Renegade 26cc Line Trimmer

Model Numbers: 101PLT25FC

101PLT25FCB

Operator’s Manual

WARNING

To reduce the risk of injury, the user must read and understand the Operator’s

Manual. Save this manual.

Before you use your new Line Trimmer read this manual carefully to learn how to

operate and maintain your product correctly. Reading this manual will help you and

others avoid personal injury and damage to the product. Although Pope designs

safe state-of-the-art products, you are responsible for using the product properly and

safely. You are also responsible for training persons you allow to use the product

about safe operation.

READ THIS INFORMATION

Introduction

Thank you for purchasing a Pope® product.

We would like you to be completely satisfi ed with your new product, so feel free to contact an authorised

service dealer for help with service, genuine Pope parts or other information you may require. Or phone

the Pope Customer Service Centre for details of your nearest dealer on 1300 134 880.

The Pope warning system in this manual identifi es potential hazards and special safety messages that help

you and others avoid personal injury, even death. DANGER, WARNING and CAUTION are signal words

that identify the level of hazard. However, regardless of the hazard, be extremely careful. Two other words

“Important” and “Note” highlight other valuable information.

Signal Word Explanation

DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death

or serious injury.

WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION Indicates a potentially hazardous situation which, if not avoided, could result in death

or serious injury.

Important Advises you of important information or instructions vital to the operation or

maintenance of the equipment.

Note Advises you of additional information concerning the operation or maintenance

of the equipment.

STOP

Contents

Safety Rules ................................................................................................................. 4

Symbols ........................................................................................................................ 5

Specifi cations .............................................................................................................. 6

Applications ................................................................................................................. 7

Features ......................................................................................................................... 7

Unpacking .................................................................................................................... 8

Assembly ...................................................................................................................... 9

Attaching the Upper Shaft with Engine to the Lower Bent Shaft Cutting Head 9

Attaching the Front Handle 9

Attaching the Grass Defl ector Shield 10

Fitting the Carry Strap 10

Operations .................................................................................................................... 11

Before you Start the Trimmer 11

Mixing the Fuel 11

Filling the Tank 11

Starting the Engine 12

To Start a Cold Engine 12

To Start a Warm Engine 12

Starting a Flooded Engine 12

Operating the Engine 13

To Advance the Cutting Line 14

To Advance the Cutting Line Manually 14

Grass Defl ector Line Trimming Cut-Off Blade 14

Maintenance ................................................................................................................. 14

Emissions Maintenance Schedule 14

Cleaning the Product 14

Replacing and Cleaning the Air Filter 15

Spark Plug 15

Replacing the Cutting Line 15

To Store the Product Long Term 16

Troubleshooting ........................................................................................................... 17

Warranty ....................................................................................................................... 18

Safety Rules

Physical Conditions of the Operator.• Do not

operate this product when tired, ill or under the

infl uence of alcohol, drugs or medication.

Clothing Requirements.• Always wear long

heavy pants, boots and gloves. Do not wear

loose clothing, jewellery , short pants, sandal or go

barefoot. Secure hair so that it is above shoulder

level to avoid entanglement in moving parts.

Protective Accessories Requirements.• Wear

safety eye protection when operating this product.

Wear hearing protection during extended periods

of operation.

C• ondition of Product before Use. Inspect the

product before each use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are

in place and secure. Replace cutting attachment

parts that are cracked, chipped or damaged in

any way. Make sure the cutting attachment is

properly installed and securely fastened. Be

sure the cutting attachment guard is properly

installed and in the position recommended by the

manufacturer. Use only fl exible, non-metallic line

recommended by the manufacturer. For example,

never use wire or wire rope, which can break off

and become a dangerous projectile.

Proper Stance• . Keep fi rm footings and balance.

Do not overreach. Keep the cutting attachment

below waist level. Keep all parts of your body

away from the rotating cutting attachment and hot

surfaces.

Exhaust Gases• . Never start or run the product

inside a closed room or building; breathing

exhaust fumes can cause illness or death.

Fuelling.• Mix and pour fuel outdoors where there

are no sparks or fl ames. Slowly remove the fuel

cap only after stopping the engine. Do not smoke

while fuelling or mixing fuel. Wipe spilled fuel from

the product. Move at least 9m from the fuelling

source and site before starting the engine.

Work Area.• Clear the area to be cut before each

use. Remove all objects such as rocks, broken

glass, nails, wire or string that can be thrown

or become entangled in the cutting attachment.

Clear the area of bystanders, pets and children.

At a minimum, keep all bystanders, pets and

children outside a 15m radius. Because there still

may be a risk to bystanders from thrown objects,

bystanders should be encouraged to wear eye

protection. If you are approached while operating

the product, stop the engine or for those products

equipped with a clutch be sure the cutting

attachment has stopped moving.

Dangerous Environments.• To avoid falling, do

not use the product in damp or wet locations.

Controlling the Product.• During carburettor

adjustments the cutting attachment may spin.

Therefore you should wear protective equipment

and observe all safety instructions when adjusting

the carburettor. Be sure the cutting head has

stopped rotating before setting down or adjusting

the product. Maintain proper control until the

cutting head has completed stopped rotating.

Use the Right Product. • Use the product for the

intended purposes only.

Read and understand all instructions. Failure to follow all instructions may result in serious personal injury

as well as damage to product.

WARNING

4

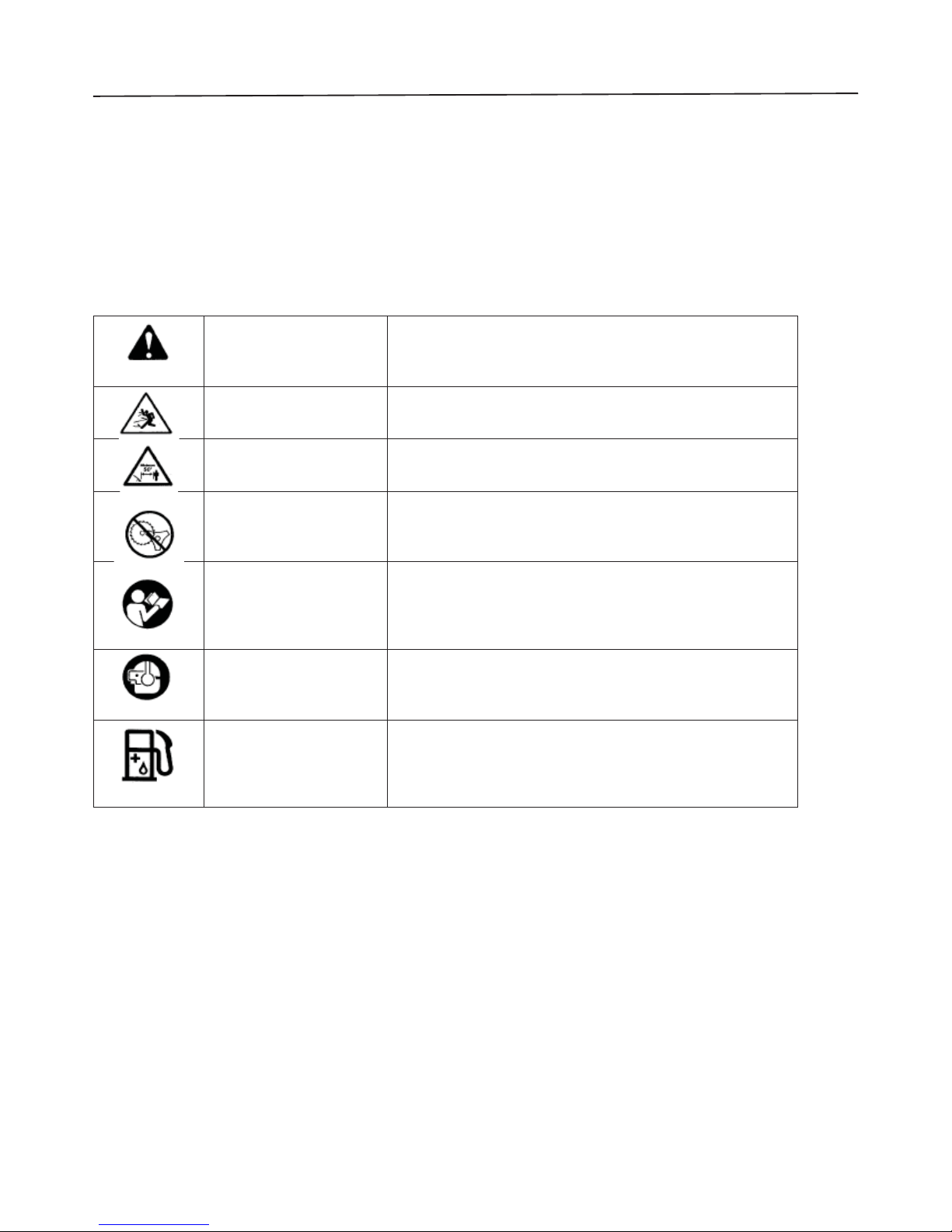

Symbols

The following symbols are located on the product. Please study them and learn their meaning. Proper interpretation

of these symbols allows you operate the product better and safer.

Symbol Name Explanation

Safety Alert Indicates danger, warning or caution. Attention is required

in order to avoid serious personal injury. May be used in

conjunction with other symbols or pictographs.

Thrown Objects Thrown objects can cause severe injury. Wear protective

clothing and boots.

Keep Bystanders Away Keep all bystanders, especially children and pets, at least 15

metres from the operating area.

No Blade Do not install any type of blade on Model No. 101PLT25FC.

Use only fl exible, non-metallic line recommended by the

manufacturer.

Read Operator’s

Manual

Read the Operator’s Manual before starting or operating

this product. Failure to follow operating instructions and

safety precautions in the Operator’s Manual can result in

serious injury.

Eye and Ear Protection Thrown objects can cause severe eye injury. Wear eye

protection when operating this product. Wear hearing

protection during extended periods of operation.

Petrol and Oil Use unleaded petrol intended for motor vehicle use with an

Octane rating of 87 ([R + M] / 2) or higher. This product is

powered by a 2 cycle engine and requires pre-mixing and 2

cycle oil.

5

Specifi cations

Model Numbers: 101PLT25FC Engine: 26cc Full Crank

101PLT25FCB

Cutting Diameter: 400 mm

Line Size: 2.00 mm

Weight (Dry): 5.1 kg

Fuel Tank Capacity: 0.5 Litres

Fuel Petrol/Oil Mix: 25:1

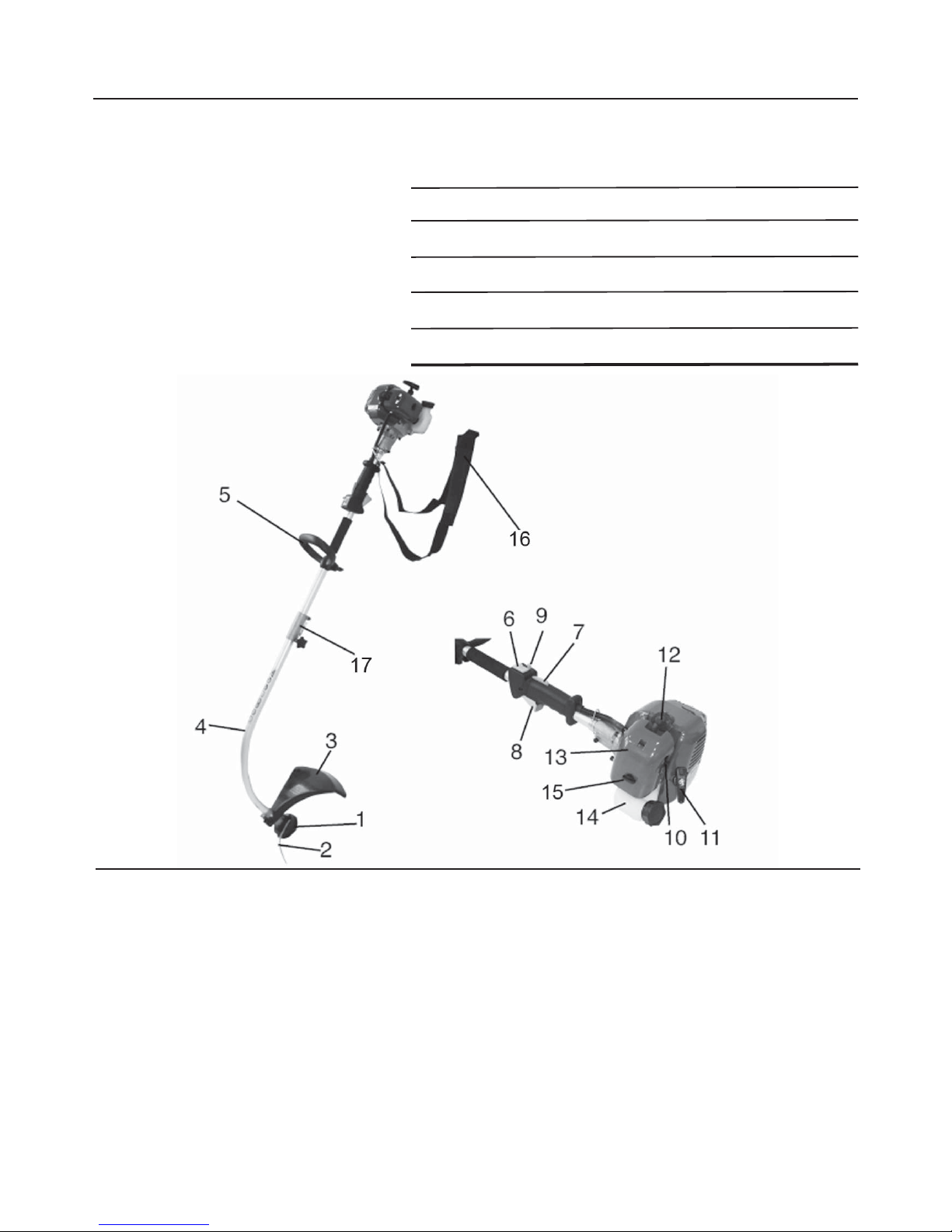

1. Line Trimmer Cutting Head

2. Cutting Line

3. Grass Defl ector Shield

4. Lower Bent Shaft

5. Front Handle

6. Engine On/Off Switch

7. Throttle Lever Release

8. Throttle Lever

9. Throttle Lock

10. Choke Lever

11. Starter Cord

12. Spark Plug Boot

13. Air Filter Housing Cover

14. Fuel Tank

15. Primer Bulb

16. Carry Strap

17. Shaft Connection Piece

6

Applications

Use this product for the following applications:

Cutting grass, weeds and light undergrowth•

Edging along sideways and driveways•

Do not attempt to use this product as a drive unit for other work tools or tool kits of any kind.•

Features

Exercise caution when using the product. Careless actions, for even a fraction of a second, can result in

serious personal injury.

Your new product is equipped with the following features:

Engine

The engine is powerful and easy to start. It is effectively counterbalanced, with a full crank which provides less

vibration and more durability.

Dual Line

The dual line permits more effi cient cutting than a single line.

Grass Defl ector

The grass defl ector helps protect you from fl ying debris. The defl ector also includes a cutting blade that

automatically trims the line to the correct length.

Ergonomic Handle Design

The design of the product provides for easy handling. It is designed for comfort and ease of grasp when

operating in different positions and at different angles.

WARNING:

Do not attempt to modify this product or create accessories not recommended for use with this product.

Any such alteration or modifi cation is misuse and could result in a hazardous condition leading to serious

personal injury and will void your guarantee.

WARNING:

7

Unpacking

Instructions

Carefully remove the product from the box•

Inspect the product carefully to make sure no breakage or damage occurred during shipping.•

Do not discard the packing material until you have carefully inspected and satisfactorily operated •

the product.

If any parts are damaged or missing, please call 1800 134 880.•

WARNING:

If any parts are missing, do not operate the product until the missing parts are replaced. Failure to do so could

result in serious personal injury.

Packing List

Renegade 26cc Line Trimmer

Model Numbers: 101PLT25FC

101PLT25FCB

Upper Shaft•

Lower Bent Shaft•

Grass Defl ector Shield•

Carry Strap•

Front Handle•

Operator’s Manual•

Tool Kit containing:•

Spark Plug Wrench, Tube Spanner with Phillips Head Screwdriver attachment (1)•

- Fuel Mixing Container (1)

- Allen Key (1)

8

Assembly

Attaching the Upper Shaft with Engine

to the Lower Bent Shaft Cutting Head

See Fig, 1, 2 and 3

Follow these steps to attach the two shafts together.

The lower bent shaft connects to the upper shaft with

engine by means of a coupler.

Loosen the knob on the coupler of the upper shaft 1.

(Fig. 1, Item 1).

Press the lever catch (Fig. 1, Item 2) and insert 2.

lower bent shaft into upper shaft with engine.

Ensure that the inner drive cable is seated by 3.

rotating cutting spool.

Ensure that the lug (Fig. 2, Item 6) is located in 4. the

hold in the lower shaft.

Retighten knob (Fig. 3)5.

To dismantle, use the steps above in reverse order.6.

Attaching the Front Handle

See Fig. 4, 5 and 6

Follow these steps to attach the front handle.

Loosen the wing nut on the fastening screw on the 1.

handle (Fig. 4, Item 1).

Remove the wing nut and the washer from the 2.

handle (Fig, 4, Item 2).

Remove the fastening screw from the handle (Fig. 3.

4, Item 3).

Push the front handle onto the upper shaft (Fig. 5).4.

Replace the fastening screw on the handle.5.

Replace the wing nut and the washer on the handle.6.

Tighten the wing nut (Fig. 6).7.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

9

Assembly

Attaching the Grass Defl ector Shield

See Figs. 7, 8 and 9

Follow these steps to attach the Grass Defl ector

Shield.

Using the Allen Key provided, loosen the 1.

fastening screw on the guard hood (Fig 7,

Item 1) and remove.

2.

Attach the grass shield to the base of the lower 3.

shaft (Fig. 8).

Screw the grass shield tightly in position with 4.

fastening screw (Fig. 9).

Fitting the Carry Strap

See Fig. 10

Follow these steps to fi t the carry strap.

The carry strap is intended to help you work safely and

ergonomically with your trimmer.

Hook the carry strap into the fastening eyelet (A).1.

Ensure the hook is securely fastened at the right 2.

operating height before attempting any work.

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Check that all moving parts operate smoothly

before you start your trimmer. Check that all

screws are securely fastened.

WARNING:

10

Operation

Before you start the Trimmer

Setting your cutting height

Slip the carry strap over the left shoulder.1.

Set the length of the carry strap in such a way 2.

that the cutting head runs parallel to the ground.

In order to establish the optimum length of the

carry strap you should make a few swinging

movements without starting the engine.

Always use the carry strap when using the

trimmer. Attach the strap as soon as you have

started the engine and the engine is running in

idle.

Switch off the engine before you take off the

carry strap.

WARNING:

Petrol is extremely flammable and explosive. A

fire or explosion from petrol will burn you and

others.

DANGER:

This product is powered by a two stroke engine and

requires pre-mixing petrol and 2 stroke oil. The oil

should be 25:1. Never mix petrol and oil directly in the

engine tank.

Use unleaded petrol intended for motor vehicle use with

an Octane rating of 87 ([R + M] /2) or higher. Purchase

fuel from a reputable fuel supplier.

Use an approved mixing container to mix the petrol and

oil in the correct quantities.

Petrol Oil

1 Litre 40 mL

2 Litres 80 mL

3 Litres 120 mL

4 Litres 160 mL

Mix only enough for your immediate needs. Fuel should

not be stored for more than 30 days.

Follow these steps to mix the fuel.

Use an approved mixing container for mixing fuel.1.

Mix the 2 stroke engine oil with unleaded petrol 2.

in the container provided at the rate of 25 parts

petrol to 1 part oil.

Mix the fuel thoroughly and also each time 3.

before re-fuelling.

Mix in small quantities. Do not mix more fuel 4.

than you expect to use within a 30 day period.

Store fuel only in a clean, safe, approved 5.

container for petrol.

Filling the Tank

Follow these steps to fi ll the tank

Always stop the engine before filling the tank.

Never add fuel to a machine with a running or

hot engine. Move at least 9 m away from the

re-fuelling site before starting the engine. Do

not smoke while filling the tank. Do not add

fuel to the tank close to an open fire or sparks.

Never add fuel to the tank in a closed or

non-ventilated area.

Clean the surface around the fuel thank to 1.

prevent contamination.

Loosen the fuel cap slowly and rest the cap on a 2.

clean surface.

Pour the fuel mixture carefully into the tank.3.

Clean and inspect the gasket. 4. Note: Replace the

fuel cap if the gasket is damaged.

Install the fuel cap and hand tighten.5.

Check for fuel leaks. If you find any leaks,

correct the problem before using the product.

WARNING:

Wipe spilled fuel from the product.6.

Move a least 9 metres away from tank re-fuelling 7.

site before starting the product.

Note: It is normal for the engine to emit smoke

during fi rst use.

Mixing the Fuel

WARNING:

11

25:1

Operation -

continued

Starting the product depends on whether the engine is

cold or warm.

The recoil starter can be damaged by abuse.

Never pull the starter cord to its full length.

Always engage the starter before cranking

the engine. Always rewind the starter cord

slowly.

WARNING:

Operating the machine with loose, missing or

damaged components could allow the engine

to over-speed, possibly causing serious

engine damage. Inspect the entire machine

for damage, loose or missing components or

fastenings and repair as necessary.

CAUTION:

A cutting blade on the underside of the grass

shield automatically cuts the cutting line to

the optimum length. This blade is covered by

a transport cover. Remove this cover before

you start working and replace it after you have

finished using the trimmer.

WARNING:

To Start a Cold Engine

Follow these steps to start a cold engine:

Lay the product on a fl at bare surface.1.

Set the choke lever to the full choke position.2.

Switch the ON/OFF switch to “I”.3.

Push the primer bulb approximately 10 times until 4.

fuel comes into the primer pump.

Using the throttle lock, set the throttle open.5.

To engage starter, hold the machine handle fi rmly 6.

with your right hand, pull the starter cord slowly until

you feel resistance.

Start the engine by pulling the starter cord upward 7.

rapidly . If necessary, repeat two or three times until

the engine starts.

Let it run for 10 seconds before moving the choke 8.

lever fully open.

Since the throttle has been secured in the open 9.

position the cutting head will start to rotate. To

release the throttle simply operate the throttle and

then by releasing it the throttle will return to idle.

Run the engine at idle speed until operating 10.

temperature is reached (2-3 minutes).

The machine should now be ready for use.11.

IMPORTANT: For maximum line trimmer performance

and operating life, allow engine to warm before use.

To Start a Warm Engine

Follow these steps to start a warm engine:

Lay the product on a fl at, bare surface.1.

Switch the ON/OFF switch to “I”.2.

Secure the throttle lever the same way as starting a 3.

cold engine.

Pull the starter cord until you fi nd resistance 4.

(engaging the starter cog) then pull sharply on the

starter.

Note:

If the product does not start, repeat the previous steps.

Check that the fuel tank has suffi cient fuel for the engine

to start or that the engine cooled suffi ciently to allow for

a “cold start”.

Starting a Flooded Engine

Disconnect the spark plug boot and use the spark 1.

plug wrench supplied to remove the plug in a

counter-clockwise direction.

If the spark plug is fouled or is soaked with fuel, 2.

clean or replace the plug as required.

Turn the product so that the spark plug hole is aimed 3.

at the ground.

Clear excess fuel from the combustion chamber by 4.

cranking the engine several times while the spark

plug is removed.

Install the spark plug fi rmly, tighten it with the spark 5.

plug wrench supplied. DO NOT OVERTIGHTEN.

Reconnect the spark plug boot.6.

Incorrect spark plug installation can result in

serious engine damage.

WARNING:

Starting the Engine

12

Operation -

continued

Operating the Trimmer

BEFORE EACH USE:

Remove dirt and debris from the product exterior.•

Inspect the engine, tank and hoses for possible •

fuel leaks and repair as necessary.

Inspect the engine cooling fi ns for accumulation of •

debris and clean as necessary.

Inspect the entire machine for damage, loose and •

missing components or fasteners and repair as

necessary.

To avoid burns from hot surfaces, never

operate unit with the bottom of the engine

above waist level.

WARNING:

Follow these steps to operate the Line Trimmer.

Start the trimmer.1.

Hold the trimmer at waist level with one hand 2.

on the trigger handle and the other hand on the

front handle.

Keep a fi rm grip with both hands while in operation.3.

Place the product on the right side of your body with 4.

the engine behind and away from your body.

Cut tall grass and weeds down in a right-to-left 5.

motion. This will prevent grass from wrapping

around the shaft housing and string head, which

may cause damage from overheating.

If grass becomes wrapped around the string head,

STOP THE ENGINE, disconnect the spark plug wire

and remove the grass.

Prolonged cutting at partial throttle will result in oil

dripping from the muffl er.

Cutting Tips

Keep the trimmer tilted toward the area being cut; 1.

this is the best cutting area.

The curved shaft trimmer cuts when passing the 2.

unit from right to left. This will avoid throwing debris

at the operator. Avoid cutting in the dangerous area

shown in Fig. 11.

Use the tip of the line to do the cutting; do not force 3.

line head into uncut grass.

Wire and picket fences cause extra line wear, even 4.

breakage. Stone and brick walls, curbs and wood

will wear the cutting line rapidly.

Avoid tree, shrubs, tree bark and wood mouldings.5.

Fig. 11

13

To Advance the Cutting Line

Follow these steps to advance the cutting line.

The cutting line is advanced by tapping the cutting head

on grass while running the engine at full throttle.

Run engine at full throttle.1.

Tap the spool retainer on ground to advance line. 2.

The line advances each time the spool retainer

is tapped.

NOTE: The line trimming cut-off blade on the grass

defl ector will cut the line to the correct length.

To Advance the Cutting Line Manually

Follow these steps to advance the cutting line manually .

Stop the engine.1.

Push the spool retainer down while pulling on the 2.

nylon line(s) to manually advance the line.

Grass Deflector Line Trimming Cut

Off Blade

The trimmer is equipped with a line trimming 1.

cut-off blade on the grass deflector.

For best cutting, advance line until it is trimmed 2.

to length by the cut-off blade.

Advance the line whenever you hear the engine 3.

running faster than normal, or when trimming

efficiency diminishes. This will maintain best

performance and keep the line long enough to

advance properly.

Operation -

continued

Maintenance

Emissions Maintenance Schedule

Maintenance, replacement or repair of the emission

control device and systems may be performed by any

recognised Toro or Pope Service Centre.

Before performing any maintenance on this

machine, stop the engine and disconnect the

spark plug wire.

WARNING:

Before Each Use

Remove dirt and debris from the product exterior.1.

Inspect the engine, tank and hoses for possible fuel 2.

leaks and repair as necessary.

Inspect the engine cooling fi ns for accumulation of 3.

debris and clean as necessary.

Inspect the entire machine for damage, loose 4.

or missing components or fasteners and repair as

necessary .

Cleaning the Product

Stop the product before cleaning.1.

Clean the exterior of the product with a damp cloth.2.

Avoid using solvents when cleaning plastic parts. 3.

Most plastics are susceptible to damage from

various types of commercial solvents and may be

damaged by their use.

Emission Part Inspect

Before

Each Use

Every

10

Hours

Every 10-

15 hours

or

Y early

Fuel Tank Assembly

(includes Fuel Line,

Fuel Cap and Fuel

Filter)

X

Clean Air Filter X X

Replace Spark Plug X

14

Maintenance -

continued

Replacing and Cleaning the Air Filter

Stop the engine.1.

Remove the spark plug boot from the spark plug.2.

Remove the air cleaner cover (Fig. 12).3.

Remove the air fi lter element (Fig. 13).4.

Inspect the element. If the element is distorted or 5.

damaged replace it with a new one.

Clean the air fi lter element by tapping it or by using 6.

compressed air.

Replace the fi lter.7.

Replace the air fi lter cover.8.

Tighten the air fi lter by turning the knob clockwise.9.

Replace the spark plug boot.10.

Spark Plug

This engine uses a NGK BPMR7A with an electrode

gap of 0.63 mm. Use an exact replacement and replace

annually. Tighten to a torque of 12-15 Nm.

Replacing the Cutting Line

See Fig. 14, 15, 16 and 17.

Follow these steps to replace the cutting line

Stop the trimmer.1.

Make sure the trimmer head has fully stopped

rotating. Contact with a rotating trimmer head

could cause personal injury.

WARNING:

Disconnect the spark plug boot.2.

Hold the bump feed and unscrew the spool retainer.3.

Remove the spool retainer by turning anti-clockwise 4.

and remove the spool from the spring head. NOTE:

Keep the spring attached to the spool.

Remove any old line remaining on the spool.5.

Cut two pieces of line, each approximately 5 m long.6.

Insert a piece of line into the slot in the spool.7.

Wind the line around following the direction of the 8.

arrows on the spool, fi lling one half only.

Ensure that about 15 cm of line is not wound. Do 9.

not overfi ll the spool. There should be at least 6

mm space between the wound line and the outside

edge of the spool.

Secure the line end temporarily in the slots on the 10.

upper/bottom fl ange.

Repeat steps 7 -10 for the line, fi lling the other half 11.

of the chamber.

NOTE:12. Ensure that both cutting lines are wound in

the same direction and that the lines do not cross.

Feed each end of the line through opposite metal 13.

eyelets.

Before pulling through completely, ensure line is 14.

released from temporary holding slot.

Push spool fi rmly back in recess and secure the 15.

spool retainer in position.

NOTE:

Check that the bump feed head is locked in place and is

installed correctly back onto the drive shaft.

NOTE:

If insuffi cient line is protruding from the bump feed head,

depress bump feed head and pull in line to manually

advance the line and to check for proper reassembly of

the bump feed head.

Fig. 12

Fig. 13

15

Maintenance -

continued

To Store the Product Long Term

(more than 30 days)

If you do not intend to use the product for more than

one month, follow these steps to store the product

long term.

Drain all of the fuel from the tank into a container 1.

approved for petrol.

Run the engine until it stops.2.

Clean all foreign materials from the product.3.

Remove the spark plug boot and then the 4.

spark plug.

Pour approximately 5 ml oil into the cylinder 5.

through the spark plug hole.

Pull the recoil starter 2 or 3 times to distribute the 6.

oil over the cylinder walls.

Reinstall the spark plug. Follow the instructions 7.

for spark plug replacement to ensure

correct tightness.

Reconnect the spark plug boot.8.

Store the product in a well ventilated place that is 9.

inaccessible to children.

Note:

Keep the product away from corrosive agents such as

garden chemicals.

Important:

Abide by all federal and local regulations for the safe

storage, handling and disposal of petrol.

Spool Retainer

First String

Slot

Second String

Spool

Arrows on

Spool

Anchor Hole

First Spring

Spring

Spring

String Head

Slots

Eyelets

Shaft

Replacing the Cutting Line

Fig. 14

Fig. 15

Fig. 16

Fig. 17

16

Troubleshooting

Problem Possible Cause Solution

Engine will not start Switch set to OFF 1.

position.

No spark.2.

No fuel.3.

Flooded engine.4.

Starter cord pulls 5.

harder now than

when new.

Set switch to the ON position.1.

Remove the spark plug. Re-attach the spark 2.

plug and lay the spark plug on the metal cylinder.

Pull the starter cord and watch for a spark at the

spark plug tip. If there is no spark, repeat the test

with a new spark plug.

Push primer bulb until the bulb is full of fuel. If 3.

the bulb does not fi ll, the primary fuel delivery

system if blocked. If the primer bulb fi lls, the

engine may be fl ooded (see next item).

Remove the spark plug. Turn the product so that 4.

the spark plug hole is aimed at the ground. Make

sure the choke lever is set to B and pull the

starter cord 10 to 14 times. This clears excess

fuel from the engine. Clean and re-install the

spark plug. With the trigger fully depressed, pull

the starter cord three times. If the engine does

not start, set the choke lever to full and follow

normal starting instructions. If the engine still

fails to start, repeat the procedure with a new

spark plug.

Contact an authorised service dealer.5.

Engine does not reach

full speed

Check oil fuel mixture.1.

Air fi lter is dirty.2.

Spark arrestor screen is 3.

dirty.

Use fresh fuel and the correct 2 stroke oil mix.1.

Clear the air fi lter.2.

Clean the spark arrestor.3.

Line will not advance

when using automatic

line lengthening

Line welded to itself.1.

Not enough line on the 2.

spool.

Line worn too short.3.

Line tangled on spool.4.

Engine speed too slow.5.

Lubricate with silicone spray.1.

Install more line.2.

Pull line while alternately pressing down on and 3.

releasing the retaining cap.

Remove line from spool and rewind.4.

Advance line at full throttle.5.

Retaining cap hard

to turn when using

automatic line

lengthening

Screw threads are dirty or

damaged.

Clean the threads and lubricate with grease. If

this does not solve the problem, replace the

retaining cap.

Grass wraps around the

trimmer head assembly

and the attachment shaft

Cutting tall grass at 1.

ground level.

Operating the product 2.

at part throttle.

Cut tall grass from the top down.1.

Operate the product at full throttle.2.

Oil drips from motor Operating the product 1.

at part throttle.

Check oil/fuel mixture.2.

Air fi lter is dirty.3.

Operate the product at full throttle.1.

Use fresh fuel and the correct 2 stroke oil mix.2.

Clean the air fi lter.3.

17

Warranty

Petrol Operated Products

Limited Warranty

Pope warrants to the original retail purchaser that this Petrol Powered Product is free from defects in material and

workmanship and agrees to repair or replace, at our option, any defective product free of charge within these time

periods from the date of purchase:

Two years for Petrol Powered Trimmer, Brushcutter and Blower Vacuum products, if the product is used •

personal, family or household use;

90 days if the Petrol Powered Trimmer, Brushcutter and Blower Vacuum products are used for any other •

purpose, such as commercial or rental.

Instructions for obtaining Warranty Service

Any part of the Pope product found in the judgement of Toro Australia Pty Ltd to be defective in material or

workmanship will be replaced by an Authorised Service Dealer for this product without charge for parts or labour.

To locate your nearest Authorised Service Dealer, refer to the list on the back page of this manual, check the

website or phone 1300 134 880.

The product, including any defective part must be returned to an Authorised Service Dealer for this product within

the warranty period. The expense of delivering the product to the Authorised Service Dealer for warranty work and

the expense of returning it back to the owner after repair or replacement will be paid for by the owner.

Proof of purchase will be required by the dealer to substantiate any warranty claim. All warranty work must be

performed by a Service Dealer authorised by Toro Australia Pty Ltd to service this product.

The warranty does not cover any product that has been subject to misuse, neglect, negligence or accident or that

has been operated in any way contrary to the operating instructions as specifi ed in the Operator’s Manual. This

warranty does not apply to any damage to the product that is the result of improper maintenance or to any product

that has been altered or modifi ed so as to adversely affect the product’s operation, performance or durability or

that has been altered or modifi ed so as to change its intended use. The warranty does not extend to repairs made

necessary by normal wear, misuse or by the use of parts or accessories which are either incompatible with the

product or adversely affect its operation, performance or durability.

Toro Australia Pty Ltd reserves the right to change or improve the design of any Petrol Product without assuming

any obligations to modify any product previously manufactured.

ALL IMPLIED WARRANTIES ARE LIMITED TO THE DURATION OF THE STATED WARRANTY PERIOD.

ACCORDINGLY, ANY SUCH IMPLIED WARRANTIES INCLUDING MERCHANTABILITY, FITNESS FOR A

P ARTICULAR PURPOSE, OR OTHERWISE, ARE DISCLAIMED IN THEIR ENTIRETY AFTER THE EXPIRA TION

OF THE APPROPRIATE TWO YEAR OR NINETY DAY WARRANTY PERIOD. TORO AUSTRALIA PTY LTD’S

OBLIGATION UNDER THIS WARRANTY IS STRICTLY AND EXCLUSIVELY LIMITED TO THE REPAIR

AND REPLACEMENT OF DEFECTIVE PARTS AND TORO AUSTRALIA PTY LTD DOES NOT ASSUME OR

AUTHORISE ANYONE TO ASSUME FOR THEM ANY OTHER OBLIGATION. TORO AUSTRALIA PTY LTD

ASSUMES NO RESPONSIBILITY FOR INCIDENTAL, CONSEQUENTIAL OR OTHER DAMAGES INCLUDING,

BUT NOT LIMITED T O EXPENSE OF RETURNING THE PETROL POWERED PRODUCT TO ANY AUTHORISED

SERVICE DEALER AND EXPENSE OF DELIVERING IT BACK T O THE OWNER, MECHANIC’S TRAVEL TIME,

TELEPHONE OR TELEGRAM CHARGES, RENTAL OF A LIKE PRODUCT DURING THE TIME WARRANTY

SERVICE IS BEING PERFORMED, TRAVEL, LOSS OR DAMAGE TO PERSONAL PROPERTY, LOSS OF

REVENUE, LOSS OF USE OF THE PRODUCT, LOSS OF TIME OR INCONVENIENCE.

The above warranty does not exclude any condition or warranty implied by the Trade Practices Act 1974 or any

other relevant legislation which implies any condition which cannot be excluded.

18

Loading...

Loading...