SUBMERSIBLE

WATER PUMP

INSTRUCTION MANUAL

HOTLINE 1300 AQUATEC

VERSION

JUNE 2016

MODEL

02EV200 - EV7200

02EV225 - EV9200

02EV250 - EV11200

02EV275 - EV13600

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 1 7/11/17 7:53 am

WELCOME TO THE WORLD OF PONDMAX™.

YOU MADE THE RIGHT CHOICE INVESTING IN THIS

QUALITY PRODUCT. THANK YOU AND ENJOY.

TECHNICAL SPECIFICATIONS

DESCRIPTION

EV7200 EV9200 EV11200 EV13600

MAXIMUM WATER FLOW(L/H)

7200 9300 11200 13600

MAXIMUM HEAD (M)

5.5 6.0 6.5 7.0

POWER CONSUMPTION* (W)

59 94 120 160

VOLTS (V)

240 240 240 240

FREQUENCY (HZ) AC

50 50 50 50

IP RATING

IPX8 IPX8 IPX8 IPX8

INLET Ø BSP THREAD (INCH)

1½ (M) 1½ (M) 1½ (M) 1½ (M)

OUTLET Ø BSP THREAD (MALE/FEMALE)

1½ (M) 1½ (M) 1½ (M) 1½ (M)

THREADED BALL JOINT INCLUDED

Yes Yes Yes Yes

THREADED BALL JOINT OUTLET - 1 1/2" MALE BSP

Yes Yes Yes Yes

CABLE LENGTH (M)

10 10 10 10

RECOMMENDED TUBING SIZE (MM) ID

40 40 50 75

OTHER MODELS AVAILABLE IN THE EVOII RANGE

EV1900 EV2900 EV3900 EV4900

EV1910

-DC

EV2910

-DC

EV3910

-DC

EV4910

-DC

MAXIMUM WATER FLOW (L/H)

1800 3000 4000 4900 1800 3000 4000 4900

MAXIMUM HEAD (M)

2.4 3.4 3.8 5.0 2.4 3.4 3.7 4.6

VOLTS (V)

240 240 240 240 12V - DC 12V - DC 12V - DC 12V - DC

SUITABLE FOR SOLAR

NO NO NO NO Yes Ye s Ye s Ye s

BEFORE USING THIS PRODUCT, PLEASE READ THESE INSTRUCTIONS OF USE CAREFULLY AND

MAKE YOURSELF FULLY FAMILIAR WITH THE UNIT. PLEASE KEEP THESE INSTRUCTIONS IN A SAFE

PLACE FOR FUTURE REFERENCE.

* SUBJECT TO VARIATION ACCORDING TO LOAD

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 2 7/11/17 7:53 am

WATERGARDENING TO THE MAXAQUATECEQUIPMENT.COM

SUBMERSIBLE

WATER PUMPS

DESIGN HIGHLIGHTS

The PondMAX EvoII Submersible Pumps have been manufactured with advanced technology to provide you with the

best quality pumps for your pond or water feature. Visit our website to view our range of pond filtration, outdoor/

underwater lighting, water treatments and general accessories.

BENEFITS INCLUDE

• Variable Frequency Motor Technology – Extra high

speed rotations of impellor.

• Open Vane Impellor Design – Handles large particles

size up to 4mm soft sediment.

• Long life Impellor Design – Ceramic shaft is wear

resistant and self-lubricated by water

• High Head Pressure – Due to extra high speed rotations

of impellor.

• Energy Ecient – Exceptional low power consumption

to high water flow conversion.

• Eco Friendly – Exceptional low dB noise rating with low

mechanical vibration.

• Marine Compatible* see warranty disclaimer

– No exposed copper.

• Tool-less Assembly - For Easy maintenance. No special

tools required.

• Rotor Stop Protection – Sensors automatically cut

power in the event that the impellor stops rotating,

reducing the chances of motor burnout.

• Soft Start – Rotor starts at low speed and increases

over a short period of time. This reduces sudden recoil

kick back on start up.

• PondMAX Fountain & Pond pumps are suitable for

use in many dierent applications including fountains,

water features, aquatic systems, aquarium applications

and hydroponics. The pumps can be used in either

submersible or in-line use applications.

• Submersible pumps are a magnetically driven

centrifugal pump, therefore they cannot suck from

a water level that is below the inlet level when used

in-line.

• Your pump has a single moving part (an impellor set)

enabling easy cleaning and maintenance.

• The models EV1900 – EV13600 Pumps have intelligent

circuitry that analyses the speed and torque of the

motor. It will increase and decrease the energy usage to

maximise eciency.

The soft start nature of the system helps to avoid

sudden jolting at start up. The intelligent system will

change the motor speed to maximise the flow of water

in the given circumstances. If the Impellor gets jammed

or stops, the circuitry will sense the state and cut the

power automatically for 3 seconds and then power up

again.

This procedure will repeat 3 times. If the rotor is still

jammed, it will activate a prolonged low state, till the

pump is turned o, and adequate maintenance is

carried out. Thus minimising motor burnout, due to

electrical heat, through lack of water flow through the

motor.

• The motor and electrical components are totally

encapsulated in epoxy resin, ensuring safe operation

under water.

• The pump has a robust bearing and shaft design so no

Oil/grease lubrication is required.

• PondMAX pumps, that have plastic impeller parts and

ceramic shafts, can be used in Marine applications as

there is no exposed copper. For Marine use, please see

warranty disclaimer.

• PondMAX Submersible Pumps are continuous rated

therefore are designed to operate 24/7.

• An optional fountain kit can be purchased and fitted

to the models EV650 – EV4900 pumps. Some of

these models include a sponge pre-filter that assists in

straining the partials in the water, to assist the fountain

nozzles becoming blocked up with debris. See your

retailer for options.

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 3 7/11/17 7:53 am

• Any damage to the equipment or unmerited operation

will bring dangers to the surrounding precincts. So if

there is any damage of the equipment, it must not to

be used. The equipment should be placed out of reach

of children.

• For your own safety, disconnect from the power supply

before any maintenance of any equipment is attempted

on the tank or water body. Always unplug the pump

from the power supply when not in use. Never pull the

cable to disconnect the plug from the power supply Grasp the plug and pull to disconnect. If required, have

a qualified electrician install a weatherproof power

supply point near to the pond or water-feature (within

the cable length of the appliance).

• Be sure the equipment is submerged completely in the

water. The depth should not be greater than 2m.

• Do not operate the pump if the appliance or any

components of the system, such as the power cable,

have been damaged. Check appliance for defects

regularly.

• Always use a properly grounded power supply that is

connected to an RCD with a rated residual operating

current not exceeding 30mA. As per AS/NZS

3350.2.41:1997

• To avoid an electric shock, do not attach the plug to

the power supply socket with wet hands. The drip loop

method should be used to prevent water from traveling

down the cable and onto the plug or power supply.

If the plug does get wet, do not unplug the cable.

Disconnect the circuit breaker that supplies power to

the power supply point. Then unplug and examine the

plug and power supply point for presence of water. If

the power point has become wet, you should consult an

electrician before using the power point again.

• Do not install or store the appliance where it will be

exposed to extreme hot or cold temperatures. Do not

use in water above 35°C.

• Do not cut the cable as this will result in voiding your

warranty.

• Care should be taken to arrange the power cable so

that it cannot be accidentally tripped over or pulled.

• Do not attempt to repair the electrical appliance

yourself. Return to an authorized service centre or place

of purchase if a fault occurs, (regular maintenance is not

considered repair and is required by user).

IMPORTANT SAFEGUARDS

Please read the operating instructions and familiarise yourself with the equipment before placing it

in service. Correct and safe use of the system requires strict compliance with the safety instructions.

For safety reasons, persons less than 16 years of age or infirm persons that are not familiar with these

instructions should not use this equipment.

PRODUCT SPECIFIC SAFEGUARDS

• Do not operate the pump without water at any time,

permanent damage may occur.

• Be sure the equipment is submerged completely in the

water. The depth should not be greater than 2m. If used

in line, the pump must have adequate flooded suction

at all times.

• The pump is designed to be used in a Garden pond/

waterfeature or Aquarium environment. It is not to be

used in any other manner or purpose.

• The pump should only be used in clean water. Do not

use the pump in, or with, any chemicals such as a

solvent or gasoline.

• All PondMAX Submersible pumps are cooled by water

flowing through the inside of the motor body. If the

pump flow becomes restricted it will overheat and could

cause permanent damage. Large tubing size is strongly

recommended to deliver adequate water flow to cool

the pump.

• The pump needs to be cleaned regularly to prevent the

pump becoming blocked, thus causing the pump to

overheat and burn out. This is not a warrantable event.

It is strongly recommended not to select a pump that

is too small for the Job required. The flow rate through

the pump needs to be enough so that a half of the rated

max flow is kept running at all times.

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 4 7/11/17 7:53 am

WATERGARDENING TO THE MAXAQUATECEQUIPMENT.COM

SUBMERSIBLE

WATER PUMPS

INSTALLATION

For your convenience, a filter-less cage has been used on this model. It has a flat section on the front nose. This is to

facilitate a vertical mount is necessary.

• A basic plastic fountain kit is not recommended for

pumps that have flow over 6000L/hour. It’s better

to use commercial fountain nozzles for higher flow.

If using fountain nozzles, it is recommended that a

sponge pre-filter be used. See your local dealer for

examples.

• If used to supply water to a waterfeature, cascade,

waterfall, etc; where a pipe is needed to be used,

use the hose tails supplied in the package. For best

results, use the bigger tubing size recommended in

the table previously. Depending on the pump size,

select the hose tail required for your tubing size and

evaluate which step on the hose tail will be used. If

you are using 50mm hose and you are connecting it

to the 40mm/50mm hose tail supplied, remember to

saw o the smaller size connection (I.E.: 40mm step).

Otherwise it will create a unnecessary restriction in the

system.

• Using a suitable thread seal tape (or other sealing

compound) apply a liberal amount on the male thread

of the hose tail.

• A omni-directional ball-joint is provided for your

convenience when used under water. This is because

the diagonal side sections of the ball-joint may seep

water when in use. The fittings pack include the

necessary O’Ring washers. Select the one that will fit

the female connection of the ball-joint. Place it firmly

in the locking nut. Now screw the locking nut of the

ball-joint onto the outlet of the pump. Fasten firmly

but do not over tighten.

• Then connect the 1 1/2” threaded bush to the outlet of

the ball joint. Then connect the hose tail to the bush

and screw in firmly. To seal adequately, use thread seal

tape on this male thread.

• Now connect the tubing to the hose tail. Remember to

use S/Steel hose clamps to fasten the hose on to the

hosetail. This is to ensure that the hose does not blow

o at a later time or there become a leak at this point

in the plumbing system.

• When used in a pond environment place the pump

in desired location; ensure the pump is on a stable

surface that is free of sludge, sand and other debris.

Position the device in the pond horizontally, on a solid

base, in such a way that it is fully covered with water

and ensure that the pump is located, at a depth, in

the water, which will not allow it to suck air from the

surface. This is known as cavitation. Cavitation is a

cause of premature impellor wear.

• Direct the hose to your desired location.

• To power up, push the plug into the power supply

outlet and switch on. Use the power supply switch for

turning the unit on and o.

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 5 7/11/17 7:53 am

1. Turn the filter case in the direction as indicated by the arrow, then lift it o.

2. Unclip the snap-fit catch under the base plate, and drawn out in the direction of the arrow.

3. Take o the base plate.

4. To maintain the impellor of the pump, turn the Impellor Cover in an anti-clockwise direction as indicated by the

arrow, to the stop position. Then separate the impellor cover from the pump motor body.

5. Lift out the impellor assembly. (Take care not to break ceramic shaft.) The black disc behind the blades is part of the

entire impellor assembly. Clean the impellor with clean water and a suitable brush taking note to remove fine

sediment on and around the back end of the impellor including the small hole through the ceramic shaft if it has one.

Replace the impellor if necessary.

6. Ensure to replace the O’ring in the correct place shown in the picture when reassembling the unit.

CLEANING INSTRUCTIONS

Begin by ensuring that the mains power supply is disconnected before attempting any maintenance or adjustment of

the unit or the water body. Remove the unit from the water. If your unit is connected to a sponge filter, the filters and

sponges will clog up over time. Please clean regularly (at least once a month) to ensure strong water flow. Failure to

maintain the unit will result in a burnt out motor and other damage.

• All EvoII Submersible pumps are water cooled, if pump

becomes restricted, or blocked, it will overheat and

could cause permanent damage.

• The motor unit of the pump is encapsulated with

epoxy resin and does not need lubrication. Regular

inspections, cleaning and maintenance of impellor is

necessary to ensure longer life. In the centre of the

impellor you may notice a small whole opening that

protrudes through the ceramic shaft from front to back.

It is paramount that this portal is kept unblocked at all

times. This is a cooling channel for the motor.

• If using a fountain kit, take o the fountain set first by

unscrewing it from the top of the pump. Examine the

nozzles to ensure all ports are unblocked. Clean with a

suitable brush if necessary.

• Maintain the filter sponge regularly according to how

long it takes for the sponge to get clogged up. When

the flow starts to be reduced, check and clean if

necessary.

• To unclip the front filter cage from the front of the

pump, twist the cage in an anti-clockwise direction and

pull forward. See below for diagram. If available, take

out the optional Internal Bio sponge and clean. If using

an optional pre-filter block sponge, slide the sponge

o the threaded core and wash out. It is recommended

that this is done in a bucket of pond water to ensure

the good bacteria that are present in the sponge are

not killed by the Chlorine in tap water. Check for wear

and tear of the sponges. Replace if necessary.

• You can help boost the biological function of your filter

sponge with a bacterial additive, available from your

local stockist.

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 6 7/11/17 7:53 am

WATERGARDENING TO THE MAXAQUATECEQUIPMENT.COM

SUBMERSIBLE

WATER PUMPS

IMPORTANT NOTES

• It is important to ensure that this is carried out

regularly as the cooling path inside the motor will

become clogged. If the impellor assembly becomes

worn or damaged it should be replaced (available

from your dealer or special orders). Failure to do

so may cause serious damage to pump. Inspect for

signs for wear and tear. The impellor set is a wearing

consumable part.

• Once the cleaning and inspection process is completed,

reassemble in the reverses manner. Reinstall the

impellor into the motor body.

To place the Impellor O’Ring around the black disc

successfully, firmly hold the disc with one hand, and

using the other hand stretch the O’Ring over the disc,

positioning it carefully into the groove. Pay attention

not to allow the O’Ring to roll forward, in-between the

black disc and the motor body.

With the impellor in the correct position, carefully place

the impellor cover back on, and then rotate clockwise

back into position.

• On some models re-insert the internal sponge back

into the filter cage and reattach to the pump. On other

models re-attach the front filter screen.

• Now re-attach the sliding base back into position to

lock the impellor cover from turning.

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 7 7/11/17 7:53 am

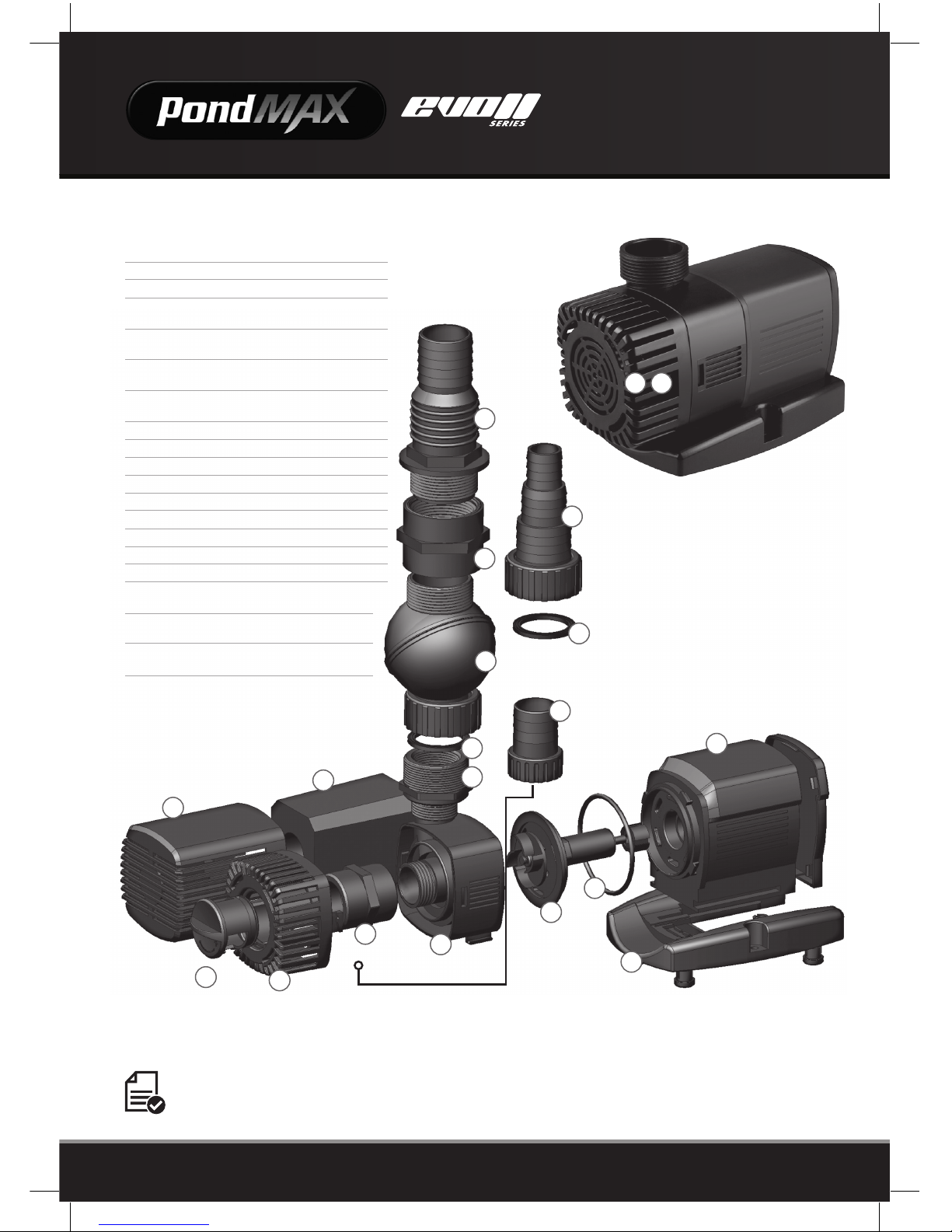

EXPLODED VIEW

Sponge Filter cage.

Internal Sponge Pre-filter Insert

Flow Adjuster Knob - [EV1900 - EV4900]

Front filter Screen - With hole for flow

adjuster - [EV1900 - EV4900]

Blanking Cap for Hole in Front Filter Screen

(optional)

1” Threaded Bush - for optional Pre-filter

Bio-sponge.

Threaded Hosetail for Inlet - 1” BSP to 25mm

Tube

Impellor Cover Housing

Impellor Assembly

Impellor cover O’ring

Sliding Base with Rubber Feet

Pump Motor Body

Reducing Bush - 1” to 1 1/2” BSP Threaded.

O’ring for Ball Joint and Hosetails, Red

Uni-directional Ball Joint for Submerged Use.

Threaded Bush - 1 1/2” BSP

Hosetail with - 1 1/2” BSP Thread to

50/40mm Tubing

Hosetail with Locking Collar - 1 1/2” BSP

Thread to 40/32/25mm Tubing

Front filter screen - (no flow adjuster)

EV7200 & EV9200 only

Front filter screen - (no flow adjuster)

EV11200 & EV13600 only

1

2

3

4

not

shown

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

1

2

3

4

5

7

8

9

10

11

6

12

13

14

15

16

17

13

18 19

NOTE: Parts and features dier from model to model. All images used are for illustrative purposes only. Not all features

depicted apply to all models in the range and these are subject to change.

IMPORTANT

These accessories and attachments are recommended for use with your PondMAX product specified in this manual. The use of any other accessories or attachments

might present a risk of injury to persons. Only use the accessory or attachment for its stated purpose.

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 8 7/11/17 7:53 am

WATERGARDENING TO THE MAXAQUATECEQUIPMENT.COM

SUBMERSIBLE

WATER PUMPS

PART

NO.

DESCRIPTION

EV1900 /

EV1910-DC

EV2900 /

EV2910-DC

EV3900 /

EV3910-DC

EV4900 /

EV4910-DC

EV-7200 EV-9200 EV-11200 EV-13600

1

Sponge Filter cage. 12EV002

2 Internal Sponge Pre-filter Insert 12EV003

3

Flow Adjuster Knob - [EV1900 EV4900]

12EV004

4

Front filter Screen - With hole for flow

adjuster - [EV1900 - EV4900]

12EV005

Not

Shown

Blanking Cap for Hole in Front Filter

Screen (optional)

12EV006

5

1" Threaded Bush - for optional Prefilter Bio-sponge.

12EV009

6

Threaded Hosetail for Inlet - 1" BSP to

25mm Tube

12EV001

7

Impellor Cover Housing 12EV010 12EV011 12EV012 12EV013 12EV014 12EV015 12EV016 12EV017

8

Impellor Assembly 12EV025 12EV026 12EV027 12EV028 12EV029 12EV030 12EV031 12EV032

9

Impellor cover O'ring 12EV033 12EV034 12EV035

10

Sliding Base with Rubber Feet

11

Pump Motor Body

12

Reducing Bush - 1" to 1 1/2" BSP

Threaded.

12EV018

13

O'ring for Ball Joint and Hosetails, Red 12EV021 (x2)

14

Uni-directional Ball Joint for

Submerged Use.

12EV019

15

Threaded Bush - 1 1/2" BSP 12EV023

16

Hosetail with - 1 1/2" BSP Thread to

50/40mm Tubing

12EV024

17

Hosetail with Locking Collar - 1 1/2"

BSP Thread to 40/32/25mm Tubing

12EV022

18

Front filter screen - (no flow adjuster)

EV7200 & EV9200

12EV007

19

Front filter screen - (no flow adjuster)

EV11200 & EV13600

12EV008

2, 9,

12, 13,

14, 17

Complete Kit EV1900-EV4910-DC

- O'rings, Inlet & Outlet, Threaded

Bushes and Uni-directional Balljoint.

13EV036

9, 13,

14, 15,

16, 18

Complete Kit For EV7200-EV9200

- O'rings, Inlet & Outlet, Threaded

Bushes and Uni-directional Balljoint.

13EV037

9, 13,

14, 15,

16, 18

Complete Kit For EV11200-EV13600

- O'rings, Inlet & Outlet, Threaded

Bushes and Uni-directional Balljoint.

13EV038

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 9 7/11/17 7:53 am

TROUBLESHOOTING

Problem Reason Solution

WATER PUMP

NOT WORKING

No Power

Check that the plug is connected and

power point turned on.

Sponges and filter media blocked with

sludge.

Clean the sponges and filters.

Impellor is blocked with sludge or lime

scale build up.

Clean the Impellor as per the instructions.

Running without sucient water.

Submerse the equipment underwater

then plug in. Refill if necessary.

Blocked Impellor chamber or

ceramic shaft is broken.

Clean the Impellor. Check for wear.

Replace if necessary.

WATER PUMP

IS NOISY

Blockage in pump. Clear the blockage.

Impellor & Shaft worn out. Replace Impellor & Shaft.

Impellor broken. Replace Impellor.

Water valve closed on the inlet or outlet. Open the valve and allow.

Unit inlet is blocked or the water pump

outlet is blocked.

Clear all blockages.

The height to which you are pumping is too

high for the given model of pump.

Select a bigger model.

Please consult your retailer for quality original PondMAX replacement parts.

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 10 7/11/17 7:53 am

WATERGARDENING TO THE MAXAQUATECEQUIPMENT.COM

SUBMERSIBLE

WATER PUMPS

Please consult your retailer for quality original PondMAX replacement parts.

Visit www.aquatecequipment.com for your nearest stockists.

E.&O.E.

LIMITED WARRANTY 2+1 YEAR

• The additional 1 Year Extended Warranty applies

when you REGISTER with Aquatec Equipment.

See enclosed for details and please retain your

proof of purchase and Warranty form.

• Warranty covers only appliance defects and

faulty material and workmanship within a 2 year

period.

• Faults arising due to accidents, misuse,

not following manufacturer’s guidelines/

instructions or power surges/spikes/brownouts

will not be covered.

• The impellor set is a consumable item and is

therefore not covered under warranty.

• Warranty will be void if any tampering removal

of warranty labels or electrical circuitry is

evident.

• Warranty will be void if the power cord is cut or

damaged in any way.

• Warranty will be void if any visible signs of

overheating are present.

• Loss of livestock, damage to property or

personal injury caused by this product will not

be covered.

• Warranty claims caused by installation faults

will not be covered.

• It is the customer’s responsibility to return

the faulty appliance for any warranty claim, to

Aquatec.

• For any warranty to be valid, an original proof

of purchase must be provided.

• Our goods come with guarantees that cannot

be excluded under the Australian Consumer

Law. You are entitled to a replacement or refund

for a major failure and for compensation for any

other reasonably foreseeable loss or damage.

You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a

major failure.

• A Warranty claim must be made within 2 years

of the date of purchase.

• If used in Marine or Salt water, due to the harsh

conditions, there is only 1 year warranty.

EXTENDED WARRANTY

• The Extended Warranty period is for an

additional 1 Year and commences on expiration

of the standard Warranty period.

• Application for Extended Warranty is FREE

of any registration cost to the purchaser

on completion of the Extended Warranty

questionnaire can be found in the box with the

item purchased or online at aquatecequipment.

com.

• Please keep a copy of the registration form in a

safe place together with your proof of purchase

(sales receipt). Both documents will be required

for any claim under this extended warranty.

• Where Aquatec determines goods are being

used in a manner contrary to the instructions,

specifications or this Warranty, Aquatec

reserves the right to terminate Extended

Warranty for such goods and will provide

written notice to the purchaser.

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 11 7/11/17 7:53 am

HOTLINE 1300 AQUATEC

PMAX EVOII 7200_9200_11200_13600 Pump Instructions.indd 12 7/11/17 7:53 am

Loading...

Loading...