Ponovo PW636i Hardware Instruction Manual

PW636i Hardware Instruction Manual

1

PONOVO POWER CO., LTD

2F, 4Cell, Tower C, In.Do Mansion

No.48A Zhichun Road, Haidian District

Beijing, China (Post Code 100098)

Office

TEL. +86 (10) 82755151 ext. 8887

FAX +86 (10) 82755257

E-Mail Info@ponovo.com.cn

Website www.ponovo.com.cn

PW636i

HARDWARE INSTRUCTION MANUAL

VERSION: PW636i-AE-2.03

DATE : 21/09/2011

This manual is the publisher of PONOVO POWER CO., LTD. To make any kind of copy of this

manual please contact PONOVO POWER CO., LTD in advance.

This manual represents the technical status for the moment of publishing. The product information,

description and specifications mentioned in the manual do not have any contact binding force and

PONOVO POWER CO., LTD remains the right to make modifications to the technical

specifications and configurations without prior notice. PONOVO POWER does not take

responsibility to the possible error/mistakes in this manual.

PW636i Hardware Instruction Manual

2

1. Preface ……………………… 3

2. Safety precaution …………. 4

3. Designed applications …… 5

3.1 Product features …………… 5

4. Operation preparation …… 6

4.1 Preparation …………………. 6

4.2 Connecting PC …………….. 6

5. General description ……… 7

5.1 Block diagram ……………… 7

5.2 DSP card …………………… 8

5.3 Front panel …………………. 8

5.4 Ethernet port ………………… 8

5.5 Current booster interface ….. 9

5.6 Pause button ………………… 10

5.7 LED indication ………………. 10

5.8 Rear panel…………………….. 12

5.9 External amplifier and low

level output interface………... 13

5.10 GPS interface ………………… 14

5.11 Multi-kits synchronization

interface ………………………. 15

5.12 IP reset ……………………….. 16

6. Hardware configuration …… 17

6.1 Current generators …………. 17

6.2 Current output configuration

in 3 current mode ……………. 17

6.3 Current in series connection in 3

current mode ………………… 19

6.4 Voltage generators ………….. 19

6.5 Connect two voltage

generators in series..………. 19

7. Binary inputs and outputs ….. 21

7.1 General Description …………. 21

7.2 Binary Input…………. …………. 21

7.3 Polarity of Binary Inputs …….. 22

7.4 Binary configuration…….. …….. 22

7.5 Isolation of Binary Inputs …….. 22

7.6 Threshold for Binary Inputs ….. 22

7.7 Binary Outputs ………………… 23

8. Getting ready for PC

controlled operation ………… 24

8.1 General description …………… 24

8.2 Set IP address ……….……… 24

8.3 Steps for setting IP address

in PC …………………………... 24

9. PW636i0-Related Products and

Accessories……………………...27

9.1 Analog Recording Unit

AR-10/AR-7D ………………………. ..28

9.2 PGPS02-GPS-based Synchronization

device …….………………………… ….29

9.3 PIRIG-B Based Synchronization

device…………………………………….29

9.4 PSS01 Circuit Breaker Simulator…30

9.5 Phpc01 Current Booster……………30

9.6 PACB108 scanning head…………..31

9.7 Low Level Output and Counter Input

Cable…….……………………………….31

9.8 Synchronization Control Cable… …31

9.9 Fiber Optic Cable……………………31

9.10 Standard Accessories...…………..31

9.10.1 Soft Bag for Test Lead……….32

9.10.2 Transportation Case…….……39

10. Specifications……….……………40

11. Appendix…….……….……………43

Contents

PW636i Hardware Instruction Manual

3

This manual gives detailed introduction to

PW636i so that user can have the reasonable,

effective and safe operation of this test kit.

This manual mainly consists of the following

parts:

Equipment and functions:

This part describes the main hardware parts

and their functions.

Panel description

This part describes the interfaces on the

panels and their applications

Technical specifications

This part describes the technical specifications

Optional accessories

This part describes the optional accessories

which will be used for dedicated applications

At the test site user should also refer to other

safety and test regulations required by his

management authorities.

This test equipment must be operated by

professional test people and careful reading of

this manual is required before operating this

test equipment.

The complete test system consists of PW636i

test equipment (used for generating analog

test signals), PowerTest test software,

Computer which has installed PowerTest

software, Test Leads/cables, etc. This manual

gives only the description to the hardware part.

Please refer to PowerTest software user

manual or PowerTest online help for details of

the software.

1.Preface

PW636i Hardware Instruction Manual

4

1. In case the power outlet for powering up the PW636i dose not have protective ground

customer must connect the ground socket of PW636i to the protective ground at the

test site

2. Please turn off the output before connecting/disconnecting the test object

3. The voltage output of over 36V is considered as dangerous and care must be taken

4. It’s not allowed to feed external voltage into the voltage/current output sockets

5. It’s not allowed to feed external current into the current/voltage output sockets

6. Disconnect the external circuit from the relay to avoid any influence to the test

7. Do not block the ventilation outlets

8. Avoid the equipment to be wet by rain

9. Do not switch-on and operate the equipment in the place having explosive gas or

water vapor

10. The 500V dangerous voltage can be in the equipment and please don’t remove the

cover by yourself

11. Please contact the manufacture for any maintenance

12. The guarantee will become invalid if PW636i is opened by the customer

2.Safety precaution

PW636i Hardware Instruction Manual

5

PW636i can be used by power plants,

substations, and relay manufactures, etc, for

the following test applications.

1. Test protective relays

2. Test transducers

3. Test energy meters

With optional AR-7D or AR-10 analog

recording unit the PW636i can even be used

for analog waveform analysis.

Product features

1. Output sources

6×32A current sources in two groups

4×300V voltage sources

2. Binary inputs

8 binary inputs for potential free or

potential contacts

3. Counter inputs

4 high speed counter inputs

4. DC measuring inputs

2 DC measuring inputs for testing

transducers

5. Binary outputs

8 binary inputs in two groups, 4 of dry

contact type and 4 of semiconductor

type

6. Low level outputs

12 low level outputs used for driving

external amplifiers or testing

Rogowski principle based relay

7. External amplifiers interface

8. GPS interface

Can receive GPS pulse signal from

optional PGPS02

9. Synchronized control interface

Used for synchronizing several

PW636i for specialized test purpose

10. Current booster interface (optional)

Used for increasing the compliance

voltage of current output for testing

high burden relays

11. AR-7D/AR-10 analog recording unit

(optional)

3.Designed applications

PW636i Hardware Instruction Manual

6

Preparation

Be sure that the following preparation/system

components are ready before operating the

test equipment:

PW636i test equipment

Main supply cable (delivered)

LAN control cable (delivered)

PC with PowerTest software properly

installed

Test leads connected to the test object

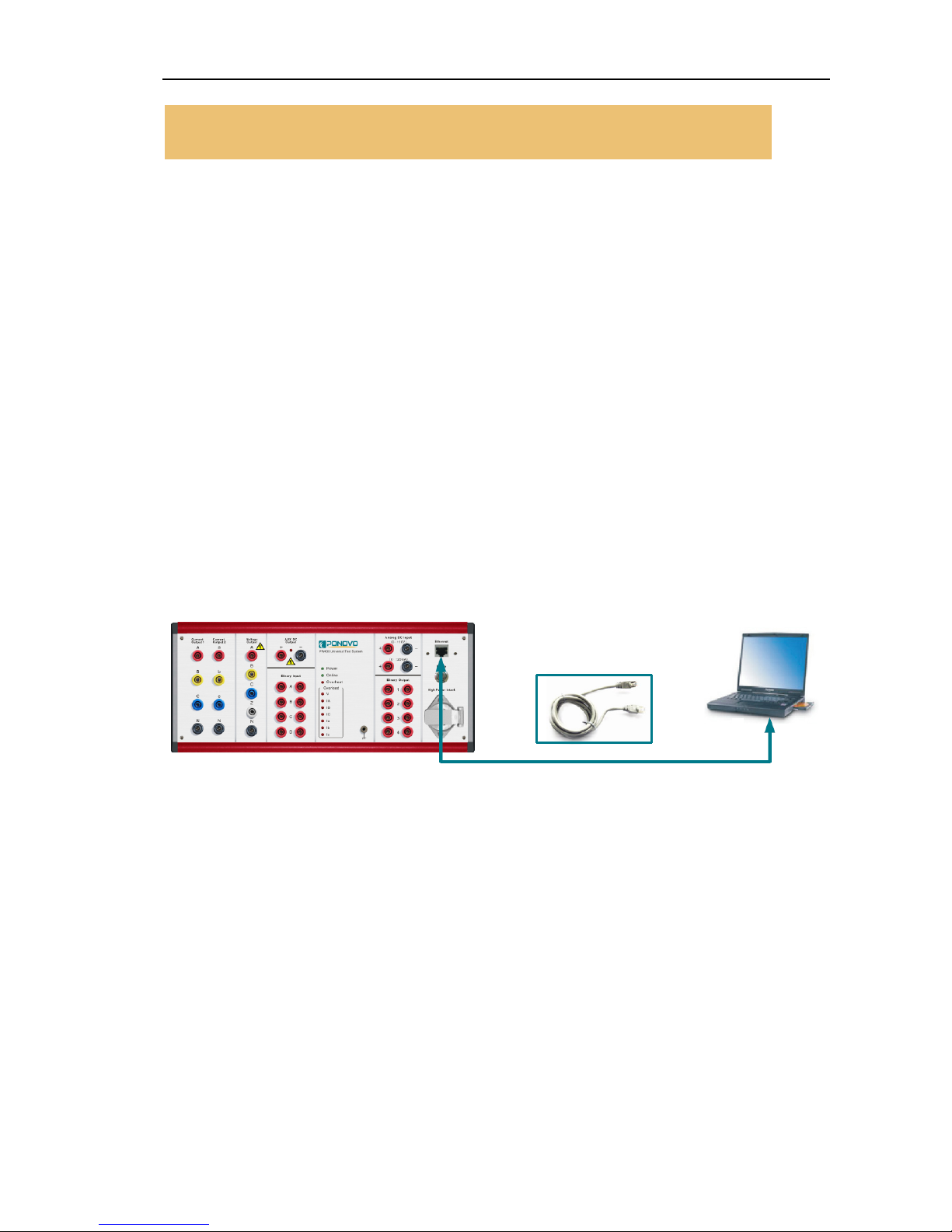

Connecting PC

1. Connect the LAN cable between PC and PW636i

2. Connect the power cables for PC and PW636i

3. Connect PW636i ground socket to the protective ground

4. Power on the PC and PW636i

5. Run PowerTest software

4.Operation preparation

PW636i Hardware Instruction Manual

7

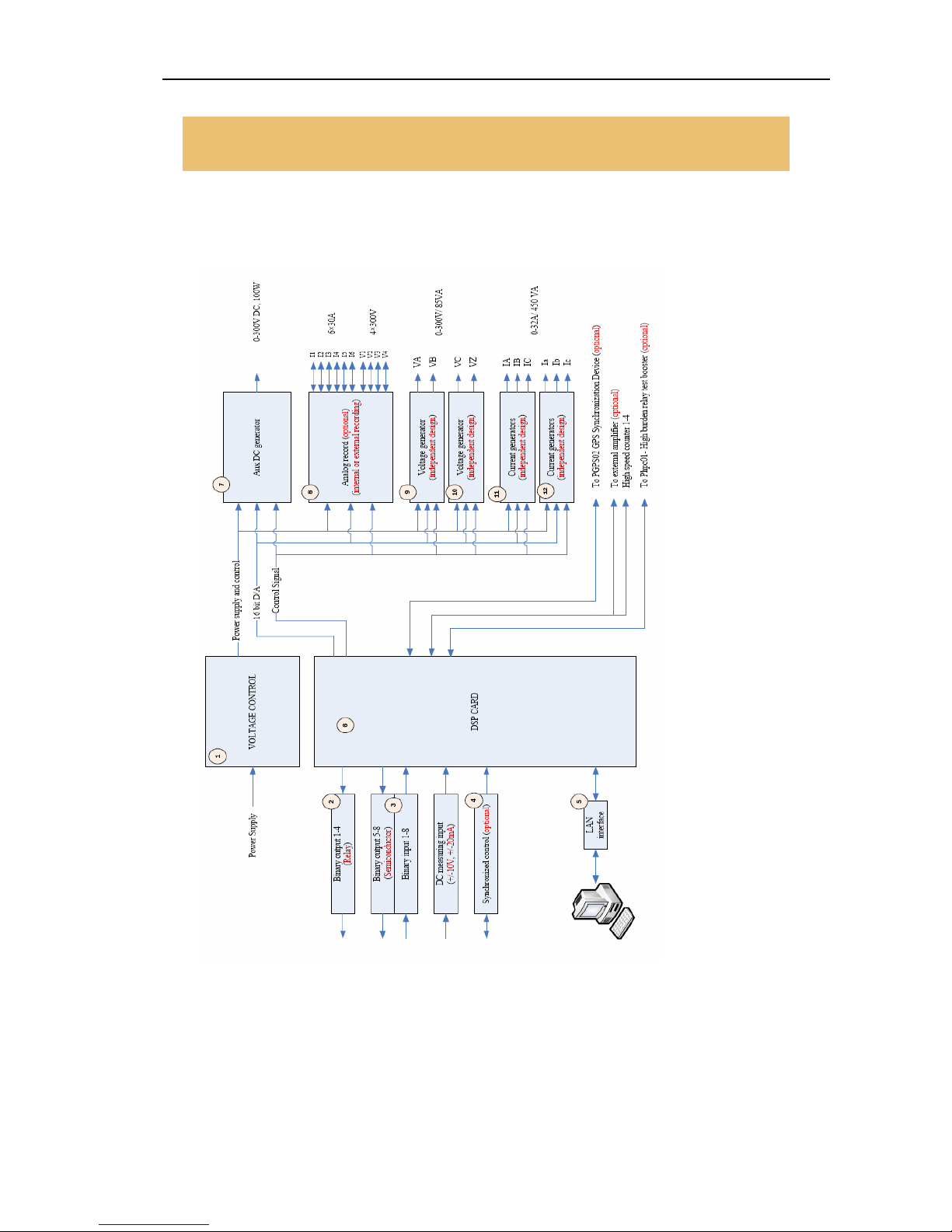

Block diagram

5.General description

PW636i Hardware Instruction Manual

8

DSP card

High performance DSP (digital signal processor) is used on the DSP card to ensure the accurate

and fast signal generation.

To get the satisfied accuracy and resolution the 32 bit D/A data converting technology is applied.

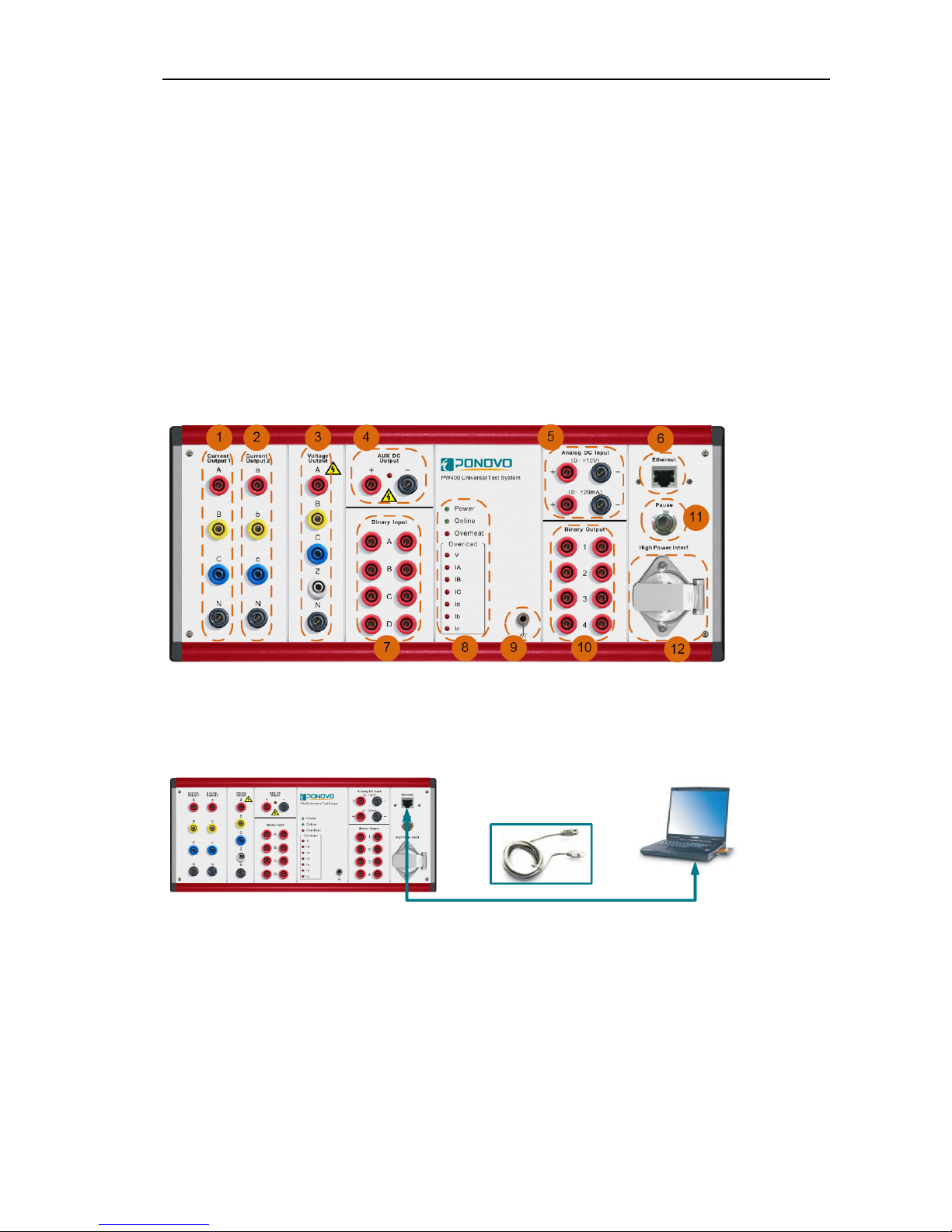

Front panel

1. Current output group 1

2. Current output group 2

3. Voltage output

4. Auxiliary DC

5. DC measuring input

6. RJ45 Ethernet PC control port

7. Binary input group 1

8. LED indication

9. Earth socket

10. Binary output group 1

11. Pause button

12. Current booster interface

Ethernet port

The Ethernet port is used to connect to external PC via Ethernet control cable.

Please refer to “Getting ready for connecting to PC” for details

PW636i Hardware Instruction Manual

9

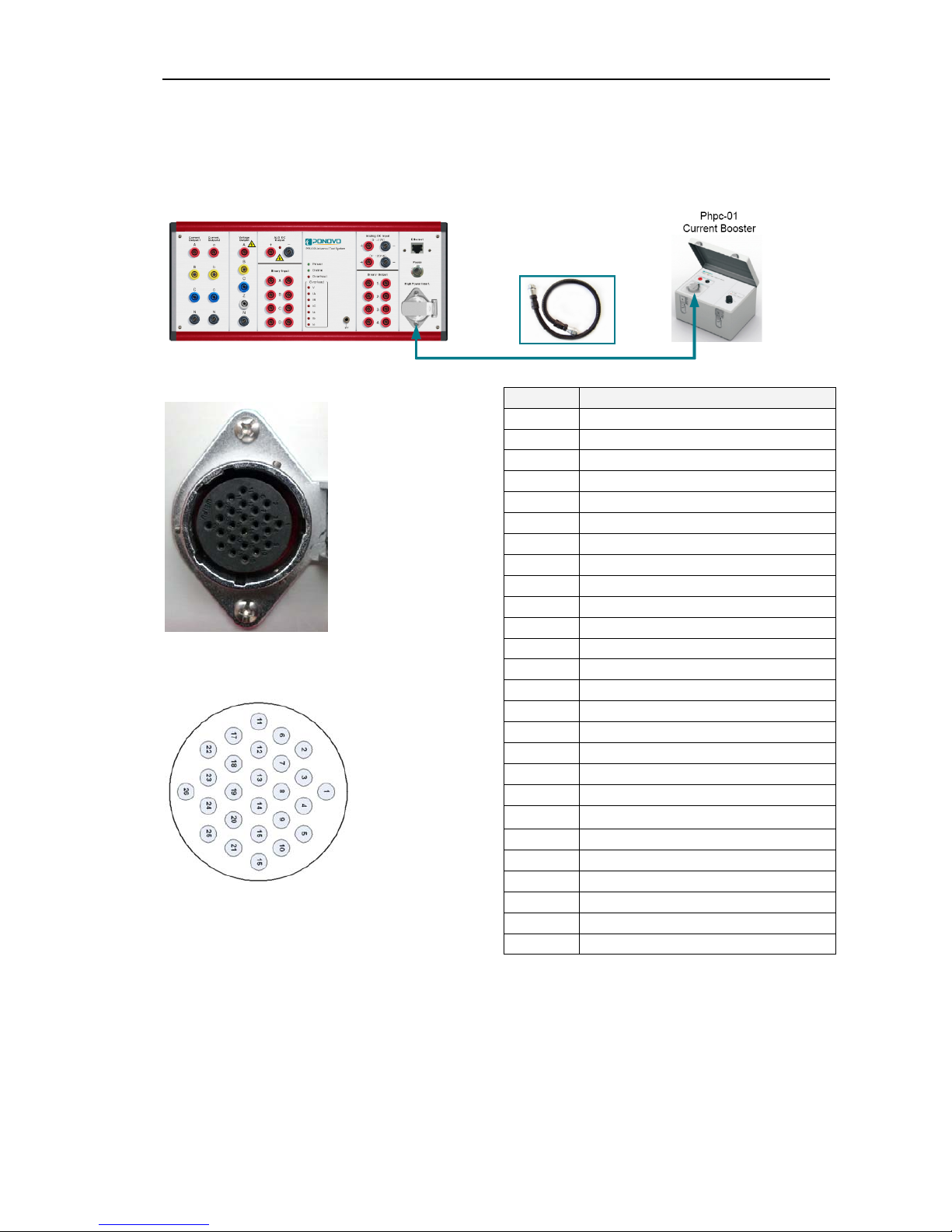

Current booster interface

This interface is used to connect to the external current booster (optional) for testing high burden

relays.

Please refer to “Current booster user manual”

for details

Pin Signal

1 Current IA

2 Current IN

3 Current IB

4 Current IN

5 Current IC

6 Current IN

7 Current Ia

8 Current In

9 Current Ib

10 Current In

11 Current Ic

12 Current In

13 Voltage VA (not used)

14 Voltage VB (not used)

15 Voltage VC (not used)

16 Voltage VZ (not used)

17 Voltage VN (not used)

18 Not used

19 Not used

20

+12V(100mA)

21 +12V GND

22 Range switcher 1

23 Range switcher 2

24 Range switcher 3

25 Range switcher 4

26 Range switcher (GND)

PW636i Hardware Instruction Manual

10

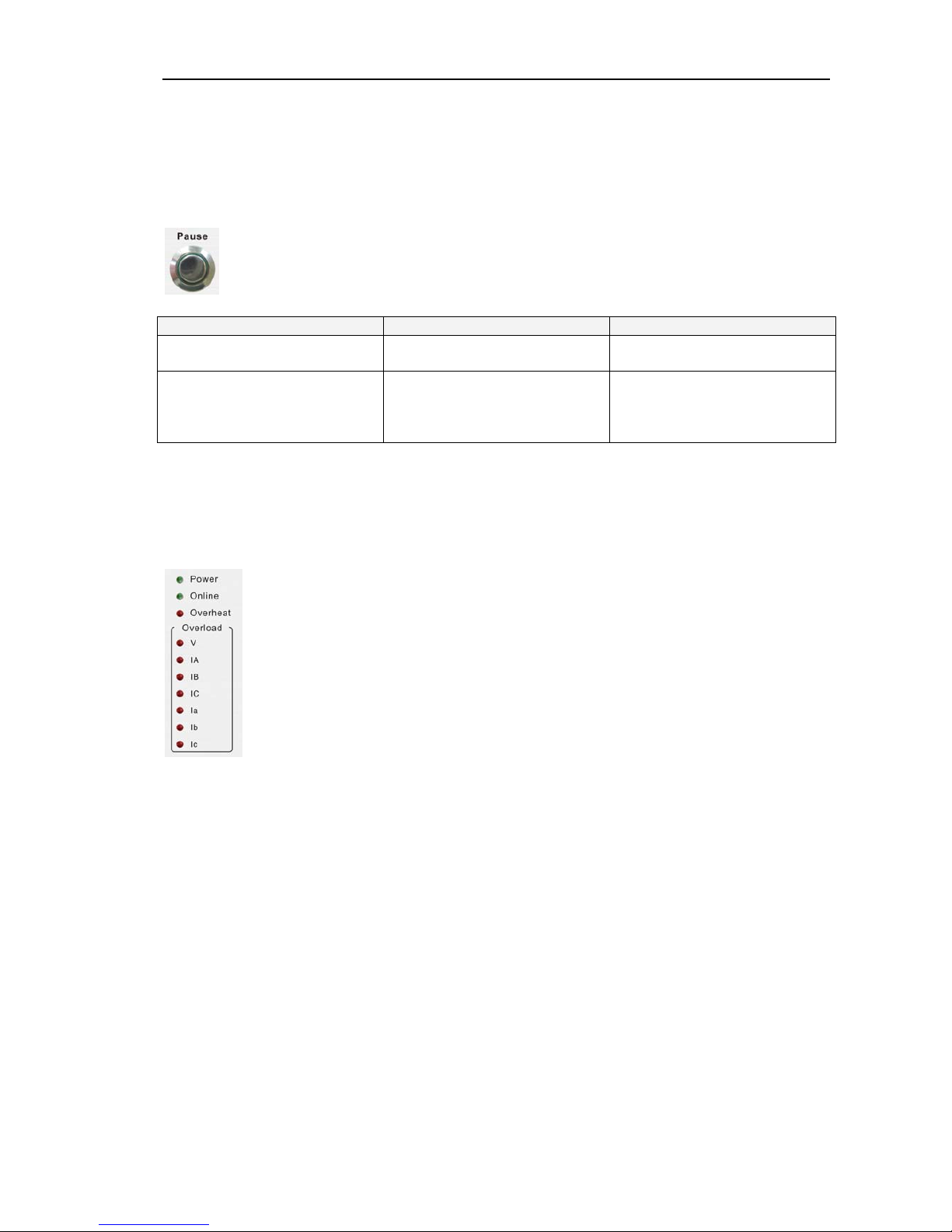

Pause button

The Pause button on the front panel is designed to cut the current/voltage outputs either for test

purpose or under emergency case.

‘Manual’ control mode ‘Auto’ control mode

Push ‘Pause’ button cut the current/voltage cut the current/voltage, PC

software will continue to run

Release ‘Pause’ button current/voltage output will be

recovered from the point

where we push the Pause

button

current/voltage output will be

recovered from the software

execution point at the moment

we release the Pause button

LED Indication

The LED indication on the front panel gives information about the hardware working conditions

In normal working condition the status of LEDs will have the following indication in ‘Power on’ and

‘Testing process’ conditions

PW636i Hardware Instruction Manual

11

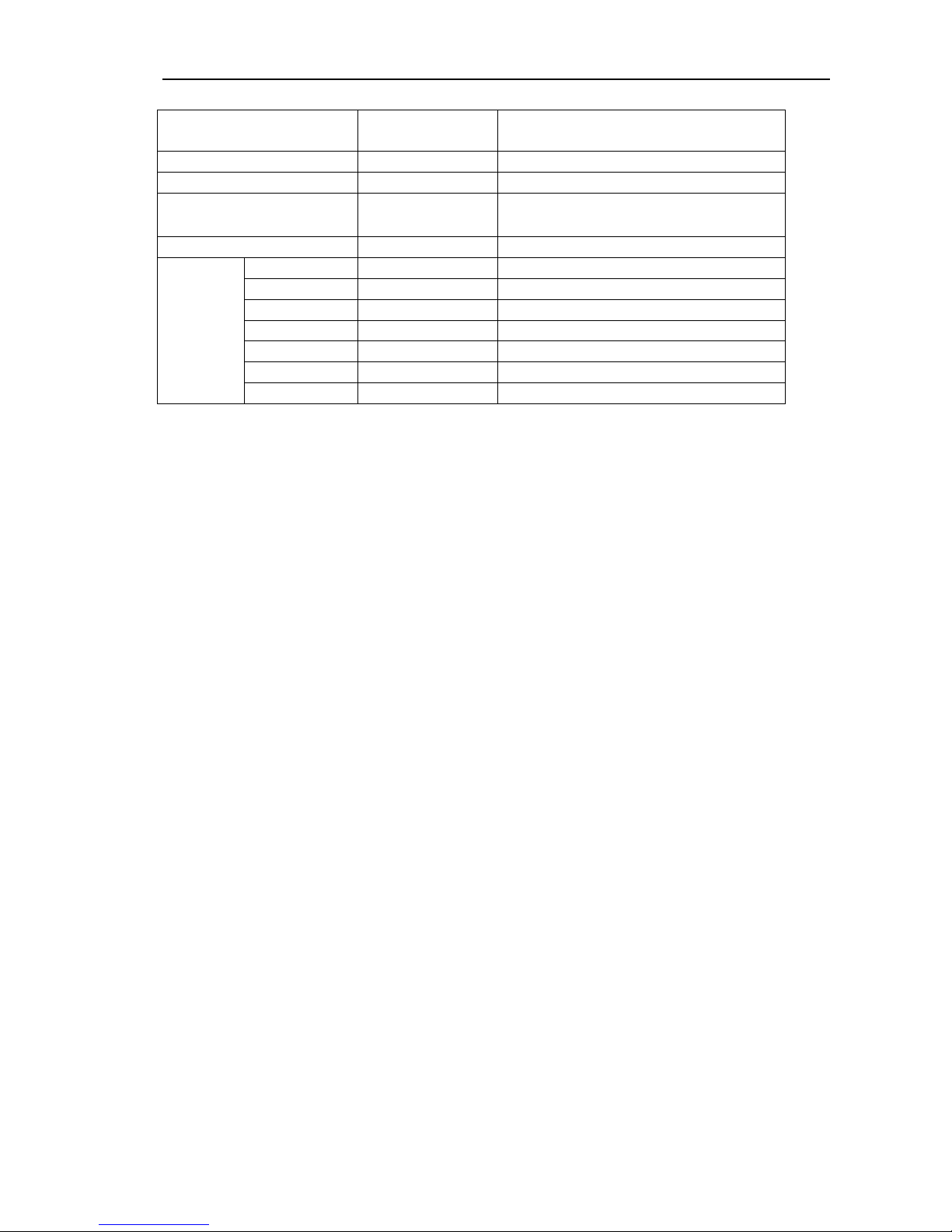

Power on

condition

All current/voltage channels are

having outputs

Power lamp Lighted Lighted

Online lamp

Not lighted Lighted and flashing

PAUSE lamp Not lighted

(push to light)

Not lighted(push to light)

Overheat lamp Not lighted Not lighted

Overload

lamp

V Not lighted Not lighted

IA Not lighted Not lighted

IB Not lighted Not lighted

IC Not lighted Not lighted

Ia Not lighted Not lighted

Ib Not lighted Not lighted

Ic Not lighted Not lighted

PW636i Hardware Instruction Manual

12

Rear panel

1. Binary input group 2

2. Binary output group 2

3. External amplifier and low level output

interface

4. Ventilation

5. Power switcher

6. GPS interface

7. Multi-kits synchronization interface

8. IP reset

9. Connector for mains supply

PW636i Hardware Instruction Manual

13

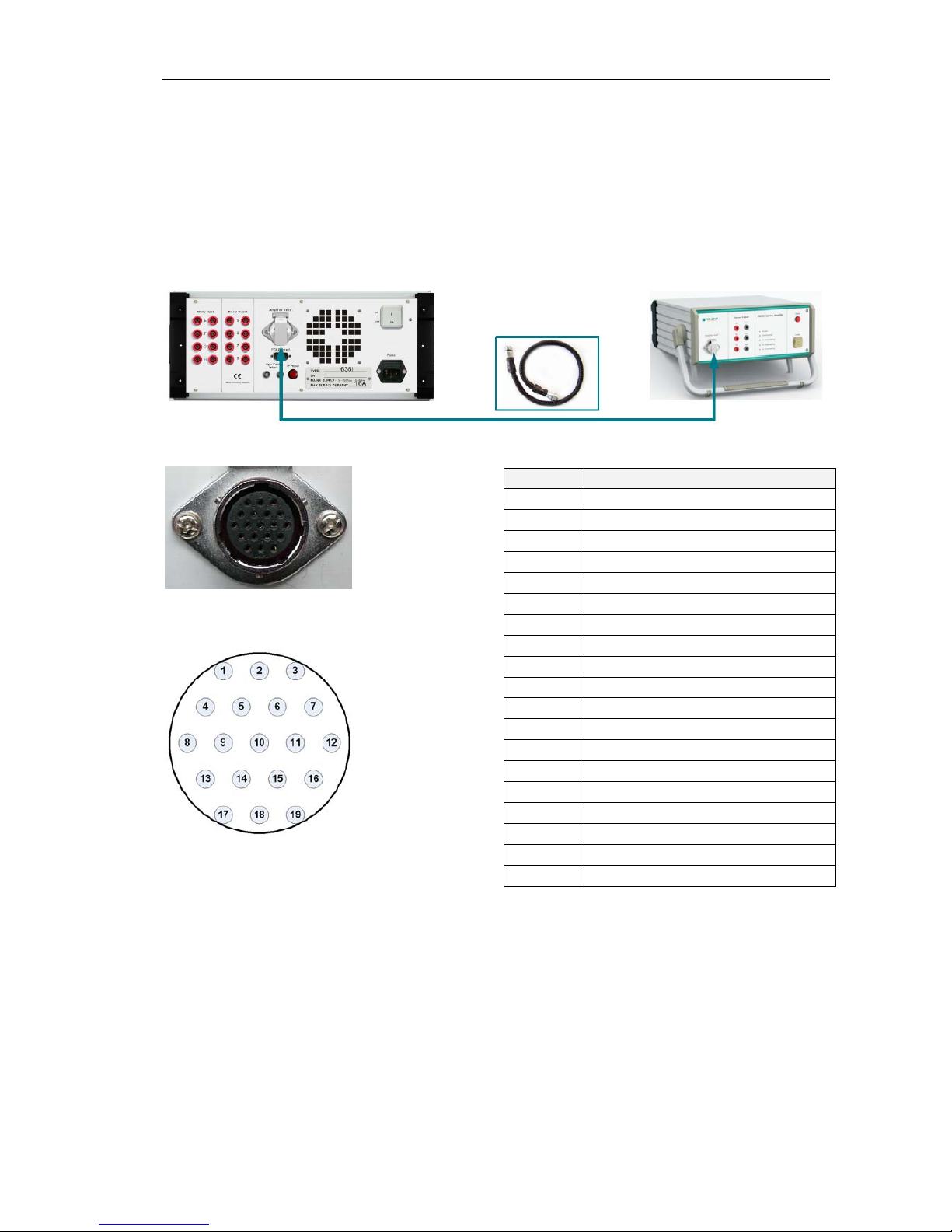

External amplifier and low lever output

interface

This interface is used to connect to external amplifier (optional) to increase the output channel and

output power.

The 12 low level outputs are to be used for testing relays with Rogowski or voltage dividers input.

For more information about the external amplifier please refer to “External amplifier user

manual”

Pin Signal

1 Low level output 1

2 Low level output 2

3 Low level output 3

4 Low level output 4

5 Low level output 5

6 Low level output 6

7 Low level output 7

8 Low level output 8

9 Low level output 9

10 Low level output 10

11 Low level output 11

12 Low level output 12

13 Low level output GND

14 Control signal

15 High speed counter 1

16 High speed counter 2

17 High speed counter 3

18 High speed counter 4

19 High speed counter GND

PW636i Hardware Instruction Manual

14

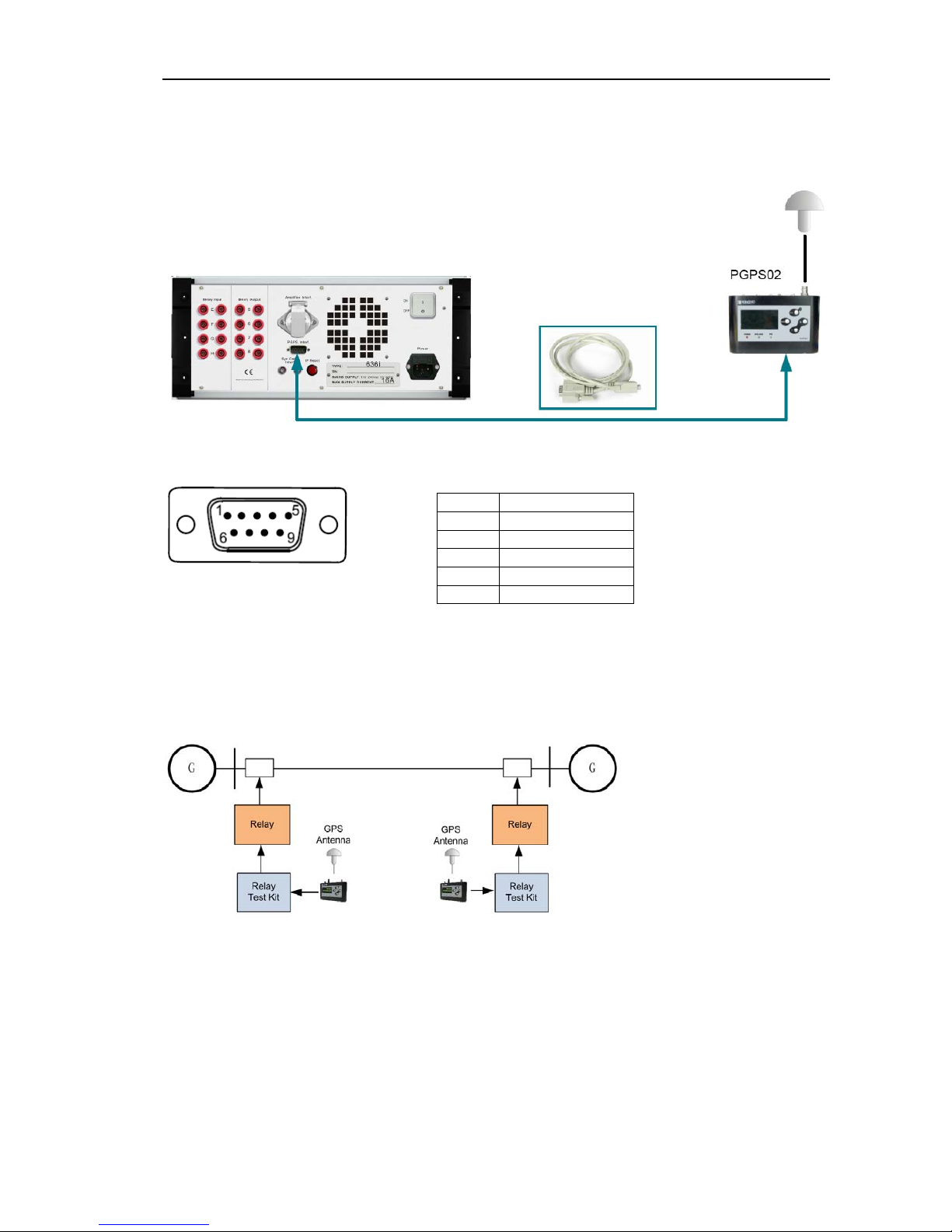

GPS interface

This interface is used to connect to our optional PGPS02 GPS-based synchronization device.

DB9 Chassis contact, male

----------------------------------------------

Note:

PPS means Pulse Per Second

----------------------------------------------

One popular application of GPS-synchronized control is for end-to-end test for line protection relay

Please refer to ‘PGPS02 user manual’ for details

Signal Contact pin

Power 1

Ready 2

PPS 3

GND 5

GND 9

Loading...

Loading...