Porsche 944 User Manual

Workshop Manuel

Volume IA - Engine, 16 valves

DR. ING. h. c. F. PORSCHE Aktiengesellschaft

As webpage by http://www.9ss1.dk/porsche944

944 Table of contents volume I-A

General

Technical data

Maintenance, Self-diagnosis

Fault diagnosis, DEE control unit

Connecting into the vehicle - 944S

Starting fault diagnosis

Functional test - actuator and input signal

List of test codes

System adaptation

Knock detection

Troubleshooting

List of fault codes

Clearing fault memory

Operating conditions for start of diagnosis

Operating instructions for System Tester 9288

Engine, Crankcase

Tightening torques for engine (16-valve)

Tolerances and wear limits

Engine, removing and installing

Engine, Crankshaft drive, Pistons

Notes on assembly for pistons, from Model 87 onward

Checking pistons and cylinder bore

Pistons from Model 89 onward

Installing cover for oil-centrifuge partition

Engine, Cylinder head, Valve drive

Camshaft salling, checking and adjusting

Camshaft salling, checking and adjusting for Model 89 onward

Applying the TOC mark on the camshaft sprocket

Camshafts and cylinder head, removing and installing

Cylinder head, installing and tightening

Camshafts, installing

Camshaft seal, installing

Camshaft specifications

Chain tensioner, removing and installing

Cylinder head, disassembling and assembling

Valve springs, removing and installing with Sauer tool

Page

0.9

03 - 1

03 - 3

03 - 5

03 - 7

03 - 13

03 - 15

03 - 17

03 - 19

03 - 29

03 - 31

03 - 32

03 - 33

10 - 0101

10 - 0102

10 - 101

13 - 101

13 - 102

13 - 103

13 - 105

15 - 101

15 - 104 a

15 - 104 b

15 - 105

15 - 110

15 - 111

15 - 112 a

15 - 112 b

15 - 113

15 - 115

15 - 118

Table of contents

Printed in Germany - XXIV, 1991

1

volume I-A Table of contents 944

Machining mating face, cylinder head

Vaive springs, removing and installing, removing valve stem seal

Valve stem seal, installing

Checking valve guides

Replacing valve guides

Checking valve seat wear limit

Valve seats, checking and machining

Checking and adjusting installation length of valve springs

Engine - Lubrication

Replacing engine oil and oil filter

Pressure-reduclng valve, removing and installing

Engine - Coating

Checking cooling and heating system for leaks

Fuel supply

Replacing fuel filter, checking injection lines for leaks and tightness

Checking delivery rate of fuel pump

Line routing, fuelsystem, M 44.40

Fuel preparation - L-Jetronic/regulation

Replacing air filter cartridge, checking intake-air guide hoses

Testing and adjusting specifications

Checking fuel pressure

Checking idle speed and CO - with catalytic convertor

Checking idle speed and CO - without catalytic convertor

Replacing air filter cartridge for Model 89 onward

Exhaust system

Exhaust system - check tightness of flanges

Ignition system

Equipment table

DEE control unit coding - 944 S, Model 87 onward

Replacing spark plugs

Equipment table, Model 89 onward

DEE control unit coding - 944 S 2, Model 89 onward

DME-Diagnosing / Troubleshooting

Page

15 - 120

15 - 121

15 - 122

15 - 123

15 - 125

15 - 130

15 - 131

15 - 133

17 - 101

17 - 102

19 - 101

20 - 101

20 - 102

20 - 103

24 - 101

24 - 102

24 - 103

24 - 105

24 - 106

24 - 107

26 - 101

28 - 101

28 - 103

28 - 104

28 - 105

28 - 107

D-24/28-1

2

Printed in Germany - XXIV, 1991

Table of contents

944 General

TYPE 944 S (16-VALVE ENGINES) - '87 MODELS ONWARD

Printed in Germany - XIII, 1987 Technical Data 0.9

General 944

TECHNICAL DATA

(Adjustment specifications and wear data are stated in the appropriate Repair Groups)

Note: US values are stated in parentheses

DRIVE UNIT

Internal engine designation

Number of cylinders

Bore

Stroke

Displacement (actual)

Compression ratio

Max. engine output to

80/1269/EC

Net power, SAE J 1349

at engine speed

Max. torque to

80/1269/EC

at engine speed

Net torque, SAE J 1349

Max. spec. power output

Net power, SAE J 1349

Fuel octane rating

Max. perm. engine speed

Engine weight (dry)

ENGINE DESIGN

Type

mm/in.

mm/in.

cc/in.3

kW/PS

kW/HP

rpm

Nm/kpm

rpm

Nm/lbft

kW l/HP l

kW l/HPI

RON/MON

rpm

kg/lbs

M 44/40

4

100/3.94

78.9/3.11

2479/151

10.9 : 1

140/190 - 135/184 Australia

140/188

6000

230/23.5 - 225/22.9 Australia

4300

230/170

56.5/76.6-54.5/74.2 Australia

56.5/75.8

95/85 - 92/82 unleaded Australia

(95/85 premium unleaded)

6840

175/386

4-cylinder, 4-stroke in-line spark ignition

engine with two balance shafts

0.10 Technical Data Printed in Germany

944 General

Crankcase

Crankshaft

Crankshaft bearings

Connecting rods

Connecting rod-bearings

Pistons

Balance shafts

Balance-shaft bearings

Cylinders

Cylinder head

Valve guide

Valve arrangement

Valve timing

Camshaft

Camshaft drive

Balance-shaft drive

Valve clearance

Two-part light alloy crankcase

Forged, 5 bearings

Plain

Cast, opt. sinter-forged

Plain

Light alloy, cast

Forged

Plain bearings with bearing shells

Light alloy

Light alloy

Press-fit, special brass

2 intake, 2 exhaust

overhead V

Two overhead camshafts, hydraulic

bucket tappets

Without bearing shells, carried in

cylinder head

Toothed belt and internal chain

Toothed belt

Self-adjusting (hydraulic)

Timing Intake opens

Intake closes

Exhaust opens

Exhaust closes

Printed in Germany - XIII, 1987 Technical Data 0.11

4° after TDC

40° after BDC

36° before BDC

4° before TDC

General 944

ENGINE COOLING

ENGINE LUBRICATION

Lubrication

Oil pressure

Oil-pressure indicator

Max. oil temperature

Oil consumption

EXHAUST SYSTEM

EMISSION CONTROL

HEATING

n = 5000 rpm

l/1000 km

Sealed cooling system, electric fan

with thermoswitch, antifreeze effective

to - 25°C

Forced-feed lubrication with

sickle-type pump, oil filter and

oil-water heat exchanger in main oil

flow and secondary water flow

integrated in crankcase

Approx. 4 bar, at operating

temperature

Pilot lamp and pressure gage

140°C

Up to 1.5

Standard

2 double-wall manifolds, branch pipe to

primary muffler, 1st and 2nd

secondary mufflers

Option: M298 or M299 and USA and

Australia as standard, catalytic

converter instead af primary muffler

Standard: engine-internal

Option: M298 or M299

and Australia

heated oxygen sensor with 3-way

catalytic converter

Hot-water heating with heat exchanger

and blower

0.12 Technical Data Printed in Germany

944 General

FUEL SYSTEM

Injection

Fuel delivery

Fuel octane rating

Fuel consumption

to 80/1268/EC or

ECE R 15/04

Constant 90 km/h

Constant 120 km/h

EC exhaust urban

cycle

ELECTRICAL SYSTEM

Suppression

Battery voltage

Battery capacity

Alternator (output)

Ignition

Firing sequence

Ignition timing

RON/MON

l/100 km

l/100 km

l/100 km

V

Ah

A/W

DME

Digital Motor Electronics

1 electric fuel pump

Standard: 95/85 - European standard

premium unleaded

possible

Opt./M298: 95/85 unleaded

- European standard premium -

Australia: 91/82 unleaded

Standard:

6.7

8.3

12.5

ECE-R 10 and 72/245/EC

12

50 - optional 63,

sports package 36

115/1610

- sports package: 90/1260

By DME

1-3-4-2

By DME

Printed in Germany - XIII, 1987 Technical Data 0.13

General 944

BODY DESIGNS

Integral all-steel body with front air dam and rear

spoiler

- as coupe, opt.: removable hardtop panel, also

available with fog lamps set in PU front air dam as

optional extra.

DIMENSIONS (at DIN curb weight)

Length

Length with opt.

extra US bumpers

Width

Height

Wheel base (in

design pos.)

Track:

Front

Rear

Ground clearance

(at per. total

weight)

Bed clearance

(at per. total

weight)

Overhang angles:

Front

Rear

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

mm/in.

4230/165.354

4290/168.90

1735/68.31

1275/50.20

2400/94.49

1477/58.2

1477/58.2

1477/58.2

1451/57.1

1451/57.1

1451/57.1

1442

120/4.72

53/2.09

14°

15°

(4290/168.90)

Rim size

7 J x 15

7 J x 16

8 J x 16

7 J x 15

7 J x 16

8 J x 16

9 J x 16

0.14 Technical Data Printed in Germany

944 General

WEIGHTS - to DIN 700 20 -

Curb weight

Front

Rear

Total

Per. axle load

Front

Rear

Per. total

weight

Per. trailer

load

Braked trailer

Unbraked

trailer

Max. car/

trailer weight

Max. drawbar

load

Per. roof load

With genuine

Porsche roof

transport

system

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

kg/lbs

Standard

640/1411

(650/1433)

640/1411

(650/1433)

1280/2822

730/1609

900/1984

1600/3527

1200/2646

1200

500/1102

500

2760/6085

2760

50/110

50

35/77

75/165

Sports package

630/1389

610/1345

(630/1389)

1240/2734

(1260/2778)

730/1609

(720/1587)

900/1984

1600/3527

(1550/3417)

up to 16% gradient

for Italy

up to 16% gradient

for Italy

for Italy

for Italy

up to 100 km/h

Australia,

standard

640/1411

640/1411

1280/2822

730/1609

920/2028

1620/3571

Printed in Germany - XIII, 1987 Technical Data 0.15

General 944

CAPACITIES

Engine (measurement with dipstick

as per Driver's Manual is definitive)

Engine oil

Engine coolant

Transmission with differential

Fuel tank

Brake-fluid reservoir

Windshield and headlight washing

fluid reservoir

Proprietary HD oils to APl

classification

SE or SF, see Driver's Manual

Approx. 6.0 l

Approx. 8.5 l

Approx. 2.0 l hypoid oil, SAE 80

to MIL-L 2105, APl classification

GL 4

Approx. 80 l, including approx.

8 l reserve

Approx. 0.2 l

Approx. 0.6 l

PERFORMANCE

Maximum speed

Acceleration from 0-100 km/h*

(0-60 mph)*

(1/4 mile

from standing

start)*

Kilometer from standing start*

CLIMBING PERFORMANCE

In % (slip limit)

*DIN curb weight and half of payload

km/h/mph

s

s

s

s

1st gear

2nd gear

3rd gear

4th gear

5th gear

228/142

7,9

(7.7)

(15.4)

27.8

62%

35.6%

21.5%

13.3%

9.4%

0.16 Technical Data Printed in Germany

944 General

Technical data - Type 944 52 - Model 89

(Values for adjustment and wear are to be found in the respective repair groups)

Notes: USA values are given in brackets

Drive unit

Internal engine designation

Bore

Stroke

Displacement (actual)

mm (in.)

mm (in.)

cm3(in.3)

Manual transmission M 44.41 (3.0 I)

104 (4.09)

88 (3.46)

2990 (182.5)

Displacement (rounded down) cm3 2969

Compression ratio

Max. engine power

88/195/EEC

Net power, SAE J 1349

at engine speed

Max. torque

88/195 / EEC

(Net torque, SAE J 1349)

at engine speed

Max. output per litre

DIN 70020

(SAE J 1349)

Speed governed by

fuel cut-off

Engine weight (dry)

kW (HP)

kW (HP)

rpm

Nm (kpm)

Nm / lbft

rpm

KW/I (HP/I)

KW/I (HP/I)

rpm

kg

10.9: 1

155 (211)

155 (208)

5800

280 (28.5)

280 (207)

4100

51.8 (70.6)

51.8 (69.6)

6480 +- 20

175

Technical data

Printed in Germany - XIX, 1989

0.17

944 Maintenance, Self-diagnosis

DME control unit error diagnosis

DME control unit error diagnosis 944 S

as from 88 model

As from model year 88, the DME control unit

944 S is capable of a self-diagnosis. That is to

say, the control unit is capable of detecting,

storing and displaying system errors. The control unit capable of diagnosis is identified by

an altered part number. A specially developed

diagnostic tester (special tool No. 9268) is

then used to read out the error memory and

to test specific components and control signals af the fuel and ignition system.

03

87/793

Important: Before diagnosis, the battery or

the connector of the DME control unit must

not be disconnected as otherwise the error

memory will be erased.

DME control unit error diagnosis

Printed in Germany - XVI, 1987

03 - 1

03

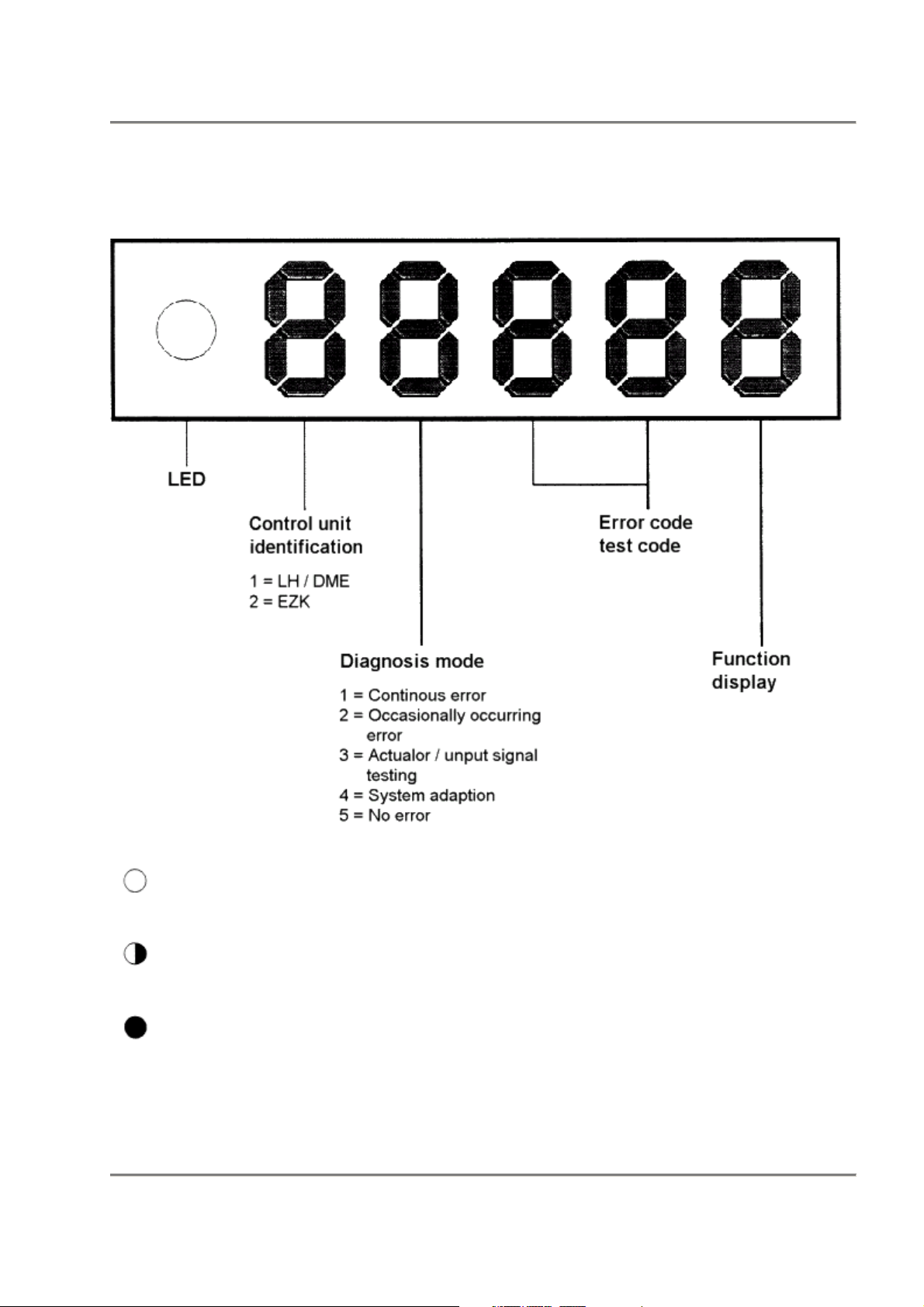

Display

Maintenance, Self-diagnosis 944

03 - 2

LED off Test sequence terminated / igniti

Flashing LED Error code / test code

LED on Ignition on

DME control unit error diagnosis

Printed in Germany - XVI, 1987

944 Maintenance, Self-diagnosis

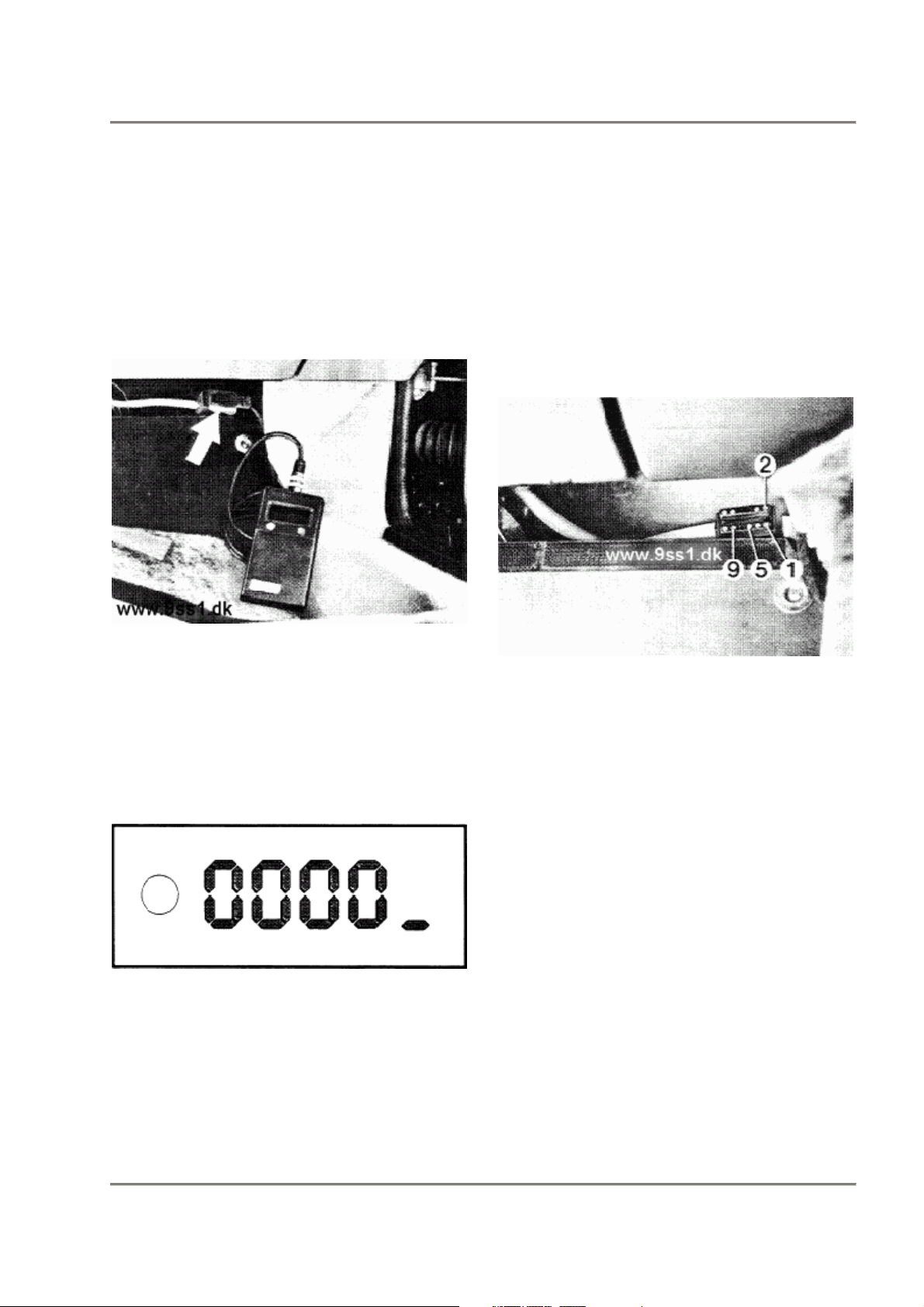

Diagnosis socket in the car

Connection in the 944 S

In the 944 S, the diagnosis socket is

attached

to a separate cable harness located above

the

DME control unit.

Pin 1 = terminal 15

Pin 2 = terminal 31

Pin 5 = terminal 30

Pin 9 = Hall generator

03

87/1012

Ignition off

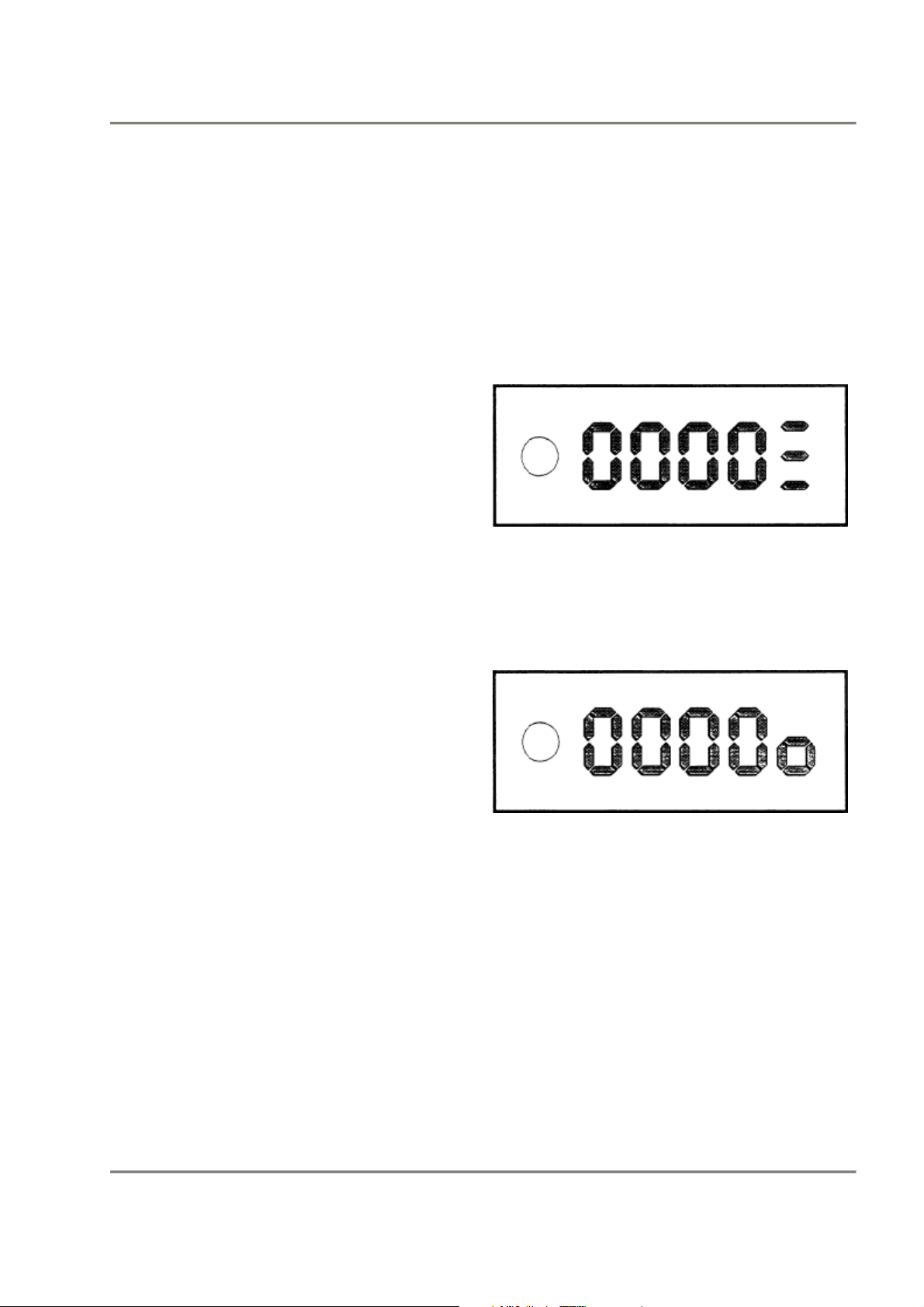

After connecting the tester, the following display must appear.

Display:

If this is not the case, check the tester terminals or check the power supply of the

diagnosis socket in the car by referring to the circuit diagram.

87/908

Connection in the 944 S

Printed in Germany - XVI, 1987

03 - 3

03

Maintenance, Self-diagnosis 944

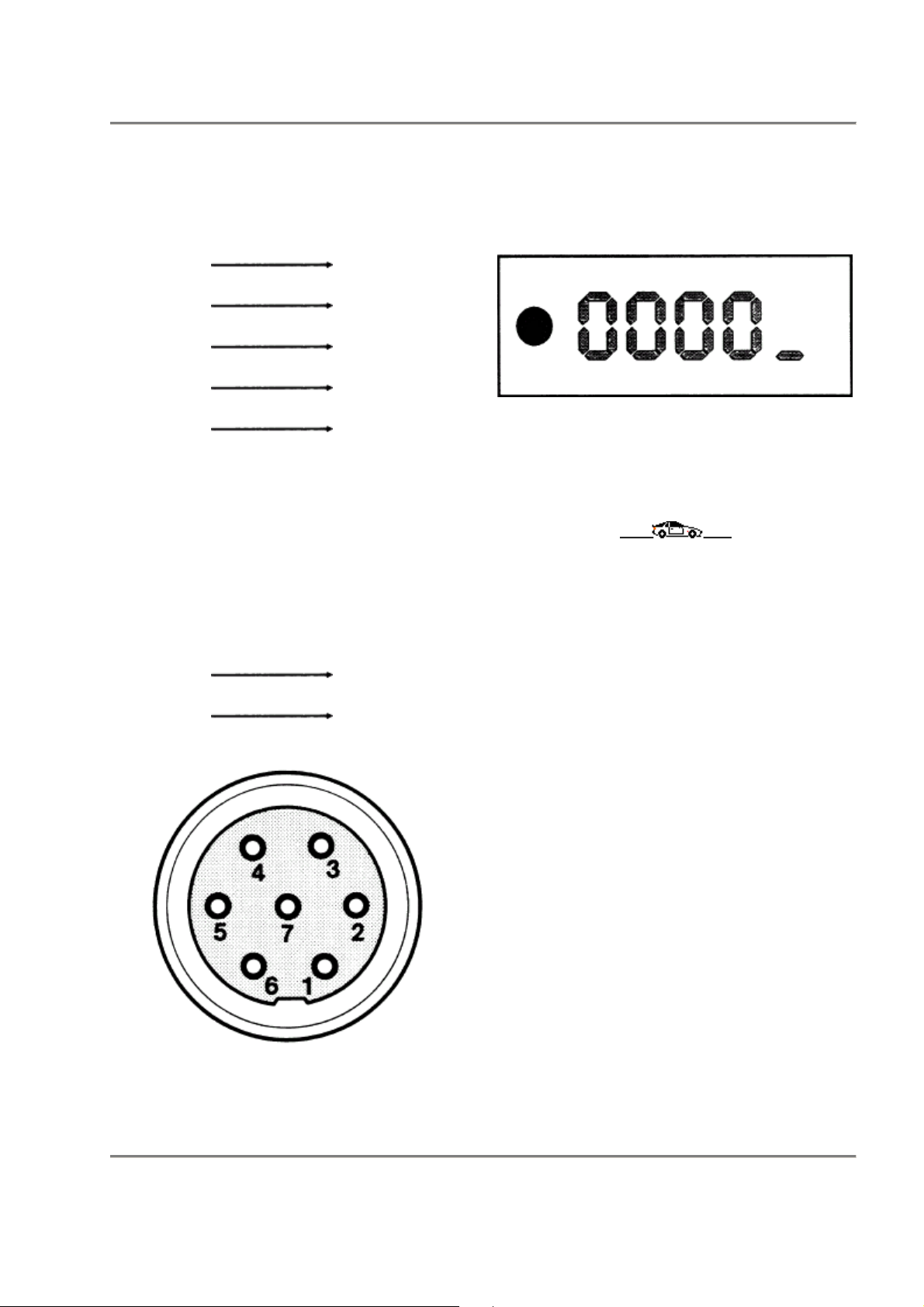

Tester cable

Diagnosis

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

plug

unused

unused

unused

unused

unused

Round plug

Pin 4

Pin 1

Pin 7

Pin 6

Pin 2

Pin 5

Pin 3

Switch on the ignition

Display:

The ignition must not be switched off

during the entire error diagnosis

procedure.

03 - 4

34

Connection in the 944 S

Printed in Germany - XVI, 1987

944 Maintenance, Self-diagnosis

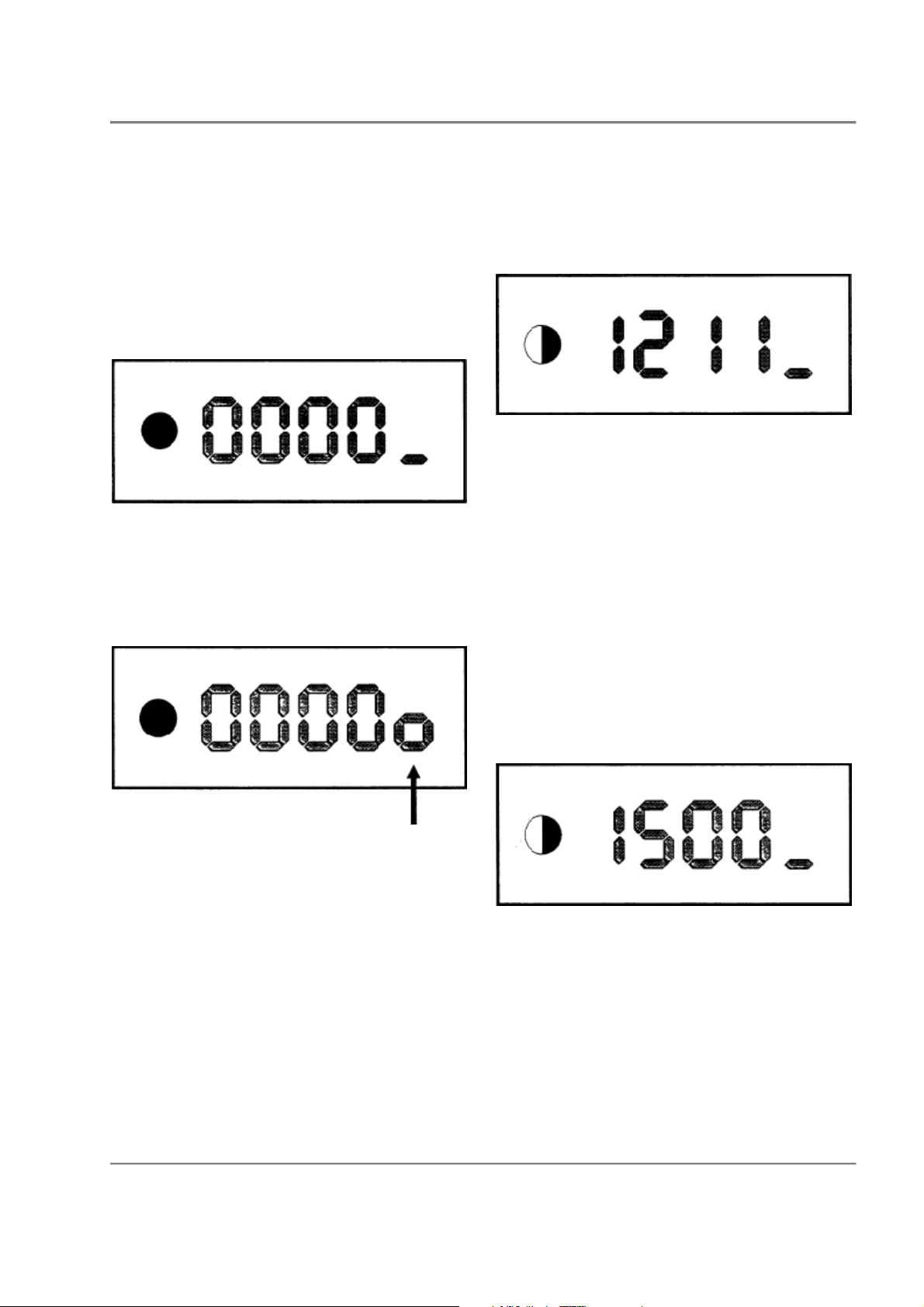

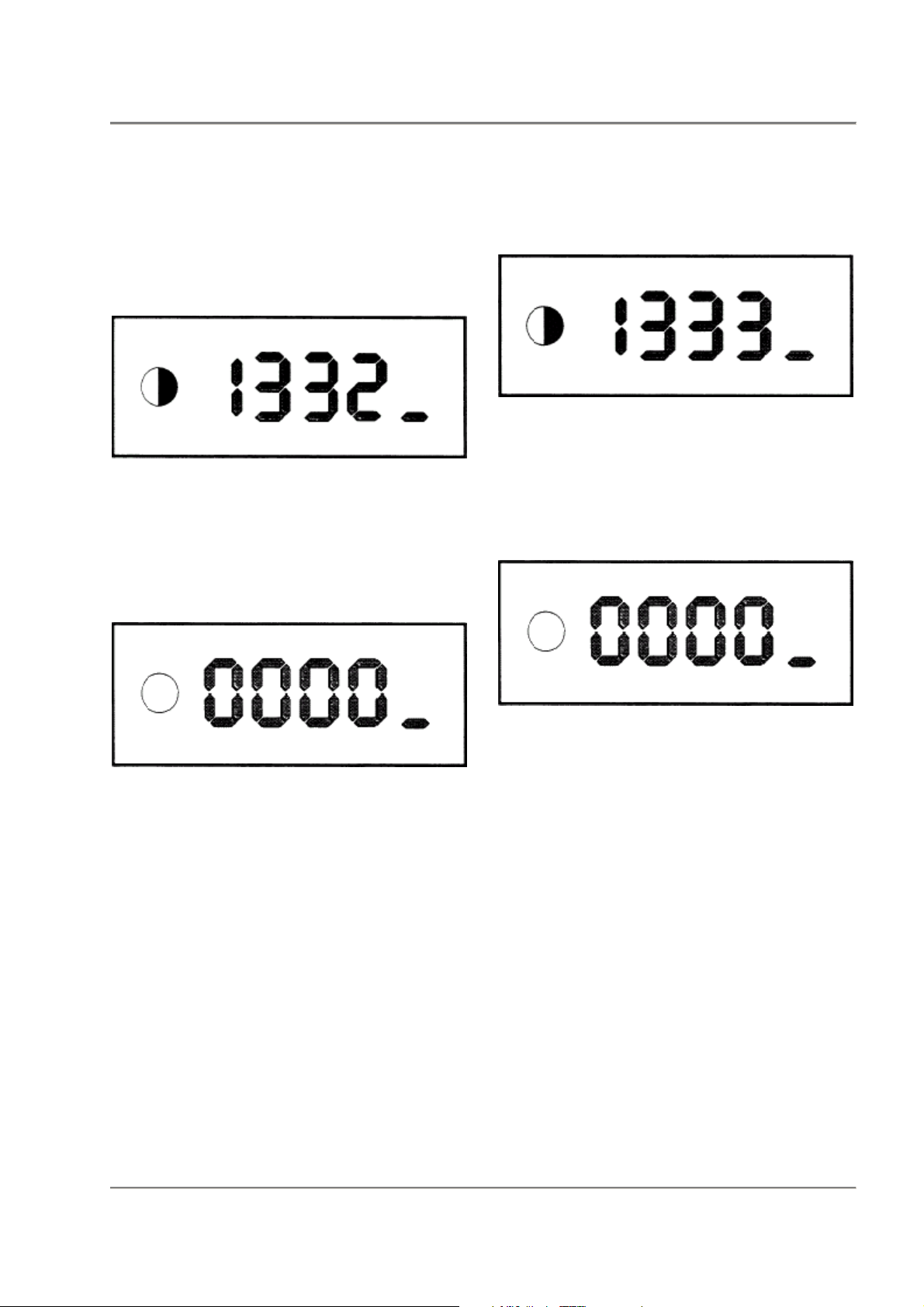

Starting error diagnosis

Condition:

Engine off

Ignition on

Display:

Press the green key until the clear symbol

appears on the function display.

Display:

If an error is displayed - take the note of the

error (e.g. 1211).

Display:

The error is displayed until the green key is

again pressed on the tester. The next

error code is then displayed. if applicable.

This must be repeated until 1000 appears on

the display.

If no error has occurred. the following display

appears.

Display:

03

Clear symbol

The diagnosis sequence for the DME control

unit then takes place.

Starting error diagnosis

Printed in Germany - XVI, 1987

03 - 5

03

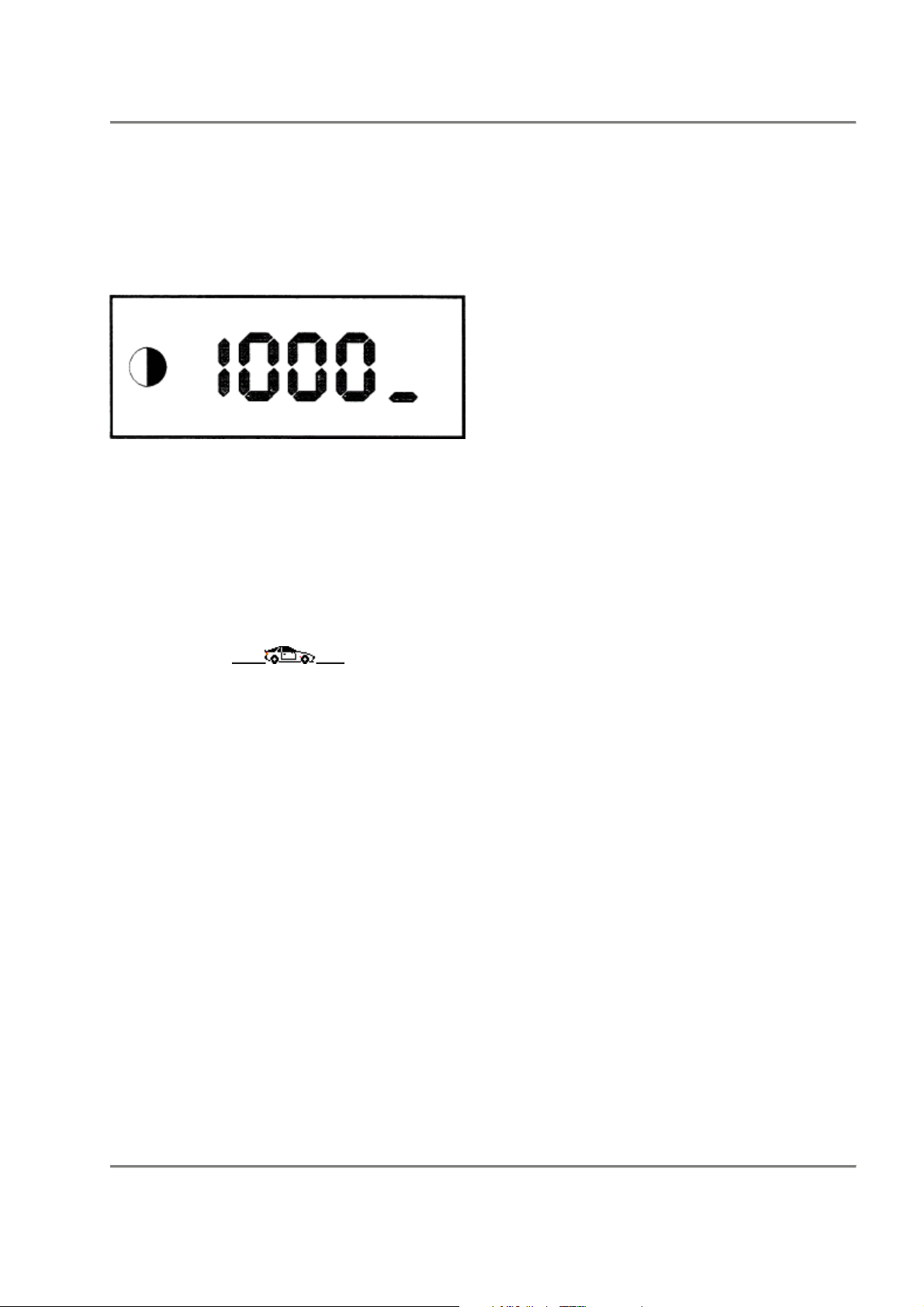

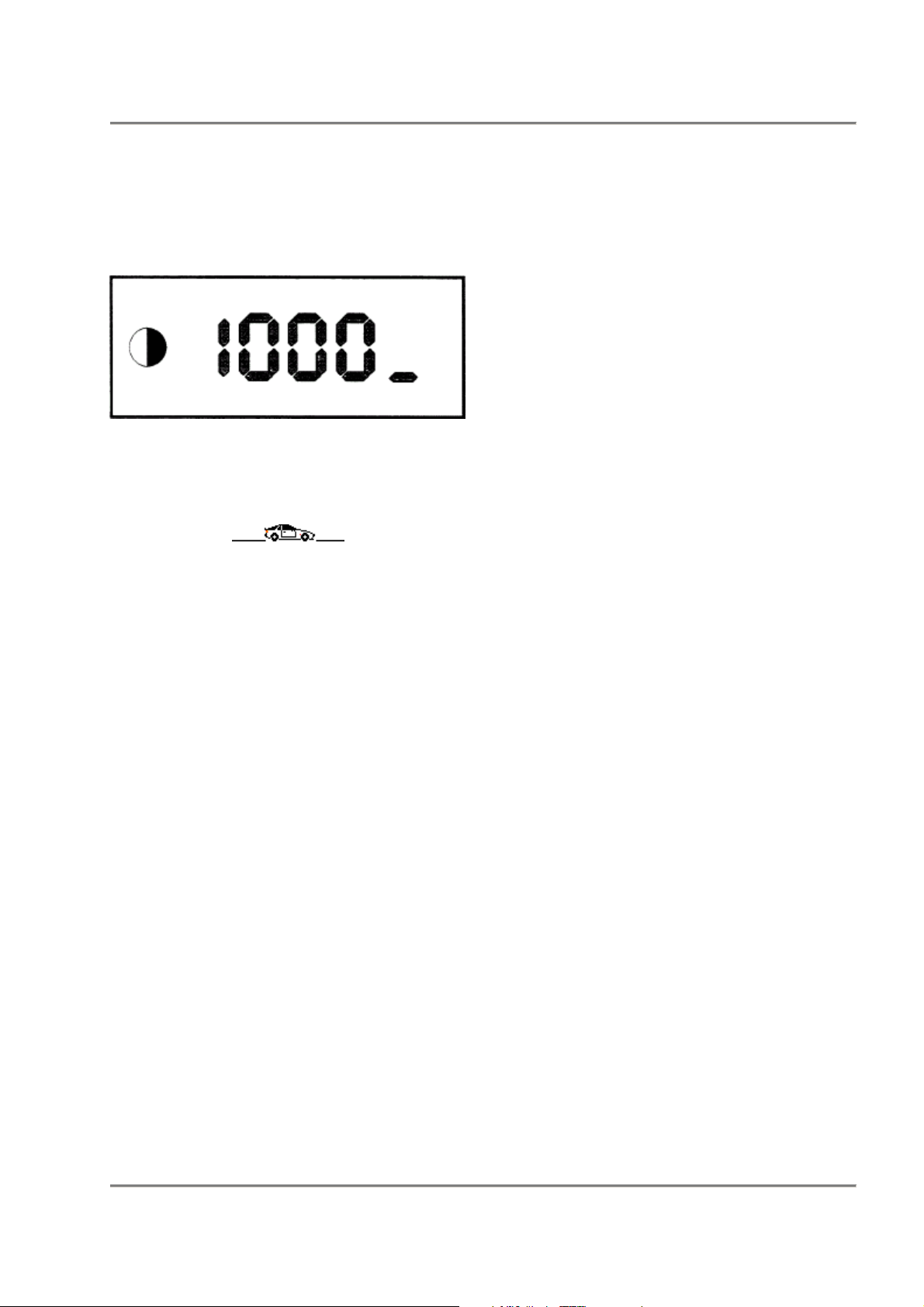

Press the green key until the clear symbol appears on the function display. The following

display must then appear.

Display:

This now terminates diagnosis of the DME

control unit.

If one or several errors (up to 5) has/have

been displayed, the error memory must be

reset; see chapter (Resetting the error

memory).

Maintenance, Self-diagnosis 944

03 - 6

Printed in Germany - XVI, 1987

Starting error diagnosis

An error display via the tester is not possible

wiring connection ara detected by the tester.

944 Maintenance, Self-diagnosis

Actuator and input signal function

checking

An actuator and input signal function check

can be carried out independently of an error

diagnosis. This function check tests

individual

components or electrical signals with

respect

to their functioning or signal paths.

Functions

ara triggered from the diagnosis tester.

During

functional checking of components, these

must audibly or tangibly operate and can

thus

be detected as being electrically in proper

working order or defective.

in

this mode, but faulty input signals or their

Starting actuator and input signal

function check

Ignition off

Press the yellow key until the function symbol

(see display) appears on the function display.

Display:

Prass the green key until the clear symbol

appears on the function display.

Display:

03

Actuator and input signal function checking

Printed in Germany - XVI, 1987

Switch on the ignition within 8 seconds.

03 - 7

03

Maintenance, Self-diagnosis 944

Press the green key until the ctear symbol

appears on the function display. This activates

the first testing step and the injection valves

are activated.

Display:

The injection valves must all operate audibly

or tangibly.

Note:

If later attempts are made to start the engine,

starting difficulties may occur because a

slight

residual amount of fuet is injected during this

testing step.

The testing steps remain in operation until the

green key is again pressed on the tester and

the clear symbol appears.

The next testing step is initiated by again

pressing the green key.

Refer to the test code list for the sequence

of

testing steps.

03 - 8

Actuator and input signal function checking

Printed in Germany - XVI, 1987

944 Maintenance, Self-diagnosis

As from the "idle contact" testing step,

specific

controls must additionally be operated on the

car for the purpose of function checking.

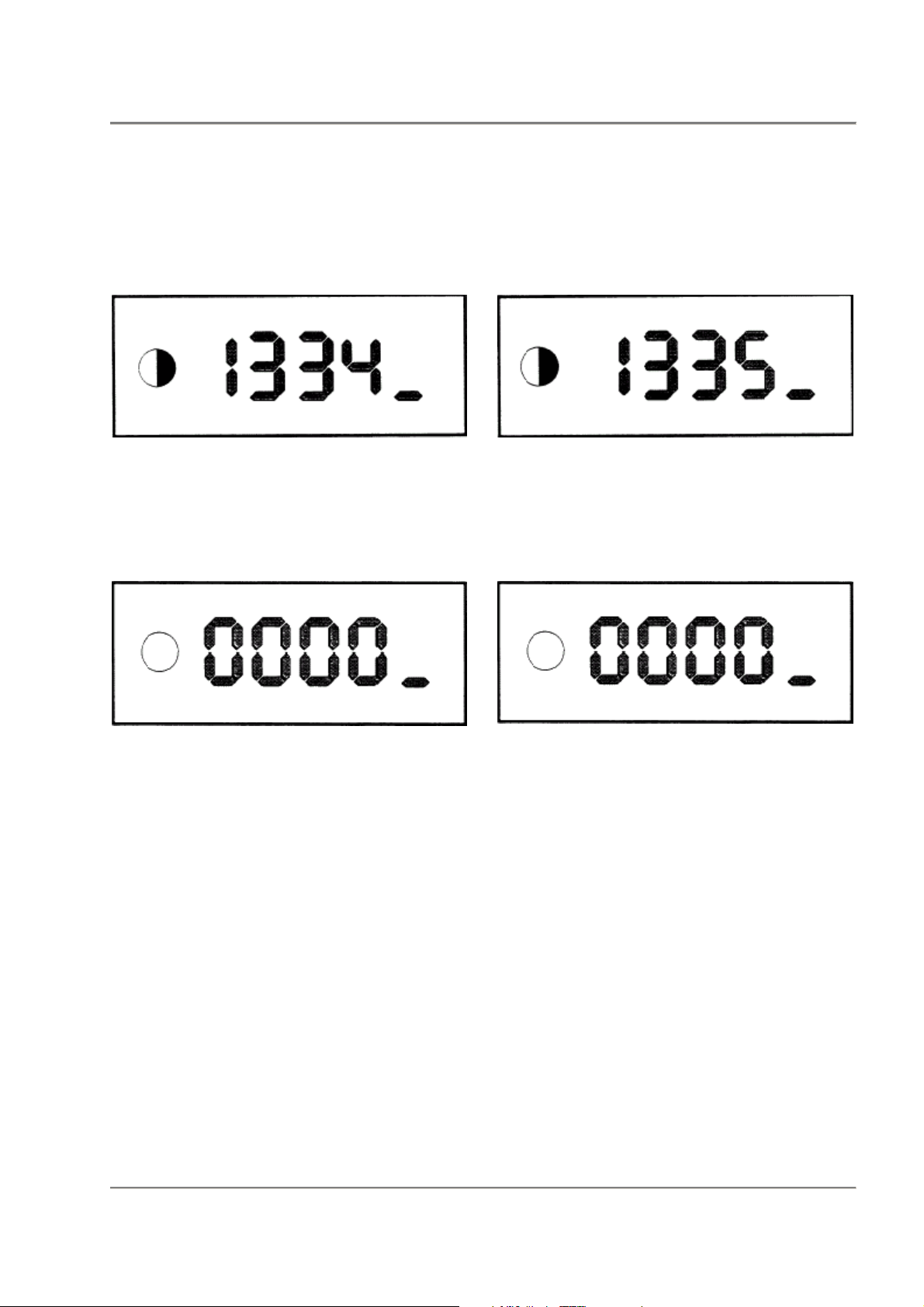

Idle contact display:

Slightly press the accelerator. The LED must

go off after approx. 20 mm and the display

will

appear After approx. 3 s.

Display:

Initiate the full load contact testing step.

Display:

Slowly press the accelerator until the full

throttle position is reached.

The LED must go off and the display will

appear after approx. 3 s.

Display:

03

If this is not the case, an error has occurred

in

the area of the idle contact (see Idle contact

troubleshooting).

If the display 0000 does not appear, it is possible to switch at all times to the next testing

step. Press the green key until the clear

symbol appears.

If this is not the case, an error has occurred

in

the area of the full load contact (see Full load

contact troubleshooting).

Actuator and input signal function checking

Printed in Germany - XVI, 1987

03 - 9

conditioning system.

03

Maintenance, Self-diagnosis 944

Initiale the air-conditioning control terminal

41

testing step.

Display:

Switch on the air-conditioning system.

The LED must go off and the display will

appear after approx. 3 s.

Display:

Initiate the air-conditioning control terminal

40

testing step.

Display:

Switch off the air conditioning system.

The LED must go off and the display will

appear after approx. 3 s.

Display:

If this is not the case, an error has occurred

in

the area of the air-conditioning system's

wiring.

In the event of an error, check with reference

to the circuit diagram.

Do not switch off the air-

If this is not the case, an error has occurred

in

the area of the air-conditioning system's

wiring.

In the even! of an error, check with reference

to the circuit diagram.

03 - 10

Actuator and input signal function checking

Printed in Germany - XVI, 1987

944 Maintenance, Self-diagnosis

Press the green key until the clear symbol

appears.

Display:

End of the actuator and input signal function

checks.

03

Actuator and input signal function checking

Printed in Germany - XVI, 1987

03 - 11

03

944

03 - 12

Blank page

944 Maintenance, Self-diagnosis

Test code list

Test code Components

1311

1321

1322

1332

1333

1334

1335

Injection valves

Rotary idle controller

Solenoid valve - tank bleeding

Idle contact

Full load contact

Air-conditioning/AC switch

Air-conditioning/compressor coupling

03

Test code list

Printed in Germany - XVI, 1987

03 - 13

03

944

03 - 14

Blank page

944 Maintenance, Self-diagnosis

System adaption

System adaption can be carried out with the

tester. That is to say. the electronic idle control

in the DME control unit is adapted to the

actual air throughput and to the current

condition of the engine.

Note:

For system adaption, it is necessary for the

engine to be at operating temperature.

Ignition off

Press the yellow key the number af times

required for the function symbol to appear

on the function display.

Display:

Display:

The engine must now idle for at least 30

seconds.

System adaption is then completed.

Ignition off

03

Press the green key until the clear symbol

appears on the function display. Start the

engine within 8 seconds. Allow the engine to

idle until the system adaption code appears.

System adaption

Printed in Germany - XVI, 1987

03 - 15

03

944

03 - 16

Blank Page

944 Maintenance, Self-diagnosis

Knock detection

Before knock detection is carried out, error

diagnosis must first of all be performed to

guarantee that no electrical error has

occurred

in the area of the knock control and the

knock

sensors.

Knock detection should not be carried out if

the customer has complained about poor

output or too high a consumption, for instance.

Condition:

The engine most be at operating

temperature

during the test. Testing most be carried out

during a test drive or on the roller test stand.

Knock detection

Engine at operating temperature

While the engine is running, simultaneously

press the yellow and the green key until the

knock detection function symbol appears

on the function display.

Display:

The tester is new in knock detection mode.

Note:

Normal driving is a prerequisite for the

test drive (roller test stand).

Start the test drive (roller test stand).

Press the green key until the clear symbol

appears on the function display.

Display:

03

Knock detection

Printed in Germany - XVI, 1987

03 - 17

03

Maintenance, Self-diagnosis 944

The tester is now active. If knocking occurs,

this will be indicated by the tester, e.g.:

Display:

After the expiry of 10000 ignitions. the

function

display will change to "r".

Display:

To restart knack detection. the green key

must be pressed until the clear symbol again

appears.

A knock display of > 2.5 (25) draws attention

to an error.

Error possibilities:

Defective cup tappets

Conical rod damage

Crank mechanism damage

To terminale knock detection mode. the

green and yellow keys must be pressed

simultaneously until the display appears.

Display:

Counting is now complete.

The number af knocks is displayed in per

mill.

In this example. 25 knocks have occurred.

Knock detection must be carried out until the

function display switches over from the clear

symbol to the knock detection symbol. This is

always the case once 10000 ignitions have

occurred. All occurring knocks are added up

and displayed as the end result.

03 - 18

Printed in Germany - XVI, 1987

Knock detection

Loading...

Loading...