Pop ProSet 1600 Series Maintenance Manual

Rivet

Tool

ProSet® 1600 Series

Maintenance Manual

Page 2 Emhart T eknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Contents

Introduction ................................................................................................................................................. 2

Safety Instructions ...................................................................................................................................... 3

Specifications.............................................................................................................................................. 4

Packaged Accessories............................................................................................................................ 4

Tool Require ment s .................................................................................................................................. 4

ProSet® 1600 Tool Dimension s .............................................................................................................. 5

Common Nosepieces ............................................................................................................................. 6

Basic Tool Operation .................................................................................................................................. 6

Front End Service ................................................................................................................................... 7

Mandrel Collection Syst em (MCS) – ProSet® 1600 MCS ...................................................................... 8

Cleaning the Collector Silencer .............................................................................................................. 8

T ool Assembly T orque Requirements ..................................................................................................... 9

ProSet® 1600/1600MCS Diagram ............................................................................................................ 10

Parts List ................................................................................................................................................... 12

Hydraulic Oil Charging Procedure ............................................................................................................ 14

Maintenance ............................................................................................................................................. 15

Safety Data ............................................................................................................................................... 16

Troubleshooting ........................................................................................................................................ 17

EC Declaration of Conformity ................................................................................................................... 18

Introduction

POP® ProSet® 1600 tools are light weigh t Air/ Hydraulic rivet setting tools rec om mende d for use with genuine

POP

Brand Rivets per following chart:

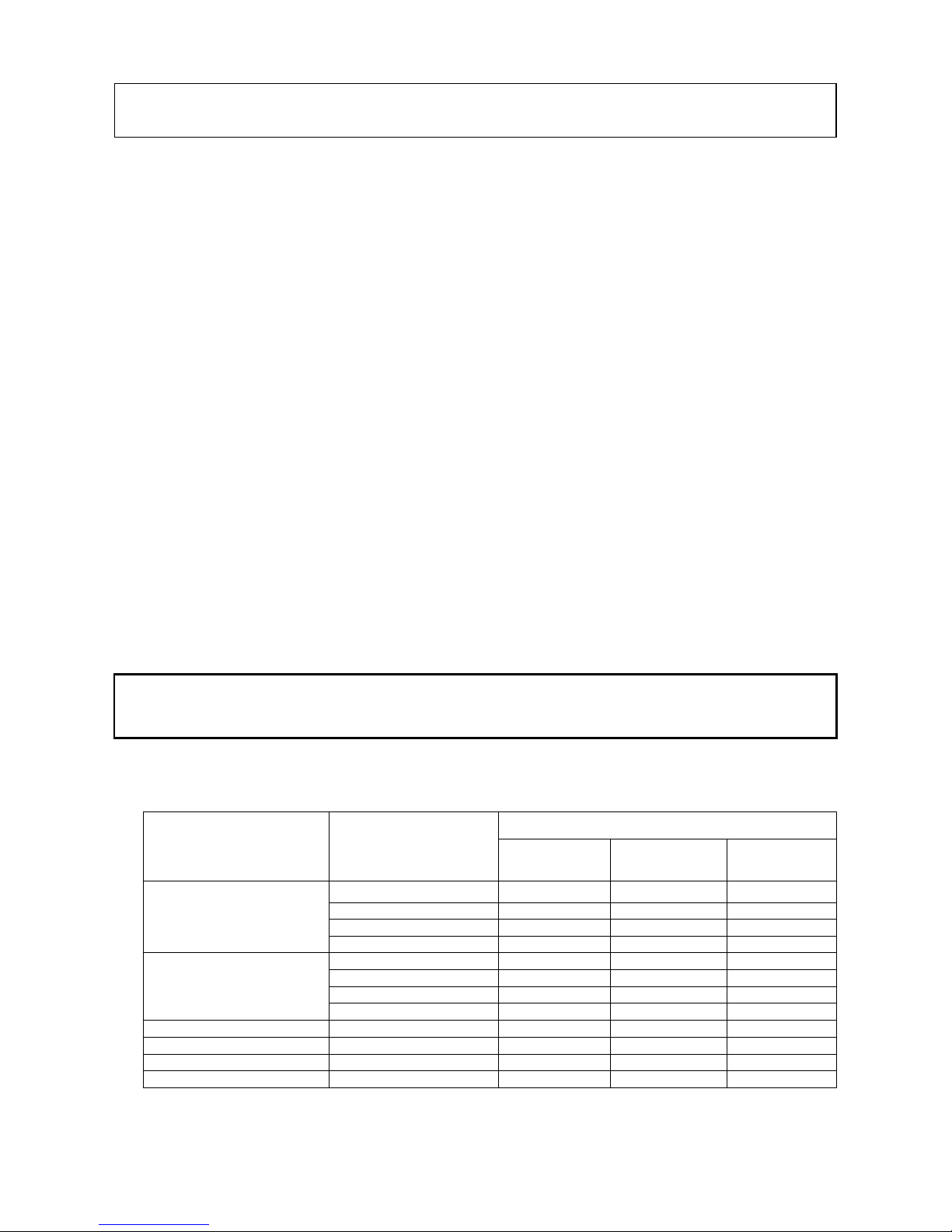

Rivet Type

Material

(Body – Mandrel)

Rivet Diameter

3/32”

(*)

[2.4 mm]

1/8”

[3.0 - 3.2 mm]

5/32”

[4.0 mm]

Open End & MultiGrip

Al – Al

Al – St / SS

St – St

(†)

SS – SS; NC – St /SS

Closed End

Al – Al

Al – St / SS; Cu – St

()

St – St

SS – SS

LSR Rivets

Al – Al

HR™ Rivets

St – St

T - Rivet

Al – St

Self Plugger

St – St

Al: Aluminum, St: Steel, SS: Stai nless Steel , Cu: Cooper, NC: Nickel Copper

(*) Use FAN239-176 Jaw pusher set up.

(†) Exclude MultiGrip

() Set air pressure at 90 psi (6.2 bar).

Emhart T eknologies - 50 Shelton Tec hnol ogy Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 3

Safety Instructions

TO INSURE PROPER FUNCTIONING AND SAFE OPERATION READ THIS MANUAL

CAREFULLY BEFORE SETTING UP OR OPERATING THE POP® ProSet™ 1600 SERIES TOOLS

1. DO NOT use this tool in a manner other than that recommended by Emhart Teknologies.

2. Always wear eye protection when using or when near a tool that is in use.

3. This tool is NOT designed for use in explosive atmospheres.

4. Inspect tool for damage before connecting to air supply including all air connections.

5. Trained personnel must perform tool repair and/or maintenance at the prescribed intervals.

6. Disconnect the air supply when adjusting, servicing or removing any part of the tool.

7. Keep fingers off the trigger when connecting the air supply or if the air supply fails.

8. Keep fingers away from the front of the tool when connecting the air supply or setting rivets.

9. DO NOT point the tool at anyone.

10. DO NOT operate tool with the nose housing removed.

11. DO NOT operate tool without the Deflector or Collector.

12. DO NOT modify the tool in any way. Modification will make void any applicable warranties

and could result in damage to the tool or physical injury to the user.

13. DO NOT look into the tool from the front or the back during use or when connected to air

supply.

14. The operating pressure must not exceed 100 psi (6.9 bar).

15. DO NOT direct tool exhaust towards anyone.

16. Wash hands if exposed to hydraulic fluid or lubricant.

17. Keep hair, fingers and loose clothing away from moving parts of the tool.

18. Emhart Teknologies recommends the use of Hearing protection when operating this tool.

Page 4 Emhart T eknologies - 50 Shelton Tec hnol ogy Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

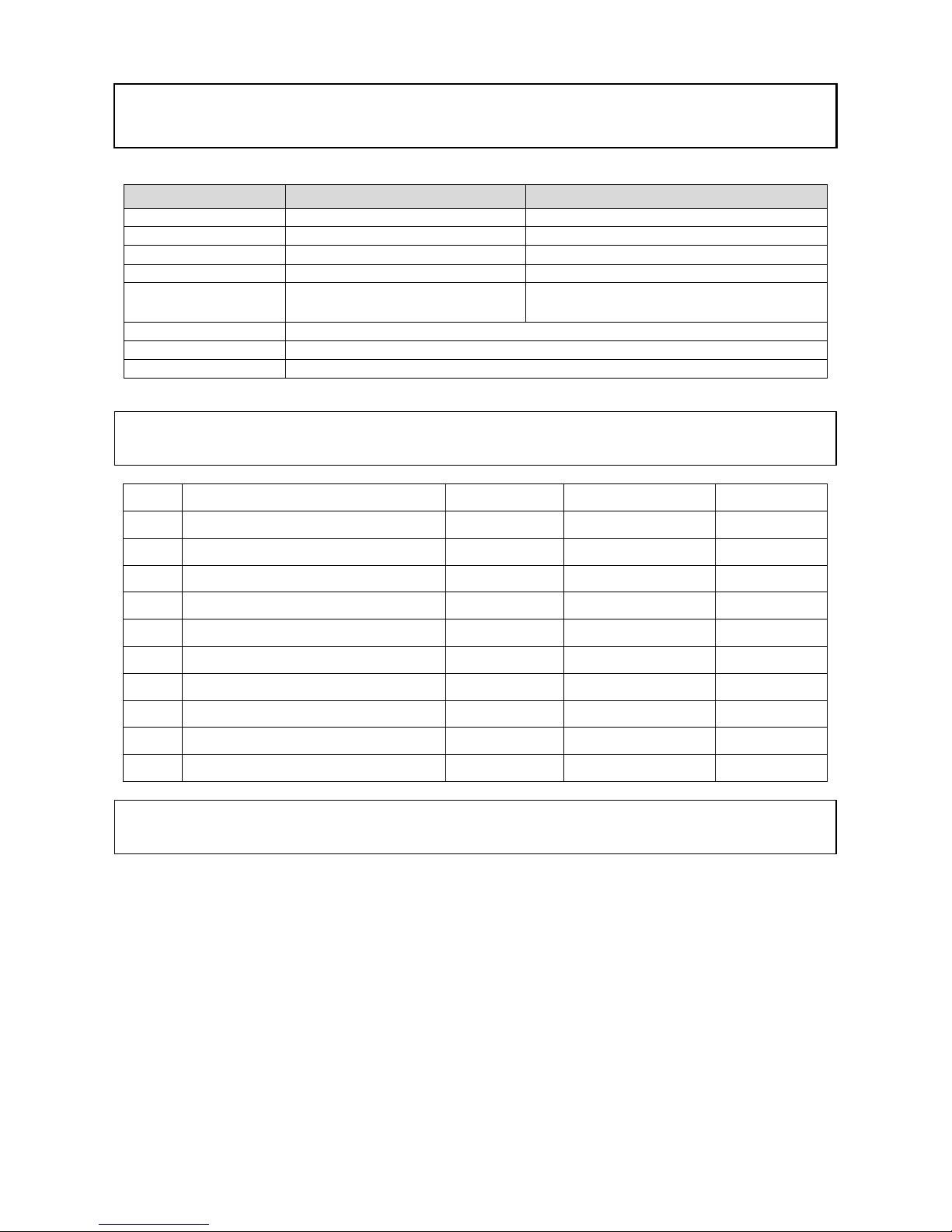

Specifications

ProSet® 1600 ProSet® 1600MCS

Weight

2.15 lbs. (0.98 kg) 2.30 lbs. (1.05 kg)

Length

10.83” (275 mm)

10.71” (272 mm)

Height

8.94” (227 mm)

8.94” (227 mm)

Stroke

0.71” (18 mm)

0.71” (18 mm)

Air Consumption

0.043 cu. ft. per rivet

(1.22 l per rivet)

2.47 scfm (max.)

(70 l /min (max.))

Pulling Force

1090 lbs. @ 90 psi (4850 N @ 0.62 MPa)

Noise Level*

L

Aeq,T

= 80.2 dB(A), LWA = 85.0 dB(A), L

Peak

= 110.4 dB(C)

Vibration Level

0.54 m/s2, Time to 2.5 m/s2 > 24hrs (EAV)

*Note: Emhart Teknologies recommends the use of Hearing Protection when operating this tool

Packaged Accessories

Qty Item PROSET1600 PROSET1600MCS Part No.

1 ProSet® 1600 Rivet Tool

-

1 Operating Instructions

P449

1 Maintenance Manual

P513

1 Nosepiece for 3 size open end ri vet s

PRN314

1 Nosepiece for 4 size open end ri vet s Installed Installed PRN414

1 Nosepiece for 5 size open end ri vet s

PRN514

1 Jaw Pusher (Assy.) for 3/32” rivets

FAN239-176

1 Air Line Assembly

FAN239-157

1 4 mm Hex. Socket Screw Key

DPN239-139

1 Warranty Card

FG2184

Tool Requirements

Air supply *

6 scfm (150

l /min) Minimum

Recommended Operating Pressure 72.5-90 psi (0.5-0.62 MPa) dry, filtered

Maximum Operating Pressure 100 psi (0.69 MPa) dry, filtered

Hydraulic Oil **

POP

®

p/n: PRG540-130 [1 qt. (.945 ml)]

Jaw Lubricant **

POP® p/n: PRG510-130 [6 oz. (177 ml)]

Seal Lubricant **

POP® p/n: PSA075508P [1 ¾ oz. (54 g)]

(*) Note: For best results and long service life, use dry, filtered air supply.

(**) Note: See lubricant safety information.

Emhart T eknologies - 50 Shelton Tec hnol ogy Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 5

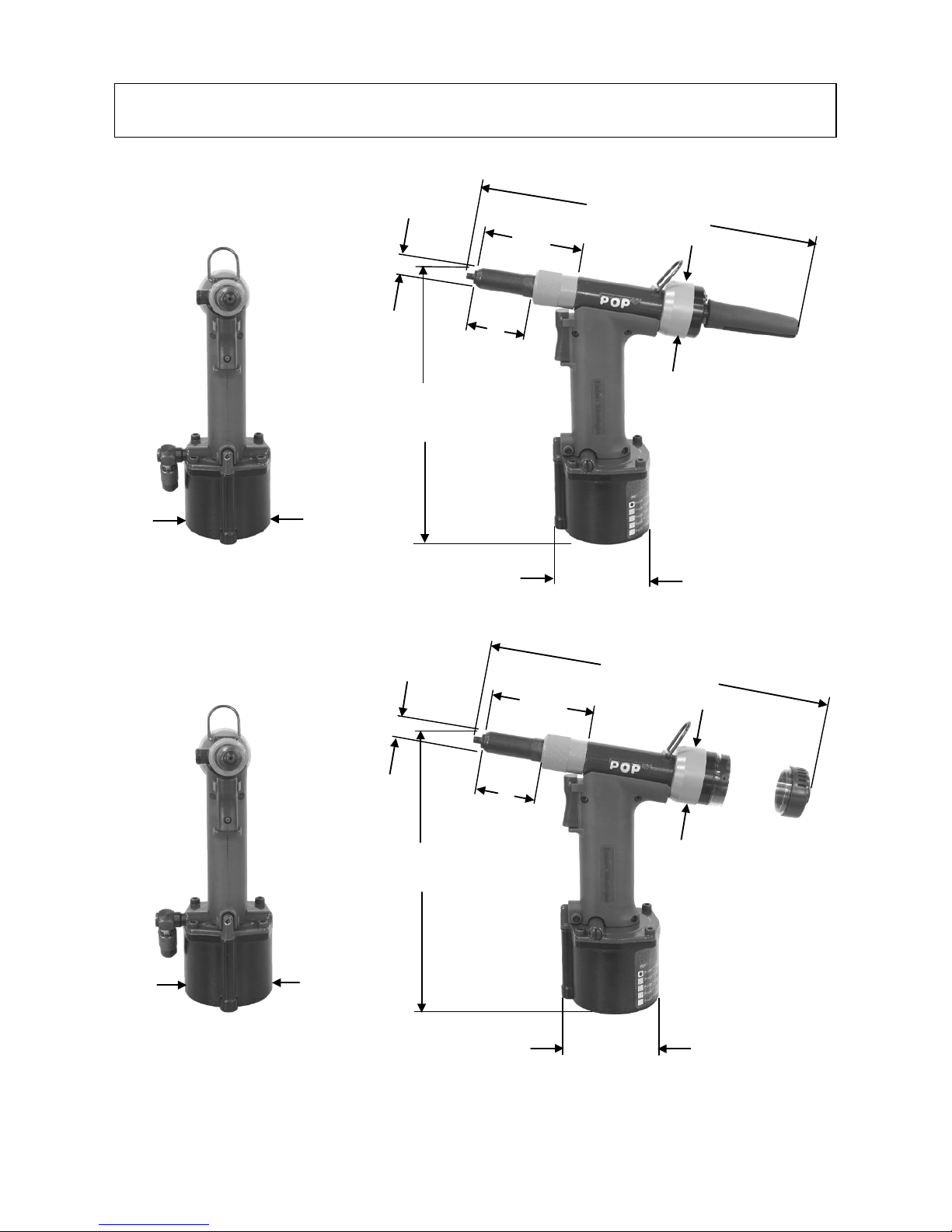

ProSet® 1600 Tool Dimensions

.682” (17.3 mm)

10.83” (275 mm)

8.94” (227 mm)

2.99” (76 mm)

3.27” (83 mm)

ProSet® 1600

1.83” (46.5 mm)

3.3” (82 mm)

1.82” (46.3 mm)

10.71” (272 mm)

3.27” (83 mm)

2.99” (76 mm)

.682” (17.3 mm)

8.94” (227 mm)

ProSet® 1600 MCS

1.83” (46.5 mm)

1.82” (46.3 mm)

3.23” (82 mm)

Page 6 Emhart T eknologies - 50 Shelton Tec hnol ogy Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Common Nosepieces

* Included with the tool

Use FAN239-176 instead of DPN239-144 (installed) when using 3/32” (2.4mm) or smaller diameter

rivets.

Basic Tool Operation

Before operating the tool check the following:

Inspect tool for damage or leaking oil – do not use tool if it is damaged or leaking oil.

Check that correct nosepiece is fitted and tightened to 60 - 65 in-lbs [6.8 – 7.3 N-m] torque.

Check that the nose housing nut (8) is tight – hand tighten only.

Connect tool to air supply – see air supply requirements (page 4).

Fit Mandrel Collector (96) – (MCS tool only).

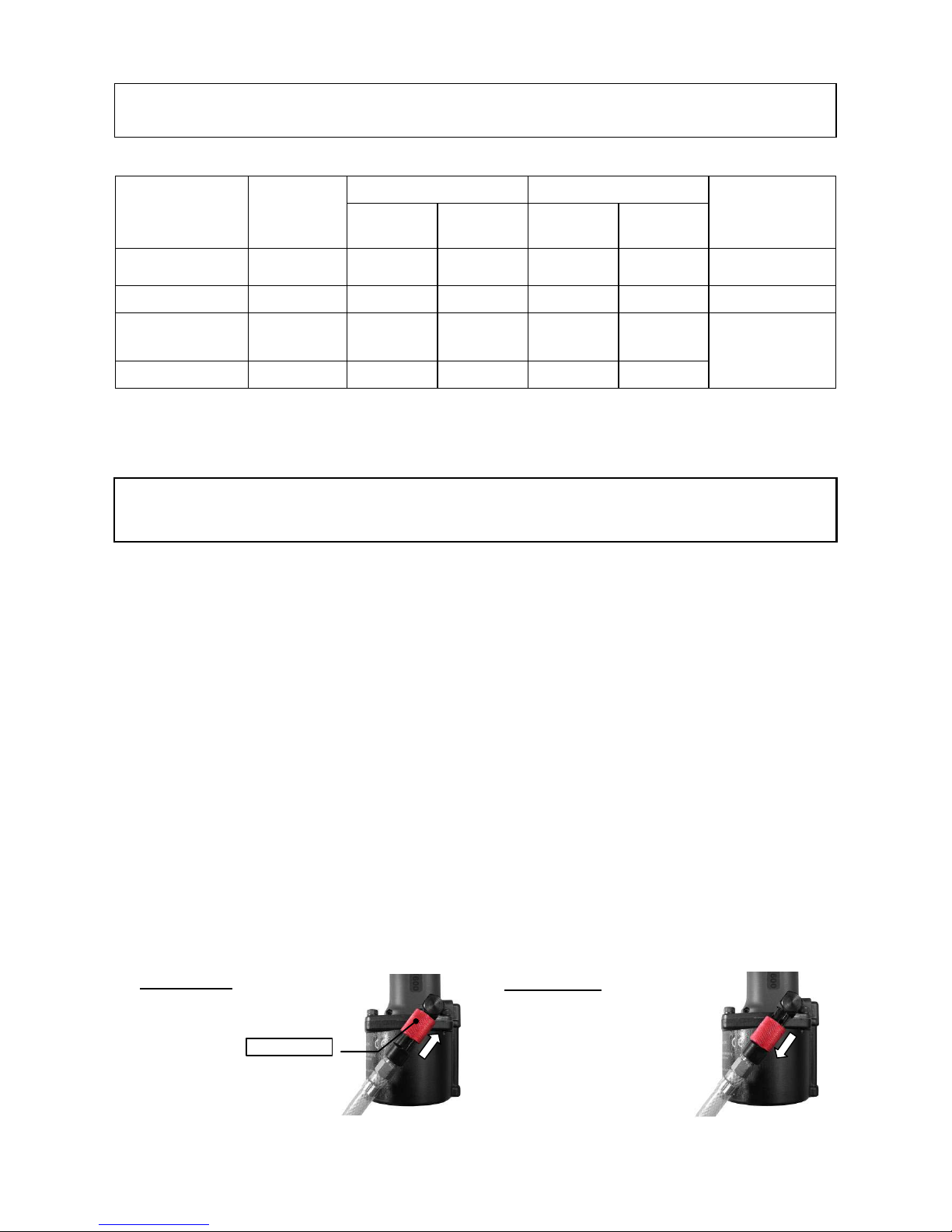

Open air supply valve by Sliding red OS Sleeve (93) on side of tool (see note below).

Insert rivet into nosepiece.

Position rivet in work piece.

Pull trigger to set rivet.

Release trigger – if equipped, MCS suction will draw mandrel into the collector.

! Note: The ProSet

®

1 600 has an OS (Open-Shut) Valve for switching the air supply ON and OFF to

save air when the tool is not in use.

Rivet Diameter Open End

Closed End HR Rivets

Jaw Pusher

Steel Mandrel

Aluminum

Mandrel

Aluminum

Body

Steel

Body

2.0 mm PRN214 - - - -

FAN239-176*

(PRG402-02 - JAWS)

3/32” (2.4 mm) PRN314* - - - - FAN239-176*

1/8” (3.2 mm) or

7/64” (2.8 mm)

PRN414* PRN424 PRN434 PRN414* PRN4HR

DPN239-144*

5/32” (4.0 mm) PRN514* PRN524 PRN534 PRN514* -

Air Supply ON: Open O S Va lv e

by sliding OS Sleeve

in the

direction shown (up).

Air Supply OFF: Close OS Valve

by sliding OS Sleev

e in the

direction shown (down).

OS Sleeve

Loading...

Loading...