PORCHESON BK 108 User Manual

User'sManualforBK108V2.0

Preface

WelcometouseOurInjectionMoldingMachineControlSystem

I.Danger

Cautions

SafetyCautions

()Pleasereaditbeforeinstallation

1.Inordertoensurethesecureoperationofthewholesystemin

caseoftheabnormalexternalpowerandthecontrolsystem's

failingtofunction,pleasesetuptheexternalsafecircuitforthe

controlsystem.

2.Uponitsfailuretodetecttheabnormalconditionsofinputand

output,thecontrolsystemcannotcontroltheoutput.Therefore,

pleasedesigntheexternalcircuitandframeworktoensurethe

safeoperationofthesystem.

1.PleasereadthisUser'sGuidancecarefullybeforeinstallation.

2.Donotdismantlethehostcomputershellandkeyboard

withoutpermission.

3.

Incaseofanyquestions,pleasedialtheafter-serviceservice

hotlineofPORCHESON.

R

1

PORCHESON

User'sManualforBK108V2.0

Contents

TECHNOLOGYCO.,LTD

SystemConfiguration&

Installation

5

BK108

Operator'sManual

SoftwareVersion:V2.0

ButtonOperation

specification

ExplanationoftheParam

eter/FunctionSetting

ExplanationoftheSystem

DebuggingandSetting

9

16

41

2003.03 Version

Allcopyrightsarereserved,anyduplicationwithoutthepriorauthorizationshallbe

forbidden.

Input/outputState

Detection

Reference&Appendices

R

53

58

2

User'sManualforBK108V2.0

Contents

Contents

Chapter1SystemConfiguration&Installation

1.SystemConfiguration&Remarksp5

2.FeaturesofthePS680AMControlSystemp5

3.InstallationandDebuggingofComputerControlSystemp6

Chapter2SpecificationsoftheButton-PressedOperations

1.FigureofKeyboardoftheOperationPanel(Seethefigurebelow)p9

2.ExplanationoftheFunctionalKeysp10

3.ExplanationoftheParameterSettingbuttonp11

4.CursorKeyp11

5.OperationModeSelectionKeyp12

6.ElectrothermalON/OFFkeyandMotorON/OFFkeyp12

7.EmergencyResetKeyp12

8.ManualOperationKeysp13

9.SettingScopeofNumericItemsp15

Chapter3:Descriptionsonsettingparameters/functions

1.Themaincontrolpanelshownwhileturningonp16

2Settingformouldcloseinformationp20

3.Setmouldopeninginformationp21

4.Settheplasticinjectinginformationp22

5.Setthepressureretaininginformationp23

6.Setplasticmelting/drawing/coolinginformationp24

7.Setthestuffauto-clearingupinformationp25

8.Setthetableinformationp26

9.Setthemouldadjustinginformationp27

10.Settheejectingforwardinformationp28

11.Setloosecoreinformationp29

12.Settheairblowinformationp30

13.Settime/countinformationp31

R

3

User'sManualforBK108V2.0

Contents

14.Settemperatureinformationp32

15.Setwarm-upinformationp33

16.Temperaturetracing/tracingcurvep34

17.SetModuleinformationp35

18.Setproductioninformationp36

19.SPCtracingrecordsforproductionadminstrationp37

20.informationmodificationpassestorecordp38

21.pressure,speedcurvep39

22.specialparameteradjustmetn/Settingp40

Chapter4InstructionsfortheSystemCommissioningSettings

1.EngineerSettingPagep41

2.DelaySettingPagep42

3.Pressure/FlowSlopeSettingPagep43

4.PressurePre-AdjustmentPagep44

5.FlowPre-AdjustmentPagep45

6.BackPressurePre-AdjustmentPagep46

7.ElectronicRulerSettingPagep47

8.SpecialFunctionOptionsPagep48

9.StandbyFunctionSettingPagep49

10.ProgrammableStandbyFunctionPagep50

11.TemperatureParameter/TimeSettingPagep51

12.MachineNo./Production-FactoryValueSettingPagep52

Chapter5Input/OutputModeInspection

1.InputInspectionPagep53

2.OutputInspectionPagep56

Reference&Appendices

1.BK108keyboardinstallationdimensionLayoutp58

2.externaldimensionsandinstallationholepositionsdrawingsforpowersupplycase

andtransformerp59

3.Exteriordimensionsandinstallationholepositiondrawingsformaincontrollerp59

4.PS800AMsystemwiringdrawingp60

5.Inputandoutputwiringdrawingp61

6.Motorheatingwiringdrawingp59

R

4

User'sManualforBK108V2.0

Chapter1SystemConfiguration&Installation

Chapter1SystemConfiguration&Installation

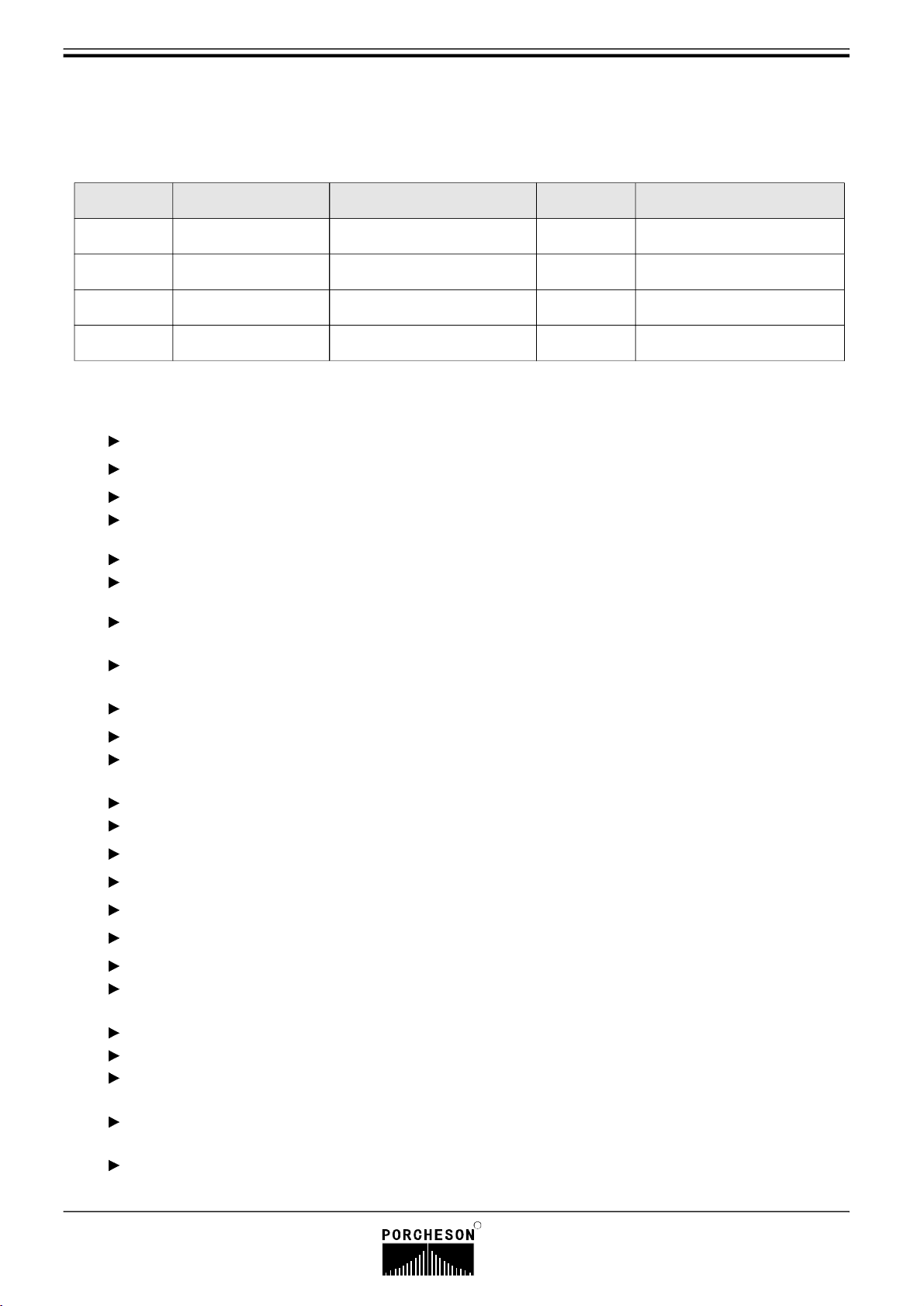

1.SystemConfiguration&Remarks

No.

1

Code

PS800AM26/28+10

2BK108320*240

3SPS300

4

DB-15F

Content

HostComputer

Keyboard

Powerpack

15-corecable

Q'ty

1Set

1Set

1Set

1

2.CharacteristicsofPS680AMControlSystem

Thewholecomputermaycontrolallfunctionsandtemperatures.

ThesystemhasbrightLCDdisplayand320*240Dot5.7''concolorous/colorful(optional)

ThesystemadoptsCPUdesignwithfastoperatingspeed,precisecontrolandhighstability.

Thecontrolhostcomputeradoptstheblockingdesignwithtime-savinginstallationandrapid

maintenance.

Ithastherealtimefunctiontodisplaytimeanddateinrealtime.

OFFIthasthescreenscreensaverfunction,itwillpoweroffwhenthereisnooperationwithin5

minutes.

With80groupsofmodedatastorage,itmayenterthemodeldescriptionandreal-timeoperating

helpinChineseandEnglish.

Theciphersettinganddatalockingcanpreventtheoperatorsfromchangingtheestablisheddata

arbitrarilytoinfluencethequalityofproducts.

Therearemultiplelanguagesforyourchoicethatdisplaydynamicallyinrealtime.

Remarks

300W

1m-5m,optional

Packingmodulussettingfunctionfor6-digitoutputmaysetthepackingmodulus.

Variousself-pluggingandteintypeprogramsareapplicablefortheself-pluggingandteincontrol

indifferenttypes.

PID(ProportionalIntegralDerivative)withselftemperaturecontrolhas6sectionsoftemperatures.

Ejectornozzletemperaturecanbecontrolledwithopenorenclosedloop.

Temperaturemaybepresetaweekinadvancetoenablemoreconvenientoperation.

Varioustypesoftravelcontrolmodes,rangetravelswitch/3-pathcoder/electricruler(optional)

VarioustypesofGlueShotways,4sectionsofGlueShotandclass-3pressurepreservation

FailureSelf-detectionfunctions,alarmdisplayandvoiceprompt

LEDindicatorsforoutputandinputmayitconvenienttoinspectandmaintainthesystem.

Inputandoutputaredonebytheopticallycoupledcircuittoisolatetheinterferenceofthe

externalcircuitry.

Intheinspectionwindow,youcaninspectallinputandoutputpointsandthemovingstatesofkey.

3-pathstandardD/Aproportionaloutput,themaximumcurrentoutput3A(PS610is2-path).

Presettingofthevoltageandrunoffvalues,proportionalvalveavailablefortheproductsinall

brandsandbetterlinearproportion.

Withremotecommunicationfunctions,itcanletyoudotheprogrammingandupgrading

softwareseasilyandremotely.

Withjustonecontroller,towhichyouconnectupto255injectionmachines;anditcanalso

monitortheproductionoftheeachmachineandprintoutareportforeachofthem.

R

5

User'sManualforBK108V2.0

Chapter1SystemConfiguration&Installation

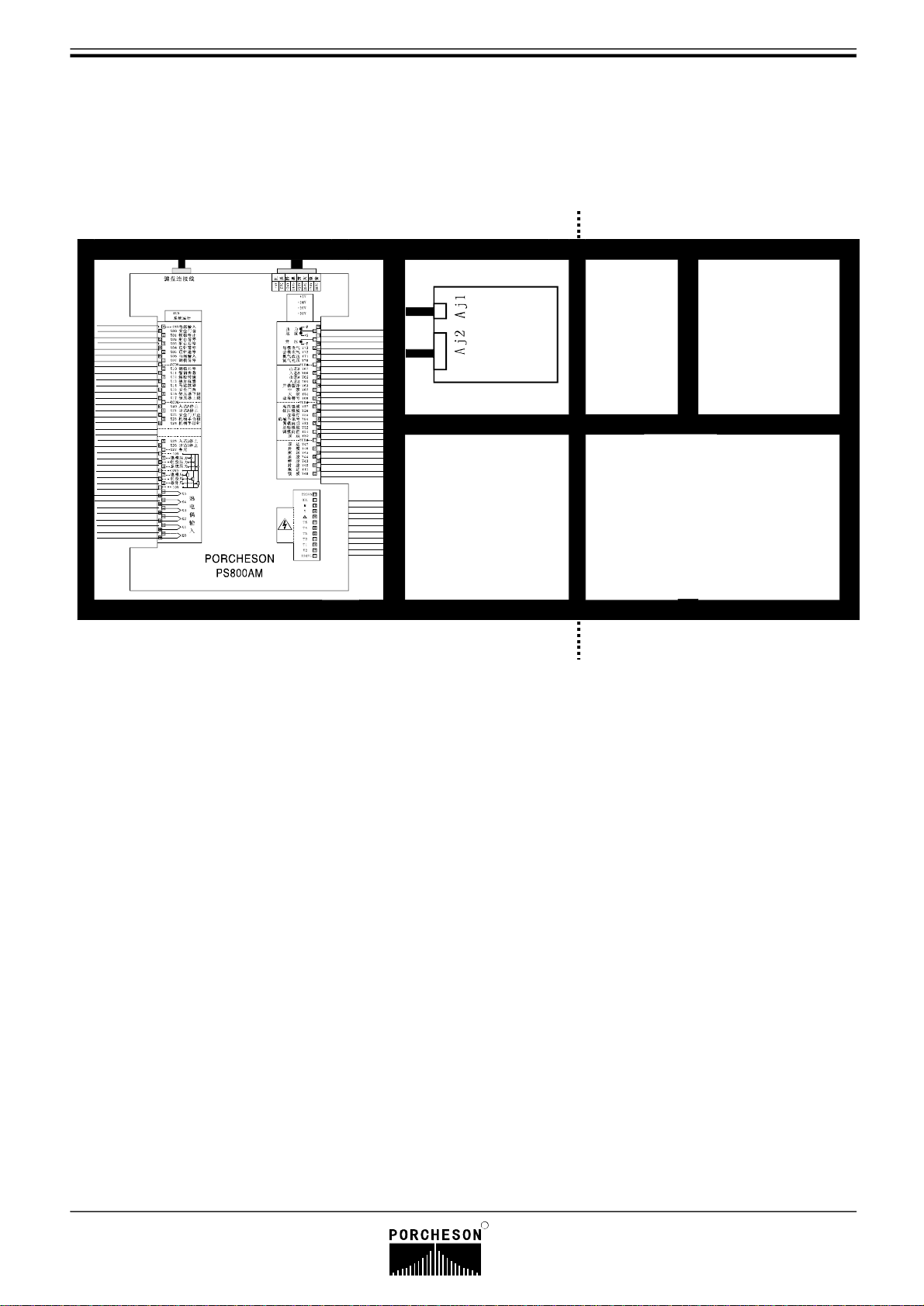

3.InstallationandDebuggingofComputerControlSystem

31CautionsuponInstallingtheControlSystem.

Thedesignofcontrolsystemissimpleandeasy,onlyone15-coreshieldingcableconnectingthe

keyboardandhostcomputershellwithflexibleandhandyinstallationandconnection.Thesketchmap

forinstallationisshownasfollows:

Strong

SPS300

POWER

Control

system.

POWER

eletricity

Equipment

Strong

Relay

eletricity

board

Equipment

Ebbeletricitysection

Strongeletricitysection

controlboxequipment;outfit(forreferenceonly)

()1Uponinstallingthehostcontrolbox,adopttheencloseddistributioncabinetatthefirstchoice.It

shallbefixedinthewell-ventilized,greaseproofanddustproofconditionsequippedwithafanand

dustproof.Thedistributionboxshallbestoredunder60?.

()2Uponfixingthehostcomputerandpowerpack,pleasekeeptheinterconnectingpartssuchasall

ACconnectorsandtransformersasfarawayfromeachotheraspossibletopreventtheelectric

waveinterferencefromtheelectronicgrid.

()3Allelectricwiresandshieldingwiresshallnotbecutoff,lengthenedorcurtailedarbitrarily.You

shouldusetheelectricwiresandshieldingwiresprovidedbythiscompanytopreventfrom

influencingthereliabilityandnormaloperationofthecontrolsystem.

()4Theshellofflamecoupleshalladopttheshieldingwire.Whentheoutershieldingofallflame

couplesadoptsthethermalcouplereticles,thereticleandmachinesshallbewellgroundedand

connectedtothegroundwiththeearthingresistancebelow10Ω.

()5Uponwiring,separatethehighandlowpressurelinefromthecomputercontrollineasmuchas

possible,donotbindallelectricalwirestogethertopreventtheinterferencefromaffectingthe

reliableoperationofcontrolsystem.

()6Uponfixingthekeyboardand15-corecommunicationconnectionsofthehostcomputer,youshall

pressandtweakwithforcetopreventthepoorconnectionfromaffectingthereliableoperationof

controlsystem.

()7PayspecialattentiontotheoilvalveoutletpublicportYCOM,itshallbeconnectedwelltoprevent

thecomputerfrominputtingwhilehavingthephenomenonofoilvalvehavingnomotion.

R

6

User'sManualforBK108V2.0

Chapter1SystemConfiguration&Installation

32InspectionoftheControlSystem.

()1Afterinstallationcompleted,carryoutanoverallinspectionifallconnectionlinesarewellfixed

includingtheswitchingpowersupply,hostcomputershell,electrothermaloutputlineandthe

thermalcoupleofkeyboard,etc.

()2Afterthelineinspectioncompleted,carryoutanelectricconnectioninspection.Firsttakeoutthe

11-digitaloutputlineplugoftheDCpowersupplyoutletport,namelythepowerpack,andthen

powerontoexamineandmeasureifthevoltageisthesameasthenominalvaluesandobserveif

theoutputindicatoronthepowerpackisnormal.

()3Poweroffafterthemeasurementcompleted,inserttheDCpowersupplytoinputtotheplugof

hostcomputershell.Afterpower-onagainforinspection,LCDonthekeyboardwilldisplaythe

normalstateofthemainpage.RevolveontheemergencystopswitchtocheckiftheRUNindicator

onthehostcomputershellturnson.Whenitturnson,itindicatesthatthesystemcanworksoundly.

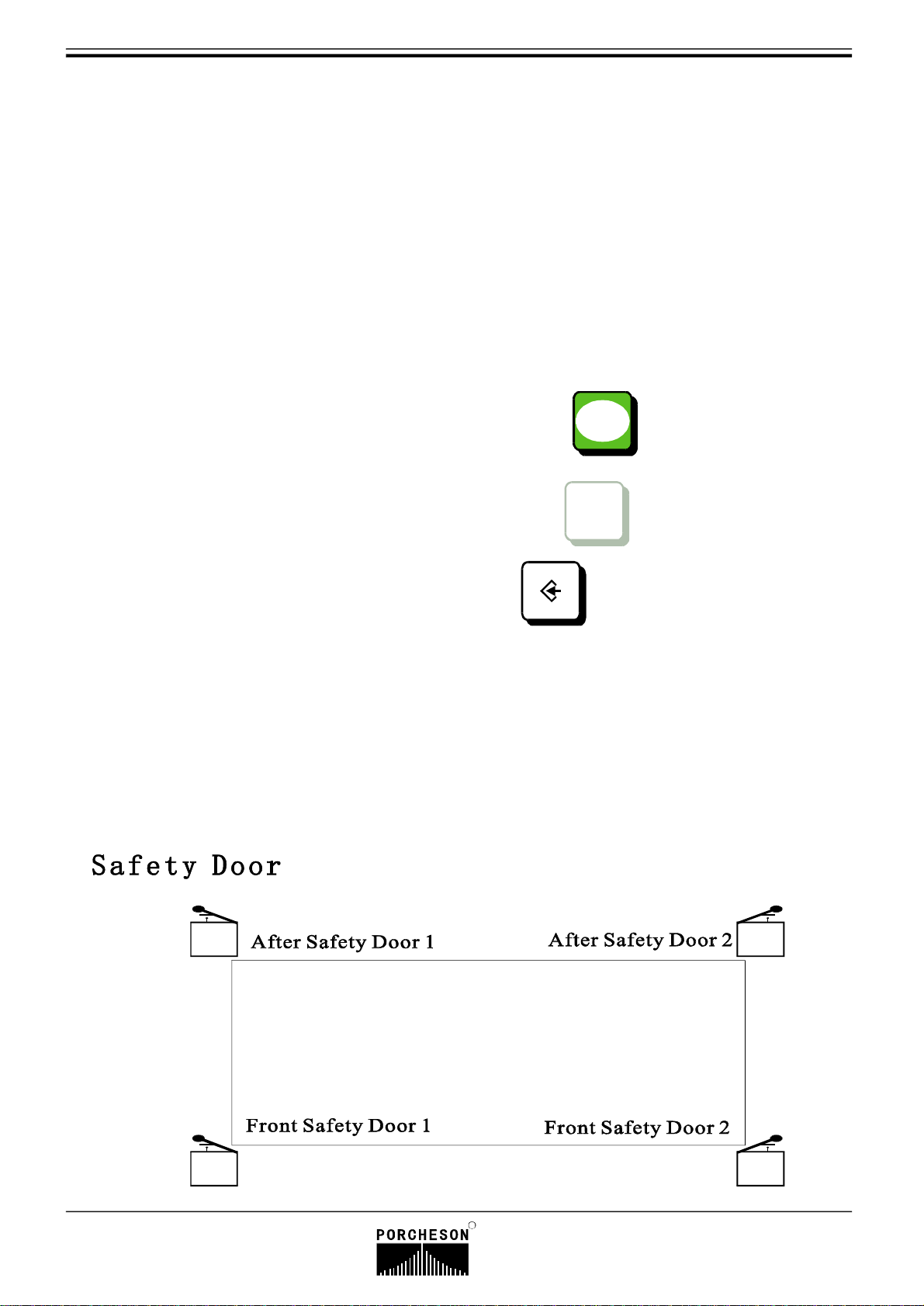

33ggingoftheControlSystem.

()1Afterthesystemhavingshownnormaloperatingstate,pressbuttononthemonitorpage

toadjustcolorandcomparison.

()2Toconducttheparametersettingandmemorytesting,pressbuttontoselectagroupof

输入

modulenumbersandthensetdatainallscreens.Pressbuttontosavedata.Disconnect

thepowerandconnectitagainafterafewtime,thesystemwillautomaticallycallthedataof

modulenumberssavedbyyou.Incaseoftheyarecorrect,itindicatesthatthememoryisallright.

()3Afterwards,setthedatainallrelevantdata(pleaseseeChapterIIIExplanationoftheParameter

Settingforthedetailedoperations).Uponsettinginthefirsttime,setthepressureandspeedaslittle

aspossibleandthenafterallmovementscomenormally,graduallyincreasethevaluestonormal

parameterstopreventfromdamagingthemechanicalperformances.

()4Afterallparameterset,savethemandcarefullyinspectifallinputandoutputpointsarenormal.

Carryoutanoverallinspectionofthealarmsystem,includingthefrontandbacksafetydoors.The

wireofsafetydoorsshallbeconnectedasstatedinthefollowingfigure.

ENTER

1

STU

资料

DATUM

LS4

LS3

LS2

LS1

R

7

User'sManualforBK108V2.0

Chapter1SystemConfiguration&Installation

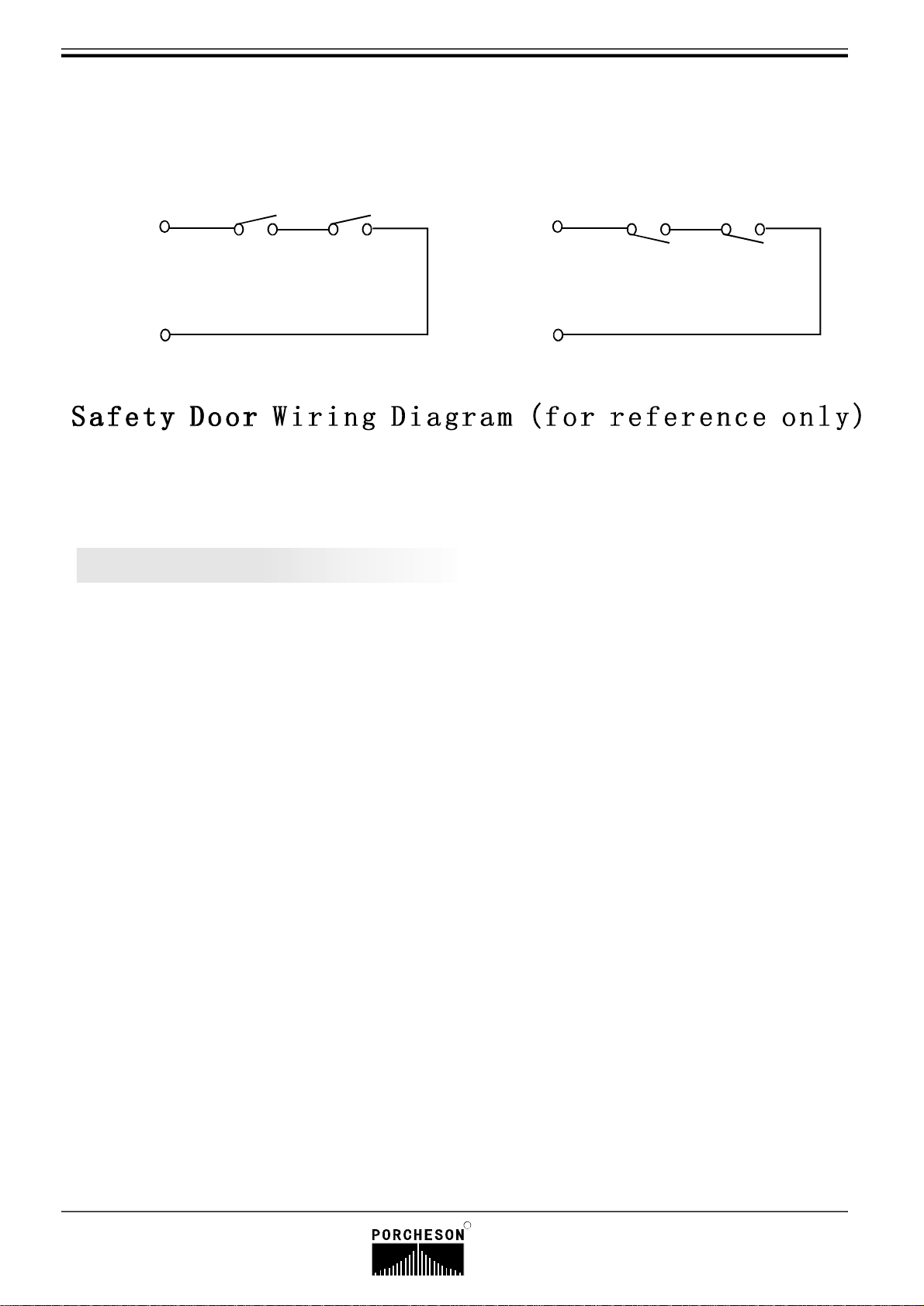

LS1LS2

LS3LS4

XCOM

X00

SafetyDoors*SpecialExplanation:

★

Whenalightturnsonandtheotherdoesnotuponclosing/openingthedoors,orincaseofother

abnormalconditions,thesystemwillissueanalarm2secondslaterforSafetyDoorFailureand

simultaneouslyterminatealloperatingoutput.Inthesemi-automaticmode,theconditionfor

opening/closingthesafetydoorsisthatthetimefromLS1,LS2,LS3,LS4allturn[OFF]toallturn

[ON]ismorethan0.5asvalidinordertopreventthetwitterofsafetydoorswitchesfromcausing

erroroperation.

XCOM

X15

R

8

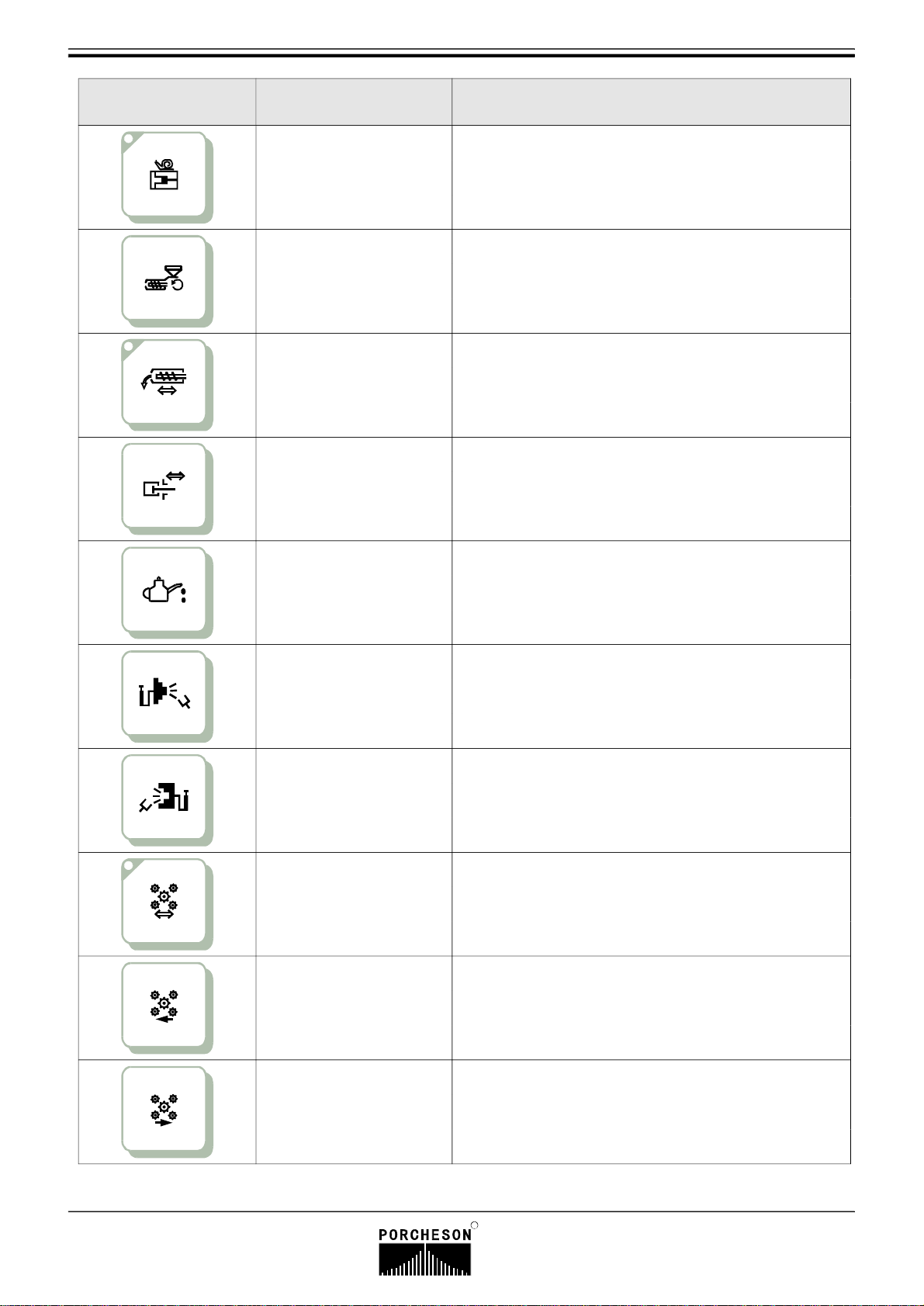

Chapter2ExplanationoftheKeyOperations

Chapter2ExplanationoftheKeyOperations

User'sManualforBK108V2.0

1.FigureofKeyboardontheOperationPanel(Seethefigurebelow)

2001.08.18

温度

射咀

实际

228

:

659.5

动模

:

螺杆

258.2

:

顶针

35.6

一段温度低

!

开锁模射胶熔胶射台/调模顶针/抽芯

M.PLTINJECTIONFEEDING

ABCDEF

789

4

12

0

5

JKLMNOPQR

STU

[]/-.

VWXYZ

清除

CLEAR

218一段208

28C

mm

mm

mm

6

3

输入

ENTER

*手动*

二段 三段

:

压力

:

流量

产量:

NOZZ/ADJ.

GHI

198

00bar

00

268899

EJE/CORE

模具编号

PS800

%

20:38:08

:68

G-6018汽车杯外壳

000r

000.0s

:

设定

000.0s

操作:

009.5s

全程:

就绪

时间

TIMETEMP.DATUM

监视

MONITOR

温度资料

帮助

HELP

手动半自动全自动

MANUALSEMI.AUTOAUTO

开模锁模

MOLDOPEN

射胶熔胶

INJECTIONFEEDING

顶退顶进

EJECTRETEJECTADV

座进座退

NOZZLEADV NOZZLERET

MOLDCLOSE

手动复位

RESET

慢速

SLOW

抽胶

DECOMP

多次顶润滑

EJECTORLUBRLCATE

公模吹气母模吹气

BLOWMALE

自动调模

AUTOMOLDADJ.

自动洗料

AUTOPURGE

BLOWFEMALE

关OFF

ON

开

资料锁

电热开/关马达开/关

HEATERON/OFF

调模退调模进

MOLDTHICK

入芯A 出芯A

COREAIN

入芯B 出芯B

COREBIN

MOTORON/OFF

调模

MOLDADJ.

MOLDTHIN

COREAOUT

COREBOUT

B108K

R

9

Chapter2ExplanationoftheKeyOperations

User'sManualforBK108V2.0

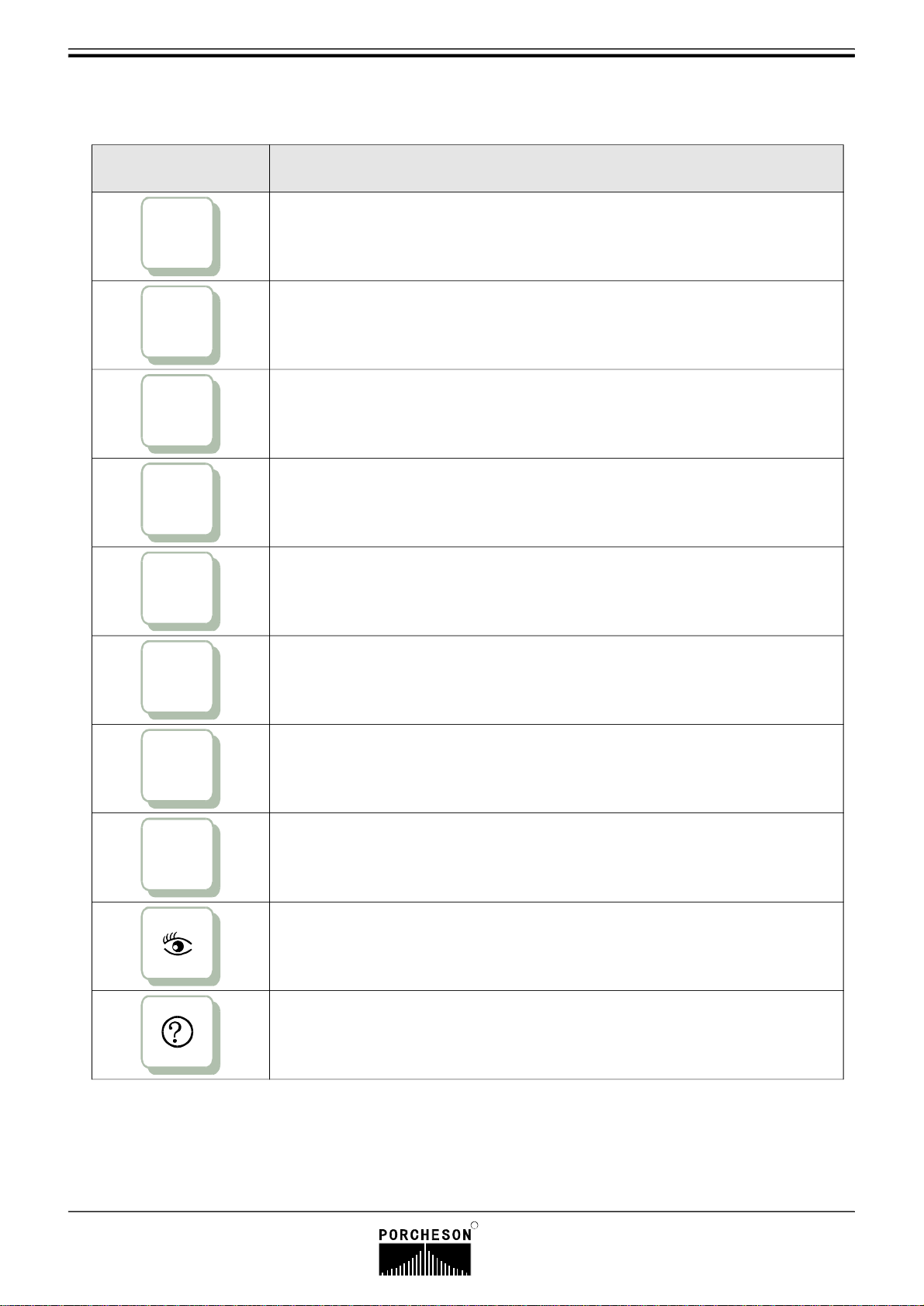

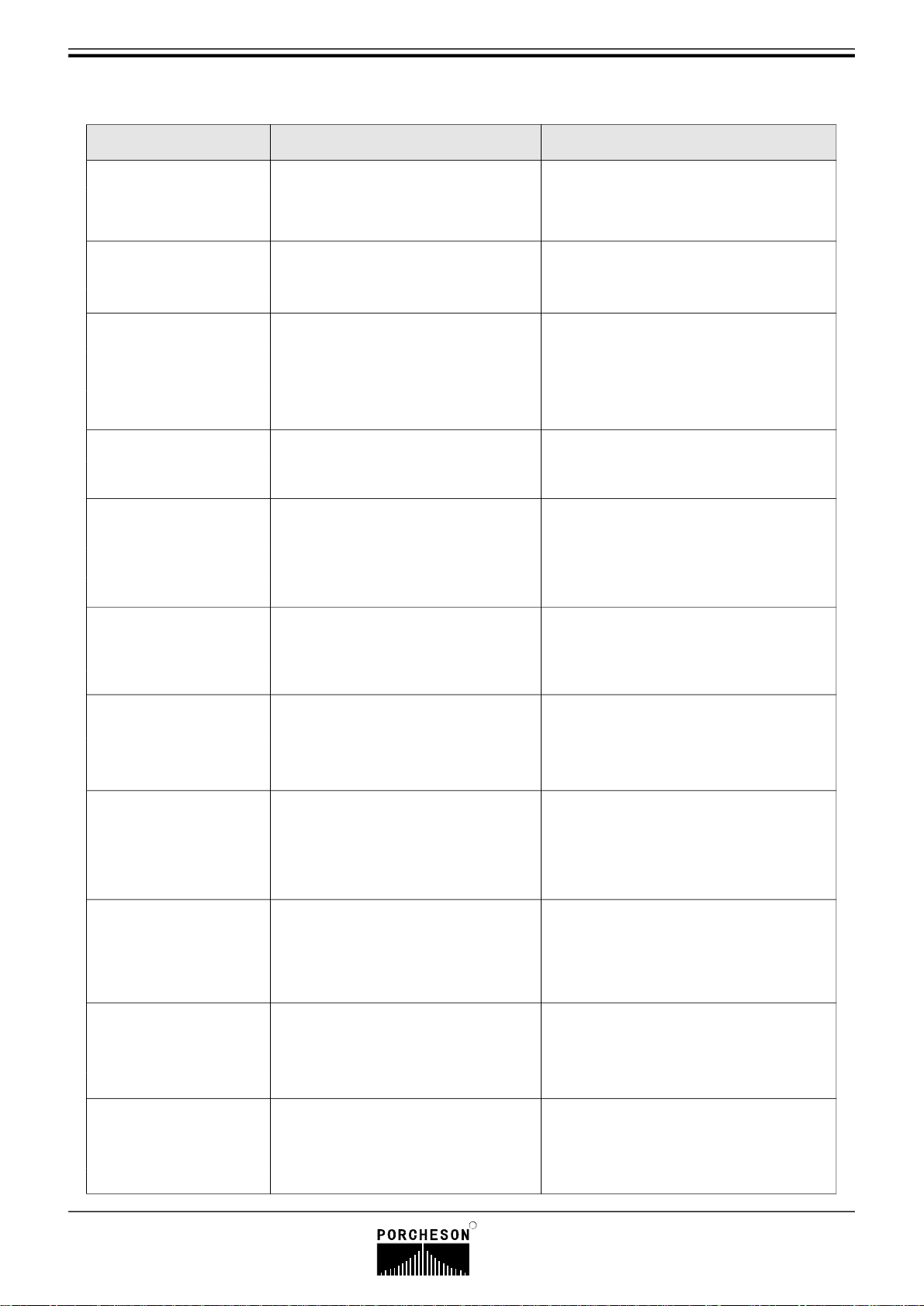

2.ExplanationoftheFunctionalKeys

KeysUsage

开锁模

M.PLT

射胶

INJECTION

熔胶

FEEDING

/调模

射台

NOZZ/ADJ.

/抽芯

顶针

EJE/CORE

时间

TIME

Enterintothescreentosetthemoldopening&lockingmovement

EnterintothescreentosettheGlueShotandpressure-preserving

movement

Enterintothescreentosetthefeeding,gluetakingandautomatic

materialremovalmovement

Enterintothescreentosetthenozzleandmodeladjustment

Enterintothescreentosetejector,self-pluggingandhuff.

Enterintothescreentosettimingandcounting.

温度

TEMP.

资料

DATUM

监视

MONITOR

帮助

HELP

Enterintothescreentosettemperatureandpre-heating.

Enterintothescreentosetthechangestomoldandproduction

facilities.

Returntothemonitorscreeninanytime.

Theon-linehelpscreenuponenteringintothecurrentstate.

R

10

Chapter2ExplanationoftheKeyOperations

User'sManualforBK108V2.0

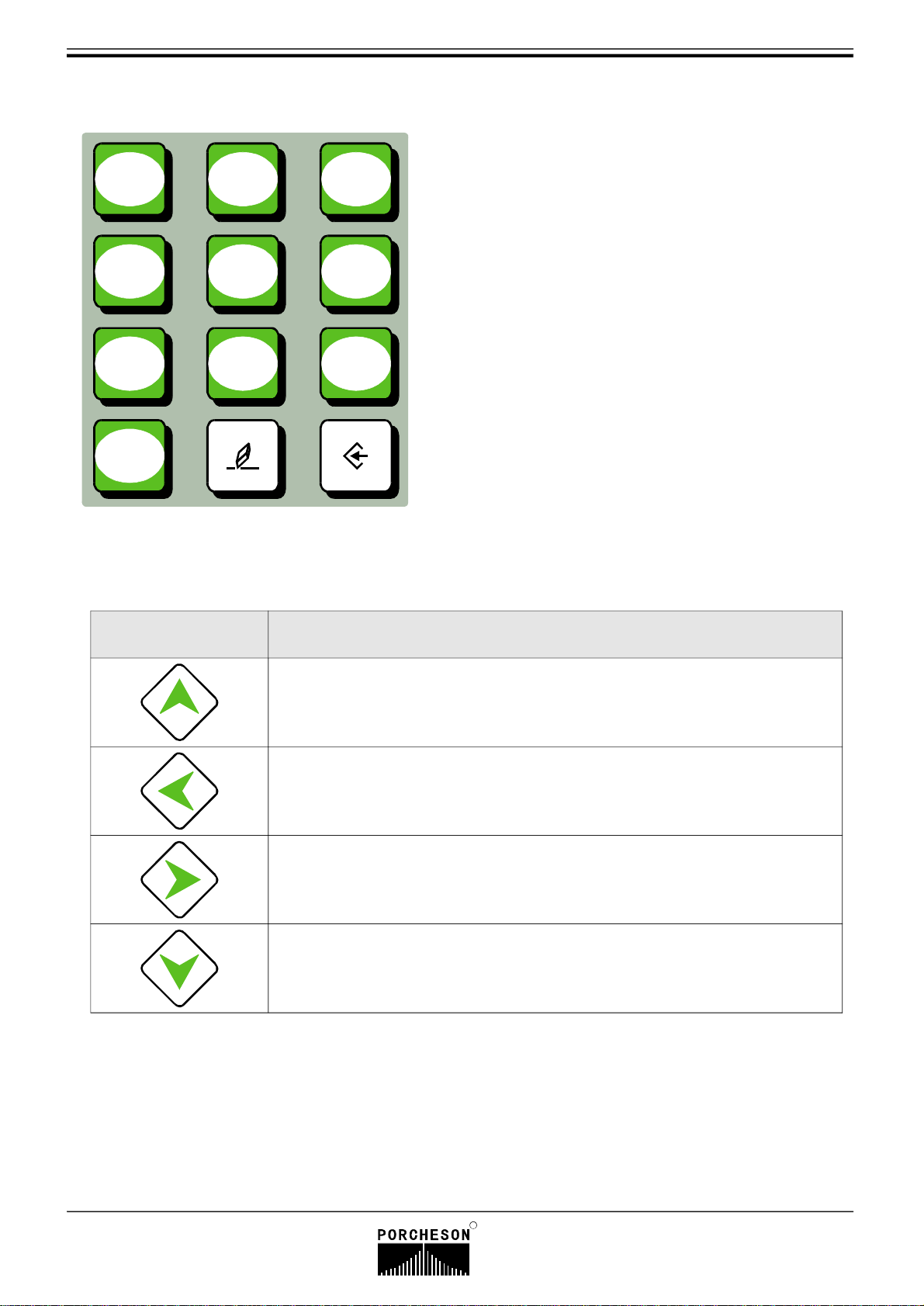

3.ExplanationoftheParameterSetting

ABC

7

45

JKLMNOPQR

12

STUVWX

[]/-.

0

89

DEF

清除

CLEAR

4.CursorKey

KeysUsage

GHI

settingscreen.WhentheelectriclockisinOFFstate,

thesetennumbersarelockedtoensurethedatawillnot

6

3

YZ

输入

ENTER

bechangedarbitrarily.Inthemeanwhile,thereare26

Englishlettersandspecialsymbolsrespectivelyon0-1

numerickeysusedfortheinputofChineseandEnglish

lettersaswellasthemachineserialnumber.[DELETE]

keyisusedtodeletetheerrorwordsduringenteringthe

parametersandserialnumbers.[INPUT]keyisusedto

selectthefunctionsduringfunctionselectionandusedto

confirmduringitemconfirmation.

0-9numerickeysareusedfordatainputinthedata

“”

Skipkey,pressingitwillskipthecursortotheupperline

Escapekey,pressingitwillmovethecursortotheleft

Escapekey,pressingitwillmovethecursortotheright

Skipkey,pressingitwillskipthecursortothelowerline

R

11

Chapter2ExplanationoftheKeyOperations

User'sManualforBK108V2.0

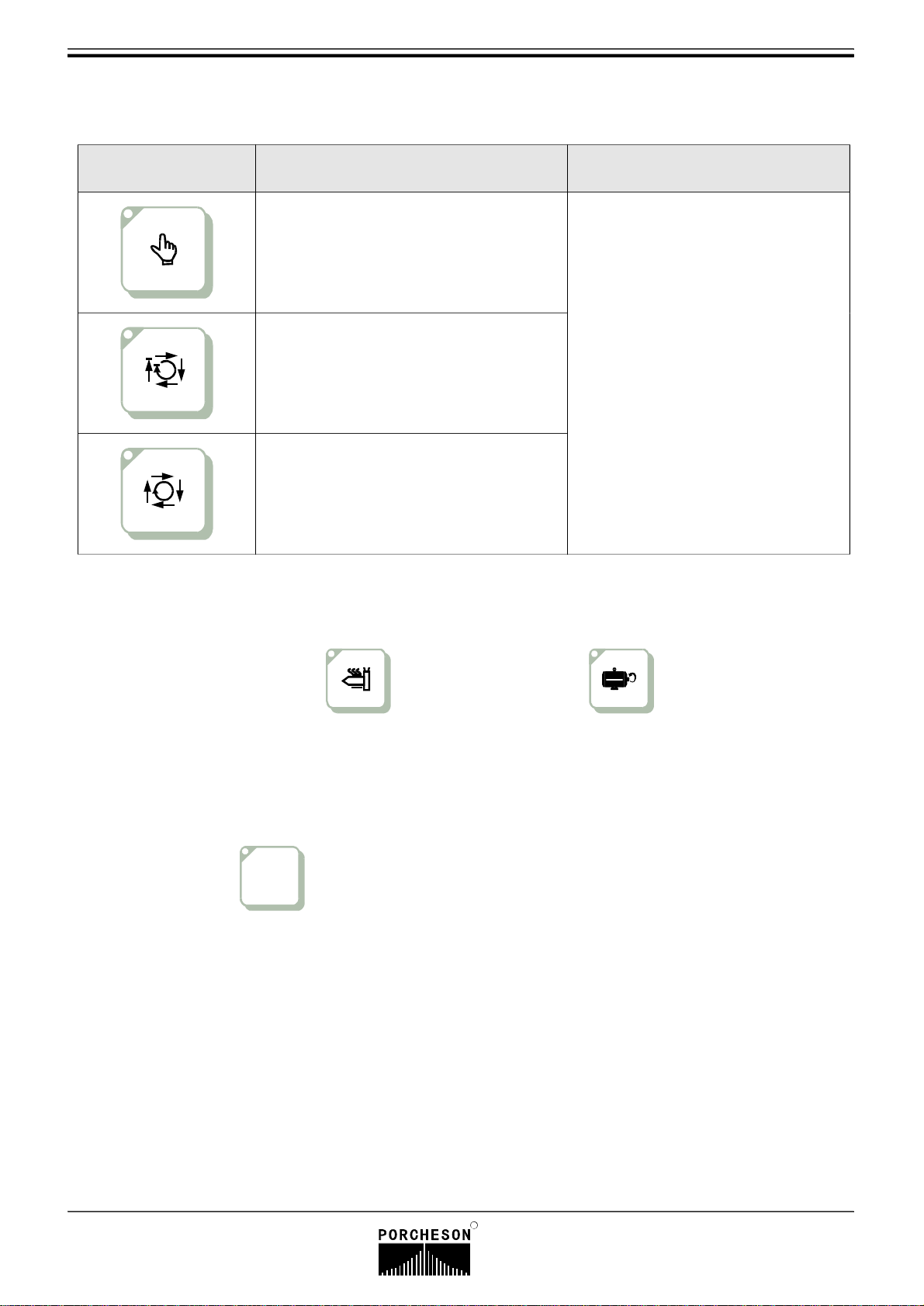

5.OperationModeSelectionKey

KeysUsage

手动

Pressingthiskeywillenterthesystem

MANUAL

半自动

intomanualstate.

Pressingthiskeywillenterthesystem

intosemi-automaticoperation

SEMI.AUTO

全自动

Pressingthiskeywillenterthesystem

intoautomaticoperation

AUTO

Remarks

Thereisanindicatorontheleftupp

erofallkeys.Pressinganykeywill

turnonthisindicator,indicatingthe

systemisinthisstate.Everytimethe

computerisstarted,thedefaultstate

ofsystemismanualoperation.In

caseofthetemperaturehasnotreach

edthesetvalue,thesystemisimposs

ibletoperformsemi-automaticand

automaticoperations.Theindicator

willnotturnonwhenthesemi-autom

atic/automaticoperationkeypressed

tillthetemperaturereachestheset

value.

电热开/关

马达开/关

6.ElectrothermalON/OFFkeyandMotorON/OFFkey

HEATERON/OFF

MOTORON/OFF

Inthemanualmode,pressthekeyonceandtheindicatorattheleftupperwillturnon,indicatingthe

functionstatehasopened.Pressingthekeyagainandthisindicatorwillturnoff,indicatingthefunction

statehasshutoff.Repeatedlypressingthiskey,thefunctionswillturnonoroffinturn.Uponthe

emergencyswitchstops,themotorwillpoweroffswiftlywithoutaffectingtheelectrothermaloperation.

紧急复位

7.EmergencyResetKey

RESET

Inanymoment,pressingthekeyonceandtheindicatorattheleftupperwillturnon,thesystemwill

skipbacktothemanualmodeandsimultaneouslyterminalallmovementoutputswithoutaffectingthe

moteandelectrothermaloperation.Thiskeyisalsousedtoreleasethekeyincaseofalarmforabnormal

conditions.

R

12

Chapter2ExplanationoftheKeyOperations

User'sManualforBK108V2.0

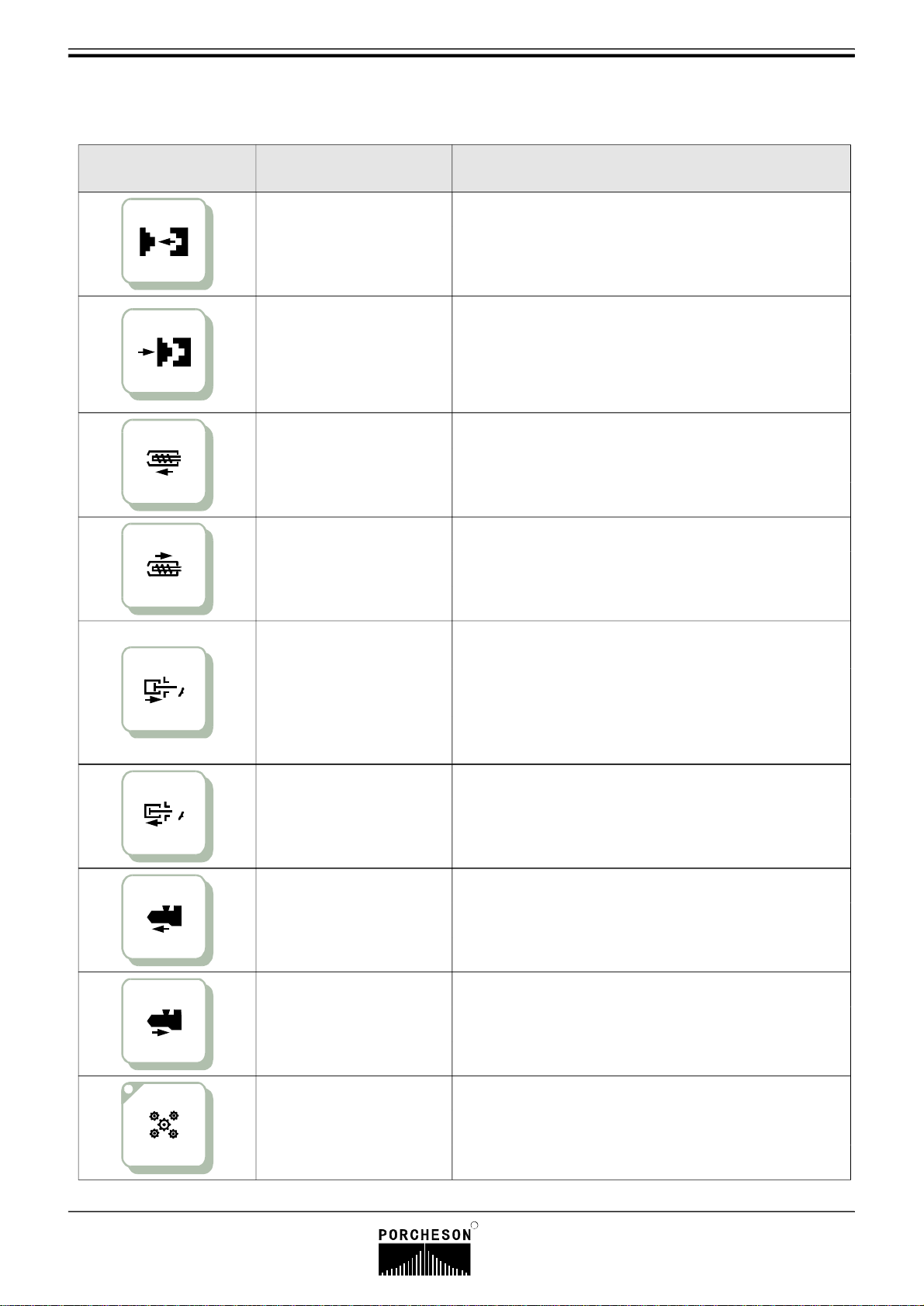

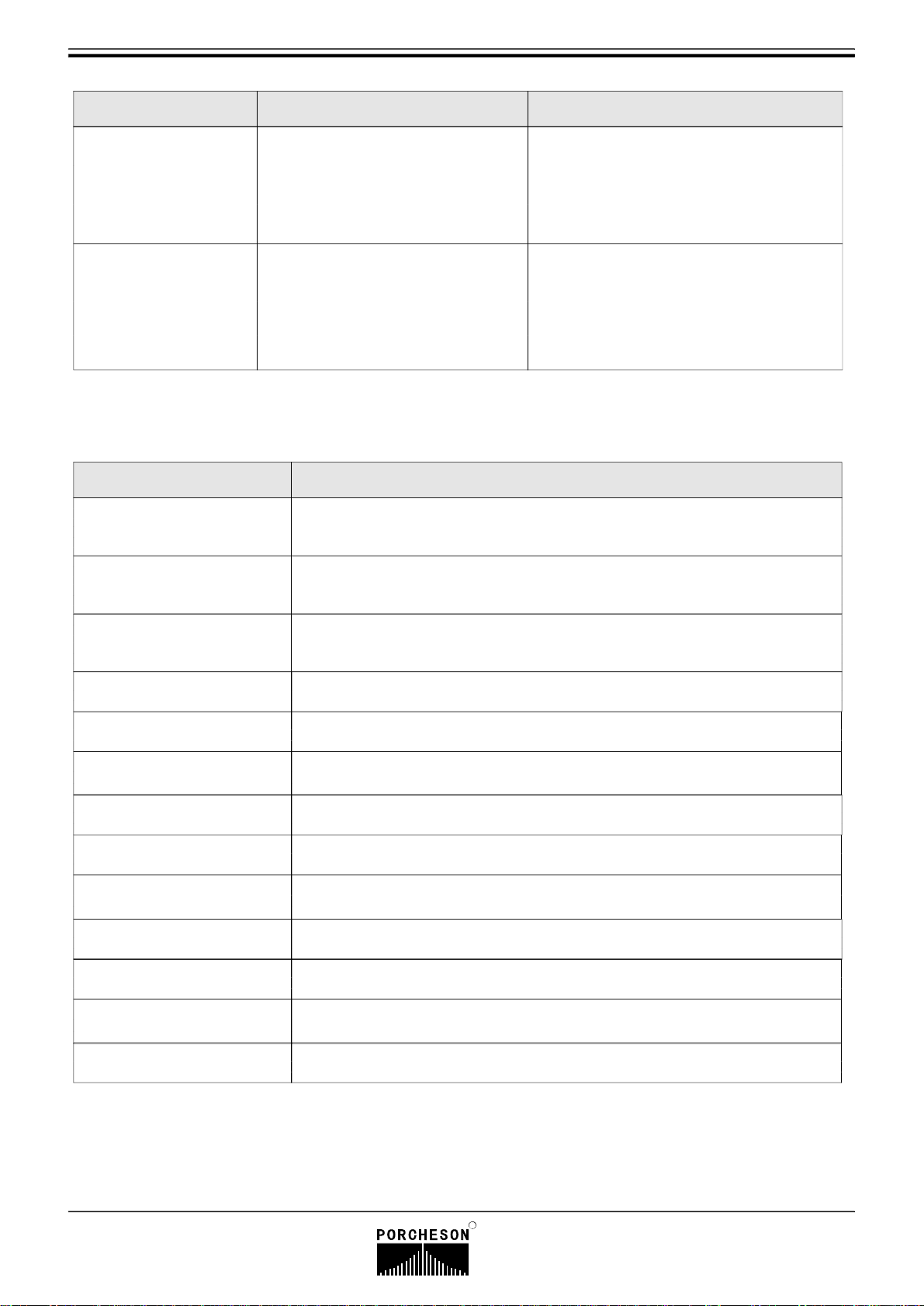

8.ManualOperationKeys

KeysUsage

开模

Model-opening

operations1

MOLDOPEN

锁模

Mold-locking

operating

MOLDCLOSE

射胶

GlueShotOperation1

INJECTION

抽胶

抽胶操作

DECOMP

OperationConditions

1.Themodelhasnotopenedtothetermination

position.

1.Normalsafetydoorinput;

2.Ejectorretractstillbumping;

3.Moldhasnotlockedtotheterminationposition;

4.Thesignals(mold-locking)ofrobothandshave

beenconnectedwhentherobothandsareselected.

1.Incaseoftimeglueshotselected,theinjection

timehasnotcompleted;

2.Incaseofthepositionselected,ithasnotreached

theglue-shotterminationposition;

3.Temperatureswithinallsectionsofmaterial

canistershallnotexceedtheleewayscope(without

temperaturealarm)

1.Temperatureswithinallsectionsofmaterialcanister

shallnotexceedtheleewayscope(withouttemper

aturealarm)

顶进

EJECTADV

顶退

EJECTRET

座进

NOZZLEADV

座退

NOZZLERET

Ejectionadvance

operation1

Liftoffoperation

Nozzleadvance

operation

Nozzlebackward

operation

1.Thetravelofejectionadvancehasnotcometothe

terminationposition;

2.Themoldhasopenedtotheterminationposition.

3.Theself-pluggingpositionlimithasconnectedor

theself-pluggingtimehascomewhenself-plugging

isselected.

4.Thesignals(ejectionadvance)ofrobothandshave

beenconnectedwhentherobothandsareselected.

1.Thetravelofliftoffhasnotcometothetermination

position;

2.Themoldhasopenedtotheterminationposition.

1Nocondition;、

1Nocondition;、

调模

Mold-adjusting

MOLDADJ.

Selection

1.Whenthesystemisinmanualstate,pressthiskey

andtheindicatorwillturnon,enablingthemanual

Mold-adjustingorpress+automaticMold-adjusting

keyforautomaticMold-adjusting.Otheroperating

keyswillnotwork.

R

13

Chapter2ExplanationoftheKeyOperations

User'sManualforBK108V2.0

KeysUsage

OperationConditions

慢速

SLOW

熔胶

FEEDING

自动清料

AUTOPURGE

多次顶针

EJECTOR

润滑

LUBRICATE

SlowState

FeedingOperation

AutomaticMaterialRem

ovalOperation

SeveralItemsOperation

LubricatingPumpWork

1.Afterthiskeyispressedandperformingthem

old-opening/lockingoperation,allflowsaresetin

slowspeed.

1.Feedinghasnotcometotheterminationposition;

2.Temperatureswithinallsectionsofmaterial

canistershallnotexceedtheleewayscope(without

temperaturealarm)

1.Selectionanduseofautomaticmaterialremoval;

2.Timesofautomaticmaterialremovalnotcompleted;

3.Temperatureswithinallsectionsofmaterialcanister

shallnotexceedtheleewayscope(withouttemper

aturealarm)

1.Theoperatingconditionsarethesameasthosefor

ejectionadvanceandliftoff;

2.Thetimeofejectorsettinghasnotcompleted.

1Nocondition;、

公模吹气

BLOWMALE

母模吹气

BLOWFEMALE

自动调模

AUTOMOLDADJ.

调模退

MOLDTHICK

调模进

MOLDTHIN

MaleMoldHuff

Operation

FemaleMoldHuff

Operation

AutomaticMoldAdjustingFlow

Mold-Adjusting

BackwardOperation

Mold-Adjusting

ForwardOperation

1.Selectionandusageofmalemoldhuff;

2.Thetimeofmalemoldhuffhasnotcompleted.

1.Selectionandusageoffemalemoldhuff;

2.Thetimeoffemalemoldhuffhasnotcompleted

1.Manualmold-adjustingkeyhasbeenselected;

2.Automaticmold-adjustingkeyfunctionhasbeen

selected.

1.Toselectthemold-adjustingusestate;

2.Themold-adjustingretracthasnotcometothe

terminationposition.

1.

Toselectthemold-adjustingusestate;

2.

Themold-adjustingadvancehasnotcome

totheterminationposition.

R

14

Chapter2ExplanationoftheKeyOperations

User'sManualforBK108V2.0

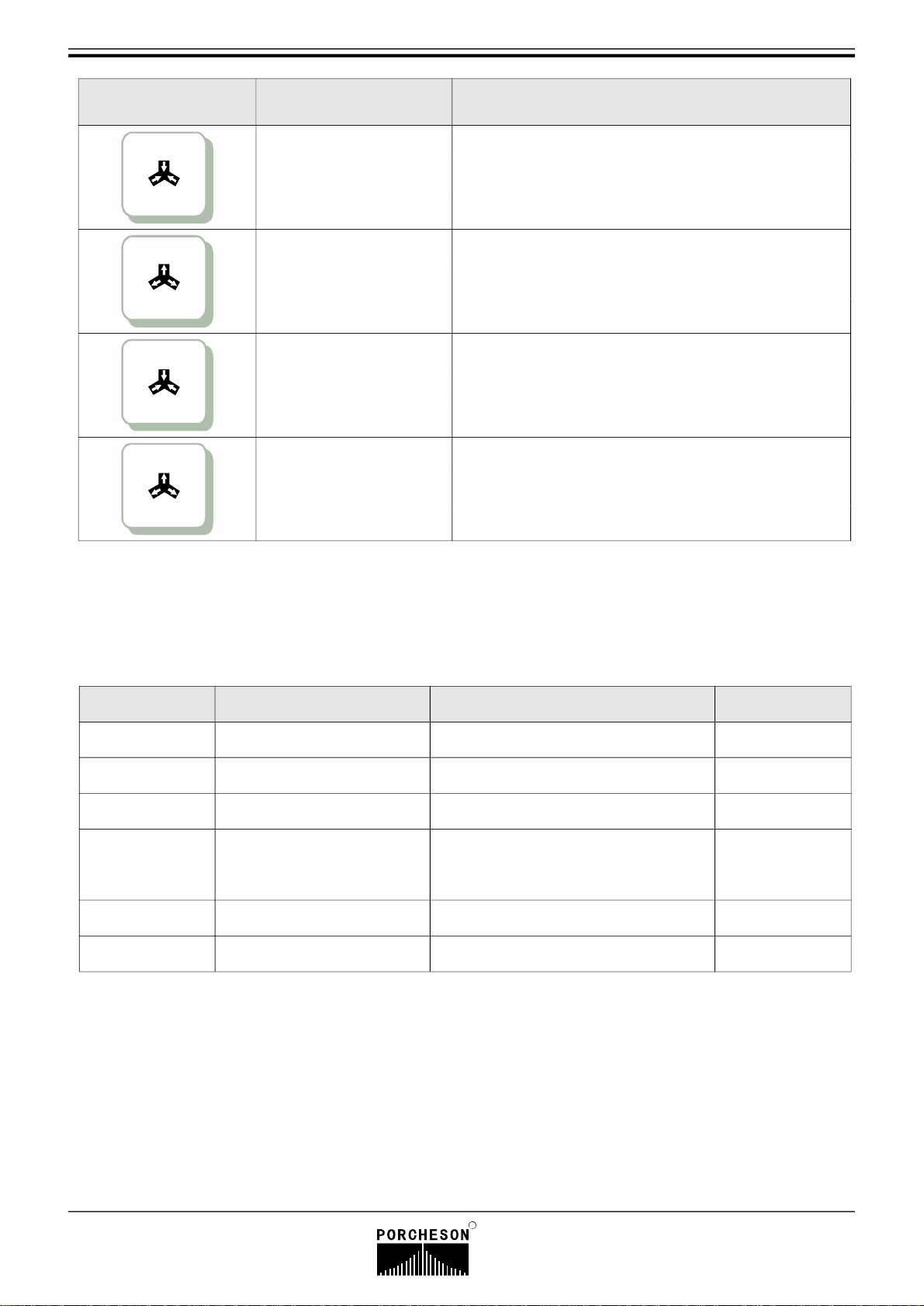

KeysUsage

OperationConditions

入芯A

COREAIN

A

出芯

COREAOUT

B

入芯

COREBIN

B

出芯

COREBOUT

Chip-insertion

OperationA

Chip-Extraction

OperationA

Chip-insertion

OperationB

Chip-Extraction

OperationB

1.SelectionandusageofSelf-pluggingA;

2.Chip-insertionAhasnotcometothetermination

positionorthetimehasnotcompleted;

3.Liftoffhasreachesitspositionortheliftofftime

hascome.

1.SelectionandusageofSelf-pluggingA;

2.Chip-insertionAhasnotcometothetermination

positionorthetimehasnotcompleted;

3.Liftoffhasreachesitspositionorthe

liftofftimehascome.

1.SelectionandusageofSelf-pluggingB;

2.Chip-insertionBhasnotcometothetermination

positionorthetimehasnotcompleted;

3.Liftoffhasreachesitspositionortheliftofftime

hascome.

1.SelectionandusageofSelf-pluggingB;

2.Chip-insertionBhasnotcometothetermination

positionorthetimehasnotcompleted;

3.Liftoffhasreachesitspositionortheliftofftime

hascome.

9.SettingScopeofNumericItems

Number

1

2

3

4

5

6

Incaseofthesetvaluesexceedtheabove-mentionedscopes,thesystemwillnotacceptthenumbers

setandkeeptheoriginalsetvalues.Forthehabitofdatainput,thedatainputofthissystemisdisplay

fromrighttoleft.

SettingItemsSettingScope

TimeSetting

PressureSetting

SpeedSetting

TemperatureSetting

StorageofMoldData

PredictedTurnout

Digital

Digital

Digital

Digital999Maximum630Cfor

actualuseCentigrade

Digital80

Digital

≤999.9

≤140

≤99

≤

≤

≤999999

Unit

Second

Bar

%

0

℃

Number

PC

R

15

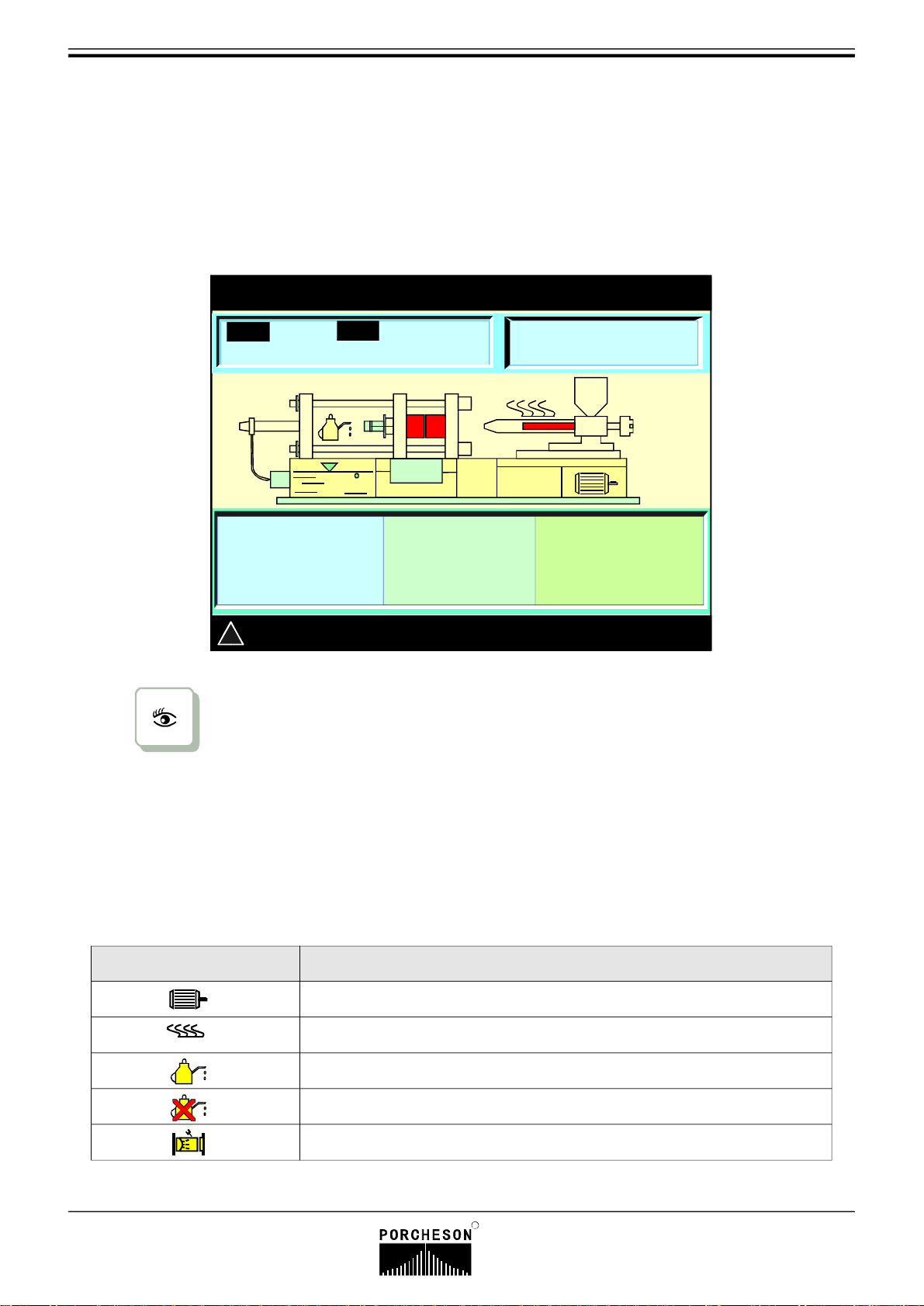

Chapter3:Descriptionsonsettingparameters/functions

Chapter3:Descriptionsonsettingparameters/functions

User'sManualforBK108V2.0

1.TheMainControlpanelwhileturningon

Connectwithpower,turntheredurgentstopswitches,theoperationlightofthecomputer-RUN

-flickers,thefollowingmenushownonthedisplay,nowthecontrolsystemisrunninganditisreadyto

operatethemachine.

2001.08.18

EJEC

228

1SEG

218

2SEG

208

*Manual*

198

4SEG

200

3SEG

MldNo.:68

G-6018汽车杯外壳

20:38:08

000r

28C

Mold:

Scrw:

Ejct

!

监视

Presskeyatanytimeafterre-turningonthecomputer,andthenenterthemenuofthemonitor

MONITOR

659.5

258.2

:

35.6

mm

mm

mm

Pres

Flux

Ylds

Machinerunwell

:

:

:

268899

PS800

00bar

00

%

Set :

Oprt

:

Cycl:

READY

000.0s

000.0s

009.5s

menuofthemachine.Thismenuisformonitoringtemperatureandmachinerunningcondition.Thenames

andnumbersofthemouldswillbesetinmouldinformationmenu.Thetemperaturescaleandcurrentoil

temperatureshowtherealvalueofeachstagethusitsinformationcannotbemodified.Eachfunctionofthe

menusisdescribedasfollows:

Thedescriptionsonmode:

Mode

Motorisrunning

Electricalheatingopened

Lubricatorislubricating.

LubricationfailingorNotreleased

Electroniceyefunction

Meanings

R

16

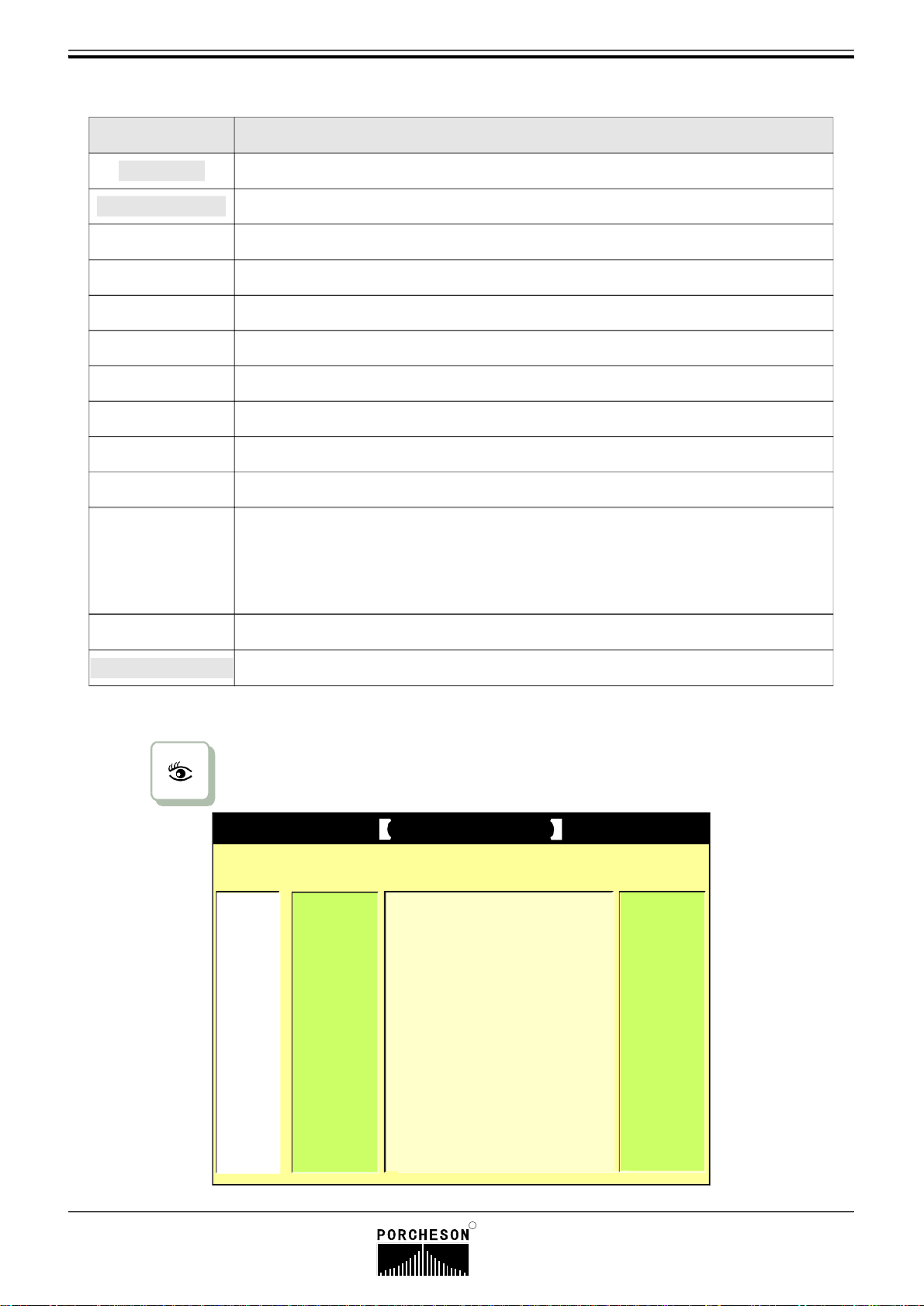

Chapter3:Descriptionsonsettingparameters/functions

User'sManualforBK108V2.0

Thedescriptionsondisplay:

Display

Manual

InjectionNozzle

Mouldnumber

Movablemould

Screw

Thimble

Pressure

Flux

Output

Set

Operation

Meaningsanddescriptions

表 示意义及说明

Therunningmodeofthemachine;

Thissectionisheating;

Thecurrentmouldnumber;

Showsthecurrentpositionofthemould.Theunit:mm;

Showsthecurrentpositionofthescrew.Theunit:mm;

Showsthecurrentpositionofthethimble.Theunit:mm;

Thesetpressurevalueofthecurrentmovement;

Thesetfluxvalueofthecurrentmovement;

Recordthenumbersofmouldopeningforcurrentmouldnumberduringthe

automaticoperationofthesystem;

Thetimevalueandcounterdataofthecurrentmovement;

Whenatimevaluesetforcurrentmovement,onlytheoperationtimeincrease

tothesettime,thenextmovementstarts.Whenitisthenumberwasset,the

actednumberswillbeshownonthedisplaytillthenumbersreachthesetcounter

date.

;

Wholeprocess

Inlowtemperature

监视

Re-presskeytoshowthefollowingmenus

MONITOR

Therealoperationcycletimeofthesystem;

Thecurrentalarmcontentsofthedisplay;

2003.01.06

Date

Happen

01日 10:03

01日 12

:08

01日 15:16

01日 15

:17

01日 15:18

01日 15:19

01日 15:20

01日 15

:21

01日 15:22

01日 15

:23

Alarmnote

Alarm content

Abnormalsensors

Clampingmouldnotcompletedontime

Plasticmeltingnotcompletedontime

Failureofmouldreleasing

Mouldopeningnotfixedontime.

Mouldopeningnotfixed

Failureofmanipulator

Failureofmotor

Endofthecycletime

Scheduledmouldopening

10:07:12

Unchain

10:03

12:08

15:16

15:17

15:18

15:19

15:20

15:21

15:22

15:23

R

17

Chapter3:Descriptionsonsettingparameters/functions

User'sManualforBK108V2.0

Descriptionsonalarmmode

Alarm

Exitsunclosed

OpenExits

Failureofsensor

inspection

Mouldopening

notfixed

Clampingmouldnot

fixedontime

Source

Themodelockingstopsandxits

unclosedshowedifyouoperate

modelockingwhileexitsunclosed

InSemiautomode,theexits

remainunopenedwhileasingle

cycleended

Inautomaticoperation,whenthe

inspectingsensorisnotON

afterthimblewithdrawinginsensor

cyclingmodeandthemid-timeis

over,itwarnsFailureofsensor

inspection

Whenejectforwardmanually,the

mouldopeningnotreachtheposition

ofstoppingmouldopening;

Clampingmouldnotcompleted

withinthetimelimitationofthe

mouldopeningorclosing

”

“”

;

“

”;

“

“

“”

;

”

Solution

Checkiftheswitchesofthefrontand

rearexitsarecorrectlyconnectedwith

inputinterfaceofX00andX15and

;

checkiftheycanbepressednormally.

Opentheexits,takeouttheproducts,

closeexitsandthancontinuethe

processing。

RemovethefailureofEjectingforward

andEjectingbackwardandjudgeif

thereareanylongcover.Theconnection

linesandthesensoritselfshouldbe

mainlyinspectedwhenthelightofX20

inputpointalwaysshines.

Re-openorcheckifthemouldopening

terminationX12hasbeenputthrough。

Checktheclampingmouldprocess,

extendproperlythetimelimitation

ofthemouldopeningorclamping

ifitisnormal.

“

”

Lowpressuremould

protectingtimeisover

FailureofExit

Plasticmeltingnot

completedontime

Failureofplastic

injection

Failureofmotor

Itwillwarnifithasnotturnedinto

highpressurewhenthelow-pressure

timeisover.

Alarmwhenthereisonlyonepress

inX00andX15;

Plasticmeltingnotcompletedwithin

thetimelimitationofplastic

“

melting

Theplasticinjectiontestingstroke

switchesX20hasnotbeenpressed

ortheelectronicrulerhasnot

reachedtheplasticinjectiontesting

pointduringplasticinjection.

Alarmwhensignalinputsmotor

protectionpointX27.

”;

Checkthemould,extendproperly

helowpressuretimeifthereis

“”

notanyredundantobjects.

Checkiftheswitchesofthefrontand

rearexitsarecorrectlyconnectedwith

inputinterfaceofX00andX15and

checkiftheycanbepressednormally.

Checktheplasticmeltingprocessand

findoutiftheplasticinplasticdrum

hasbeenrunout.Extendproperly

thetimelimitationofplasticmelting

“”

ifitisnormal.

Checkplasticinjectionprocessand

adjustthedeviationvalueofplastic

injectiontesting;(e.g.:stroke).Strap

inputinterfaceX20oncommon

interface(XCOM)whennottest

plasticinjection.

Checkifthereisaprotectionontheoil

hydraulicmotorcausedbyrelay

againstoverload.

Cycletimeisover

WhenAutoproductioncycletime

islongerthanset[cycletime]

Checktheautoproductionprocess,

extendproperlytheset[cycletime]if

itisnormal.

R

18

Chapter3:Descriptionsonsettingparameters/functions

User'sManualforBK108V2.0

Alarm

SourceSolution

KnockoutcoreAnot

completed.

KnockoutcoreBnot

completed.

Thesetoutputreached

Machinehaschosenknockoutcore

AandB.Itrequiresthattheknockout

spaceoftheknockoutcoremusthave

beenconnectedwhenejectforward

ormulti-ejectforward

Themachinestopswhentheoutput

stoppingmachinefunctionstartedor

thenumbersofmouldopeninghave

reachedthesetoutputnumber.

;

Descriptionsonoperation/promptmode

Alarm

Hightemperaturein1,2,3,

4,5stagesInjectionnuzzle.

Lowtemperaturein1,2,3,

4,5stagesInjectionnuzzle.

Therealtemperaturerelatedtothestageofthemachinehopperishigher

thanthesettoplimitedvalue.

Therealtemperaturerelatedtothestageofthemachinehopperishigher

thanthesettoplimitedvalue.

Checkifthestopswitchesoftheknockout

coreAandBareconnectedcorrectlyand

iftheycanbepressednormally.Setastop

modeinfunctionmenuforknockoutcore

AandBwhenyoudonotusetheknockout

corefunction.

Solution:Ifyouneedthemachinecontinues

runningaftertheoutputreached,justsetthe

[stopafteralarm]inproductionmenuas

[out];orresetthetotalmouldopeningofthe

currentmouldnumber.

Source

Temperatureshortcircuitn

1,2,3,4,5stagesInjection

nuzzle

Autostuffclearingup

completed

Automouldadjusting

completed

Automouldadjusting

notcompleted

Entermanualmodefirst

Functionsnotselected

Startmotor

NextcyclePrepared

Sensorprepared

Exitmouldadjusting

modefirst

Entermouldadjusting

modefirst

Therealtemperaturerelatedtothestageofthemachinehopperishigher

thanthesettoplimitedvalue.

Afterthesetnumbermovementcompletedandwhileautostuffclearing

up.

Automouldadjustingcompletedwhenusingmouldautoadjusting.

Automouldadjustingnotcompletedwhenusingmouldautoadjusting.

Whenoperatemanualkeysinautomode.

Certainfunctionhasnotbeenselectedwhenmanualoperateitskeys.

Howtoselectmotor:Promptwhenthesemi-auto/autokeysarepressed,

asthemotorhasnotbeenstarted.

Inautomode,themid-timebetweencompletingacycleandstarting

nextcycle.

Themid-timehasnotbeenreachedafterwithdrawingthimblesduring

autosensorcycling.

Whenoperatenon-[adjustforward,backwardandautomouldadjusting]

keysinmouldadjustingmode.

Whenoperate[adjustforward,backwardandautomouldadjusting]keys

innon-mould-adjustingmode.

R

19

Loading...

Loading...