Page 1

2001 Pontiac Aztek

Radiator Support

Replacement

(Upper)

Removal Procedure

1. Remove all related panels and

components including front fascia

supports, right and left (1).

2. Restore as much of the damage as

possible to factory specifications.

1

1

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

2001 Pontiac Aztek

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the Radiator Support Assembly.

5. Remove the damaged Radiator

Support Assembly.

2001 Pontiac Aztek 1-1

Page 2

Radiator Support

Replacement

(Upper)

Installation Procedure

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in) apart.

1. Drill 8 mm (5/16 in) plug weld

holes as necessary in locations

noted from the original panel.

2. Prepare all attachment surfaces as

necessary.

3. Apply weld-thru primer to all baremetal surfaces.

4. Position the Radiator Support

Assembly.

5. Plug weld accordingly.

6. Clean and prepare all welded

surfaces.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

7. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

8. Refinish as necessary.

9. Install all related panels and

components.

1-2 2001 Pontiac Aztek

Page 3

Radiator Support

Replacement

(Lower)

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the Lower Radiator Support.

5. Remove the damaged Lower

Radiator Support.

2001 Pontiac Aztek 1-3

Page 4

Radiator Support

Replacement

(Lower)

Installation Procedure

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in) apart.

1. Drill 8 mm (5/16 in) plug weld

holes as necessary in locations

noted from the original panel.

2. Prepare all attachment surfaces as

necessary.

3. Apply weld-thru primer to all baremetal surfaces.

4. Position the Lower Radiator

Support.

5. Plug weld accordingly.

6. Clean and prepare all welded

surfaces.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

7. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

8. Refinish as necessary.

9. Install all related panels and

components.

1-4 2001 Pontiac Aztek

Page 5

Rail Replacement

(Upper)

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the Front Upper Rail.

5. Remove the damaged Front Upper

Rail.

2001 Pontiac Aztek 1-5

Page 6

Rail Replacement

(Upper)

Installation Procedure

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in) apart.

1. Drill 8 mm (5/16 in. ) plug weld

holes as necessary in locations

noted from the original front upper

rail.

2. Prepare all attachment surfaces as

necessary.

3. Apply weld-thru primer to all baremetal surfaces.

4. Position the Upper Rail.

5. Plug weld accordingly.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

6. Clean and prepare all welded

surfaces.

7. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

8. Refinish as necessary.

9. Install all related panels and

components.

1-6 2001 Pontiac Aztek

Page 7

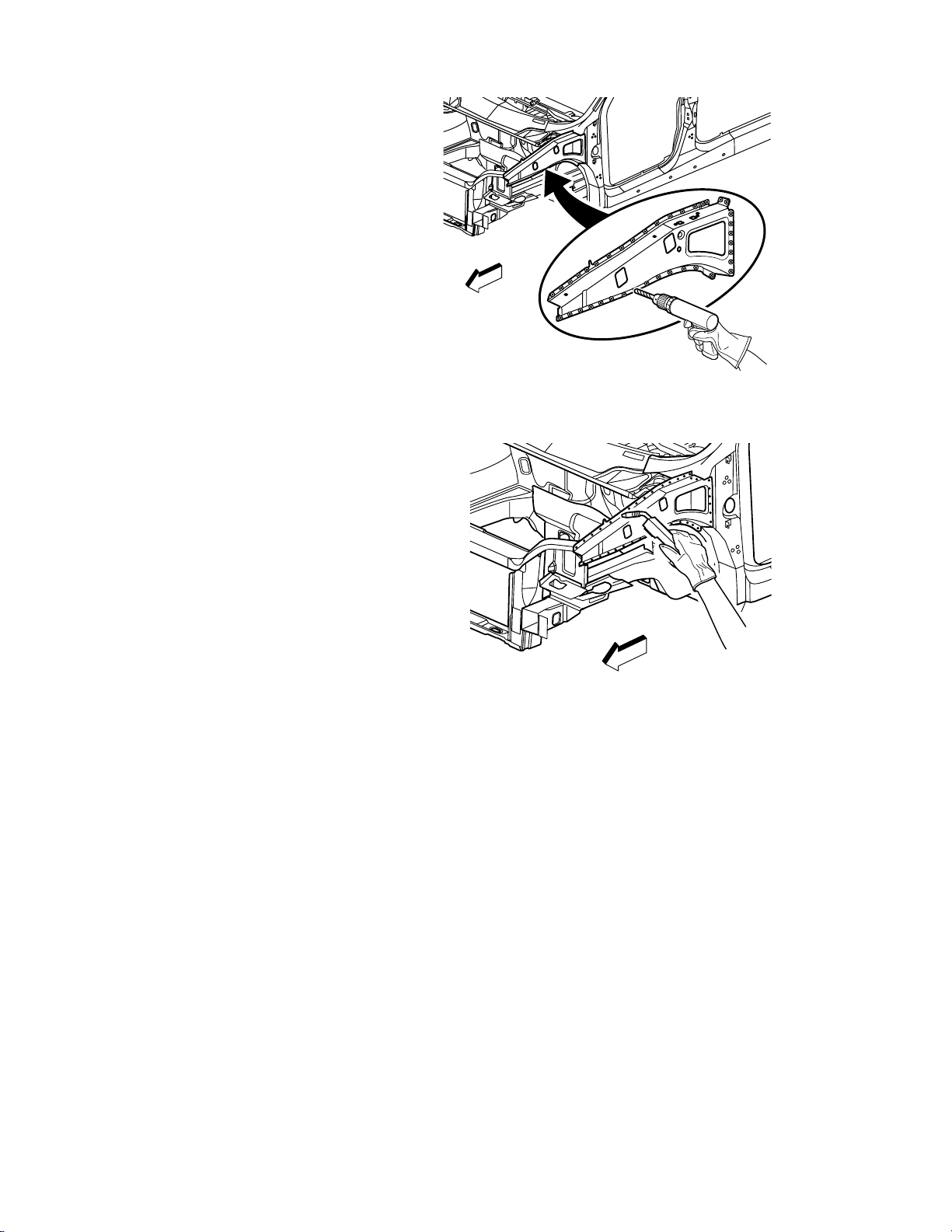

Wheelhouse

1

Replacement

(Front)

Removal Procedure

1. Remove all related panels and

components in the area of the

damaged apron extension (1).

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the service part.

5. Remove the damaged apron

extension.

2001 Pontiac Aztek 1-7

Page 8

Wheelhouse

Replacement

(Front)

Installation Procedure

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in) apart.

1. Drill 8 mm (5/16 in.) plug weld

holes in the service part as

necessary in the locations noted

from the original panel.

2. Prepare all attachment surfaces as

necessary.

IMPORTANT: Prior to refinishing,

refer to the publication GM4901MD-01 GM Approved Refinish

Materials for recommended

products. Do not combine paint

systems. Refer to paint

manufacturer’s recommendations.

3. Apply weld-thru primer to all bare

metal surfaces.

4. Position the apron extension.

5. Plug weld accordingly.

6. Clean and prepare all welded

surfaces.

7. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadening materials

• Sealers

8. Refinish as necessary.

9. Install all related panels and

components.

1-8 2001 Pontiac Aztek

Page 9

Rail Sub-Assembly

Replacement (Front

Lower)

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

4. Separate the floor pan

reinforcement (1) weld flanges from

the inside of the lower rail. Care

must be taken not to damage the

weld flanges.

IMPORTANT: Do not damage any

inner panels or reinforcements.

5. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the Front Lower Rail.

1

6. Remove the damaged rail.

2001 Pontiac Aztek 1-9

Page 10

Rail Sub-Assembly

Replacement (Front

Lower)

Installation Procedure

1. Prepare the mating surfaces of the

floor pan reinforcement (1).

2. Turn the weld flanges outward (2)

to be welded to the front lower rail.

3. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from removal.

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

4. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from the original panel.

5. Prepare all attachment surfaces as

necessary.

6. Apply weld-thru primer to all baremetal surfaces.

2

1

7. Position the service part

8. Plug weld accordingly.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

9. Clean and prepare all welded

surfaces.

10. Apply the following as necessary :

• Anti-corrosion materials

• Sound deadeners

• Sealers

11. Refinish as necessary.

12. Install all related panels and

components.

1-10 2001 Pontiac Aztek

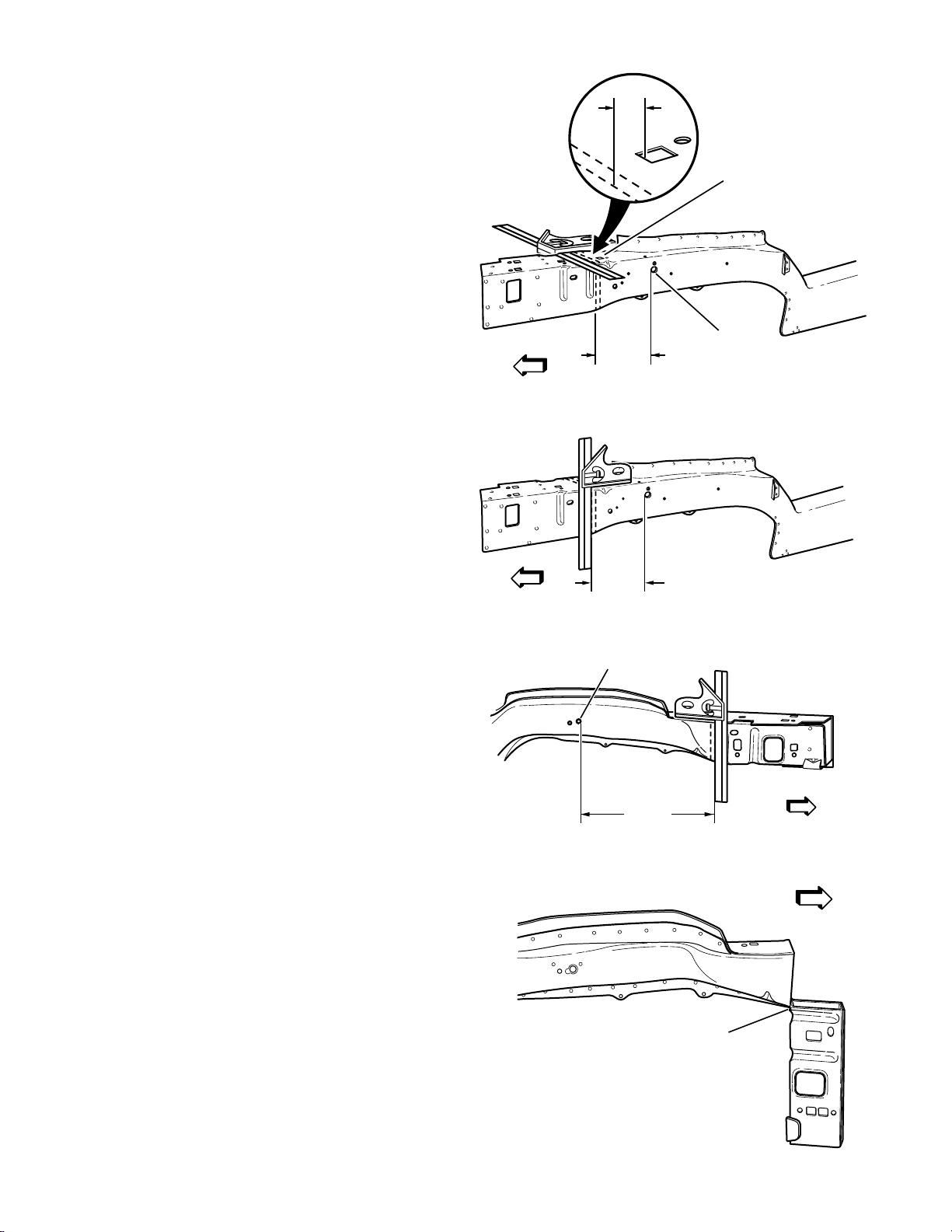

Page 11

35MM

Left Front Lower

Rail Sectioning

IMPORTANT: If the damage exceeds the

recommended area for sectioning and the

rail cannot be straightened, the complete

rail must be replaced.

Sectioning procedures have been

developed to simplify repair of the lower

rails, providing the majority of the

damage can be returned to factory

specifications. This allows the damaged

front section to be replaced without

performing a full rail replacement. The

rails come as a complete assembly. The

front portion of the rail and bumper

brackets are also serviced separately.

IMPORTANT: Failure to follow the

instructions included with the service rail

may lead to improper rail sectioning,

which may compromise the structural

integrity of the vehicle.

Removal of Damaged

Left Front Rail

1. On top of the rail, locate the cut-out

1

square (1). From the front edge of

the square, measure forward 25 mm

and scribe a line.

2. Add 10 mm and scribe a second line

(1). The second line (35 mm) is the

cut location. The additional 10 mm

will be used to create a flange for

welding the new service part to the

vehicle.

402MM

3. On the outboard side of the rail,

1

locate the brake line pass-thru hole

(1). At the larger hole, pull the tape

measure from the forward edge of

the hole and mark a line at 392

mm. Scribe a line with a straight

edge, making sure it is square to

inboard and top rail markings.

4. Measure forward 10 mm and scribe

a second line. The second line (402

mm) is cut location.

—continued

2001 Pontiac Aztek 1-11

Page 12

Removal of Damaged

Left Front Rail con’t

5. Locate hole (1), on the inboard side

of the rail. Measure forward 140

mm (5-1/2 in.) and mark the

location. Scribe a straight line on

the rail.

6. Measure forward 10 mm (13/32 in.)

and scribe a second line. The

second line [150 mm (5-29/32 in.)]

is the cut location (2).

1

7. Make certain all three sides are

aligned. Cut through three sides of

the rail.

8. On the bottom of the damaged rail,

scribe a line from the outboard to

the inboard cut locations and cut

the remainder of the rail (1) from

the vehicle.

9. Remove the damaged section of rail.

150MM

2

1

(LEFT OUTBOARD)

1-12 2001 Pontiac Aztek

Page 13

Left Front Lower

Rail Sectioning

Preparing Service Part for

Installation

1. On original rail, cut and remove 10

3

1

4

2

mm (13/32 in.) of the outboard (1)

and downward (2) turned flanges of

the rail. Cut 10 mm (13/32 in.)

gaps along the corners of the

original rail (3).

2. Step the top, bottom and side tabs

inward (4) to allow the service part

to fit over the original rail.

3. Clean and prepare mating surfaces

as necessary.

Installation Procedure

1. Position the service part over the

original rail. Align and check fit

using three-dimensional measuring

equipment.

2. Stitch weld along the entire

sectioning joint. Make 25 mm (1

in.) welds along the seam with 25

mm (1 in.) gaps between them.

3. Go back and complete the stitch

weld. This will create a solid weld

joint with minimal heat distortion.

4. Clean and prepare all welded

surfaces.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

5. Prime with two-part catalyzed

primer.

6. Apply sealers and anti-corrosion

materials as necessary.

7. Install all related panels and

components.

2001 Pontiac Aztek 1-13

Page 14

Right Front Lower

Rail Sectioning

Removal of Damaged

Right Front Rail

1. On top of rail, locate the last cutout square. From the rear edge of

the square (1), measure forward 8

mm (5/16 in.) and scribe a line.

2. Add 10 mm and scribe a second

line. The second line is the cut

location. The additional 10 mm

(13/32 in.) will be used to create a

flange for welding the new service

part to the vehicle.

3. On the outboard side of the rail,

locate the fixturing hole (2).

Measure forward 150 mm (5-29/32

in.) and mark location. Scribe a

straight line on the rail.

4. Measure forward 10 mm (13/32 in.)

and scribe a second line. The

second line [160 mm (6-5/16 in.)] is

the cut location.

18MM

1

2

160MM

160MM

5. On the inboard side of the rail,

locate the brake line pass-thru hole

(1). At the larger hole, pull the tape

measure from the forward edge of

the hole and mark a line at 376

mm. Scribe a line with a straight

edge, making sure it is square to

inboard and top rail markings.

6. Measure forward 10 mm and scribe

a second line. The second line (386

mm) is the cut location.

7. Make certain all three sides are

aligned. Cut through three sides of

the rail.

8. On the bottom of the damaged rail,

scribe a line from the outboard to

the inboard cut locations and cut

the remainder of the rail (1) from

the vehicle. Remove the damaged

section of rail.

1

386MM

1

(RIGHT OUTBOARD)

1-14 2001 Pontiac Aztek

Page 15

Right Front Lower

Rail Sectioning

1

3

Preparing the Undamaged

Portion of the Rail for

Installation

1. On original rail, cut and remove 10

mm of the outboard (1) and

downward (2) turned flanges of the

rail. Cut 10 mm gaps along the

corners of the original rail.

4

2

2. Step the top, bottom and side tabs

inward (3) to allow the service part

to fit over the original rail.

3. Clean and prepare mating surfaces

as necessary.

Installation Procedure

1. Position the service part over the

original rail. Align and check fit

using three-dimensional measuring

equipment.

2. Stitch weld along the entire

sectioning joint. Make 25 mm

(1␣ in.) welds along the seam with 25

mm (1 in.) gaps between them.

3. Go back and complete the stitch

weld. This will create a solid weld

joint with minimal heat distortion.

4. Clean and prepare all welded

surfaces.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

5. Prime with two-part catalyzed

primer.

6. Apply sealers and anti-corrosion

materials as necessary.

7. Install all related panels and

components.

2001 Pontiac Aztek 1-15

Page 16

Door Frame

Sectioning—Outer

(Front Hinge Pillar)

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Cut the panel where sectioning is to

be performed.

5. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the service part.

6. Remove the damaged Front Hinge

Pillar.

1

1

1-16 2001 Pontiac Aztek

Page 17

Door Frame

Sectioning—Outer

1

(Front Hinge Pillar)

Installation Procedure

1. Cut the replacement service part in

corresponding locations to fit the

remaining original panel. The

sectioning joint should be trimmed

to allow a gap of one-and-one-half

times the metal (1) thickness at the

sectioning joint.

2. In the Front Hinge Pillar, create a

50 mm (2 in.) backing plate (1)

from the unused portion of the

Door Frame Opening. Trim the

backing plate as necessary to fit

1

2

behind the sectioning joint.

3. In the rocker locations, create a 100

mm (4 in.) backing plate (2) from

the unused portion of the door

frame opening. Trim the backing

plate as necessary to fit behind the

sectioning joint.

4. Drill 8 mm (5/16 in.) plug weld

holes along the sectioning cut on

the remaining original part

—continued

2001 Pontiac Aztek 1-17

Page 18

Door Frame Sectioning—Outer

(Front Hinge Pillar)

Installation Procedure con't

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

5. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from the original panel.

6. Prepare all attachment surfaces as

necessary.

7. Apply weld-thru primer to all baremetal surfaces.

8. Fit the backing plate (1) halfway

into the sectioning joint (2). Clamp

and plug weld to the vehicle.

9. Align the Front Hinge Pillar using

three-dimensional measuring

equipment.

10. Plug weld accordingly.

11. To create a solid weld with

minimum heat distortion, make 25

mm (1 in.) stitch welds along the

seam with 25 mm (1 in.) gaps

between them. Then go back and

complete the stitch weld.

IMPORTANT: Prior to refinishing,

refer to publication GM 4901M-D01 GM Approved Refinish Materials

for recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

12. Clean and prepare all welded

surfaces.

25MM

(1/2 IN)

2

1

13. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

14. Refinish as necessary.

15. Install all related panels and

components.

1-18 2001 Pontiac Aztek

1

1

Page 19

Door Frame

Sectioning—Outer

(Center Pillar)

Removal Procedure

1. Remove all related panels and

components.

1

1

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Cut the panel where sectioning is to

be performed.

5. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the service part.

6. Remove the damaged Center Pillar.

2001 Pontiac Aztek 1-19

Page 20

Door Frame

Sectioning—Outer

(Center Pillar)

Installation Procedure

1. Cut the replacement Center Pillar

in corresponding locations to fit the

remaining original panel. The

sectioning joint should be trimmed

to allow a gap of one-and-one-half

times the metal (1) thickness at the

sectioning joint.

2. In the Center Pillar, create a 50 mm

(2 in.) backing plate (1) from the

unused portion of the Door Frame

Opening. Trim the backing plate as

necessary to fit behind the

sectioning joint.

3. In the rocker locations, create a 100

mm (4 in.) backing plate (2) from

the unused portion of the door

frame opening. Trim the backing

plate as necessary to fit behind the

sectioning joint.

1

1

2

2

4. Drill 8 mm (5/16 in.) plug weld

holes along the sectioning cut on

the remaining original part.

—continued

1-20 2001 Pontiac Aztek

Page 21

Door Frame Sectioning—Outer

(Center Pillar)

Installation Procedure con't

25MM

(1 IN)

2

1

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

5. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from the original panel.

6. Prepare all attachment surfaces as

necessary.

7. Apply weld-thru primer to all baremetal surfaces.

8. Fit the backing plate (1) halfway

into the sectioning joint (2) clamp

and plug weld to the vehicle.

9. Align the Center Pillar using threedimensional measuring equipment.

10. Plug weld accordingly.

100mm

(4 IN)

11. To create a solid weld with

minimum heat distortion, make 25

mm (1 in.) stitch welds along the

seam with 25 mm (1 in.) gaps

between them. Then go back and

complete the stitch weld

IMPORTANT: Prior to refinishing,

refer to publication GM 4901M-D01 GM Approved Refinish Materials

for recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

12. Clean and prepare all welded

surfaces.

13. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

14. Refinish as necessary.

1

15. Install all related panels and

components.

1

2001 Pontiac Aztek 1-21

Page 22

Door Frame

Sectioning—Outer

(Rear Lock Pillar)

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Cut the panel where sectioning is to

be performed.

1

1

5. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the service part.

6. Remove the damaged Rear Lock

Pillar.

1-22 2001 Pontiac Aztek

Page 23

Door Frame

Sectioning—Outer

(Rear Lock Pillar)

1

1

2

Installation Procedure

1. Cut the replacement Rear Lock

Pillar in corresponding locations to

fit the remaining original panel. The

sectioning joint should be trimmed

to allow a gap of one-and-one-half

times the metal (1) thickness at the

sectioning joint.

2. In the Rear Lock Pillar, create a 50

mm (2 in.) backing plate (1) from

the unused portion of the Door

Frame Opening. Trim the backing

plate as necessary to fit behind the

sectioning joint.

3. In the rocker locations, create a 100

mm (4 in.) backing plate (2) the

unused portion of the door frame

opening. Trim the backing plate as

necessary to fit behind the

sectioning joint.

4. Drill 8 mm (5/16 in.) plug weld

holes along the sectioning cut on

the remaining original part.

—continued

2001 Pontiac Aztek 1-23

Page 24

Door Frame Sectioning—Outer

(Rear Lock Pillar)

Installation Procedure con't

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2in.) apart.

5. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from the original panel.

6. Prepare all attachment surfaces as

necessary.

7. Apply weld-thru primer to all baremetal surfaces.

8. Fit the backing plate (1) halfway

into the sectioning joint (2) clamp

and plug weld to the vehicle.

9. Align the Center Pillar using threedimensional measuring equipment.

10. Plug weld accordingly.

25MM

(1 IN)

2

1

11. To create a solid weld with

minimum heat distortion, make 25

mm (1 in.) stitch welds along the

seam with 25 mm (1 in.) gaps

between them. Then go back and

complete the stitch weld.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

12. Clean and prepare all welded

surfaces.

13. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

14. Refinish as necessary.

15. Install all related panels and

components.

100mm

(4 IN)

1

1-24 2001 Pontiac Aztek

1

Page 25

Door Frame

Sectioning—Outer

(Rocker Sectioning)

Removal Procedure

1. Remove all related panels and

components.

1

1

1

1

30mm

(1 3/16 IN)

2

30mm

(1 3/16 IN)

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

4. By measuring from the lower edge

of the guide hole (1) downward 30

mm (1-3/16 in.), locate and mark

for sectioning of the Front Hinge

Pillar and the Center Pillar.

5. With quarter panel removed (2),

locate and mark for sectioning of

the Rear Lock Pillar.

6. Scribe a line horizontally to the

rocker.

IMPORTANT: Do not damage any

inner panels or reinforcements.

7. Cut the panel where sectioning is to

be performed.

—continued

2001 Pontiac Aztek 1-25

Page 26

Door Frame Sectioning—Outer

(Rocker Sectioning)

Removal Procedure con't

8. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the Rocker Panel.

9. Remove the damaged Rocker Panel.

1-26 2001 Pontiac Aztek

Page 27

Door Frame

Sectioning—Outer

(Rocker Sectioning)

Installation Procedure

1. Cut the replacement service part in

corresponding locations to fit the

remaining original panel. The

sectioning joint should be trimmed

to allow a gap of one-and-one-half

1

1

2

1

times the metal (1) thickness at the

sectioning joint.

2. In the Rear Lock Pillar, create a 50

mm (2 in.) backing plate (1) from

the unused portion of the Door

Frame Opening. Trim the backing

plate as necessary to fit behind the

sectioning joint.

3. Use the lower hinge reinforcement

(2) as the backing plate in the front

Hinge Pillar and the Center Hinge

Pillar.

4. Drill 8 mm (5/16 in.) plug weld

holes along the sectioning cut on

the remaining original part.

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1 in.) apart.

5. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from the original panel and

along the sectioning cut.

—continued

2001 Pontiac Aztek 1-27

Page 28

Door Frame Sectioning—Outer

(Rocker Sectioning)

Installation Procedure con't

6. Prepare all attachment surfaces as

necessary.

7. Apply weld-thru primer to all baremetal surfaces.

8. Fit the backing plate (1) halfway

into the sectioning joint (2). Clamp

and plug weld to the vehicle.

9. Align the Rocker Panel using threedimensional measuring equipment.

10. Plug weld accordingly.

11. To create a solid weld with

minimum heat distortion, make 25

mm (1 in.) stitch welds along the

seam with 25 mm (1 in.) gaps

between them. Then go back and

complete the stitch weld.

2

25MM

(1 IN)

1

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

12. Clean and prepare all welded

surfaces.

13. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

14. Refinish as necessay.

15. Install all related panels and

components.

1

1

1

1-28 2001 Pontiac Aztek

Page 29

Roof Outer

Replacement

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners

• Anti-corrosion materials

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the roof panel.

5. Remove the damaged roof panel.

2001 Pontiac Aztek 1-29

Page 30

Roof Outer

Replacement

Installation Procedure

1. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from the original panel.

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

2. Prepare all attachment surfaces as

necessary.

3. Apply weld-thru primer to all baremetal surfaces.

4. Position the roof panel.

5. Plug weld accordingly.

6. Clean and prepare all welded

surfaces.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-00

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

7. Apply the following as necessary:

• An anti-corrosion primer

• Sound deadeners

• Sealers

8. Refinish as necessary.

9. Install all related panels and

components.

1-30 2001 Pontiac Aztek

Page 31

Quarter Panel

Replacement

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

1

1

1

1

3. Note the location and remove the

following as necessary:

• Sealers

• Sound deadeners (1)

• Anti-corrosion materials

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Cut the quarter panel where

sectioning is to be performed (1).

5. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the service part.

6. Remove the damaged quarter.

2001 Pontiac Aztek 1-31

Page 32

Quarter Panel

2

Replacement

Installation Procedure

1. Cut the replacement quarter panel

in corresponding locations to fit the

remaining original panel. The

sectioning joint should be trimmed

to allow a gap of one-and-one-half

times the metal thickness at the

sectioning joint.

2. Create a 50 mm (2 in.) backing

plate from the unused portion of the

service part Trim the backing plate

as necessary to fit behind the

sectioning joint.

3. Drill 8 mm (5/16 in.) plug weld

holes (1) along the sectioning cut

on the remaining original part (2).

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

4. Drill 8 mm (5/16 in.) plug weld

holes in the service part as

necessary in the locations noted

from the original panel and along

the sectioning cut.

5. Prepare all attachment surfaces as

necessary.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

6. Apply weld-thru primer to all baremetal surfaces.

—continued

50MM

(2 IN)

1

25MM

(1 IN)

50MM

(2 IN)

1-32 2001 Pontiac Aztek

Page 33

Quarter Panel Replacement

Installation Procedure con't

7. Fit the backing plate halfway into

the sectioning joint, clamp and plug

weld to the vehicle.

1

CAUTION: THE FUEL FILLER

OPENING MUST BE PROPERLY

SEALED PRIOR TO

POSITIONING THE QUARTER

PANEL. FAILURE TO PROPERLY

SEAL THE QUARTER PANEL

COULD RESULT IN EXHAUST

GAS LEAKAGE INTO THE

INTERIOR OF THE VEHICLE,

CAUSING PERSONAL INJURY.

8. Install GM P/N 12399117 Sealing

Strip between outer wheelhouse and

quarter panel gas door pocket.

9. Install service quarter panel leaving

a gap of one and one half times the

thickness of the metal (1) at the

sectioning joint.

10. Plug weld accordingly.

11. To create a solid weld with

minimum heat distortion, make 25

mm (1 in.) stitch welds along the

seam with 25 mm (1 in.) gaps

between them. Then go back and

complete the stitch weld.

12. Clean and prepare all welded

surfaces.

13. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

14. Refinish as necessary.

15. Install all related panels and

components.

2001 Pontiac Aztek 1-33

Page 34

Rail Sectioning—

Rear

Removal Procedure

IMPORTANT: Rear rail sectioning may

require replacement of the rear floor panel.

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Perform the necessary procedures to

gain access to the rear rail.

5. Locate and drill out all factory welds.

Note the number and location of

welds for installation of the rear rail.

6. Mark the cut location by measuring 5

mm (1/4 in.) from the rear edge of the

second gauge hole rearward

7. Cut the rear rail section.

8. Remove the damaged rear rail section.

1-34 2001 Pontiac Aztek

5mm

(0.25 in)

Page 35

5mm

(0.25 in)

Rail Sectioning—

Rear

Installation Procedure

1. Mark the cut location on the service

rail by measuring 5 mm (1/4 in.)

from the front edge of the second

gauge hole forward.

2. Cut the rear rail service part.

3. Cut and remove 30 mm (1 and 3/16

in.) from the flanges on either side

of the service section rail to create

30 mm (1 and 3/16 in.) tabs (1).

1

1

2

1

2

4. Cut 5 mm (1/4 in.) wide gaps in the

bottom corners (2).

5. Step the tabs inward (1) to allow the

service rail section to fit inside of

the original rear rail.

IMPORTANT: The metal of the rear

rail is of a heavy gauge. However, the

tabs can be created using the

appropriate tools.

6. Weld the tabs together along the

lower edges (2).

—continued

2001 Pontiac Aztek 1-35

Page 36

Rail Sectioning—Rear

Installation Procedure con’t

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

7. Drill 8 mm (5/16 in.) plug weld

holes along the sectioning cut on

the original rail. Locate these holes

13 mm (1/2 in.) from the edge and

spaced 40 mm (1/2 in.) apart.

8. Prepare all attachment surfaces as

necessary.

9. Turn the weld flange downward for

rewelding (2).

10. Apply weld-thru primer to all baremetal surfaces.

11. Align the service part over the

stepped tab using three-dimensional

measuring equipment.

2

1

12. Plug weld accordingly.

1-36 2001 Pontiac Aztek

—continued

Page 37

Rail Sectioning—Rear

Installation Procedure con’t

13. To create a solid weld with

minimum heat distortion, make 25

mm (1 in.) stitch welds along the

seam with 25 mm (1 in.) gaps

between them. Then go back and

complete the stitch weld.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

14. Clean and prepare all welded

surfaces.

15. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

16. Install all related panels and

components.

2001 Pontiac Aztek 1-37

Page 38

Floor Panel

Replacement

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the rear body opening right and left

lower reinforcements, gaining access

to the rear floor panel.

5. Locate Rear Floor Panel to midfloor overlay seam.

6. Cut rearward of the mid-floor. Use a

straight line to cut Rear Floor

Panel.

—continued

1-38 2001 Pontiac Aztek

Page 39

Floor Panel Replacement

Removal Procedure con’t

7. Locate and drill out all factory

welds. Note the number and

location of the welds for installation

of the Rear Floor Panel.

8. Remove the damaged Rear Floor

Panel.

2001 Pontiac Aztek 1-39

Page 40

Floor Panel

Replacement

Installation Procedure

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

1. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from the original rear outer

wheelhouse.

2. Drill 8 mm (5/16 in.) plug weld

holes at the forward edge of the rear

floor panel.

3. Prepare all attachment surfaces as

necessary.

4. Apply weld-thru primer to all baremetal surfaces.

5. Position the rear floor panel to

overlap the mid-floor panel.

6. Plug weld accordingly.

7. Drill 8 mm (5/16 in.) plug weld

holes in the service part as

necessary in locations noted from

the original panel.

8. Position right and left lower

reinforcements to the rear body

opening.

9. Plug weld accordingly.

1-40 2001 Pontiac Aztek

Page 41

Floor Panel Replacement

Installation Procedure con’t

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

10. Clean and prepare all welded

surfaces

11. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

12. Refinish as necessary.

13. Install all related panels and

components.

2001 Pontiac Aztek 1-41

Page 42

Panel Replacement

– Rear End

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Locate and drill out all factory

welds. Note the number and

location of welds for installation of

the rear body opening right and left

lower reinforcements, gaining access

to the rear floor panel.

5. Remove the Rear End Panel.

1-42 2001 Pontiac Aztek

Page 43

Panel Replacement

– Rear End

Installation Procedure

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

1. Drill 8 mm (5/16 in.) plug weld

holes in the service part as

necessary in locations noted from

the original panel.

2. Prepare all attachment surfaces as

necessary.

3. Apply weld-thru primer to all baremetal surfaces.

4. Position the Rear End Panel.

5. Plug weld accordingly.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

6. Clean and prepare all welded

surfaces.

7. Apply the following as necessary:

• Anti-corrosion materials

• Sound deadeners

• Sealers

8. Refinish as necessary.

9. Install all related panels and

components.

2001 Pontiac Aztek 1-43

Page 44

Wheelhouse

Replacement –

Rear Outer

Removal Procedure

1. Remove all related panels and

components.

2. Restore as much of the damage as

possible to factory specifications.

3. Note the location and remove the

following as necessary:

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

IMPORTANT: Do not damage any

inner panels or reinforcements.

4. Using a suitable tool, trim off the

damaged rear wheelhouse.

IMPORTANT: The original weld

flange can be used as an attachment

surface for installation of the new

wheelhouse.

5. Note the number and location of

welds for installation of the Rear

Outer Wheelhouse.

1

6. Remove the damaged Rear Outer

Wheelhouse.

1-44 2001 Pontiac Aztek

Page 45

Wheelhouse

Replacement –

Rear Outer

Installation Procedure

IMPORTANT: In any area damaged

beyond recognition, space plug weld

holes every 40 mm (1-1/2 in.) apart.

1. Drill 8 mm (5/16 in.) plug weld

holes as necessary in locations

noted from the original Rear Outer

Wheelhouse.

2. Prepare all attachment surfaces as

necessary.

3. Apply weld-thru primer to all baremetal surfaces.

4. Position the Rear Outer

Wheelhouse.

5. Plug weld accordingly.

IMPORTANT: Prior to refinishing,

refer to publication GM4901M-D-01

GM Approved Refinish Materials for

recommended products. Do not

combine paint systems. Refer to

paint manufacturer’s

recommendations.

6. Clean and prepare all welded

surfaces

7. Apply the following as necessary:

1

1

• Anti-corrosion materials

• Sound deadeners (1)

• Sealers

8. Refinish as necessary.

9. Install all related panels and

components.

2001 Pontiac Aztek 1-45

Page 46

Aztek Plastic Panel Identification

1

1

3

2

1

3

1

1

1

1

1

1. TPO (Thermoplastic Olefin)

2. Xenoy

3. Polypropylene Energy Foam

1-46 2001 Pontiac Aztek

Page 47

Aztek Metal Panel Identification

1

1

1

1

3

2

2

1

1

2

1

1. TSGS (Two Sided Galvanized Steel)

2. UHSS (Ultra High Strength Steel)

3. AL (Aluminum)

1

2001 Pontiac Aztek 1-47

Page 48

Body Dimensions

WIDTH

1058

1052

1163

1456

1081

982

Point-to-Point

Ø

789

807

807

801

808

994

944

807

HEIGHT

C

L

LENGTH

1-48 2001 Pontiac Aztek

970

1117

744

1130

91

U

18

1139

1122

T

Ø

V

W

X

1164

2100

Body Side

768

1136

Y

Z

DATUM

LINE

Page 49

Body Dimensions

C

L

WIDTH

WIDTH

355 716 687 747 740

355 716 687 747 740

Ø

C

L

HEIGHT

LENGTH

925

N

1038

O

852

1019

1028

1159 1181

P

R

433

Q

470

Engine Compartment

206

DATUM

LINE

S

Ø

2001 Pontiac Aztek 1-49

Page 50

Body Measurements

DRIVER SIDE

Ø

WIDTH

C

L

WIDTH

HEIGHT

LENGTH

450

450

663

A

542 538

584

B

1105

538542

580

C

953

845

259

259

419

470

470

411

113

E

175

474

474

411

406

450

450

415

432 432 432

432432432

462 504 528 567

432 432 432

432 432 432

653

571

C

L

DATUM

LINE

F

G

1071

1425

H

1928

I

2555

J

K

2801

3062

L

M

1-50 2001 Pontiac Aztek

D

Ø

Underbody

Page 51

Frame Dimensions

905

905

Point-to-Point

2001 Pontiac Aztek 1-51

Loading...

Loading...