Pop PNT1000L-PC Maintenance Manual

POP

NUT

™

PNT1000L-PC

Main te na nc e Ma nu al

Page 2 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Contents

Introduction ............................................................................................................................................... 3

Safety Instructions .................................................................................................................................... 4

Specifications............................................................................................................................................ 5

Tool Parts ..............................................................................................................................................6

Packaged Accessories .......................................................................................................................... 6

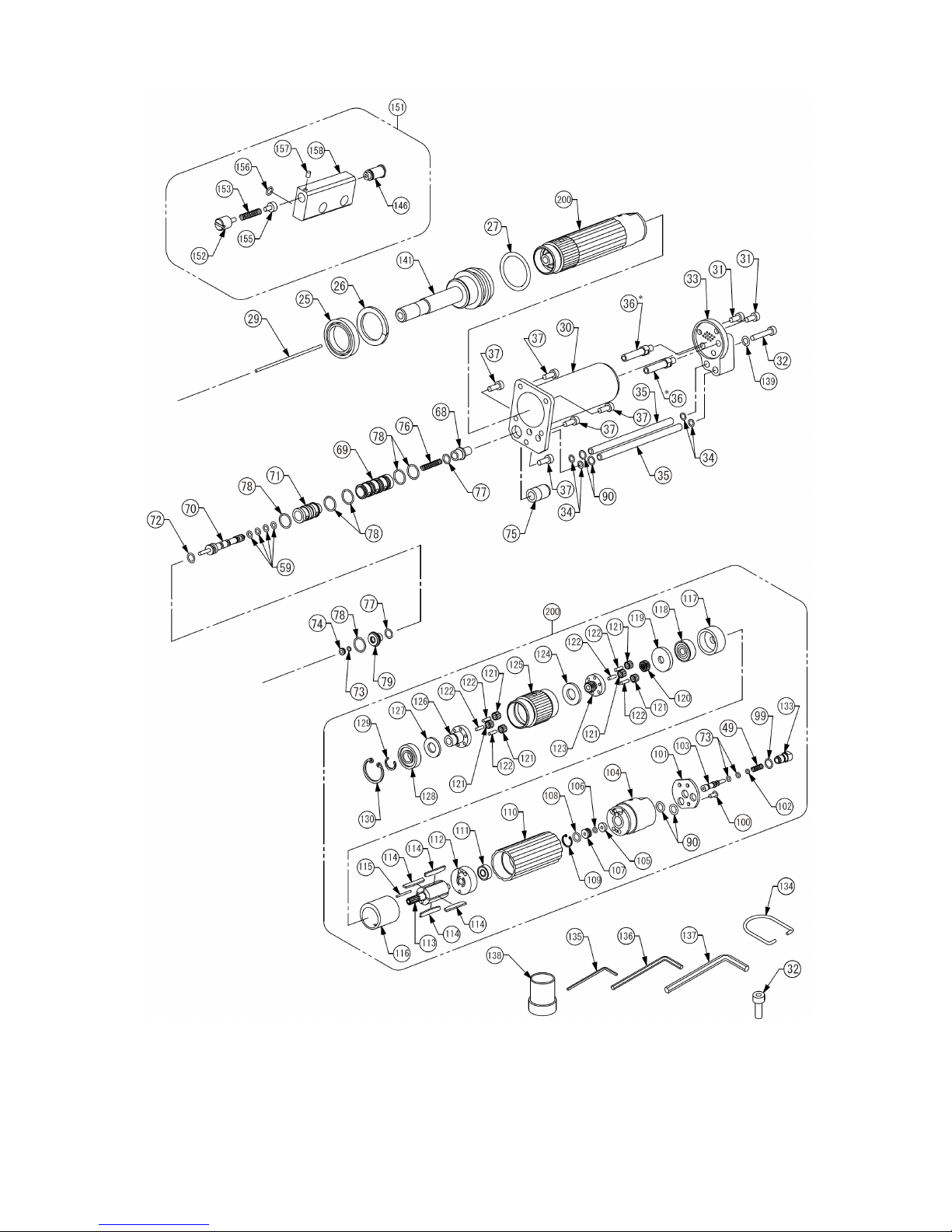

PNT1000L-PC Diagram ............................................................................................................................ 8

Parts List................................................................................................................................................. 10

Tool Setup ............................................................................................................................................... 12

Mandrel and Nosepiece installation ....................................................................................................13

Basic Tool Operation............................................................................................................................... 14

Mandrel & Nosepiece Adjustment ....................................................................................................... 14

Setting Force Valve Spring Selection .................................................................................................. 15

Tool Operation..................................................................................................................................... 16

Setting Force Adjustment........................................................................................................................ 18

Adjustment for Standard POP NUTs™ ............................................................................................... 18

Adjustment for ST & Thin Wall POP NUTs™ ...................................................................................... 18

Adjustment of Setting Force................................................................................................................ 18

Maintenance ........................................................................................................................................... 19

Clean & Lube Mandrel ........................................................................................................................ 19

Lubricate Rotating Parts...................................................................................................................... 19

Recharging Hydraulics ........................................................................................................................ 20

Troubleshooting ...................................................................................................................................... 22

Safety Data ............................................................................................................................................. 24

EC Declaration of Conformity ................................................................................................................. 26

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 3

Introduction

The PNT1000L-PC is a lightweight tool for installing POP® brand POP NUT™ blind rivet nuts and other blind

threaded inserts by adjusting the setting force to the insert being installed rather than stroke like traditional

blind rivet nut tools. Controlling the setting force has the following benefits:

• No stroke adjustment is needed for the same nut in multiple application grips.

• Eliminated application & nut damage due to “double stroking”.

• Proper set achieved even with a small gap between the nut flange and Nosepiece.

Table 1 lists the POP NUT™ blind rivet nuts that can be fastened using this tool. The Nosepiece and Mandrel

must be changed to fit some sizes of POP NUT™. (See Table 5, Mandrel and Nosepiece Requirements table

in the Specification section)

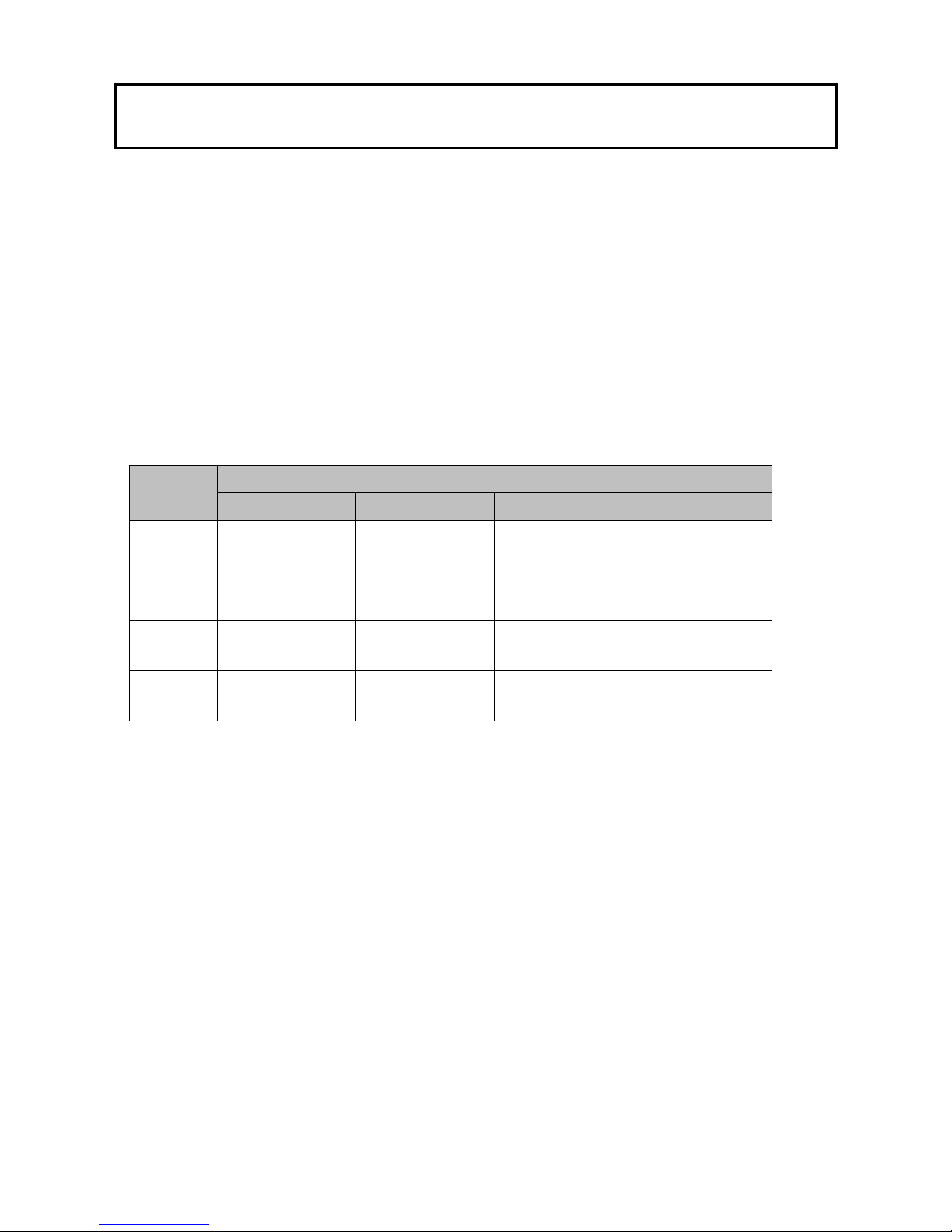

Table 1: POP NUT™ blind rivet nut range

Material

Thread

Size

Aluminum

Steel

Steel RLT

Stainless

M6X1.0

¼-20

M8X1.25

5/16-18

M10X1.5

3/8-16

*

M12X1.75

1/2-13

*

* Need to set tool at 0.55 MPa [80 psi] Minimum.

Page 4 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

Safety Instructions

TO INSURE PROPER FUNCTIONING AND SAFE OPERATION READ THIS MANUAL

CAREFULLY BEFORE SETTING UP OR OPERATING THE POP NUT SERIES TOOLS

DEFINITIONS:

• CAUTION! – Failure to observe this precaution could result in physical damage

or minor injury.

• WARNING! – Failure to observe this precaution could result in physical damage,

serious injury or even death.

CAUTION!

1. DO NOT use this tool in a manner other than that recommended by Emhart Teknologies.

2. DO NOT modify the tool in any way. Modification will void any applicable warranties and could result

in damage to the tool or physical injury to the user.

3. Disconnect air supply when adjusting, servicing or removing any part of the tool.

4. Trained personnel must perform tool repair and/or maintenance at prescribed intervals.

5. Only use genuine Emhart Teknologies parts for tool maintenance and repair.

6. Do not operate the tool with the Nose Housing removed.

7. Keep fingers away from the front of the tool when connecting the air supply or using the tool.

8. Do not attempt to turn the Mandrel when the air supply is connected.

9. Keep hair, fingers and loose clothing away from moving parts of the tool.

10. Do not direct tool exhaust towards anyone. The tool uses lubricated air and may eject oil mist or

debris.

11. Do not use organic solvents to clean the tool, this may damage the tool.

12. Wash hands thoroughly if exposed to hydraulic fluid or lubricant.

WARNING!

1. DO NOT exceed the maximum recommended air pressure of 0.6 MPa (87 psi / 6.0 bar).

2. DO NOT point the tool at anyone when in use.

3. Always wear safety rated eye protection when using or when near a tool in use.

4. Always wear safety rated hearing protection when using or when near a tool in use.

5. Inspect the tool and connections for damage, worn or loose parts before connecting to the air supply.

If damaged, stop use immediately and have the tool repaired or replaced.

6. This tool is not designed for use in explosive atmospheres.

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 5

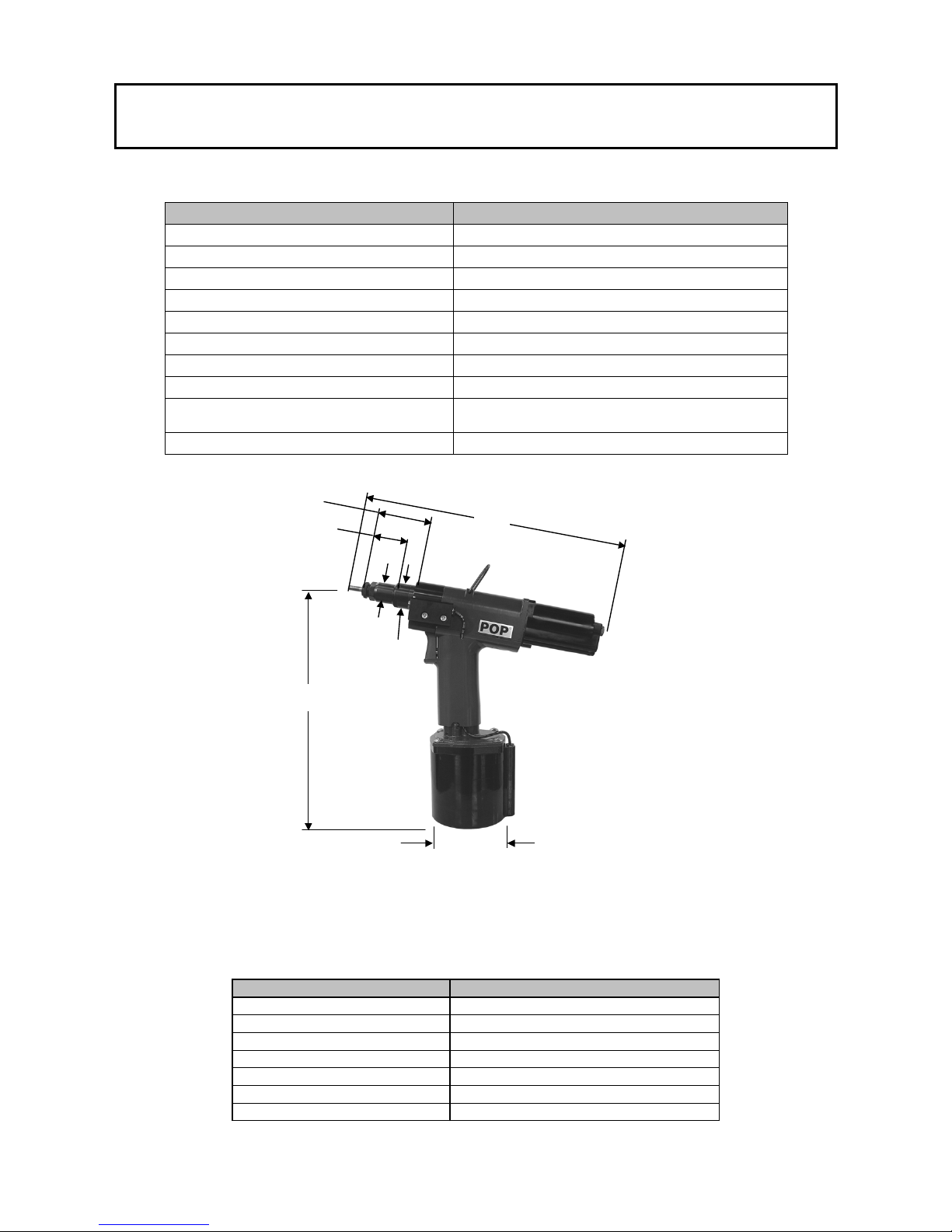

Specifications

Table 2: Tool Specifications

Feature

Specification

Weight

2.77 kg (6.11 lbs)

Overall length

315 mm (12.4 in)

Overall height

295 mm (11.6 in)

Tool Stroke

1.3 – 10.5 mm (0.05 – 0.413 in)

Pulling Force

24.3 kN @ 5.0 bar ( 5463 lbf @ 72.5 psi)

Air Supply

0.5 – 0.6Mpa (5 – 6 bar) (72.5 – 87 psi)

Hydraulic Oil

See Table 3, Specified Hydraulic Oils

Setting capacity

See Table 1, POP NUT™ blind rivet nut range

Tool Noise Level*

L

Aeq,T

= 80.3 dB(A), LWA = 88 dB(A),

L

Peak

= 106.8 dB(C)

Tool Vibration Level

0.40 m/s2, Time to 2.5 m/s2 > 24hrs (EAV)

*Emhart recommends the use of hearing protection when operating this tool

Figure 1: Tool Dimensions (mm)

Hydraulic oil

Use only Emhart Teknologies specified hydraulic lubrication oils as shown in Table 3.

Use of any other oil could reduce the tool performance or even damage the tool.

Table 3: Specified Hydraulic Oils

Company name

Product name

Mobile

Mobile DTE26

Shell

Shell Telus Oil C68

Idemitsu

Daphne Hydro 68A

Cosmo

Cosmo Olpas 68

Esso

Telesso 68

Nisseki

FBK RO68

Mitsubishi

Diamond Lube RO68 (N)

315

φ28

(71)

(38)

φ31.5

295

106

Page 6 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

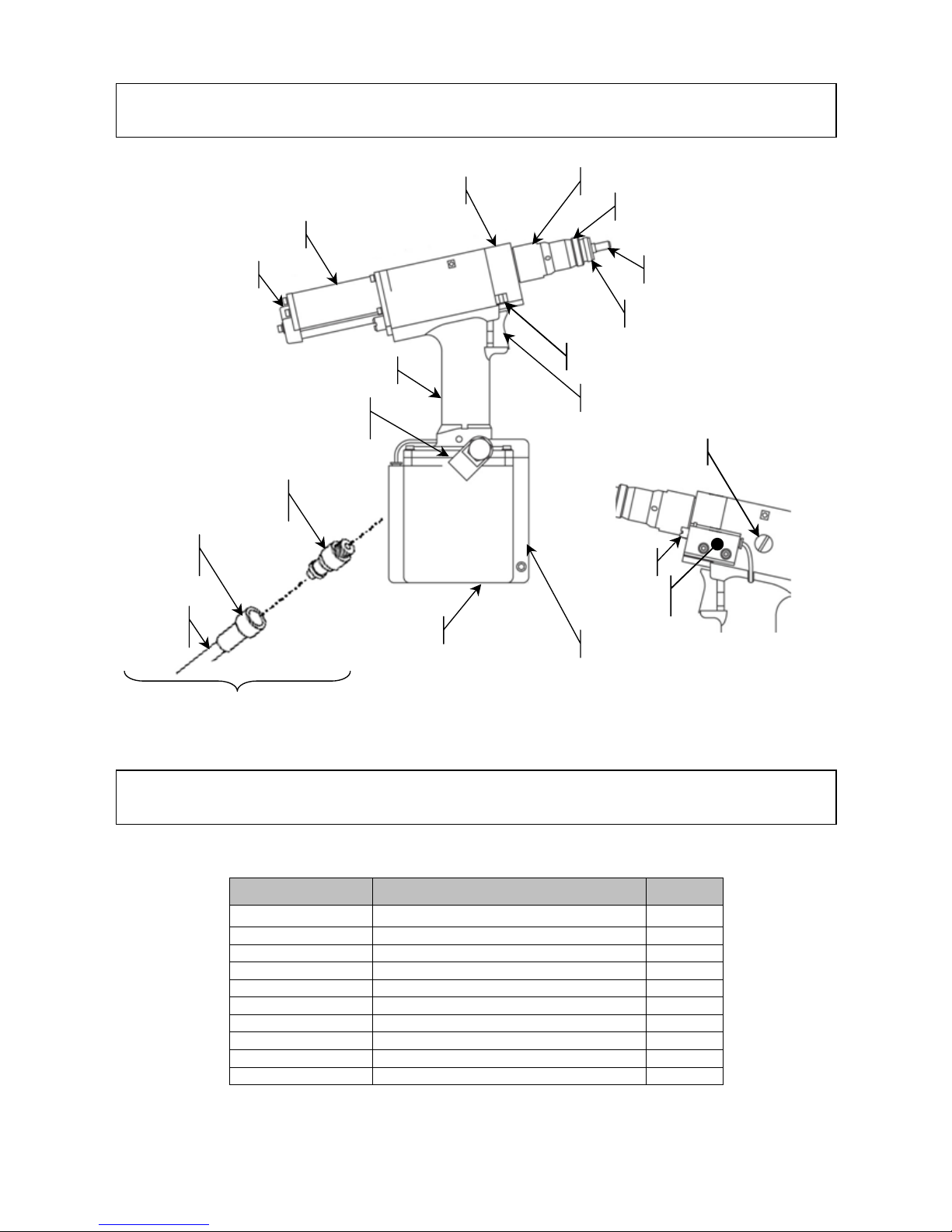

Tool Parts

Figure 2: Tool Parts Diagram

Packaged Accessories

Table 4: Packaged Accessories

Part No.

Item

Qty

PNT1000L-PC-T

PNT1000L-PC POP NUT™ Tool

1

PNT600-132

Hook

1

PNT600-133

Hex wrench 1.5 mm

1

PNT600-136

Hex wrench 3 mm

1

DPN239-139

Hex wrench 4 mm

1

DPN907-006

Cap screw M4 X 20

1

DPN277-185

POP NUT™ Mandrel Release

1

FG2245

Operating Instructions

1

FG2268

Maintenance Manual

1

FG2222

Warranty Card

1

Front Case

Fill Screw

Rear Case

Exhaust Holes

Handle

Swivel Air Fitting

¼ NPTF

Air Fitting

(Not Included)

Coupler

(Not Included)

Air Hose

(Not Included)

Chamber

Setting Force

Control Valve

Adjuster

Exhaust Holes

Trigger

Control Knob

Mandrel

Nosepiece/Anvil

Lock Nut

Nose Housing

Not included

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 7

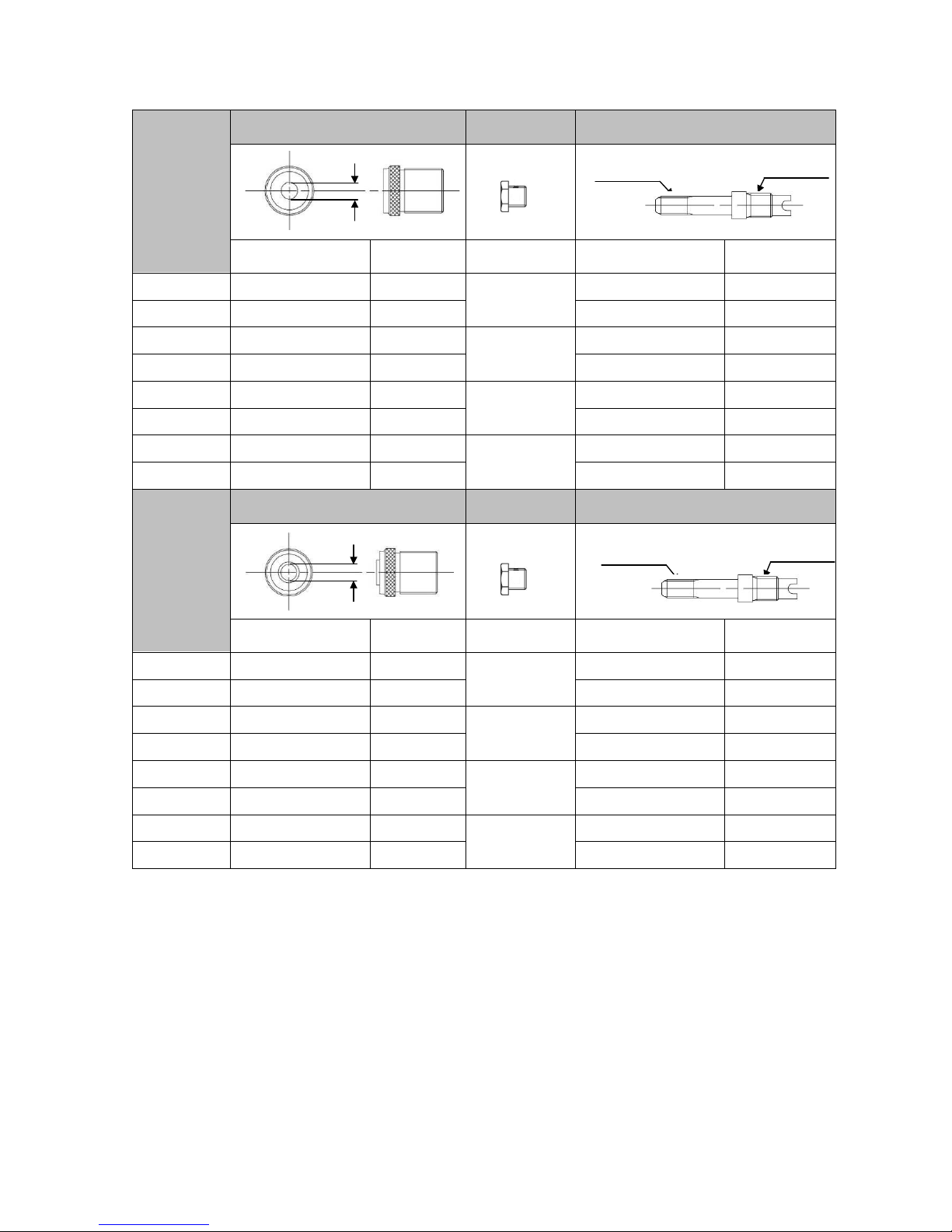

Table 5: Mandrel and Nosepiece requirements

Flat Nosepiece

Mandrel

Adapter

Mandrel

Thick Wall

(Std & ST)

POP NUT

Thread size

Part No.

I.D.

Part No.

Part No.

Thread size

M6X1.0

PNT1000-02-6

φ6.1

PNT600-01-6

M6X1.0

M8X1.25

PNT1000-02-8

φ8.1

PNT1000-58

PNT600-01-8

M8X1.25

M10X1.5

PNT1000-02-10

φ10.1

PNT1000-01-10A

M10X1.5

M12X1.75

PNT1000-02-12

φ12.1

-

PNT1000-01-12A

M12X1.75

1/4-20

PNT1000-02-420

φ 6.5

PNT600-01-420

1/4-20

5/16-18

PNT1000-02-8

φ8.1

PNT1000-58

PNT600-01-518R

5/16-18

3/8-16

PNT1000-02-10

φ10.1

PNT1000-01-616R

3/8-16

1/2-13

PNT1000-02-813

φ12.8

-

PNT1000-01-813

1/2-13

Piloted Nosepiece

Mandrel

Adapter

Mandrel

Thin Wall

(TK,TL,TH)

POP NUT

Thread size

Part No.

I.D.

Part No.

Part No.

Thread size

M6X1.0

PNT1000-02-6P

φ6.1

PNT600-01-6P

M6X1.0

M8X1.25

PNT1000-02-8P

φ8.1

PNT1000-58

PNT600-01-8P

M8X1.25

M10X1.5

PNT1000-02-10P

φ10.1

PNT1000-01-10P

M10X1.5

M12X1.75

PNT1000-02-12P

φ12.1

-

PNT1000-01-12P

M12X1.75

1/4-20

PNT1000-02-420P

φ6.5

PNT600-01-420

1/4-20

5/16-18

PNT1000-02-8P

φ8.1

PNT1000-58

PNT600-01-518

5/16-18

3/8-16

PNT1000-02-10P

φ10.1

PNT1000-01-616

3/8-16

1/2-13

PNT1000-02-813P

φ12.8

-

PNT1000-01-813

1/2-13

* Refer to the Tool Setup section for details of Nosepiece and Mandrel installation.

I.D.

Thread size

M8X1.0

I.D.

Thread size

M8X1.0

Page 8 Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614

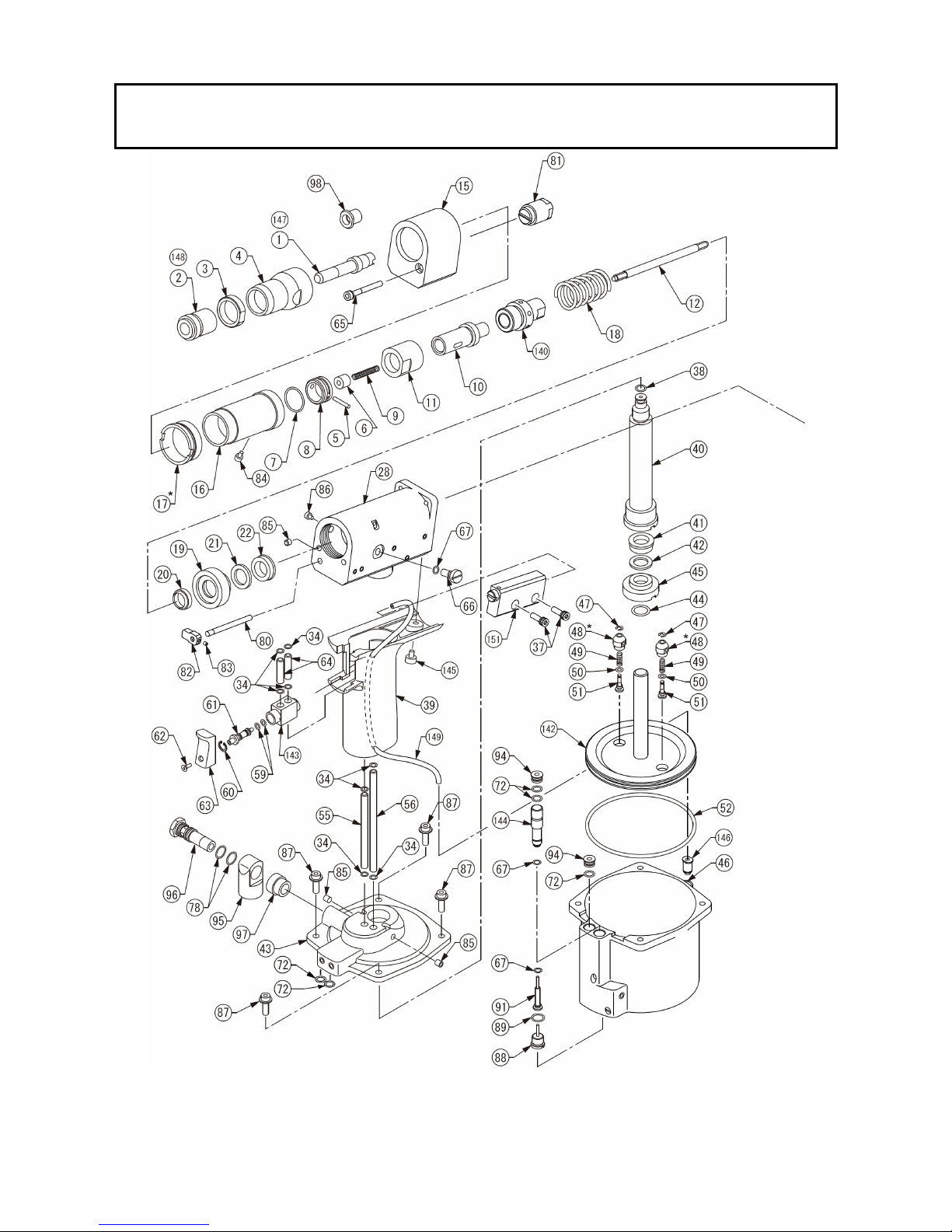

PNT1000L-PC Diagram

Emhart Teknologies - 50 Shelton Technology Center, Shelton CT 06484 - Tel. (203) 924-9341 - Fax (800) 225-5614 Page 9

Loading...

Loading...