Porsche 911 TURBO 2003 User Manual

911 turbo

Technical data

Front Wheel, Suspension

Wheel suspension

Suspension

Torsion bar

Height adjustment at DIN curb weight

Shock absorbers double-action hydraulic

Manufacturer Bilstein -different configuration from Mod. 89

Anti-roll bar 0 18 mm -from Model 77 onward 0 20 mm

independent wheel suspension with

control arms and spring struts

one round torsion bar per wheel, longitudinal

" 18.8 mm

Page 44 -1

shock absorber struts

onwards

from Model 85 onward 0 22 mm

Technical data

Printed in Germany -VII, 1989

40 -01

40

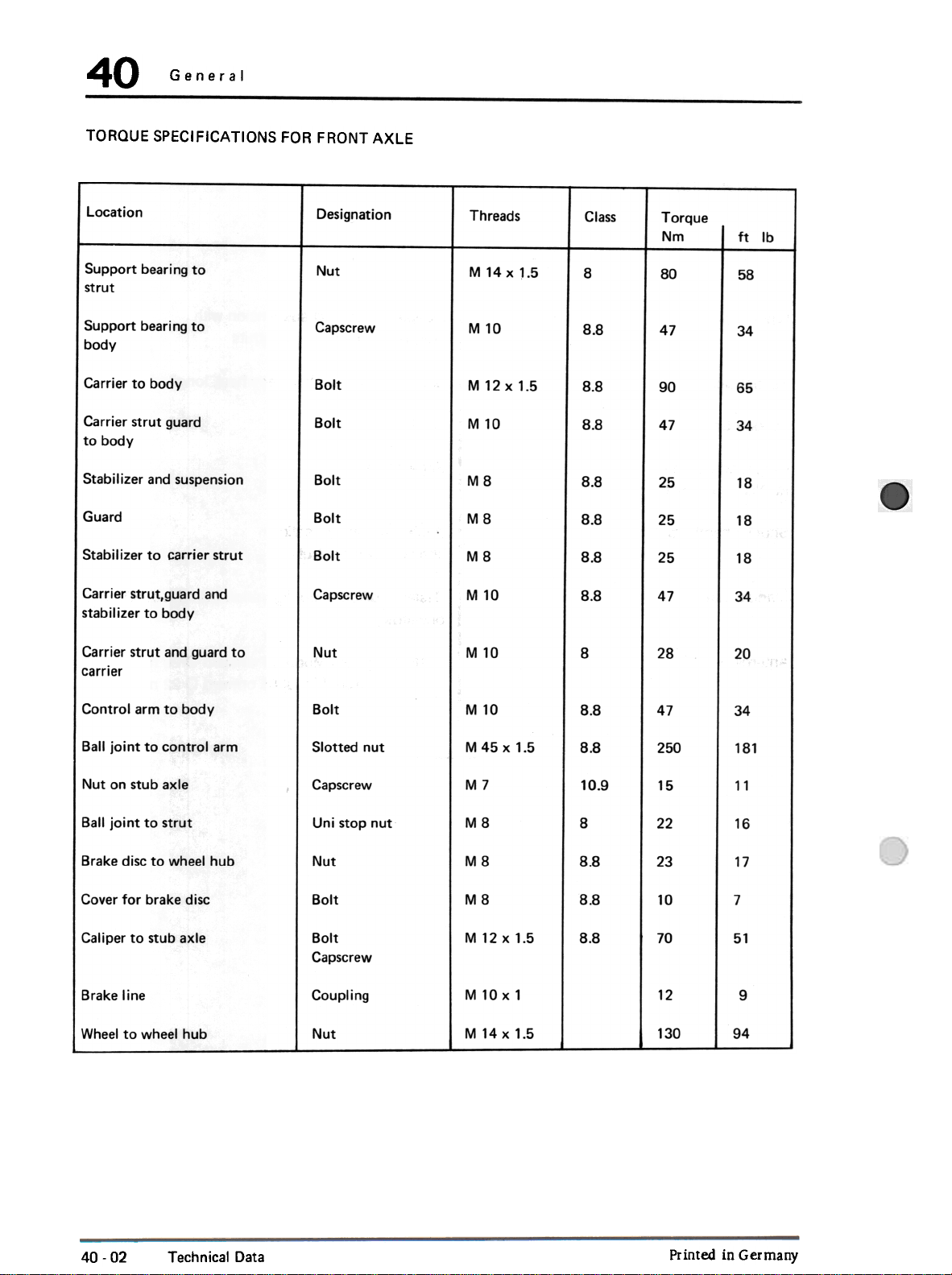

TORQUE SPECIFICATIONS FOR FRONT AXLE

General

Location

Support bearing to

strut

Support bearing to

body

Carrier to body

Carrier strut guard

to body

Stabilizer and suspension

Guard

Stabilizer to carrier strut

Carrier strut,guard and

stabilizer to body

Carrier strut and guard toI

carrier

Designation

Nut

Capscrew

Bolt

Bolt

Bolt

Bolt

Bolt

Capscrew

Nut

Threads

M 14 x 1.5

M 10

M 12 x 1.5

M 10

M8

M8

M8

M 10

M 10

Class

8

8.8

8.8

8.8

8.8

8.8

8.8

8.8 47

8

90

47

25

25

25

28 20

Torque

Nm

80

47

ft Ib

58

34

65

34

18

18

18

34

Control arm to body

Ball joint to control arm

Nut on stub axle

Ball joint to strut

Brake disc to wheel hub

Cover for brake disc

Caliper to stub axle Bolt

Brake line

Bolt M 10

Slotted nut

Capscrew

Uni stop nut

Nut M8

Bolt M8

Capscrew

Coupling

Nut

8.8 47

M 45 x

M7

M8

5

8.8

250

10.9 15

8

8.8

22

23 17

8.8 10 7

M 12 x 1.5

M 10 x 1

M 14 x 1.5 130

8.8

70

12 9

34

181

11

16

51

94Wheel to wheel hub

40-02

Technical Data

Printed in Germany

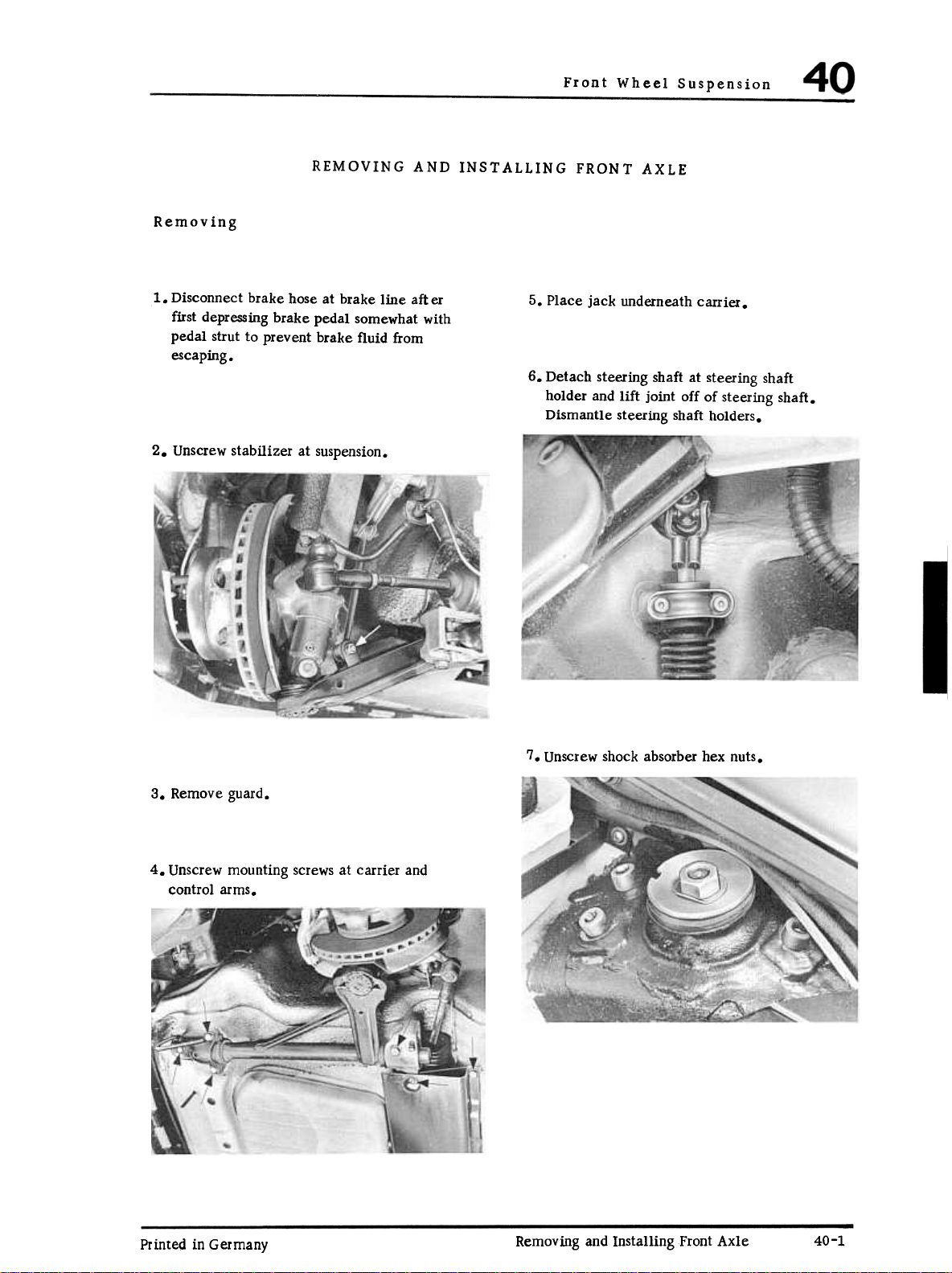

Removing

Front Wheel Suspension

REMOVING AND INSTALLING FRONT AXLE

1. Disconnect brake hose at brake line aft er

first depressing brake pedal somewhat with

pedal strut to prevent brake fluid from

escaping.

2. Unscrew stabilizer at suspension.

5. Place jack underneath carrier.

6. Detach steering shaft at steering shaft

holder and lift joint off of steering shaft.

Dismantle steering shaft holders.

7. Unscrew shock absorber hex nuts.

3. Remove guard.

4. Unscrew mounting screws at carrier and

control arms.

Printed in Germany

Removing and Installing Front Axle 40-1

Front Wheel Suspension

8. Lower complete front axle assembly.

Installing

1. Raise complete front axle assembly.

Note

Do not turn the steering wheel quickly from

lock to lock when the car is raised, to

prevent tIle cup from popping off at the

steeritlg gear or tie rod (air compensation).

2. Secure top of shock absorbers to body.

3. Secure bottom of front axle to body

(carrier and control arms).

4. Connect brake hoses.

5. Bleed brakes.

6. Torque all mounting scra-ls to specifications.

40-2

Removing and Installing Front Axle

Printed in Germany

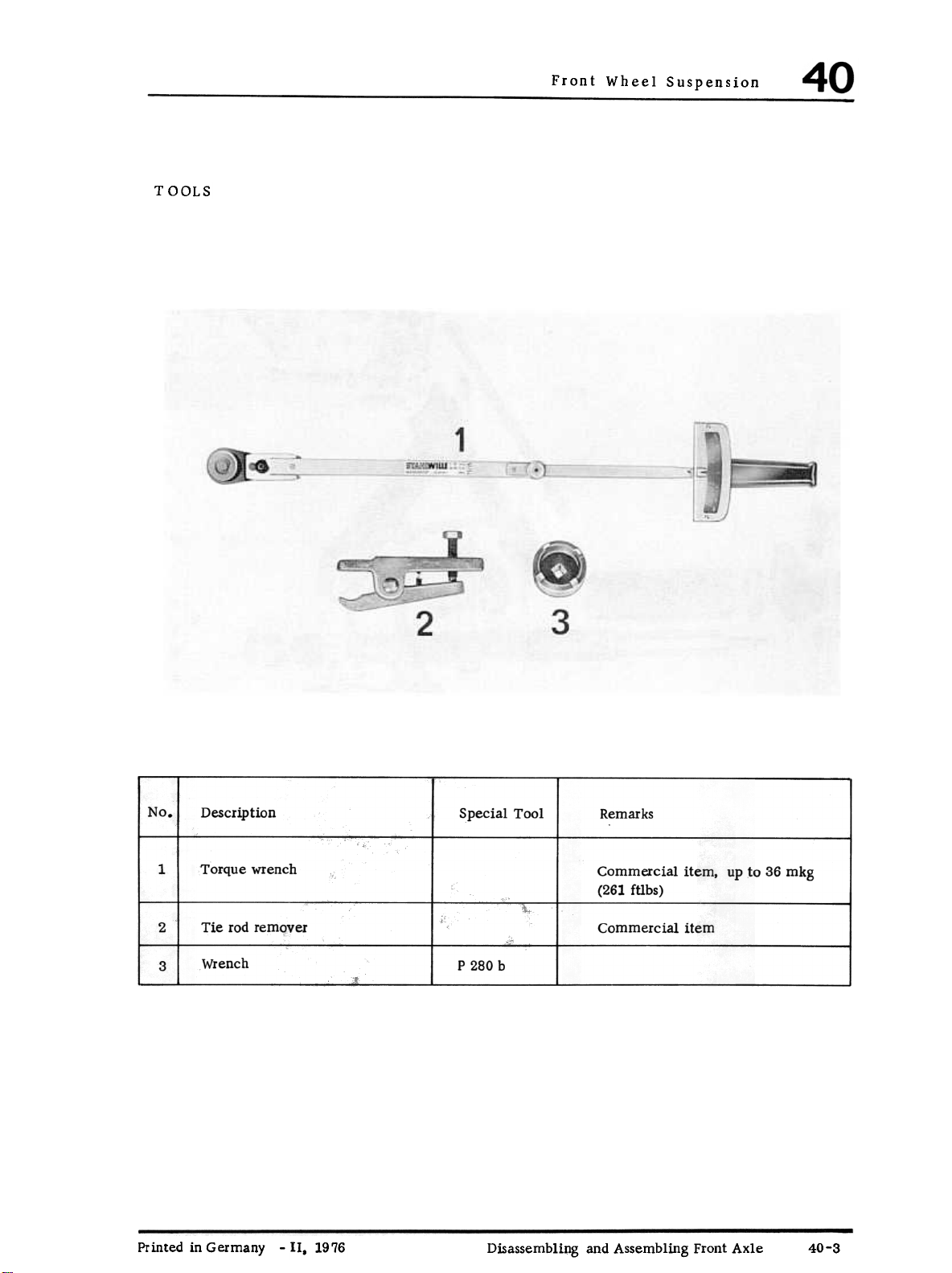

T GalS

Front Wheel Suspension

No.

Description

Torque wrench1

2

Tie rod remover

Wrench

3

Printed in Germany -II. 1976

Special Tool

Remarks

Commexcial item, up to 36 mkg

(261 ftlbs)

Commercial item

P 280 b

Disassembling and Assembling Front Axle 40-3

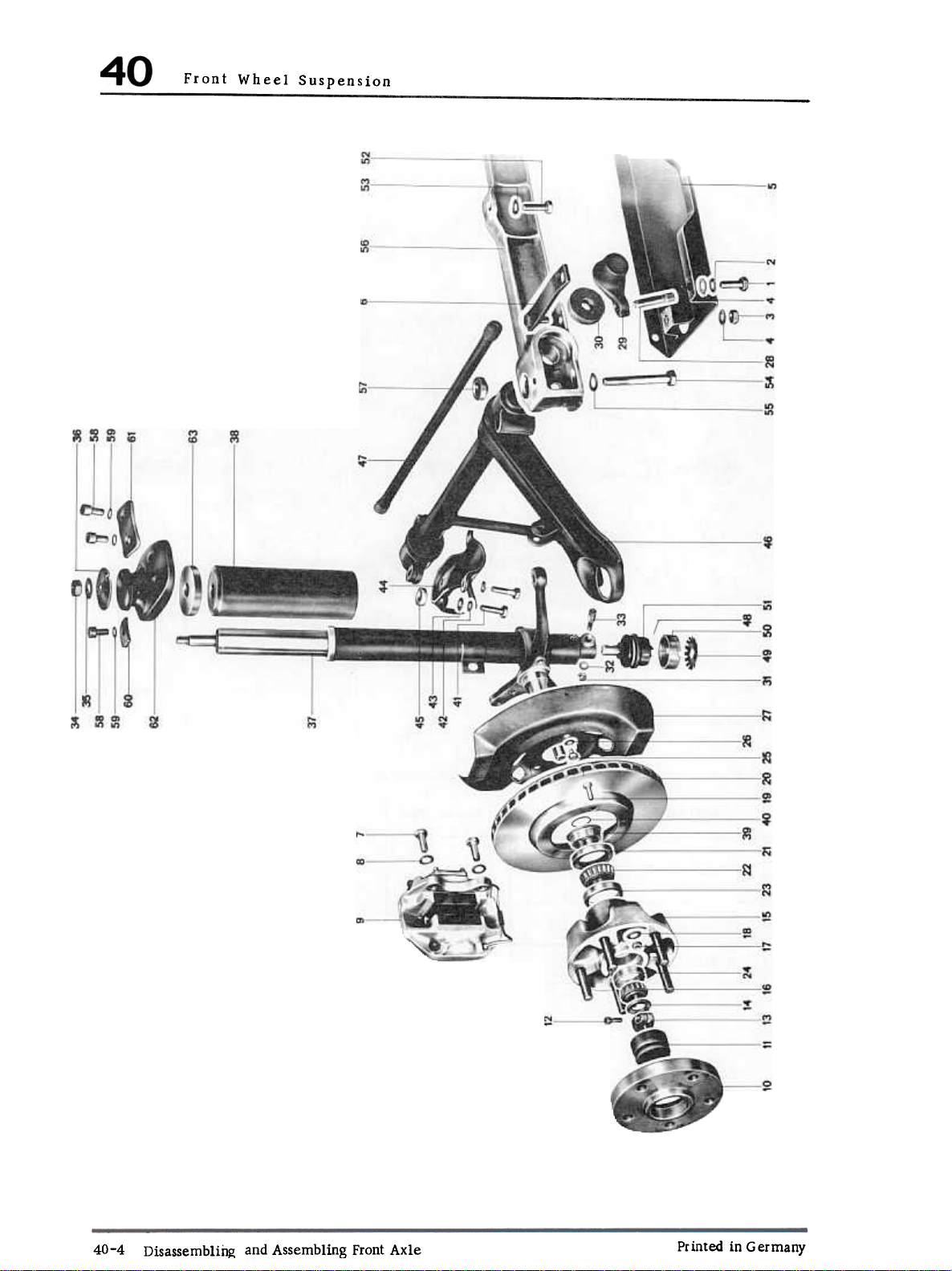

Front Wheel Suspension

40-4 Disassembling and Assembling Front Axle

Printed in Germany

Front Wheel Suspension

No

1

2

3

4

5

6

8

9

Designation

Capscrew M 10

Washer

Hex nut, self-

locking

Washer

Guard

Strut

Hex hd screw

Washer

Caliper

Amt.

2

2

2

4

1

2

2

2

1

Removing

Notes

Installing

Torque to

specifications

Replace, if

necessary

Torque to

specifications

Torque to

specifications

Replace, if

necessary

10

Spacer

Cap

12

13

15

16

Capscrew

Clamping nut 1

Tab disc14

Wheel hub

Taper roller bearing 1

17 Hex nut M 8

1

1

1

1

1

5 Torque to

Torque to

specifications

Must just barely turn

with screwdriver

Clean, check for wear'

multi-purpose lubricant

Clean, check and

lubricate. If necessary.

replace.

specifications.

lfill hub with ca. 60 g

111

Printed in Germany

Dismantling and Assembling Front Axle

40-5

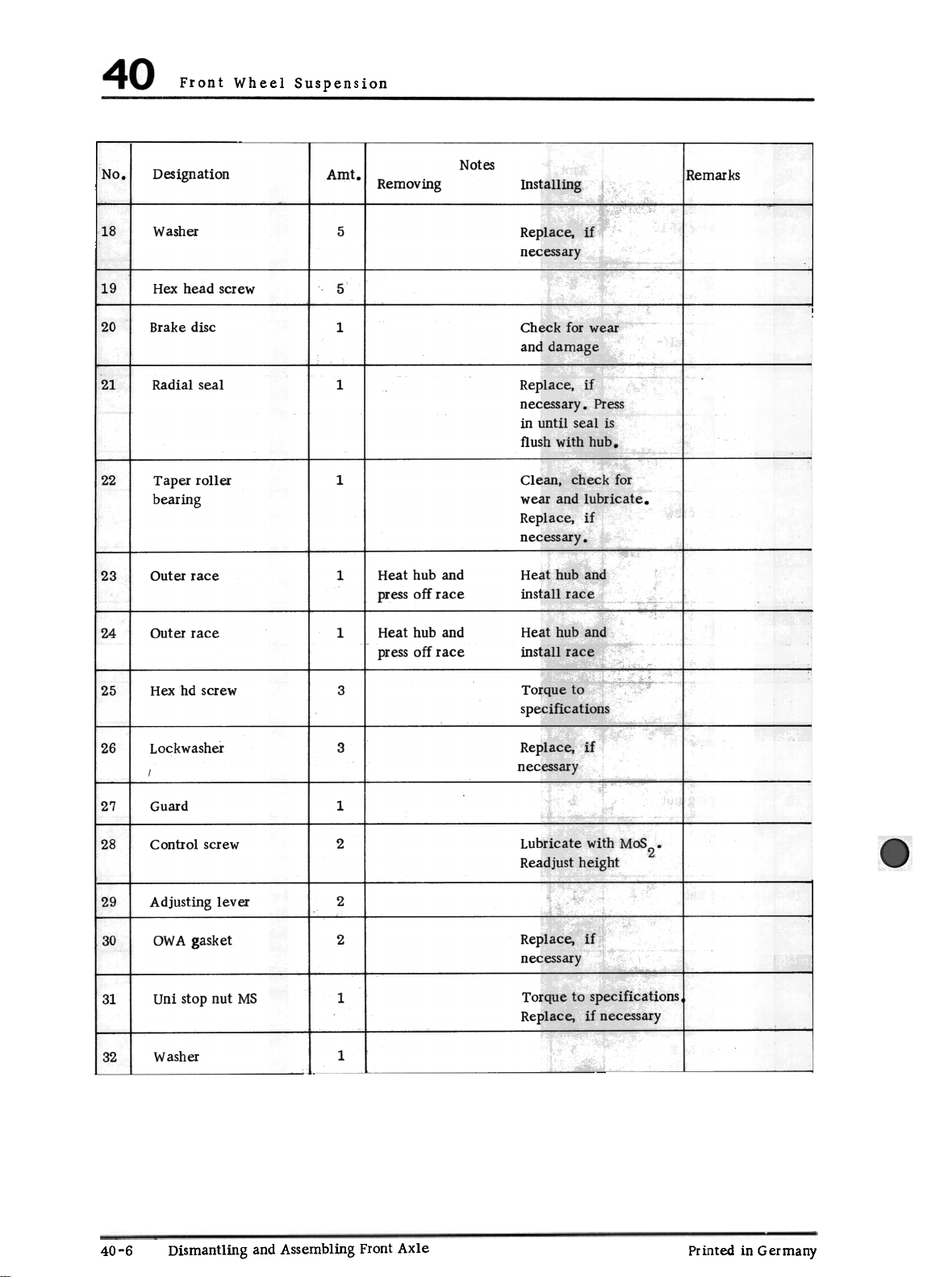

Front Wheel Suspension

No.

Designation

18 Washer 5

19 Hex head screw

120

22 Taper roller

123

124 Outer race

Brake disc

Radial seal 1 Replace, if

bearing

Outer race

Amt

Removing

Notes

Installing

Replace, if

necessary

5

1 Check for wear

and damage

necessary. Press

in until seal is

flush with hub.

1

Clean. check for

wear and lubricate.

Replace. if

necessary.

1

1

Heat hub and

press off race

Heat hub and

press off race

Heat hub and

install race

Heat hub and

install race

125

Hex hd screw

26 Lockwasher

27

Guard

28

129 I

30

Control screw

Adjusting lever

OWA gasket

Uni stop nut MS

32

Washer

3

Torque to

specifications

3

Replace. if

necessary

1

2

Lubricate with MoS2°

Readjust height

2

2

Replace, if

necessary

1

1

Torque to specifications,

Replace, if necessary

IRemarks

121

131

40-6

Dismantling and Assembling Front Axle

Printed in Germany

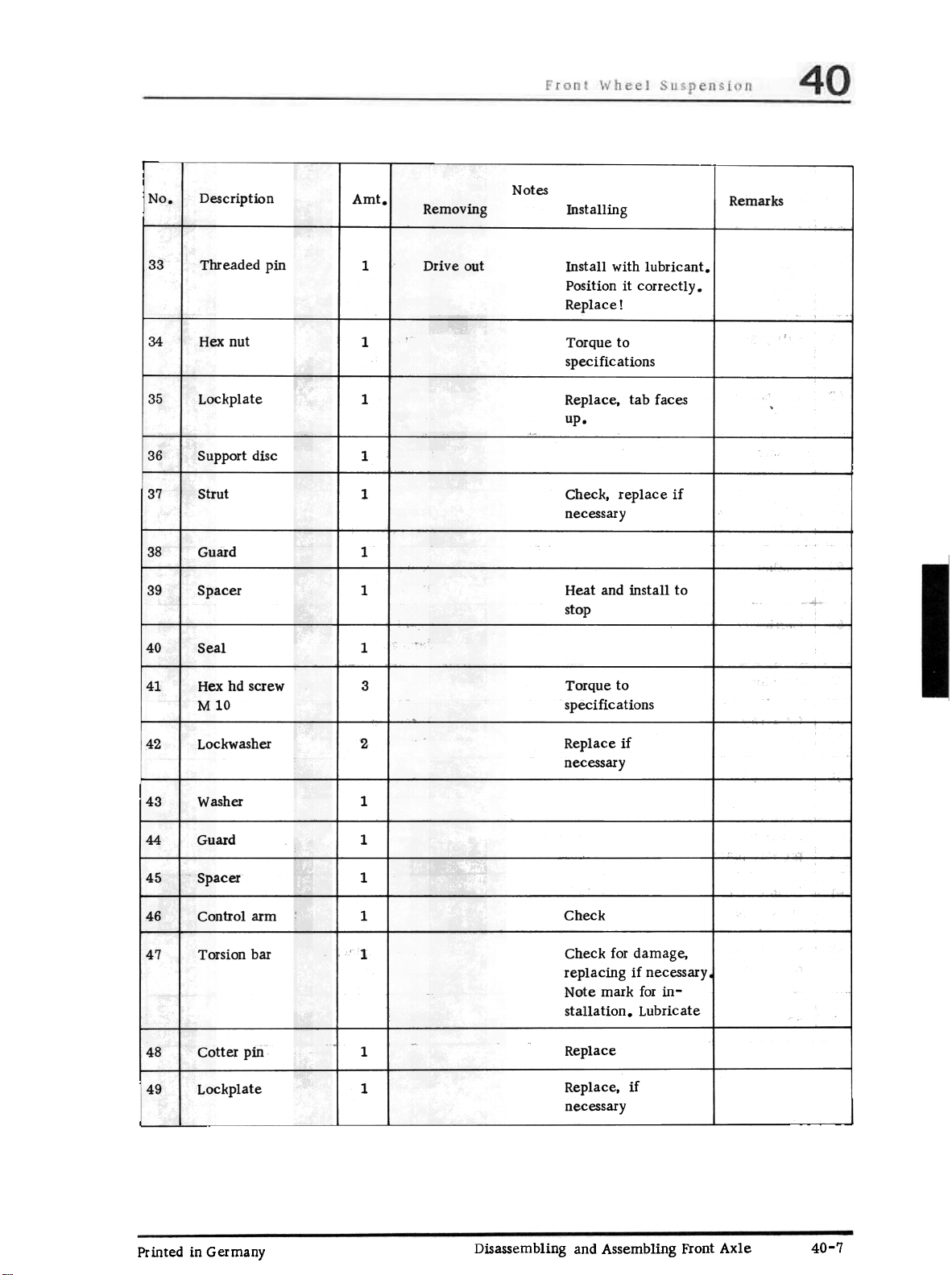

No.

Description

Amt

Removing

Notes

Installing

Remarks

33 Threaded pin

34 Hex nut

35

36 Support disc 1

37 Strut 1

38 Guard 1

39

40

Lockplate

Spacer

Seal

41 Hex hd screw

M 10

1

Drive out

Install with lubricant

Position it correctly.

Replace!

1

Torque to

specifications

1 Replace, tab faces

up.

Check, replace if

necessary

1

1

3

Heat and install to

stop

Torque to

specifications

42

Lockwasher

Washer43

Guard44 1

45

46 Control arm

47

48

49

Spacer

Torsion bar 1

Cotter pin

Lockplate

2

Replace if

necessary

1

1

1

1

1

Check

Check for damage,

replacing if necessary

Note mark for in-

stallation. Lubricate

Replace

Replace. if

necessary

Printed in Germany

Disassembling and Assembling Front Axle

40-7

40 Front Wheel Suspension

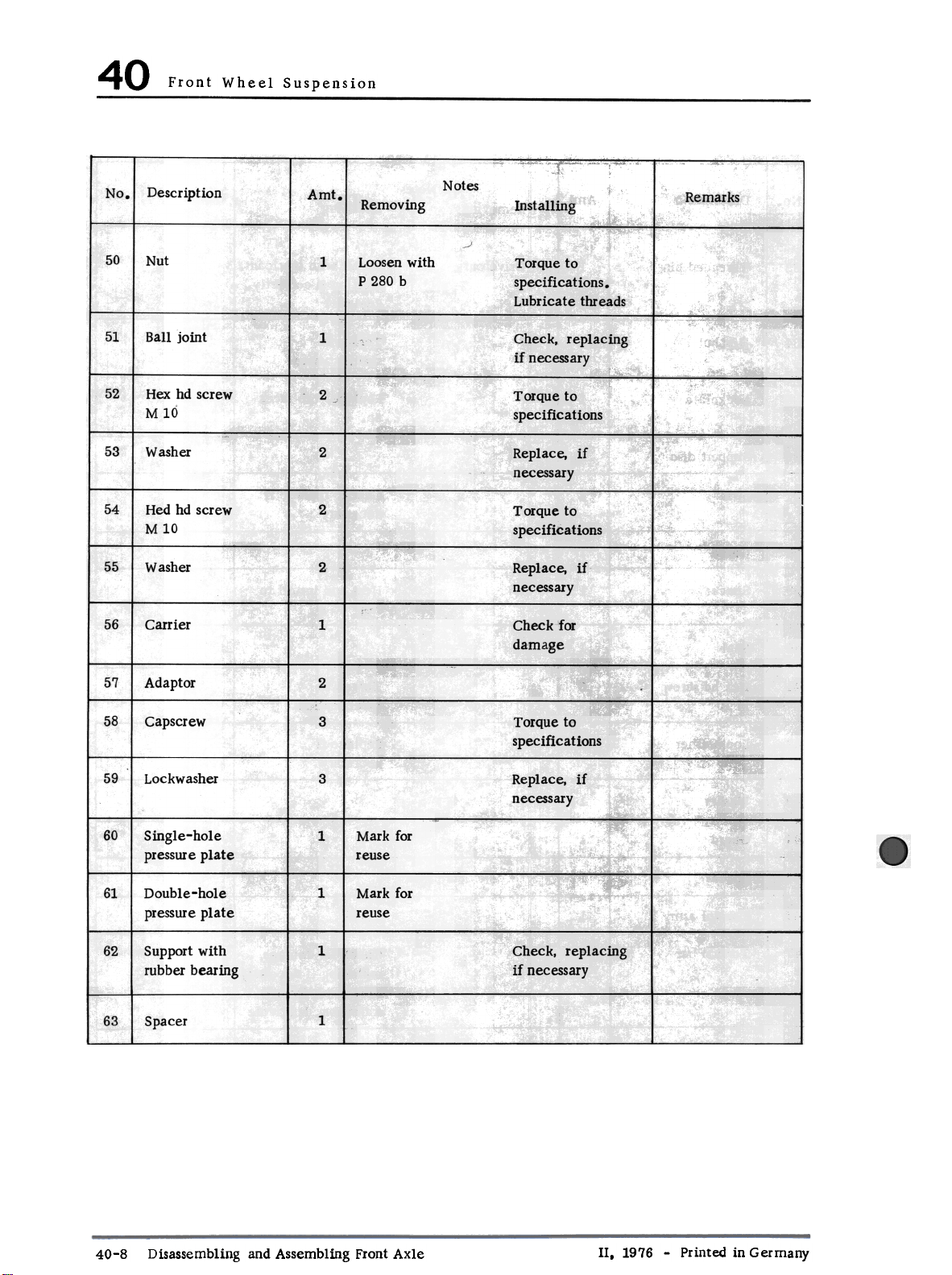

No

Description

50

Nut

51

Ball joint

52

Hex hd screw

M 10

53

Washer

54

Hed hd screw

M1O

55

Washer 2

56 Carrier

Amt,

1

1

2

2

2

1

Removing

Loosen with

P 280 b

Notes

Installing

Remarks

Torque to

specifications.

Lubricate threads

Check, replacing

if necessary

Torque to

specifications

Replace, if

necessary

Torque to

specifications

Replace, if

necessary

Check for

damage

57

Adaptor

58

Capscrew

59

Lockwasher 3

60

Single-hole

pressure plate

Double-hole

61

pressure plate

Support with

62

rubber bearing

63

Spacer

2

3

1

1

1

1

Torque to

specifications

Replace. if

necessary

Mark for

reuse

Mark for

reuse

Check, replacing

if necessary

40-8

Disassembling and Assembling Front Axle

II, 1976 -Printed in Germany

911 turbo

Technical data

Rear Wheel, Suspension

Wheel suspension

Suspension

Torsion rod

Height adjustment at DIN curb weight

Adjustment of spring strut angle

Shock absorber

Manufacturer

Anti-roll bar

independent wheel suspension with

semi-trailing arms

one round torsion bar per wheel, transverse

0 26 mm -up to the end of Mod. 88

0 27 mm -from Mod. 89 onward*

Page 44 -2

Page 44 -2

double-action hydraulic shock absorbers

Bilstein -different configuration from Mod. 89

onward

018 mm -up to the end of Mod. 84

0 20 mm -from Mod. 85 to end of Mod. 88

018 mm -from Mod. 89 onward**

* Splines also modified in conjunction with new transverse rear axle tube

Angle also modified because of new transverse rear axle tube

Technical data

Printed in Germany -VII, 1989

42 -01

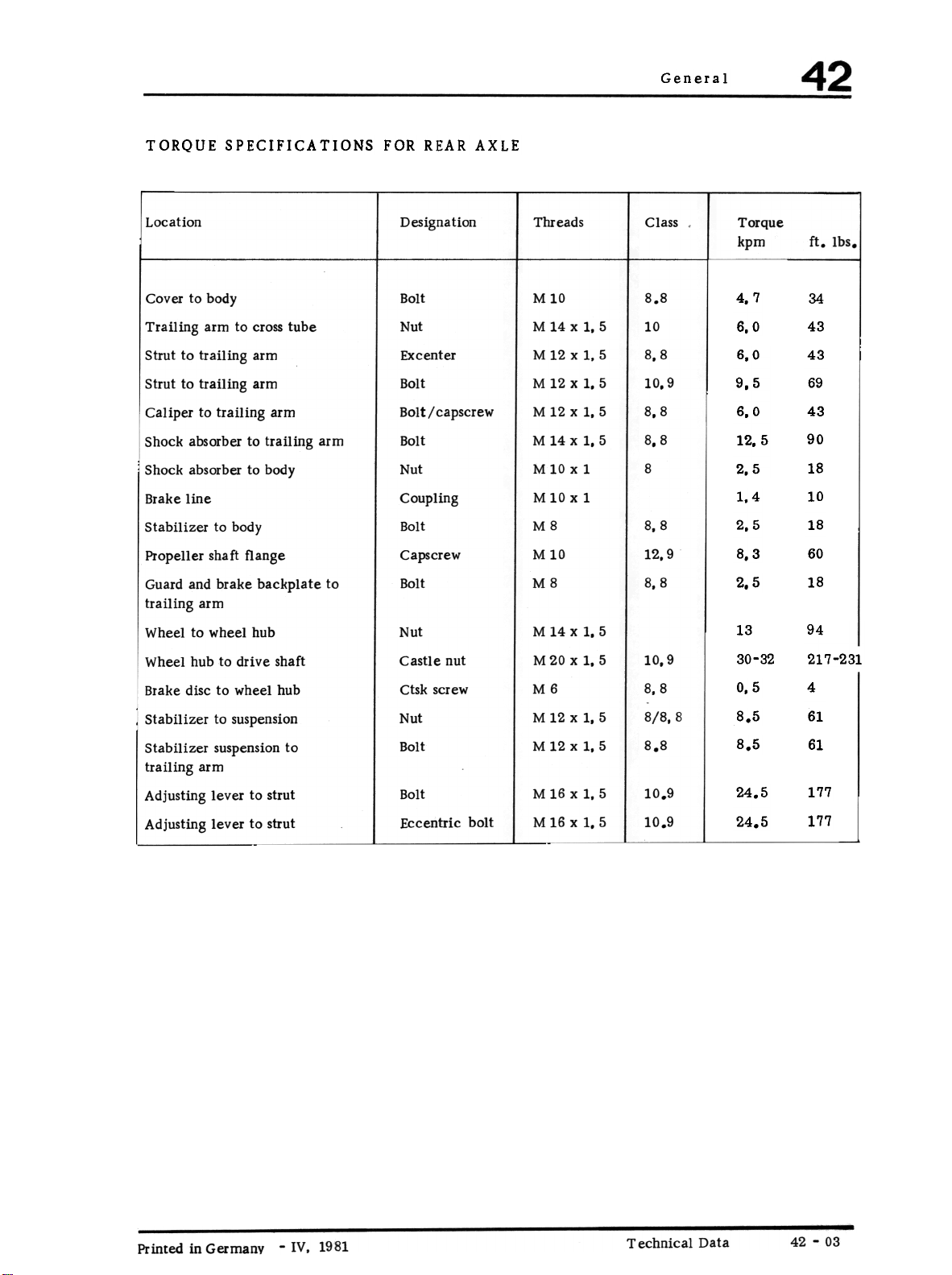

TORQUE SPECIFICATIONS FOR REAR AXLE

General

Location

Cover to body

Trailing arm to cross tube

Strut to trailing arm

Strut to trailing arm

Caliper to trailing arm

Shock absorber to trailing arm

Shock absorber to body

Brake line

Stabilizer to body

Propeller shaft flange

Guard and brake backplate to

trailing arm

Wheel to wheel hub

Wheel hub to drive shaft

Brake disc to wheel hub

Stabilizer to suspension

Stabilizer suspension to

trailing arm

Adjusting lever to strut

Adjusting lever to strut

Designation

Bolt

Nut M 14 x I, 5

Excenter

Bolt

Bolt/capscrew

Bolt

Nut

Coupling

Bolt

Capscrew

Bolt

Nut

Castle nut

ctsk screw

Bolt

Bolt

Eccentric bolt

Threads Class

MIO

M 12 x I, 5

M 12 x I, 5

M 12 x 1. 5 43

M 14 x I, 5

M 10 x 1

M 10 x 1

M8

M 10

M8

M 14 x I, 5

M 20 x I, 5

M6

M 12 x I, 5

M 12 x I, 5

M 16 x I, 5

M 16 x I, 5

8.8

10

8,8

10,9

8,8

8.8

8

8,8

12,9

8,8

10.9

8,8

8/8.8

8.8

10.9

10.9

Torque

kpm

4.7

6.0

6,0

9,5

6,0

12,5

2,5

1,4

2,5

8,3

2,5

13

30-32

0,5

8.5Nut

8.5

24.5

24.5

ft. Ibs

34

43

43

69

90

18

10

18

60

18

94

217-231

4

61

61

177

177

I

Removing

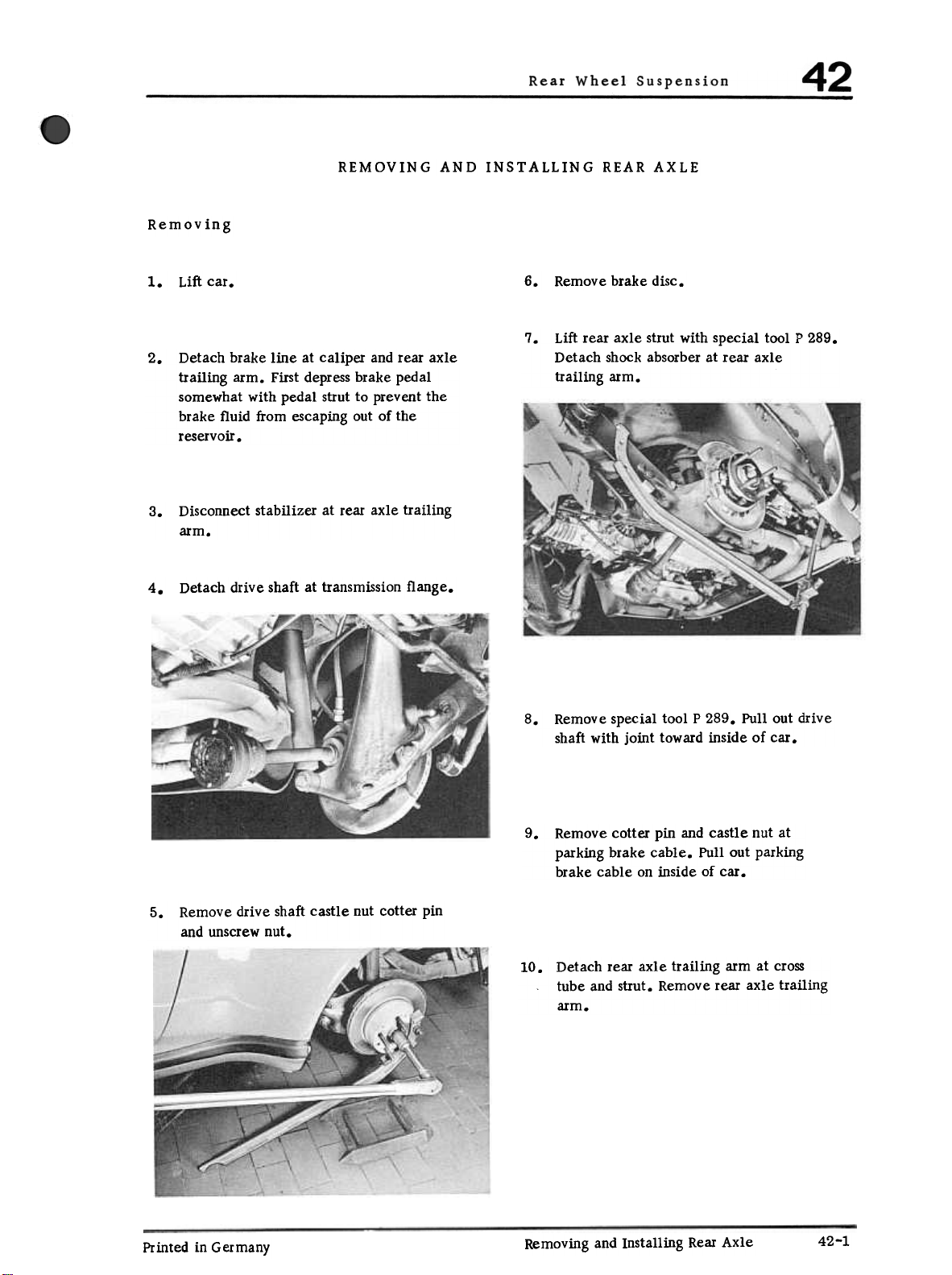

REMOVING AND INSTALLING REAR AXLE

1. Lift car.

2. Detach brake line at caliper and rear axle

trailing arm. First depress brake pedal

somewhat with pedal strut to prevent the

brake fluid from escaping out of the

reservoir .

3. Disconnect stabilizer at rear axle trailing

arm.

4. Detach drive shaft at transmission flange.

6. Remove brake disc.

7. Lift rear axle strut with special tool P 289.

Detach shock absorber at rear axle

trailing arm.

8. Remove special tool P 289. Pullout drive

shaft with joint toward inside of car.

5. Remove drive shaft castle nut cotter pin

and unscrew nut.

Printed in Germany

9. Remove cotter pin and castle nut at

parking brake cable. Pullout parking

brake cable on inside of car.

10. Detach rear axle trailing arm at cross

tube and strut. Remove rear axle trailing

arm.

Removing and Installing Rear Axle

42-1

Rear Wheel Suspension

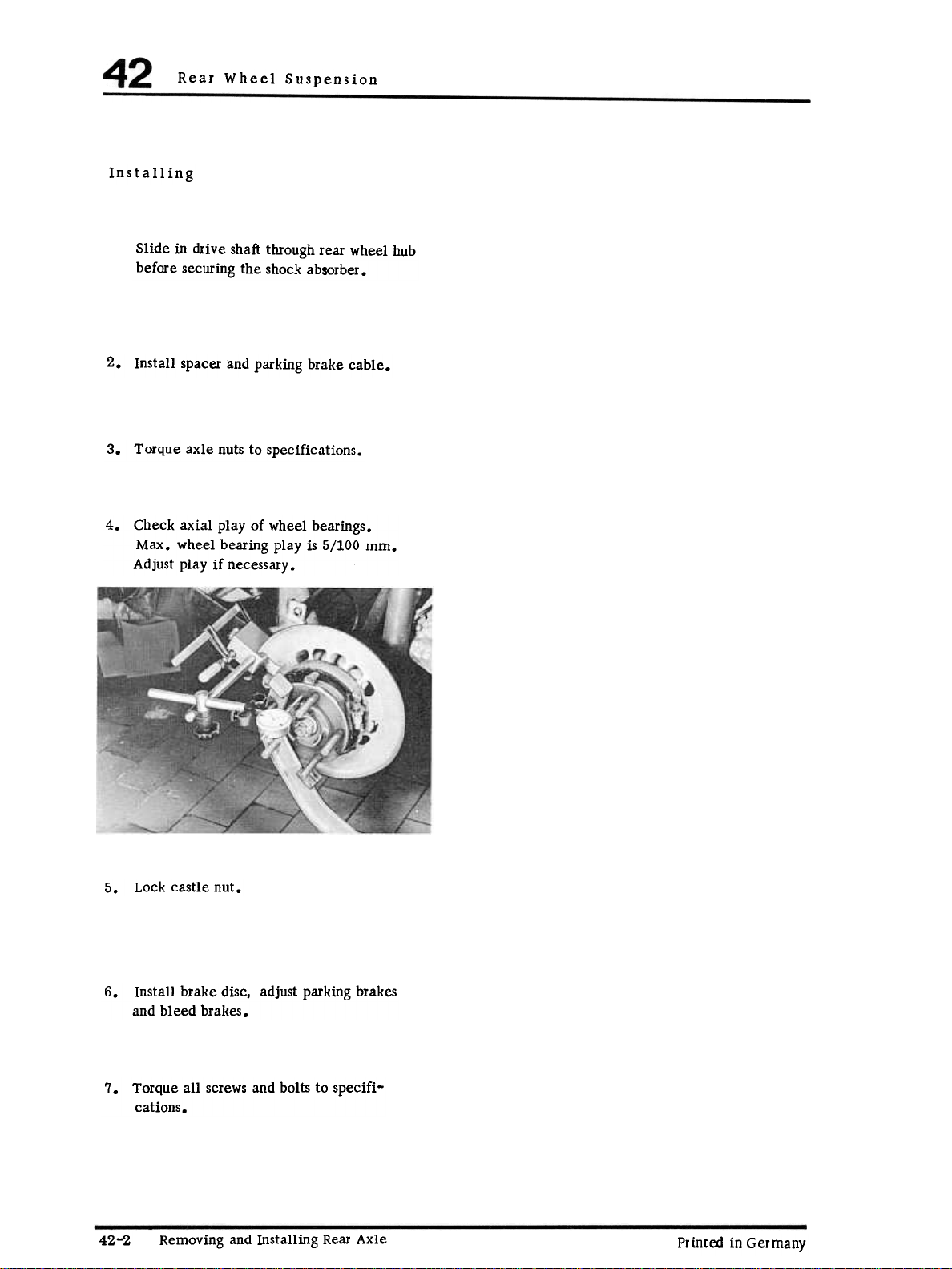

Installing

Slide in drive shaft through rear wheel hub

before securing the shock absorber.

2. Install spacer and parking brake cable.

3. Torque axle nuts to specifications.

4. Check axial play of wheel bearings.

Max. wheel bearing play is 5/100 mm.

Adjust play if necessary.

5. Lock castle nut.

6. Install brake disc, adjust parking brakes

and bleed brakes.

7. Torque all screws and bolts to specifi-

cations.

42-2

Removing and Installing Rear Axle

Printed in Germany

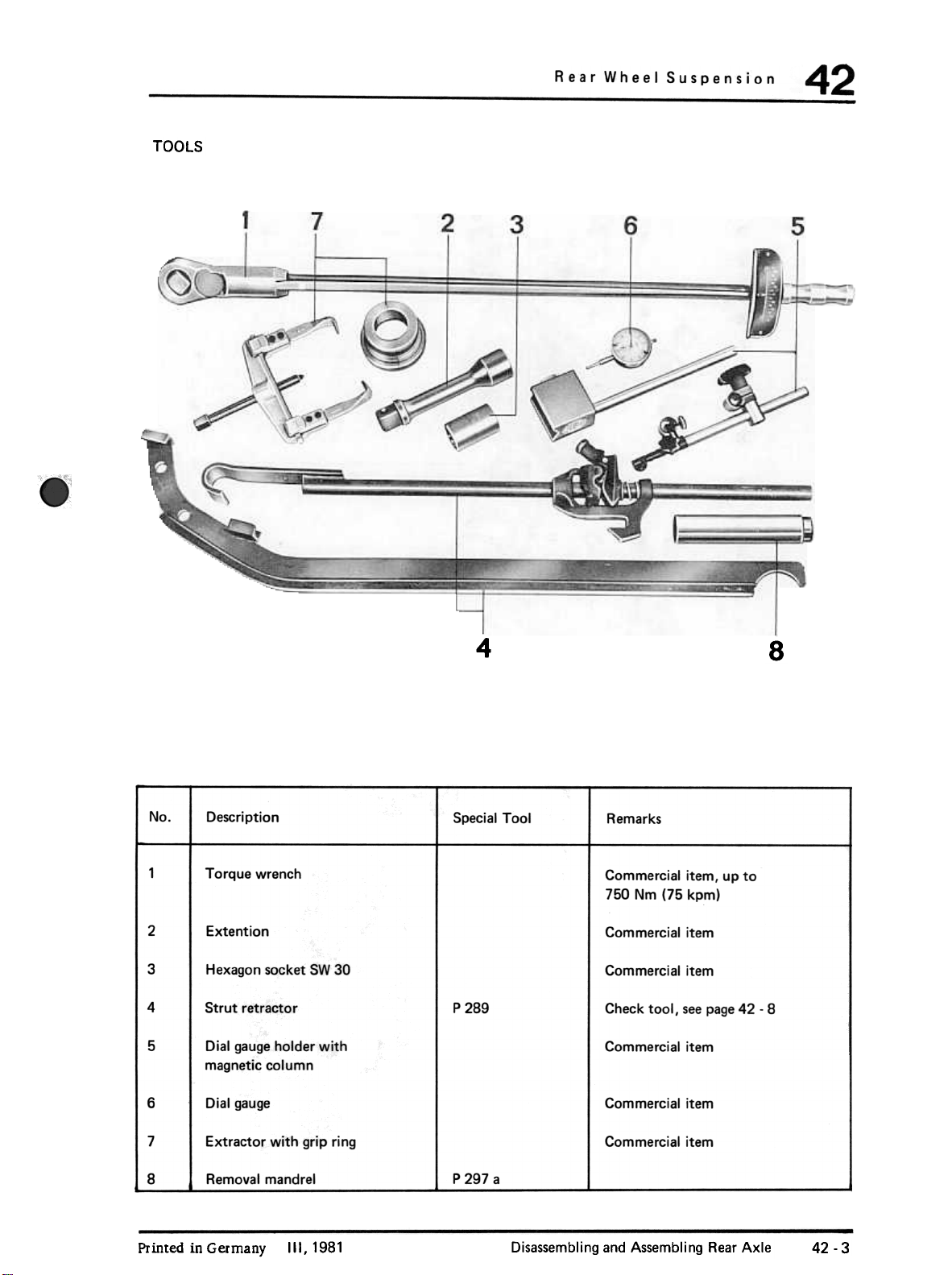

TOOLS

No

1

2

3

4

Description

Torque wrench

Extention

Hexagon socket SW 30

Strut retractor

5 Dial gauge holder with

magnetic column

6 Dial gauge

4

Special Tool

P 289

8

Remarks

Commercial item, up to

750 Nm (75 kpm)

Commercia! item

Commercial item

Check tool, see page 42 -8

Commercial item

Commercial item

7 Extractor with grip ring

8 Removal mandrel

Printed in Germany

111,1981

P 297 a

Commercial item

Disassembling and Assembling Rear Axle

42-3

Rear Wheel Suspension

=

~-

,

~ R 0

~~~ 8

H,---8

~---'-\

2 2~="'." t

N

~-

In-

N

IW)~

N

~~

,-

I

~

" -~

,

~ ~

'", *

"'." -;;: ~

~ ..

':.

.

2

0

~

~

i-"

~

~

~~---\

11 .-.c ~~r ."., ,

~-

R'

~

~

~-

-

..

"

81)

to)

.N

-CO)

..

e "

./ ,-ft

,

42-4

Disassembling and Assembling Rear Axle

Printed in Germany

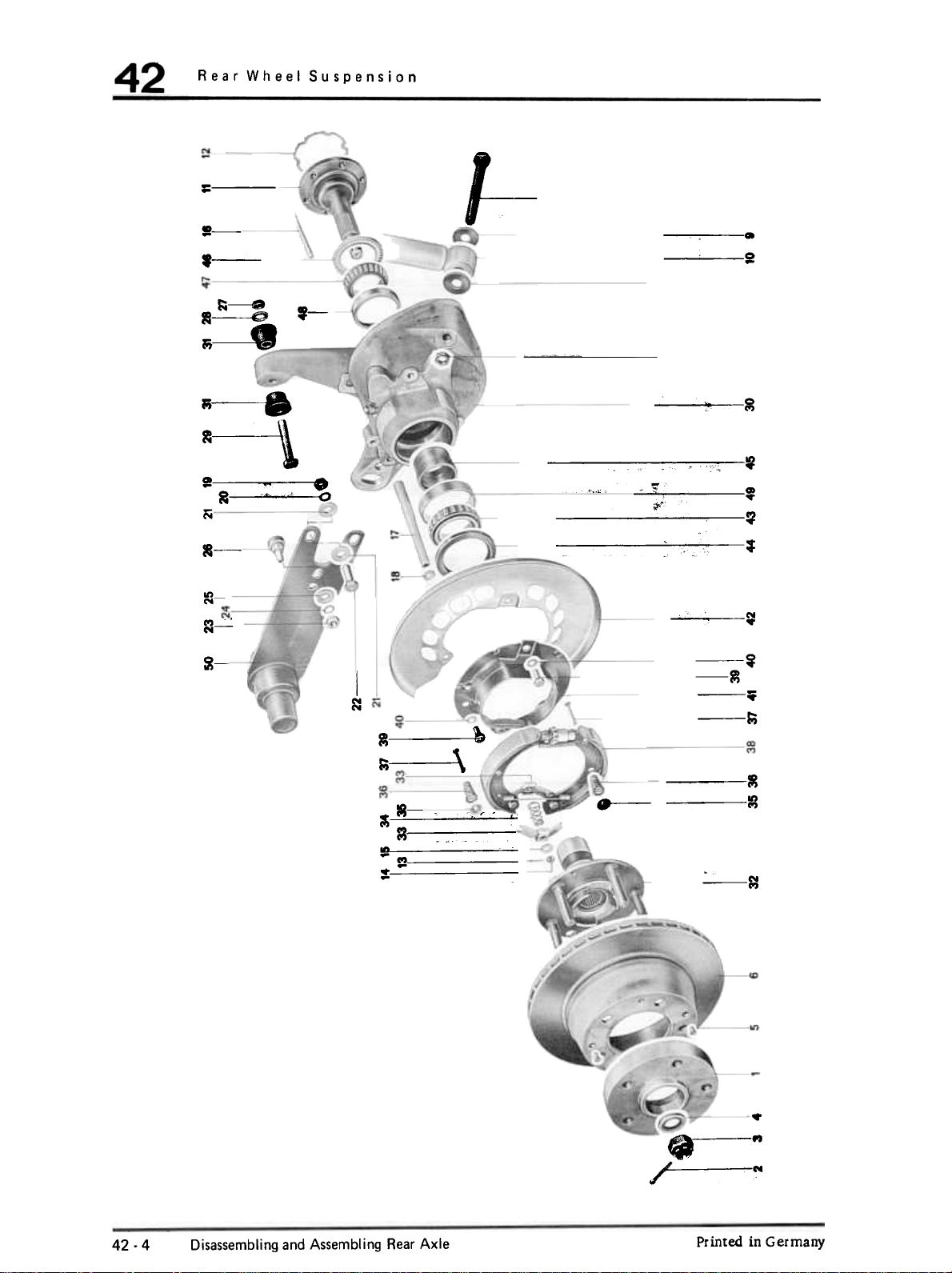

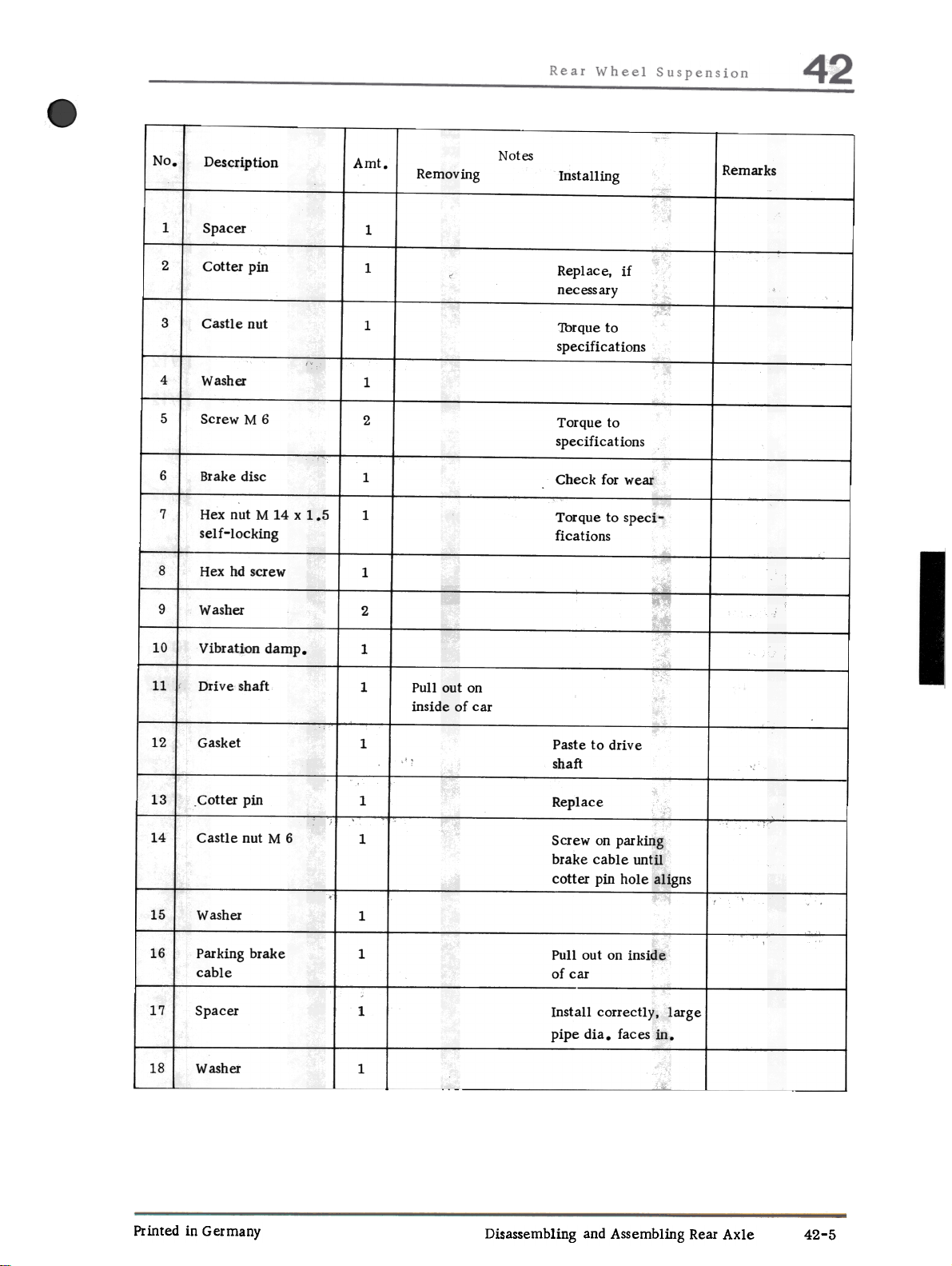

No.

Description

Amt.

Removing

Notes

Installing

Remarks

1

Spacer

2

3

Castle nut

4

Washer

5

Screw M 6

6

Brake disc

7

Hex nut M 14 x 1.5

self-locking

8

Hex hd screw

9

Washer

10

Vibration damp.

11

Drive shaft

Cotter pin

1

1

Replace. if

necessary

1

1

2

1

1

1

2

1

1

Pullout on

inside of car

Thrque to

specifications

Torque to

specifications

Check for wear

Torque to speci-

fications

12

Gasket

13

Cotter pin

14

Castle nut M 6

15

Washer

Parking brake

cable

17

Spacer

18 Washer

1

1

1

1

1

1

Paste to drive

shaft

Replace

Screw on parking

brake cable until

cotter pin hole aligns

Pullout on inside

of car

Install correctly, large

pipe dia. faces in.

1

16

Printed in Germany

Disassembling and Assembling Rear Axle

42-5

Rear Whee

Suspension

No

Description

19 Nut M 12 x 1.5

20

Lockwasher 2

21

22

Washer

Bolt 2

23 Nut M 12 x 1.5

24

25 Washer

26 1

27

28 Washer 1

Camberexcenter

Toe excenter

Self-locking nut

M 14 x 1.5

Oty

Removing

2

4

2

2Lockwasher

1

Mark position

1

for reinstallation

Note When:

Installing

Torque: 120 Nm

Torque: 85 Nm

only with

camber excenter

Special

Instructions

page 42 -11

page42-11

page 42 -11

page 42 -11/12

page 42 -11/12

page 42 -11/12

page 42 -101

29 Bolt

30

Trailing arm

31 2

Flange block

32 Wheel hub

33

35

36

34

Spreader

Spring

Spring retainer

Spring

37 Pin

38 Brake shoes

with adjuster

1

1

1 Drive out

with P 297 a

2

1

2

2

2

1

page 42 -10

page 42 -10/12

Press in to stop

Press into outer

wheel bearing

I nstall correctly

Install correctly

Check for

correct fit in

spring retainer

42-6

Disassembling and Assembling Rear Axle

V, 1984 -Printed in Germany

Rear Whee

Suspension

No.

39

40

41

42

43

44

45

46

47

Description

Bolt

Oty

Lockwasher 3

Brake backplate 1

Guard 1

Taper roller

bearing, outer

Shaft seal

Spacer

Shaft seal

Taper roller

bearing, inner

Note When:

Removing

3

Installing

Torque: 25 Nm

Replace if

necessary

1

Check, lubricate

taper rollers with

multiple purpose

grease

1

1 Install in correct

1 Press into stop

1

Press in to stop

position

Check, lubricate

taper rollers.

Drive on hub

until bearing rests

on spacer.

Special

Instructions

48 Outer bearing race

49

50

Outer bearing race

Strut

1 Heat arm and

drive out

1 Heat arm and

drive out

1

Heat arm and

drive in with

suitable mandrel

Heat arm and

drive in with

suitable mandrel

Strut angle

specified on page

42 -01 and 44 -1

Two-piece rear

axle strut since

1977 models for

correction of

car height and

wheel load

difference with

an excenter

bolt. Struts ad-

justed in plant

that entire

range for higher

adjusti ng is

available.

Printed in Germany

V, 1984

Disassembling and Assembling Rear Axle

42-7

Rear Wheel Suspension

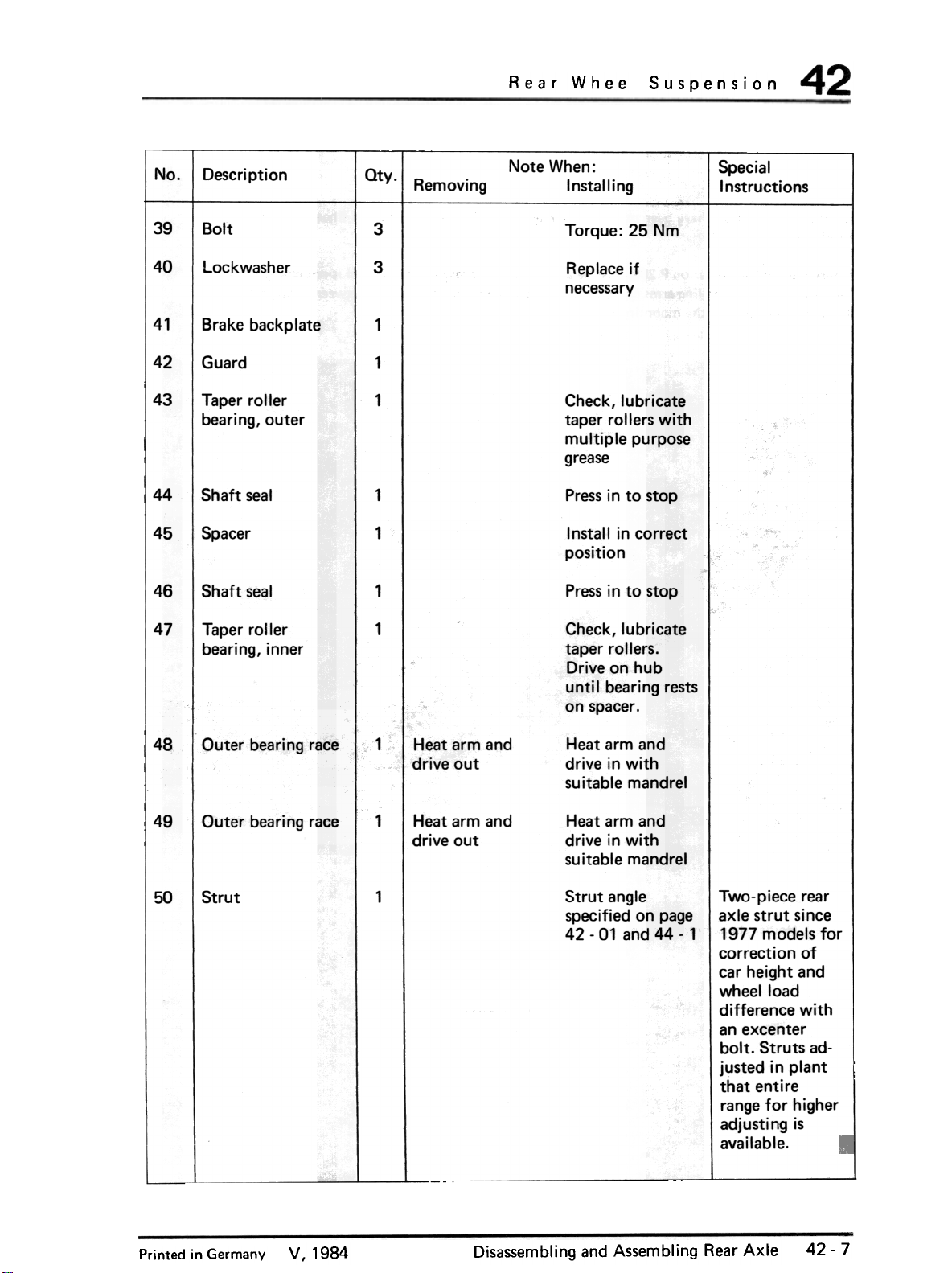

MACHINING STRUT RETRACTOR P 289

Various modifications have been made on the rear axle of 911/911 Turbo cars since the beginning of

production.

Consequently the holder on P 289 must be adapted to the present state. If tool is not changed, the

light alloy rear axle trailing arms could be damaged when clamping the tool between spring strut and

trailing arm to tighten the mounting bolts.

Holder shape before machining

)

42-8

Disassembling and Assembling

Printed in Germany

DISMANTLING AND ASSEMBLING INSTRUCTIONS

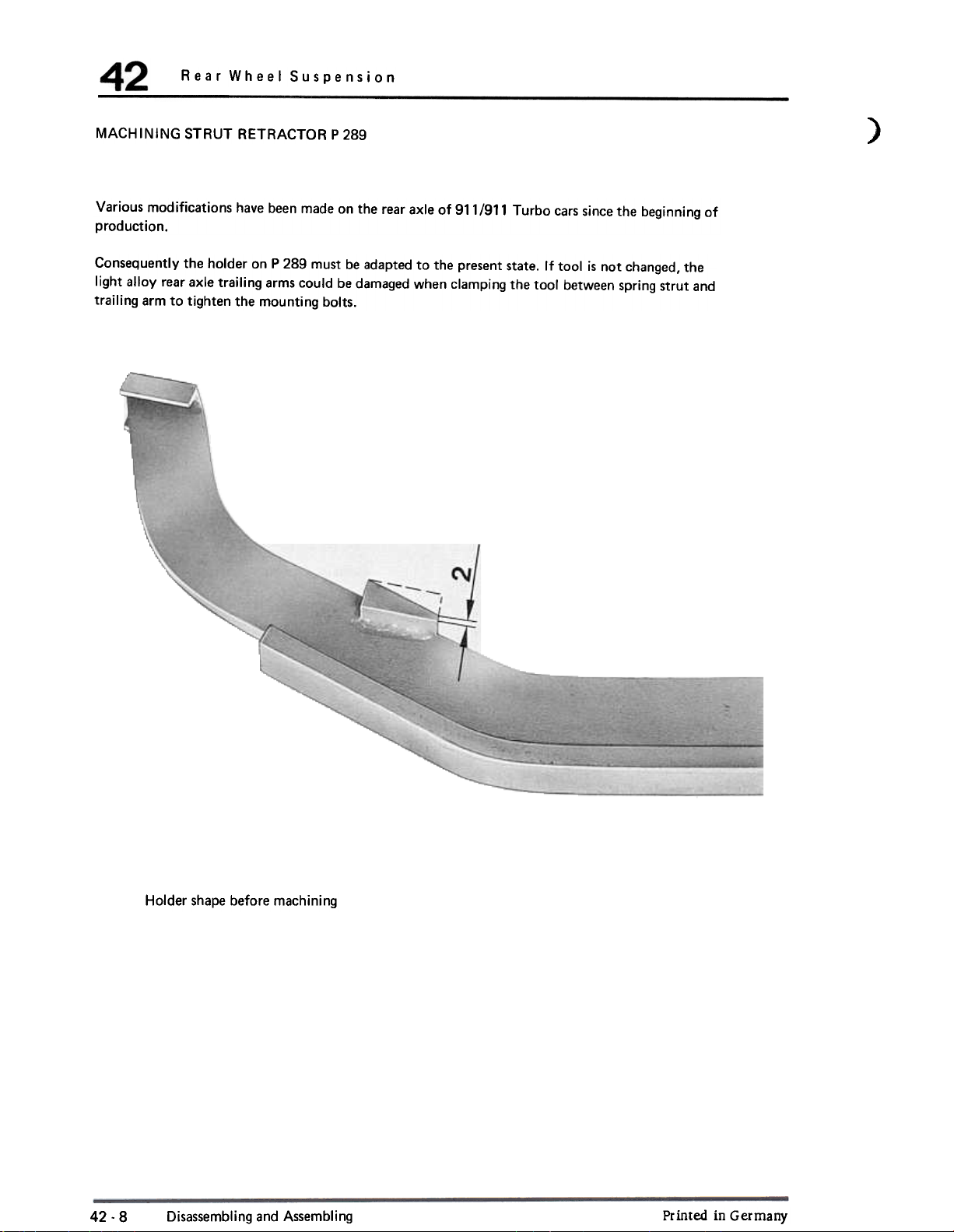

Disassembling

1. Drive out rear wheel hub with special

tool P 297 a.

2. Pull wheel bearings off of rear wheel hub.

Use extracter with grip ring. Only grab hold

of bearing at rollers.

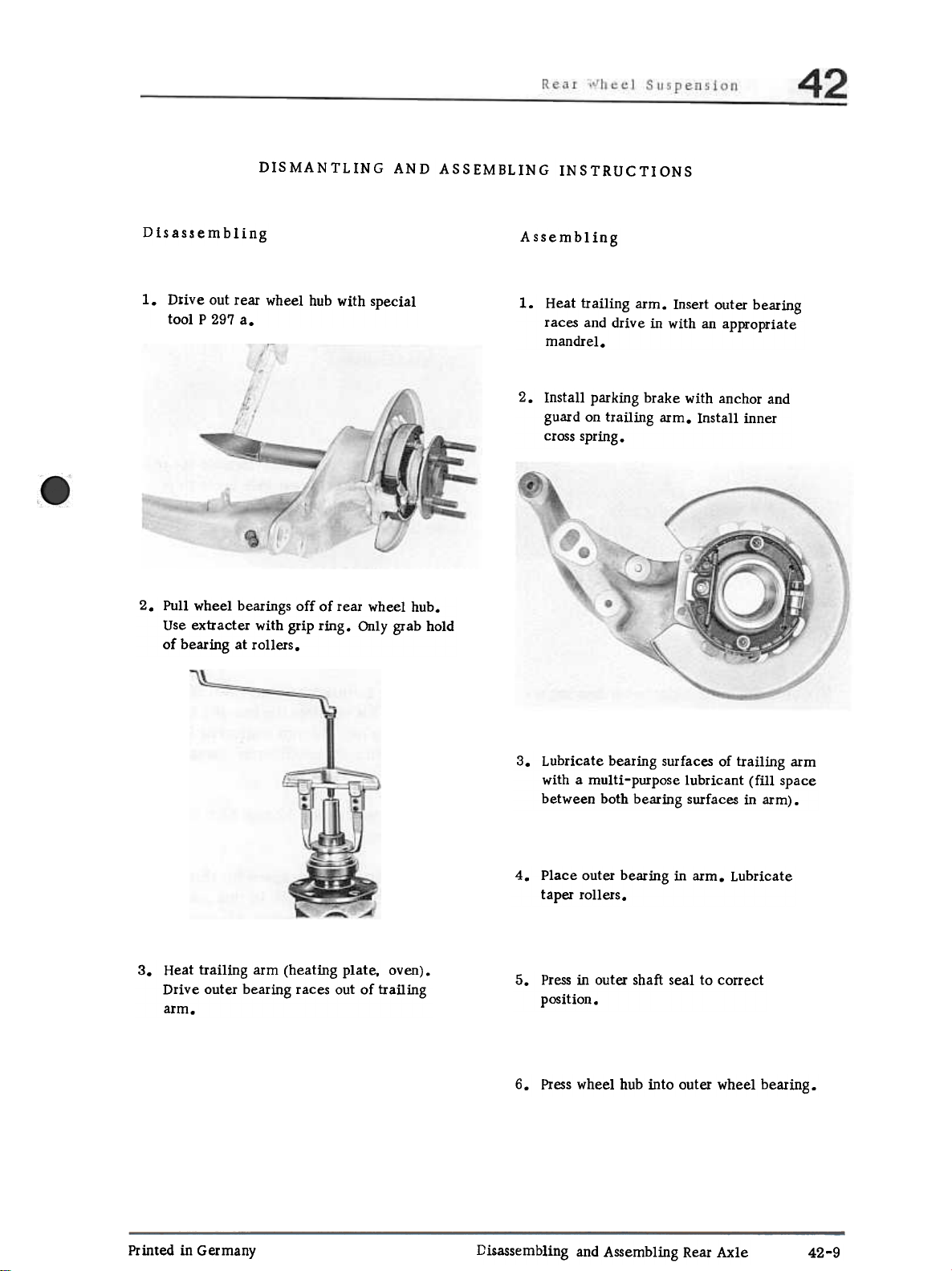

Assembling

1. Heat trailing arm. Insert outer bearing

races and drive in with an appropriate

mandrel.

2. Install parking brake with anchor and

guard on trailing arm. Install inner

cross spring.

3. Heat trailing arm (heating plate, oven).

Drive outer bearing races out of trailing

arm.

3. Lubricate bearing surfaces of trailing arm

with a multi-purpose lubricant (fill space

between both bearing surfaces in arm).

4. Place outer bearing in arm. Lubricate

taper rollers.

5. Press in outer shaft seal to correct

position.

6. Press wheel hub into outer wheel bearing.

Printed in Germany

Disassembling and Assembling Rear Axle

42-9

Rear Wheel Suspension

9. Bolt rear axle trailing arm on body

(refer to information note for point 11).

Slide in propeller shaft with drive shaft.

10. Adjust rear wheel bearings.

11. Adjust parking brake. Bleed brakes.

Torque all screws and bolts to

specifications.

Note:

The bolting and tightening torques for rear

axle trailing arms to rear axle cross tube

and rear axle trailing arms to spring struts

have been changed.

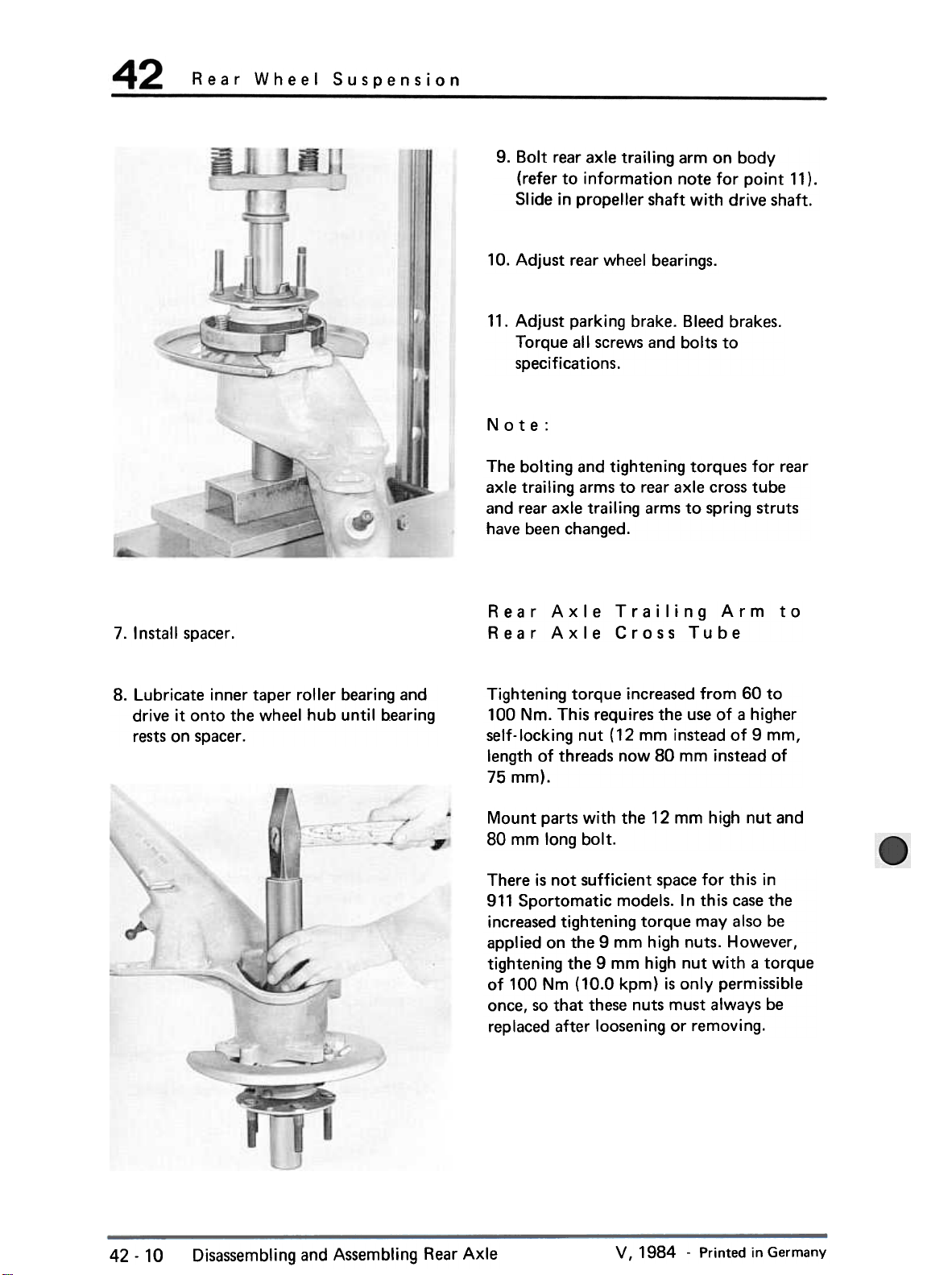

7. Install spacer.

8. Lubricate inner taper roller bearing and

drive it onto the wheel hub until bearing

rests on spacer.

Rear Axle Trail

Rear Axle Cross

Arm to

Tube

Tightening torque increased from 60 to

100 Nm. This requires the use of a higher

self-locking nut (12 mm instead of 9 mm,

length of threads now 80 mm instead of

75 mm).

Mount parts with the 12 mm high nut and

80 mm long bolt.

There is not sufficient space for this in

911 Sportomatic models. In this case the

increased tightening torque may also be

applied on the 9 mm high nuts. However,

tightening the 9 mm high nut with a torque

of 100 Nm (10.0 kpm) is only permissible

once, so that these nuts must always be

replaced after loosening or removing.

ing

42-10

Disassembling and Assembling Rear Axle

V, 1984 -Printed in Germany

Rear Wheel Suspension

Rear Axle Trai

ng Arm to Spring Strut

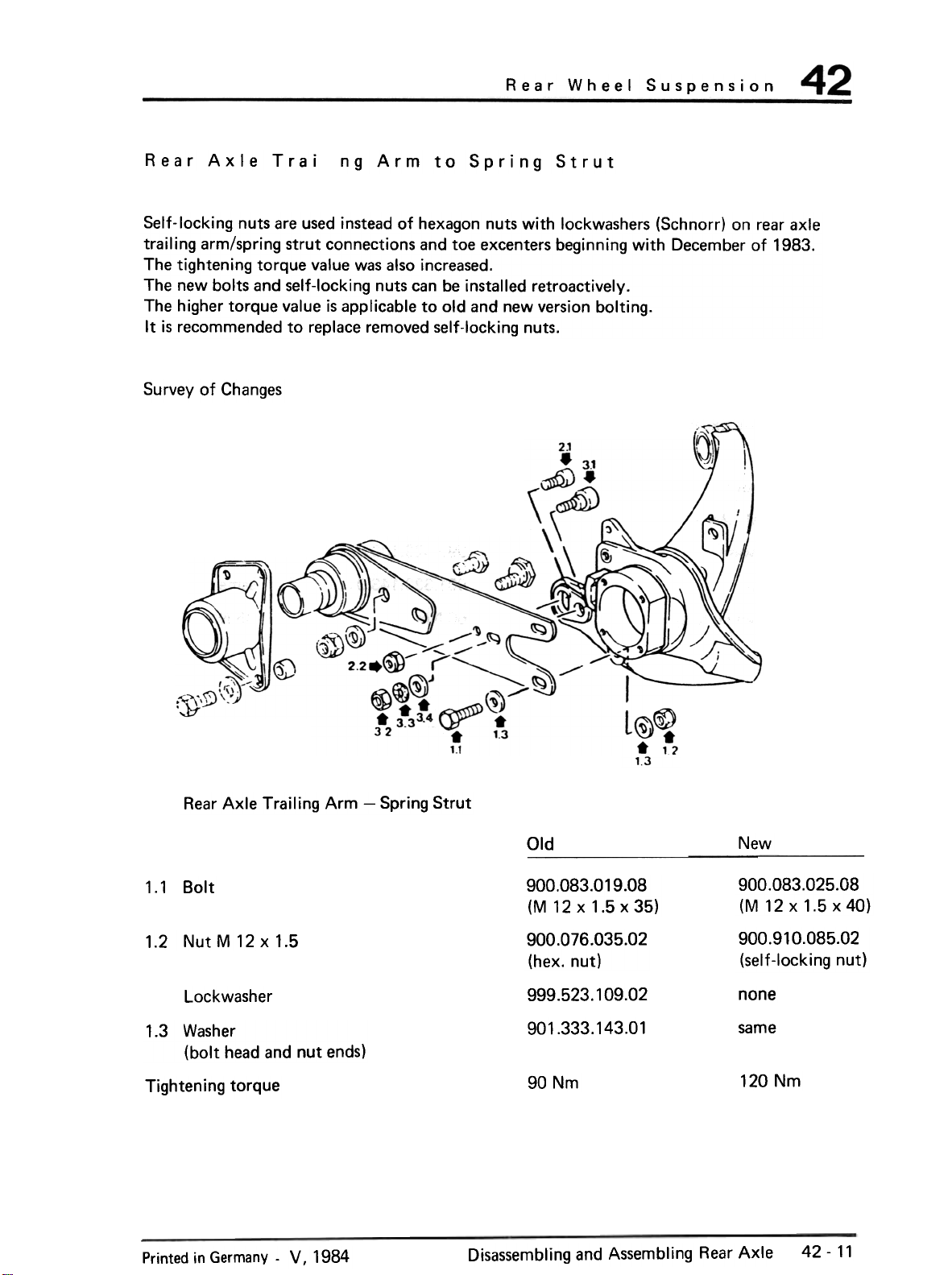

Self-locking nuts are used instead of hexagon nuts with lockwashers (Schnorr) on rear axle

trailing arm/spring strut connections and toe excenters beginning with December of 1983.

The tightening torque value was also increased.

The new bolts and self-locking nuts can be installed retroactively.

The higher torque value is applicable to old and new version bolting.

It is recommended to replace removed self-locking nuts.

Survey of Changes

Rear Axle Trailing Arm -Spring Strut

Bolt1 .1

1.2 Nut M 12 x 1.5

Lockwasher

1.3 Washer

(bolt head and nut ends)

Tightening torque

Printed in Germany -V I 1984

Old

900.083.019.08

(M 12 x 1.5 x 35)

900.076.035.02

(hex. nut)

999.523.109.02

901.333.143.01

90 Nm

Disassembling and Assembling Rear Axle

New

900.083.025.08

(M 12 x 1.5 x 40)

900.910.085.02

(self-locking nut)

none

same

120 Nm

42 -11

Loading...

Loading...