Page 1

Page 2

WKD

471

820

© Dr. Ing. h. c. F. Porsche Aktiengesellschaft

Printed in Germany.

Reprint, even partial, is not allowed without our prior per-

mission.

Due to the continuous development of our vehicles

variations may occur between the equipment and specification of your vehicle, and the description in the Drivers

Manual.

Some of the equipment described in the Drivers Manual

is not standard. Your authorised Porsche dealer will be

pleased to advise you on later installation possibilities.

Should your Porsche be fitted with equipment not described in this handbook, please refer to your Porsche

dealer.

Because of different legal requirements in individual

countries, the equipment of your vehicle may vary

slightly from that shown in the Drivers Manual.

1.3 Μ 7/82

1983 Edition

Page 3

You have chosen a Porsche.

This choice indicates a special class

of driver. Fairness on the road, consideration, ability and a technical

interest would be characteristic

of you. We have therefore set out

in this manual all the information

you need to know to drive your

Porsche. We wish you many miles

of safe and pleasurable driving

in your

Page 4

Page 5

Index

A

Acceleration diagram 9697

Accessories 54

Airconditioning 3639

Air filter change 67

Air inlet grills 3435

Alarm system 9

Aluminum wheels 57

Ashtrays 41

Automatic gearbox 4751,62

Automatic seat belts 1617

Β

Battery 76

Before beginning a journey 8

Belts 1617

Blinker warning light 24

Brake beddingin 52

Brake disc pads 52,53

Brake fluid 65,91

Brake system 18,52,90

Breakdown hints 59

Bulb replacement 7780

Bulb table 81

Cigarette lighter 41

Clock 41

Clutch 18

Cockpit layout 32

Collapsible tyre 70

Concentrated wash system 31,66

Cooling fan 63

Cooling fluid 53,6364,91

Cooling fluid temperature gauge 24

Cooling system 63

D/E

Databank 6,103

Dimensions 93

Dipparklightheadlight flasher switch ... 29

Dipstick 60

Dipswitch 29

Direction indicator switch 29

Door guard light 11

Doors 10

Door lockingcentral 1011

Door locks 53

Electrical system 7483

Emergency starting 85

Engine number 7

Fuel consumption 87

Fuel gauge 25

Fuel tank 66,91

Full power performance 95

Fuses 74

Fuse table 75

G

Gearbox 4651

Gearbox oil level 6162

Gear changing diagram 9899

Glove box 44

Grills Fresh air 3435

Guarantee 110

Η

Handbrake 18

Hazard warning lights 28

Headlights 22,83

Headlight adjustment 40,82

Headlight beam regulator 40

Headlight flasher 29

Headlight washer 31,54,65

Heating 35

Hood lock 45

Hydraulic fluid 67

c

Car care instructions 5558

Carpets 58

Central door locking 1011

Central warning light 24

Central warning unit 3233

Chassis number 7

4

F

Fan belt 39,87

Filling capacities 91

Fog lights, front and rear 22

Footbrake 18,52

Footwell light 10,12

Front seats 1314

I

Identification plate 6

Ignition switch 2021

Interior light 10,12

Interior mirror 15

Instrument panel 20

Instrument illumination 22

Page 6

J/K/L

Jack 59,73

Jacking points 7273

Keys 8,9

Leather 58

Lights 7780

Light switch 19

Lockup wheel nuts 71

Longlife guarantee 108109

Loudspeaker balance control 40

Luggage compartment door 45

light 12

Μ

Main beam warning unit 24

Maintenance 59

Maintenance record 104105

schedule 106107

Makeup mirror 44

Maximum rpm 46,52

Minor paint damage 56

Ο

Oil change 6162

Oil consumption 52,87

Oil filter change 61

Oil level Engine 60

Oil level gearbox 6162

Oil pressure gauge 26

OilsRecommended 92

Ρ

Paint care 55

Paint code number 7

Parking light 29

Performance 90

Polishing 55

Power steering 67

Puncture 7172

R

Rear screen heating 28

Rear screen wiper 43

Rear seats 13

Rear seat storage compartment 41

Rear view mirror 15

Relays 74

Revolution counter 23

Roof rack loading 52,89

Runningin tips 52

s

Safety belts 1617

Seats 1314

Sliding sunroof 4243

Snow chains 54,89

Spare wheel 70

Sparking plugs 87

Spot and stain removal 56

Starter motor 20

Starting the engine 21

Steering 67

Steering lock 2021

Steering wheel adjustment 13

Sun visors 44

Τ

Tachometer 25

Technical data 8799

Tempostat 30

Tool tray 59

Towing 49,84

Trailer weights 89

Transmission diagram 9899

Transmission ratios 88

Tyres, tyre pressures 6869,89

u/v

Underseal 56

Upholstery 58

Ventilation 3435

Voltmeter 26

w

Warning lights 2427

Warning unitCentral 3233

Washing the vehicle 55

Water containers 54,63,65

Weights 89

Wheel adjustment 89

Wheel changing 7173

Wheel nuts, lockable 71

Windows 5657

Window regulators 10

Windscreen washers 31

Windscreen wipers 31

Wing mirrors 15

Winter operation 5354

Winter tyres 54,89

Wiperwasher switch 31

5

Page 7

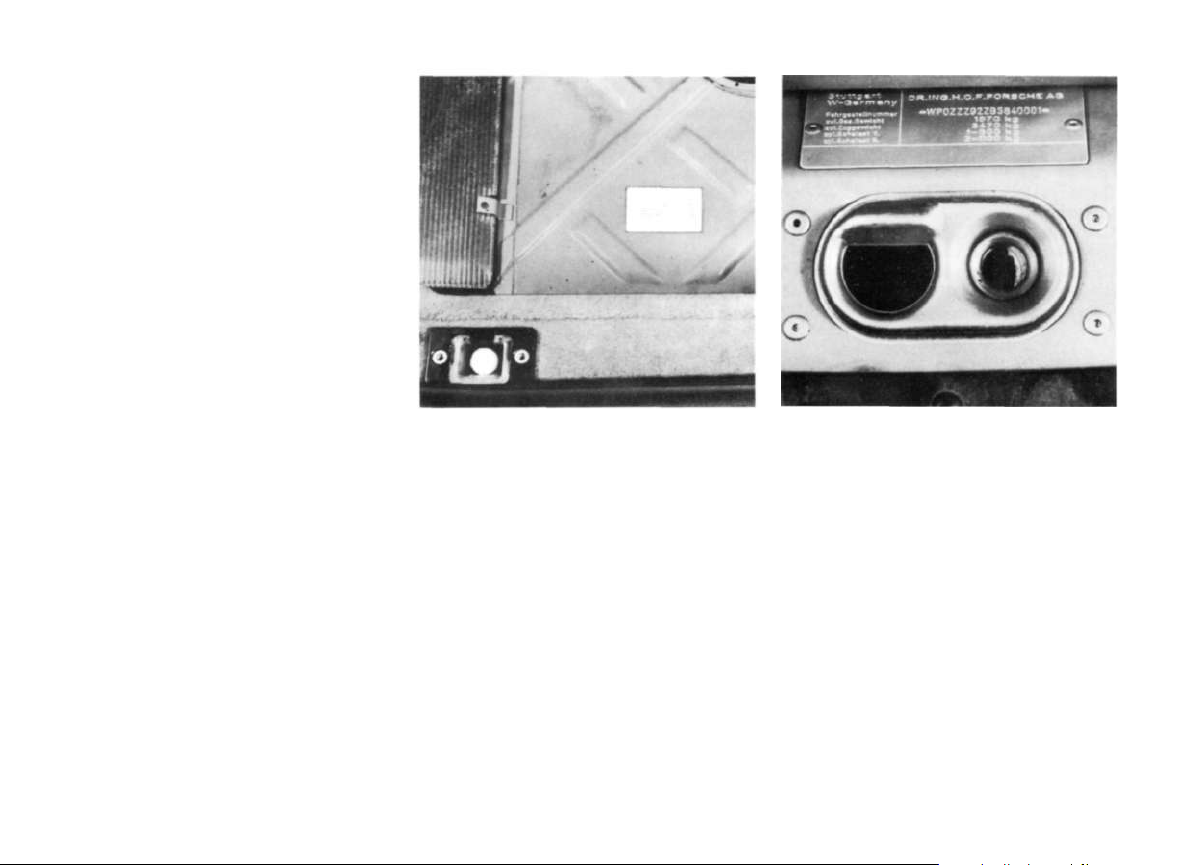

Location of Identification Plate,

Chassis Number, Engine Number

and Paint Number

When ordering spare parts or submitting

inquiries, always quote chassis and engine

numbers to ensure correct and prompt service.

6

Data bank

The data bank is fixed on the floor in the rear of

the luggage compartment next to the spare

wheel well.

Identification plate

The identification plate is riveted on the

front cross member, behind the bonnet lock.

Page 8

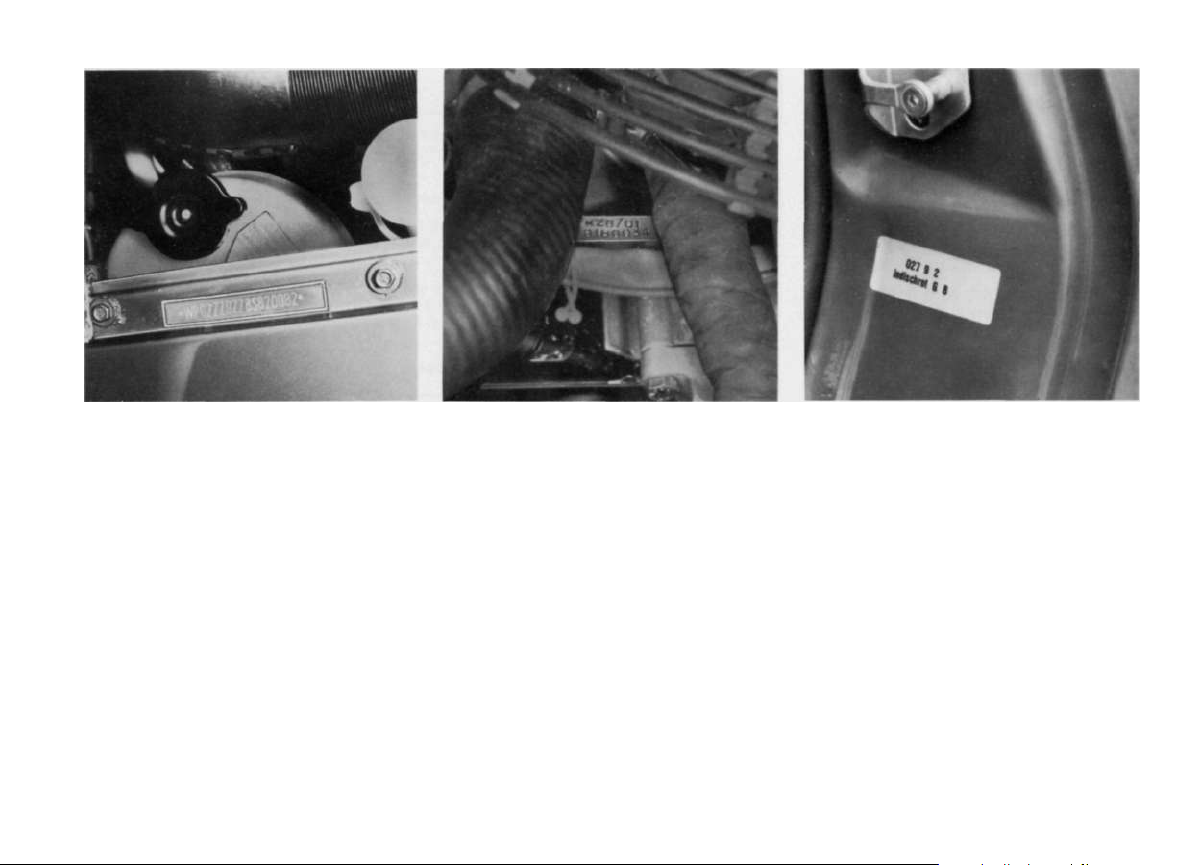

Chassis number

Engine number

Paint number

The chassis number is stamped on the top of

the right wheel arch in the engine compartment and is visible through a cut-out in the

wing flansch.

The engine number is stamped on the front

reinforcing rib in the top half of the crankcase.

The paint number plate is fixed on the left

hand door lock pillar.

7

Page 9

For your own safety, you should,

before a journey,

Keys

check pressures and condition

of the tyres

clean the windows and light lenses,

front and rear

turn the ignition on, and check that

headlamps and turn indicators

are functioning

take note of the central warning

light

adjust rear view mirrors to give

uninterrupted rear vision

fasten seat belts, so should

the passengers.

Have the oil level in the automatic

transmission checked regularly,

even in-between the recommended

maintenance intervals.

8

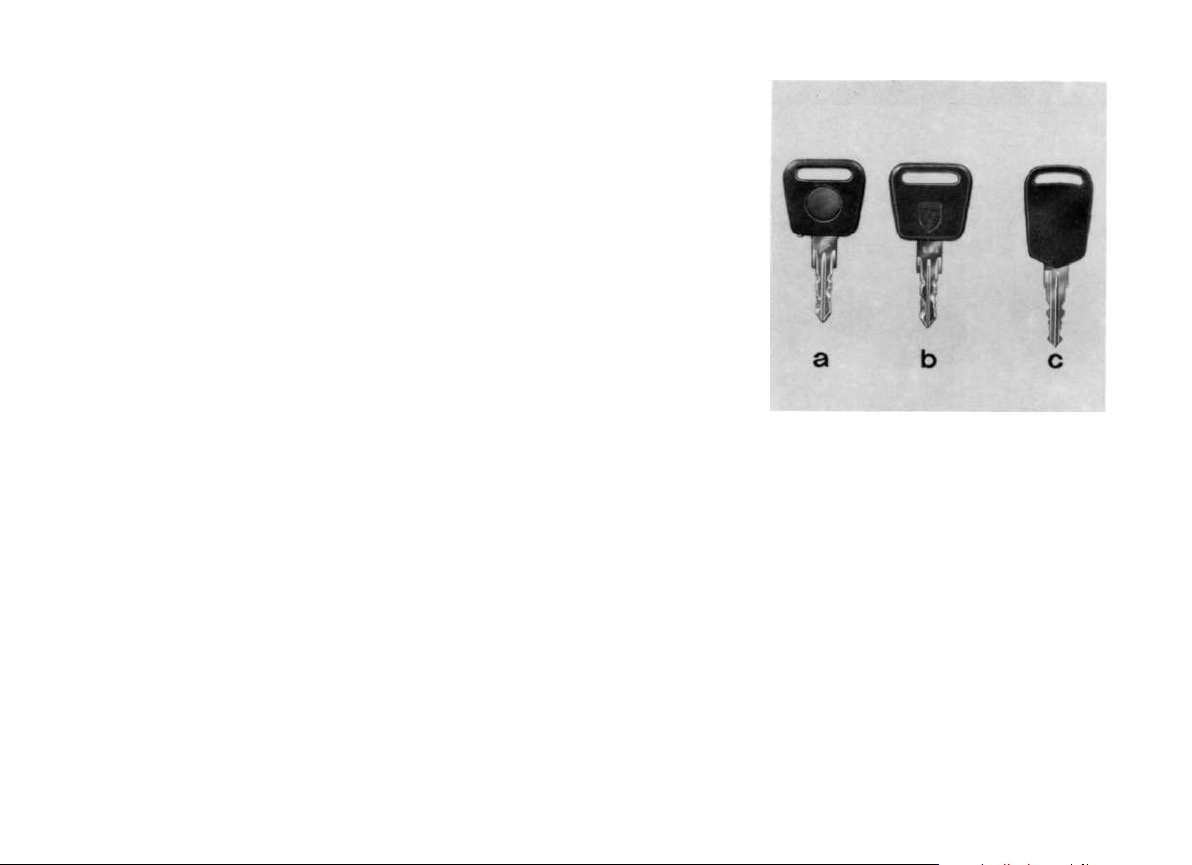

With the vehicle you receive two master and

two auxiliary keys. The two master keys fit all

locks, the auxiliary keys do not fit the glove

compartment lock.

Vehicles with a rear seat storage compartment receive two additional keys for the

compartment lock.

One master key has a built-in flash light. The

light is on as long as the contact button is depressed.

When the light begins to fade, the battery

must be replaced with one of the same type.

A discharged battery could leak and damage your clothing.

By virtue of the new format for the master

and auxiliary keys, the unauthorised manufacture of keys is almost completely elimi-

nated. This means however, that you yourself will not be able to get replacement keys

cut, you must order them from the manufacturer.

a Master key

b Auxiliary key

c Rear seat storage compartment key

Should you need new keys, you must give

the key number. This number is noted on

the plastic tab, that you receive with the

keys. Keep this tab somewhere safe, not in

the vehicle.

Page 10

Application Positions

Door Locks

Steering/Starter

ignition switch

Luggage

Compartment

Door Lock

Tank Filler Cap

Glove

Compartment

Switching Alarm system on and off.

Locking and unlocking the doors.

Lockable.

Switching alarm system on and off. Opening lug-

gage compartment door.

Only lockable with an auxiliary key.

The S-Key should, for reasons of safety, not be

lent out to other persons

Lockable.

Alarm system

If your car is equipped with an alarm system

you will have received two S-keys instead of

the normal master keys. The alarm system

can be activated only with the S-key by locking the doors or closing the luggage compartment door and turning the key to the

left. If the doors are locked with the auxiliary

key then the door will be mechanically locked but there is no contact to activate the

alarm. The alarm system is switched off automatically when a door or the luggage compartment is opened with the S-key. If the luggage compartment door is opened while the

alarm system is switched on, the key must

be turned to the left to reactivate the alarm

system. If the drivers or passenger side door,

engine compartment hood or the luggage

compartment door is opened while the

alarm is activated a specially protected siren

will sound for about 30 seconds. The engine

cannot be started.

In the interest of safety the S-Key should never be lent out to other persons. For this reason the fuel filter cap can only be locked

with the auxiliary key. This key can be used

as a"workshop key" and can also be handed

over at filling and service stations.

9

Page 11

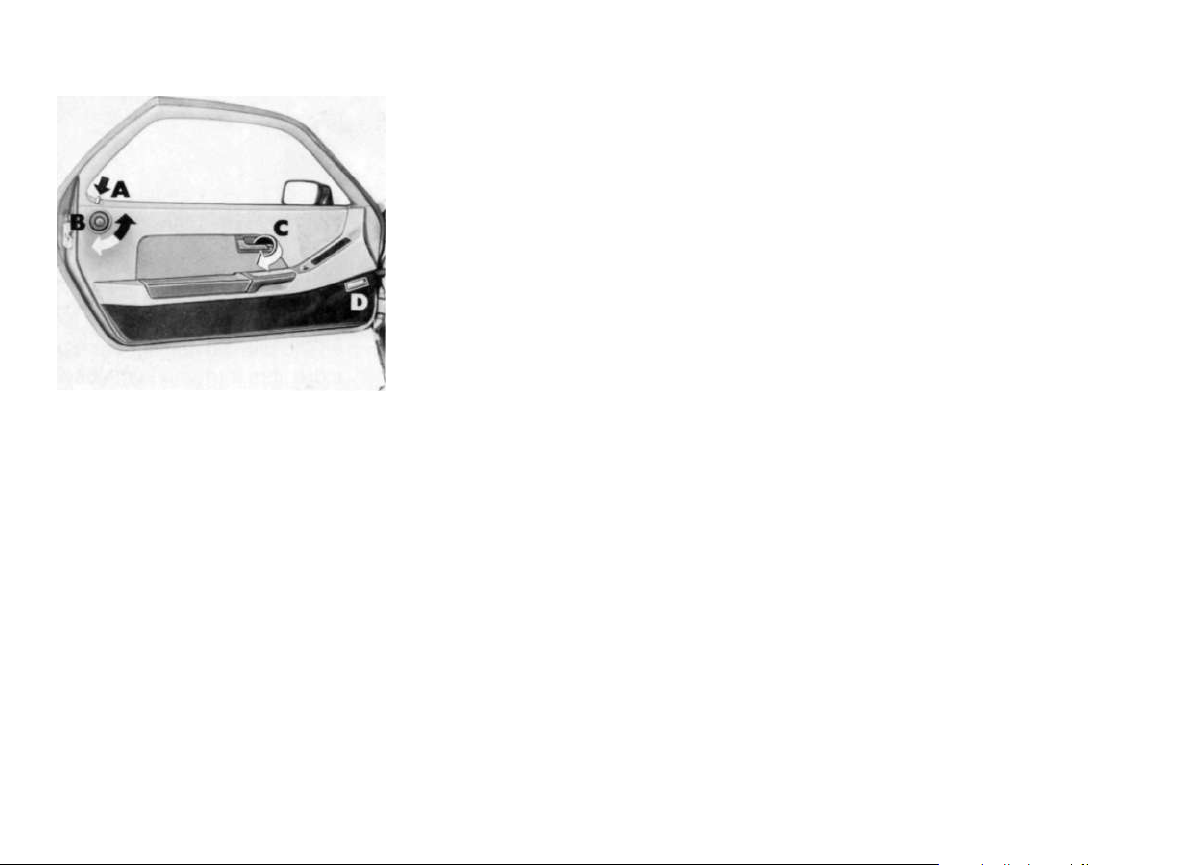

Doors

The doors are opened from the outside by

pulling the inset door handle, and from

inside, by pulling lever (C).

Access to the storage compartments in the

door is obtained by pressing the safety

knob, and tipping the armrest outwards.

The window regulators are operated by the

rocker switches in the middle console.

10

Warning: To avoid injury to unknowing occu-

pants of the vehicle, (e. g. children) by the

closing of the windows, the ignition key

should always be withdrawn when leaving

the vehicle, if only for a short period.

The footwell lights (D) mounted forward in

the lower part of the door trimcone on, with

the switch in the appropriate position, when

the door or the luggage compartment door

is opened. Each light can also be switched

on or off individually by means of the integrated switch.

Central door locking

By means of the central door locking system

both doors are electrically locked or unlocked by operating one lock.

When the doors are locked the locking buttons (A) must be fully retracted. If this is not

the case the lock on that door is not properly

engaged. Re-open the door, close it properly and re-lock it.

Page 12

On vehicles with central locking the passenger door can be locked and unlocked by

turning the knob (B) as well as with the key.

To prevent being accidentally locked out of

the vehicle it is impossible to lock the door,

while open, either using the knob (B) or with

the key.

Central locking is only possible when both

driver and passenger doors are closed. If

one door is locked before the other is closed

it will automatically unlock when the other

door is closed.

A mechanical locking or unlocking of the

individual doors is only possible when the

ignition is switched on or when the ignition

key is turned to pos. 1. This cut out of the

electrical function prevents the doors from

locking in the case of a short circuit or if

deformed in an accident.

When the ignition is switched off but with the

key still in the ignition lock the doors can be

centrally locked using either the key or the

knob (B).

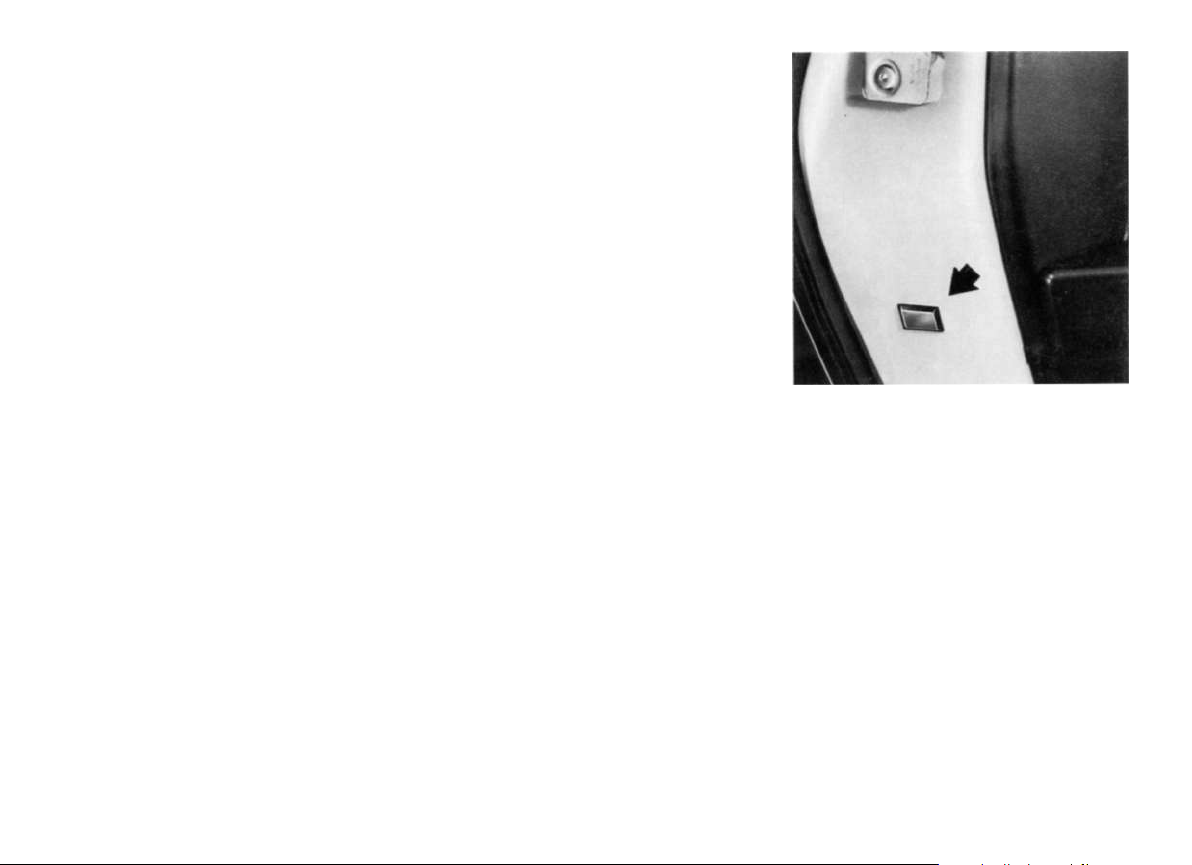

Door guard lights

The door guard lights come on when a door

or the luggage compartment door is opened.

11

Page 13

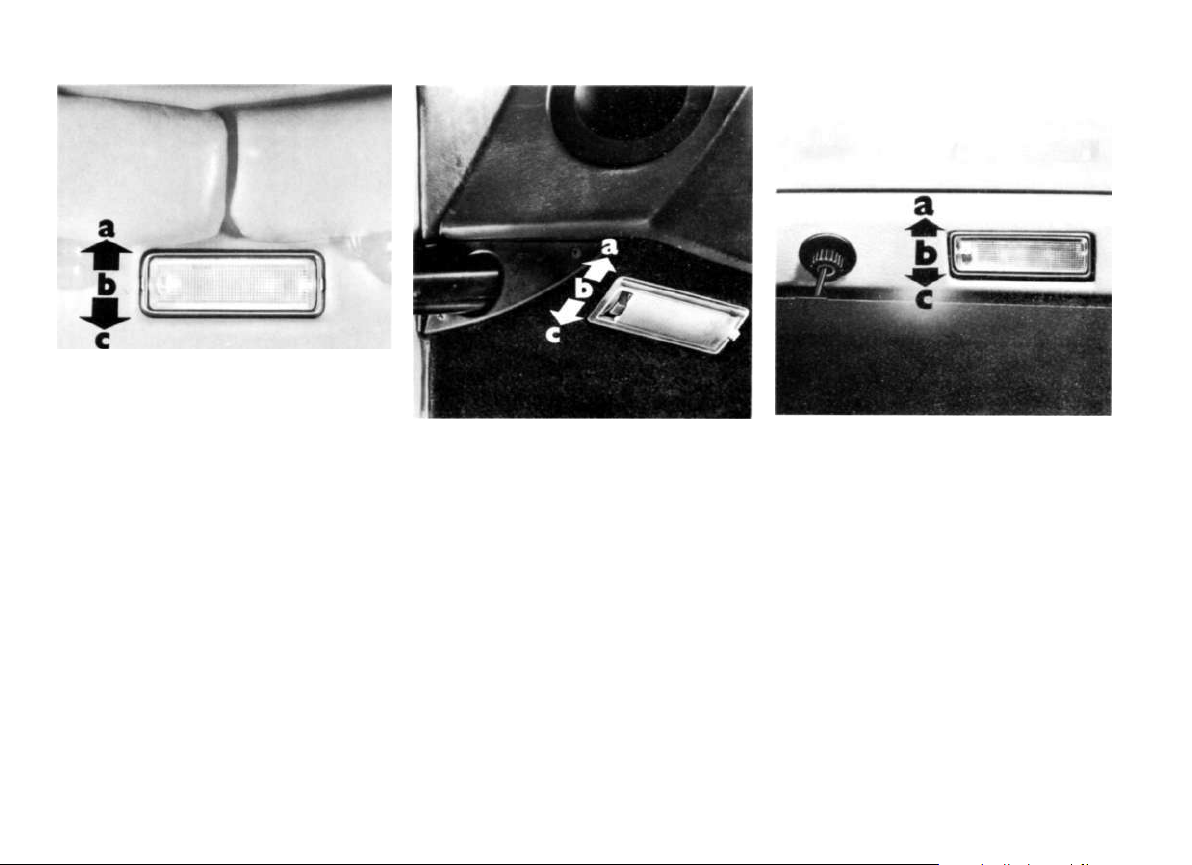

Interior lights

The interior lights, which are independent

from one another, come on, with the switch

in the appropriate position, as soon as a

door or the luggage compartment door is

opened. The interior lights mounted in the

roof lining can be switched as following by

tipping the light cover:

a - light switched on permanently

b - light switched off permanently

c - light comes on only when a door or lug-

gage compartment door is opened.

12

The footwell lights mounted forward in the

lower part of the door trim have following

switch positions:

a - light comes on only when a door or lug-

gage compartment door is opened

b - light switched off permanently

c - light switched on permanently.

The luggage compartment light in the rear

lid has the following switch positions:

a - light comes on only when a door or lug-

gage compartment door is opened

b - light switched off permanently

c - light switched on permanently.

Page 14

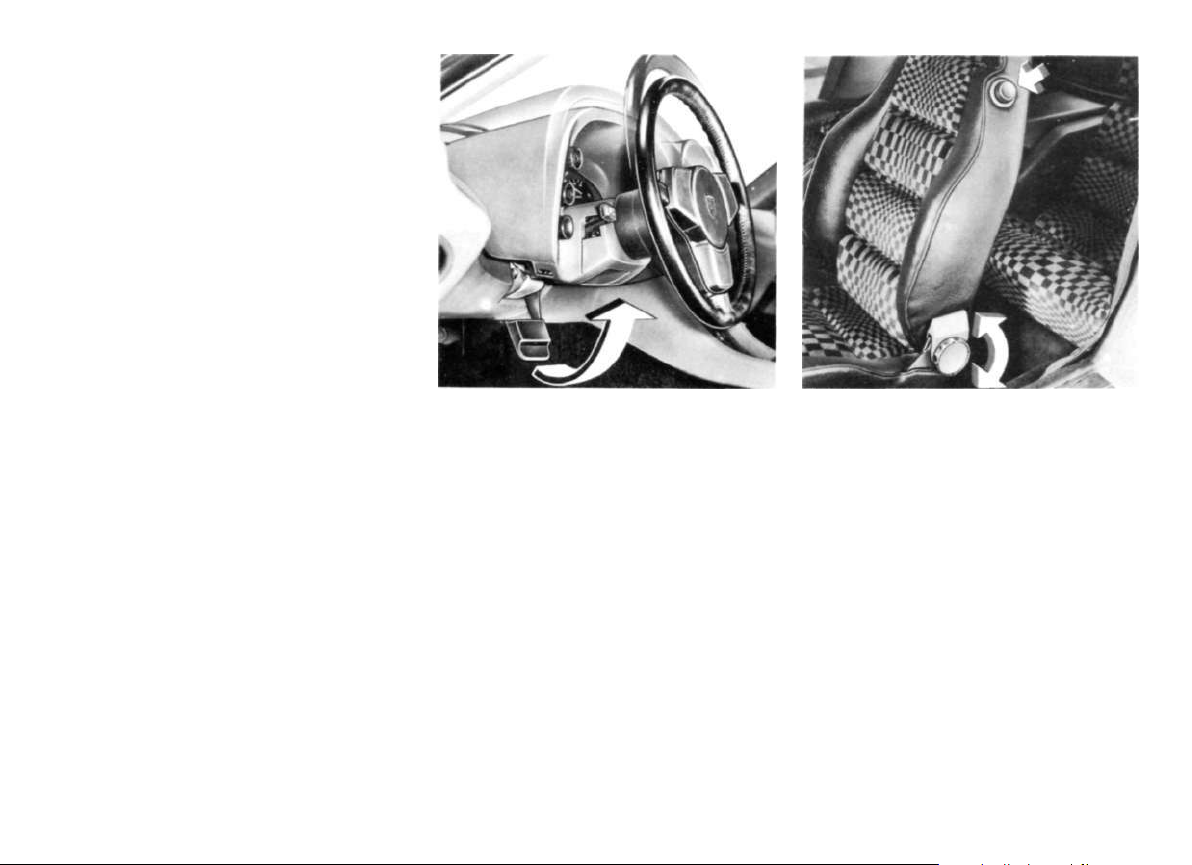

Front seats

Correct seat positioning is imperative for

safe and tireless driving. To enable individual

seating comfort, the seats are adjustable for

and aft and the backrest angle is adjustable.

To find the most suitable seat position, we

suggest the following procedure:

1 Pull the locking lever at the front of the

seat upwards, and slide the seat until your

leg is straight when fully depressing the

clutch pedal. You should not however

have to outstretch your foot to reach this

position. Let the locking lever down, and

ensure that the seat is locked in a ratchet

on the seat slides. Never try to adjust the

seat whilst driving, as a sudden change of

seat position could cause you to lose

control of the vehicle.

2 Grip the top half of the steering wheel.

Then set the backrest angle so that with

fully outstretched arms, your shoulders

still contact the backrest.

Then check the steering wheel position, and

view of the instruments.

For optimum legroom and view of the instru-

ments, the steering wheel and instrument

console can be released, adjusted, and then

re-locked.

The backrests are secured in position to

stop them tipping forward during braking; to

release, press the button on the side of the

backrest.

Similarly, the rear seat backrests can be released, and tipped forward, thereby giving

more luggage room in the rear.

13

Page 15

a - For and Aft adjustment

b - Height adjustment

c - Backrest adjustment

Electric seat adjustment Hand operation

In vehicles fitted with electrical seat adjustment, the controls for the electric motors

which adjust the seat for/aft, height, and

rake angle can be found mounted in the outside flanks of the seats.

14

To prevent damage to the belt lock and to

the seat cover, care should be taken that the

belt lock is pushed outwards so that it cannot jam between the seat and seat backrest

when the seat is moved forward.

Manual operation of the seat is also possible

in case of possible electrical malfunction. To

do this pull the locking lever at the front of

the seat upwards and slide the seat to

achieve the desired seating position, then

release the lever.

Page 16

Rear view mirrors

Before beginning a journey you should ensure that the rear view mirrors are properly

adjusted.

The interior rear view mirror is stuck directly

on the windscreen. This enables a very short

mirror stem to be used thereby obviating

vibration, and a blurred image.

The mirror is adjusted to the anti-dazzle

position by pressing the lever underneath it.

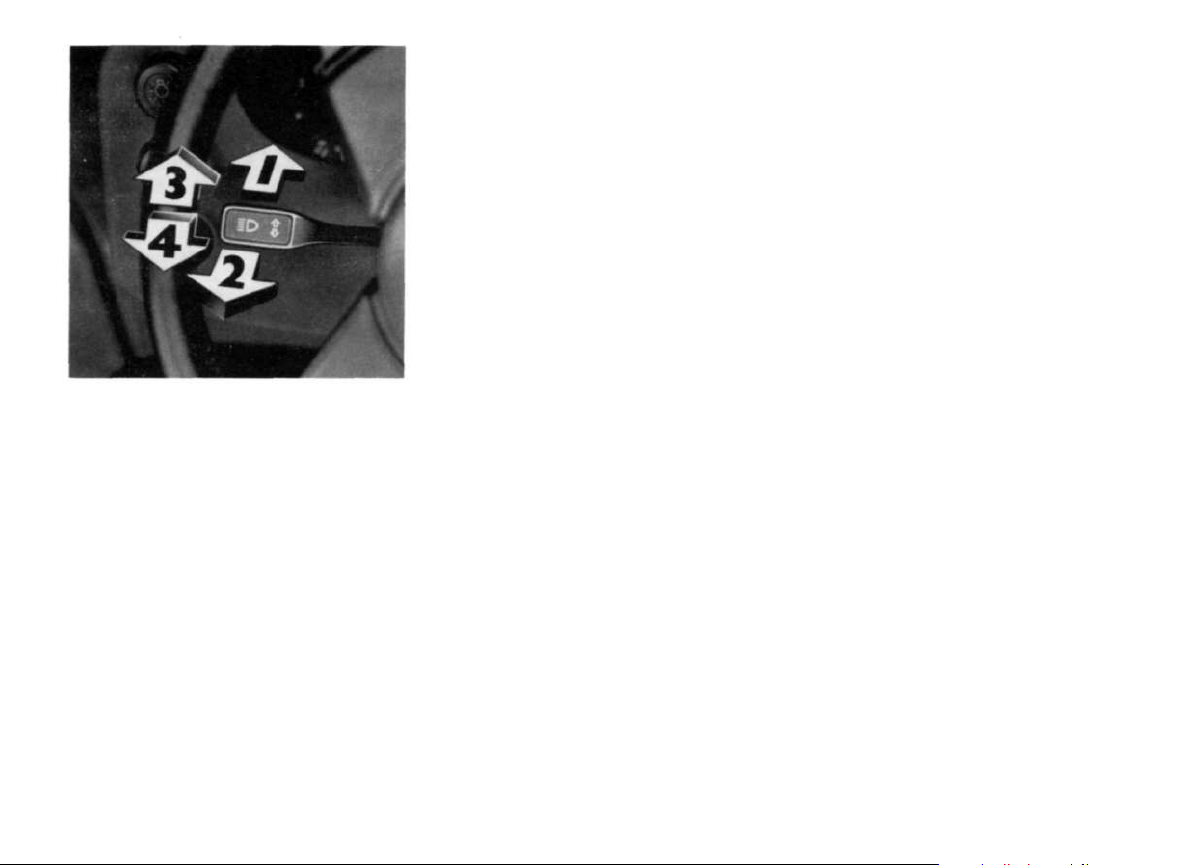

The electrically adjustable wing mirrors can

be set with the switch in the driver's door.

The passenger door wing mirror is adjustable by the same switch, by pressing the

rocker switch beside the adjuster switch into

the appropriate position.

When necessary, the wing mirrors can also

be adjusted by hand.

The wing mirrors are also electrically heated

when the rear window heating is turned on.

15

Page 17

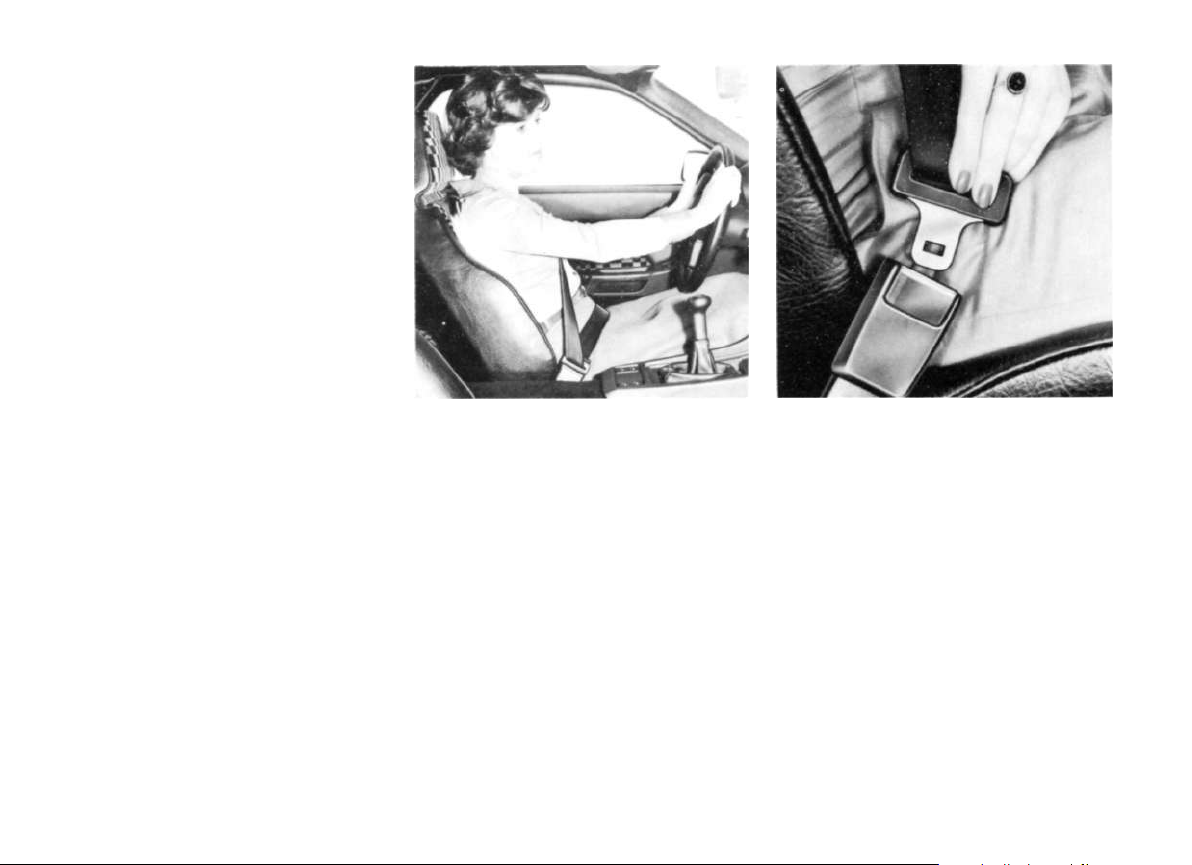

Safety belts

Your Porsche is equipped with safety belts

as standard fittings. All occupants of the car

should wear safety belts for their own safety,

on every journey. To remind you of this, a

warning light in the middle console comes

on for approx. 6 seconds, every time the

ignition is turned on.

The lap and shoulder belts as fitted are not

suitable for children under 140 cm (4 ft. 6

ins.) tall. To stop them distracting the driver's

attention, and for their own safety, children

under 12 years old should always travel in

the rear seats.

Never use one seat belt for two people.

Loose clothing affects the fit of the seat belt.

You should therefore take your coat off, because a correct seating position and freedom of movement are important for comfort

and safety.

Do not run the belt over fragile objects in

your pockets, e. g. spectacles, pens or a

pipe etc. as these could represent additional hazards.

Please remember when driving abroad, that

in some countries the wearing of seat belts

is compulsory.

Putting on the belts

Decide the best seating position for yourself. Take hold of the sliding buckle and pull

the belt firmly over chest and hips. Press the

buckle into the respective anchor point until

you hear that the latch is locked. Slide the

plastic loop up to the buckle.

Avoid twists in the webbing when putting

on the belt.

16

Page 18

The lap part of the belt must always stay taut

over the pelvis. After putting the belt on, you

should therefore pull the shoulder part of the

belt upwards as shown in the picture. Now

and again during the journey, you should

repeat this procedure to ensure that the lap

belt is always taut.

The locking mechanism in the roll-up unit is

so designed, that by rapid acceleration or

braking, cornering or driving on steep in-

clines, the belt is locked. This locking system

reacts more quickly to the retardation of the

car than to any pull on the belt.

Releasing the belts

To release the belt, press the red button

marked "press". The buckle then springs out

of the anchorage, whether there is any loading on the belt or not.

Make sure that the belts are always fully retracted when not in use. This will prevent

them becoming dirty and avoid unnecessary damage to the belts themselves.

You should check your seat belts regularly

for signs of damage to the webbing. Make

sure that the locks and anchorage points are

in good condition. If the belts have been

subjected to high loads or stretched in an

accident, have them replaced in the interests of your own safety.

Back seat safety belts

The back seats are equipped with automatic lap belts. Do not twist the belt when putting it on. The belt is released by pressing

the red button.

Warning. Please do not make any alterations

or additions.

In case of doubt please consult your authorized dealer or, if you live in Great Britain contact

Porsche Cars Great Britain

26-30 Richfield Avenue

Reading

Berkshire RG1 8PH

17

Page 19

Footbrake

Clutch

Handbrake

The handbrake is cable operated to the rear

wheels only. It is applied by pulling the lever

upwards.

To release the brake, the lever must be pulled upwards whilst pressing the button in the

end of the lever until the ratchet is cleared,

and then letting the lever downwards.

The central warning light and the handbrake

warning light will go out when the brake lever

is fully released. (See Automatic warning

unit.)

18

To reduce the pedal effort necessary when

braking, your Porsche has a brake servo unit.

The vacuum necessary to operate this unit is

taken from the engine inlet manifold, when

the engine is running.

Please note that with a defective servo unit,

or when the vehicle is being towed with the

engine turned off, the braking effort required

is considerably increased as soon as the

vacuum reservoir is used up.

With properly bled and functioning brakes,

the free movement at the brake pedal will

remain constant. This free travel before the

brakes start to operate can be 20 mm (0.8

ins.).

Should this free travel suddenly become

bigger, either air has entered the system, or

one of the brake circuits has malfunctioned.

A malfunction of one of the brake circuits or

the loss of brake fluid would cause the central warning light to blink. (See Central warning unit.)

Due to the hydraulic operation of the clutch,

a free travel of the clutch pedal of 2.5 mm is

necessary.

Should this free travel suddenly become

bigger, it could mean a malfunction of the

clutch. Please consult your workshop for

rectification.

Page 20

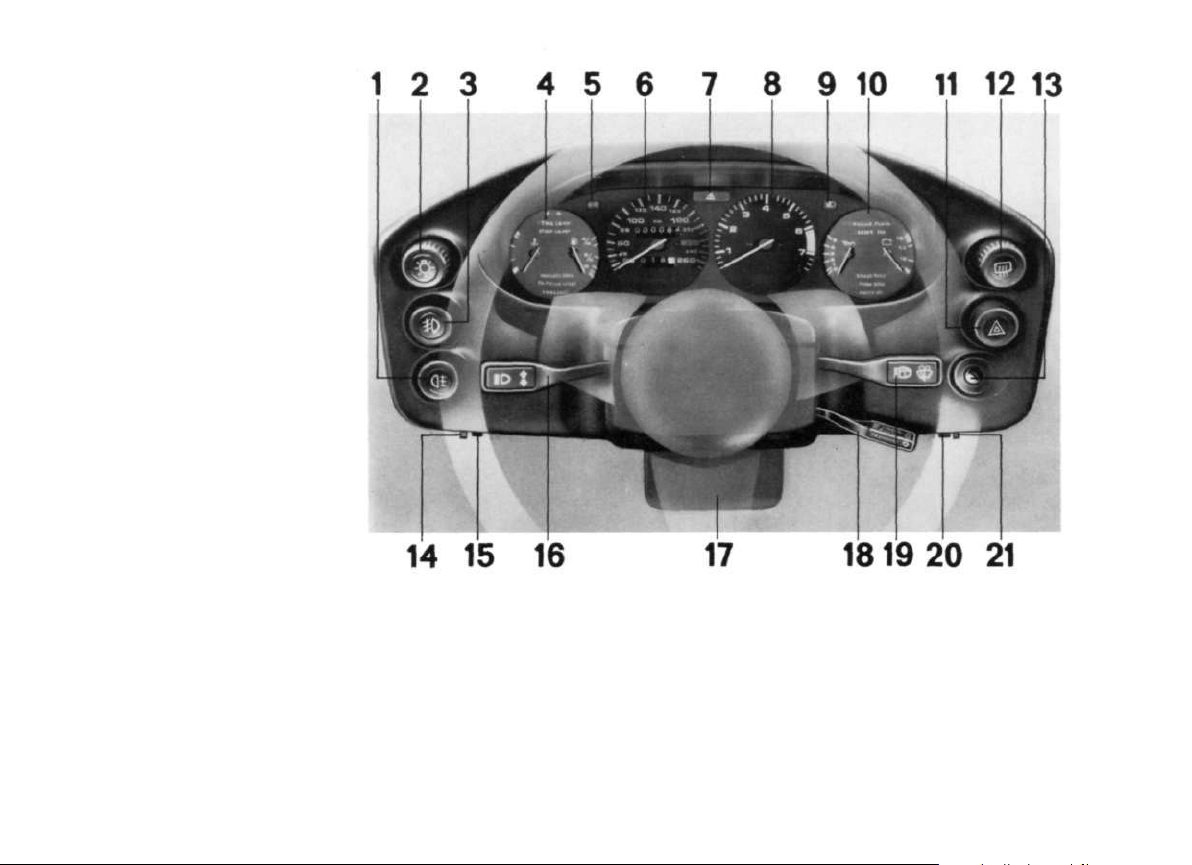

Instrument Panel

1 Rear fog lamp

(on vehicles without rear fog light:

buttton for re-setting trip meter)

2 Light switch

3 Front fog lamps

4 L.H. combination instrument

5 Turn flasher warning light

6 Speedometer

7 Central warning light

8 Rev. counter

9 Main beam warning light

10 R. H. Combination instrument

11 Hazard light switch

12 Heated rear window switch

13 Ignition switch and Steering column lock

14 Instrument panel illumination dimmer

control

15 Trip meter reset

(only on vehicles with rear fog light)

16 Turn indicator-Dipswitch-Parking light

and Headlamp flasher lever

17 Locking lever for steering column and

instrument height adjustment

18 Tempostat

19 Wiper - washer lever

20 Concentrated washer system

21 Wiper-delay adjuster

20

Page 21

1 -Steering unlocked, and all electrical cir-

cuits are operational except direction indicator - reversing lights, wing mirror ad-

justment, rear screen heating and fresh

air fan.

2 -Ignition is switched on. All circuits can

now be operated. With the motor

stationary, the central warning light and

the individual lights are on for control

purposes.

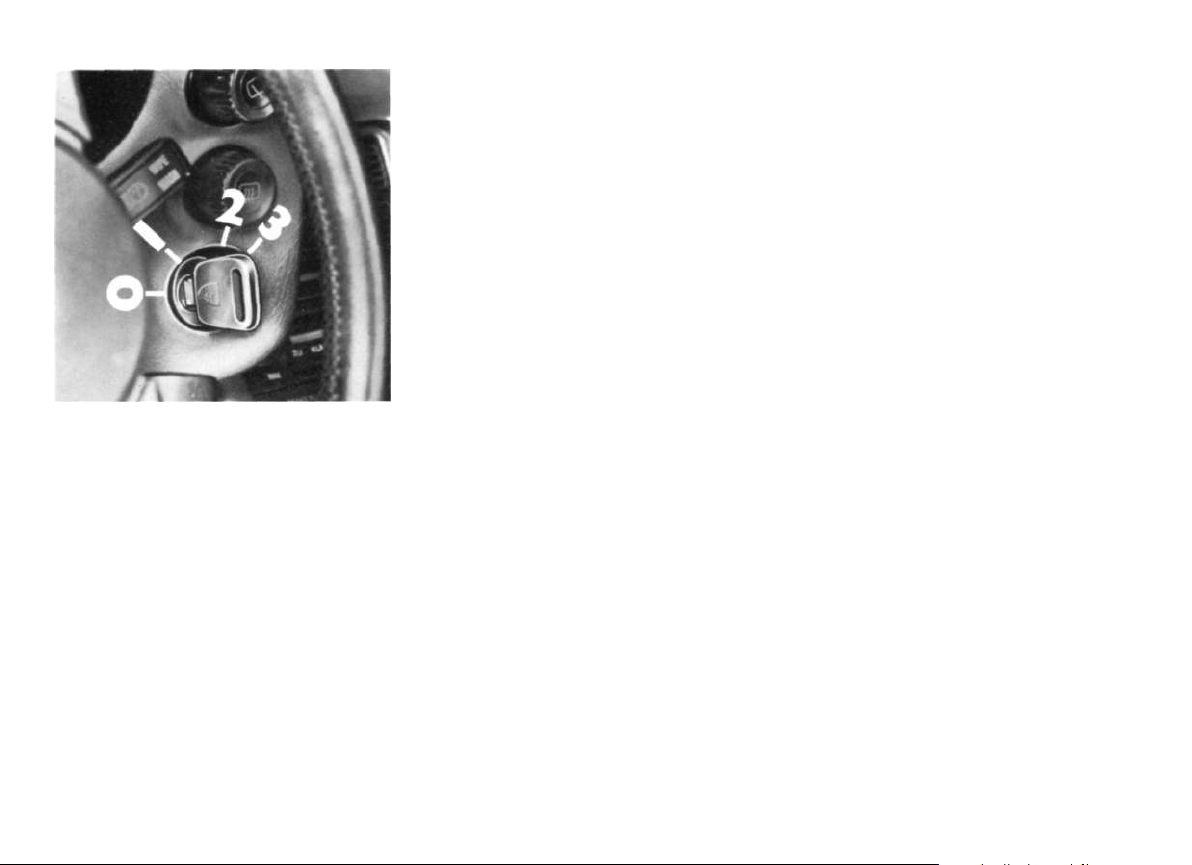

Steering lock and ignition switch

The ignition key has 4 positions:

0 -The steering is locked. All circuits con-

nected to the ignition switch are off.

This is the only position in which the ignition key can be withdrawn, and the

steering lock only operates after the key

is withdrawn.

The parking lights can be operated with

the switch in this position by using the

direction indicator lever.

20

3 - By turning the key to the right, the starter

motor is operated. As soon as the engine

fires, release the key. It will spring back

to position 2. With the engine running,

the central warning light and the other

warning lights should go out except the

brake warning light, which will go out

after the first application of the brakes

(see central warning unit). During the

operation of the starter motor, the items

with heavy electrical consumption, e. g.

headlights, rear screen heating, wipers/

washers, will be interrupted.

The starter motor should not be operated for

longer than 10-15 seconds. If the engine

does not fire, repeat the starting procedure

after a pause of approx. 10 seconds. Every

time the starter motor is operated, the key

must be returned to position 1 before trying

again, as a device is built into the ignition

switch to prevent inadvertent operation of

the starter motor whilst the engine is running.

Page 22

Starting the engine

neutral, but drive off immediately while

avoiding high rpm and full throttle until the

engine has reached its normal operating

temperature.

Warning: Never turn the key back to posi-

tion 1 whilst the vehicle is moving.

It is in your own interest to always remove

the ignition key when leaving the vehicle, if

only for a short period, and to ensure that

the steering lock is fully engaged. This is

done by rocking the steering wheel left and

right. This might also be necessary to re-

lease the lock when turning on the ignition.

When the engine is cold, component parts

being controlled in dependence of the temperature automatically provide the correct

fuel-air mixture required for starting.

Therefore, special starting instructions are

not necessary.

With a hot engine we recommend that

you fully operate the accelerator when starting. Do not allow the engine to warm up in

By cold weather, it is recommendable to

depress the clutch pedal when starting the

engine, even when the vehicle is in neutral.

Never start the engine or let it run in confined spaces. The exhaust contains the colourless and odourless gas, carbon monoxide, which is poisonous, even in small

quantities.

Please take note of the hints on running-in.

21

Page 23

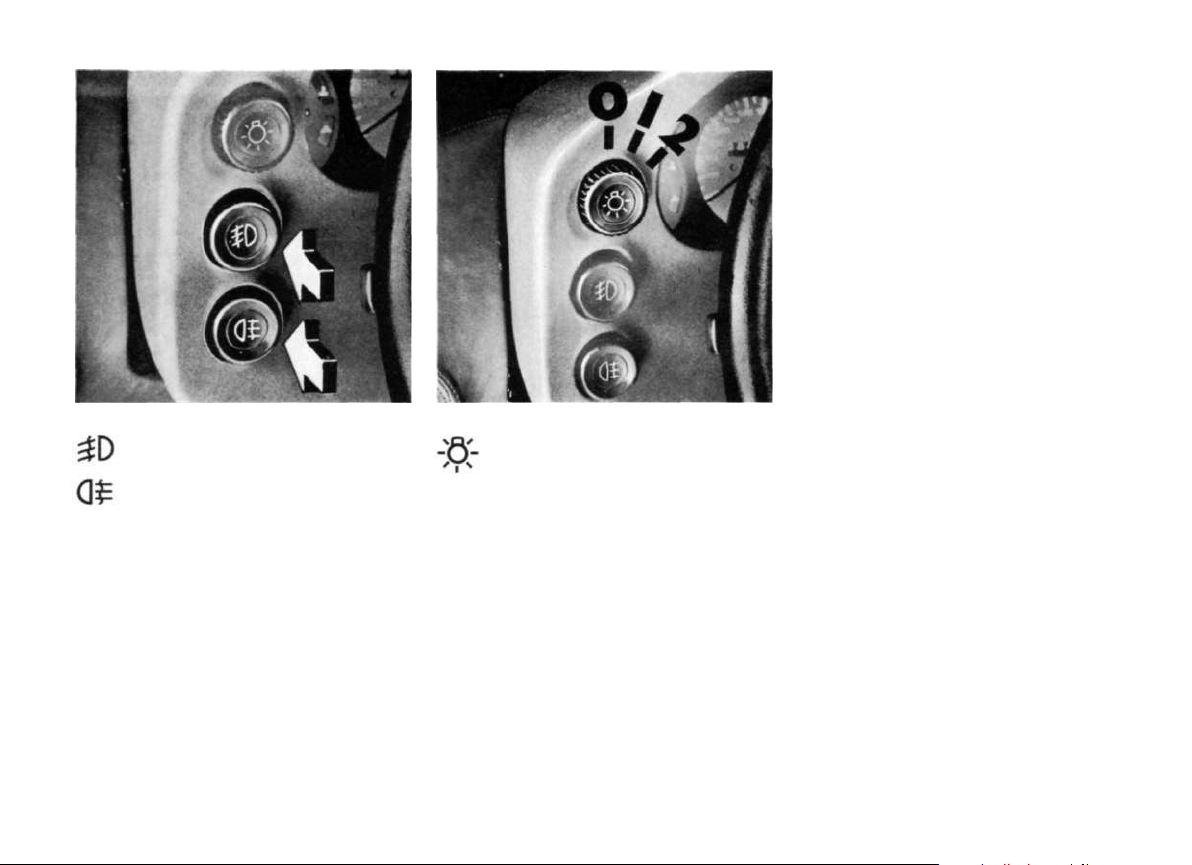

Fog lights

Rear fog lights

(on vehicles without rear fog light: .

button for re-setting trip meter)

The fog lights and the rear fog light can be

switched on in addition to the headlights by

pressing the respective switch. The lamp built

into the switch comes on when fog lights are

switched on. (The rear fog light operates only

when the front fog lights are switched on.)

Note: Take account of the varying laws in different lands controlling the use of fog lights.

22

Light switch

Switch in position 1: Sidelights

Switch in position 2: Headlights

In both of the switch positions the following

are also on: Backlights, Number plate lights

and instrument illumination. With the ignition

tion turned on, and the switch in position 2, the

headlights are elevated.

Instrument illumination

When the headlights are switched on the in-

strument illumination and Automatic gear selector illumination (vehicles fitted with automatic transmission) comes on automatically.

The illumination intensity of the instruments

is controlled by turning the knurled wheel

under the instrument panel.

Page 24

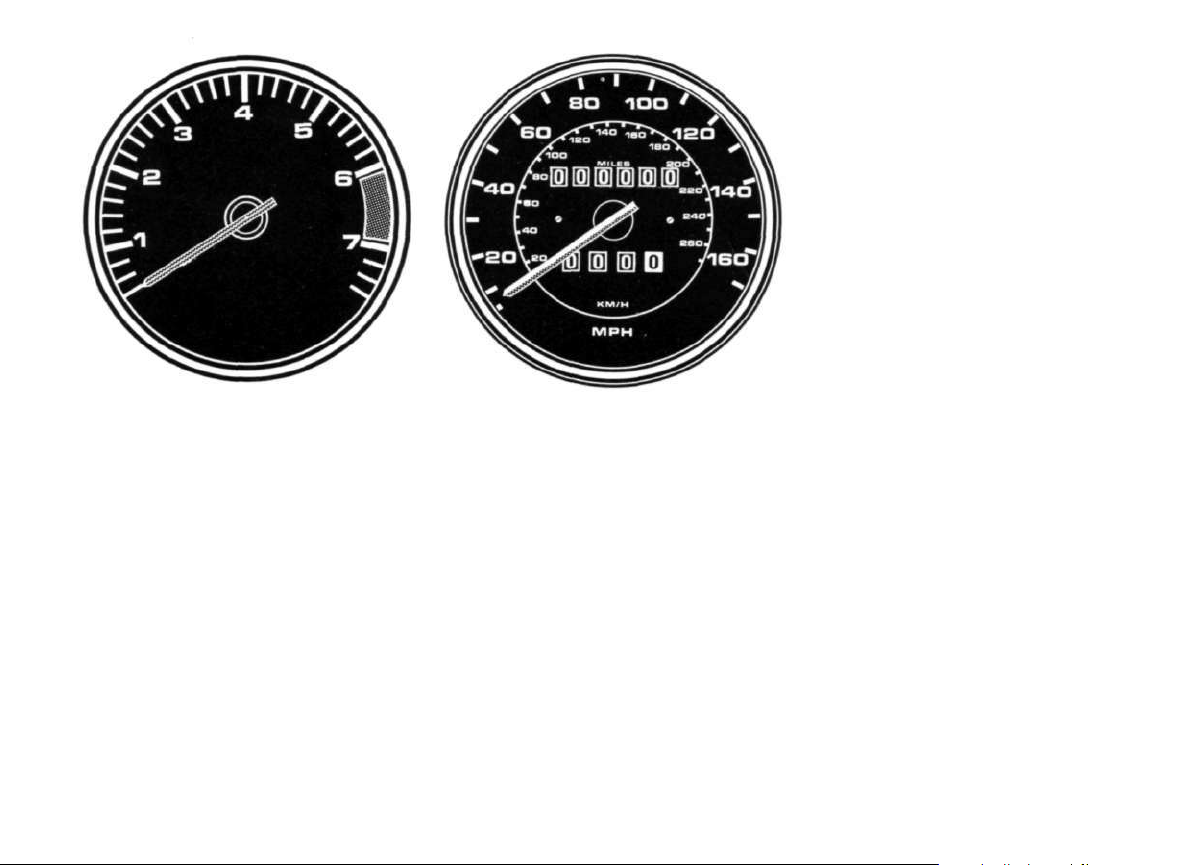

Revolution counter

Speedometer

The transistorised revolution counter indicates the number of thousands of revolutions per minute of the engine.

The red range on the scale of the instrument

is a visible warning of the maximum permitted revolutions per minute. Should you inadvertantly, during acceleration, exceed these

revolutions, a built in governor in the distributor cuts out the ignition current.

The electronic speedometer shows the

speed in miles and kilometres per hour.

The upper odometer registers the total mileage driven. The trip odometer can be set

back to zero when the ignition is on, by pressing the button under or in the left hand side

of the instrument console.

23

Page 25

Main beam warning light

Red Range-Warning

The main beam warning light in the instrument console lights when the headlamps

are on main beam. It goes out when dipped

beam is selected.

Blinker warning light

The blinker warning light flashes at the same

frequency as the blinker lights. Should one

of the blinker lights fail, the flashing is noticeably quicker.

Central warning light

The central warning light in the instrument

console lights when a fault occurs in one of

the systems in the vehicle. See "Automatic

warning unit".

Cooling fluid

Temperature Gauge

White Range - engine cold

Avoid over-revving the engine or labouring

Middle Range - normal

The temperature gauge needle should normally stay in this range. It is not unusual, when

the engine is being highly stressed, that the

needle tends towards the red range, but it

should return to the middle when the engine

loading is reduced.

If the needle goes into the red range it means

that the engine is being overloaded (by high

outside temperatures) and the warning light

will come on.

Warning light

If the warning light comes on, check that the

cooling fan is working. If the fan is not rotating,

the V-belt may be slack or broken; if so, it must

either be tightened or renewed. In cars with

air-conditioning, the electric fan located in front

of the air-conditioning condenser must also

operate. If it does not, there is a fault in the power supply or the temperature switch.

Allow the engine to cool down and drive to the

nearest authorized workshop, keeping a con-

stant check on the temperature gauge.

Avoid idling, crawling and engine speeds over

4000 rpm.

Consult the chapter on the cooling system.

24

Page 26

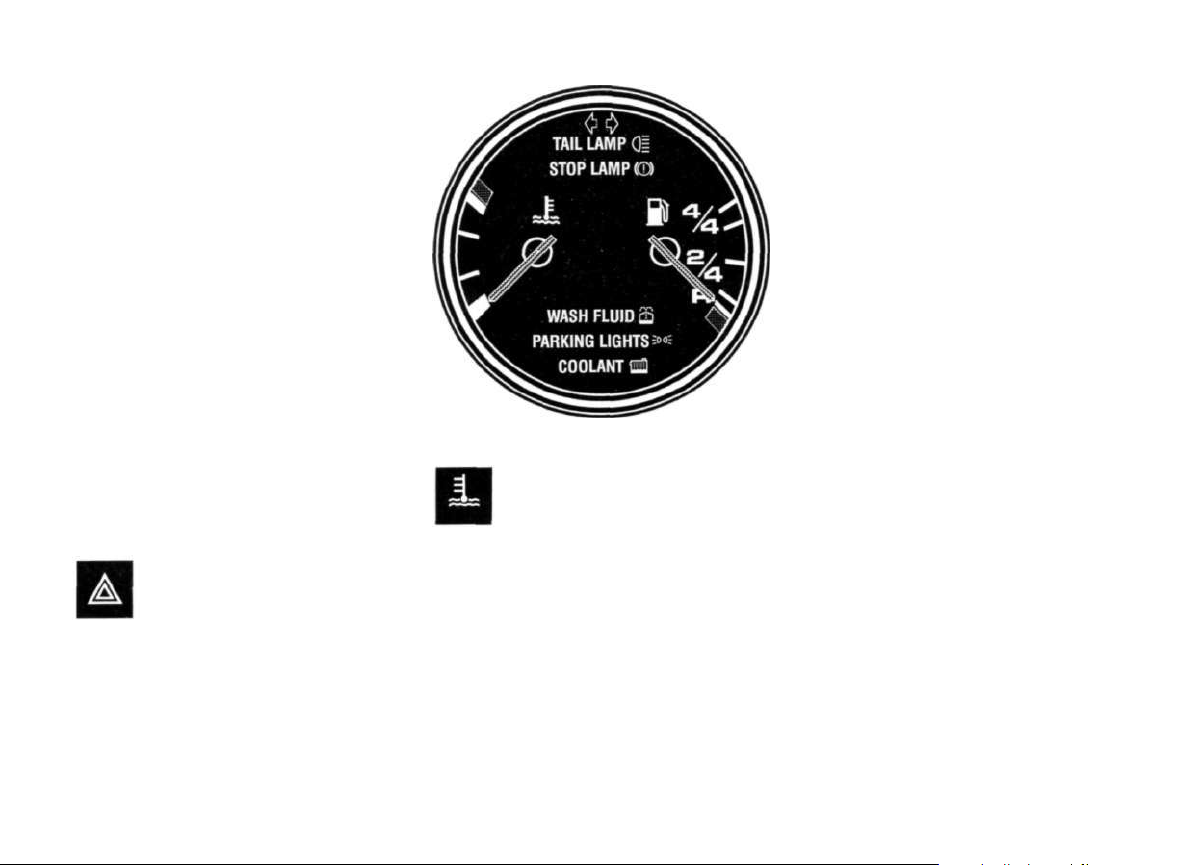

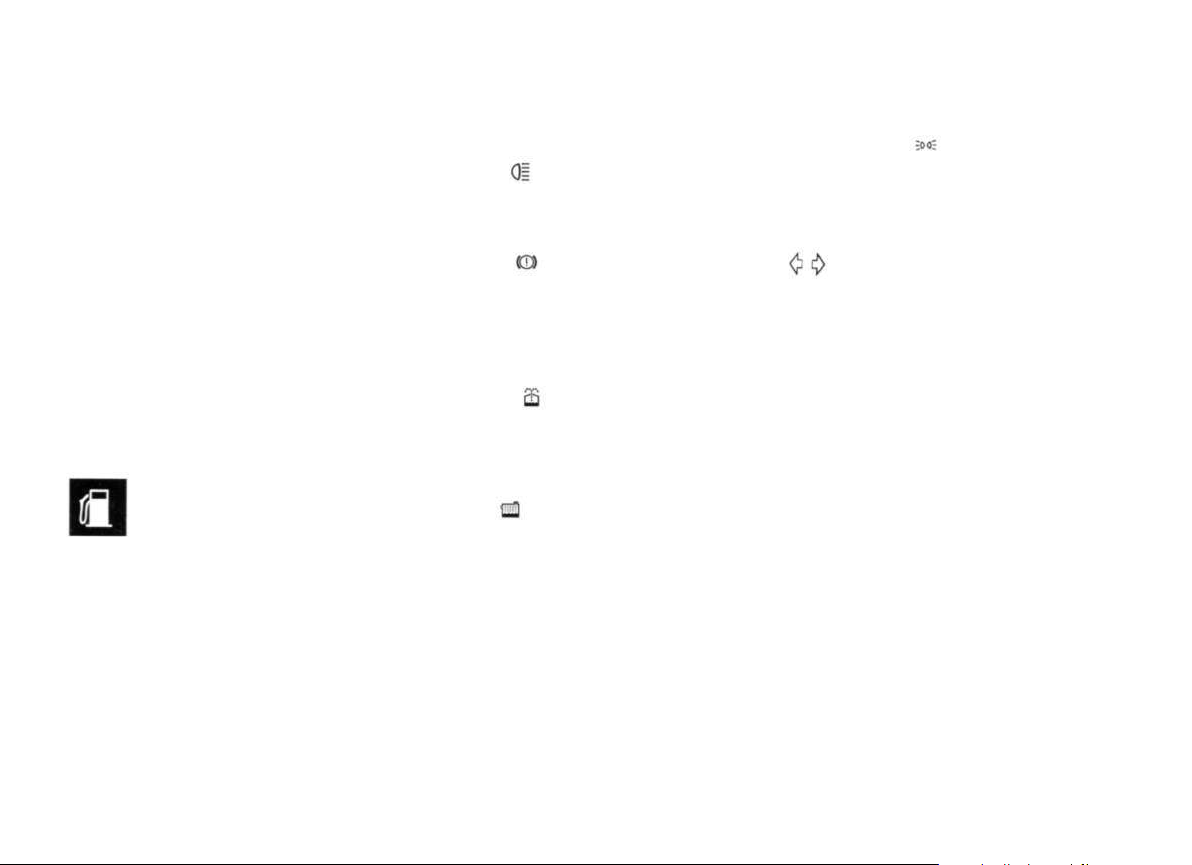

Warning Lights

(see also Central Warning Unit)

TAIL LAMP

The warning light comes on when a tail light

ceases to function.

Consult the chapter on the cooling system.

PARKING LIGHTS

This light comes on in the Combi-lnstrument

when the sidelights are turned on and goes

out again when the headlights are turned on.

Fuel Gauge

With the ignition turned on the gauge shows

the amount of fuel in the tank. If the level is too

low the fuel warning light comes on.

Warning light

The warning light comes on when about 8 liters

(7 Imp. qts) are left in the tank. The tank should

be filled at the next opportunity.

STOP LAMP

The warning light comes on when the ignition

is switched on and must go out after the first

brake application. If a brake light bulb is defec-

tive the warning light will not go out.

WASH FLUID

The warning light comes on before the screen-

wash water runs out, indicating that about 2

liters (1.75 Imp. qts.) of water remain.

COOLANT

The coolant warning lamp lights up as soon

as the coolant level in the expansion tank drops

below the minimum permissible level. The

warning lamp may come on when the car is

started and then go out again after a short

time. This is due to the volume of the coolant

increasing as it warms up, and thus exceeding

the minimum permissible coolant level.

It is essential to top up the coolant and, if necessary, to have the cooling system checked

for leaks.

Trailer Indicator Light

The blinker warning light for the trailer operation flashes at the same frequency as the blinker lights. Should a trailer blinker fail the frequently is noticeably quicker.

25

Page 27

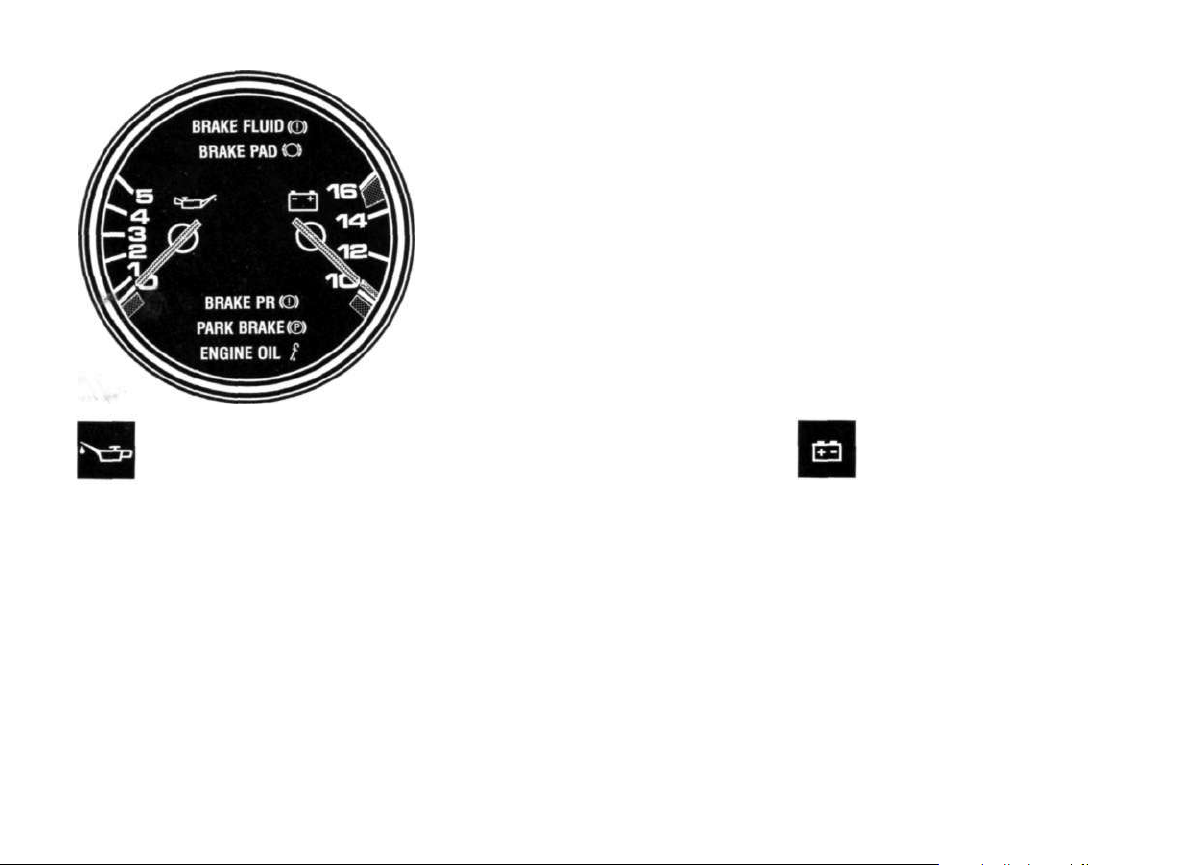

Oil Pressure Gauge

Voltmeter

Engine oil pressure is shown in bar. At 5000

rpm with the engine at normal operating temperature the oil pressure should be about 5

bar. A slight drop in oil pressure at higher temperatures is normal.

Should the oil pressure suddenly drop while

driving or should the red oil pressure warning

light come on, the engine should be turned off

immediately. If the oil level is correct the next

workshop should be called in to rectify the

fault.

26

Warning Light

The warning light comes on when the ignition

is turned on and goes out as soon as the cor-

rect operating pressure is reached. Should

the light come on during driving, this indicates

that the oil pressure is not correct.

In this case stop immediately.

If the oil level is correct the next workshop

should be called in to rectify the fault.

The voltmeter shows the overall condition of

the charging system. The needle should nor-

mally stay in the range 12-14 volts when the

engine is running. A temporary drop under 12

volts when starting the engine is normal.

Warning Light

The warning light checks the function of the

alternator. It comes on when the ignition is

Page 28

turned on and goes out as soon as engine rpm.

are high enough. If the warning light flickers or

comes on during driving, it can mean that the

fan belt is loose or broken. The fault could also

lie however in the regulator or the alternator.

In the latter cases the journey can be continued but only to the next workshop. Electrical

consumption should be kept to a minimum.

Warning Lights

(see also "Central Warning Unit")

BRAKE FLUID

The warning light blinks when the fluid level

drops below the allowable minimum.

BRAKE PAD

The light comes on when brake pads are worn

down to the allowable minimum.

BRAKE PR

The light blinks when one brake circuit fails.

PARK BRAKE

The light comes on when the handbrake is on

or not fully released.

ENGINE OIL

With the vehicle level and the ignition turned

on, the warning light will come on if there is

less than 6 liters (1.32 Imp. galls.) of oil in the

sump.

27

Page 29

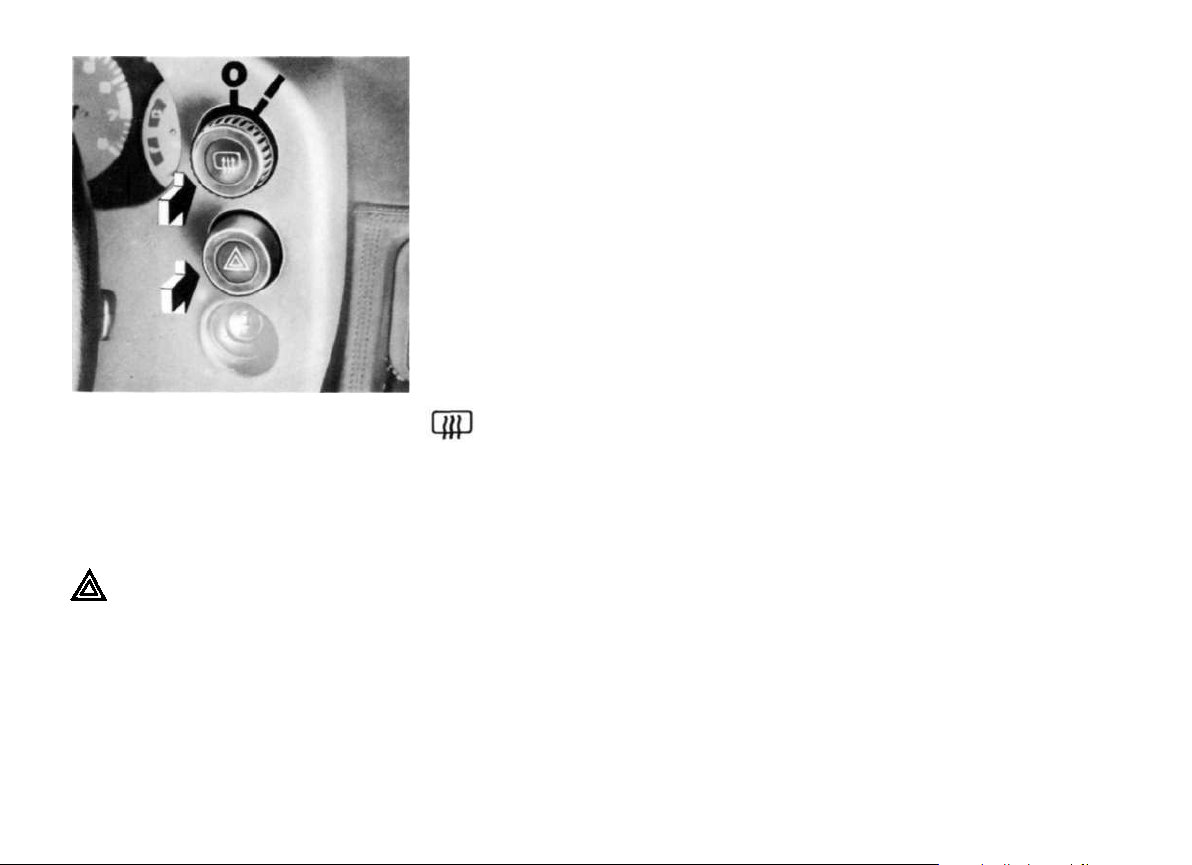

Rear screen heating

The heating for the rear screen and outside

mirrors is operated by the combined twistpush-pull switch in the instrument panel. The

switch is illuminated when the heating is on.

Switch in the pushed-in position

Hazard light switch

When the hazard light switch is operated, all

4 flashing lights flash simultaneously.

The hazard light switch is operative in any of

the ignition switch positions.

28

Switch in pulled-out position

0 - Rear screen heating off.

1 -Rear screen heating on. The heating is

so regulated that the rear screen will not

mist up.

0 -Full heating for de-icing. After approx. 15

minutes the heating turns off, automatically.

1 - Full heating for de-icing. After approx. 15

minutes a relay switches the heating

down to demisting power.

Page 30

Direction indicator- Dip - Parking

light - Headlight flasher switch

This switch operates the headlight flasher, the

dipped and main beams, the direction indicators and the parking lights.

Direction indicator

Push the lever upwards beyond the overcentre position - Right blinker.

Push the lever down beyond the over-centre

position - Left blinker.

If the lever is only pushed to the over-centre

position, the blinkers only operate until the

lever is released.

The malfunction of a blinker light is apparent

by a faster flashing rate. The direction indicators only operate when the ignition is on.

With the ignition key removed, the lever in the

up position turns the right hand parking lights

on, and in the down position the left hand parking lights.

Parking lights are the front and rear sidelights

of the respective side.

Main and dipped beam

With the light switch in position 2, main beam

is selected by pushing the lever towards the

instrument panel, and dipped beam by pulling

the lever back towards the steering wheel. With

main beam selected, the blue light in the instrument panel comes on.

Headlight flasher

The headlight flasher is operated by pulling

the lever right back towards the steering wheel,

and the headlights stay on as long as the lever

is held in this position. The headlight flasher

operates also when the vehicle lighting is not

on.

29

Page 31

1 Set/accelerate

2 Reset

3 Cancel

Tempostat

(Automatic speed control)

The Tempostat will maintain any desired

speed with the range 50-200 km/h (30 to

120 mph) without your foot being on the accelerator. Independent of this, you can

brake, change gear and accelerate as normal.

The operation of the Tempostat is controlled by the antenna lever behind the wiper

antenna.

The speed being travelled at any point in

time can be fed into the electronic control

unit by moving the lever forewards (position

1).

You can then take your foot off of the accelerator and this speed will be maintained.

By braking or stopping, the unit cuts itself

out, but the last speed fed into the unit remains registered. This registered speed can

be recalled by moving the lever downwards

(position 2). However, should the ignition be

turned off, the registered speed is cancelled from the unit.

If the registered speed is too low, you can

increase speed with the accelerator or by

moving the lever forewards to position 1 and

holding until the desired speed is attained,

and then letting the lever free. This speed is

now fed in to the unit and registered.

If the registered speed is too high, pull the

control lever towards the steering wheel

(position 3) or brake; this interrupts the Tempostat control, until the required lower

speed is attained, and then move the lever

forewards to position 1. Again this new

speed is registered and maintained.

Note: When you depress the clutch, the

speed control is interrupted, but when the

clutch is released, the speed control takes

over again.

To avoid accidentally overrevving the engi-

ne, do not move the gearshift lever into neutral at road speed above 50 km/h (30 mph)

while the cruise controle is engaged.

If you exceed the speed registered in the

control unit, e.g. during overtaking by using

the accelerator, as soon as you come off of

the accelerator, the registered speed will be

automatically resumed. On a steep incline

either up or down, it is possible that the vehicle will not maintain the registered speed

in a high gear, then you must change down,

to avoid labouring the engine by uphill, or to

ensure sufficient engine retardation by

down hill driving.

We do not recommend use of the tempostat

in heavy traffic or when road conditions are

unsuitable (eg. winding or slippery roads).

30

Page 32

5 Wipers and washers. By pulling the lever

towards the steering wheel, the electric

washers as well as the wipers are switched on.

6 Head lamp washers. By pushing the lever

towards the instrument panel, the headlamp washers are operated, but only when

the headlights are on. Refer to paragraph

on headlamp washers.

Wipewash lever

The wipewash lever has 6 switch positions.

0 Wipers off

1 Slow wipe

2 Fast wipe

3 Very fast wipe

4 Delay wipe. The wipers operate automa-

tically at regular intervals. The delay interval can be adjusted by turning the knurled

knob A under the right hand side of the

instrument panel.

The windscreen should be sufficiently wet

before the wipers are actuated to avoid

scratching it. The wiper blades should be

checked regularly, and replaced at least

once a year.

Concentrated washer system

With the concentrated washer system, even

dirt embedded in siliconbased polishes can

be removed from the screen.

A short press on the switch Β under the right

hand side of the instrument panel causes

the concentrated Porsche cleaning solution

to be pumped onto the screen. The duration

of the spray is controlled by a time relay to

avoid too heavy consumption of the solution. If necessary the operation can be repeated.

The windscreen washers and wipers can

then be operated to finish off the cleaning

process.

31

Page 33

Cockpit Layout

1 Side window demisting

2 Instrument panel

3 Air conditioning

4 Cancelling button for Auto. Warn unit

5 Center vent

6 Safety belt warning light

7 Glove compartment lock

8 First aid box holder

9 Wing mirror adjuster

10 Bonnet lock

11 Horn

12 Power window switch

13 Sunroof switch

14 Rear screen wiper switch

15 Selector lever

16 Clock

Page 34

Central Warning Unit

Priority 1 - The central warning light flashes

together with the individual warning light.

The following functions have priority 1:

Brake circuit failure, Brake fluid level, Oil

pressure, Oil level.

If a malfunction is indicated here the vehicle

must be stopped and turned off immediately. The fault must be rectified.

Functions that do not require immediate

attention are:

Priority 2 - The central and individual warning lights come on continuously.

The following functions have priority 2:

To increase driving and operational safety

an automatic warning system has been

developed, that shows the driver, via an

unmistakeable warning light that comes on

in the instrument panel, that there is a possible malfunction. This is done automatically

without the driver having to do anything.

The warning lights for the various functions

are located in the Combi-instruments.

32

Should a malfunction occur the central

warning light in the instrument console will

come on. At the same time the light for the

individual function will also come on, indicating what is malfunctioning.

The function control is divided into two

priority groups. Functions that are essential

for driving and operational safety are:

Brake pad wear, Hand brake, Cooling fluid

level, Cooling fluid temperature, Fuel tank

reserve, Screen washer water level, Brake

lights, Tail lights.

These functions show the need for part

replacement, re-filling, change of driving

mode or release of the handbrake, but not

for an immediate halting of the journey or

visit to a workshop.

Page 35

With the ignition turned on (engine not run-

ning) all individual warning lights and the

central warning light must come on to indic-

ate operational readiness. If the engine oil

level is too low the central warning light will

flash, (lack of engine oil can, in comparison

with all other functions, only be checked

with the engine turned off and with the vehi-

cle level.)

The warning light for the brakelights must go

out with the first brake application. The

remaining lights go out when the engine is

started.

By pressing the button (arrow) in the middle

of the console the central warning light can

be turned off in the case of priority 2 mal-

functions. It cannot be turned off in priority 1

cases because immediate action is neces-

sary to rectify the fault.

When the handbrake is applied or not fully

released the central warning light cannot be

turned off. Only when the handbrake is fully

released does the central warning light go

out.

Note: If the vehicle is tow or roll started the

warning lights will not go out. The engine

must be turned off and restarted with the

ignition key.

33

Page 36

Ventilation grills

1 De-icing jets for windscreen

2 De-icing jets for side windows

3 Fresh air jets for passenger compart-

ment

4 Fresh air jets for footwells

5 Air jet in glove box

The height of the jet stream can be altered

by tipping the horizontal bars in the grill. The

lever in the grill adjusts the lateral air flow.

34

Central air inlet grills

The central air inlet grills provide ventilation

for the interior. If the air flow should become

uncomfortable the central air inlet grills can

be closed by means of a lever mounted at

the side of the grills.

In the defrost position the grills are closed

automatically.

Page 37

Side air inlet grills

To avoid misting up of the side windows, air

inlet grills are built into the door trim panels.

The direction of the air stream can be adjusted by the grills, and the airflow can be regulated by a lever.

A- Air inlet grill closed

B- Air inlet grill open

35

Page 38

Automatically controlled

air conditioning

The air conditioning only functions with the

engine running. The cooling effeciency is

dependent on engine revolutions. If more

cooling is required it is necessary - especially in city or stop-go conditions - to increase

engine rpm.

By automatically controlled air conditioning

the air conditioner compressor is switched on

automatically in position AUTO and Bl. The

engine runs at a higher idle speed in this position.

36

A maximum cooling effect is achieved with

the fan switch at pos. 4, the windows closed

and the side and center vents fully open.

When the air conditioner is switched on additional cooled air is fed via a vent to the glove compartment.

If the vehicle has stood for a long time in direct sunlight, it is recommended that the air

conditioning be turned on with the windows

open, to provide through ventilation.

The air conditioning must be operated for a

short period at least once a month.

This is especially important during the cold

weather when the air conditioning is not

needed.

This operation is necessary to lubricate the

expansion valve and the seals on the mainshaft.

Should the air conditioning become defective, that is to say if warm air comes from

the inlet grills, the air conditioning must be

turned off immediately or otherwise the

cooling compressor can be damaged.

Page 39

The automatic controls the temperature inside the car according to the programme

chosen and the temperature control lever

position.

The interior temperature is kept constant

even under changing climatic conditions.

Cold and warm air is blended automatically

by means of air mixer valves which are ope-

rated by a servo motor. The servo motor is

switched and controlled via inside and outside temperature sensors as well as the

coolant thermometer.

The following controls make an individual regulation of the air conditioning possible:

Temperature control lever for adjusting the

required interior temperature with temperature scale. The adjusted temperature is

equal to the temperature in the middle of

the vehicle interior.

As heat output is dependent on the coolant

temperature, the full heating capacity is delivered only after the engine has reached normal operating temperature.

Programme control lever to enable the automatic air conditioner to meet individual requirements several programmes are available.

Air conditioner and blower fan

switched off.

Automatic heater control. No cooling is possible on this position because compressor is switched off

for fuel ECOnomy. This programme is recommended when outside air temperatures are below

+5° C (40° F).

37

Page 40

An airstream is also

directed toward the windshield.

Automatic temperature control.

Heating and cooling (during normal

weather conditions). Air is distributed according to a predetermined

programme to suit the outlet temperature. The center vent may be

closed manually.

Same as position AUTO in addition

the defrost vents are opened. This

position is recommended during

wet and humid weather (rain, heavy

snowfall) to prevent the windscreen

from fogging up. It also provides

better cooling at head level and in

the footwells when outside air temperatures are very high.

Defrost position: provides fastest

possible defrosting of the iced or

fogged up front screen and side

windows. With this programme the

maximum heating effect and highest blower fan speed are switched

on automatically and the full air flow

is directed to the windscreen and

the side vents. The center vent is

closed automatically.

To prevent uncomfortable draughts, in positions the automatic control first comes into operation at coolant temperatures above approx. 45° C. Below

these temperatures the uncooled fresh air is

prevented from entering the footwell by a cold

start shut off device.

Blower fan switch

To provide air circulation when the vehicle is

standing still or at low speeds the blowerfan

runs at low speed even when the switch is in

the 0 position. Should you require increased

air flow the blower fan can be switched from

positions 1 to 4.

38

Page 41

Tensioning the V-belt

Checking cooling medium level

The tension of these compressor V-belt is

checked every 20.000 km. If the airconditioner is used frequently the V-belt tension

should also be checked between the service intervals.

The three mounting bolts (A) must be

loosened for tensioning the V-belt. Correct

the V-belt tension with tensioning nut (B)

and tighten the mounting bolts (A). The Vbelt is correctly tensioned when it can be

depressed approx. 5 mm using thumb pressure, between both V-belt pulleys.

Due to the fact that the system loses coolant it is necessary to check the coolant level

at the reservoir at least once a year.

Should air bubbles be visible at the inspection glass of the reservoir (arrow) for an

extended period, with the air conditioner

switched on, this indicates a lack of coolant.

Air bubbles will be normally visible for a short

time.

If necessary have the system re-filled in an

appropriately equipped service workshop.

39

Page 42

Headlight beam regulator

The height of the headlight beams can be regulated to the laden condition of the vehicle

with the knob (B). This enables maximum

road illumination without dazzling other road

users.

The normal headlight beam setting is obtained by turning the rotary knob as far as the

noticeable stop, i. e. the white dot must be

in line with "0" (see also "Headlight adjustment").

40

The beam setting must be corrected as

shown in the table when the vehicle load is

increased. Turning the knob clockwise raises the beams and vice versa. The correc-

tion should be checked by observing the

dipped beam cut-off (e. g. on the back of the

vehicle driving ahead of you).

Loudspeaker balance control

The volume of the loudspeakers in the door

and in the rear of the vehicle can be balanced by turning the loudspeaker balance control knob (A).

Page 43

Cigarette lighter

The element is heated by pushing the lighter in. When the correct temperature is

reached, the lighter springs out to the

normal position. With the lighter out, the

socket can be used for electrical auxiliaries

such as compressor or handlamp, with a

consumption of up to 120 watts at 12 volts.

Clock

The left-hand push-button beneath the display is used for setting the hour. The right-hand

push-button is used for setting minutes.

A brief press of a button (best done with a ball

point pen) will put the time forward by one hour

or one minute.

Prolonged pressure on the button(s) will cause

the hours and/or minutes to be displayed in

sequence.

In order to set the time accurate to the very

second, press the minute button at the very

moment you hear the time signal on your car

radio.

Ashtray

The ashtray is mounted in the middle console in front of the gear lever. To empty the

ashtray pull the tray upwards out of the

housing.

Rear seat storage compartment

The storage compartment is opened by

pressing the button and lifting the lid. For

security reasons, the storage compartment

is lockable.

On vehicles with a rear seat storage compartment a second ashtray can be found on

the tunnel in front of the compartment.

41

Page 44

Electric Sliding Roof

Manual Operation

The sunroof is operated by a spring loaded

rocker switch on the middle console. Appropriate movement of the switch opens or

closes the sunroof. When released the

switch returns to the neutral position and

the roof stops in the required position. The

drive mechanism is equipped with a safety

clutch which disengages when a certain

resistance is met, thus excluding the possibility of accidental injuries.

42

We do not recommend that the sliding sun

roof be operated at speeds in excess of 100

km/h. The force required to overcome the

resistance of the air pressure at higher

speeds can cause damage to the sliding

roof.

A hand crank is provided for manual operation in the event of an electrical failure. To do

this the cover of the sunroof drive must be

removed. Pull the cover down at the rear and

unhook the spring. Unscrew the now visible

slotted screw with the screwdriver tip of the

hand crank. Before inserting the fork-end of

the crank remove spacers which were under

the screw. Turn the knurled screw of the

crank into the threaded hole in the drive

Page 45

Rear screen wiper

shaft making sure that the lugs engage in the

slots. The roof can then be moved by turning

the crank.

If the roof is only about half open, it is recommended that you close the roof by turning

the slotted screw instead.

The rear screen wiper is switched on by a

press switch in the middle console. To prevent the rear screen from becoming

scratched it should be sufficiently wet

before operating the wiper.

The wiper motor is mounted in the bodywork

of the vehicle and not in the luggage compartment door, and drives the wiper with a

clutch, that disengages and engages automatically when opening or closing the door.

43

Page 46

Glove box

Sun visors

Make up mirror

The glove box is opened by pulling the

handle set into the lid. For security reasons,

the glove box is lockable.

44

The front sun visors can be either pulled

down in front of the screen or swung to the

side in front of the door windows to prevent

dazzle from the sun.

The rear sun visors can be swung back to the

rear window.

The make up mirror can be found on the rear

side of the passengers sun visor. On vehicles with leather interior a lighted make up

mirror is installed in the roof lining behind the

passengers sun visor (except on vehicles

with sun roof). By pressing the button the

mirror swings out from the roof lining.

Page 47

Luggage compartment door

(See notes under "Alarm system" if your car

is equipped with an alarm system.)

To open the door

Insert key into the lock and turn it to the right

and lift the door. Two gas-struts will then

open the door fully.

To close the door

Push the door down until it can be heard to

lock.

Never drive with the luggage compartment

door ajar or open, as then exhaust fumes

could enter the vehicle.

Engine compartment Hood top

To release the hood

Pull the lever on the left hand cowl side

panel underneath the instrument panel.

To open the hood

Lift the hood top slightly and release the

safety catch by pressing the lever upwards.

Make sure the windscreen wipers are not

tilted forward!

When the vehicle lights are on, a lamp on the

underside of the hood top lights automatically.

45

Page 48

Manual gearbox

The fully synchronised gearbox permits

rapid gear changes without the need to

double declutch. Be sure however that the

clutch is fully depressed before engaging or

disengaging a gear.

The gear positions are shown in the diagram

on the right.

46

Reverse should only be selected after the

vehicle has come to a complete stillstand.

To shift from 1 st into reverse gear, the gearshift

lever must first be moved into neutral position

between 4th and 5th gear.

With the ignition on, the reversing lights

come on automatically when reverse gear is

selected.

Permissible rpm before shifting down.

5-4 gear 4800 rpm

4-3 gear 4800 rpm

3-2 gear 4700 rpm

2-1 gear 4400 rpm

Page 49

Automatic gearbox

The automatic gearbox facilitates the driv-

ing of the vehicle. The individual gears are

selected automatically, depending on the

position of the gear selector lever, the

speed of the vehicle and the position of the

accelerator.

For safety reasons, the motor can only be

started with the selector lever in positions Ρ

or Ν.

The selector lever has six positions, and is

fitted with a mechanical lockout, to avoid inadvertent selecting of the wrong gear.

The lockout button must be pressed when

changing from

Ρ

R

Ν

?

. .. to

... to ...

... to ...

... to ...

. .

R

.

Ρ

R

1

At speeds in excess of 15 km/h (10 mph) a

hydraulically operated mechanical lockout

avoids changing into R or P.

The selectorlever console is illuminated.

Operation

Before selecting a gear with the engine run-

ning and the car stationary, either the handbrake must be on, or the footbrake operated. The brakes should only be released

when you wish to drive away, as the vehicle

will creep as soon as gear is selected. Do not

accelerate while selecting a gear.

At speeds in excess of 50 km/h (30 mph) Ν

should not be selected. Should however Ν

be selected inadvertantly during driving, the

accelerator should be released to allow the

engine to attain tickover revolutions, before

the gear is selected again. This avoids overloading the fluid clutch.

It is extremely important for correct functioning of the automatic gearbox, that the

correct fluid level is maintained. For this

reason you should check the fluid level frequently, between the normal servicing of

the vehicle.

If there is no automatic transmission fluid in

the gearbox or the torque convertor, the

engine must not be started, nor must the

vehicle be towed.

The automatic gearbox and the torque convertor are both filled with ATF, simultaneously. The back axle is filled with Hypoid oil. For

filling amounts see the chapter "Filling capacities".

47

Page 50

Selector positions

D

This is the gear to select for normal driving.

The three forward gears are automatically

engaged, according to the load on the

engine and the speed of the vehicle.

2

This is the gear to select for mountainous

terrain, as well as for long uphill or downhill

stretches. The engine's power is better utilised, and also the retardation affect of the

engine is greater. The vehicle pulls away in

1st gear and changes automatically into 2nd

gear. 3rd gear is locked out. During driving,

this position can be selected, even with the

accelerator depressed. However, as 2nd

gear is then immediately engaged, this

should not be done at speeds in excess of

150 km/h (90 mph).

1

This position should be selected when it ap-

pears advisable to hold the vehicle in 1st

gear, e. g. steep up or downhill stretches, or

when operating with a trailer in mountainous

terrain.

The vehicle remains in 1st gear, and 2nd and

3rd gears are locked out.

This position can be selected from position

2 during driving by pressing the lockout button, but should only be done at speeds

lower than 60 km/h (35 mph).

Ρ

Must only be selected when the vehicle is

stationary.

In this position, the driving wheels are mechanically locked. To select Ρ the lockout

button must be pressed.

Ρ should only be selected after the handbrake has been applied, and should be disengaged before the handbrake is released.

The engine can be started in this position.

Ν

In this selector position, no gears can be

engaged. It is the same as neutral in a man-

ual gearbox, and should be selected when

the vehicle is stationary for any length of

time, e. g. traffic jam. This position should

only be selected when the engine r. p. m. are

at tickover.

The engine can be started in this position.

R

This position must only be selected at tick

over, and with the vehicle stationary. The

lockout button has to be pressed to select

R. At speeds in excess of 15 km/h (10 mph) a

hydraulically operated lockout prevents R

and Ρ from being engaged. With the ignition

on, the reversing lights come on automatically when R is selected.

48

Page 51

Waiting Trailer operation

For short waiting periods, e. g. traffic lights,

the vehicle can be left in gear, and held stationary with the footbrake.

For longer waiting periods, with the engine

running, position Ν should be selected.

Never hold the vehicle stationary on a hill

with the accelerator. Always apply the hand

or footbrake.

This avoids unnecessary warming up of the

torque convertor or gearbox.

Stop start driving

For stop start driving, e. g. traffic jam, posi-

tion 1 should be selected.

Parking

When parking, or manouvering in confined

spaces, the speed can be adjusted with the

brakes, and very little acceleration is requir-

ed.

Selector position 2

For inclines, up or down, select position 1 in

good time, to attain maximum engine power

or retardation, and thereby reduce the loading on the brakes. For mountainous terrain

only use selector position 1.

Being towed

When the engine is not running, the oil pump

for the automatic gearbox is not driven, and

therefore the gearbox is not lubricated. The

following points must therefore be noted:

1. Selector

2. Towing speed must not exceed 50 km/h

(30 mph).

3. Maximum towing distance 50 km (30

miles).

4. For greater distances, the vehicle must be

transported on a trailer.

Tow or push starting

If your Porsche is fitted with automatic gearbox, it cannot be tow or push started.

in position N.

49

Page 52

The shift points given here are theoretical road speeds. There may be certain variations in practice as a result of ma-

nufacturing tolerances, the temperatures of components and automatic transmission fluid as well as tyre slip.

Up shifts

In selector position "D" the automatic up

and down shifts are dependent on a combination of road speed and accelerator pedal

position. The shift points vary between the

part throttle and full throttle positions.

50

A) When you drive with a gentle pressure on

the accelerator pedal the transmission

shifts from 1 st to 2nd gear approx. 30 km/h

(20 mile/h) and into 3rd gear approx. 45

km/h (28 mile/h) in order to preserve fuel

and reduce noise levels.

B) During full throttle acceleration or kick-

down the transmission holds 1st and 2nd

gears longer for better acceleration. It then

shifts from 1st to 2nd at approx. 100 km/h

(60 mile/h) and into 3rd gear at approx. 160

km/h (100 mile/h).

Page 53

The shift points given here are theoretical road speeds. There may be certain variations in practice as a result of manufacturing tolerances, the temperatures of components and automatic transmission fluid as well as tyre slip.

Down shifts

A) When you drive with gentle pressure on

the accelerator pedal the transmission

shifts down from 3rd to 2nd gear at approx.

35 km/h (23 mile/h) and into 1st gear at approx. 20 km/h (12 mile/h).

B) When you drive at full throttle the trans-

mission shifts down from 3rd to 2nd gear

at approx. 80 km/h (50 mile/h) to provide

better acceleration or hill climbing ability

on gradients and then shifts to 1st gear at

approx. 50 km/h (30 mile/h).

C) If you press the accelerator pedal down

beyond the pressure point to actuate the

kick-down switch, the down shifts take

place at higher road speeds to provide maximum acceleration. The down shift from

3rd to 2nd gear takes place at approx. 130

km/h (80 mile/h) and 1st gear is selected

at approx. 70 km/h (45 mile/h). The up-shift

points for kick-down acceleration are the

same as those given for full throttle acceleration.

51

Page 54

Tips for "Running-in" Maximum permitted revolutions Roof Racks

There are no particular rules to be observed

when "running-in" your new Porsche, however the following tips will be helpful in obtaining the optimum running properties.

Despite the most modern manufacturing

methods with their high precision, it cannot

be completely avoided that the moving

parts have to wear in with each other. This

wearing-in occurs mainly in the first 1000 km

(600 miles).

Oil consumption can be somewhat higher

than normal during the "running-in" period.

Therefore you should

never over-rev a cold engine, either in neutral or in gear,

continually change the demands made

upon the engine and transmission,

never exceed 5000 rpm in the individual

gears,

always change gear in good time, and thereby keep the engine in the optimum revolution range (note the Transmission diagram).

This of course also applies after running-in.

The red range on the rev-counter scale is a

visual warning.

When the maximum permissible engine speed

is reached, the governor built into the distributor cuts off the ignition current, and thereby

prevents the engine from being overrevved

during acceleration.

Bedding-in new brake pads

New disc pads have to bed-in, and do not

therefore have the full braking ability in the

beginning. To compensate for this reduced

braking ability for approx. the first 200 km

(120 miles) a little more pedal pressure is

necessary. This also applies after having the

disc pads renewed at a later date.

Please note: New tyres do not posess their

full road-holding ability. Therefore only

drive at lower speeds for the first 200 km

(120 miles).

Normal commercially available roof racks

cannot be fitted.

If an original Porsche rack (as available hitherto) is fitted, the permissible roof load is 35

kg. With the "New Porsche Roof Transport

System" you can transport a wide variety of

sports and hobby equipment, up to a roof load

of 75 kg. There are many different racks to

choose from.

Your Porsche dealer will be glad to advise you

on the versatility of the "New Roof Transport

System".

To ensure minimum noise, maximum econo-

my and a desirable level of safety when driv-

ing with an unloaded roof rack, you should not

exceed a maximum speed of 180 km/h.

When the roof rack is loaded, the recommended maximum speed depends on the nature, size and weight of the load. You should

not however exceed a speed of 140 km/h at

any time. Make sure that the load is firmly and

securely fastened.

52

Page 55

Tips for winter operation

Engine oil Cooling fluid

Before the onset of the colder weather, have

the engine filled with oil of the correct viscosity. See chapter on "filling capacities".

Battery

The battery capacity drops with lower temperatures, but the demands made upon the

battery generally increase. Therefore, have

the battery checked and charged, if necessary, in good time. Also have the acid content checked, and the terminals greased.

See chapter "Check and care of battery".

Corrosion protection

The salt spread on winter roads can have a

detrimental effect on your car's bodywork.

You should therefore wash the car as often

as convenient in accordance with our care

instructions. Have a preservative applied

and the underseal checked in an authorized

workshop before and after the cold weather

season.

The vehicle should not be driven without

anti-freeze at temperatures below freezing

point. The all-season cooling fluid in the

cooling system, put in by the manufacturer,

offers protection down to -30°C (Northerly

lands -40°C).

Nevertheless it is advisable to have the cooling fluid checked to make sure that the necessary protection is afforded, at the onset

of colder weather. When necessary, top up

with antifreeze. For amounts see chapter

"Filling capacities".

Brakes

After driving for extended periods on salt

covered roads a film can form on the brake

discs and pads which considerably reduces

friction and thus the braking effect.

Door and window seals

To prevent the freezing of the rubber seals

on the doors and hood top, they should be

treated with talcum powder or glycerine.

Door locks

To prevent the door locks freezing up, the

lock cylinders should be masked when

washing the vehicle, to avoid ingress of

water. Should however the locks still freeze

up, a proprietory de-icing solution can be

used to free them. A warmed-up key can

also be useful, but never use force.

53

Page 56

Water reservoirs

To ensure the function of the screen and

headlight washers under frost conditions,

anti-freeze should be added to the water. A

mixture of one part household spirit to three

parts water also works very well.

Winter tyres and snow chains

Due to the reduced effectiveness of summer tyres in winter we recommend the fitting of special winter tyres when snow and

ice are expected.

If M + S tyres are used in the winter, they

must be fitted to all 4 wheels. Be acquainted

with the different laws in different lands governing maximum speeds with these tyres.

54

Snow chains can only be mounted on the

driving wheels, and only the fine link chains

recommended by Porsche for the normal

series tyres should be used. This ensures

that the clearance between the wheel and

wheelhouse is maintained. However, note

the chain manufacturers recommendations.

Your authorized dealer will be pleased to

advise you in choosing the appropriate winter tyres and snow chains.

Additional equipment

It can be helpful during winter to keep a

handbrush and scraper in the vehicle, to

clear the screens of ice and snow, as well as

a board to put under the jack and some dry

sand to help traction when pulling away on

icy slopes.

Page 57

Car care instructions

Regular and correct care helps to maintain

the value of your car and is also a precondition for the long-life guarantee.

Washing

The best method of protecting your car from

the damaging effects of the environment is

frequent washing and the re-application of a

preservative.

The salt spread on winter roads, road dust

and dirt, airborne industrial emissions, dead

insects, bird droppings etc. can have a damaging effect on the bodywork if allowed to

remain on the car for a long time.

Salts have a particularly corrosive effect on

body seams, flanges and joints.

It is therefore necessary to clean such areas

thoroughly with a sponge when you wash

the car - or after going through an automa-

tic car wash, then rinse them with water and

rub dry with a leather.

New cars should be washed carefully with

plenty of clear water to protect the fresh

paintwork. Dark paint finishes show up the

smallest of surface damage (scratches) mo-

re readily than light colors. Dark colors are

also slightly more susceptible to scratches

because the composition of their pigments

and therefore require special care and attention.

Use an abundant supply of water, a soft

sponge or wash brush and a suitable, mild

car shampoo. Begin by spraying the body

thoroughly with water to rinse away loose

dirt. Do not wash your Porsche in bright sun-

light or while the bodywork is still hot. After

washing, rinse the car plenty of water and

then leather dry. Remember to clean the

seams, flanges and joints!

Do not use the same wash leather for rub-

bing down as you use for cleaning the windshield and windows.

The moisture which gets on to the brakes

during a car wash can reduce braking efficiency or make the brakes pull unevenly. Always test the brakes a few times after wash-

ing your car to make sure they are properly

dried off.

Dust should never be wiped off the car with a

dry cloth since dust particles are abrasive

and could dull and damage the surface finish.

Preservation

The paintwork contains certain fats which

maintain its high lustre and prevent it becoming brittle. Climatic effects can remove

these fats from the paintwork. This should be

counteracted by applying a paint preservative in good time to restore the fats and thus

retain the high lustre.

Please use only the preservatives and washing agents recommended by your Porsche

dealer. Provided it is washed and treated

with preservative regularly, the brand new

finish of your car will be retained for years to

come. Apply the paint preservative after the

car wash and polish it dry to obtain a bright

finish or simply add a preservative to the fi-

nal rinse water and rub down with a leather.

Polishing

The use of polishes is recommended only after it becomes evident that the normal preservatives no longer produce the desired finish.

Caution: Do not apply silicone polishes to

the windshield or windows.

The paintwork of your car is exposed to all

manner of mechanical and chemical stres-

ses, particularly climatic ones such as bright

sunlight, rain, frost and snow. Ultraviolet

light, rapid changes in temperature, rain,

snow, industrial dust and chemical deposits

constantly attack the paint which is only able to withstand such exposure in the long

term if it is given regular care and attention.

Matt painted parts should not be treated

with preservatives or polishes as this will

spoil the matt effect.

55

Page 58

Spots and stains

Tar stains, grease, oil spots and dead insects

cannot always be removed by washing alone. They can cause discoloration if allowed

to remain on the paintwork. They should

therefore be removed without delay with a

suitable cleaner (tar, stain or insect remover). Wash the affected area immediately after treating it.

Minor paint damage

Minor paint damage, such as scratches, scores or chips caused by flying stones, should

be covered immediately with paint before

corrosion sets in. However, if there are already traces of corrosion they must first be removed carefully and thoroughly. Coat the

area with a rust-proofing primer (applicator

or aerosol) and finish off with a top coat. The

paint code and color number are found on a

label close to lock on the left door pillar.

Undersealing

The underside of the car is durably protect-

ed by a factory-applied undersealing material.

As it is not possible to exclude the risk of da-

mage to this protective coating in day-today driving, it is advisable to have the underside of the car inspected at certain intervals

- preferably before the start of the cold season and again in the spring - and the undersealing repaired as necessary.