Porsche 930 TURBO - 1989 GENERAL DATA, 930, 1977 930, 1978 930, 911 Turbo 1989 User Manual

General Data

TRANSMISSION TYPE 930

The following transmissions are installed in the 930 Turbo:

930/30 -4-speed with rear axle final drive 9/38 (standard)

930/32 -4-speed with rear axle final drive 9/36 (not for USA)

The following transmission is installed from 1977 Models:

930/33 -4-speed with a final drive ratio of 9/38

From 1978 Models with the following transmission:

930/34 -4 gears with final drive ratio of9/38

General data

911 turbo

Five-speed transmission G50/50

88-227

A new five-speed transmission has been installed in the 911 Turbo worldwide from Model 89 onward.

This gearbox corresponds to the G 50/00 Carrera gearbox with regards to construction and repair.

The gearbox has been reinforced, however, and the transmission ratios modified to suit the

high engine performance of the turbo engine.

Refer to the Carrera workshop manual (Page 30-0102) for maintenance information.

Five-speed transmission G50/50

Printed in Germany -VII, 1989

30-02

General Data

MANUAL TRANSMISSION TORQUE SPECIFICATIONS

Location

Designation

Threads

Material

Torque

NM (kpm)

Drive shaft

Nut

M 30xl.5

8.8

210 -230

(21.0 -23.0)

Drive shaft

Nut

M 20xl.5

C 35 V

160-180

(16-18)

Driven shaft

Nut

M 24xl.5 8

190-100

(19-20)

Stub axle

Stub axle

Stretch bolt

Hex hd screw

M IOxl.5

M IOu. 5

8.8

8.8

(2. 6 -3. 0)

(3. 0 -4. 6)

26-30

39-46

Transm. case

Vent

M 14xl.5 9 S 20 K

20-30

(2 -3)

Gearshift rod

Conical scr.

M 8xl.25

8.8

23-26

(2.3-2.6)

Shift cover Mid-grip nut

M 8xl.25 X 12 Cr

No 18.8

22-25

(2.2-2.5)

Backup light

switch

Gear housing

M 18xl.5 MS 25-35

(2.5-3.5)

Gearshift

forks

M 6xl.O

8.8

9-11(0.9-1.1)

Hex nut

M 8xl.25

8 22-25

(2.2-2.5)

Clamp, gears, transm.I

case, front and side

covers

Hex nut

Shift lock,

transm. case

Hex hd screw

M lOxl.5

8.8

15-18

(1.5-1.8)

24-26

(2.4-2.6)

Hex hd screw

M 8xl.25

8.8

Selector

forks

11.9

135-140

(13.5-14)

Ring gear,

differential

Hex hd screw M 12xl.25

12.9

150-160

(15-16)

Hex hd screw M 12xl.25

5t 37-5.8

20-25

(2-2.5)

Plug with

magnet

M 24x1.5

Con. 1:16

Transm. case

oil drain

5.8

20-25

(2-2.5)

Plug

M 30x1.5

Con. 1:16

Gear housing

Oil filler

5.8

20-25

(2-2.5)

Plug

M 16xl.5

Reverse gear

Lock

Technical Data

30-03

Printed in Germany -IV. 1981

Location

Designation

Threads

Material

Torque

Nm (kpm)

Guide tube

Capscrew

M 6xl.O

8.8

8-10

(0.8-1.0)

Clutch and

starter gear

Capscrew

M 8xl.O

8.8

20-'-5

(2.0-2.5)

Starter

Hex nut

M lOxl.5

8

46-50

(4.6-5.0)

Mech. controls

Holder to base

Hex hd screw

M6

8.8 6

(0.6)

Base to tunnel

Socket head

capscrew

M8

8.8 21

(2.1)

ICon. screw in

shift rod end

Con. screw

M8

8.8

15

(1.5)

COIl. screw in

coupling

Con. screw

M8

8.8 15

(1.5)

Clamp

Hex hd screw

M8

8.8

25

(2.5)

30-04 Technical Data

Printed in Germany

General

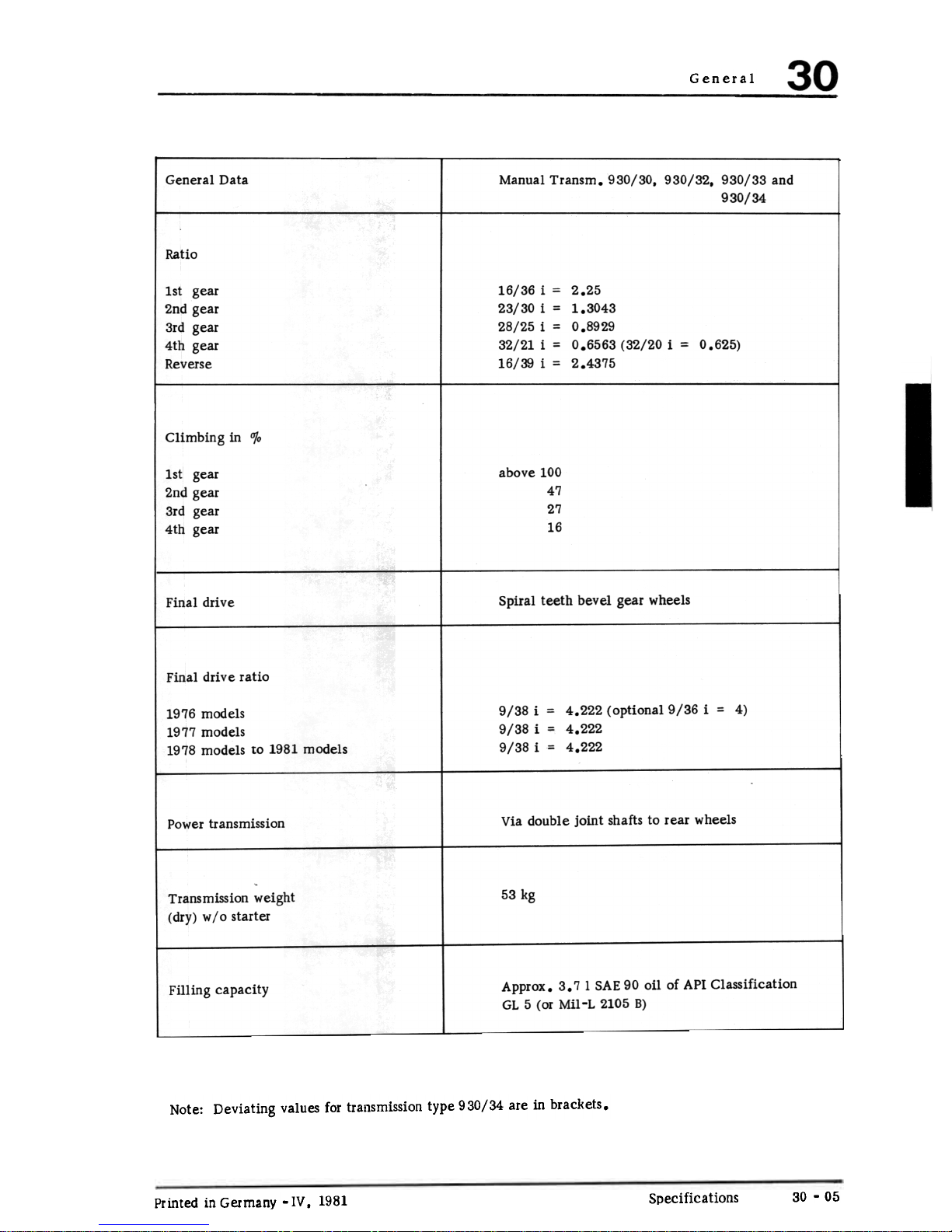

General Data Manual Transm. 930/30, 930/32. 930/33 and

930/34

Ratio

1st gear

2nd gear

3rd gear

4th gear

Reverse

16/36 i = 2.25

23/30 i = 1.3043

28/25 i = 0.8929

32/21 i = 0.6563 (32/20 i = 0.625)

16/39 i = 2.4375

Climbing in 0;0

abo

1st

2nd

3rd

4th

Spiral teeth bevel gear wheels

Final drive

Final drive ratio

9/38 i = 4.222 (optional 9/36

9/38 i = 4.222

9/38 i = 4.222

= 4)

1976 models

1977 models

1978 models to 1981 models

Via double joint shafts to rear wheels

Power transmission

53 kg

Transmission weight

(dry) w /0 starter

Approx. 3.7 1 SAE 90 oil of API Classification

GL 5 (or Mil-L 2105 B)

Filling capacity

Note: Deviating values for transmission type 930/34 are in brackets.

30 -05

Specifications

Printed in Germany -IV. 1981

ve

100

47

27

16

gear

gear

gear

gear

General Data

Technical Data

Printed in Germany -III. 1978

30-07

1

-III, 1978Printed in Germany

Removing and Installing Clutch Disc 30 -1

30 Clutch, Control

Removing and Installing Clutch Disc

Printed in Germany

30 -2

Clutch, Control

Notes when

No.

Description

I

Qty.

Remarks

Removing

Installing

1

Clutch bolts

6

Unscrew evenly

Tighten evenly and

diagonally

torque: 2.0-2.5 mkg

(14 -18. 5 ft Ibs)

la

Clutch bolts

DIN 931 from

Trans. No. 776

0013 or 776 1011

9

Unscrew evenly

Tighten evenly and

diagonally.

torque: 2,0-2, 5 mkg

(14 -18, 5 ft Ibs)

2

Washer

6

Replace, if needed

3

Ring gear

1

Check for wear

4

Pressure plate 1

5

Throwout bearing 1

Don't wash. Wipe

with dry rag. Coat

guide tube contact

surface with MoS

lubricant. 2

Don't subject to

pressure -danger

of damage!

6

Clutch disc Check for wear.

Center with clutch

centering tool 9102

1

Removing and Installing Clutch Disc

30 -3

Printed in Germany -IV, 1981

Clutch, Control

REMOVING AND INSTALLING

Removing

Note

1. Hold flywheel with toothed segment P 201 a

and spacer sleeve. Make sure that spacer sleeve

fits engine with adequate clearance.

Clutch linings cannot be replaced.

If applicable, the entire disc is to be replaced.

2. Loosen bolts holding clutch pressure plate to

flywheel evenly and diagonally one or two

threads, until the spring pressure stops (pre-

vents distortion on clutch pressure plate).

5. Check disc with lining for lateral runout.

Permissible lateral run out on 225 mm .

diameter is max. 0.6 mm.

CHECKING CLUTCH DISC

1. Check teeth. The clutch disc must move

easily in axial direction on drive shaft with-

out radial play.

2. Check rivets. Replace clutch disc if in

doubt.

3. Check clutch lining. If clutch lining has oil

spots, is burnt, torn or worn at spots, install

a new disc.

4. Check lining thickness. Thickness of di'lc

+

with riveted lining (no tension) is 10.1 -

0.3 mm. Wear limit (no tension) is 8.5 mm

for symmetrical wear.

Printed in Germany

Removing and Installing Clutch Disc

30 -4

Clutch, Control

CHECKING CLUTCH PRESSURE

PLATE/DISC

The MFZ clutch pressure plate from Fichtel and

Sachs is not designed for reconditioning or repairing.

The inspection is limited to dry cleaning and

removing dust with compressed air and emery

cloth, and a thorough visual! examination.

1. Clean clutch. If necessary. clean bearing

surface of pressure plate with emery cloth.

Remove burnt spots by polishing. Clean entire

assembly thoroughly with compressed air.

2. Check ends of diaphragm springs for traces

of wear from clutch release bearing. Wear

up to a depth of 0, 3 mm is not serious.

4. Check spring connections between pressure

plate and cover for cracks. Check tightness

of rivet connections. Replace pressure plates

with damaged or loose rivets.

3. Check friction surface of pressure plate for

cracks, burnt spots and wear. Check with

steel ruler. Pressure plates which are tapered

up to 0, 3 mm toward inside, can still be

used (check with feeler gauge blade).

-I, 1976

Removing and Installing Clutch Pressure Plate and Disc 30 -5

Printed in Germany

30 Clutch, Control

Installing

1. After cleaning. check clutch contact surface

of flywheel for wear. If necessary, machine

surface and smooth with emery cloth. Replace

the flywheel, if necessary.

2. Lubricate needle bearing in flywheel with

about 1 cm3 (1,5 grams) of MoS2 grease.

3. Install clutch with special tool 9102 to

center in flywheel.

4. Center clutch pressure plate on flywheel.

5. Tighten bolts evenly and diagonally to prevent

distortion on cover. Tighten bolts to specified torque. Use Special Tool P 201 a and a

spacing sleeve to hold the flywheel.

30 -6

Printed in Germany

Removing and Installing Clutch Pressure Plate and Disc

Clutch. Controls

ADJUSTING CLUTCH FROM 1977 MODELS (with clutch servo on transmission)

Note

Because of the clutch servo it is no longer

possible to check the clutch play exactly at the

clutch pedal. This is why the clutch play of

cars with a servo clutch has to be checked at

the transmission adjusting lever.

Check and adjust clutch, see Repair Manual 911,

Main Group 7 -Page 2.1 -2/3.

30 -7

Printed in Germany -II. 1976

DISASSEMBLING AND ASSEMBLING CLUTCH

Disassembling and Assembling Clutch

III, 1978 -

Printed in Germany

30 -8

Note When

Removing

Special

Instructions

No.

Description

Qty.

Installing

1

Bolt

9

2

Washer

9

If necessary. replace

3

Pressure plate

1

4

Drive plate

1

Check for wear.

center with a mandrel

5

Starter gear ring

1

6

Release bearing

1

Only possible,

when pressure

plate not loaded

(without 3

brackets)

Check. replace if

necessary. Do not

wash, only wipe off

dry. Coat sliding

surfaces for guide tube

with MoS multipur-

2

pose grease

Don't subject to

pressure -danger

of damage!

7

Capscrew

9

8

Flywheel

1

DISASSEMBLING AND ASSEMBLING CLUTCH

1. Three clips can be used to facilitate installation of clutch pressure plate.

These clips are mounted on all spare part

clutch pressure plates and must be removed

after installation. It is recommended to keep

these clips on hand for later repair jobs.

2. Since the clutch ~oncerned is pulled and the

release bearing is designed accordingly. the

release bearing must never be subjected to

pressure in direction of drive plate.

Consequently never place removed pressure

plate on release bearing.

When installing or assembling engine and

transmission also make sure that release lever

is not exerting force on bearing.

Printed in Germany -IV. 1981

Disassembling and Assembling Clutch

30 -9

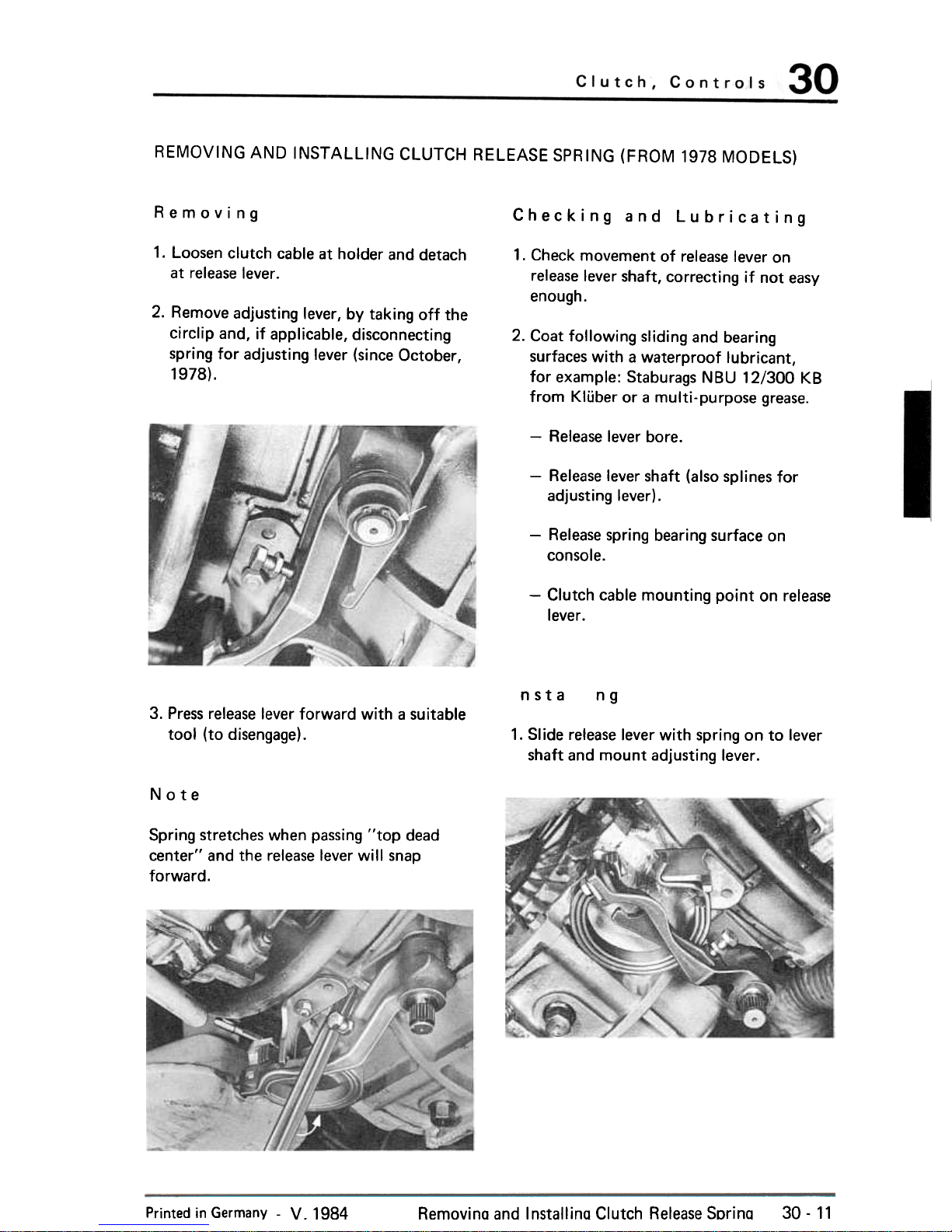

REMOVING AND INSTAlliNG CLUTCH RELEASE SPRING (FROM 1978 MODELS)

Removing

Checking and Lubricating

1. Loosen clutch cable at holder and detach

at release lever.

1. Check movement of release lever on

release lever shaft, correcting if not easy

enough.

2. Remove adjusting lever, by taking off the

circlip and, if applicable, disconnecting

spring for adjusting lever (since October,

1978).

2. Coat following sliding and bearing

surfaces with a waterproof lubricant,

for example: Staburags NBU 12/300 KB

from Kli.iber or a multi-purpose grease.

-Release lever bore.

-Release lever shaft (also splines for

adjusting lever).

-Release spring bearing surface on

console.

-Clutch cable mounting point on release

lever.

nsta

ng

3. Press release lever forward with a suitable

tool (to disengage).

1. Slide release lever with spring on to lever

shaft and mount adjusting lever.

Note

Spring stretches when passing "top dead

center" and the release lever will snap

forward.

Printed in Germany -V. 1984

Removina and Installina Clutch Release Sorina

30-11

Clutch, Controls

2. Press back release lever with a suitable tool

until release spring passes the top dead

center point (lever snaps against stop on

console) .

3. Remove adjusting lever again and mount

as close as possible to release lever.

4. Make basic clutch adjustment.

Removing and Installing Clutch Release Spring

Printed in Germany

30-12

Clutch

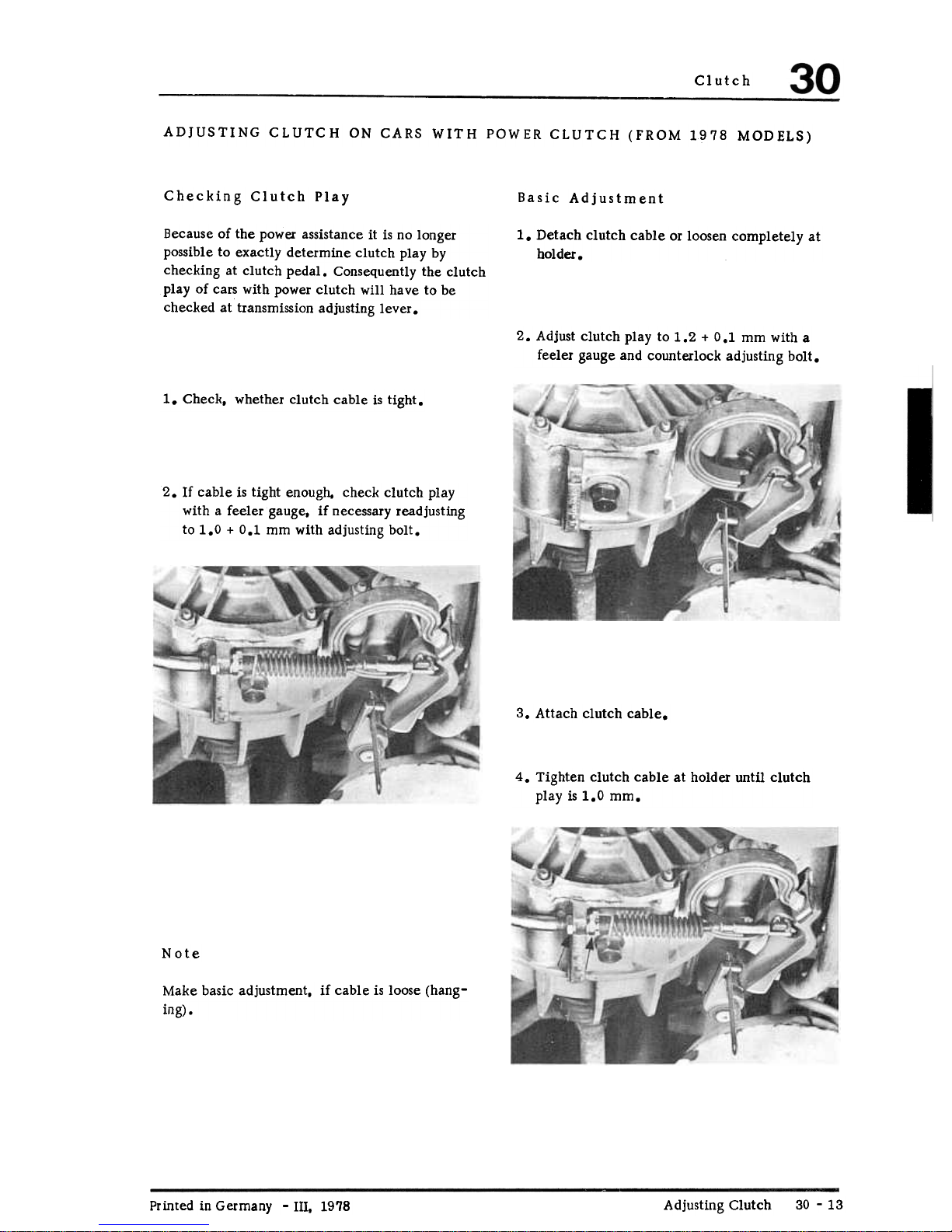

ADJUSTING CLUTCH ON CARS WITH POWER CLUTCH (FROM 1978 MODELS)

Checking Clutch Play

Basic Adjustment

1. Detach clutch cable or loosen completely at

holder.

Because of the power assistance it is no longer

possible to exactly determine clutch play by

checking at clutch pedal. Consequently the clutch

play of cars with power clutch will have to be

checked at transmission adjusting lever.

2. Adjust clutch play to 1.2 + 0.1 mm with a

feeler gauge and counterlock adjusting bolt.

1. Check, whether clutch cable is tight.

2. If cable is tight enough, check clutch play

with a feeler gauge, if necessary readjusting

to 1.0 + 0.1 mm with adjusting bolt.

3. Attach clutch cable.

4. Tighten clutch cable at holder until clutch

play is 1.0 mm.

Note

Make basic adjustment, if cable is loose (hang-

ing) .

Adjusting Clutch

30 -13

Printed in Germany -Ill. 1978

Note

5. Measure release travel.

Clutch cable tightness is correct, if when engaged

the release lever just lifts off of stop.

a) Apply calipers with clutch engaged (see

figure) and read distance I (e.g. 101.9 mm).

b) Disengage clutch and measure distance II

as shown in figure (e.g. 74.7 mm).

Note

If adjusting room on clutch cable holder is not

sufficient, also adjust front end at pedals. For

this purpose, adjust stop on floor plate that relea-

.+

se travel on release lever lS 27 -0.5 mm.

c) Dimension I less dimension II (in example,

101.9 mm minus 74.7 mm= 27.2 mm)

gives the release travel.

Printed in Germany

Adjusting Clutch

30 -14

911 turbo

Clutch, Control

Clutch mechanism, disassembling and assembling, from Model 89 onward

C!f~

1 2

155/30

30 -15

Clutch, Control

911 turbo

Note when:

I Installing

No.

Description

Oty.

Removing

1

Hexagon head screws

M 6 x 16

1

2

Bracket

1

Install in correct position

3

Bearing cover 1

Pack with grease, use

Olista Longtime 3 EP

Needle bearing with as-

sembly hole

4

1

Install in correct posi-

tion, assembly hole

points outwards

5

Clutch release lever shaft

Pull out with hexagon he-

ad bolt

M6x40

1

6

Sealing ring

2 Check, replace if neces-

sary, install in correct po.

sition

7

Clutch release lever

1

8 1

9

Needle bearing without as-

sembly hole

Plastic bushing 1

I nstall in correct posi-

tion, closed side points

towards needle bearing,

bushing not installed on

gearboxes with through

bore

Note

Lubricate all sliding surfaces of the clutch release mechanism with Olista Longtime 3EP,

Part Number 000.043.024.00

Clutch mechanism, disassembling and assembling, from Model 89 onward

Printed in Germany -VII, 1989

30 -16

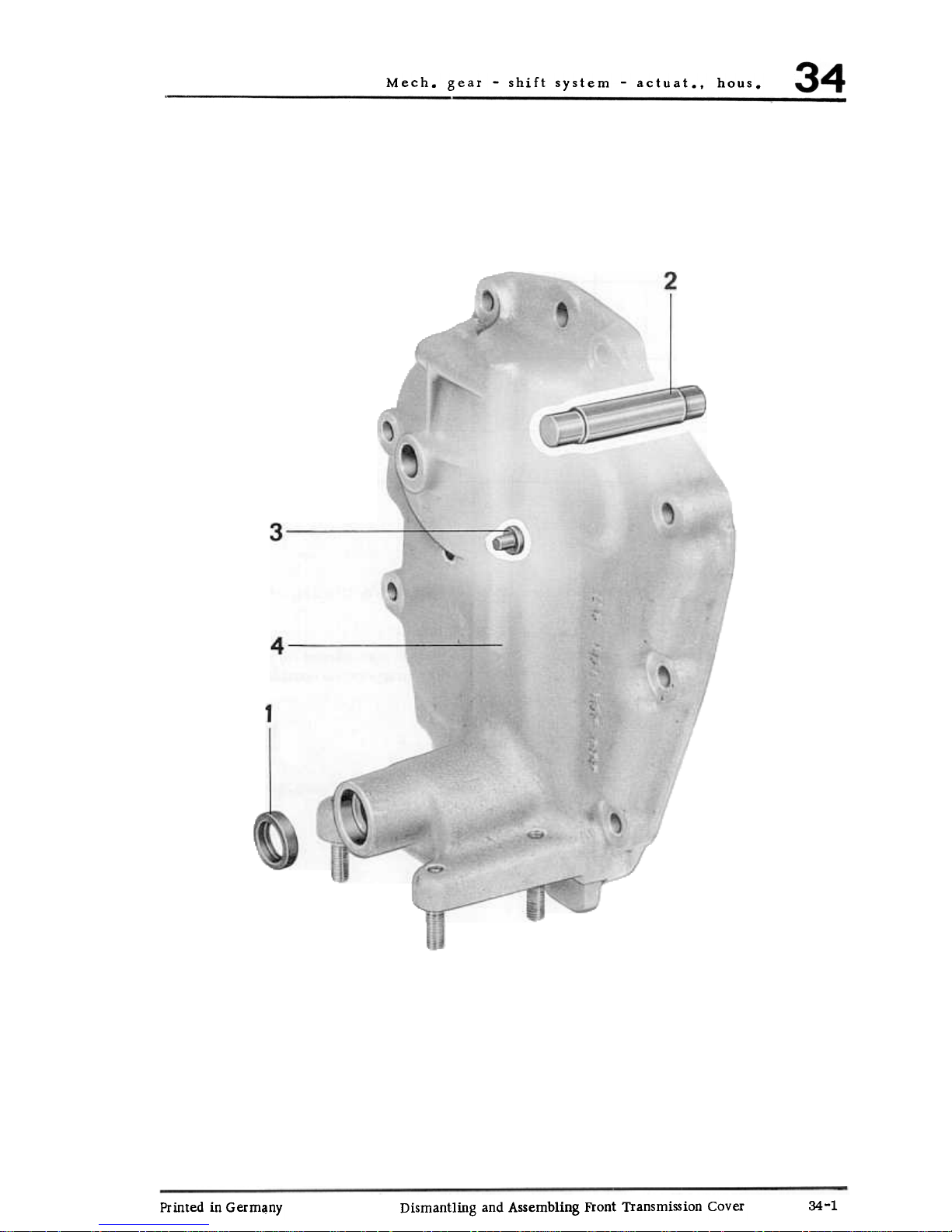

gear -shift system -actuat.. hous.

Printed in Germ~ny

Dismantling and Assembling Front Transmission Cover

34-1

Mech. gear -shift system -actuat.. hous.

Notes

No.

Designation

Amt.

Remarks

Removing

Installing

1

1

Sea]

Pry out with

screwdriver .

Drive onto stop

with appropriate

mandrel

Reverse shaft

1

2

Drive out.

Heat cover to

0

ca. 120 C and

drive in

3

Operating

lever spacer

1

Drive out

Heat co~er to

ca. 120 C and

drive in

I

4

Front housing

cover

1

DISMANTLING AND ASSEMBLING INSTRUCTIONS

Dismantling

1. Pry out seal for main selector rod with a

screwdriver .

Assembling

:J.. Drive in main selector rod seal to stop

with an appropriate mandrel.

2. Drive out reverse gear shaft and operating

lever spacer.

Mech. gear -shift system -actuat.. house

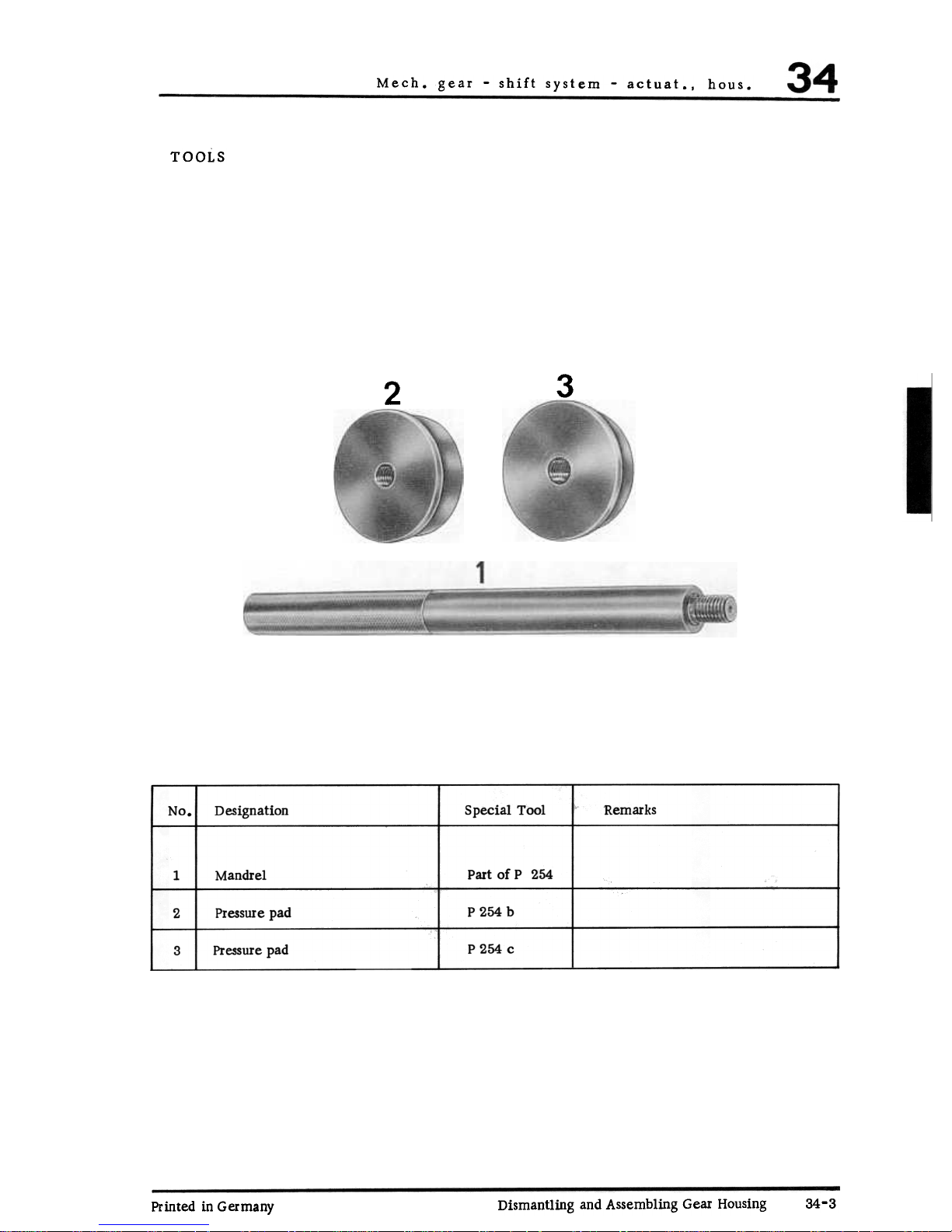

TOOLS

3

2

Designation

Special Tool Remarks

No

Mandrel

Part of P 254

1

Pressure pad

P 254 b

2

Pressure pad

P 254 c

3

Dismantling and Assembling Gear Housing

34-3

Printed in Germany

Manual Transmission/Controls

Case

Printed in Germany

34-4 Dismantling and Assembling Gear Housing

gear -shift system -actuat.. hous.

Notes

Designation

Amt.

Remarks

Removing

Installing

1

Cotter pin

1

Replace

Washer

2

1

3

Operating lever

1

4

Operating lever

shaft

1

Coat with

univexsal

lubricant

Washer

5

1

6

Plug

1

Torque to

specifications

Cotter pin7

1

Replace

8

Pin

1

9

Reverse operating

lever

1

10

ReveIse rod

1

Removing with

small screw-

driver.

11

Snap ring

2

Install

correctly.

12

Outer race with

snap ring

Drive out with

P 254 b.

1 Heat gear hsg. to

0

ca. 120 C and

drive in with

P 254 b.

13 Outer race with

snap ring

Drive out with

P 254 c.

1 Heat gear hsg. to

0

ca. 120 C and

drive in with

P 254 c.

1 Drive out

from inside

14

Operating lever spacer

15

Gear housing

1

34-5

Printed in Germany

Dismantling and Assembling Gear Housing

Mech. gear -shift system -actuat.. hous.

DISMANTLING AND ASSEMBLING INSTRUCTIONS

Dismantling

Note

1. Remove snap rings for bearing outer races

with P 254 b or 254 c.

The bearing outer races have different

inside diameters. The bearing outer race

with the largest inside diameter belongs

to the driven shaft cylindrical roller

bearing.

Assembling

1. Heat gear housing to about 1200 C and

drive in outer races with P 254 b or P 254 c.

Printed in Germany

34-6 Dismantling and Assembling Gear Housing

Mech. gear -shift system -actuat.. hoDs.

TOOLS

No.

Designation

Special Tool Remarks

Pressure pad

P 254 d

1

Local Manufac.

2 Hook

Mandrel

P 375

3

Pressure pad

P 254 a

4

P 265 c

5 Pressure pad

Printed in Germany Dismantling and Assembling Transmission Case

34-7

gear -shift system -actuat.. house

Printed in Germany

34-8 Dismantling and Assembling Transmission Case

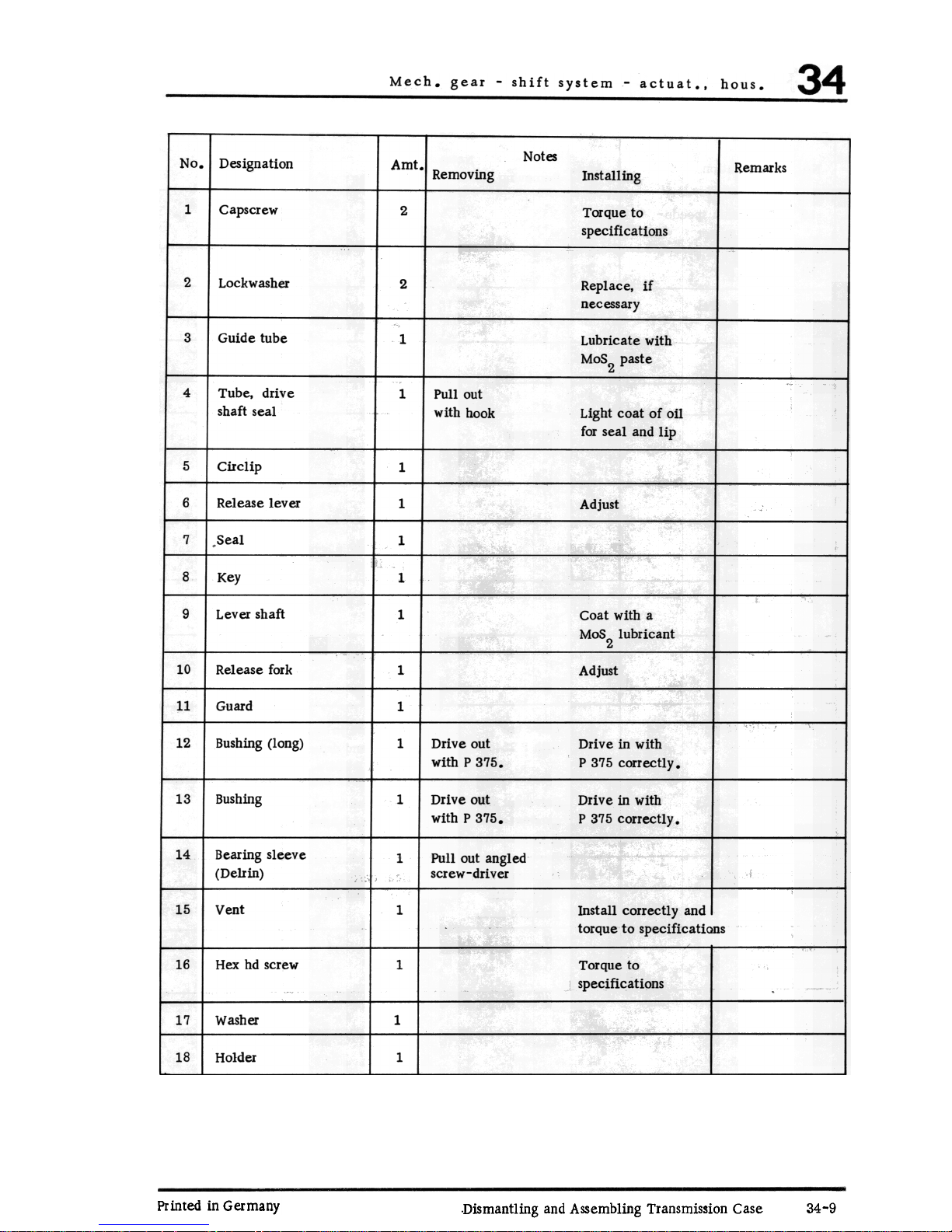

Notes

Designation

Amt

Remarks

Removing

Installing

1

Capscrew

2

Torque to

specifications

2

Lockwasher

2

Replace. if

necessary

3

Guide tube

1

Lubricate with

MoS2 paste

4

Tube, drive

shaft seal

1

Pullout

with hook

Light coat of oil

for seal and lip

5

Circlip

1

6

Release lever

1

Adjust

7

Seal

1

8

Key

1

Lever shaft9

1

Coat with a

MaS lubricant

2

10 Release fork

1

Adjust

Guard11

1

12

Bushing (long)

1 Drive out

with P 375.

Drive in with

P 375 correctly.

Bushing

13

1

Drive out

with P 375.

Drive in with

P 375 correctly.

14

Bearing sleeve

(Delrin)

1 Pullout angled

screw-driver

15 Vent 1

Install correctly and I

torque to specifications

16 Hex hd screw 1

Torque to

specifications

Washer17

1

18

Holder

1

Printed in Germany

34-9

Dismantling and Assembling Transmission Case

Loading...

Loading...