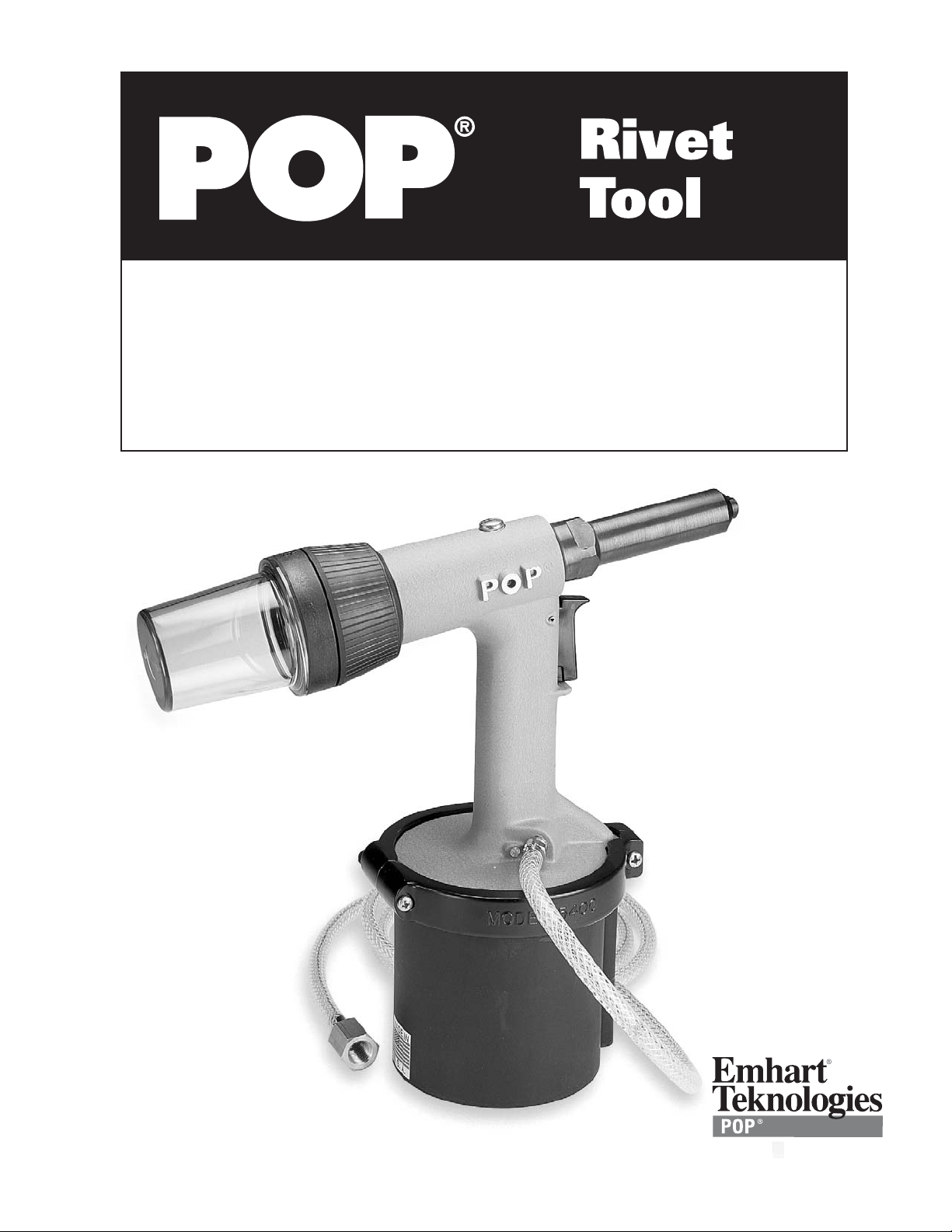

Pop PRT5400, PRT5400LS, MCS5400, MCS5400LS Operator And Maintenance Manual

5400 Series Rivet Tools

PRT5400 / PRT5400LS / MCS5400 / MCS5400LS

Operator and Maintenance Manual

IMPORTANT

READ THE FOLLOWING SAFETY INSTRUCTIONS CAREFULLY.

DISCONNECT TOOL FROM AIR SUPPLY BEFORE ATTEMPTING SERVICE.

SERVICE SHOULD ONLY BE PERFORMED BY TRAINED PERSONNEL.

WARNING: SERVICE PROCEDURES SHOULD BE PERFORMED ONLY BY

TRAINED SERVICE PERSONNEL.

INSTRUCTION MANUAL

Page 2 EMHART TEKNOLOGIES • 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 • www.emhart.com

SAFETY INSTRUCTIONS

1. Always wear

eye protection

when operating the tool.

2. To avoid injury

do not point the tool at anyone.

3.

Do not exceed recommended maximum air pressure

(100 psi max.).

4.

Disconnect the tool from the air supply

when not in use for an extended period of time

or before proceeding with any maintenance procedures. Take care to control air hoses when disconnecting to prevent whipping.

5.

Do not attempt to operate the tool with the Nose Housing removed.

This exposes potential

pinch points and could result in injury.

6.

Do not tamper with the Clamp Screws or Fill Screw.

Loosened screws may result in

malfunction or injury due to air or hydraulic pressure.

7.

Do not operate the tool without either the deflector (PRT Option) or the collector (MCS

Option) installed on the tool.

Spent rivet mandrels may be forcefully ejected.

8.

Always clear the tool of spent rivet mandrels

before setting a new fastener. Failure to do so may

result in tool jams or forceful ejection of spent mandrels.

9.

Use caution when holding the tool at an angle

since compressed air is released through

the Intensifier Chamber and may be directed toward the operator. Do not direct exhaust towards

anyone.

10. Inspect the tool at regular intervals for damage and proper function.

Replace damaged parts

immediately. Do not connect a damaged tool to an air supply.

11.

Use only genuine Pop®brand replacement parts.

EMHART TEKNOLOGIES • 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 • www.emhart.com Page 3

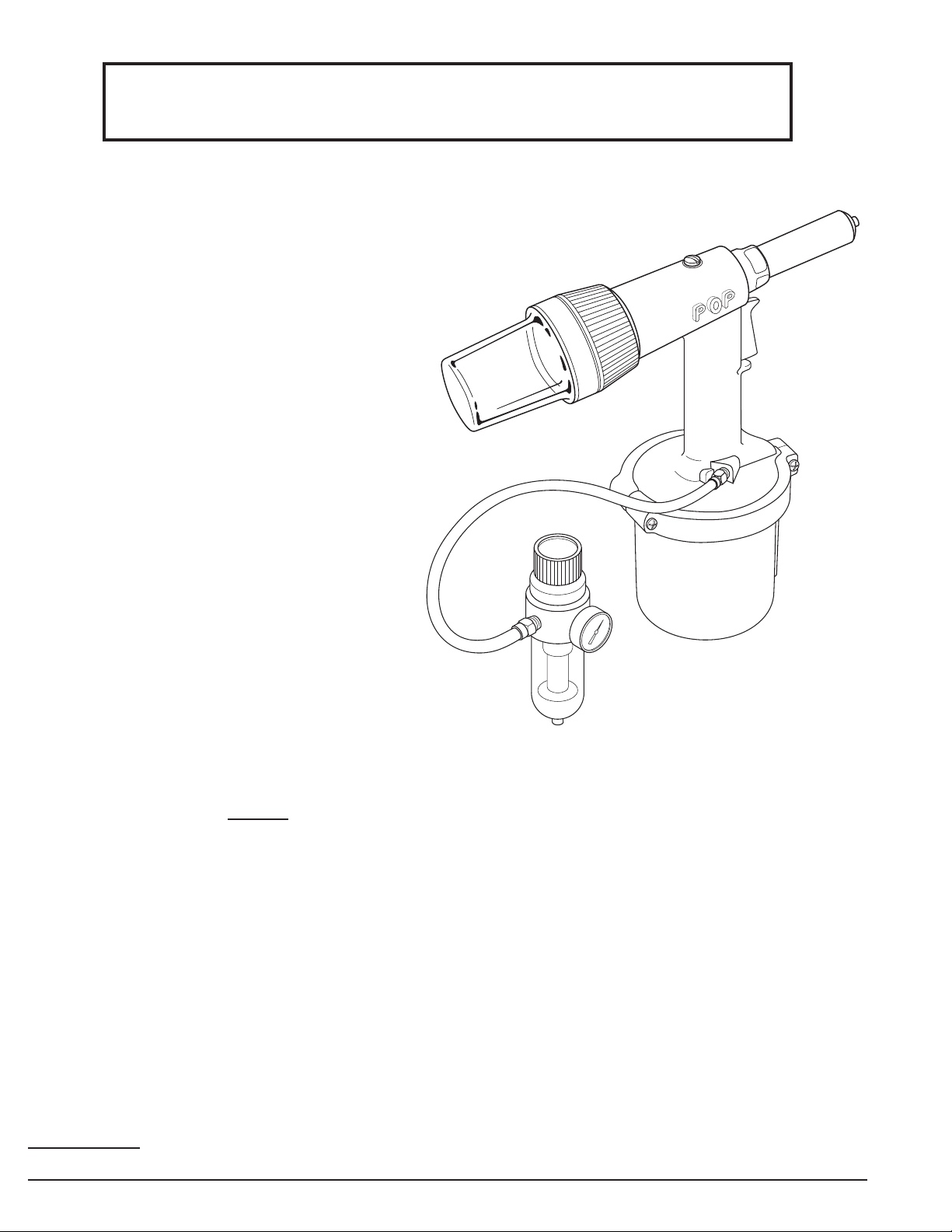

DESCRIPTION AND MODEL IDENTIFICATION

The 5400 Series tools are lightweight air-hydraulic Rivet Tools capable of setting all commercial blind

rivets up to and including 1/4" (6.4mm) diameter in all materials. Four models are available.

PRT5400 Standard model without mandrel collector.

MCS5400 Standard model with automatic vacuum mandrel collector attached.

PRT5400LS Long stroke version without mandrel collector.

MCS5400LS Long stroke version with automatic vacuum mandrel collector attached.

To determine model check length and height specifications or shipping carton label. Models PRT5400 and

MCS5400 are shipped set up for 3/16" (4.8 mm) and smaller diameter rivets. A simple front end parts change

is required to for setting larger diameter rivets. Refer to Service Procedures, Section 1 of this manual for more

information. All the necessary parts are included in the carton. Models PRT5400LS and MCS5400LS are

shipped set up for 1/4" (6.4 mm) diameter rivets. Parts to convert for smaller rivets are included in the carton.

Page 4 EMHART TEKNOLOGIES • 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 • www.emhart.com

PACKED IN CARTON - MODELS PRT5400 and MCS5400

Part Number Part Name Data

Model 5400 Rivet Tool Assembled with air line

PRG540-56 Deflector Safety device - PRT5400 (LS) only

MCS5400-8 Collector bottle MCS5400(LS) only

PRT5500-8 Jaw Pusher 1/4" (6.4mm) diameter rivets

PRG540-44 Jaws 1/4" (6.4mm) diameter rivets

PRN414 Nosepiece 1/8" (3.2mm) open end rivets

PRN514 Nosepiece 5/32" (4.0mm) open end rivets

PRN811 Nosepiece 1/4" (6.4mm) open end rivets

PRG540-127 Screw Use for Hydraulic oil replacement

P342 Operator's Instructions

P343 Instruction Manual

PACKED IN CARTON - MODELS PRT5400LS and MCS5400LS

Part Number Part Name Data

Model 5400 Rivet Tool Assembled with air line

PRG540-56 Deflector Safety device - PRT5400 (LS) only

MCS5400-8 Collector bottle MCS5400(LS) only

PRT5500-6 Jaw Pusher 3/16" (4.8mm) and smaller dia. rivets

PRG540-46 Jaws 3/16" (4.8mm) and smaller dia. rivets

PRG540-43 Mandrel Guide Tube 3/16" (4.8mm) and smaller dia. rivets

PRN414 Nosepiece 1/8" (3.2mm) open end rivets

PRN514 Nosepiece 5/32" (4.0mm) open end rivets

PRN614 Nosepiece 3/16" (4.8mm) open end rivets

PRG540-127 Screw Use for Hydraulic oil replacement

P342 Operator's Instructions

P343 Instruction Manual

SPECIFICATIONS

PRT5400 MCS5400

Weight: 2.1 Kg (4.63 lbs.) 2.25 Kg (4.96 lbs.)

Length: 296.75mm (11.68 in.) 322.10mm (12.66 in.)

Height: 306.23mm (12.13 in.) 306.23mm (12.13 in.)

Stroke: 18mm (.708 in.) 18mm (.708 in.)

Pulling Force: 15.1 kN (3400 lbs.) 15.1 kN (3400 lbs.)

Operating Pressure: 5.8 bar (85 psi.) 5.8 bar (85 psi.)

Air Consumption: .57 litres/rivet (.02 cu.ft.) .57 litres/rivet (.02 cu.ft.)

+.057 cu.m/min. (2 scfm)

PRT5400LS MCS5400LS

Weight: 2.15 Kg (4.74 lbs.) 2.3 Kg (5.07 lbs.)

Length: 304.75mm (12.00 in.) 326.49mm (12.93 in.)

Height: 336.59mm (13.25 in.) 336.59mm (13.25 in.)

Stroke: 26mm (1.02 in.) 26mm (1.02 in.)

Pulling Force: 15.1 kN (3400 lbs.) 15.1 kN (3400 lbs.)

Operating Pressure: 5.8 bar (85 psi.) 5.8 bar (85 psi.)

Air Consumption: .78 litres/rivet (.028 cu.ft.) .78 litres/rivet (.028 cu.ft.)

+.057 cu.m/min. (2 scfm)

THEORY OF OPERATION

When the tool is connected to an air supply and the Trigger is operated, pressurized air pushes the air

piston which acts on the Hydraulic Ram Assembly. The Hydraulic Ram Assembly forces hydraulic fluid from the

reservoir in the handle into the main hydraulic bore where it moves the hydraulic piston together with the

attached pulling mechanism rearward. As the pulling Jaws move rearward they close on and grip the rivet mandrel and set the rivet.

When the trigger is released air at line pressure forces the hydraulic piston forward to the starting position. As

the hydraulic piston moves forward the hydraulic fluid is also forced back returning the hydraulic fluid and the

Ram Assembly and air piston to the starting position. The compressed air used to set the rivet is quietly exhausted through the base of the Intensifier Chamber.When the hydraulic piston is fully returned the broken rivet mandrel is released as the Jaws are forced open again by the Nosepiece.

If the tool is equipped with a Mandrel Collection System (MCS models) the mandrel will be drawn out of the tool

and deposited in the Collector Bottle.

EMHART TEKNOLOGIES • 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 • www.emhart.com Page 5

Note: Numbers in bold type refer to call out numbers in illustration.

Page 6 EMHART TEKNOLOGIES • 50 Shelton Technology Center, Shelton, CT 06484 • Tel. (877) EMHART1 • Fax: (800) 225-5614 • www.emhart.com

PREPARATION FOR OPERATION

CAUTION:

Do not connect to air supply until all tool parts are properly installed.

Wear eye protection when operating this tool.

AIR SUPPLY REQUIREMENTS

1. Use a dry, filtered air supply regulated to 75

- 85 psig (5 - 6 bar). A minimum of 3.0 scfm

(85.0 liters / min.) is recommended. It is not necessary and undesirable to lubricate the air supply. Excess oil, water or debris in the air supply

will necessitate more frequent tool service and

significantly reduce the operating efficiency of

the Mandrel Collection System. If the recommended operating pressure is exceeded the

tool may not function because there is a built in

pressure limiter.

2. For optimum performance connect the tool air

line to an air supply line at least as large in

diameter as the air line supplied with the tool -

6.35mm (1/4 in.) minimum.

3. A lightweight, 6' (1.83 m) air line is supplied

attached to the tool to minimize operator

fatigue. Attaching an air line coupler at the tool

adds weight and changes the balance of the

tool.

PRT5400 / MCS5400

1. Select and attach the appropriate Nosepiece

(12-A, 12-B, 12-C) based on the rivet size /

mandrel diameter.The PRT5400 and MCS5400

Models arrive assembled with Nosepiece 12-C

suitable for 3/16" (4.8mm) diameter open end

rivets. To convert for smaller size rivets it is only

necessary to change the Nosepiece.

2. To set up the tool for 1/4" (6.4mm) diameter open end rivets attach Nosepiece 12-D, install Jaws 3-B, and

Jaw Pusher 22-B and remo

ve Mandrel Guide Tube 71. Refer to SERVICE PROCEDURES. A wide variety

of Nosepieces are available from your POP distributor for special rivets and special applications or to

improve access problems.

3. Attach Deflector 47 or Collector 58 before operating tool.

PRT5400LS / MCS5400LS

1. Select and attach the appropriate Nosepiece (12-A, 12-B, 12-C, 12-D) based on the rivet size /

mandrel diameter. The PRT5400LS and MCS5400LS Models arrive assembled with Nosepiece 12-D suitable for 1/4" (6.4mm) diameter open end rivets.

2. To convert for smaller size rivets attach the appropriate Nosepiece (12-A, 12-B, 12-C) and install Jaws 3-A,

Jaw Pusher 22-A and Mandrel Guide Tube 71. Refer to SERVICE PROCEDURES.

3. Attach Deflector 47 or Collector 58 before operating tool.

0

0

4

5

L

E

D

O

M

Loading...

Loading...