PORCHESON TB118 User Guide

User'sManualforTB118V2.2

WelcometouseOurInjectionMoldingMachineControlSystem

SafetyCautions

()Pleasereaditbeforeinstallation

Preface

Danger

Cautions

Note

1.Inordertoensurethesecureoperationofthewholesystemincaseof

theabnormalexternalpowerandthecontrolsystem'sfailingtofunction,

pleasesetuptheexternalsafecircuitforthecontrolsystem.

2.Uponitsfailuretodetecttheabnormalconditionsofinputandoutput,

thecontrolsystemcannotcontroltheoutput.Therefore,pleasedesign

theexternalcircuitandframeworktoensurethesafeoperationofthesystem.

1.PleasereadthisUser'sGuidancecarefullybeforeinstallation.

2.Donotdismantlethehostcomputershellandkeyboardwithoutpermission.

3.Incaseofanyquestions,pleasedialtheafter-serviceservicehotline

ofPORCHESON.

1.Withtheconstantupgradingandimprovementofthesystem,thechanges

intherelevantinformationandtechnicalparameterswillnotbeinformed

inadvance.

2.Ifthereisdeficiencyinthismanual,pleasedonothesitatetogiveyour

commentsandsuggestions.

R

1

User'sManualforTB118V2.2

Statement

Pleasereadthemanualcarefullybeforeyouusethis

system.PORCHESONCompanywillonlyberesponsible

forthemaintenanceoftheproblemsexistinthesystem

itself,andwillnotberesponsibleforthefaultcausedby

Preface

improperoperationunauthorizedmaintenancenatural

disastersorthesystemdamageordatalosscausedby

,

,,

otherabnormalsituations.Thechangesinthemanualwill

notbeinformedinadvance.Thecontentsinthemanual

areforreferencethecompanywillnotberesponsible.

,

forthelossescausedbythemisunderstandingofthe

manual.Theremaybedifferencesbetweentheactual

objectsandtheabstractimage,butthefunctionsare

Consistent.

AccordingtotheCopyrightLawtheCompanyowns

andretainstheexclusiveownershipofallworkswithout

,

,

thewrittenapprovaloftheCompany,anydeletionrevision,

,

reproductionorimitationofthemanualarenotpermitted.

R

2

User'sManualforTB118V2.2

Contents

PORCHESON

TB118

Operator'sManual

TECHNOLOGYCO.,LTD

SystemConfiguration&

Installation

ButtonOperation

specification

ExplanationoftheParam

eter/FunctionSetting

Productionmanagement

1

5

12

35

ExplanationoftheSystem

DebuggingandSetting

Input/outputState

Detection

2009.07 Version

Allcopyrightsarereserved,anyduplicationwithoutthepriorauthorizationshallbe

forbidden.

R

Reference&Appendices

41

55

63

3

User'sManualforTB118V2.2Contents

Contents

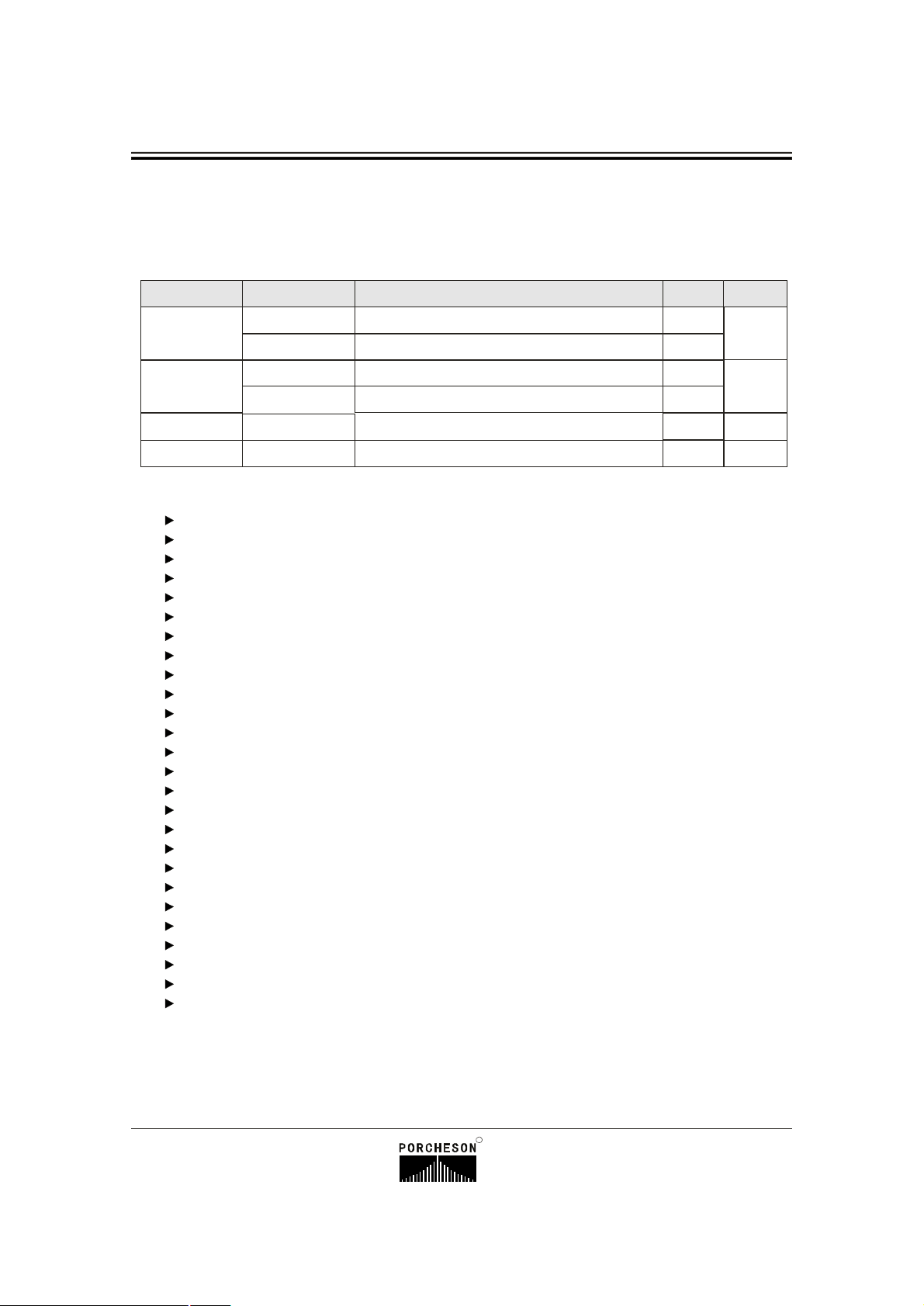

Chapter1SystemConfiguration&Installation

1.SystemConfiguration&Remarksp6

2.FeaturesofthePS860AMControlSystemp6

3.InstallationandDebuggingofComputerControlSystemp7

Chapter2SpecificationsoftheButton-PressedOperations

1.FigureofKeyboardoftheOperationPanel(Seethefigurebelow)p10

2.ExplanationoftheFunctionalKeysp11

3.ExplanationoftheParameterSettingbuttonp12

4.CursorKeyp12

5.OperationModeSelectionKeyp13

6.ElectrothermalON/OFFkeyandMotorON/OFFkeyp13

7.ManualOperationKeysp14

8.SettingScopeofNumericItemsp16

Chapter3:Descriptionsonsettingparameters/functions

1.Themaincontrolpanelshownwhileturningonp17

2Settingforcelerityinformation.P21

3Settingformouldcloseinformationp22

4.Setmouldopeninginformationp23

5.Settheplasticinjectinginformationp24

6.Setthepressureretaininginformationp25

7.Setplasticmelting/drawing/coolinginformationp26

8.Setthestuffauto-clearingupinformationp27

9.Setthetableinformationp28

10.Setthemouldadjustinginformationp29

11.Settheejectingforwardinformationp30

12.Setloosecoreinformationp31

13.Settheairblowinformationp32

14.Settime/countinformationp33

15.Settemperatureinformationp34

16.Setwarm-upandobservationp35chartofinformation

17.SetModuleinformation.P36

18.Amendnoteinformation.P37

19.specialparameteradjustmetnSetting.P38

R

4

User'sManualforTB118V2.2Contents

Chapter4

Chapter5InstructionsfortheSystemCommissioningSettings

Chapter6Input/OutputModeInspection

Reference&Appendices

productionmanagement

1.SetporductionImformationp40

2.SPCTrackNotePagep41

3.Pressure/SpeedcurveSettingPagep42

4.TemperatureTrackPagep43curve

5.p44Alarmnote

6.USBSettingPagep45

1.EngineerSettingPagep46

2.DelaySettingPagep47

3.Pressure/FlowSlopeSettingPagep48

4.PressurePre-AdjustmentPagep49

5.FlowPre-AdjustmentPagep50

6.BackPressurePre-AdjustmentPagep51

7.ElectronicRuler/SettingPagep52PressureInspection

8.SpecialFunctionOptionsPagep53

9.StandbyFunctionSettingPage.P56

10.ProgrammableStandbyFunctionPage..P57

11.TemperatureParameter..P58

12.MachineNo./Production-FactoryValueSettingPagep59

1.InputInspectionPagep60

2.KeyinspectionPagep62

3.OutputInspectionPagep63

1.Tb118keyboardinstallationdimensionLayoutp66

2.Tc118keyboardinstallationdimensionLayoutp67

3.externaldimensionsandinstallationholepositionsdrawingsforpowersupplycase

andtransformerp68

4.Exteriordimensionsandinstallationholepositiondrawingsformaincontrollerp68

5.systemwiringdrawingp69

6.Motorheatingwiringdrawingp70

7.CommonInterferenceSuppressionMethodp71

5R6

User'sManualforTB118V2.2

Chapter1SystemConfiguration&Installation

1.SystemConfiguration&Remarks

Chapter1SystemConfiguration&Installation

No.Content

1HostComputer

2Keyboard

3.Powerpack

4.Messagecable

Code

PS660AM24/24+9+3

PS860AM

T118B(colour)

TC118(Colour)

PW600B600W

DB-15F

27/28+10+3

"800*48016:97inch/TFT

"800*48016:97inch/TFT

1To8optionalmeter

ElectronicRuler

ElectronicRuler

Q'ty

1Set

1Set

1Set

1Set

1Set

1Set

2.CharacteristicsofPS860AMControlSystem

Thewholecomputermaycontrolallfunctionsandtemperatures.

ThesystemhasbrightLCDdisplayand800*4807inch?concolorous/colorful(optional)

ThesystemadoptstwoCPUdesignwithfastoperatingspeed,precisecontrolandhighstability.

Thecontrolhostcomputeradoptstheblockingdesignwithtime-savinginstallationandrapid

maintenance.

Ithastherealtimefunctiontodisplaytimeanddateinrealtime.

With999groupsofmodedatastorage,itmayenterthemodeldescriptionandreal-timeoperating

helpinChineseandEnglish.

Theciphersettinganddatalockingcanpreventtheoperatorsfromchangingtheestablisheddata

arbitrarilytoinfluencethequalityofproducts.

Therearemultiplelanguagesforyourchoicethatdisplaydynamicallyinrealtime.

Packingmodulussettingfunctionfor6-digitoutputmaysetthepackingmodulus.

Variousself-pluggingandteintypeprogramsareapplicablefortheself-pluggingandteincontrol

indifferenttypes.

Ejectornozzletemperaturecanbecontrolledwithopenorenclosedloop.

PID(ProportionalIntegralDerivative)withselftemperaturecontrolhas(6+1)sectionsoftemperatures.

Temperaturemaybepresetaweekinadvancetoenablemoreconvenientoperation.

VarioustypesofGlueShotways,4sectionsofGlueShotandclass-3pressurepreservation

FailureSelf-detectionfunctions,alarmdisplayandvoiceprompt

Inputandoutputaredonebytheopticallycoupledcircuittoisolatetheinterferenceofthe

externalcircuitry.

Theoutputvalueofpressure,speed,currentcanhavereal-timedynamicobservation,

anditisnotnecessarytoinstallanotherammeter

Intheinspectionwindow,youcaninspectallinputandoutputpointsandthemovingstatesofkey.

3-circuitstandardD/Aproportionoutputwithmax.currentas3A

Presettingofthevoltageandrunoffvalues,proportionalvalveavailablefortheproductsinall

brandsandbetterlinearproportion.

Remarks

Optional

Optional

R

User'sManualforTB118V2.2

Chapter1SystemConfiguration&Installation

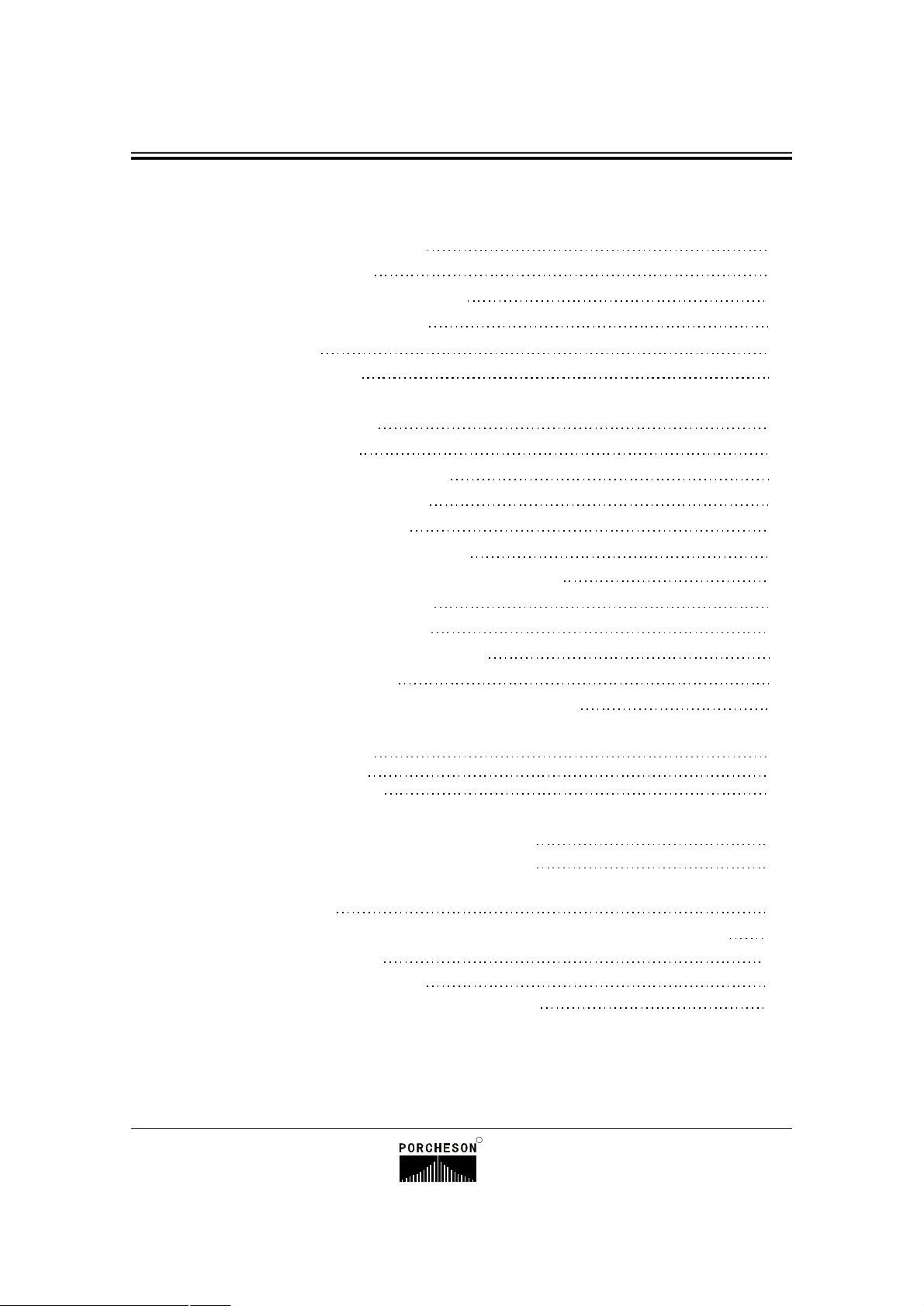

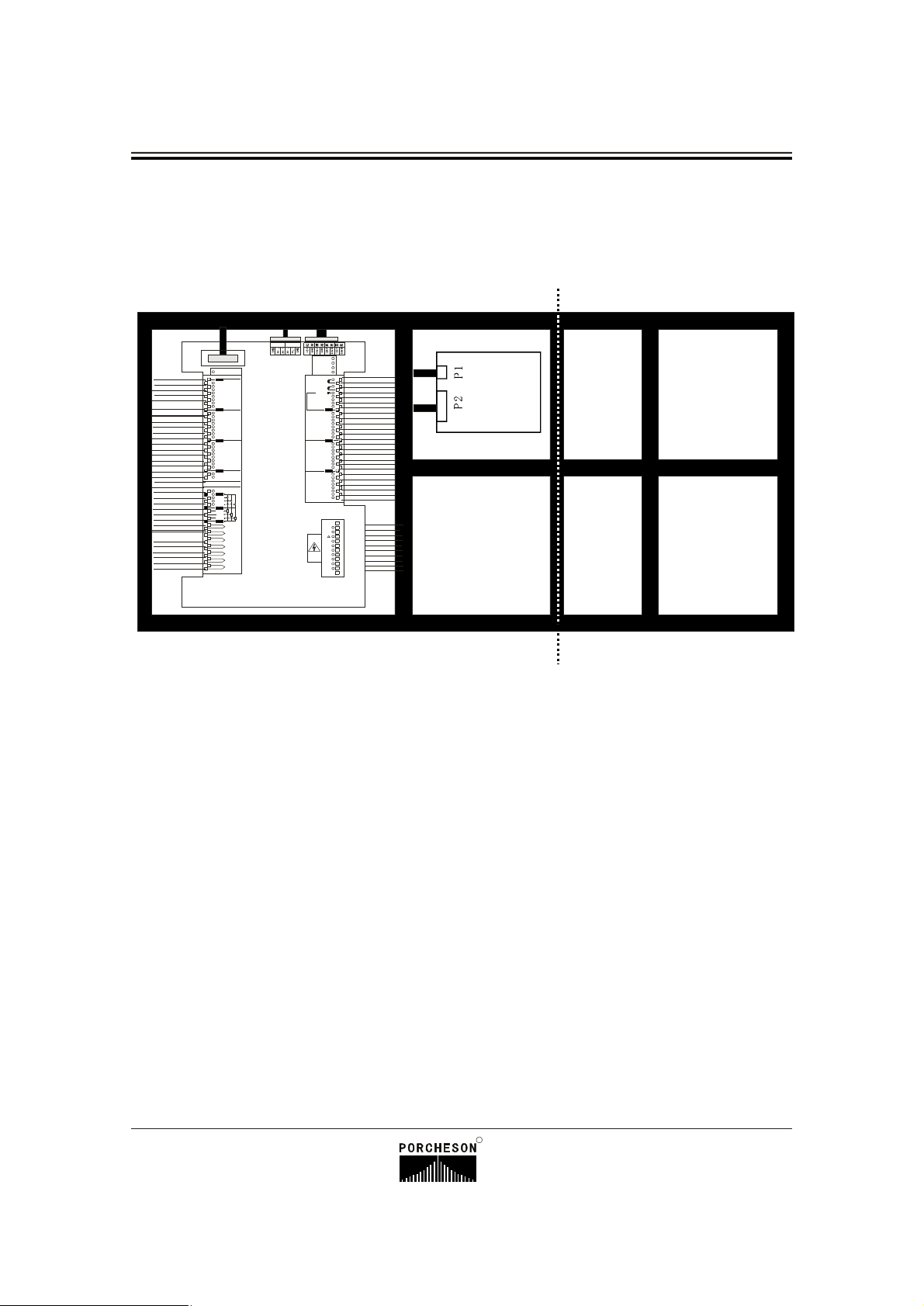

3.InstallationandDebuggingofComputerControlSystem

31CautionsuponInstallingtheControlSystem.

Thedesignofcontrolsystemissimpleandeasy,onlyone15-coreshieldingcableconnectingthe

keyboardandhostcomputershellwithflexibleandhandyinstallationandconnection.Thesketchmap

forinstallationisshownasfollows:

*

*

停止

A停止

压

力

检

测

电

子

尺

K6油温

K5五段

K4四段

K3三段

K2二段

K1一段

K0射咀

PORCHESON

CAN_BUS1CAN_BUS2

+5V(3A)

+24V(3A)

+24V(8A)

+38V(3A)

-

PF压力

+

-

速度背压S

+

-

Y73

3

备用

Y72

2

备用

Y71

1

母模吹气

Y70

0

公模吹气

YCOM

Y67

B

7

出芯

Y66

B

6

入芯

Y65

A

5

出芯

Y64

A

4

入芯

Y63

3

开模缓冲

Y62

中泵

2

Y61

大泵

1

Y60

故障警号

0

YCOM

Y57

高压锁模

7

Y56

低压锁模

6

Y55

塑机顶进完

5

Y54

塑机开模完

4

Y53

3

调模向后

Y52

差动锁模

2

Y51

调模向前

1

Y50

顶退

0

YCOMXCOM

Y47

顶进

7

Y46

6

开模

Y45

5

座退

Y44

4

抽胶

Y43

3

熔胶

Y42

2

射胶

Y41

1

座进

Y40

锁模

0

L

火线

12

M

11

Y

10

9

OIL

8

T5

7

T4

6

T3

5

T2

4

T1

3

T0

2

零线 N

1

PS860AM

Ebbeletricitysection

PW600B

POWER

Relay

board

Control

system.

POWER

Strong

eletricity

Equipment

eletricity

Equipment

Strong

eletricity

Equipment

Strongeletricitysection

Strong

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

+

1

2

3

-

2

2

2

+

-

+

-

+

-

+

-

+

-

+

-

+

-

+

RS232通信口

RUN系统运行

+24V

X00

安全门前

X01

马达起动毕

X02

射胶保护罩

X03

锁模停止

X04

电眼输入

X05

熔胶转速

X06

射台前停

X07

射台后停

XCOM

X10

备用

X11

备用

X12

顶退保护板

X13

顶针前停

X14

顶针退停

X15

安全门后

X16

备用

X17

备用

XCOM

X20

微调齿数

X21

调模前停

X22

调模后停

X23

机械手合模

X24

机械手顶针

X25

入芯A

X26

出芯

X27

马达故障

入芯B停止

X30

出芯B停止

X31

缺油报警

X32

+24V

锁模

射胶

系统

ADG

锁模

射胶

顶针

+10V

controlboxequipmentoutfit(forreferenceonly)

()1Uponinstallingthehostcontrolbox,adopttheencloseddistributioncabinetatthefirstchoice.It

shallbefixedinthewell-ventilized,greaseproofanddustproofconditionsequippedwithafanand

dustproof.Thedistributionboxshallbestoredunder50?.

()2Uponfixingthehostcomputerandpowerpack,pleasekeeptheinterconnectingpartssuchasall

ACconnectorsandtransformersasfarawayfromeachotheraspossibletopreventtheelectric

waveinterferencefromtheelectronicgrid.

()3Allelectricwiresandshieldingwiresshallnotbecutoff,lengthenedorcurtailedarbitrarily.You

shouldusetheelectricwiresandshieldingwiresprovidedbythiscompanytopreventfrom

influencingthereliabilityandnormaloperationofthecontrolsystem.

()4Theshellofflamecoupleshalladopttheshieldingwire.Whentheoutershieldingofallflame

couplesadoptsthethermalcouplereticles,thereticleandmachinesshallbewellgroundedand

connectedtothegroundwiththeearthingresistancebelow10Ω.

()5Uponwiring,separatethehighandlowpressurelinefromthecomputercontrollineasmuchas

possible,donotbindallelectricalwirestogethertopreventtheinterferencefromaffectingthe

reliableoperationofcontrolsystem.

()6Uponfixingthekeyboardand15-corecommunicationconnectionsofthehostcomputer,youshall

pressandtweakwithforcetopreventthepoorconnectionfromaffectingthereliableoperationof

controlsystem.

()7PayspecialattentiontotheoilvalveoutletpublicportYCOM,itshallbeconnectedwelltoprevent

thecomputerfrominputtingwhilehavingthephenomenonofoilvalvehavingnomotion.

R

7

User'sManualforTB118V2.2

32InspectionoftheControlSystem.

()1Afterinstallationcompleted,carryoutanoverallinspectionifallconnectionlinesarewellfixed

includingtheswitchingpowersupply,hostcomputershell,electrothermaloutputlineandthe

thermalcoupleofkeyboard,etc.

()2Afterthelineinspectioncompleted,carryoutanelectricconnectioninspection.Firsttakeoutthe

11-digitaloutputlineplugoftheDCpowersupplyoutletport,namelythepowerpack,andthen

powerontoexamineandmeasureifthevoltageisthesameasthenominalvaluesandobserveif

theoutputindicatoronthepowerpackisnormal.

()3Poweroffafterthemeasurementcompleted,inserttheDCpowersupplytoinputtotheplugof

hostcomputershell.Afterpower-onagainforinspection,LCDonthekeyboardwilldisplaythe

normalstateofthemainpage.RevolveontheemergencystopswitchtocheckiftheRUNindicator

onthehostcomputershellturnson.Whenitturnson,itindicatesthatthesystemcanworksoundly.

33ggingoftheControlSystem.

Chapter1SystemConfiguration&Installation

()1Afterthesystemhavingshownnormaloperatingstate,pressbuttononthemonitorpage

toadjustcolorandcomparison.

()2Toconducttheparametersettingandmemorytesting,pressbuttontoselectagroupof

modulenumbersandthensetdatainallscreens.Pressbuttontosavedata.Disconnect

thepowerandconnectitagainafterafewtime,thesystemwillautomaticallycallthedataof

modulenumberssavedbyyou.Incaseoftheyarecorrect,itindicatesthatthememoryisallright.

()3Afterwards,setthedatainallrelevantdata(pleaseseeChapterIIIExplanationoftheParameter

Settingforthedetailedoperations).Uponsettinginthefirsttime,setthepressureandspeedaslittle

aspossibleandthenafterallmovementscomenormally,graduallyincreasethevaluestonormal

parameterstopreventfromdamagingthemechanicalperformances.

()4Afterallparameterset,savethemandcarefullyinspectifallinputandoutputpointsarenormal.

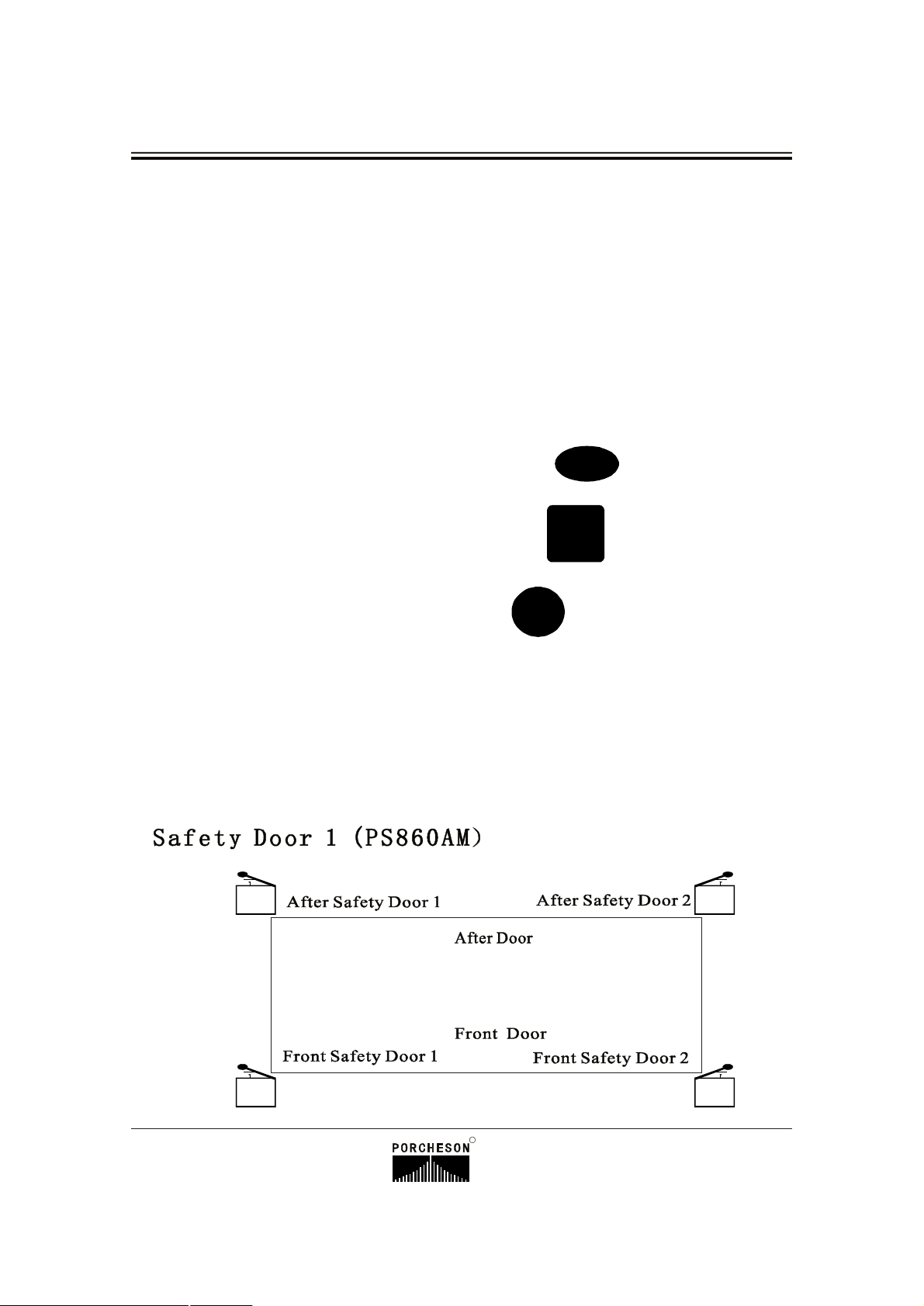

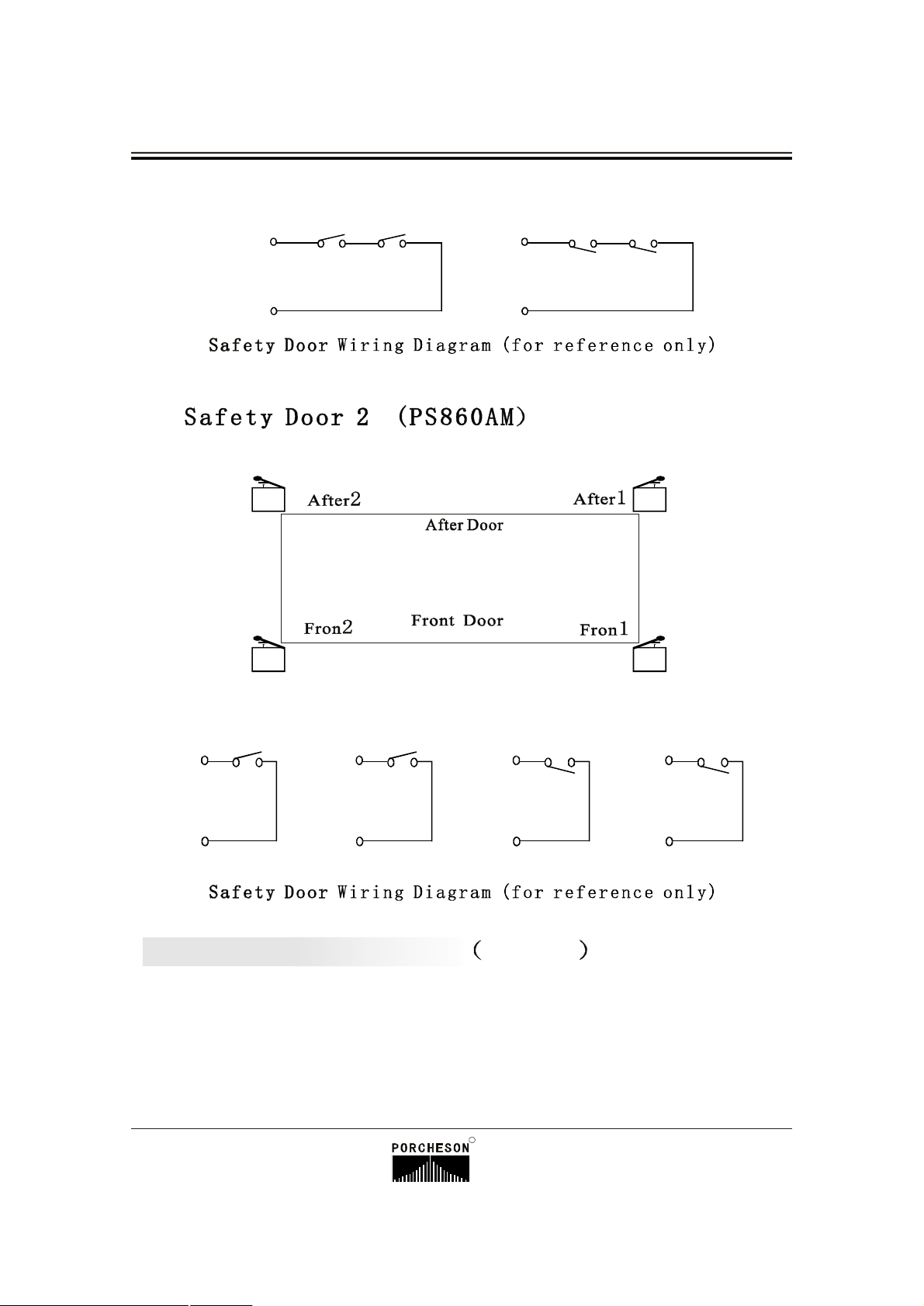

Carryoutanoverallinspectionofthealarmsystem,includingthefrontandbacksafetydoors.The

wireofsafetydoorsshallbeconnectedasstatedinthefollowingfigure.

输入

ENTER

LS4

1STU

资料

DATUM

LS2

LS3

LS1

R

8

User'sManualforTB118V2.2

Chapter1SystemConfiguration&Installation

XCOM

X00

LS4

LS3

LS1LS2

LS3LS4

XCOM

X15

LS2

LS1

LS1

XCOM

X00

SafetyDoors*SpecialExplanation:

★

WhenX00=ON/X15=OFForclosing/openingthedoors,orincaseofother

abnormalconditions,thesystemwillissueanalarm2secondslaterforSafetyDoorFailureand

simultaneouslyterminatealloperatingoutput.Inthesemi-automaticmode,theconditionforopening/

closingthesafetydoorsisthatthetimefromLS1,LS2,LS3,LS4allturn[OFF]toallturn[ON]is

morethan0.5asvalidinordertopreventthetwitterofsafetydoorswitchesfromcausing

erroroperation.

XCOM

X01

LS3

XCOM

X15

X00=OFF/X15=ON

PS860AM

R

LS2

LS4

XCOM

X16

9

User'sManualforTB118V2.2

Chapter2ExplanationoftheKeyOperations

Chapter2ExplanationoftheKeyOperations

1.FigureofKeyboardontheOperationPanel(Seethefigurebelow)

R

10

User'sManualforTB118V2.2

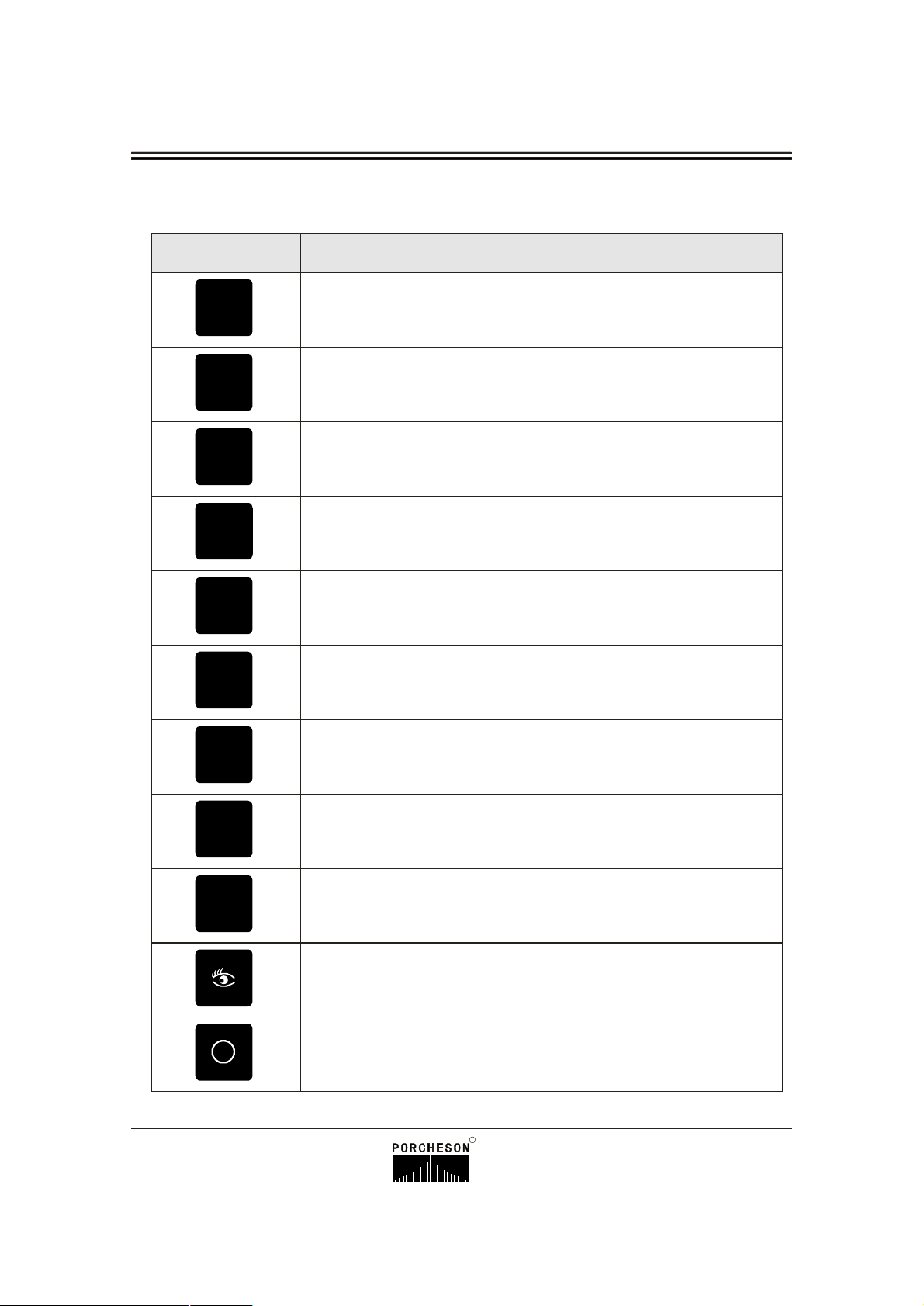

2.ExplanationoftheFunctionalKeys

KeysUsage

Chapter2ExplanationoftheKeyOperations

开锁模

M.PLT

射出

INJECTION

储料

FEEDING

座台调模

/

NOZZ/ADJ.

托模中子

/

EJE/CORE

时间

TIME

温度

TEMP.

Enterintothescreentosetthemoldopening&lockingmovement

EnterintothescreentosettheGlueShotandpressure-preserving

movement

Enterintothescreentosetthefeeding,gluetakingandautomatic

materialremovalmovement

Enterintothescreentosetthenozzleandmodeladjustment

Enterintothescreentosetejector,self-pluggingandhuff.

Enterintothescreentosettimingandcounting.

Enterintothescreentosettemperatureandpre-heating.

资料

DATUM

快速设定

CELERITYSET

监视

MONITOR

帮助

?

HELP

Enterintothescreentosetthechangestomoldandproduction

facilities.

、Enterintosettingcelerityonetwosettingpage

Returntothemonitorscreeninanytime.

Theon-linehelpscreenuponenteringintothecurrentstate.

R

11

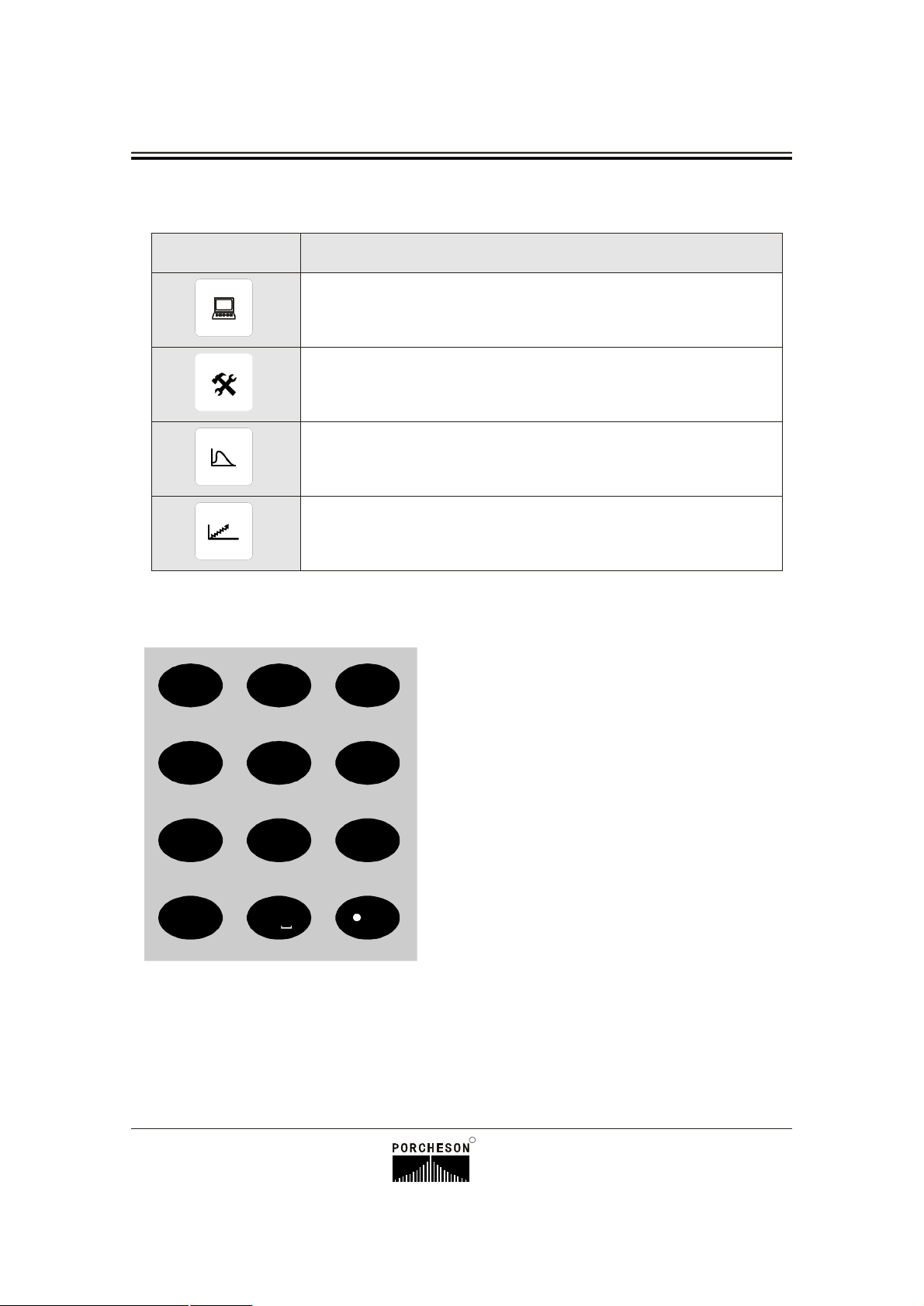

User'sManualforTB118V2.2

KeysUsage

连接

PC

PCLINK

诊断

DIAGNOSE

曲线

CURVE

生产管理

FLOWCHART

Chapter2ExplanationoftheKeyOperations

EnterintothescreentosetUSB

Enterintothescreentosetalarm

EnterintothescreentoSpeedandTemperatureTrackcurve

EnterintothescreentoSettingporductionImformationandSPC

TrackNote

3.ExplanationoftheParameterSetting

7ABC

4

JKL

1

STU

清除

CLEAR

8

5

2

0

DEF

MNO

VWX

9GHI

6

PQR

3

[]/-.

settingscreen.WhentheelectriclockisinOFFstate,

thesetennumbersarelockedtoensurethedatawillnot

bechangedarbitrarily.Inthemeanwhile,thereare26

Englishlettersandspecialsymbolsrespectivelyon0-1

YZ

numerickeysusedfortheinputofChineseandEnglish

lettersaswellasthemachineserialnumber.[DELETE]

keyisusedtodeletetheerrorwordsduringenteringthe

parametersandserialnumbers.[INPUT]keyisusedto

selectthefunctionsduringfunctionselectionandusedto

confirmduringitemconfirmation.

0-9numerickeysareusedfordatainputinthedata

“”

R

12

User'sManualforTB118V2.2

4.CursorKey

KeysUsage

Chapter2ExplanationoftheKeyOperations

Skipkey,pressingitwillskipthecursortotheupperline

Escapekey,pressingitwillmovethecursortotheleft

Escapekey,pressingitwillmovethecursortotheright

Skipkey,pressingitwillskipthecursortothelowerline

5.OperationModeSelectionKey

KeysUsage

手动

Pressingthiskeywillenterthesystem

MANUAL

半自动

SEMI.AUTO

电眼自动

SENR.AUTO

时间自动

TIME.AUTO

intomanualstate.

Pressingthiskeywillenterthesystem

intosemi-automaticoperation

Pressingthiskeywillenterthesystem

intosenr-automaticoperation

Pressingthiskeywillenterthesystem

intotime-automaticoperation

Remarks

Thereisanindicatorontheleft

upperofallkeys.Pressinganykey

willturnonthisindicator,indicating

thesystemisinthisstate.Everytime

thecomputerisstarted,thedefault

stateofsystemismanualoperation.

Incaseofthetemperaturehasnot

reachedthesetvalue,thesystemis

impossibletoperformsemi-automatic

senr-automaticandtimeautomatic

operations.Theindicatorwillnotturn

onwhenthesemi-automatic

automaticandtime

automaticoperation

、senr-

keypressedtillthetemperaturereaches

thesetvalue.

、

R

13

User'sManualforTB118V2.2

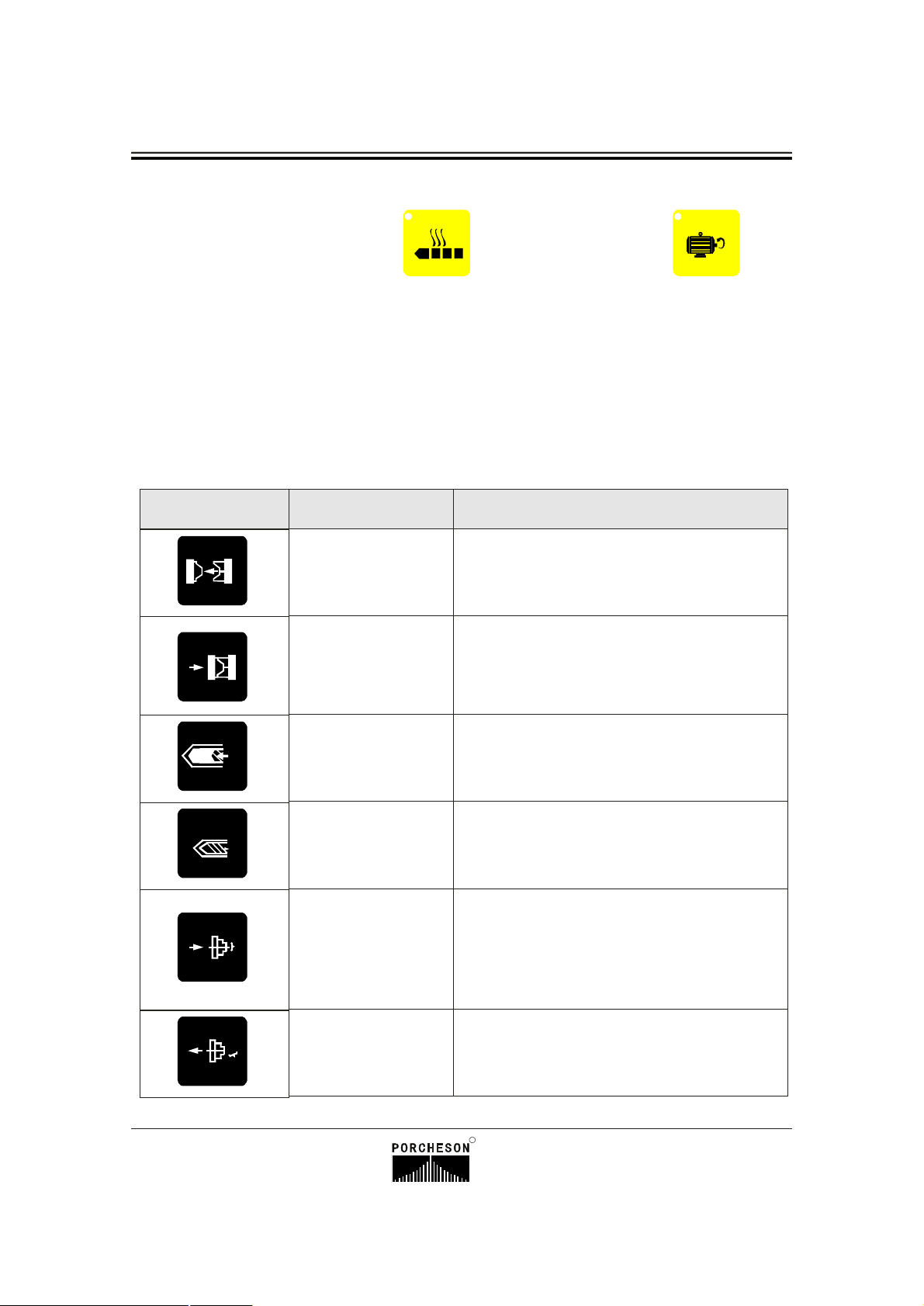

Chapter2ExplanationoftheKeyOperations

电热开/关

6.ElectrothermalON/OFFkeyandMotorON/OFFkey

HEATERON/OFF

马达开/关

MOTORON/OFF

Inthemanualmode,pressthekeyonceandtheindicatorattheleftupperwillturnon,indicating

thefunctionstatehasopened.Pressingthekeyagainandthisindicatorwillturnoff,indicatingthe

functionstatehasshutoff.Repeatedlypressingthiskey,thefunctionswillturnonoroffinturn.

Upontheemergencyswitchstops,themotorwillpoweroffswiftlywithoutaffectingtheelectro

thermaloperation.

7.ManualOperationKeys

Keys

开模

MOLDOPEN

锁模

MOLDCLOSE

Usage

Model-opening

operations

Mold-locking

operating

OperationConditions

1.Themodelhasnotopenedtotheterminationposition.

1.Normalsafetydoorinput;

2.Ejectorretractstillbumping;

3.Moldhasnotlockedtotheterminationposition;

4.Thesignals(mold-locking)ofrobothandshavebeen

connectedwhentherobothandsareselected.

射出

INJECT

射退

SUCKBACK

托模进

EJECTADV.

托模退

EJECTRET.

GlueShotOperation1

Decompression

Ejectionadvance

operation1

Liftoffoperation

1.Incaseoftimeglueshotselected,theinjectiontimehasnotcompleted;

2.Incaseofthepositionselected,ithasnotreachedtheglue-shot

terminationposition;

3.Temperatureswithinallsectionsofmaterialcanistershallnotexceed

theleewayscope(withouttemperaturealarm)

1.Whentheelectronicrulerisoffduty,thetimeforlaunching

backisinadequate;

2.Whentheelectronicrulerisonduty,thepositionforlaunching

outisinadequate;

3.Theactualtemperatureofthereelhastobeinthesetupscope

(notemperaturealarm)andthetimeforcoldstartofthescrew

isadequate;

1.Modeopeninghascometotheterminateposition;

2.Theneutronwithdrawallimithasbeenconnectedandthetime

forwithdrawalofneutronisadequate;(whenselectneutron)

3.Mechanicalhandsignals(traymode)hasbeenconnected

(whenselectmechanicalhand);

4.Whentheelectronicrulerisonduty,thepositionoftraymode

hasnotreachedtheterminalposition;

5.Whentheelectronicrulerisoffduty,choosethetrip:hasnot

reachedthestopposition.choosethetime:thetimecalculation

oftraymodeisnotadequate;

1.Whentheelectronicrulerisonduty,thepositionoftraymode

hasnotreachedtheterminalposition;

2.Whentheelectronicrulerisoffduty,choosethetrip:has

reachedthestopposition.choosethetime:thetime

calculation

R

oftraymodeisnotadequate;

②

①

①

②not

14

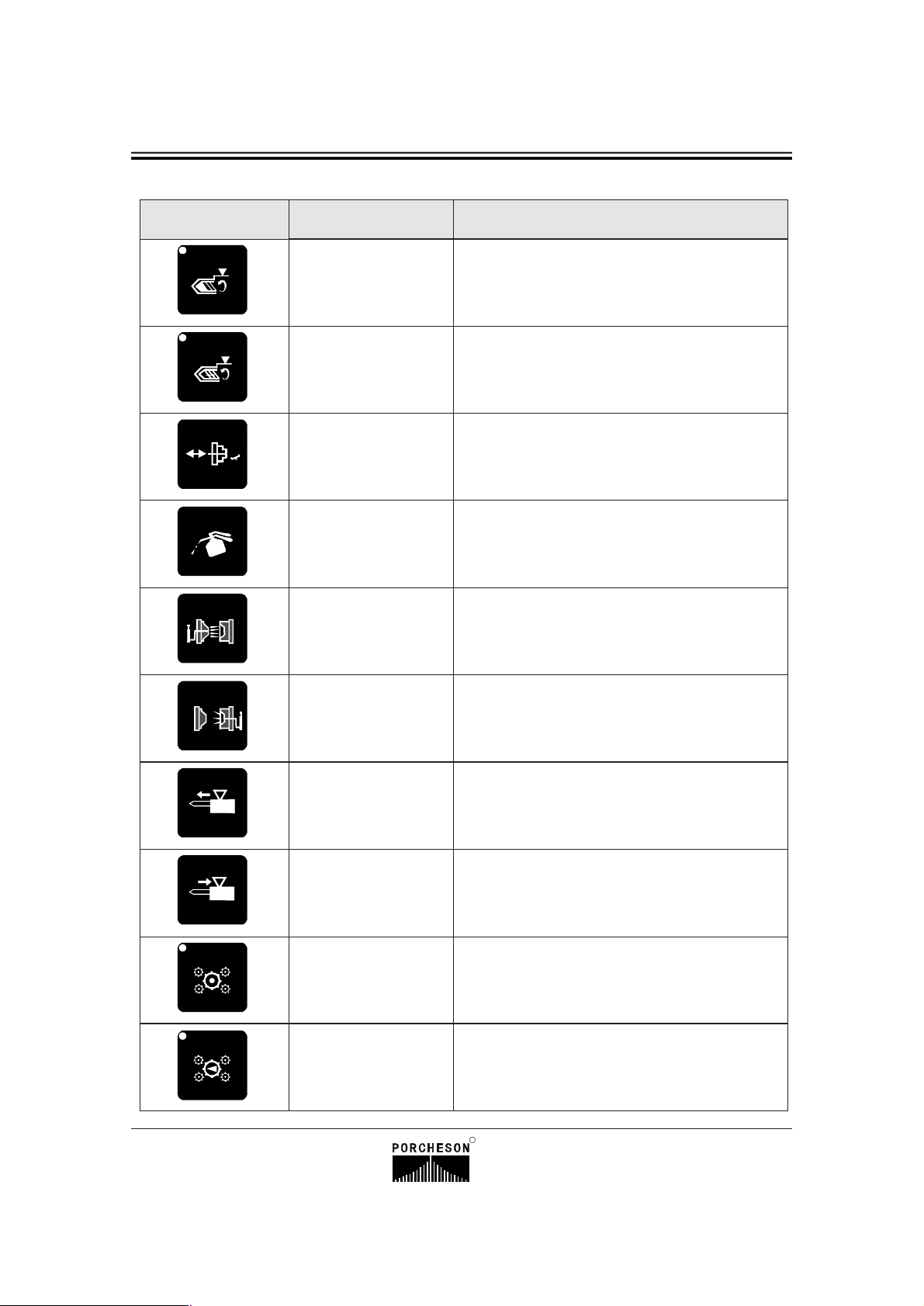

Chapter2ExplanationoftheKeyOperationsUser'sManualforTB118V2.2

KeysUsageOperationConditions

储料

CHARGE

自动清料

AUTOPURGE

多次托模

EJECTOR

润滑

LUBR.

公模吹气

AIRBLST.MOV.

母模吹气

AIRBLST.STN.

FeedingOperation

AutomaticMaterialRem

ovalOperation

SeveralItemsOperation

LubricatingPumpWork

MaleMoldHuffOperation

FemaleMoldHuff

Operation

1.Feedinghasnotcometotheterminationposition;

2.Temperatureswithinallsectionsofmaterialcanistershallnot

exceedtheleewayscope(withouttemperaturealarm)

1.Selectionanduseofautomaticmaterialremoval;

2.Timesofautomaticmaterialremovalnotcompleted;

3.Temperatureswithinallsectionsofmaterialcanistershallnot

exceedtheleewayscope(withouttemperaturealarm)

1.Theoperatingconditionsarethesameasthosefor

advanceandliftoff;

2.Thetimeofejectorsettinghasnotcompleted.

1.Lubricatetotaltimehavenoend

1.Selectionandusageofmalemoldhuff;

2.Thetimeofmalemoldhuffhasnotcompleted.

1.Selectionandusageoffemalemoldhuff;

2.Thetimeoffemalemoldhuffhasnotcompleted

ejection

座台进

NOZZLEADV.

座退台

NOZZLERET.

调模

MOLDADJ.

调模退

MOLDTHICK

Nozzleadvanceoperation

Nozzlebackwardoperation

Mold-adjustingSelection

Mold-Adjusting

BackwardOperation

1.Whentheblocklimitselectionisoffduty,thereisnoconditions;

2.Whentheblocklimitselectionisonduty,thelockmodestops

ON.Hasnotreachedtheblockstopposition;b.thetime

②

calculationoftheblockisnotenough;

1Nocondition;、

1.Iftransfersmodebyhand,pressthisbuttoninthemanualstate,

theindicationlightwillbeon,thatmeansyoucantransfermode

byhand;

2.Ifautomaticallytransfersmode,pressthebuttontwiceinthe

manualstate,andtheindicationlightwillbeon,thatmeans

youcanconductautomatictransferofmode;

1.Enterthestateofmanualmodetransfer;

2.Themold-adjustingretracthasnotcometotheterminationposition.

R

①

15

Chapter2ExplanationoftheKeyOperationsUser'sManualforTB118V2.2

KeysUsage

调模进

Mold-Adjusting

MOLDTHIN

中子A进

A

COREAIN

中子A退

A

COREAOUT

中子B进

B

COREBIN

中子退B

B

COREBOUT

ForwardOperation

Chip-insertion

OperationA

Chip-Extraction

OperationA

Chip-insertion

OperationB

Chip-Extraction

OperationB

OperationConditions

1.Toselectthemold-adjustingusestate;

2.Themold-adjustingadvancehasnotcome

totheterminationposition.

1.SelectionandusageofSelf-pluggingA;

2.Chip-insertionAhasnotcometothetermination

positionorthetimehasnotcompleted;

3.Liftoffhasreachesitspositionortheliftofftime

hascome.

1.SelectionandusageofSelf-pluggingA;

2.Chip-insertionAhasnotcometothetermination

positionorthetimehasnotcompleted;

3.Liftoffhasreachesitspositionorthe

liftofftimehascome.

1.SelectionandusageofSelf-pluggingB;

2.Chip-insertionBhasnotcometothetermination

positionorthetimehasnotcompleted;

3.Liftoffhasreachesitspositionortheliftofftime

hascome.

1.SelectionandusageofSelf-pluggingB;

2.Chip-insertionBhasnotcometothetermination

positionorthetimehasnotcompleted;

3.Liftoffhasreachesitspositionortheliftofftime

hascome.

8.SettingScopeofNumericItems

Number

1

2

3

4

5

6

7

Incaseofthesetvaluesexceedtheabove-mentionedscopes,thesystemwillnotacceptthenumbers

setandkeeptheoriginalsetvalues.Forthehabitofdatainput,thedatainputofthissystemisdisplayfrom

righttoleft.

SettingItemsSettingScope

TimeSetting

PressureSetting

SpeedSetting

BackPressure

TemperatureSetting

StorageofMoldData

PredictedTurnout

Digital

≤600.00

Digital

≤160.0

Digital

≤99.9

Digital 160.0

≤

Digital999.9()Measure

≤

Digital600.0(set)

≤

Digital999

Digital

≤

≤99999999

R

Unit

Second

Bar

%

Bar

℃

Number

PC

16

User'sManualforTB118V2.2

Chapter3:Descriptionsonsettingparameters/functions

Chapter3:Descriptionsonsettingparameters/functions

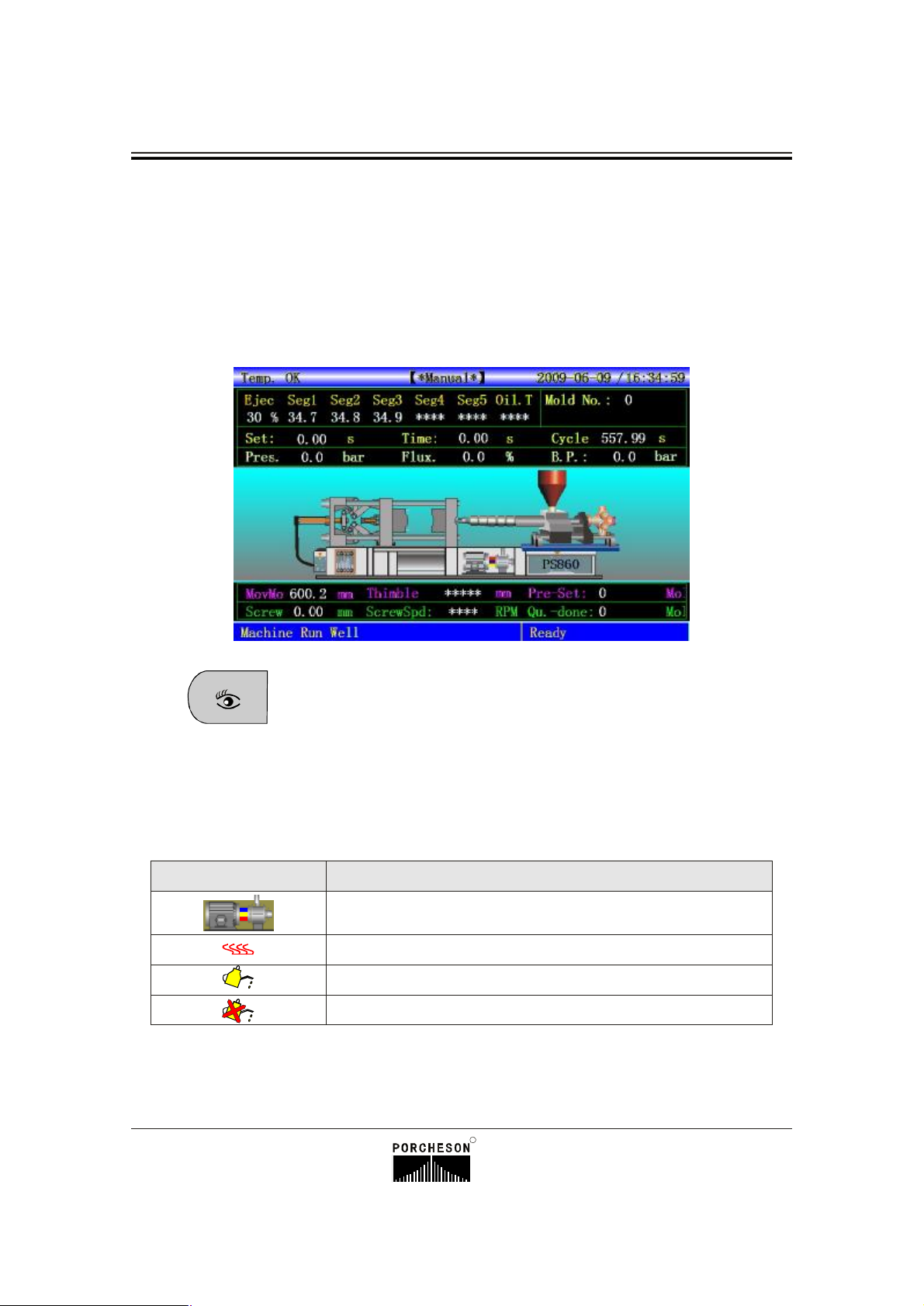

1.TheMainControlpanelwhileturningon

Connectwithpower,turntheredurgentstopswitches,theoperationlightofthecomputer-RUN

-flickers,thefollowingmenushownonthedisplay,nowthecontrolsystemisrunninganditisreadyto

operatethemachine.

监视

Presskeyatanytimeafterre-turningonthecomputer,andthenenterthemenuof

themenuofthemachine.Thismenuisformonitoringtemperatureandmachinerunning

condition.Thenamesandnumbersofthemouldswillbesetinmouldinformationmenu.The

temperaturescaleandcurrentoiltemperatureshowtherealvalueofeachstagethusitsinformation

cannotbemodified.Eachfunctionofthemenusisdescribedasfollows:

Thedescriptionsonmode:

MONITOR

monitor

Mode

Meanings

Motorisrunning

Electricalheatingopened

Lubricatorislubricating.

Thelubricatorunsuccessfulunchin

R

17

User'sManualforTB118V2.2

Thedescriptionsondisplay:

Chapter3:Descriptionsonsettingparameters/functions

Display

Manual

InjectionNozzle

Mouldnumber

Movablemould

Screw

Thimble

Pressure

Flux

Preparemoldnumber

Output

Set

Operation

Wholeprocess

Meaningsanddescriptions

Therunningmodeofthemachine;

Thissectionisheating;

Thecurrentmouldnumber;

Showsthecurrentpositionofthemould.Theunit:mm;

Showsthecurrentpositionofthescrew.Theunit:mm;

Showsthecurrentpositionofthethimble.Theunit:mm;

Thesetpressurevalueofthecurrentmovement;

Thesetfluxvalueofthecurrentmovement;

Thenumberofmodeopeningofthecurrentmodeofthepredictedproduction;

Recordthenumbersofmouldopeningforcurrentmouldnumberduringthe

automaticoperationofthesystem;

Thetimevalueandcounterdataofthecurrentmovement;

Whenatimevaluesetforcurrentmovement,onlytheoperationtimeincrease

tothesettime,thenextmovementstarts.Whenitisthenumberwasset,the

actednumberswillbeshownonthedisplaytillthenumbersreachthesetcounter

date.

;

Therealoperationcycletimeofthesystem;

Inlowtemperature

TheLuopoleturnssoon

Whentheactualtemperatureisnotinthescopeofsetupscope,itwill

abnormalstateofthecurrenttemperatureineacharea;displaythe

Thenumberofrotationofthescrewinoneminute(unit:RPM);

R

18

Descriptionsonalarmmode

Chapter3:Descriptionsonsettingparameters/functionsUser'sManualforTB118V2.2

Alarm

Exitsunclosed

OpenExits

Failureofsensor

inspection

Mouldopeningnotfixed

Clampingandopen

mouldnotfixedontime

Lowpressuremould

protectingtimeisover

Source

Themodelockingstopsandxits

unclosedshowedifyouoperate

modelockingwhileexitsunclosed

InSemiautomode,theexits

remainunopenedwhileasingle

cycleended

Inautomaticoperation,whenthe

inspectingsensorisnotON

afterthimblewithdrawinginsensor

cyclingmodeandthemid-timeis

over,itwarnsFailureofsensor

inspection

Whenejectforwardmanually,the

mouldopeningnotreachtheposition

ofstoppingmouldopening;

Clampingmouldnot

completedwithinthetime

limitationofthemouldopening

orclosing

Itwillwarnifithasnotturnedinto

highpressurewhenthelow-pressure

timeisover.

”

“”

;

“

”;

andopen

“

”;

“

“”

Solution

Checkiftheswitchesofthefrontandrearexits

arecorrectlyconnectedwithinputinterface

ofX00X01andX15X16andcheckifthey

;

、、

canbepressednormally.

Opentheexits,takeouttheproducts,

closeexitsandthancontinuetheprocessing

RemovethefailureofEjectingforward

andEjectingbackwardandjudgeifthere

areanylongcover.Theconnectionlines

andthesensoritselfshouldbemainly

inspectedwhenthelightofX04input

pointalwaysshines.

Re-operateunlocking,orcheckpositionof

lockWhentheelectronicruler

opening.

isonduty,attheposition.

Whenthecheck

②

whetherX12isconnected.

Checktheclampingmould

process,extendproperlythetime

limitationofthemouldopeningor

clampingifitisnormal.

Checkthemould,extendproperlyhe

lowpressuretimeifthereisnotany

redundantobjects.

①

checkthenumber

electronicrulerisoffduty,

andopen

“

”

”

。

FailureofExit

Plasticmeltingnot

completedontime

Failureofplasticinjection

Failureofmotor

Cycletimeisover

Alarmwhenthereisonlyonepress

inX00X01andX15X16、、;

Plasticmeltingnotcompletedwithin

thetimelimitationofplastic

melting“”;

Theplasticinjectiontestingstroke

switchesX20hasnotbeenpressed

ortheelectronicrulerhasnot

reachedtheplasticinjectiontesting

pointduringplasticinjection.

Alarmwhensignalinputsmotor

protectionpointX16.

WhenAutoproductioncycletime

islongerthanset[cycletime]

R

Checkiftheswitchesofthefrontandrear

exitsarecorrectlyconnectedwithinput

interfaceofX00X01andX15X16

andcheckiftheycanbepressednormally.

Checktheplasticmeltingprocessand

findoutiftheplasticinplasticdrum

hasbeenrunout.Extendproperly

thetimelimitationofplasticmelting

“”

ifitisnormal.

Checkplasticinjectionprocessand

adjustthedeviationvalueofplastic

injectiontesting

Checkifthereisaprotectionontheoil

hydraulicmotorcausedbyrelayagainst

overload.

Checktheautoproductionprocess,

extendproperlytheset[cycletime]if

itisnormal.

、、

19

Chapter3:Descriptionsonsettingparameters/functionsUser'sManualforTB118V2.2

AlarmSourceSolution

KnockoutcoreAnot

completed.

KnockoutcoreBnot

completed.

Machinehaschosenknockoutcore

AandB.Itrequiresthattheknockout

spaceoftheknockoutcoremusthave

beenconnectedwhenejectforward

ormulti-ejectforward

;

Checkifthestopswitchesoftheknockout

coreAandBareconnectedcorrectlyand

iftheycanbepressednormally.Setastop

modeinfunctionmenuforknockoutcore

AandBwhenyoudonotusetheknockout

corefunction.

Themachinestopswhentheoutput

Thesetoutputreached

stoppingmachinefunctionstartedor

thenumbersofmouldopeninghave

reachedthesetoutputnumber.

Descriptionsonoperation/promptmode

Alarm

Hightemperaturein1,2,3,

4stagesInjectionnuzzle.,5,

Lowtemperaturein1,2,3,

4stagesInjectionnuzzle.,5,

Temperatureshortcircuitn

1,2,3,4stagesInjection

,5,

nuzzle

Autostuffclearingup

completed

Automouldadjusting

completed

Automouldadjusting

notcompleted

Entermanualmodefirst

Therealtemperaturerelatedtothestageofthemachinehopperishigher

thanthesettoplimitedvalue.

Therealtemperaturerelatedtothestageofthemachinehopperislower

thanthesetdownlimitedvalue.

Therealtemperaturerelatedtothestageofthemachinehopperishigher

thanthesettoplimitedvalue.

Afterthesetnumbermovementcompletedandwhileautostuffclearing

up.

Automouldadjustingcompletedwhenusingmouldautoadjusting.

Automouldadjustingnotcompletedwhenusingmouldautoadjusting.

Whenoperatemanualkeysinautomode.

Solution:Ifyouneedthemachinecontinues

runningaftertheoutputreached,justsetthe

[stopafteralarm]inproductionmenuas

[out];orresetthetotalmouldopeningofthe

currentmouldnumber.

Source

(Maximumtemperaturevalues=thesetuptemperaturevalue+thesetupmaximumvalue).

(=thesetuptemperaturevalue-thesetupmaximumvalue).

hesetdownlimitedvalue

Functionsnotselected

Startmotor

NextcyclePrepared

Sensorprepared

Exitmouldadjusting

modefirst

Entermouldadjusting

modefirst

Certainfunctionhasnotbeenselectedwhenmanualoperateitskeys.

Howtoselectmotor:Promptwhenthesemi-auto/autokeysarepressed,

asthemotorhasnotbeenstarted.

Inautomode,themid-timebetweencompletingacycleandstarting

nextcycle.

Themid-timehasnotbeenreachedafterwithdrawingthimblesduring

autosensorcycling.

Whenoperatenon-[adjustforward,backwardandautomouldadjusting]

keysinmouldadjustingmode.

Whenoperate[adjustforward,backwardandautomouldadjusting]keys

innon-mould-adjustingmode.

R

20

User'sManualforTB118V2.2

2

Settingforcelerityinformation

.

快速设定

CELERITYSET

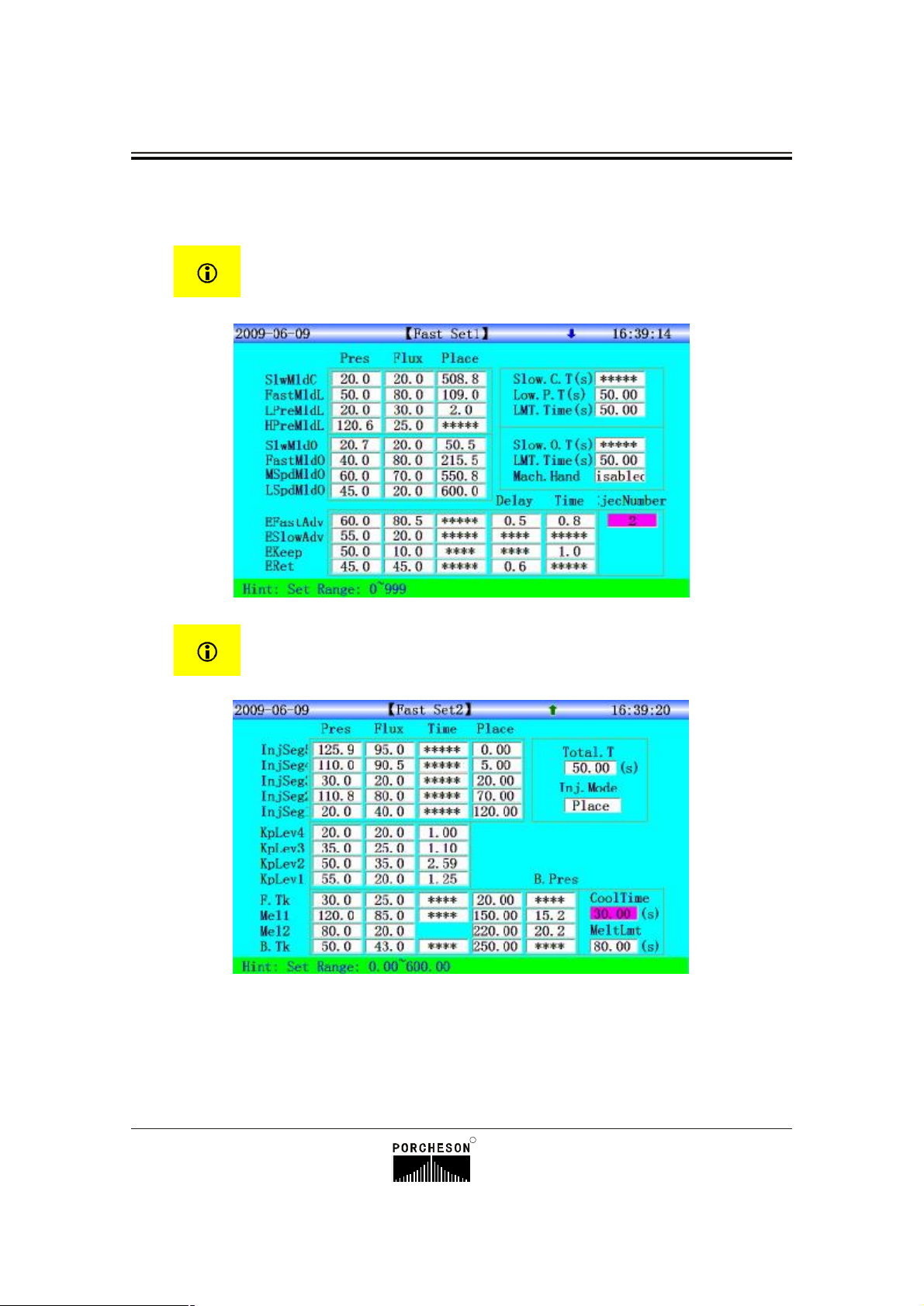

Presskey,enterthemenuforsetting,nowthemenuisasfollowing:celerityoneinformation

Chapter3:Descriptionsonsettingparameters/functions

快速设定

Presskeytwice,enterthemenuforsetting,nowasfollowing:celeritytwoinformation

CELERITYSET

Quicksetting1and2menusareparametersclustermenuscommonusedbyjetmoulding

machines.Thesetwomenuscanprovideimportantparametersneededdailyadjustmentby

machines,including:mouldclamping,mouldopen,injection,holdpressure,plasticization,

ejectorforward.

R

21

User'sManualforTB118V2.2

Chapter3:Descriptionsonsettingparameters/functions

3.SetmouIdcloseinformation

开锁模

Presskey,enterthemenuforsettingmouldclose,nowthemenuisasfollowing:

M.PLT

Descriptionsonsettingparameters/process/functionmode

LowQuicSlow

H.Pr

205020120Pres

20803025Flux

508.8

(1).Process:whilemouldclose,enterslowclampingfirst,andthanenterfastclampingwhenthestrokearrivesat

[508.8],andthanenterlowpressureclampingwhenstrokerunsanother[109.0],andhighpressure

clampingwhenstrokerunsanother[2.0]tillclampingcompleted.Itmouldprotectiontime

isover]whenthelowpressuretimeisoverbutnotenter

(2).Slowmodelocking:whenthedynamicmodeelectronicruleris[offduty],thetimeforslowlockofthemode.

(3).Lowpressureprotection:Setasmallerlow-pressuretimeformouldclose,itisbesttobefitting,otherwise,

themouldcannotbeprotected.

(4).Timelimitationtomoldopenandclose:timelimitationtomoldopenandclose,pleasesetitlonger,

anditisbettertobefitting,otherwise,thesystemalarms[moldopen/closenotcompletedontime].

(5).Differentialmouldclose:pressinputkeystoselect[on]or[off],outputwhenselect[on]forquickmouldclose

Y52,notoutputwhenselect[off]forquickmouldcloseY52,

109.02.0

thanenter

alarms[lowpressure

thehighpressureyet

R

22

Loading...

Loading...