or installing the heating and fresh-air

control, vent the cooling system (see Repair

Group 19).

115 -96

85-6

85 15 19 Removing and installing heating and fresh-air control

986853 Printed in Germany, 1996

Page 14

Boxster

Ventilation

85 11 06

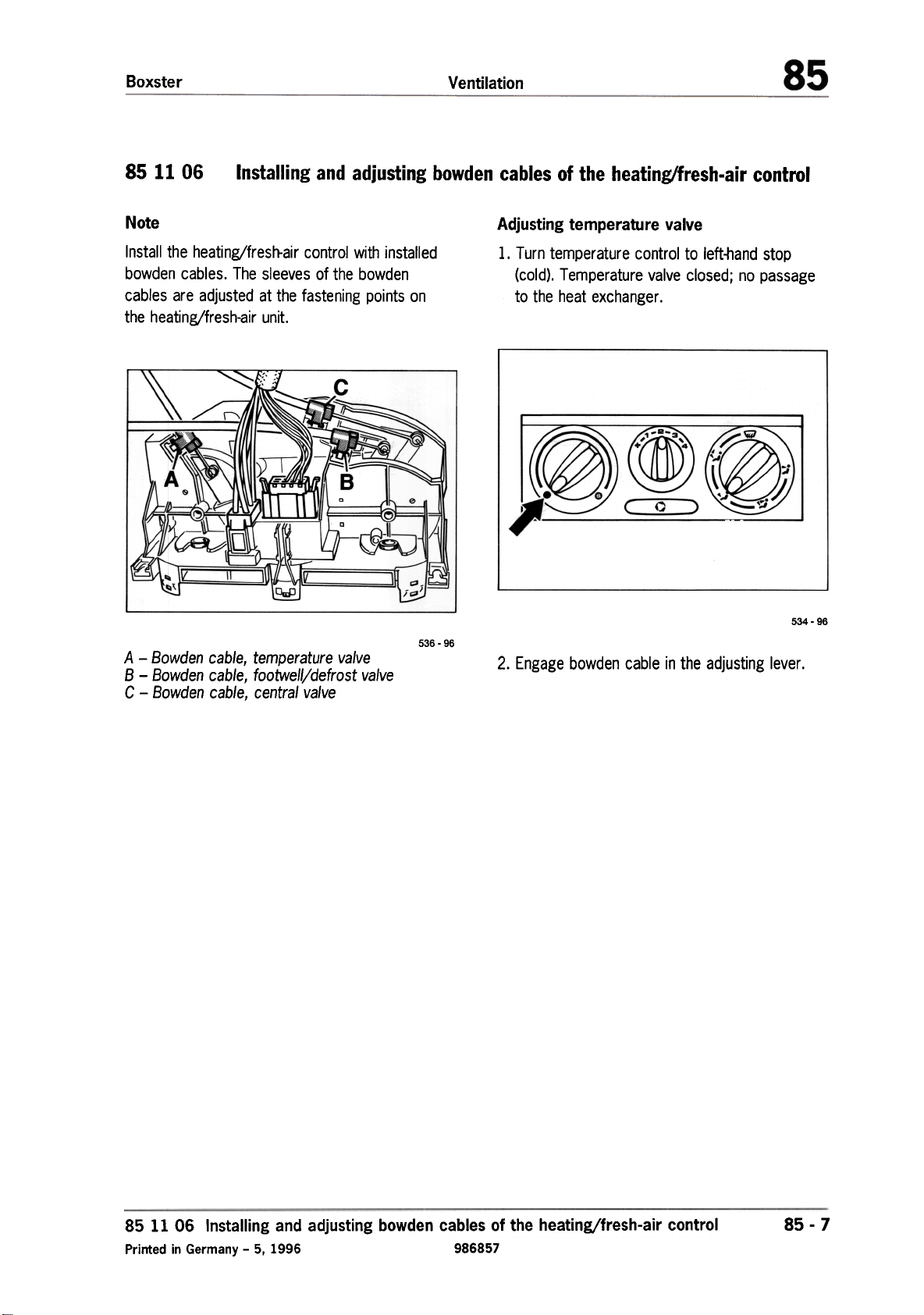

Note

Install the heating/fresh-air control with installed

bowden cables. The sleeves of the bowden

cables are adjusted at the fastening points on

the heating/fresh-air unit.

Installing and adjusting bowden cables of the heating/fresh-air control

c

A

...

/"

B

0

\\

h

~I

00

A -Bowden cable, temperature valve

B -Bowden cable, footwelVdefrost valve

C -Bowden cable, central valve

"';~

536 -96

Adjusting temperature valve

1. Turn temperature control to left-hand stop

(cold). Temperature valve closed; no passage

to the heat exchanger.

534 -96

2. Engage bowden cable in the adjusting lever.

~

,"-~

85 11 06 Installing and adjusting bowden cables of the heating/fresh-air control

Printed in Germany -5, 1996 986857

85 -7

Page 15

Ventilation

Boxster

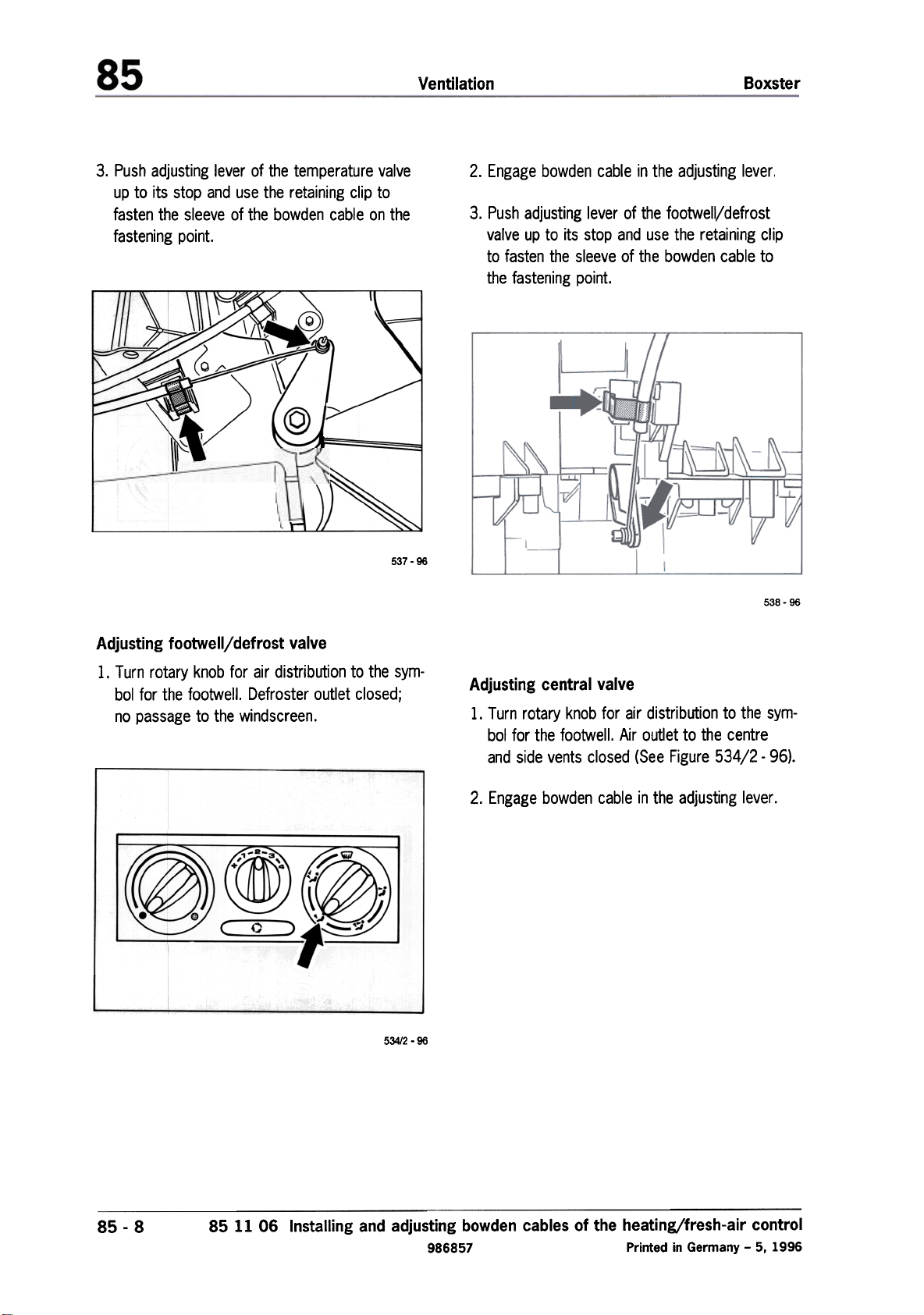

3. Push adjusting lever of the temperature valve

up to its stop and use the retaining clip to

fasten the sleeve of the bowden cable on the

fastening point.

\)

~(o))

IU-

y

://:

')

/"

-/

537 -96

2. Engage bowden cable in the adjusting lever.

3. Push adjusting lever of the footwelljdefrost

valve up to its stop and use the retaining clip

to fasten the sleeve of the bowden cable to

the fastening point.

538 -96

Adjusting footwelljdefrost valve

1. Turn rotary knob for air distribution to the symbol for the footwell. Defroster outlet closed;

no passage to the windscreen.

53412 -96

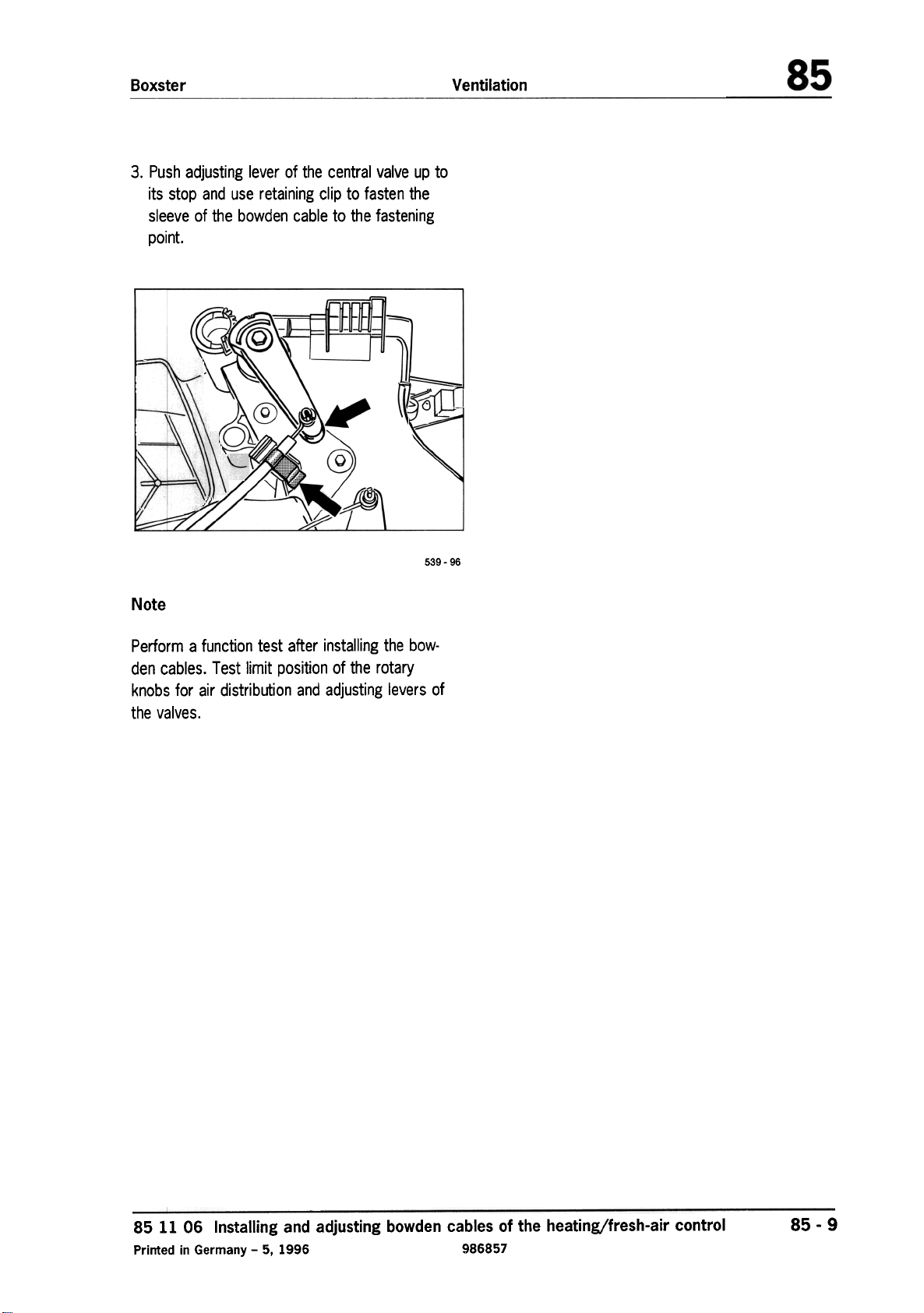

Adjusting central valve

1. Turn rotary knob for air distribution to the symbol for the footwell. Air outlet to the centre

and side vents closed (See Figure 534/2 -96).

2. Engage bowden cable in the adjusting lever.

~

85-8

85 11 06 Installing and adjusting bowden cables of the heating/fresh-air control

986857 Printed in Germany -5, 1996

Page 16

3. Push adjusting lever of the central valve up to

its stop and use retaining clip to fasten the

sleeve of the bowden cable to the fastening

point.

~

VentilationBoxster

539 -96

Note

Perform a function test after installing the bowden cables. Test limit position of the rotary

knobs for air distribution and adjusting levers of

the valves.

85 11 06 Installing and adjusting bowden cables of the heating/fresh-air control

Printed in Germany -5, 1996 986857

85 -9

Page 17

VentilationBoxster

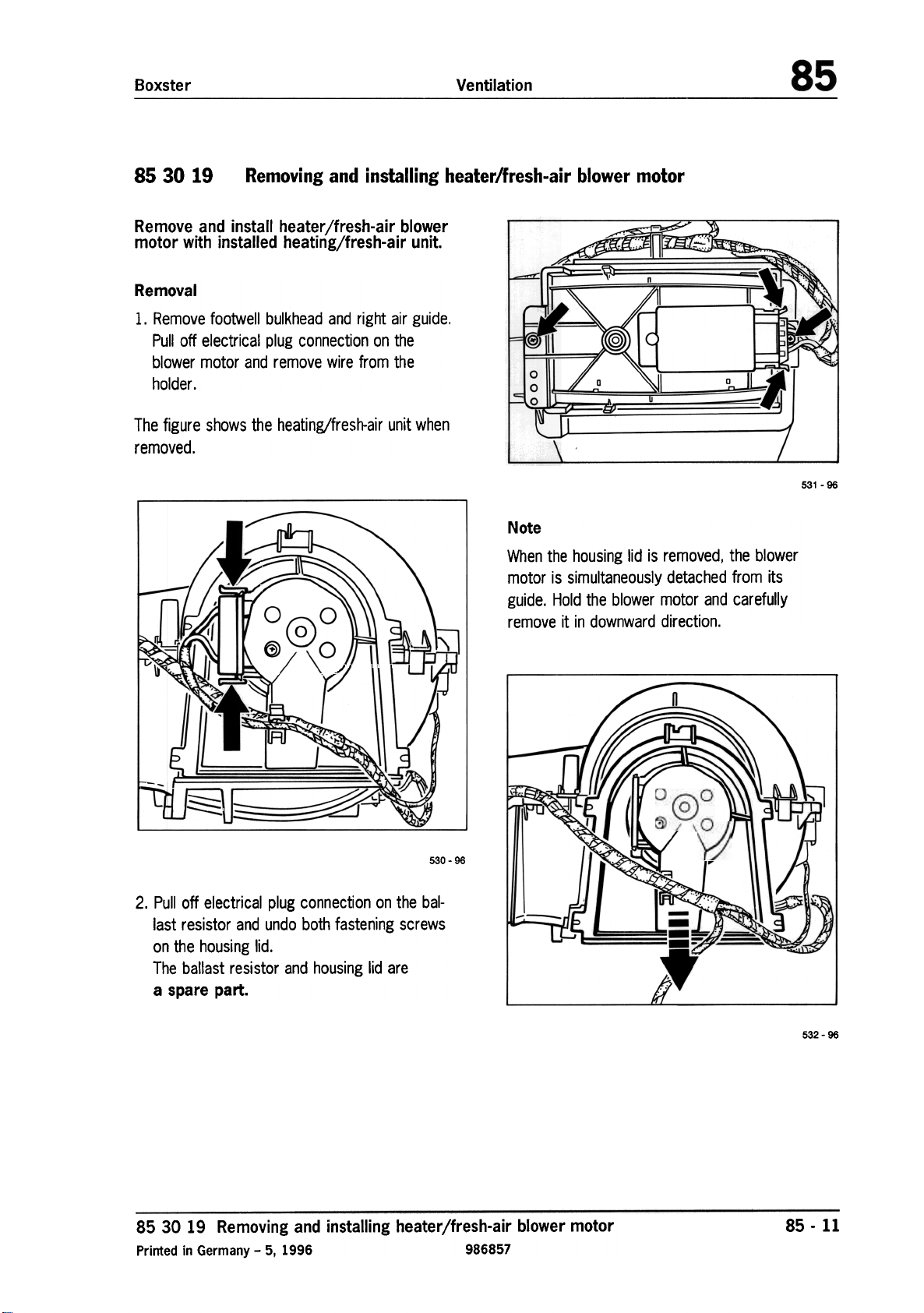

85 30 19 Removing and installing heater/fresh-air blower motor

Remove and install heater/fresh-air blower

motor with installed heating/fresh-air unit.

Removal

1. Remove footwell bulkhead and right air guide.

Pull off electrical plug connection on the

blower motor and remove wire from the

holder.

The figure shows the heating/fresh-air unit when

removed.

Note

531 -96

""""

J'

cb

j

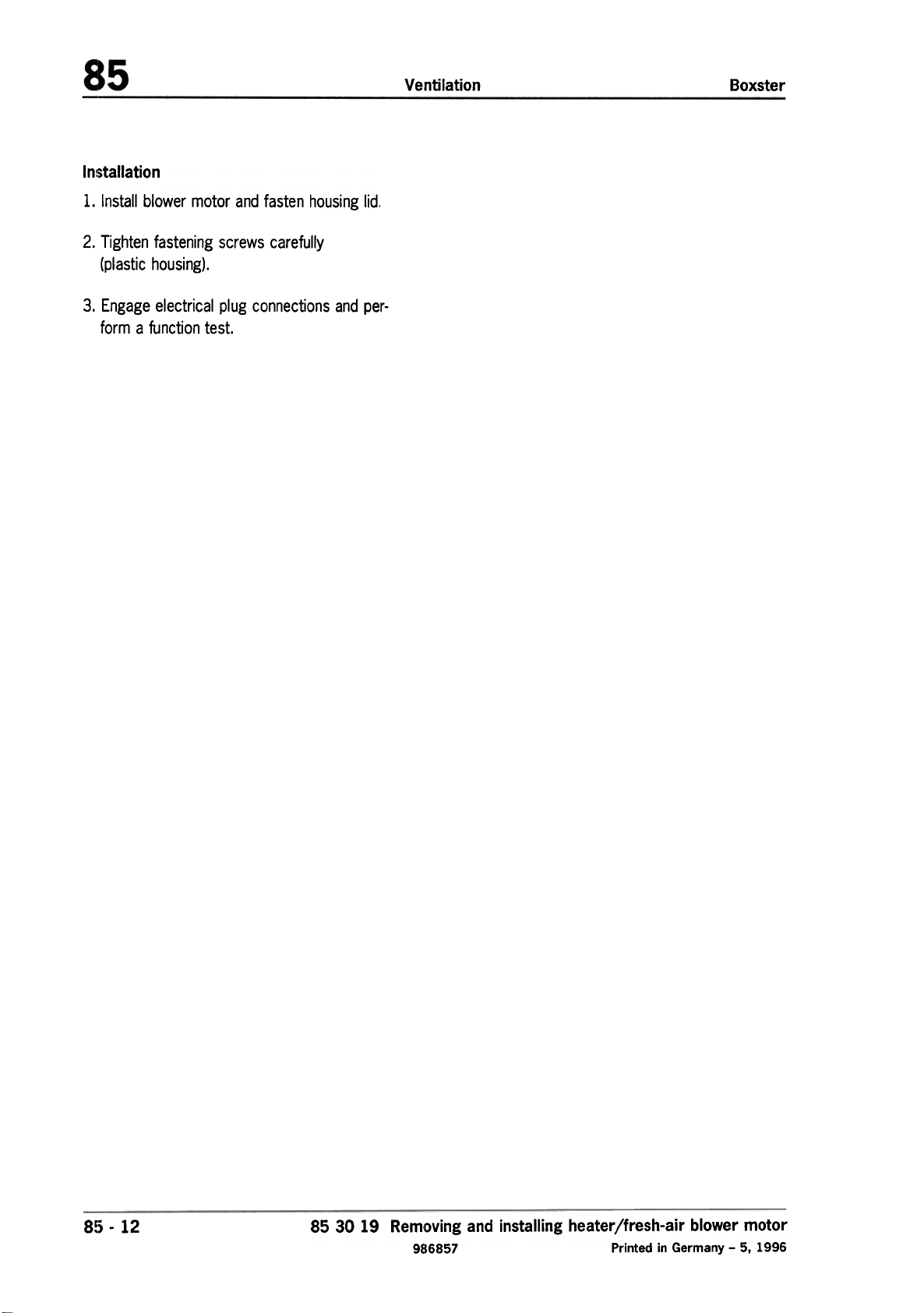

530-96

2. Pull off electrical plug connection on the bal-

last resistor and undo both fastening screws

on the housing lid.

The ballast resistor and housing lid are

a spare part.

When the housing lid is removed, the blower

motor is simultaneously detached from its

guide. Hold the blower motor and carefully

remove it in downward direction.

~

-

-

I~

a

{/

,hr~

;-

85 30 19 Removing and installing heater/fresh-air blower motor

Printed in Germany -5, 1996 986857

532-96

85 -11

Page 18

In!;tallation

1. Install blower motor and fasten housing lid,

2. Tighten fastening screws carefully

(plastic housing).

3. Engage electrical plug connections and perform a function test.

Ventilation

Boxster

8~) -12

85 30 19 Removing and installing heater/fresh-air blower motor

986857 Printed in Germany -5, 1996

Page 19

Boxster

Ventilation

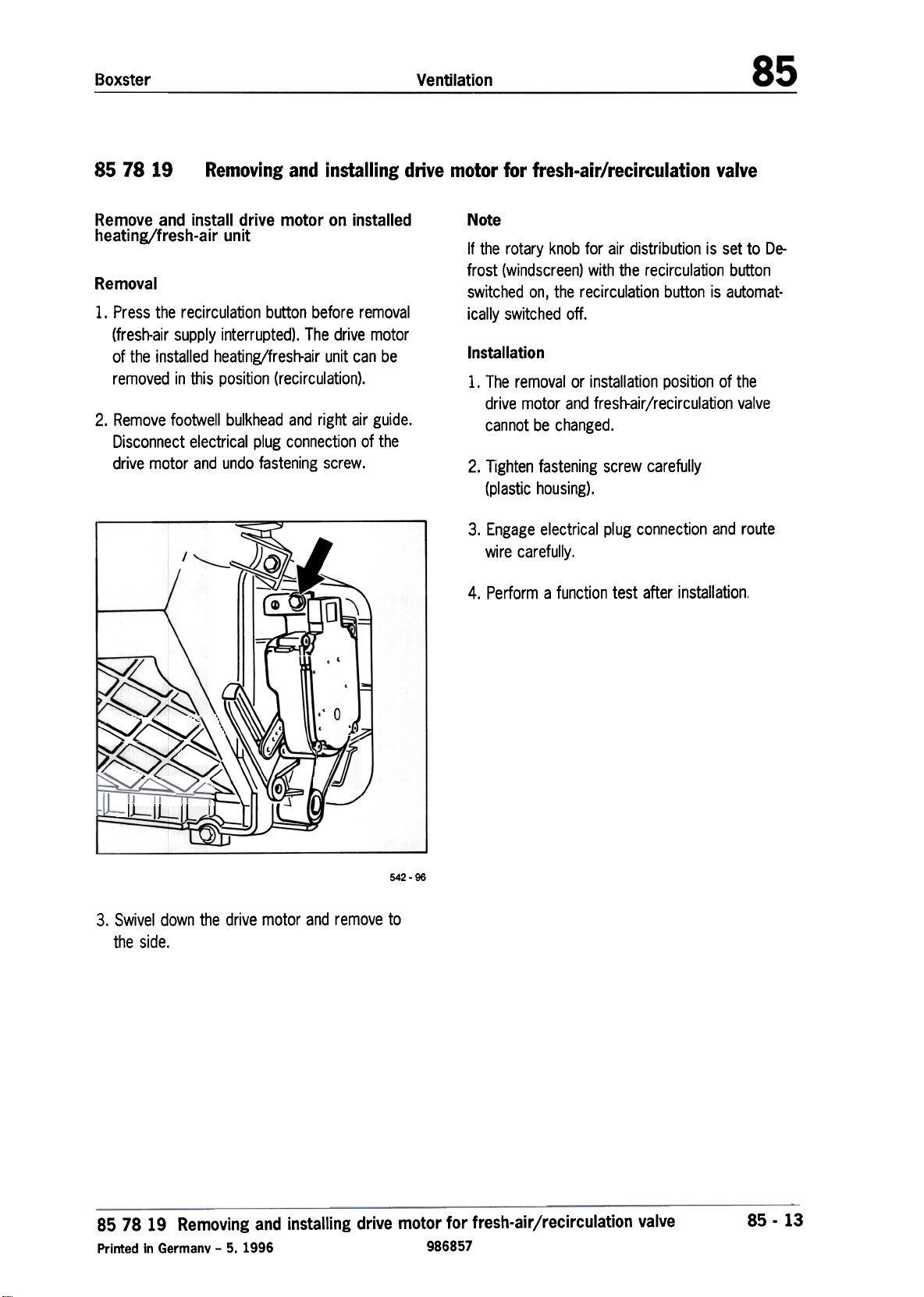

85 78 19 Removing and installing drive motor for fresh-air/recirculation valve

I~emove and install drive motor on installed

heating/fresh-air unit

Removal

1. Press the recirculation button before removal

(fresh-air supply interrupted), The drive motor

of the installed heating/fresh-air unit can be

removed in this position (recirculation).

2. Remove footwell bulkhead and right air guide.

Disconnect electrical plug connection of the

drive motor and undo fastening screw.

/ '-

I

~~~'-

Note

If the rotary knob for air distribution is set to Defrost (windscreen) with the recirculation button

switched on, the recirculation button is automat-

ically switched off.

Installation

1. The removal or installation position of the

drive motor and fresh-air/recirculation valve

cannot be changed.

2. Tighten fastening screw carefully

(plastic housing),

3. Engage electrical plug connection and route

wire carefully.

4. Perform a function test after installation.

~

-<

~

542 -96

3. Swivel down the drive motor and remove to

the side.

85 78 19 Removing and installing drive motor for fresh-air/recirculation valve

Printed in Germany -5. 1996 986857

85 -13

Page 20

Boxster

Ventilation

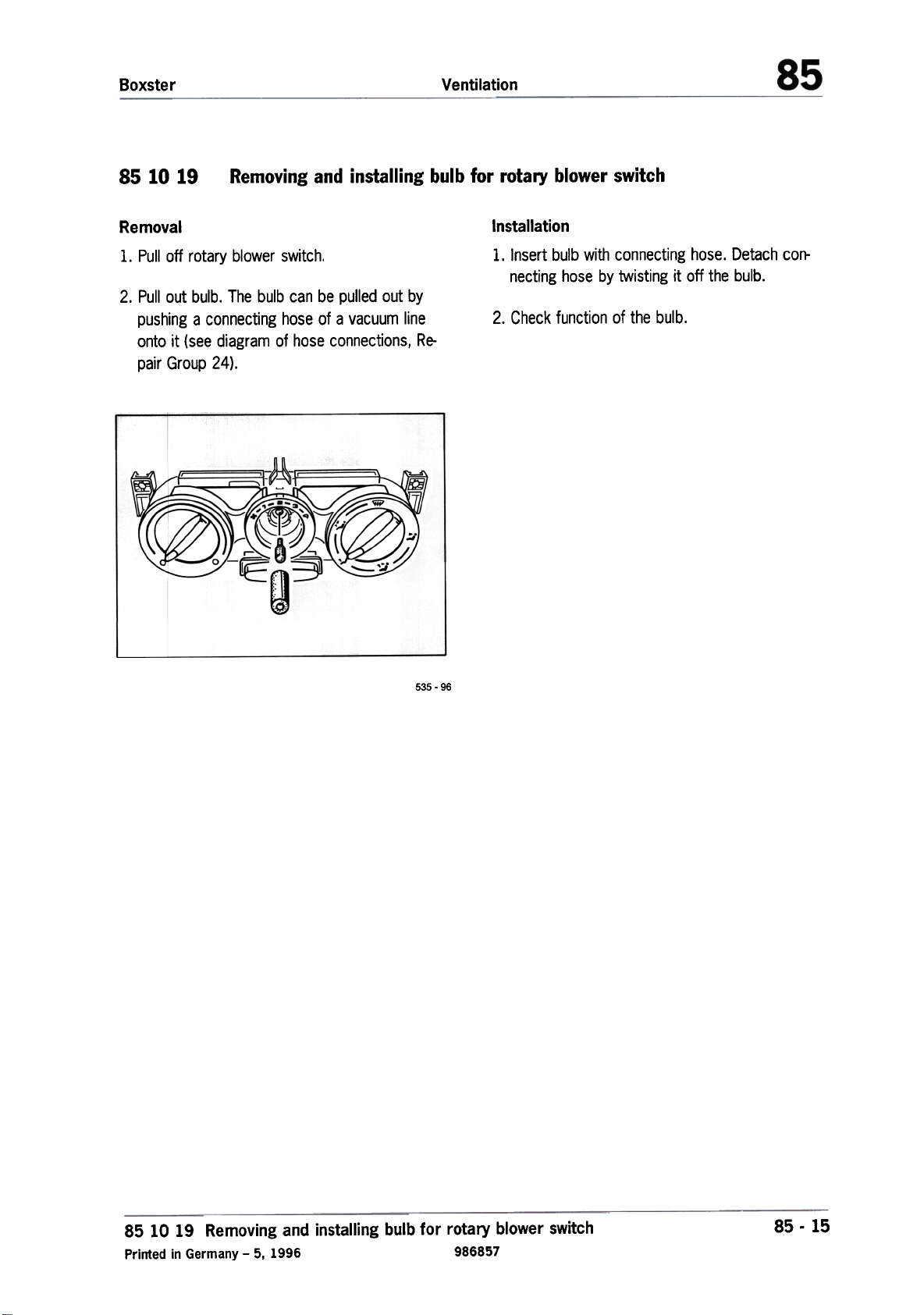

85 10 19

Removal

Removing and installing bulb for rotary blower switch

1. Pull off rotary blower switch.

2. Pull out bulb. The bulb can be pulled out by

pushing a connecting hose of a vacuum line

onto it (see diagram of hose connections, Re-

pair Group 24).

Installation

1. Insert bulb with connecting hose. Detach connecting hose by twisting it off the bulb.

2. Check function of the bulb.

535 -96

85 10 19 Removing and installing bulb for rotary blower switch

Printed in Germany -5, 1996 986857

85 -15

Page 21

Boxster

Air conditioning

8703

The refrigerant R 134a which is used is known

as a safety refrigerant. This means that this refrigerant is non-flammable, non-explosive, nontoxic, non-irritating, odorless and tasteless. Des-

pite this, you should still follow the points below.

1. Avoid all contact with liquid or gaseous refrigerants. Treat affected skin in the same way as

in the case of freezing. Rinse immediately with

cold water and then consult a physician. Wear

safety goggles to protect your eyes. If refrige-

rant still gets in your eyes, consult a physician

immediately. Wear rubber gloves to protect

your hands.

2. When carrying out repairs on the air-conditioning system, the system must be emptied by

suction and the refrigerant must be purified.

Chlorine-free refrigerants must also not be

allowed to escape into the atmosphere and

must be disposed of correctly.

Due to their chemical composition, different refrigerants must not be mixed with each other

(not even in small quantities),

Safety regulations when handling refrigerant R 134a

4. Refrigerant bottles must not be thrown and

must not be subjected to direct sunlight or

other heat sources for an extended period

when full. The maximum permissible temperature of a filled refrigerant bottle must not ex-

ceed 45 °C.

3. Never perform welding work on parts of the

closed air-conditioning system or in its immediate vicinity. Whether or not the system is filled

with refrigerant, the heating causes a very

strong overpressure which can cause damage

to the system or even lead to an explosion.

R 134a is completely non-toxic at normal tem-

peratures, but it decomposes upon contact

with a flame or at high temperatures.

87 03 Safety regulations when handling refrigerant R 134a

Printed in Germany -1996 986871

87. 1

Page 22

Air conditioning

Boxster

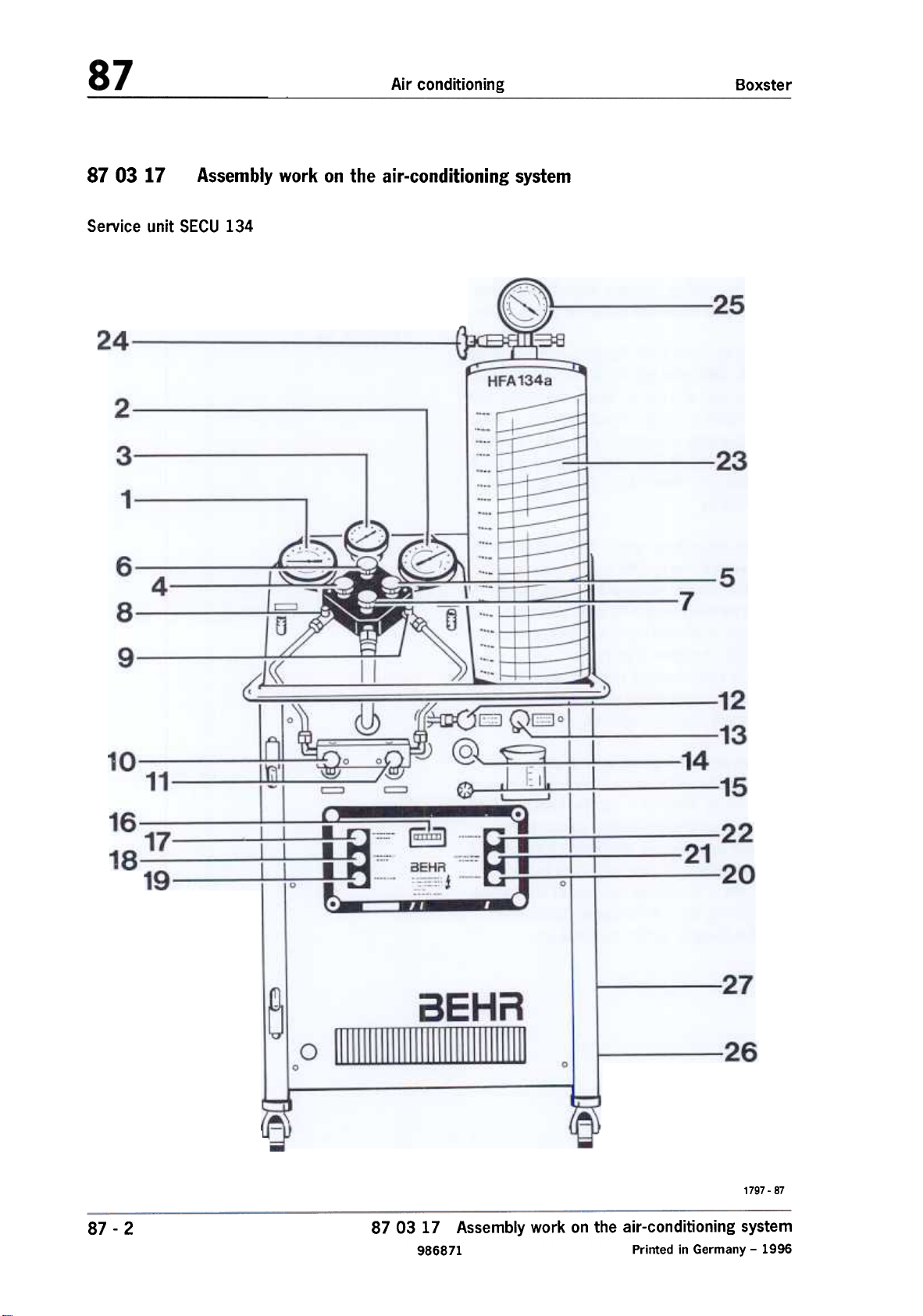

87 03 17

Service unit SECU 134

Assembly work on the air-conditioning system

87-2

1797 -87

87 03 17 Assembly work on the air-conditioning system

986871 Printed in Germany -1996

Page 23

Boxster

Air conditioning

1 -Low-pressure pressure gauge

2 -High-pressure pressure gauge

3 -Torr meter

4 -Low-pressure shut-off valve (blue)

5 -High-pressure shut-off valve (red)

6 -Torr meter shut-off valve (black)

7 -Vacuum pump shut-off valve (yellow)

8 -Low-pressure flange

9 -High-pressure flange

10 -Refrigerant inlet shut-off valve

11 -Refrigerant outlet shut-off valve

23 -Filling cylinder with weight scale

24 -Filling cylinder shut-off valve

25 -Filling cylinder high-pressure gauge

26 -Refrigerant oil suction nozzle

27 -Refrigerant oil reservoir inspection glass

Note

The manufacturer's operating and repair instruc.

tions must be observed when carrying out all

work on the service unit.

12 -Refrigerant oil inlet shut-off valve

13 -Refrigerant oil vent valve

14 -Moisture indicator

15 -Oil tank vacuum flange

16 -Hourmeter

17 -Pilot light SUCTION END

18 -Pressure switch SUCTION/CLEANING

19 -Main switch ON/OFF

20 -Pressure switch HEATING

21 -Pilot light FAULT

22 -Pressure switch VACUUM PUMP

87 03 17 Assembly work on the air-conditioning system

Printed in Germany -1996 986871

87-3

Page 24

Air conditioning

Boxster

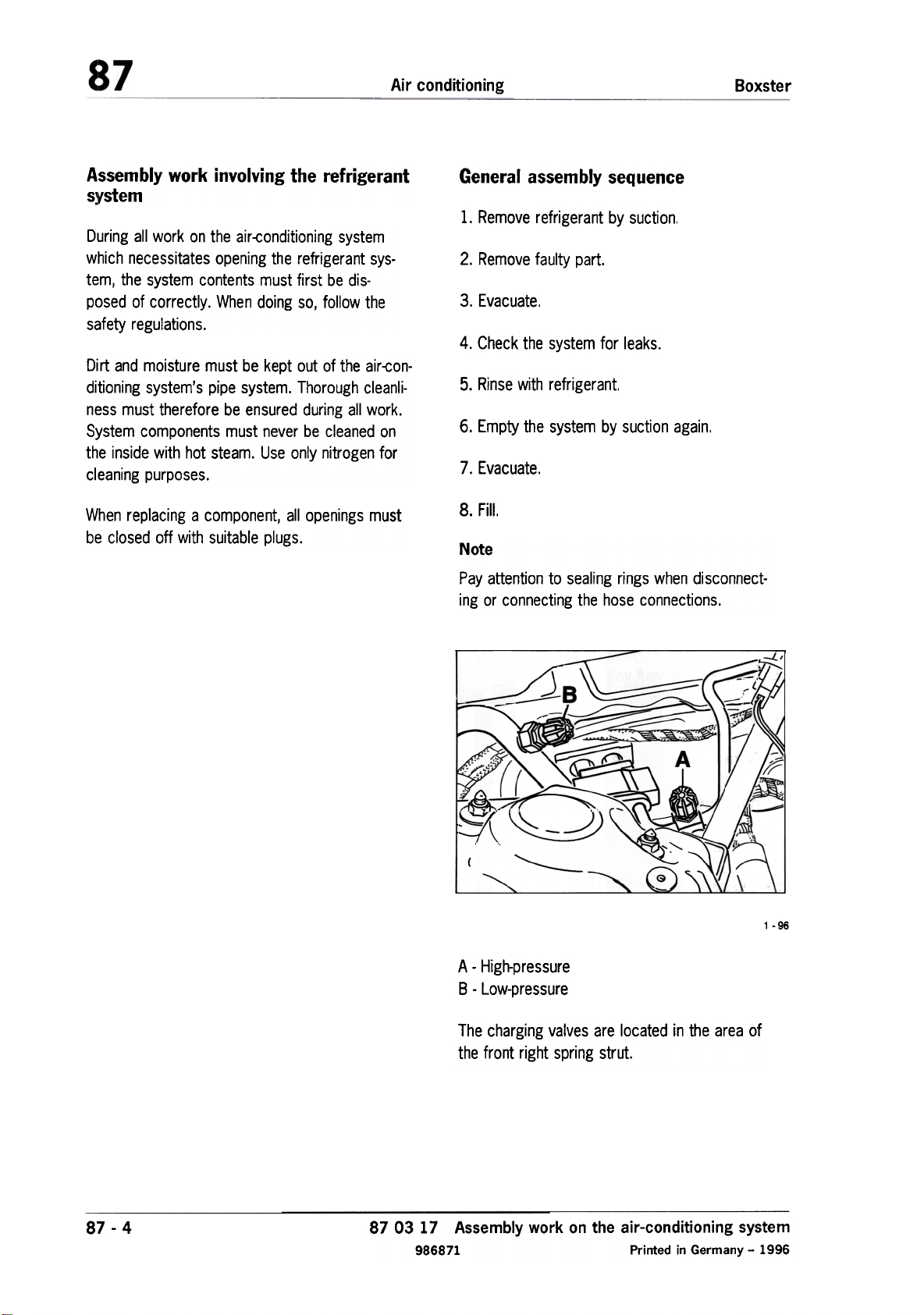

Assembly work involving the refrigerant

system

During all work on the air-conditioning system

which necessitates opening the refrigerant sys-

tem, the system contents must first be dis-

posed of correctly. When doing so, follow the

safety regulations.

Dirt and moisture must be kept out of the air-conditioning system's pipe system. Thorough cleanliness must therefore be ensured during all work.

System components must never be cleaned on

the inside with hot steam. Use only nitrogen for

cleaning purposes.

When replacing a component, all openings must

be closed off with suitable plugs.

General assembly sequence

1. Remove refrigerant by suction.

2. Remove faulty part.

3. Evacuate.

4. Check the system for leaks.

5. Rinse with refrigerant.

6. Empty the system by suction again.

7. Evacuate.

Fill.

Note

Pay attention to sealing rings when disconnect-

ing or connecting the hose connections.

~

A

I;

,

:

/

\.

A -High-pressure

B -Low-pressure

The charging valves are located in the area of

the front right spring strut.

1 -96

87-4

8.

~::.~:::::::::=::::=:::.;.,,-'

~~~

87 03 17 Assembly work on the air-conditioning system

986871 Printed in Germany -1996

Page 25

Boxster

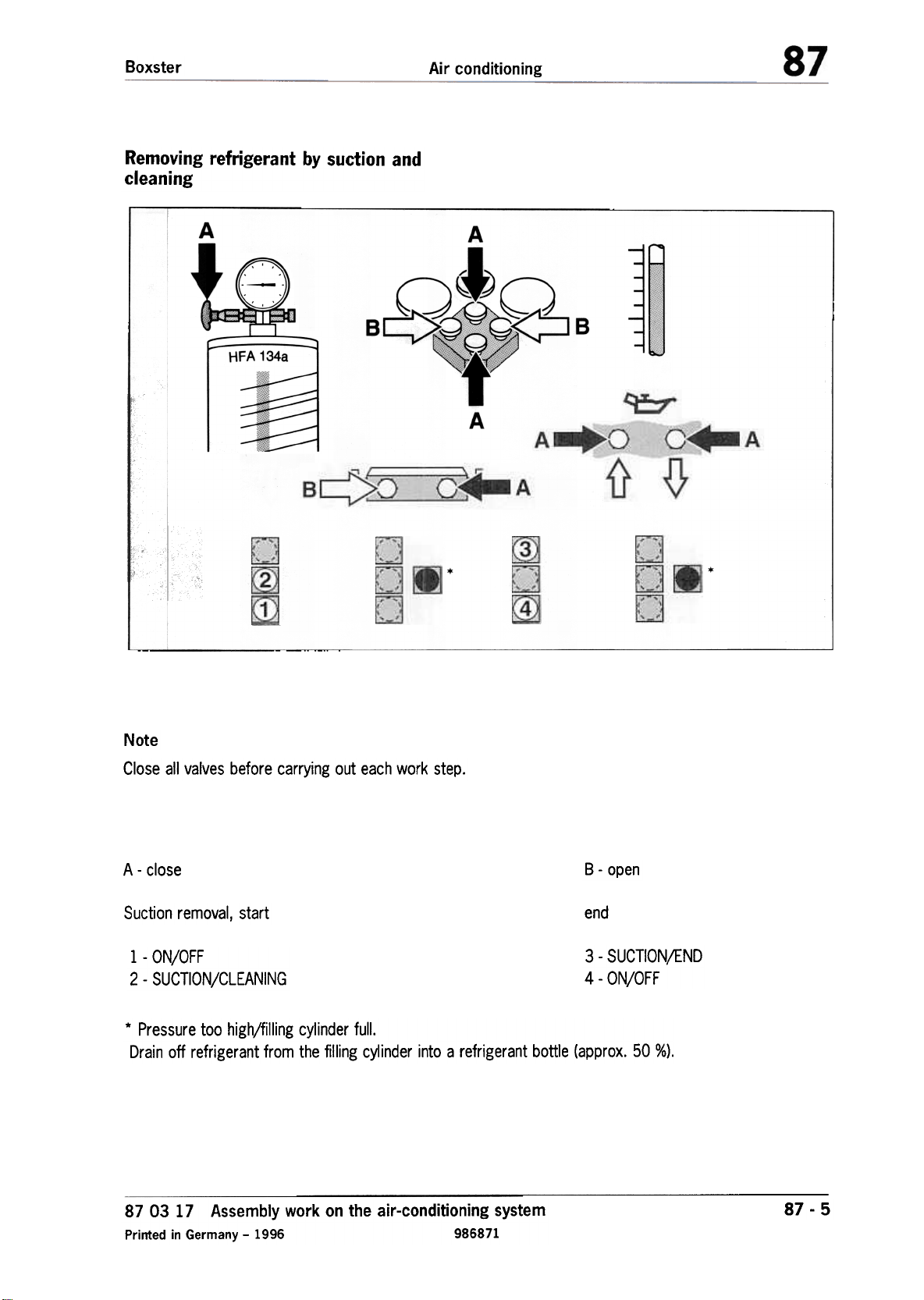

Removing refrigerant by suction and

cleaning

Air conditioning

A

A

B

A

Note

Close all valves before carrying out each work step.

A-close

Suction removal, start

1 -ON/OFF

2 -SUCTION/CLEANING

* Pressure too high/filling cylinder full.

Drain off refrigerant from the filling cylinder into a refrigerant bottle (approx. 50 %).

B -open

end

3 -SUCTIONjEND

4 -ON/OFF

87 03 17 Assembly work on the air-conditioning system

Printed in Germany -1996 986871

87-5

Page 26

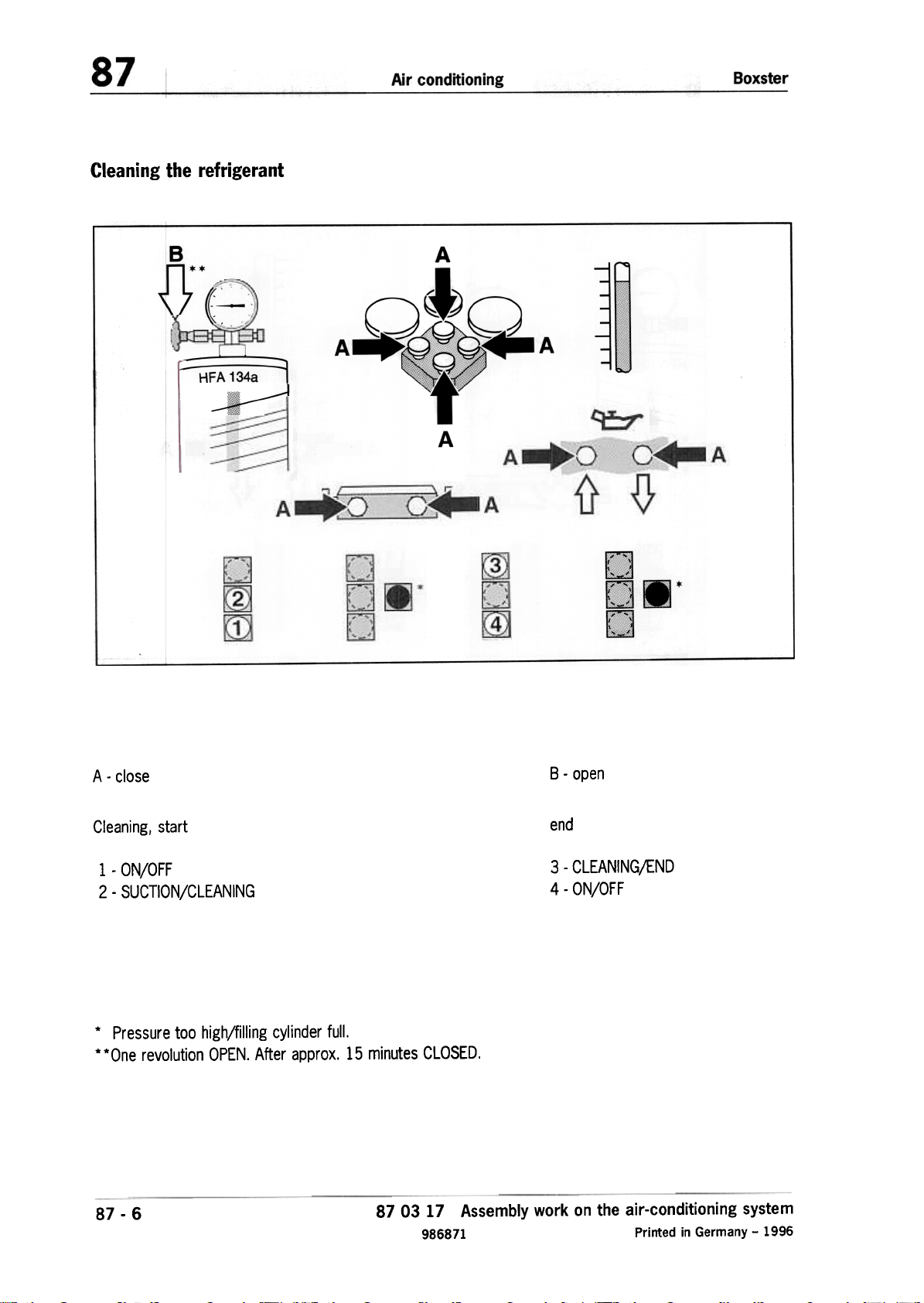

(:Ieaning the refrigerant

BJJ'(-..

.:::::~~~~~=~

A

A

A

A-close

Cleaning, start

1 -ON/OFF

2 -SUCTION/CLEANING

* Pressure too high/filling cylinder full.

**One revolution OPEN. After approx. 15 minutes CLOSED.

87 -6

87 03 17 Assembly work on the air-conditioning system

986871 Printed in Germany -1996

B -open

end

3 -CLEANING/END

4 -ON/OFF

Page 27

Boxster

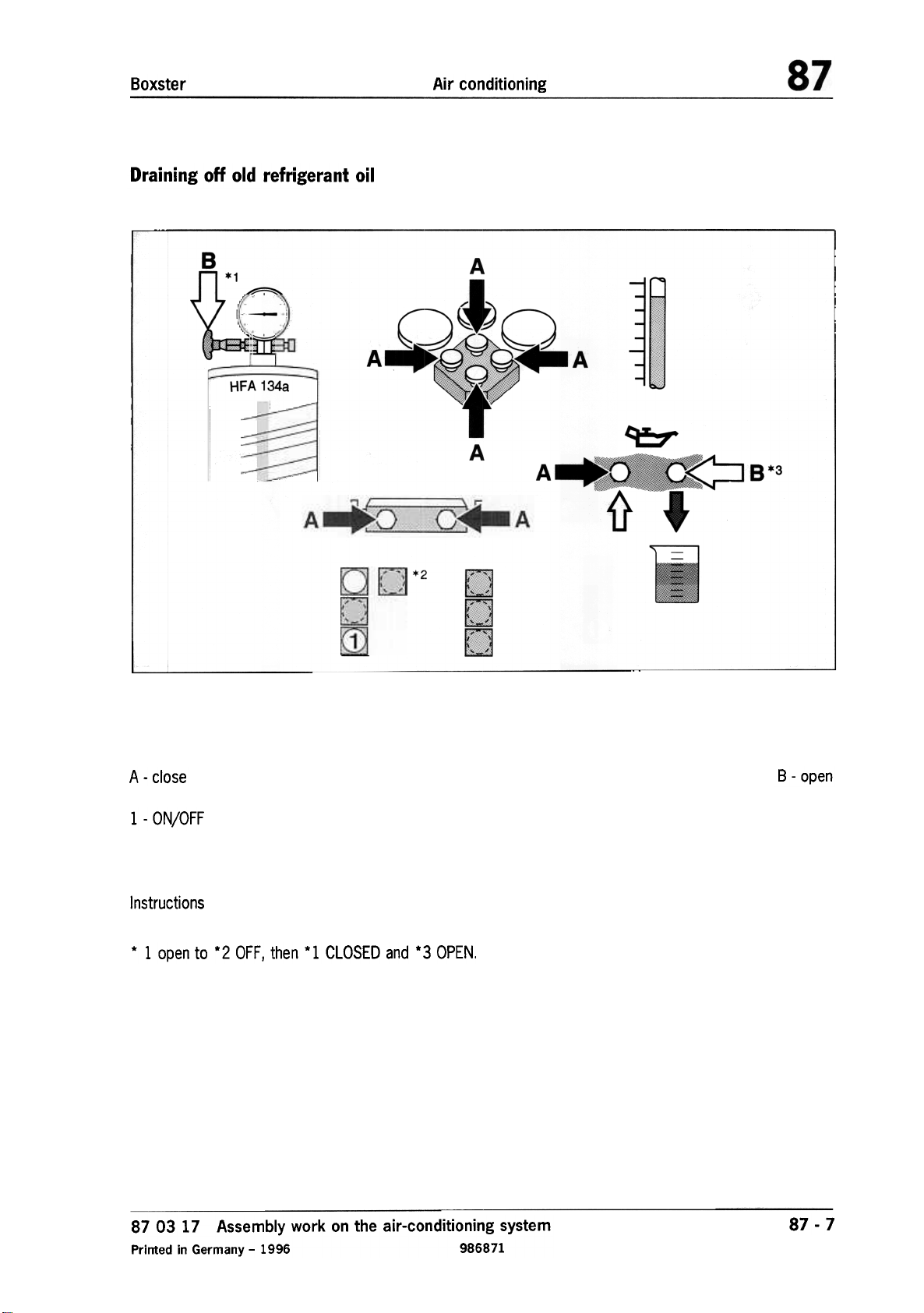

Draining off old refrigerant oil

Air conditioning

B

A

~

-

~

m

HFA 134a

~.

A

A 8*3

"1} """'f

*2

A -close

1 -ON/OFF

Instructions

* 1 open to *2 OFF, then *1 CLOSED and *3 OPEN.

87 03 17 Assembly work on the air-conditioning system

Printed in Germany -1996 986871

B -open

87-7

Page 28

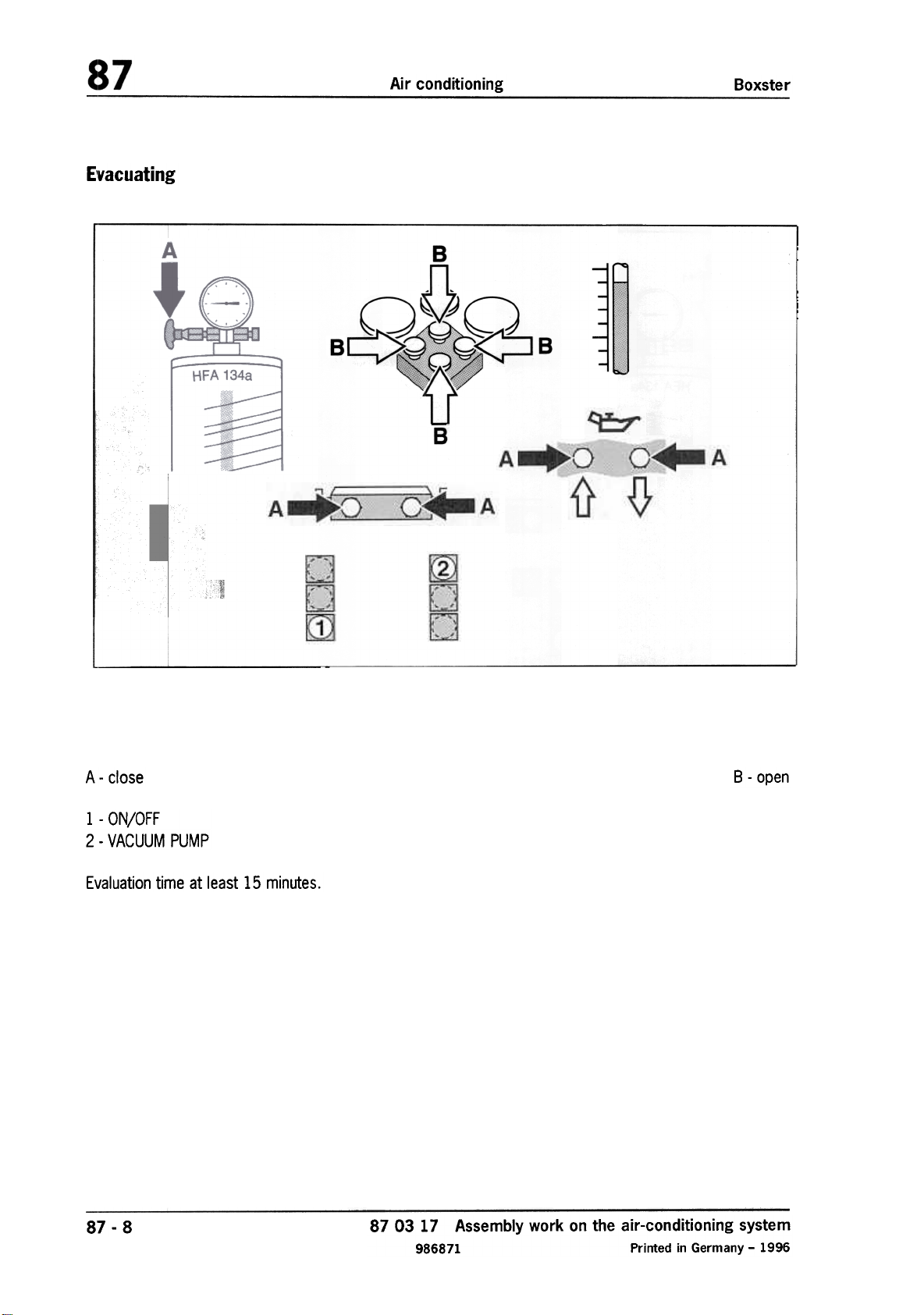

E'vacuating

Air conditioning

B

Boxster

B

A -close B -open

1 -ON/OFF

2 -VACUUM PUMP

Evaluation time at least 15 minutes.

87 -8

87 03 17 Assembly work on the air-conditioning system

986871 Printed in Germany -1996

Page 29

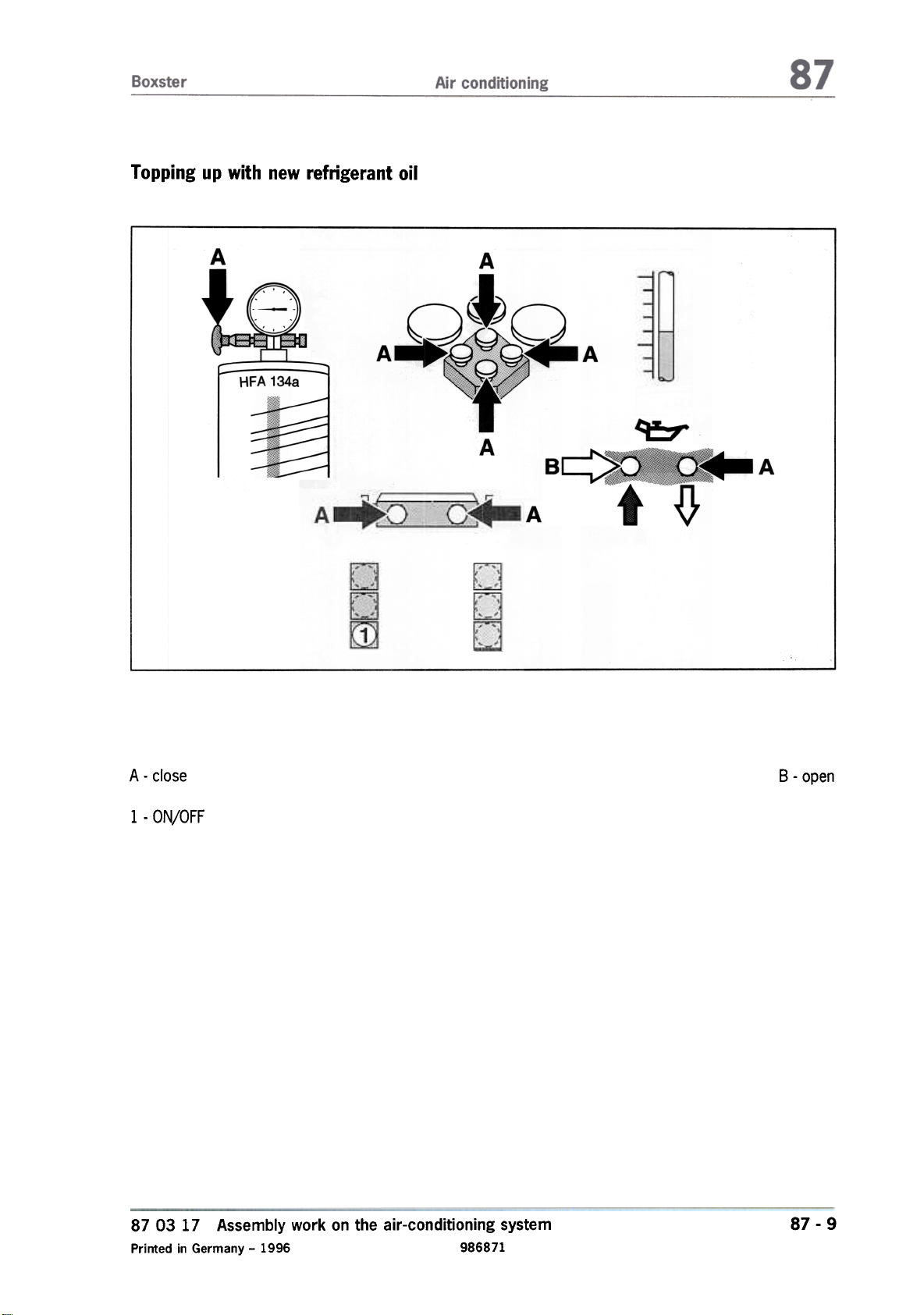

Topping up with new refrigerant oil

A

A

A -close

1 -ON/OFF

87 03 17 Assembly work on the air-conditioning system

Printed in Germany -1996 986871

B -open

87 -9

Page 30

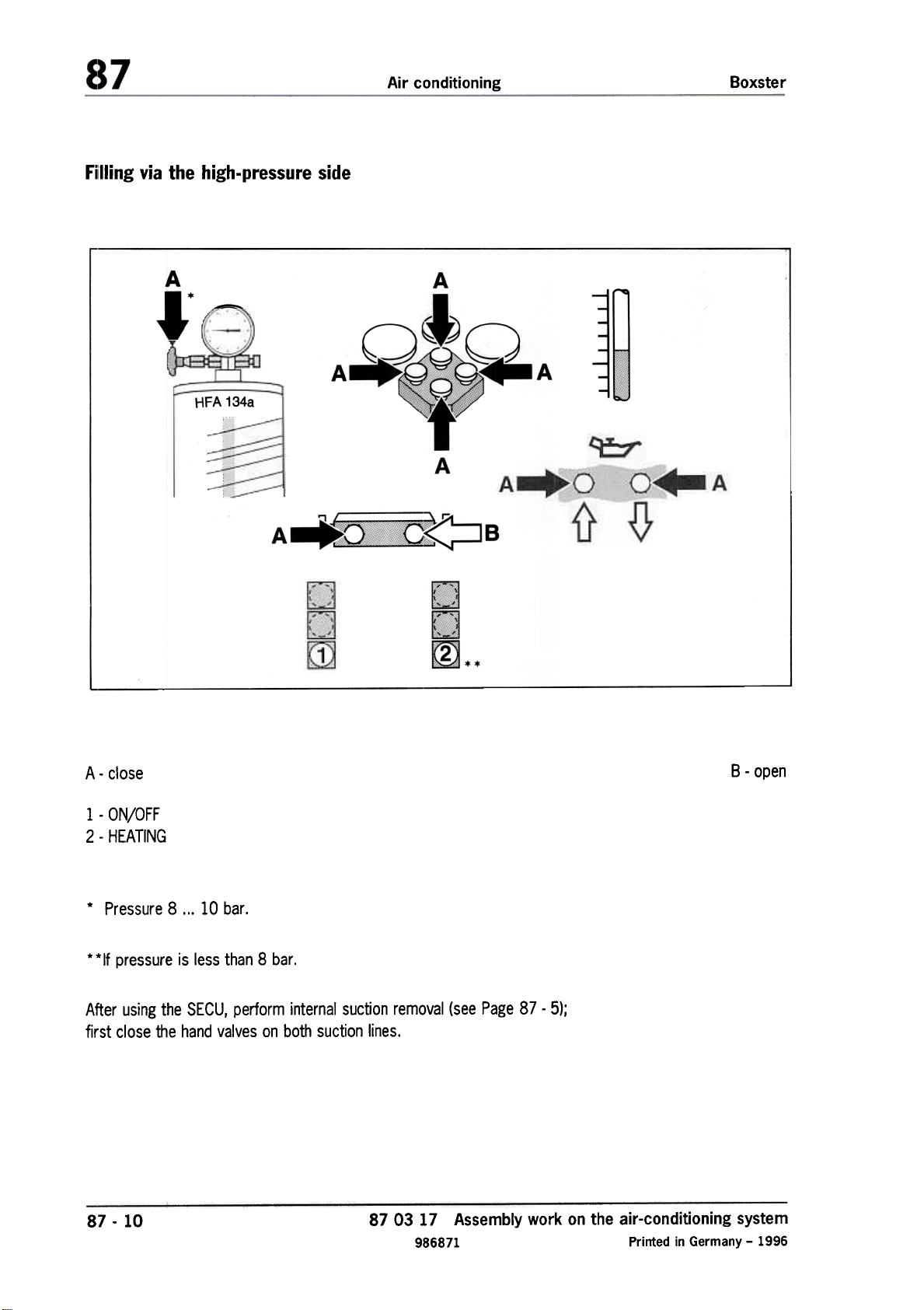

Filling via the high-pressure side

Air conditioning

Boxster

AI'

A

.-.

-

HFA 134a

A

A -close

1 -ON/OFF

2 -HEATING

* Pressure 8 ...10 bar.

* * If pressure is less than 8 bar.

After using the SECU, perform internal suction removal (see Page 87 -5);

first close the hand valves on both suction lines.

87 -10

87 03 17 Assembly work on the air-conditioning system

986871 Printed in Germany -1996

B -open

m

Page 31

Boxster Air conditioning

Refilling the air-conditioning system

Note

In the event of insufficient refrigeration

performance, remove the refrigerant by suction,

top up with the stipulated quantity and check the

system for leaks.

1. Remove the refrigerant by suction using the

service unit.

2. Determine the refrigerant oil quantity after the

refrigerant has been removed by suction.

3. Fill up with new refrigerant oil.

4. Evacuate.

5. Fill with the stipulated amount of refrigerant.

6. Check the system for leaks,

87 03 17 Assembly work on the air-conditioning system

Printed in Germany -16, 1997 986871

87 -11

Page 32

Distribution of the oil quantity in the refrigerant circuit

Total oil quantity

195:t 15 cm3

After suction removal from the system, the

following quantities remain in the

condenser 2 x 20 cm3

evaporator

approx. 40 cm3

approx. 30 cm3

fluid tank

with lines

compressor

approx. 30 cm3

approx. 50 cm3

circulating oil quantity

in the refrigerant circuit

approx. 60 cm3

Note

In new vehicles, the amount of oil removed by

suction is approx. 15 ...40 cm3.

Oil removed by suction must be returned to the

system.

Refrigerant oil removed from a previously run

air-conditioning system may no longer be used

(special-category waste).

After the refrigerant has been removed by

suction and a component has been replaced,

the oil quantity must be determined and topped

up by the quantity remaining in the removed

component.

87 -12

87 03 17 Assembly work on the air-conditioning system

986871 Printed in Gennany -16, 1997

Page 33

87

Nominal values for pressures and temperatures

Note

The temperature of the air from the "centre" dashboard vents must lie within the prescribed tolerance

range within 5 minutes, depending on the ambient temperature (see diagram).

General test prerequisites

Close doors, windows and sliding roof

Insert temperature probe into centre vent

Measure ambienttemprature

Open all dashboard vents

Switch ignition on

Press recirculating-air button

Set temperature control to maximum cooling

Switch fresh-air blower to stage 4

Start engine

Operate air condition while idling

Set engine speed to 2000 rpm (start of time measurement)

If the prescribed nominal values are not reached, the cooling system must be checked for leaks and re-

paired.

10

u

0

8

oS

Q)

'-

~

"'ro

'-

6

Q)

Co

E

Q)

4

c:

~

Q)

~

2

Q)

u

Centre vent temperature as a function of ambient temperature

15

20

25

Ambient temperature in °C

30 35 40

87 Nominal values for pressures and temperatures

Printed in Germany, 1996 9868713

87 -13

~

Page 34

Air conditioning

f\lominal values for pressures and temperatures

30

25

Boxster

20

15

10

L~ """""""

5

15

High pressure in cold circuit as a function of ambient temperature

1,8

1,7

20

Ambient temperature in °C

25 30

~

35 40

1,6

,-

(0

~:)

1,5

.!:

(I)

,-

::J

(II

(II

1,4

(I)

1-

1:1-

:~

1,3

(:)

_.J

Low pressure in cold circuit as a function of ambient temperature

8:7 -14

15 20 25

Ambient temperature in DC

30

87 Nominal values for pressures and temperatures

9868713 Printed in Germany, 1996

35 40

.

~~::;;:~~..~

k~~::::::::~

[~::::::::::;;;;;;;~c:::::::~..

.-

Page 35

Boxster Air conditioning

87 83 19

Removing and installing pressure switch for the air-conditioning system

Removal

1. Remove the cover above the heatingjair-conditioning system.

2. Remove refrigerant by suction using the service unit.

3. Pull off the cable plug on the pressure switch.

4. Undo and unscrew the pressure switch.

Installation

1. Replace the O-ring on the pressure switch and

wet it with refrigerant oil.

Tightening torque: 3 Nm (2.2 ftlb)

2. Refrigerant oil removed from a previously run

air-conditioning system may no longer be used

(special-category waste).

2-96

87 83 19 Removing and installing pressure switch for the air-conditioning system

Printed in Germany -1996 986871

87 -15

Page 36

Boxster

Air conditioning

87 55 19

Removing and installing the fluid tank

Removal

1. Remove the cover above the heating/air-conditioning system and fluid tank.

2. Remove refrigerant by suction using the service unit.

3. Undo the hose clamp on the fluid tank. Undo

both hexagon-head bolts on the fluid tank and

remove the fluid tank upwards. Immediately

close lines with plugs so that they are air-tight.

Note

The fluid tank must be replaced if the system

suffers from operational faults (e.g. accident

damage or air-conditioning system depress-

urized),

Refrigerant oil removed from a previously run airconditioning system may no longer be used

(special-category waste).

Installation

1. Do not remove the plug until shortly before installation. Replace the a-ring on the branch

piece and on the refrigerant line, and wet the

new O-rings with refrigerant oil.

2. Tighten both hexagon-head bolts on fluid tank

with 6 Nm (4.4 ftlb).

3. Determine the quantity of the refrigerant oil

and fill up again with refrigerant oil (volume

removed by suction + 30 cm3).

3-96

87 55 19 Removing and installing the fluid tank

Printed in Germany -1996 986871

87 -17

Page 37

Boxster

Air conditioning

87 34 19

Removal

Removing and installing the compressor

1. Remove the cover above the heating/airconditioning system.

2. Remove refrigerant by suction using the

service unit.

3. Remove the left seat.

Disconnect the battery and cover the terminal

or battery. Remove the lid for the engine

compartment and rear wall flap behind the

seats.

4. Relieve the drive belt on the tensioning pulley

and remove the belt.

5. Detach the battery positive connector at the

B+ connection on the engine. Undo the B+

connection (2 screws M6) on the engine and

put it aside.

6. Remove the fluid of the power steering in

the supply tank until below the connection.

Remove the servo-tank (bayonet lock).

Observe the marking (arrow) during

installation. Seal off the connection

against dirt.

7. Undo the compressor fastening screw

between the intake pipes, cylinders 4 and 5.

," "'" L

26-96

8. Undo the refrigerant lines at the compressor.

Immediately close the connections and lines

with plugs so that they are air-tight.

"

I

/

...:--/

~

87 34 19 Removing and installing the compressor

Printed in Germany -12, 1997 986871

,

25-96

«0

j (-

,,-?--=

..?.-=

~I

,p

.I

r

? -",,:jJ

99-96

87 -19

~:

Page 38

Air conditioning

Boxster

9. Undo the front compressor fastening screws

(2 ea.) and disconnect the electrical plug

connection.

\

27-96

10. Carefully remove the compressor to the

front.

Installation

Note

New compressors are under pressure and are filled with the required amount of oil for the refrigerant circuit. The remaining oil quantity in the in-

dividual components must therefore be taken

into account.

1. First, open the cap on the high-pressure side

and relieve the pressure from the compressor

(A).

2. Open the oil filler screw (8) on the compressor.

Ii"

~

III

3. Empty approx. 80 cm3 of refrigerant oil out

of the compressor and into a measuring

glass. The remaining quantity of oil (approx.

120 cm3) remains in the compressor.

Note

Refrigerant oil from the compressor or

refrigerant oil removed by suction from a

previously run air-{;onditioning system may no

longer be used (special-category waste),

4. Tightening torque for the compressor

fastening screws on the engine

(screws M8): 23 Nm (17 ftlb.)

5. Tightening torque for refrigerant line

(screws M8 x 32): 23 Nm (17 ftlb.)

Use fastening screws from the new

compressor. Replace O-rings and wet

with refrigerant oil.

6. Do not remove the plugs for the lines and

compressor connection until shortly before

installation.

7. Tightening torque for oil filler screw

(MID xI): 26...36 Nm (19...27 ftlb.:

Always replace the sealing ring.

fr:

78-96

~B

~~~d

87 -20

87 34 19 Removing and installing the compressor

986871 Printed in Germany -12, 1997

Page 39

Boxster

Running-in regulations for new compressor

Note

Fill the air-conditioning system (fluid) via the high-

pressure side from the refrigerant circuit with

the engine "OFF"

Air conditioning

If possible, all air outlet nozzles "OPEN",

circulating air "CLOSED"

2. Start the engine and allow idle speed to stabilize (approx. 5 seconds).

3. Set the fan to max. output.

4. Switch on the air-conditioning system (AC

switch) and allow it to run uninterrupted for at

least 2 minutes at 1500 rpm.

5. After 2 minutes uninterrupted compressor

operation time, the oil distribution in the airconditioning system is completed and the

compressor can be run up to the max. engine

speed.

87 34 19 Removing and installing the compressor

Printed in Germany -1996 986871

87 -21

Page 40

Boxster

Air conditioning

8770 19

Removal

1. Remove the cover above the heatingjair-conditioning system.

2. Remove refrigerant by suction with the service

unit.

3. Undo the air-conditioning lines at the expan-

sion valve. Close connections and lines immedi-

ately with plugs so that they are air-tight.

4. Undo the expansion valve and remove it. Im-

mediately close the lines to the evaporator

with plugs so that they are air-tight.

Removing and installing the expansion valve

~

3. Tightening torques:

Screw M5

Screw M6

6 Nm (4.5 ftlb)

9 Nm (6.5 ftlb)

\

/'-

~

81-96

Installation

1. Do not remove plugs until shortly before installation. Replace O-rings and wet the new rings

with refrigerant oil.

2. Refrigerant oil removed by suction from a pre-

viously run air-conditioning sytem may no

longer be used (special-category waste).

'=P_~l~1)

/-

Page 41

87 01 19

Removal

Installing and removing the heating/air-conditioning unit

1. Remove the covers over the heating/air-conditioning system, battery and fluid tank. Discon-

nect and remove the battery.

2. Remove refrigerant by suction using the service unit.

3. Detach the air-conditioning lines at the expan-

sion valve. Close the connections and lines

with plugs immediately so that they are air-

tight.

4. Remove the steering wheel and loosen the

steering column panel. Observe the safety

regulations for handling airbag units (see Re-

pair Group 69).

5. Undo the central screw (clamp) on the steering column switch from below and pull it for-

wards slightly. Remove the cover at the top

and disconnect the electrical plug connec-

tions. Remove the steering column switch.

6. Detach the instrument panel and unclip the

right side upwards. Disconnect the electrical

plug connections.

108 -96

7. Remove the steering column cover (4 screws).

107-96

87 01 19 Installing and removing the heating/air-conditioning unit

Printed in Germany, 1996 9868725

109 -96

87 -25

Page 42

Air conditioning

8. Remove the radio and heatingjair-conditioning

controller. Unclip the switch panel on the left

and on the right. Disconnect the electrical

plug connections. Undo the retaining frame in

the center and remove it.

Boxster

111 -96

14. Undo the center tunnel support on the support frame at the top and on the tunnel

holder at the bottom.

110 -96

9. Remove the left side nozzle and disconnect

the electrical plug connection. Unclip and

remove the sun sensor cover and defrost

panel.

10. Undo the interior monitoring system and disconnect the electrical plug connection.

11. Remove the air guide at the bottom right.

Remove the passenger's airbag unit. Ob.

serve the safety regulations for handling air.

bag units (see Repair Group 69).

12. Remove the front cover of the center con-

sole. Undo the fuse holder and diagnosis

plug in the left footwell.

13. Undo the control panel at the bottom, center, left and right. Carefully remove the con-

trol panel and detach the loudspeaker cable.

~

~

1--\0

~

10

II'

112 -96

15. Remove the left air guide. Only loosen the defrost channel. Undo and remove the center

air distributor casing.

16. Disconnect the central plug connections

(2 ea.) from the heaterjair-conditioning unit.

~

87 -26

87 01 19 Installing and removing the heating/air-conditioning unit

9868725 Printed in Germany, 1996

Page 43

Boxster

17. Disconnect the battery positive terminal on

the current distributor and the current distributor on the cover front wall.

~--_':_'-""'--::-";':;"'~\'

~

, (

Air conditioning

--

~-

/

d

18. Disconnect both heating hoses upstream of

the heat exchanger with the standard hose

clamp. Disconnect the heating hoses on the

heat exchanger and plug the connections.

19. Undo the heater/air-conditioning unit on the

lid firewall (3 nuts). Pull off the water drainage hose from the heater/air-conditioning

unit.

20. Undo the holder of the heater/air-conditioning unit from the passenger's side at the top

right.

":I;;

114-96

21. Carefully lower and remove the heater/airconditioning unit downwards into the footwell.

Do not damage the electrical plug connections or cables.113-96

Installation

1. Ensure that the air distributor casing and air

guides are correctly positioned. Engage the

electrical plug connections and carefully lay

the electrical cables (do not pinch).

2. Observe the safety regulations for handling airbag units

(see Repair Group 69).

.

~

87 01 19 Installing and removing the heating/air-conditioning unit

Printed in Germany, 1996 9868725

87 -27

Page 44

Air conditioning

Boxster

3. Set the steering column switch:

Use a depth gauge to measure between the

end of the steering axle and the metal cover

of the steering column switch (see figure).

Adjustment dimension 55 :t 0.5 mm

4. Replace the seal between the current distribu-

tor and firewall if necessary. After fitting the

current distributor on the firewall (tightening

torque 15 Nm), tighten the battery cable with

a new M8 hexagon nut. Tightening torque:

15 Nm (11 ftlb).

~

6. The heat exchanger is connected to the engine-cooling system, and coolant flows

through it when the engine is running. The cool-

ing system must be bled after removal or installation of the the heaterjair-conditioning unit

(see Repair Group 19).

55 t 0,5

115-~

5. Replace the a-rings for the refrigerant lines at

the expansion valve and wet the new O-rings

with refrigerant oil.

Note

If the heatingjair-conditioning unit is replaced,

the refrigerant oil in the evaporator must be

topped up. Determine the quantity of the refrige-

rant oil and top up again with refrigerant oil (vol-

ume removed by suction + 20 cm3).

Refrigerant oil removed by suction from a pre-

viously run air-conditioning system may no

longer be used (special-category waste).

87 -28

87 01 19 Installing and removing the heating/air-conditioning unit

9868725 Printed in Germany, 1996

Page 45

Boxster

Air conditioning

87 50 19

Removal

Removing and installing the condenser

1. Remove the cover above the heatingjair-conditioning system.

2. Remove the refrigerant by suction using the

service unit.

3. Completely remove the front spoiler. Remove

the air guide to the condenser and pull off the

electrical plug connection on the temperature

sensor.

4. Undo the refrigerant line on the condenser. Immediately close connections and lines with

plugs so that they are air-tight.

5. Undo the fastening screws (2 screws) from

the condenser and pull the condenser to the

side out of the holder.

Installation

1. Do not remove the plugs for the lines and condenser connection until shortly before installa-

tion.

2. Replace a-rings and wet the new a-rings with

refrigerant oil.

3. Tightening torques:

Refrigerant lines M610 Nm (7.4 ftlb)

Condenser 4.0 :to.5 Nm

(3.0 :t 0.4) Nm

When loosening or tightening the M8 refrigerant

lines on the condenser, always counter with a

21-mm open-ended wrench.

4. Determine the quantity of the refrigerant oil

and top up again with refrigerant oil (volume

removed by suction + 20 cm3).

146-96

Note

Refrigerant oil removed by suction from a previously run air-conditioning system may no

longer be used (special-category waste),

87 50 19 Removing and installing the condenser

Printed in Germany, 1996 9868725

87 -29

Page 46

Boxster

Air conditioning

87 27 19

Removal

1. Use a standard strap wrench to securely hold

the pressure plate, and undo the fastening

Removing and installing the magnetic coupling

screw.

~~~

~

"

209 -96 210 -96

Installation

1. Place the magnetic coil on the compressor

housing. The locking pin must engage in the

locking hole.

~;;:;;;; ~~I

~

'

2. Screw a screw M8 into the thread of the

pressure plate until the pressure plate can be

removed manually. Remove the spacer

washers.

3. Use standard Seeger circlip ring pliers to

remove the Seeger circlip ring. Manually

remove the belt pulley.

4. Unscrew the cable of the magnetic coil from

the compressor housing. Remove the Seeger

circlip ring. Remove the magnetic coil from

the compressor housing.

2. Install the Seeger circlip ring. The slanted surface (arrow) of the Seeger circlip ring faces upwards (to the fastening screw).

1930 -87

~I

~

87 27 19 Removing and installing the magnetic coupling

Printed in Germany, 1996 9868725

87 -31

Page 47

Air conditioning

3. Tighten the pressure plate fastening screw.

Tightening torque: 14 Nm (10 ftlb)

Check the air gap of the magnet coupling

1. Check the air gap between the pressure plate

and belt pulley with a depth gauge.

Boxster

211 -96

2. Place a rule on the outer edge of the belt pulley. Use a depth gauge to measure up to the

pressure plate. Apply battery voltage to the

magnetic coupling and measure the distance

(air gap) to the attracted pressure plate. Al-

ways measure at at least three points on the

pressure plate in order to obtain a mean value.

Distance: 0.5 mm :t 0.15 mm

3. If the air gap is not in the tolerance range, it

must be adjusted with the aid of the spacer

washers.

Page 48

Boxster

Air conditioning

87 20 19

Removing and installing drive motors of the heating/air-conditioning

unit

Note

Removal and installation of drive motor for tem-

perature valve, central valve and footwell/de-

frost valve. Removal or installation is performed

with the heating/air-conditioning unit installed.

Drive motor for temperature valve

-"

~-./\

vr

@

",

\

nL

!/

Removal

1. Remove footwell bulkhead and air guides. Unclip centre console cover at the front and

remove the footwell vent (3 screws).

2. Press pivot pin on the adjusting lever together

and disengage the deflection lever.

3. Unscrew drive motor of the heating/air-condi-

tioning unit and disconnect the electrical plug

connection.

Drive motor for footwelljdefrost

Drive motor for central valve

\V

./

~~

-

549 -96

/

\

; I';;!~\':

552 -96

1. Unscrew drive motor with bracket from the

heating/air-conditioning unit (2 screws).

2. Swivel drive motor to the side and disengage

the deflection lever.

3. Disconnect electrical plug connection and detach bracket from the drive motor.550 -96

-,

,

87 20 19 Removing and installing drive motors of the heating/air-conditioning unit

Printed in Germany -5, 1996 9868733

87 -33

Page 49

Installation

1. Ensure that the deflection levers are seated

correctly.

2. Tighten fastening screws carefully

(plastic housing).

3. Engage electrical plug connections and route

wire carefully.

4. Perform function test after installation of the

drive motors.

Air conditioning Boxster

87 -34 87 20 19

Removing and installing drive motors of the heating/air-conditioning unit

9868733 Printed in Germany -5, 1996

Page 50

Boxster Air conditioning

87 20 19 Removing and installing drive motor for fresh-air/recirculation valve

Removing and installing drive motor on the

installed heating/air-conditioning unit

Removal

1. The recirculation button must be pressed before removal (fresh-air supply blocked). The

drive motor can be removed from the installed

heatingjair-conditioning unit in this position (re-

circulation).

2. Remove footwell and right air guide. Disconnect electrical plug connection of the drive

motor and undo fastening screw.

3. Disengage pivot pin on the adjusting lever with

a screwdriver.

/'

-=======~ \ \ \

\.

0

A~o

_"\

Installation

1. The removal or installation position of the

drive motor and fresh-air/recirculation valve

cannot be changed.

2. Ensure that the deflection lever of the outsideair valve is seated correctly.

3. Tighten fastening screw carefully

(plastic housing).

4. Engage electrical plug connection and route

wire carefully.

5. Perform a function test after installation.

1--,

7.

551/1 -96

4. Swivel down the drive motor and remove it to

the side.

87 20 19 Removing and installing drive motor for fresh-air/recirculation valve

Printed in Germany -5, 1996 9868733

87 -35

Page 51

Boxster

Air conditioning

87 59 19 Removing and installing outside temperature sensor

Removing and installing outside temperature sensor on the installed heating/air-conditioning unit

Removal

1. Remove footwell bulkhead and right-hand air

guide. Remove drive motor for fresh-air/recir-

culation valve.

2. Pull off electrical plug connection on the outside temperature sensor. Turn temperature

sensor by 900 and pull it out.

..

I~

,- -

1= 0-

I-

i\

---

---

Installation

1. Place temperature sensor on the intake duct

and turn by 900 (tighten),

2. Engage electrical plug connection and route

the wire carefully.

3. Install drive motor for fresh-air/recirculation

valve and perform a function test.

607/1 -96

87 59 19 Removing and installing outside temperature sensor

Printed in Germany -5, 1996 9868737

87 -37

Page 52

Boxster

Air conditioning

87 82 19

Removal

1. Pull off cover for temperature sensor ..Undo

three T orx screws of the right side vent and

carefully pull the side vent out of the dashboard. One Torx screw is located behind the

cover.

Removing and installing interior temperature sensor

2. Press locking tabs together slightly and

remove temperature sensor from the dashboard.

Installation

1. Engage electrical plug connection, ensuring

that the temperature sensor is seated

properly in the dashboard.

2. The cover simultaneously serves as the intake

grille for the fan and must not be closed off.

608 -96

3. Pull off electrical plug connection.

87 82 19 Removing and installing interior temperature sensor

Printed in Germany -5, 1996 9868737

87 -39

Page 53

Boxster

Air conditioning

87 58 19

Removing and installing footwell blower outlet sensor

Removal

1. Remove footwell bulkhead. Unclip centre console cover at the front and remove the foot-

well vent (3 screws).

2. Turn blower outlet sensor by 900 and pull it

out.

Installation

1. Position temperature sensor on the heating/airconditioning unit housing and turn by 900

(tighten),

2. Engage the electrical plug connection and

route the wire carefully.

609 -96

3. Pull electrical plug connection off blower outlet

sensor.

87 58 19 Removing and installing footwell blower outlet sensor

Printed in Germany -5. 1996 9868737

87 -41

Page 54

Boxster

Air conditioning

87 78 19 Removing and installing blower driver

Removal

1. Remove footwell bulkhead and right ai( guide.

Unscrew fastening screw and detach the

blower driver from the heatingjair-conditioning

unit housing from below.

I

~,IV>"~~-~ =

~

I~

n~E;!:;::::1

610 -96

Installation

1. Engage the electrical plug connection and

slide the blower driver into the upper bracket.

2. Tighten the fastening screw carefully (plastic

housing). Install the air guide and footwell bulkhead.

3. Perform function test on heater/fresh-air

blower motor.

2. Pull blower driver out of the upper bracket

and remove in downward direction.

3. Pull off the electrical plug connection,

87 78 19 Removing and installing blower driver

Printed in Germany -5, 1996 9868737

~~

87 -43

Page 55

Page 56

Air conditioning Boxster

Ilrlstallation

1.. After installation, check whether the fan can rotate freely.

2. Tighten front wheel to the specified torque

(130 Nm (96 ftlb.)}.

~~7 -46

87 53 19

9868737

Removing and installing fan for condenser

Printed in Germany -5, 1996

Page 57

Boxster

Air conditioning

87 69 19

Removing and installing ballast resistor for fan motor

Note

The ballast resistor is available as a spare part

and can be replaced by crimping it onto the old

wires.

1. Disconnect the battery and cover the terminal

or battery.

6. Using a commercially available crimping tool,

join the wires with crimp connectors.

7. After crimping, solder the crimp connectors.

Slide heat-shrink tubing over the crimp connec-

tors and then shrink the tubing with a hot-air

gun.

2. Unclip ballast resistor from the holder from

below. 8. Carefully route the wires and, if necessary, fix

in place with plastic tape.

/i

'

645 -96

3. Cut off wires approx. 30 mm behind the old

ballast resistor.

4. Slide heat-shrink tubing over the wires to

the plug connection (2 x) and to the fan motor

(1 x).

5. Shorten wires of the new ballast resistor to approx. 30 mm and strip approx. 5 mm of insulation off all wire ends.

87 69 19 Removing and installing ballast resistor for fan motor

Printed in Germany -5, 1996 9868737

~~

87 -47

Page 58

Boxster

Air conditioning

87 02 19

2. Unscrew fastening screws (2 ea.) and pull the

heating/air conditioning control out of the

Installing and removing the heating/air conditioning control

dashboard.

437.97

Performing system test1. Unclip cover.

1. Connect and switch on the Porsche System

Tester 2.

2. Select air conditioning and menu item "System

test".

The following conditions must be

observed for the system test:

Vehicle speed < 10 km/h

Engine start detected and 10 seconds

elapsed since engine start

Terminal 15 supply voltage OK

3. Disconnect the plug connections

Note

Basic adaptation to the system must be

performed with a new heating/air conditioning

control. This is indicated by flashing of the

displays for approx. 5 to 10 seconds each time

the ignition is switched on.

Basic adaptation is performed during the system

test.

5 Volt supply voltage OK

Engine temperature < 110°C

Outside temperature> 3 °C

The following tests are performed:

Display of all segments in the control module

The drive motors are traversed across the

entire range once

The measured positioning travel is subjected

to a plausibility test and stored as a fault if

necessary

87 02 19 Installing and removing the heating/air conditioning control

Printed in Germany -12, 1997 9868749

87 -49

Page 59

Two different voltage values are set on the

fresh-air fan and tested

The A/C circuit is tested via the DME

All fault paths are tested, and any faults are

stored

Basic adaptation has been completed after the

system test. The display must no longer flash.

Air conditioning

Boxster

87 -50

87 02 19

Installing and removing the heating/air conditioning control

9868749 Printed in Germany -12, 1997

Page 60

Technical Manual

T echnicallnformation

Group 9

Electrics

-~~TL"".-

Page 61

Boxster

Foreword

Foreword

The workshop documentation for the Boxster model has the designation "Boxster" Technical Manual

and contains Technical Information as well as instructions on Repairs.

The integration of the technical information published in the "Boxster' Technical Manual with the

descriptive matter on repairs provides the user with a complex reference work that combines into one

book associated or cross-referenced material of relevance to workshops and originating from various

information media.

The "Boxster" Technical Manual consists of 15 folders, subdivided into the following Groups

0 Entire vehicle -General

0 Diagnosis, part 1 (up to Repair Group 45) *1

0 Diagnosis, part 2 (as of Repair Group 69) *2

1 Engine, part 1 (up to Repair Group 13) *3

1 Engine, part 2 (as of Repair Group 15) *4

2 Fuel, exhaust, engine electronics

3 Transmission, manual transmission

3 Transmission, automatic transmission

4 Running gear

5 Body

6 Body equipment, exterior

7 Body equipment, interior

8 / 9 Air conditioning / Electrics

9 Circuit diagrams, part 1 (up to and including the '99 model) *5

9 Circuit diagrams, part 2 (as of the '00 model) *6

*1

The two folders with Group 0 are to be regarded as one folder; i.e. file the "Technical Information"

notices only in front of the repair descriptions in the folder "Group 0 -Diagnosis, part 1"

(up to Repair Group 45).

*2

The second folder "Group 0 -Diagnosis, part 2" (as of Repair Group 69) includes the further

Repair Groups belonging to Group O.

.3

The two folders with Group 1 are to be regarded as one folder; i.e. file the "Technical Information"

notices only in front of the repair descriptions in the folder "Group 1 -Engine, part 1" (up to

Repair Group 13).

*4

The second folder "Group 1 -Engine, part 2" (as of Repair Group 15) includes the further Repair

Groups belonging to Group 1.

Foreword

Printed in Germany -34, October 1999

VORW.CHP

Page 62

Foreword

*!j

The two folders with Group 9 are to be regarded as one folder; i.e. file the "Technical Information"

Boxster

notices only in front of the repair descriptions in the folder "Group 9 -Circuit diagrams, part 1" (up to

the '99 model).

.Ei

The second folder "Group 9 -Circuit diagrams, part 2" (as of the '00 model) includes the further

circuit diagrams belonging to Group 9.

The "Boxster" Technical Manual has the same structure in each folder, with the following breakdown for

all Groups:

Title page, "Boxster" Technical Manual

> Foreword

Title page: "Technical Information"

> Table of Contents, Technical information

> Technical information

Title page: "Repair"

> Repair Groups: overview

> Table of Contents, repairs

> General/technical data

> Instructions on repairs

As can be seen from the breakdown, the published Technical Information is in the front part of each

folder -numbered according to the Groups. The Table of Contents assigned to each Group will be

periodically updated.

Following the Technical Information, separated by a title page, the instructions on repairs -assigned

according to the Groups or broken down into Repair Groups -are included in the folder.

The instructions on repairs will be extended and updated by means of supplements.

Note

Sheets that already exist in the "Boxster" Technical Manual and are updated or revised and thereby

exchanged by a supplement are designated "Replacement sheet". Revisions or technical modifications on

pages of these replacement sheets are identified for the user with a vertical bar at the margin.

VORW.CHP

Foreword

Printed in Germany -34, October 1999

Page 63

Boxster

Overview of repair groups

Group 0: Entire vehicle -General

Maintenance

Group 0:

Group 0:

Group 1:

Group 1:

Diagnosis

Sales check

On-board diagnosis

DME diagnosis

Tiptronic diagnosis

ABS diagnosis

Diagnosis

Airbag diagnosis

Seat memory diagnosis

Heating diagnosis

Alarm system diagnosis

PCM diagnosis

ParkAssistent diagnosis

HBA diagnosis

Engine

Engine -Crankcase, suspension

Engine -Crankshaft, pistons

Engine

Engine -Cylinder head, valve drive

Engine -Lubrication

Engine -Cooling

0

03

0

01

03

24

37

45

0

69

72

80

90

91

91

94

1

10

13

1

15

17

19

Group 2:

Group 3:

Group 3:

Fuel, exhaust, engine electronics

Fuel supply, control

Exhaust system, turbocharging

Fuel system, electronic injection

Fuel system, K-Jetronic

Exhaust system

Starter, power supply, cruise control

Ignition system

Transmission, manual transmission

Clutch, control

Manual transmission -Actuation, housing

Manual transmission -Gears, shafts, into gearsh,

Final drive, differential, differential lock

Transmission, automatic transmission

Torque converter

Automatic transmission -Actuation, housing

Automatic transmission -Gears, control

Final drive, differential, differential lock

2

20

21

24

25

26

27

28

3

30

34

35

39

3

32

37

38

39

Overview of repair groups

Printed in Germany -34, October 1999

REPGRU.CHP

Page 64

Overview of repair groups

Boxster

(iroup 4:

(iroup 5:

(iroup 6: 6

Running gear

Front wheel suspension, drive shafts

Rear wheel suspension, drive shafts

Wheels, tires, suspension alignment

Anti-Lock Brake System (ABS)

Brakes -Brake mechanics

Brakes -Hydraulics, regulator, booster

Steering

Body

Body front

Body center, roof, frame

Body rear

Lids, flaps

Door front, central locking system

Body equipment, exterior

Sliding roof

Convertible top, hardtop

Bumpers

Glazing, window control

Exterior equipment

Interior equipment

Passenger protection

<:iroup 7: Body equipment, interior

Linings, insulation

Seat frames

Seat upholsteries, covers

4

40

42

44

45

46

47

48

5

50

51

53

55

57

60

61

63

64

66

68

69

7

70

72

74

<:iroup 8:

(iroup 9

(:roup 9:

<:iroup 9:

Air conditioning

Heating

Ventilation

Air conditioning

Auxiliary air conditioning system

Electrics

Instruments, alarm system

Radio, telephone, on-board computer, navigation

Windshield wiper and washer system

Lights, lamps, switches exterior

Lights, lamps, switches interior, theft protection

Circuit diagrams

Wiring (up to and including the '99 model)

Circuit diagrams

Wiring (from the 'DO model)

8

80

85

87

88

9

90

91

92

94

96

9

97

9

97

REPGRU.CHP

Overview of repair groups

Printed in Germany -34, October 1999

Page 65

Boxster

Contents

9

9

90

90

25

90

25

90

50

90

12

91

915715

917519

911019

911219

911319

91

911215

19

37

19

15

Electrics

General

Work instructions after disconnecting the battery. .

Instruments, alarm system

Removing and installing instrument cluster. Disassembling and assembling instrument cluster. Removingandinstallinghorn Setting ahead the total mileage counter in the instrument cluster. ...

Radio, telephone, on-board computer, navigation

Setting hands-free microphone to telephone type. Removing and installing sensor for ParkAssistent Removing and installing display and operator control unit (PCM)

Removing and installing navigation unit. Removing and installing GPS antenna. Retrofitting mobile communication systems. Adjusting (calibrating) PCM navigation unit.

9- 1

90- 1

90- 3

90- 5

90- 7

91

91

91

91

11

91

91

13

91

15

1

3

7

9

92

92 19 19

92 27 19

921519

9266

92 60 19

92 56 19

92 78 19

92 67 19

92 72 19

94

941

941

94 a

944

941

942

3

Windshield wiper and washer system

Removing and installing wiper link. Removing and installing wiper blades. Removing and installing wiper motor. Non-adjustable spray nozzles. Removing and installing tank for windscreen washer system. ..

Removing and installing pump for windscreen washer system. ..

Removing and installing pump for headlight washing system. ..

Removing and installing fluid level indicator. Removing and installing spray nozzle for headlight washing system

Lights, lamps, switches exterior

Removing and installing headlights. Headlights -basic adjustment in body. Removing and installing main light switch. Removing and installing hazard warning light switch. .

Masking film for left/right-hand traffic. Bulb overview and installation instructions.

92 -1

92 -3

92 -5

92- 7

92 -9

92 -11

92-13

92-15

92-17

94- 1

94- 3

94- 7

94- 9

94-11

94-15

519505519719513

9 Electrics

Printed in Germany -32, 1999

1

986TOC

Page 66

Contents

Boxster

94 23 19

94 27 19

9467 19

94 56 19

94 53 19

94 33 19

9429 19

94 70 19

9423 19

94 57 19

94 58 19

9494 19

94 1505

94 1501

94 78 19

94 79 19

9498 19

Removing and installing halogen bulb. ...; Removing and installing bulb for parking light. Removing and installing bulb for fog light. Removing and installing bulb for direction indicator light. Removing and installing bulb for side direction indicator light. Removing and installing bulb for taillight. Removing and installing bulb for number plate light. Removing and installing bulb for raised brake light. Removing and installing gas discharge lamp (Litronic headlights) ...,

Removing and installing control module for gas discharge lamp. Removing and installing ignition unit for gas discharge lamp. Removing and installing servo motor for automatic headlight beam

adjustment. Left / right traffic conversion for Litronic headlights. Troubleshooting on Litronic headlight (dipped beam) Removing and installing angle sensor for automatic headlight beam

adjustment. Removing and installing angle sensor for automatic headlight beam

adjustment. Removing and installing control module for automatic headlight beam

adjustment.

.94.94.94.94-

.94-

.94.94.94.94-

.94.

.94-

94-39

94-41

94-43

94-45

17

19

21

23

25

27

29

31

33

35

37

94-47

94 -49

Lights, lamps, switches interior, theft protection

Removing and installing signal converter/immobiliser 96 -1

Removing and installing passenger compartment monitoring sensor. ...96 -3

AdditionalalarmsystemM534 96.5

Radio remote control in hand-held transmitter does not function. 96 -7

Vehicles with alarm system without radio remote control. 96. 9

Bulb overview and installation instructions. 96 -11

Removing and installing bulb for door warning light. 96 -13

Removing and installing bulb for luggage compartment light. 96 -15

Removing and installing bulb for interior light. 96 -17

Removing and installing bulb for instrument cluster. 96 -19

Teaching hand-held transmitter. 96 -21

Reading out and transferring remote control. 96 -23

Disassembling and assembling hand-held transmitter. 96 -27

'.

~.

986TOC

9 Electrics

Printed in Germany -32, 1999

Page 67

Boxster

General

9

Work instructions after disconnecting the battery

Effect of disconnection or total discharge of the battery on electrical

systems in the vehicle, subsequent

measures:

1. Never disconnect battery with engine running.

2. Never start engine without securely connected

battery.

3. Do not use a boost charger to start the

engine.

4. Whenever possible, use jump leads with overvoltage protection.

5. Always disconnect the battery terminals before carrying out welding work on the vehicle.

6. Wiring harness plugs of control modules or

other electronic components must be connected or disconnected with the ignition off.

Exception: vehicles with the additional

equipment M 536 (alarm siren with tilt

sensor).

Note concerning M 536:

Control module memories:

Values and faults stored in the control modules

can be deleted if the battery is disconnected or

completely discharged.

Remedy:

If possible, all fault memories should be

checked and, if necessary, printed out before

the battery is disconnected.

Supply voltage fault entry:

The entry "supply voltage" could be stored in

various control modules if the battery has been

completely discharged.

Remedy:

Delete the "supply voltage" entry from the

control modules in question.

Test drive after connecting the battery:

The fault memories of all vehicle control modules should be read out again after the test drive.

In order to avoid triggering the alarm siren (in-

stalled on right next to the battery) of vehicles

with M 536, the battery must be disconnected

with the ignition on (all loads must be switched