Pop Bolt MCS5800-HEX Maintenance Manual

POP Bolt™ Power Tool

MAINTENANCE MANUAL ADDENDUM

MCS5800-HEX

2 MCS5800-HEX MANUAL ADDENDUM

1. POP Bolt™ Tool

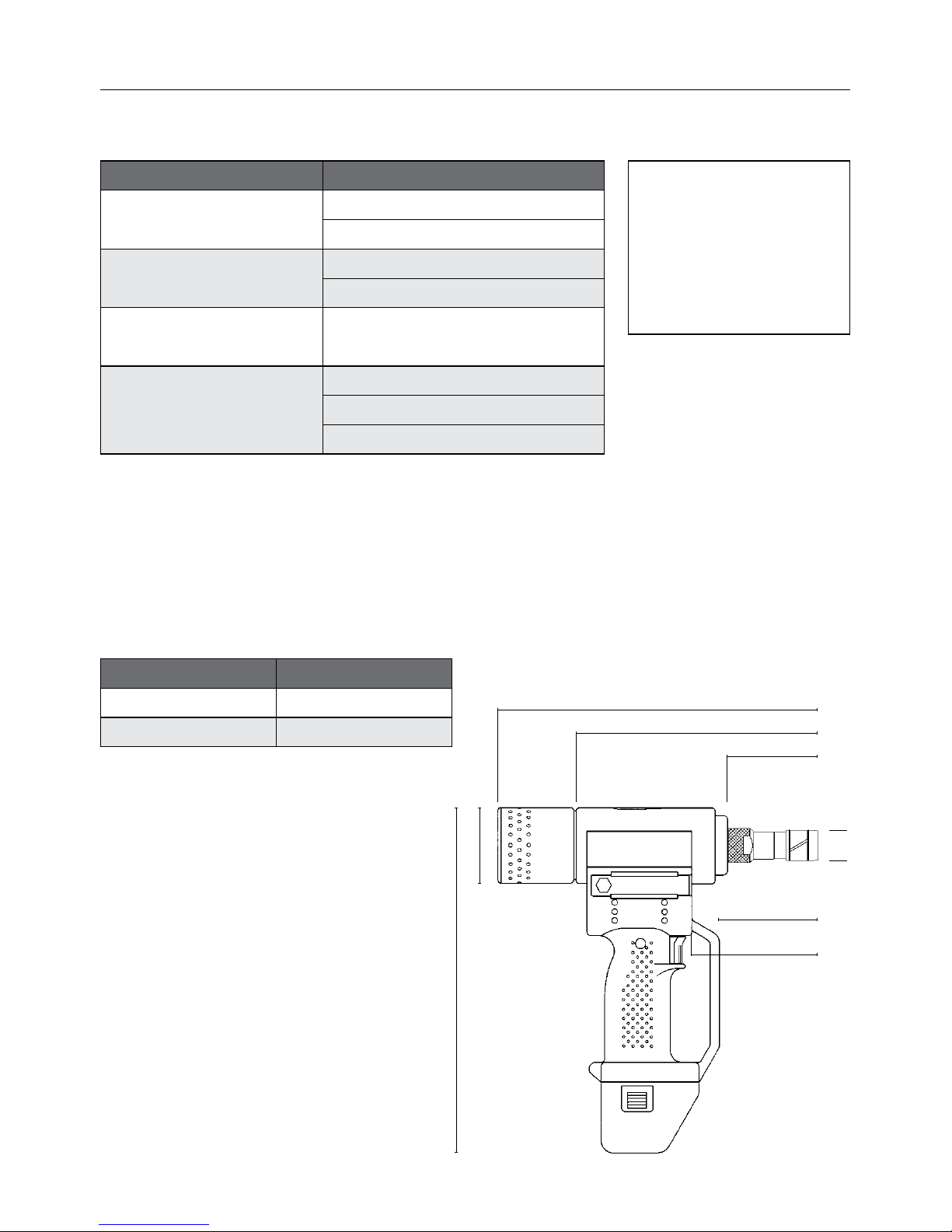

1.1 Work Capacity

1.3 POP Bolts™ per battery charge

Style Description

Hex Washer Head Bolt

PBS-HWH-8-M6 (Steel)

PBSS-HWH-A2-M6 (Stainless Steel)

Slotted Truss Head Bolt

PBS-THS-8-M6 (Steel)

PBSS-THS-A2-M6 (Stainless Steel)

Twinfix

PBSS-TFX-A2-M6 (Stainless Steel)

Collar

PCS-6S (Steel)

PCSS-6S (Stainless Steel)

PCA-6S (Aluminium)

1.2 Equipment/Accessories

Nosepiece: PSL600CJ-70A

Jaws A: PSL600CJ-59/12L (Standard)

Jaws B: PSL600CJ-59/14L (Recommended for nominal to max grip)

Bolt Material Rivets / Charge

M6 Steel 500

M6 Stainless Steel 400

260 mm

192 mm

62 mm

68 mm

92 mm

300 mm

ø66 mm

ø23.5 mm

Note

When using the

MCS5800-HEX tool,

all references to ‘rivets’ in

the MCS5800 Operating

Manual, should read

‘POP Bolts™’.

3MCS5800-HEX MANUAL ADDENDUM

2. Maintenance and Inspections

No. Item Purpose

2.1

Spraying lubricant into the

Jaws

Maintains proper Jaw operation and extends

the service life

2.2 Cleaning Jaws/Jaw Case

To remove metal particles and prevent slippage or sticking of Jaws

To prevent early wear damage on Jaws and Jaw Case

2.3 Exchange of Hydraulic oil

To restore stroke

2.4 Replacing the Nosepiece

Because of wear or damage

2.5

Replacing the Jaw opener

assembly

Because of damage

2.6 Replacing Jaws

Because of wear or damage

2.7 Replacing Jaw pusher spring

Because of weaken and worn damage

2.8 Replacing the Jaw case

Because of damage

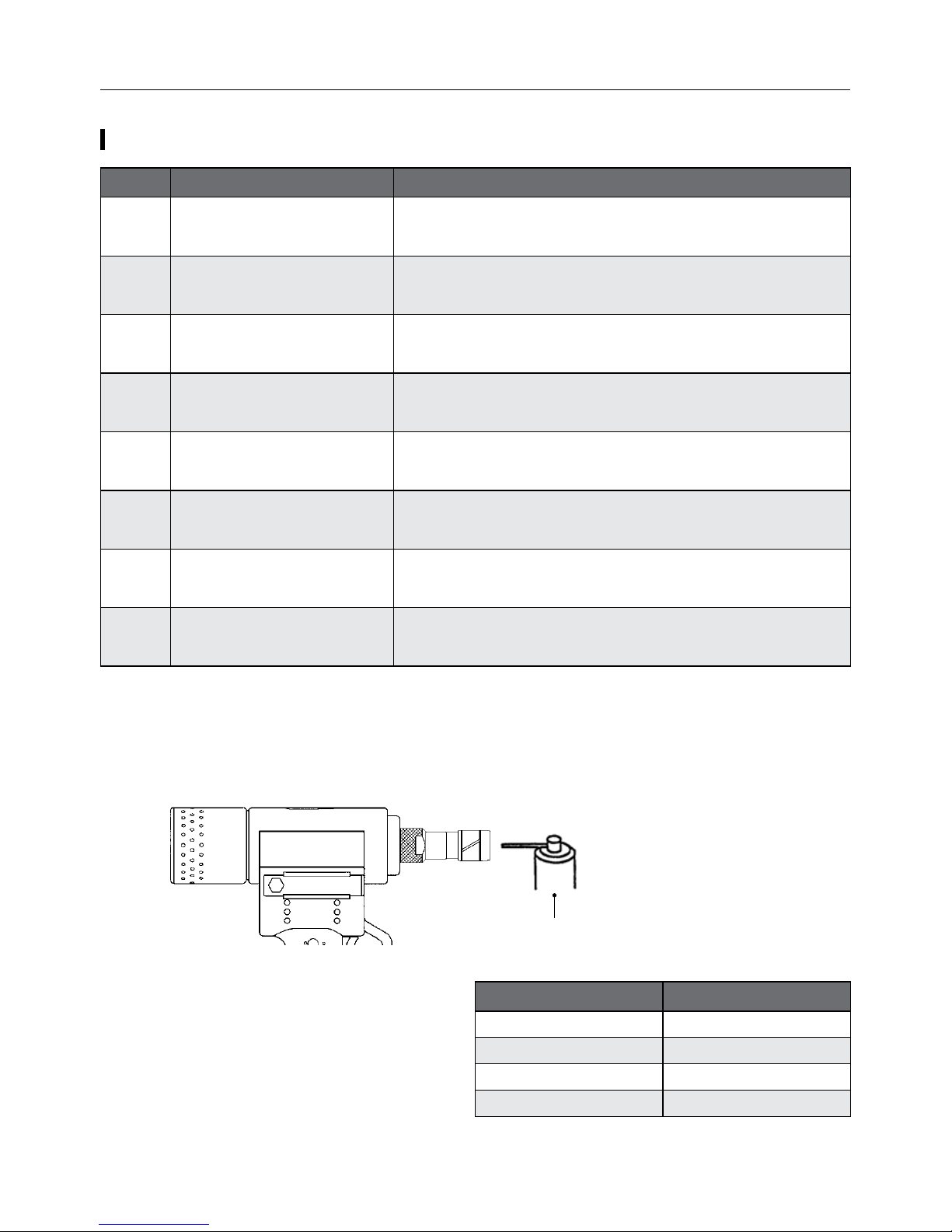

2.1 Spraying lubricant into the Jaws

Lubricating and rust-proofing agents (CRC type) should be sprayed into the Nosepiece hole

approximately every 2,000 pcs in order to maintain proper Jaws operation.

Manufacturer Product Name

Kure Industries Inc. CRC5-56

Three Bond Inc. 1801B

Musashi Holtz Inc. Holtz Top Oil MH241

Lesupi Inc. Pikka

Lubricant

(Reference)

Table 2

Loading...

Loading...