Porsche 928, 1987 928, 1986 928, 1988 928, 1989 928 Workshop Manual

...

Workshop Manual

l

DR. ING. h. c. F. PORSCHE Aktiengesellschaft

The Workshop Manual is only for the internal use of the Porsche Dealer Organization.

@ 1977 Dr. Ing. h.c. F. Porsche Aktiengesellschaft

Sales, D-7140 Ludwigsburg

All rights resewed - Printed in Germany XX, 1986

WKD 481 621

Print No. W 42-608-126-l

List of Repair Groups

General

Technical Data Paae 0.1

Repair Groups

Maintenance, Self-diagnosis

Group

03

Engine

Engine, Crankcase

Engine, Crankshaft, Pistons

Engine, Cylinder Head and Valve Drive

Engine, Lubrication

Engine, Cooling

Fuel Supply

Air Flow Controlled Fuel injection

Exhaust System/Emission Contrds

Starter, Power Supply, Cruise Control

Ignition System

10

13

15

17

19

20

24

26

27

28

Transmission

Chassis

Clutch, Controls

30

Torque Converter

32

Manual Transmission, Controls, Case

34

Manual Transmission, Gears, Shafts

35

Automatic Transmission, Controls, Case

37

Automatic Transmission, Gears, Valve Body

38

Differential, Transaxle System

39

Front Wheel Suspension

40

Rear Wheel Suspension, Axle Shaft

42

Wheels, Tires, Alignment

44

Antiblock System

45

Brakes, Mechanical

46

Brakes, Hydraulics

47

Steering

48

Body-Front Section

50

Body-Center Section

51

Body-Rear Section

53

Lids

55

Doors

57

Hardtop

61

Bumpers

63

Glasses, Window Control

64

Exterior Equipment

66

Interior Equipment

68

Seats

72

Seat Covers

74

Heating,

Heater

80

Ventilation,

Ventilation

85

Air Condition

Air Conditioner

87

Electrics

Instruments, Fuel Gauge, Alarm System

Radio

Windshield Wipers and Washer

Exterior Lights, Lamps, Switches

Interior Lights

Wiring

90

91

92

94

96

97

Printed in Germany - XX, 1997

928 Table of contents Volume III

a

General Data

Technical

data

Tightening torques

Torque Converter

Removing and installing torque convener

32-101

Removing and installing selector lever cover frame

37-101

Removing and installing selector lever cable

37-103

Adjusting selector lever cable

37-105

Removing and installing starter locking and backup light switch

37-107

Adjusting starter locking and backup light switch

37-109

Checking adjustment of selector lever cable and starter locking / backup light switch

37-l 11

Bowden cable for control pressure, removing and installing (service solution)

37-113

Bowden cable for control pressure, adjusting

37-115

Removing and installing transmission

37-l 17

Adjusting transmission suspension

37-123

Disassembling and assembling front convener housing

37-125

Disassembling and assembling front converter housing (‘87 models onward)

37-l 30

Removing and installing rear transmission case

37-131

Removing and installing rear transmission

37.135

Disassembling and assembling transmission

37-143

Transmission I Gears, Valve Body

Checking transmission operation

....................

Checking operation

...........................

Checking operation (87 models onward)

................

Troubleshooting.

............................

Removing and installing shift valve casing

...............

Disassembling and assembling shift valve housing

..........

Disassembling and assembling shift valve casing (‘87 models onward)

Removing and installing lower cover

..................

Disassembling and assembling lower cover

..............

Replacing ATF and filter

........................

Flushing ATF cooler and lines

.....................

Removing and installing governor

...................

Checking governor

...........................

Removing and installing vacuum modulator

..............

Removing and installing primary pump.

................

38-101

38-l 10

38-11 Oa

38-111

38-123

38-l 25

38-130a

38-131

38-133

38-137

38-141

38-143

38-145

38-147

38-149

Page

30-0101

30-0105

-

Table of contents

1

Prlnwd in Germany - XXXV, 1999

Volume III

Table of contents

929

Disassembling and assembling secondaty pump ...............

38-l 55

Disassembling and assembling gear assembly

................

38-l 57

Disassembling and assembling one-way clutch

................

38-163

Disassembling and assembling clutch K 1

..................

36-l 69

Disassembling and assembling clutch K 2

..................

38-177

Differential I Transaxle system

Removing and installing final drive ......................

Disassembling and assembling final drive

..................

Disassembling and assembling differential

..................

Disassembling and assembling bearing assembly

..............

Disassembling and assembling bearing assembly / Determining thickness of

shims for bearing assembly ..........................

Adjusting drive pinion and ring gear. .....................

Adjusting drive pinion and ring gear. .....................

Adjusting drive pinion and ring gear. .....................

Adjusting drive pinion and ring gear. .....................

Adjusting drive pinion and ring gear. .....................

Adjusting drive pinion and ring gear. .....................

Disassembling and assembling central tube

.................

Checking central tube .............................

PSD-Diagnosis I Troubleshooting .......................

39-l 01

39-107

39-113

39-l 19

39-123

39-125

39-127

39-128

39-130

39-133

39-135

39-137

39-139

D39-201

2

l

Table of contents

Printed In Genany - XXXV. 1999

928

General Data

30

a

4 - SPEED AUTOMATIC TRANSMISSION (UP TO '86 MODELS)

1 - Front converter casing

2 - Automatic transmission

a

3 - Final drive

Transmission Type

A 28.01

A 28.02

A 28.03

A 28.04

A 28.05

0 A 28.06

A 28.07

A 28.08

A 28.09

A 28.11

installed in

928 S, USA series / '83 and '84 models for Japan

928 S, Special option for Europe / rest of the

world,

'84 models

928 S, Special option (M 251) Europe / rest

of the world 3/84 onward (as 28.02, but

rear axle transmission ratio 13 : 33)

928 S, USA series / '85 models for Japan

928 S, Special option Europe / '85 models

rest of the world

928 S, Special option (M 251) Europe / '85 models

rest of the world (as A 28.05, but with

rear axle transmission ratio 13 : 33)

928 S, USA series / '86 models for Japan

928 S, Special option Europe / '86 models

rest of the world

928 S, Special option (M 251) Europe / '86 models

rest of the world (as A 28/08, but with

rear axle transmission ratio (13 : 33)

928 S, Australia series, special option (M 299)

for FGR, Switzerland, Austria, Sweden

('86 models)

0

Printed in

Germany-XX,1988

Technical Data

30 - 0101

30

Technical Data

General Data

920

0

4-speed automatic transmlsslon (‘87 models onward)

1 - Front converter casing

3 - Final drive

2 - Automatic transmission

Type

Key-number

Equipment Installed In model

a

A28.12 -

928 S 4 USNJap. 87188

A28.14 - 928 S 4 R.d.W. 87188

A28.16 -

928 S 4 worldwide 89/90/91

A28.18 -

928 GTS worldwide 92/93

30 - 0102

Technical Data

Printed in Germany - XXXI, 1993

928

General Data

30

a

Technical Data

Tmsmlsslon DeslgnatTon

1

A 28 02 12 1 6

E 05065

T

-r

[ - @zFc,985

1 = 5 - speed transmission

6 = Automatic

Transmission for 8 cylinder vehicles

Limited-slip differential 40 %

Country code

Transmission type

A 28 = four speed automatic

A 22 = three-speed automatic

G 28 = five-speed manual transmission

72227012

01

722316 02.~

A28.01

7222702501 72231602...=

A28.07

722 270 14

01

722 318 02...=

A 28.02/03

7222702601 72231602.~

A28.11

7222701701

72231602...=

A28.04

722 270 21

01 722 326 02...=

A 28.12/14

722 270 18

01 722 318 02...=

A 28.0.5/06

7222703201 72236003...=

A28.16

722 270 21

01

722 318 02...=

A 28.08/09

7222703401 72236003...=

A28.18

Technlcal Data

Printed in Germany - XXXI, 1993

30 - 0102a

30

General Data 928

Technical Data

Transmlssion

numbers

(12 dlglts)

A2814

T

Index for varlants

wlthln the assembly number

0 = no differential

1 = normal differential

2 = ZF limited slip differential

3 = proportional slip differential

Model year

Serlal

number

J = 1988

e.g. 00903

K = 1989

L = 1990

M = 1991

Note:

As from model ‘88. the gear box number will be readable from below, stamped on the rear stiffening

rib of the rear-axle housing

* As of MY ‘92, the model letter is omitted.

30 - 0102b Technical Data

a

Printed in Germany - XXXI. 1993

928

30

General data

Ratios

1st gear

2nd gear

3rd gear

4th gear

RDckw&tsgang

Final drive

Final drive ratio

(Stall speed)

Capacity, rear

axle final drive

Oil grade

Capacity, auto.

unl with

converter

A28.0 1/04/07/l 2

R8.02/03/05/06/08/09/11/14/16/18

Fully automatic 4-speed sun-an&planet transmis

368

2941

I,44

1 ,oo

5,14

Drive pinion without hypoid displacement

m

A 28/t 6

3,87

2,25

I,4

1 ,oo

5,59

15

: 33 i = 2,200 14 : 33

i = 2,357 (A 28.02/05/08)

13 : 33

i = 2,538 (A 28.03/06/09/

11/14/16’18)

A 28.01 =

A 28.02/03/05/06/08/09/l 1 =

2200...2600rpm 2200...2600rpm

up to MY ‘86 = approx. 2.7 I

from MY ‘87 to ‘90 = approx. 3.0 I

MY ‘91 = 2.3 I*

as of MY ‘92 = 1.9 I

Multigrade transmission oil 75 W 90 to MIL L 2105 B or

API classtication GL5

Total capacity = approx. 8.01 (‘87 models onward,

approx. 9.31). Capacity for fluid change with converter

= approx. 6.01 (‘87 models onward, approx. 7.31) ATF Dexron II D

* refer to Technical Information No. l/91 of 08.3.91

0

Technlcal Data 30 - 0103

Printed in Germany - XXXI. 1993

928

General 30

TIGHTENING TORQUE FOR AUTOMATIC TRANSMISSION

Threads

Description

Material

Torque

Nm (ftlb)

Location

Primary pump

to front cover

Bolt M8

Bolt MlOxl

Bolt

M8

Bolt

M6

Plug M 27 x 1.5

8.8

10.9

8.8

10.9

-

20 (14)

14 (10)

13 19)

11 (8)

70 (51)

Plug

(converter)

Front cover

to transmission case

Support flange

to transmission case

Plug

(brake band B 1

mount)

Catch plate on range

selector shaft

Bolt M6

M6

M6

8.8

8.8

8.8

8 (6)

8 (6)

8 (6)

8 (6)

8 (6)

Bolt

Leaf spring

to transmission case

Starter interlock

and backup light switch

to transmission case

1 Bolt

Range selector lever

to shaft

1 Bolt M6

Bolt

M6

8.8

8.8

Secondary pump

to transmission case

Governor axial hold

on shaft

Nut

M6

8 6 (4.3)

Printed in Germany

VI I I, 1984

Tightening Torques 30 0105

30

General

928

TIGHTENING TORQUE FOR AUTOMATIC TRANSMISSION

Location

Description

Threads

Material Torque

Nm (ftlt

Lower cover

with reinforcement plate

Bolt

M5

5.8

4 (3)

Lower cover assy.

to transmission case

Bolt

M6

8.8

8 (6)

Plug (test connection

for modulating, governor

and operating pressure)

Plug M8xl

-

13 (9)

Vacuum unit bracket

Kickdown solenoid valve

End plate on valve body

housing

Bokt

Solenoid

Bolt

M6 8.8

8 (61

M14x1.5 -

20 (14)

M4

8.8

3.3 (2.3)

End plate on drive

housing

Bolt M4

8.8

3.3 (2.3)

Drive housing to valve

body housing

Valve body housing

to transmission

Bolt M5

4.8

0.15

(0.1 I)

Bolt

M6

8.8

8 (6)

ATF filter to lower cover

Bolt

M5

8.8

4 (3)

d

0

30 - 0106

Tightening Torques

Printed in Germany

928

General Data

30

a

Tightening torques (automatic transmission)

Location

Threaded plug (ATF pan)

ATF pan to transmission case

Front converter casing to

transmission case

Carrier plate to converter

Rear transmission cas to

transmission case

Bearing assembly to

rear transmission case

Final drive to transmission

case

Collar nut (drive pinion)

ATF filler tube to ATF pan

ATF reservoir to ATF pan

Thread

MlOxl

ME

M8

M8

M 10

ME

M 10

M 26x 1.5

M 24

M6

* As of MY ‘92 (transmission type A28.18) = 450 Nm (332 ftlb),

Tightening Torque Nm (ftlb)

22 (12)

8 (5.9)

23 (17)

46 (34)

42 (31)

33 (24)

46 (34)

380* (280)

78 (58)

6 (4.4)

0

Tightening torques (automatic transmission)

30-0107

Printed in Germany - XXXI, 1993

928

Torque Converter

32

a

TOOLS

No.

Description

Special Tool

Remarks

1

Transmission

holder

9216

2

Grip plate

9301

3

Mandrel

9310

4

Depth

gauge

-

Standard

tool

a

Printed in Germany -

VIII, 1984

Removing and Installing Torque Converter

32 101

32

Torque Converter

928

REMOVING AND INSTALLING TORQUE CONVERTER

I-

i .-.-. -.-.-.- .-.-.-.

-‘-‘-‘-‘-‘-

/I-.

I

i

y.<- ’

i

.c’

0-I

@ -9

1

4123

/

!

I

:/-

j

a

32-102

Removing and Installing Torque Converter

Printed in Germany

928

Clutch, Automatic Torque Converter

32

NC

Description

!tY.

I

i

4

a

5

l I5

Mounting bolt

Panhead bolt 8

Washer 8

Front converter

casing

Torque

converter

lutomatic

transmission

T

6

1

1

1

-

Removing

Note When:

Installing

Lift out carefully

with Special Tool

9301

Tightening torque:

46 Nm (34 ftlb)

Tightening torque:

23 Nm (17 ftlb)

Renew if badly worn

or if particles are

found in ATF

Lubricate drive flange

and bearing pin with

MoS multi-purpose

i

gre se.

Place

transmission upright

and insert carefully

using Special Tool

9301.

Note

installation depth.

Printed in Germany

- XVI,1987

Removing and Installing 32 - 103

Torque Converter

32

Clutch, Automatic Torque Converter

928

a

/

NOTES ON REMOVING AND INSTALLING

r

I'

Removinq

l.Remove transmission.

./ ,. , J

,/ ‘”

-yp? pf./

w

/ ;gzp,$ :

2.Using Special Tool 9216, attach

transmission to assembly support.

6.Attach Soecial Tool 9301 to

torque converter and carefully

lift out converter.

3.Place transmission upright and

working through the openings in ~~

the converter casing, remove

converter mounting bolts.

!

4.Remove mounting bolts for

converter casing and remove

casing.

Installinq

Note:

5.Measure installation depth of

converter and make a note for

reassembly.

Up to '86 models = approx. 16 mm

'87 models onward = approx. 28 mm

If the ATF smells burnt or if the

fluid contains particles of pad

material, torque converter and ATF

cooler must be rinsed.

If particles of metal are found in

the ATF pan, the torque converter

must be replaced. Rinsing will not

remove all metal particles and

damage to the transmission may

result.

32 - 104 Removing and Installing

Torque Converter

Printed in Germany

928

Clutch, Automatic Torque Converter

32

l.Rinse torque converter with

Special Tool 9310. To rinse, fill

converter with approx. 11 of

kerosine, insert the rinsing pin

and use a hand drill to turn the

pin at low speed. Then drain

kerosine off through drain plug.

Repeat rinsing 2 - 4 times until

the kerosine drained from the

converter is clean.

2.Attach Special Tool 9301 to

torque converter.

3.Coat drive flange and bearing

pin of converter with MoS2

multi-purpose grease.

4.Place transmission upright and

carefully insert converter,

turning unit in both directions

to engage the teeth.

5.Check installation depth of

converter.

Up to '86 models = approx. 16 mm

'87 models onward = approx. 28 mm

Printed in Germany - XVI,1987

Removing and Installing

32 - 105

Torque Converter

928 Automatic Transmission/Controls, Case

37

REMOVING AND INSTALLING SELECTOR LEVER COVER FRAME

Removing

1. Remove selector lever grip and take off

rubber boot.

2. Move selector lever to position “2” and

push rear locking bar forward against stop

with a suitable tool (e. g. scribe).

3. Move selector lever to position “R”,

disconnect gate and push forward as far as

possible.

4. Push front locking bar forward against stop

with a suitable tool (e. g. scribe).

5. Move selector lever to position “P” and

press out cover frame carefully with a

suitable screwdriver applied at the left rear

corner.

6. Move selector lever to position “N” and

remove frame inclined toward rear.

Installing

1. Move selector lever to position “3”.

2. Push gate in frame forward all the way,

3. Install cover frame in correct position and

move selector lever to position “P”.

4. Push cover frame forward and move right

side to correct installed position (this is

done by lifting left rear corner slightly

and pushing down on right side).

5. Push down on left rear corner until frame

fits in center console correctly.

Printed in Germane - VIII, 1984

Removing and Installing Selector Lever

37-101

Cover Frame

37

Automatic Transmission/Controls, Case

928

6. Position selector lever between “R” and

“P”, disconnect gate on selector lever and

push forward.

7. Push front locking bar toward rear until it

engages.

8. Move selector lever to position “3” and

push rear locking bar toward rear until it

engages.

a

9. Attach gate in selector lever, install

rubber boot in correct position and

install selector lever grip.

IO. Move selector lever in and out of all

positions and make sure that cover frame

fits properly.

a

a

A - Locked

6 - Unlocked

37 - 102

Removing and Installing Selector Lever Cover Frame

Printed in Germany

928

Automatic Transmission/Controls, Case

37

REMOVING AND INSTALLING SELECTOR LEVER CABLE

Removing

1. Unscrew ground strap of battery on body.

2. Remove selector lever grip and take off

rubber boot.

3. Remove cover frame (see page 37 101).

4. Pull bulb holder carrier out of retaining

clips.

5. Mark location of selector lever base for

reinstallation and remove mounting screws.

6. Loosen intermediate muffler shield and

push aside as far as possible.

7. Disconnect selector lever cable on trans.

mission lever and detach cable sleeve on

brackets.

23

--- 7 -:+@*> : ---,

i

F ,/’

c-

8. Take off ball head, hexagon nut and

mounting parts.

9. Attach tailing wire on cable and pull out

selector lever base with cable by pulling

forward at an angle.

10. Remove cable circlip on selector lever

and detach cable sleeve on selector lever

base.

a

Printed inGermany VIII, 1984

Removing and Installing Selector

37 103

Lever Cable

37

Automatic Transmission/Controls, Case

928

Note:

Installing

1. Attach cable sleeve on selector lever base,

tightening the hexagon nut carefully.

2. Push cable on to selector lever pin and

install circlip.

3. Attach tailing wire, pulled forward during

removal, on cable and pull cable toward

rear, whereby one person should guide in

the selector lever base and a second person

must pull wire and cable.

4. Install selector lever base in correct

position (watching mark) and tighten

mounting screws with 15 Nm/ll ftlb.

5. Install cover frame and selector lever grip.

Place selector lever at “N”.

If light opening of gate and letter “N” are

not exactly opposite each other in cover

frame, remove cover frame again and reposition selector lever base in slots.

6. Mount selector lever cable on transmission

as specified.

7. Adjust selector lever cable (see page

37 - 105).

37 - 104

Removing and Installing Selector Lever Cable

Printed in Germany

928

Automatic Transmission/Controls, Case

37

ADJUSTING SELECTOR LEVER CABLE

1. Move selector lever to position “N”.

2. Place range selector lever on transmission

in “N”.

Note:

Bolt for range selector lever must be

tightened for adjustments.

3. Adjust ball end on cable that attachment is

possible without tension.

l

Printed in Germany - VI II, 1984

Adjusting Selector Lever Cable

37 - 105

928

Automatic Transmission/Controls, Case

37

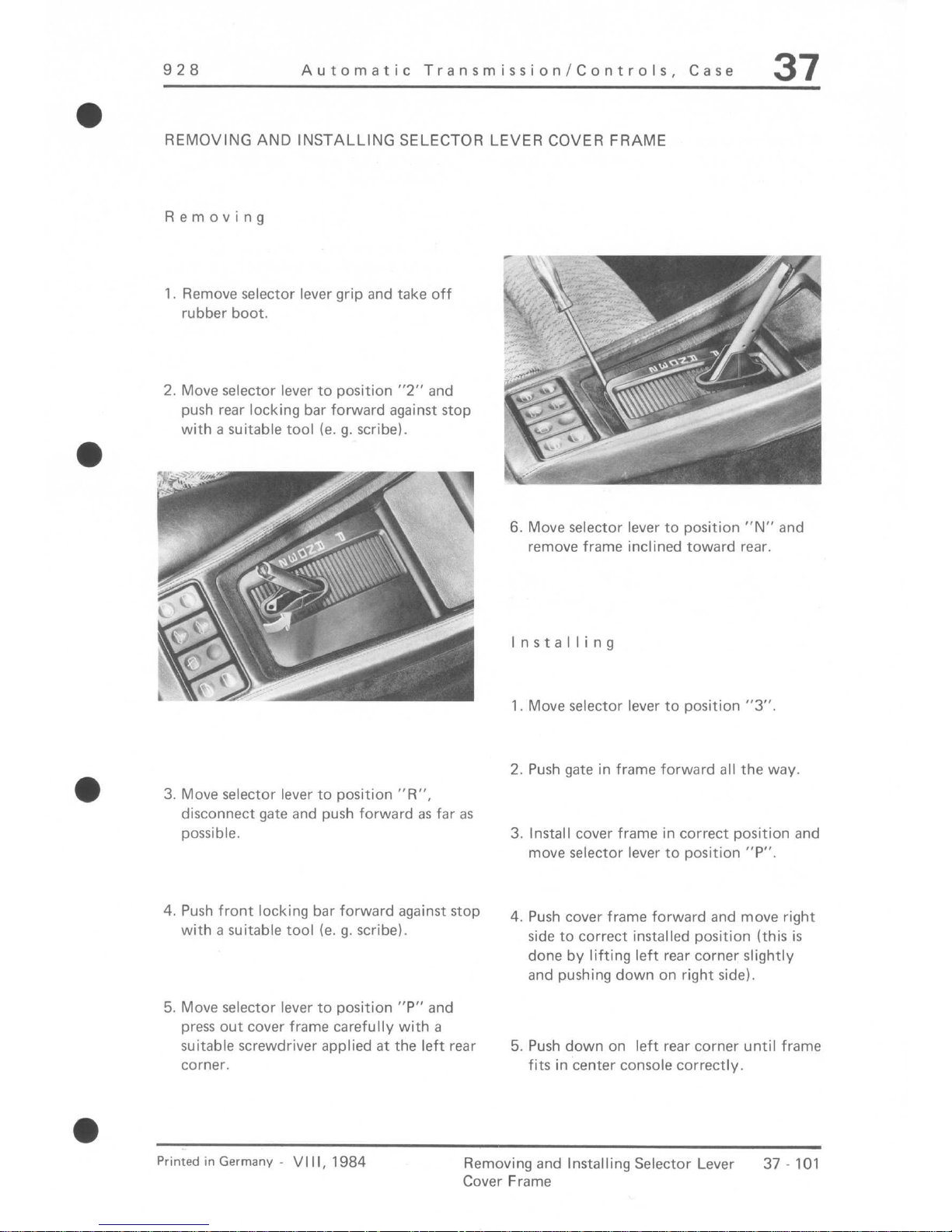

REMOVING AND INSTALLING STARTER LOCKING AND BACKUP

LIGHT SWITCH

Removing

1. Disconnect selector lever cable.

- in

I q&.‘.

2. Remove bolt for range selector lever and

pull off lever.

3. Unlock plug by turning white plastic ring

(arrow) upwards in direction of arrow.

IWJ

--- --

I

4. Pry off plug carefully with two screw

drivers applied on cable outlet and bar.

‘/ -

-,fy!y;@-@+-q

i3

.-w-y _.. YQ;)(: ..

2

? .-”

-a

? --’

-‘,&

+ of j,%gg$ -’

.:‘y $g ,(

5. Remove switch mounting screws and take

off switch.

Installing

1. Install switch with both mounting screws,

but do not tighten.

Printed in Germany -

VI I I, 1984

Removing and Installing Starter Locking

37.107

and Backup Light Switch

37

Automatic Transmission/Controls, Case

928

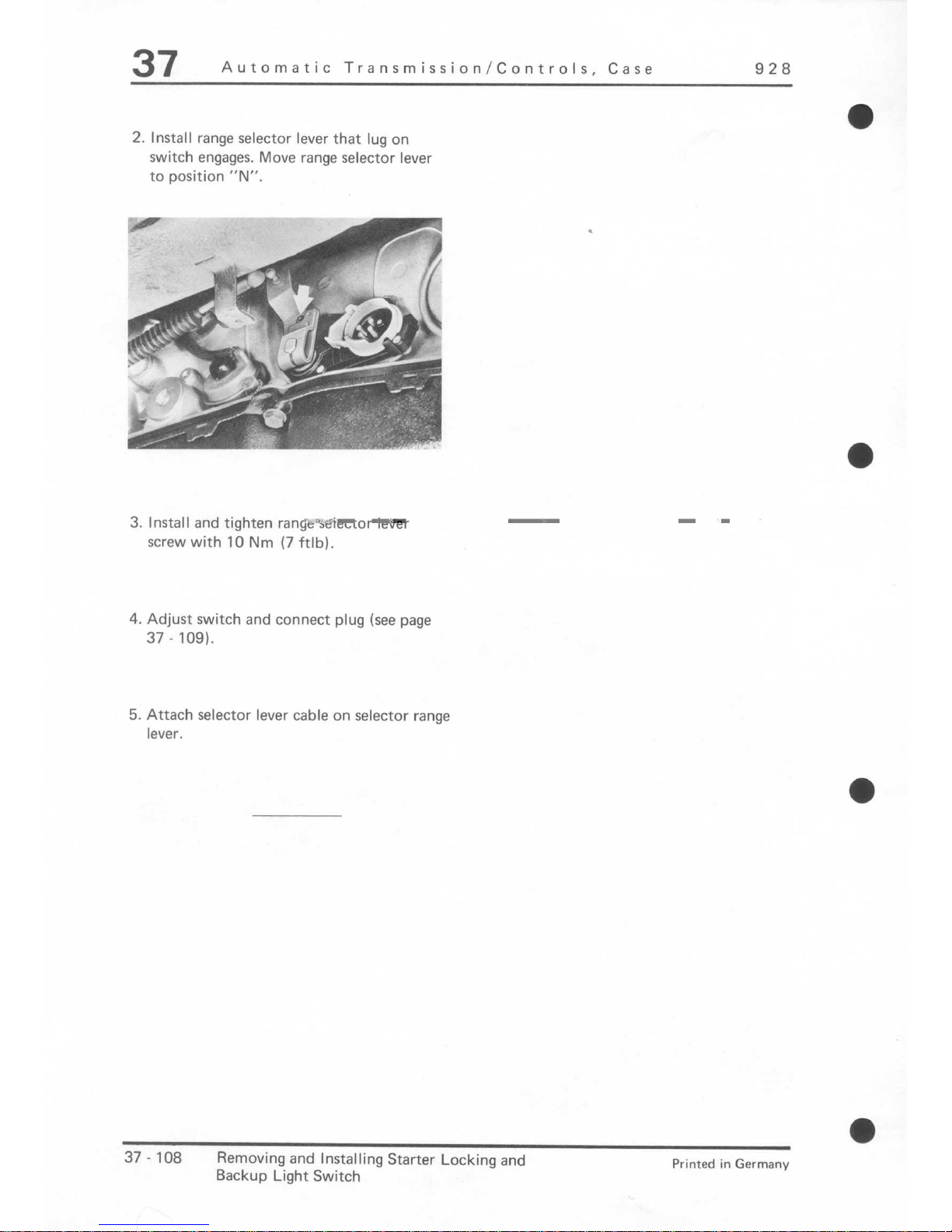

2. Install range selector lever that lug on

switch engages. Move range selector lever

to position “N”.

3. Install and tighten range selector lever

screw with 10 Nm (7 ftlb).

4. Adjust switch and connect plug (see page

37 - 109).

5. Attach selector lever cable on selector range

lever.

a

37.108

Removing and Installing Starter Locking and

Backup Light Switch

Printed

in Germany

928

Automatic Transmission/Controls, Case

37

ADJUSTING STARTER LOCKING AND BACKUP LIGHT SWITCH

I. Insert locating pin made of 4 mm dia.

welding wire for 4 mm dia. drill) through

lug into locating bore in switch housing.

2. Tighten switch mounting screws with

10 Nm (7 ftlb) and pull out locating pin.

3. Press on plug and turn white plastic ring

down.

Printed inGermany

VIII, 1984

Adjusting Starter Locking and Backup 37 - 109

Light Switch

928 Automatic Transmission/Controls, Case

37

CHECKING ADJUSTMENT OF SELECTOR LEVER CABLE AND

STARTER LOCKING/BACKUP LIGHTSWITCH

Move selector lever to position “N”. Run

engine at fast idle speed.

Pull up parking brake lever and press down

on brake pedal for following tests.

6. Starting engine should only be possible

in “p” or ,TN”,

7. Backup lights must be on in position “R”.

1. Move selector lever to position “R”. Engine

speed must drop as gear engages.

2. Move selector lever to position “P”. Engine

speed should increase as reverse gear

disengages.

3. Repeat test in point I.

4. Move selector lever to position “N”. Engine

speed should increase as reverse gear

disengages.

5. Move selector lever to position “D”. Engine

speed should drop as gear engages.

Printed in Germanv VIII, 1984

Checking Adjustment of Selector Lever

37 111

Cable and Starter Locking/Backup Light Switch

928

Automatic Transmission/Controls, Case

37

a

NOTES ON REMOVING AND INSTALLING

Removing

l.Remove top and bottom halves of air

filter(l6-valve engines only)

2.Disconnect control cable at engine.

16-valve engines

!

2B~~fi~

i)

1.

l 1 ,;.? .y;-_ /F; .._ 1, *;\,

!

[‘: .__.

t’

; i ‘T

,..:s,

‘Y., I

h. b, I’ ” yi -‘13

.e

‘/.LI,,,j;,;,,; 4

F

T.;,- .-a “.-- ~1

32-valve engines (up to '86 models)

. . .

;.d

.A,.

.;

tr

/#-., CA”

I

32-valve engines ('87 models onward)

3.Sever bowden cable behind threaded

connector.

4.Disengage control cable from transmission by pressing locking

tab of guide as arrowed (arrow A)

and turning guide anti-clockwise

(arrow B).

Printed in Germany - XVI,1987 Bowden Cable for Control Pressure, 37 - 113

Removing and Installing

(Service Solution)

37

Automatic Transmission/Controls, Case

928

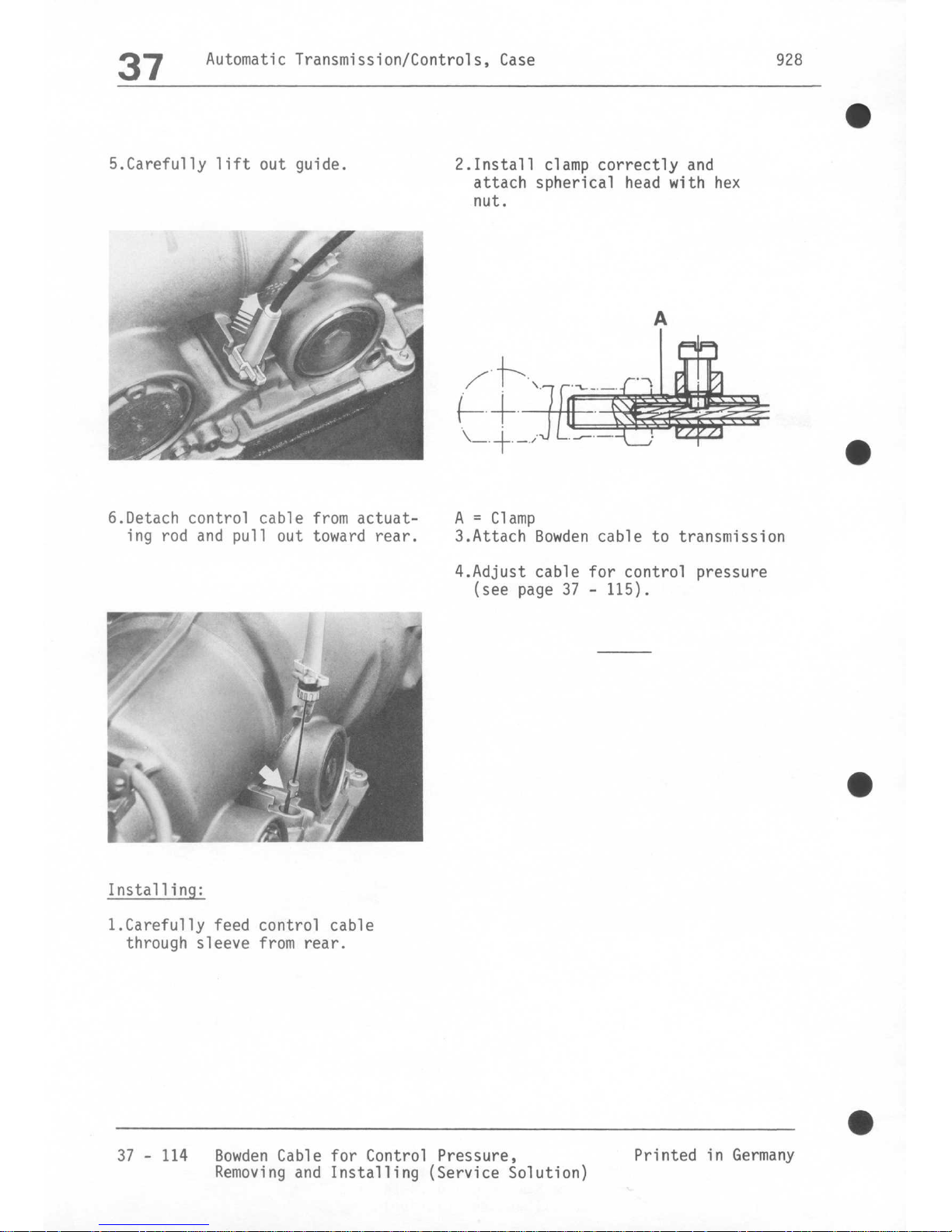

5.Carefully lift out guide.

6.Detach control cable from actuating rod and pull out toward rear.

Installing:

l.Carefully feed control cable

through sleeve from rear.

2.Install clamp correctly and

attach spherical head with hex

nut.

A = Clamp

3.Attach Bowden cable to transmission

4.Adjust cable for control pressure

(see page 37 - 115).

37 - 114 Bowden Cable for Control Pressure,

Printed in Germany

Removing and Installing (Service Solution)

928

Automatic Transmission/Controls, Case

37

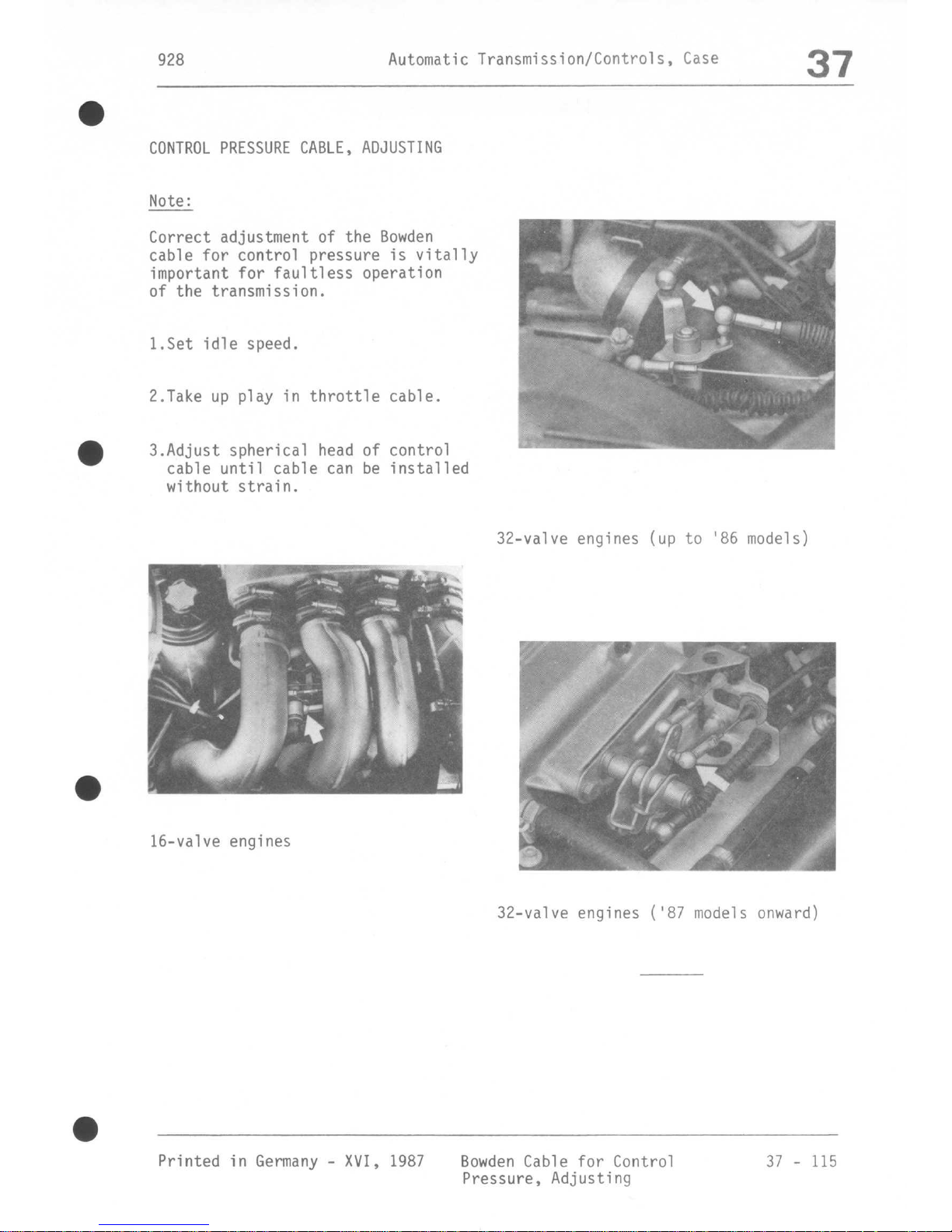

CONTROL PRESSURE CABLE, ADJUSTING

Note:

Correct adjustment of the Bowden

cable for control pressure is vitally

important for faultless operation

of the transmission.

l.Set idle speed.

2.Take up play in throttle cable.

3.Adjust spherical head of control

cable until cable can be installed

without strain.

32-valve engines (up to '86 models)

m

’ 6 .I

-

.%

” ,

-t

.? .!

r ’

” h!

.+d: 1

-1

16-valve engines

.

I

32-valve engines ('87 models onward)

Printed in Germany - XVI, 1987 Bowden Cable for Control

37 - 115

Pressure, Adjusting

Loading...

Loading...