Pompetravaini TCD 25/125, TCD 32/125, TCD 40/125, TCD 50/125, TCD 65/125 Disassembly & Assembly Instructions

...

(Rev. 2.0_10-2010)

DISASSEMBLY & ASSEMBLY

INSTRUCTIONS

SINGLE STAGE

CENTRIFUGAL PUMPS

TC...

MCU-...

2

INTRODUCTION

The liquids handled by the pumps and also their parts could be potentially dangerous for persons and

environment: provide their eventual disposal in conformity with the laws into force and a proper

environment management.

The present manual is not assigned for pumps subjected to the ATEX 94/9/CE directive. In case the

pump is assigned in environments subjected to the application ATEX 99/92/CE directive or in case the

pump is provided with a nameplate indicating the ATEX stamp, it strictly forbidden proceed to start up

the pumps but necessary to consult POMPETRAVAINI for clarifications.

For pumps subjected to the ATEX 94/9/CE directive it is available a dedicated integrative manual.

These instructions are for the maintenance personnel for maintenance and/or repair of the indicated pump series.

Disassembly and assembly require expertise and knowledge of the procedures, therefore the work must be carried out

by qualified personnel. These instructions must be carefully read and understood in conjunction with the section

drawings and tables contained in the manual and enclosed, prior to attempt any work on the pumps. For safety,

installation and maintenance instructions consult the manual “INSTALLATION & OPERATING INSTRUCTIONS FOR

CENTRIFUGAL PUMPS” attached to the pump at time of shipment. Consult also any other attached instructions for

accessories and/or components included with the pumps such as mechanical seals, heat exchangers, flushing systems,

instrumentation, etc. Before operating or working on the pump it is recommended to adopt safety precautions wearing

safety attire (hat, glasses, gloves, shoes, etc.) and have ready the necessary tools required for the work to be done.

Do not subject the pump of its components to sudden mechanical impacts and /or distortions.

Do not damage or scratch the sealing faces. Pay particular attention not to damage flat gaskets and O-Rings. Careful

not to leave foreign matters such as moults, screws, washers, rags, etc. in the pump.

When requesting spare parts or technical information for the pump, always quote the pump model number and serial

number which is printed on the pump nameplate: therefore it is recommended not to remove the pump nameplate or, in

case this action will be necessary, write the serial number on the pump (for example on the flange).

Should additional information be required, please do not hesitate to contact POMPETRAVAINI or the closest

representative. Should there be any difficulties in repairing the pump, it is recommended to send the pump for repair to

POMPETRAVAINI or the local authorised representative.

Pump repairs and/or service carried out by customer or unauthorised personnel are not guaranteed by

POMPETRAVAINI or by its subsidiaries.

Note: Pump parts list identify all pump components by item number (VDMA) in connection with the sectional drawings.

All drawings are for reference purpose and not are certified for construction, however should additional

information be required, contact POMPETRAVAINI or its closest representative.

INDEX

1 - Steps to be followed prior to pump disassembly

2 - Disassembly and assembly of pumps series TCH - TCT - TCA & MCU-CH / CHT / CHA group 1 - 2 - 3

2.1 - Disassembly

2.2 - Assembly

3 - Disassembly and assembly of pumps series MCU-CH group 3 NS and 4 NS

3.1 - Disassembly

3.2 - Assembly

4 - Disassembly and assembly of pumps series TCD and MCU-OD

4.1 - Disassembly

4.2 - Assembly

5 - Mechanical seals assembly

5.1 - Pumps series TCH - TCT - TCA - MCU-CH - MCU-CHT - MCU-CHA

5.2 - Pumps series TCD - TCD/SP - MCU-OD - MCU-OD/SP

6 - Replacing the packing rings

7 - Spare parts

8 - Section drawings and typical options

9 - Nomenclature of pump parts

10 - Engineering tables

In preparing this manual, every possible effort has been made to help the customer and operator with the proper installation and operation of the

pump. Should you find errors, misunderstandings or discrepancies please do not hesitate to bring them to our attention.

Disassembly & assembly instructions single stage centrifugal pumps TC… - MCU-…

3

1 - STEPS TO BE FOLLOWED PRIOR TO PUMP DISASSEMBLY

Should pump repairs be required, it is recommended to acquire full familiarity of the procedures to be followed by

studying these instructions and the “Operating Manual for Centrifugal Pumps”.

FOLLOW THE SAFETY INSTRUCTIONS LISTED UNDER CHAPTER 2 OF THE AFORE MENTIONED

OPERATING MANUAL.

It is important to adhere to the following before working on the pump:

- use the appropriate steps to stop the pump

- close the isolating valves at suction and discharge piping

- wear the safety clothing (hard hat, safety glasses, gloves, safety booths, etc.)

- disconnect the electrical power to the motor and all the electrical instrumentation and, if necessary, disconnect the

electrical cables

- if the pump is handling hot liquids, let it cool down to ambient temperature

- drain the pump casing through by removing the drain plugs, rinse the pump with neutral liquid, if required

- adopt all safety precautions when the pump handles hazardous liquids, pollutant or toxic; these liquids

as well as the liquid used for rinsing the pump must be collected and disposed of with the maximum caution

caution and always in compliance with the local safety regulations.

To remove the pump and the motor (if required) from the installation proceed as follows:

- remove the bolts on the suction and discharge flanges

- disconnect any flushing lines, accessories and/or instrumentation connected to the pump assembly

- remove the coupling guard

- remove the coupling spacer, if present

- remove the motor, if necessary, by removing the anchor bolts from motor feet or from the motor flange in the case of

monoblock assemblies

- remove the pump by removing the bolts from the pump’s feet

- disconnect the pump from the installation with caution, do not damage any components

- refer to the “Operating manual for centrifugal pumps” for instructions on transporting the pump.

2 - DISASSEMBLY AND ASSEMBLY OF PUMPS SERIES

TCH - TCT - TCA

MCU-CH / CHT / CHA group 1 - 2 - 3

2.1 - DISASSEMBLY

(See the section drawings from fig. 2 to fig. 11 of chapter 8).

Remove the oil from the bearing frame through the draining plug VDMA 903.4 (dispose of the oil in compliance with the

local safety regulations).

Remove the bolts from the studs VDMA 902.2, this allows removal of the rotor from the pump casing. Pumps with vortex

impeller (series TCT and MCU-CHT) are fitted with spacer ring VDMA 110 which must be removed from the casing or

from the casing cover.

Remove the impeller nut VDMA 922 (for cast iron construction) or VDMA 925 (for stainless steel construction) so that

the impeller VDMA 230 can then be removed from the shaft VDMA 210, remove then the key VDMA 940.2.

Pumps with open impeller (series TCA and MCU-CHA) are fitted with two wear plates VDMA 135 and 135.2; to remove

the wear plates the screws VDMA 900.1 and 900.2 must be removed.

Remove the bolts from studs VDMA 902.1, if pump is fitted with mechanical seal, remove the bolts from the studs

VDMA 902 of the seal cover and separate the casing cover VDMA 161 from frame VDMA 330.

The seal stationary face if fitted in the seal cover, remove it if replacement is required.

For pumps with packed stuffing box it is required to remove the nuts from studs VDMA 902.3, remove the seal gland

VDMA 452 attached to the cooling cover VDMA 165 and finally remove the packing rings VDMA 461.

Removal of mechanical seal(s) and of packing should be carried out carefully to prevent damaging any of the various

components. Remove the shaft sleeve VDMA 524 with the seal rotating element still on the sleeve together with the

locating ring VDMA 485. If the locating ring requires replacement be sure to mark its location prior to removal.

For “CARTRIDGE” type mechanical seal insert the seal spacers prior to removal of the seal. The seal spacers will block

the seal with its sleeve, loosen then the set screws that lock seal sleeve to the pump shaft, remove the nuts from the

studs that attach the seal flange to the pump and slide the Seal Cartridge out.

To completely disassemble the bearing frame proceed as described below.

Remove the splash ring VDMA 507. With a gear puller remove the half coupling from the pump shaft and the key VDMA

940. When dealing with Monoblock design remove also the lantern VDMA 341. Remove the two bearing covers VDMA

360.1 and/or 360.2 complete of radial seal rings VDMA 421 and 421.1 or 421.5.

Remove the retaining rings VDMA 932 or bearing nut VDMA 923, applying a slight pressure push the shaft out, together

with the bearings, toward the free end. The pressure should be such that the axially fixed bearing will be removed from

the shaft. The last bearing should be removed from the shaft with the help of a gear puller.

Disassembly & assembly instructions single stage centrifugal pumps TC… - MCU-…

4

2.2 - ASSEMBLY

Visually and dimensionally examine the components to be replaced. Verify the integrity of the component and quantify

the degree of wear (for the main dimensions see tab. 2 - 3 - 4 - 6 of chapter 10). When new parts are required always

insist on original parts from POMPETRAVAINI.

In case of doubts or should there be any questions regarding the above, do not hesitate to contact POMPETRAVAINI or

the nearest authorised representative.

To replace the wear ring VDMA 502 it is required to loosen the set screws VDMA 904, using a puller or in the event of

difficulty the wear ring can be machined on a lathe.

Pumps with open impeller (series TCA and MCU-CHA) must have the proper clearance between the wear plates and

the impeller (contact the factory for specific values).

It is good practice to replace all gaskets and packing rings (even if they do not show evidence of defects), bearings and

mechanical seals that show wear grooves and excessive tolerances.

Clean each components using suitable cleaning agents and compatible with the materials of construction. Bearings

must be decreased with a solvent such as Naphtha, allow them to dry and then lubricate with oil. To help with the

bearing installation it is recommended to pre-heat the bearings to approximately 80 0C.

If there are no complications and the components do not show any defects, wear and scratches on the sealing faces,

the assembly steps will be by proceeding the reverse of the disassembly.

Fitting of mechanical seals or packing rings are described in chapters 5 or 6. See chapter 10, tab. 2 - 3 - 4, for

dimensions details.

During assembly the fitting of the various components must be free of interference and damages.

For a positive placement of the gaskets it is suggested to use a compatible fluid (example oil) to help keeping the

gaskets in the sealing area.

See fig. 17 of chapter 10 for torque values of bolts and screws.

After the assembly it is suggested to hydrotest the pump for leakage. The test pressure should be at least 1.2 times the

maximum working pressure ma not less than 4 bar. The seal chamber of pumps fitted with double back to back

mechanical seals, should also be pressurised.

3 - DISASSEMBLY AND ASSEMBLY OF PUMPS SERIES

MCU-CH group 3 NS and 4 NS

3.1 - DISASSEMBLY

(See the section drawings of fig. 12 - 13 - 14 of chapter 8).

Drain the oil from the bearing frame by removing the drain plug VDMA 903.4.

Remove the bolts from the studs VDMA 902.2 so that the rotor may be removed from the pump.

Place the rotor assembly in the vertical position with the drive end toward the bottom.

Loosen the impeller nut VDMA 925 and remove the impeller VDMA 230 from the shaft VDMA 210. Remove the bolts

VDMA 914 and remove cover VDMA 471.1 (pay attention to the stationary seal element that is left in the cover, for back

to back double seal arrangement).

Remove the shaft sleeve VDMA 524 with the seal rotating element still on the sleeve together with the locating ring

VDMA 485. If the locating ring requires replacement be sure to mark its location prior to removal.

For pumps with packed stuffing box it is required to remove the nuts from studs VDMA 902.3, remove the seal gland

VDMA 452 attached to the cooling cover VDMA 165 and finally remove the packing rings VDMA 461.

Removal of mechanical seal(s) and of packing should be carried out carefully to prevent damaging any of the various

components. Remove the cover VDMA 161 and the mechanical seal cover VDMA 471 or the seal gland VDMA 452. The

seal stationary element is still in the seal cover, remove it if replacement is required.

For “CARTRIDGE” type mechanical seal insert the seal spacers prior to removal of the seal. The seal spacers will block

the seal with its sleeve, loosen then the set screws that lock seal sleeve to the pump shaft, remove the nuts from the

studs that attach the seal flange to the pump and slide the Seal Cartridge out.

To completely disassemble the bearing frame proceed as described below.

Remove the splash ring VDMA 507. With a gear puller remove the half coupling from the pump shaft and the key VDMA

940. Remove the screws VDMA 901.2, remove the casing cover VDMA 163 together with the outer ring of the roller

bearing VDMA 323. In the event the outer ring of the roller bearing requires replacement, it is necessary to remove the

snap ring VDMA 932.3 and then utilise the external extraction holes.

Rotate the bearing frame with the drive shaft end upward, remove screws VDMA 901 and bearing cover VDMA 360.2.

Remove the shaft VDMA 210 with bearings VDMA 320. To replace these bearings remove first the bearing nut VDMA

923.

3.2 - ASSEMBLY

Assembly procedures are same as given under paragraph 2.2 (for components type and dimensions see tab. 5 of

chapter 10).

Disassembly & assembly instructions single stage centrifugal pumps TC… - MCU-…

5

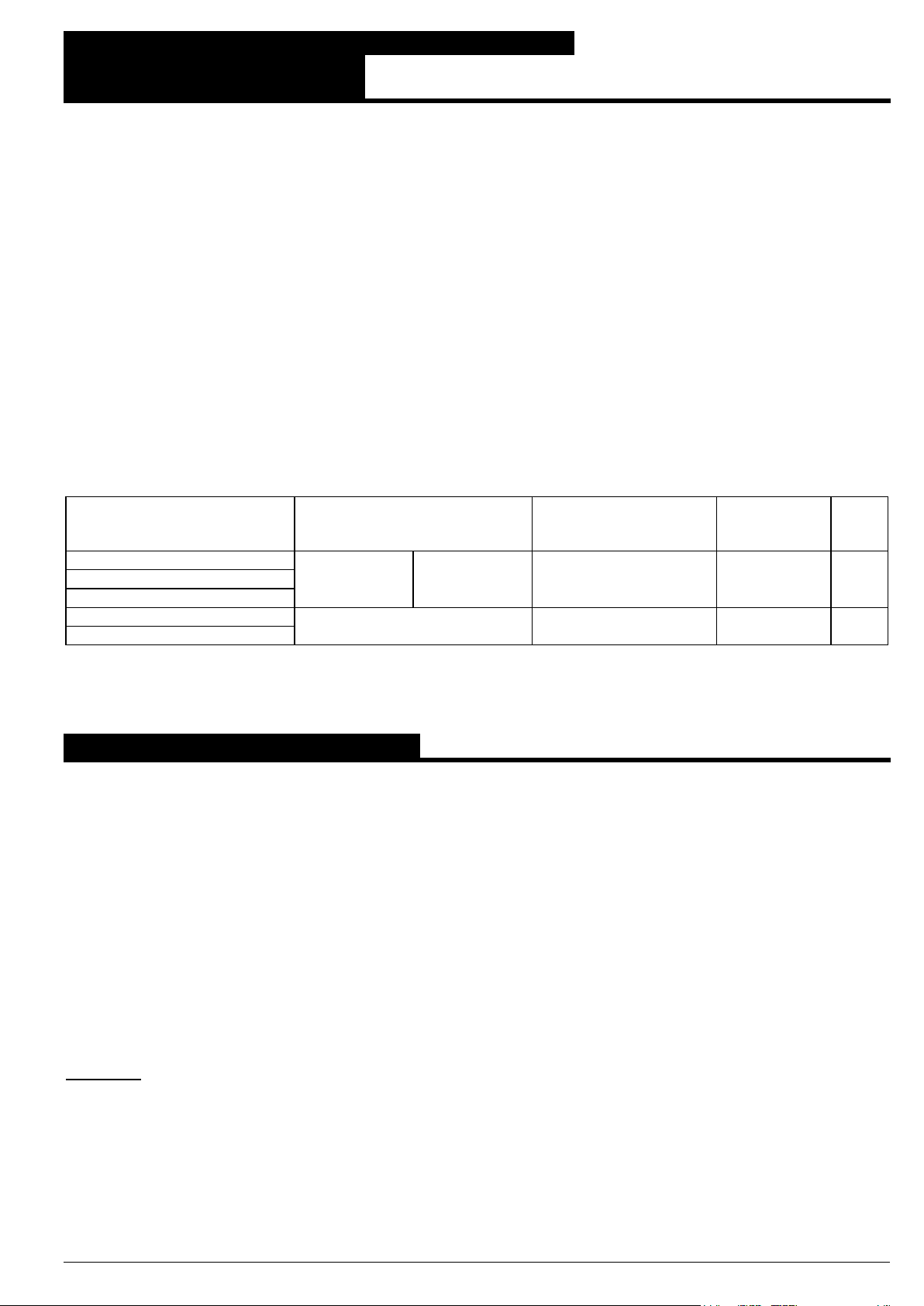

4 - DISASSEMBLY AND ASSEMBLY OF PUMPS SERIES

PUMP MODEL

BEARINGS TYPE

SHAFT SEAL RINGS

TYPE

MECHANICAL

SEAL

Ø (mm)

OIL

KG.

25 - 32 - 40 - 50 - 65/ 125

Seal side

N°1 6206 C3

(30x62x16)

Drive side

N°1 6305 C3

(25x62x17)

N°1 AS25357

(25x35x7)

Ø30

0,20

25 - 32 - 40 - 50 - 65 - 80 / 160

25 - 32 - 40 - 50 / 200

65 - 80 - 100 / 200

N°2 6308 C3

(40x90x23)

N°1 AS35477

(35x47x7)

Ø40

0,40

40 - 50 - 65 - 80 / 250

TCD and MCU-OD

4.1 - DISASSEMBLY

(See the section drawings of fig. 15 and 16 of chapter 8).

Drain the oil from the bearing frame by removing the drain plug VDMA 903.4.

Remove the bolts from the studs VDMA 902.2 so that the rotor may be removed from the pump.

Remove the impeller nut VDMA 922 (for Cast Iron construction) or VDMA 925 and 922 (for Stainless Steel construction)

and remove impeller VDMA 230 from the shaft VDMA 210, remove key VDMA 940.2. Remove screws VDMA 900.1 and

cooling plate VDMA 167.

Remove the screws VDMA 901.1 or, for /SP construction, the bolts from studs VDMA 902.1.

Remove the casing cover VDMA 163, loosen the set screws on the rotating element of the mechanical seal, remove

both elements of the mechanical seal. For the /SP design remove also the reducing flange VDMA 184.

To completely disassemble the bearing frame proceed as described below.

With a gear puller remove the half coupling from the pump shaft and the key VDMA 940.

Remove screws VDMA 901 and bearing cover VDMA 360.

Remove the retaining rings VDMA 932.3, push the shaft VDMA 210 out toward the free end, together with the bearing

VDMA 320.1. Remove the snap ring VDMA 932 and the bearing VDMA 320.1.

4.2 - ASSEMBLY

For assembly procedures see paragraph 2.2 in combination with the tab. 1 below that contains the specific components

dimensions pertaining this pump series only.

Tab. 1 - Pumps series TCD - MCU-OD and /SP

5 - MECHANICAL SEALS ASSEMBLY

5.1 - Pumps series TCH - TCT - TCA - MCU-CH - MCU-CHT - MCU-CHA

NOTE: Where available, read the specific instructions of the used mechanical seal as well as the following

information.

Mechanical seal different than the one originally fitted in the pump may be used. Note however, that the primary

dimensions must be the same and the material of construction must be suitable with the liquid handled. For more

information and the assembly dimensions pls contact POMPETRAVAINI or its closest representative.

Clean the stationary seal element removing encrustation, oxidation and deposit of the flushing liquid. Lubricate the seat

and the elastomers of the stationary seat with oil that is compatible with the seal elastomers. Push the prepared seal

stationary seat in the seal cover VDMA 471 or casing cover VDMA 161, be sure to centre the anti-rotating pin is

installed.

Pumps fitted with double mechanical seals will have the outboard (drive end) installed as above, while the internal seal

(impeller side) will have the stationery seat fitted in the casing cover VDMA 161 for the case of double back to back

seals, or in the seal retainer VDMA 542 in the case of double seals in series (tandem).

Clean the shaft sleeve VDMA 524 with extra fine emery cloth. Cleaning strokes should be axially.

Install the seal locating ring VDMA 485, if previously removed, in the original location. If the mechanical seal is fitted with

set screws on its collar the seal locating ring VDMA 485 may not be present.

CAUTION! The position of the seal locating ring will vary with the seal working length.

In the event the new mechanical seal has a working length different than the original seal, it will be required

to relocate the seal locating ring accordingly.

Lubricate with compatible oil the sleeve and the elastomers of the seal rotating element.

Push the seal rotating element on the sleeve helping with a rotating motion until it rests against the locating ring VDMA

485. Tighten set screws if fitted in the mechanical seal.

For pumps having double mechanical seals back to back, the above procedure apply for both seal rotating elements.

Should the mechanical seals be with conical single spring pay particular attention to their rotation direction.

Pumps fitted with double mechanical seals in series (tandem), will require fitting the rotating seal element impeller side

(inside seal), followed by the seal insert VDMA 542 with the stationary seal face element, locate the snap ring VDMA

932.1 on the sleeve VDMA 524 and fit the rotating element of the external mechanical seal. After these assembly steps,

Disassembly & assembly instructions single stage centrifugal pumps TC… - MCU-…

6

install the seal cover VDMA 471 on the shaft, the cooling cover VDMA 165 with the studs in place, then all the required

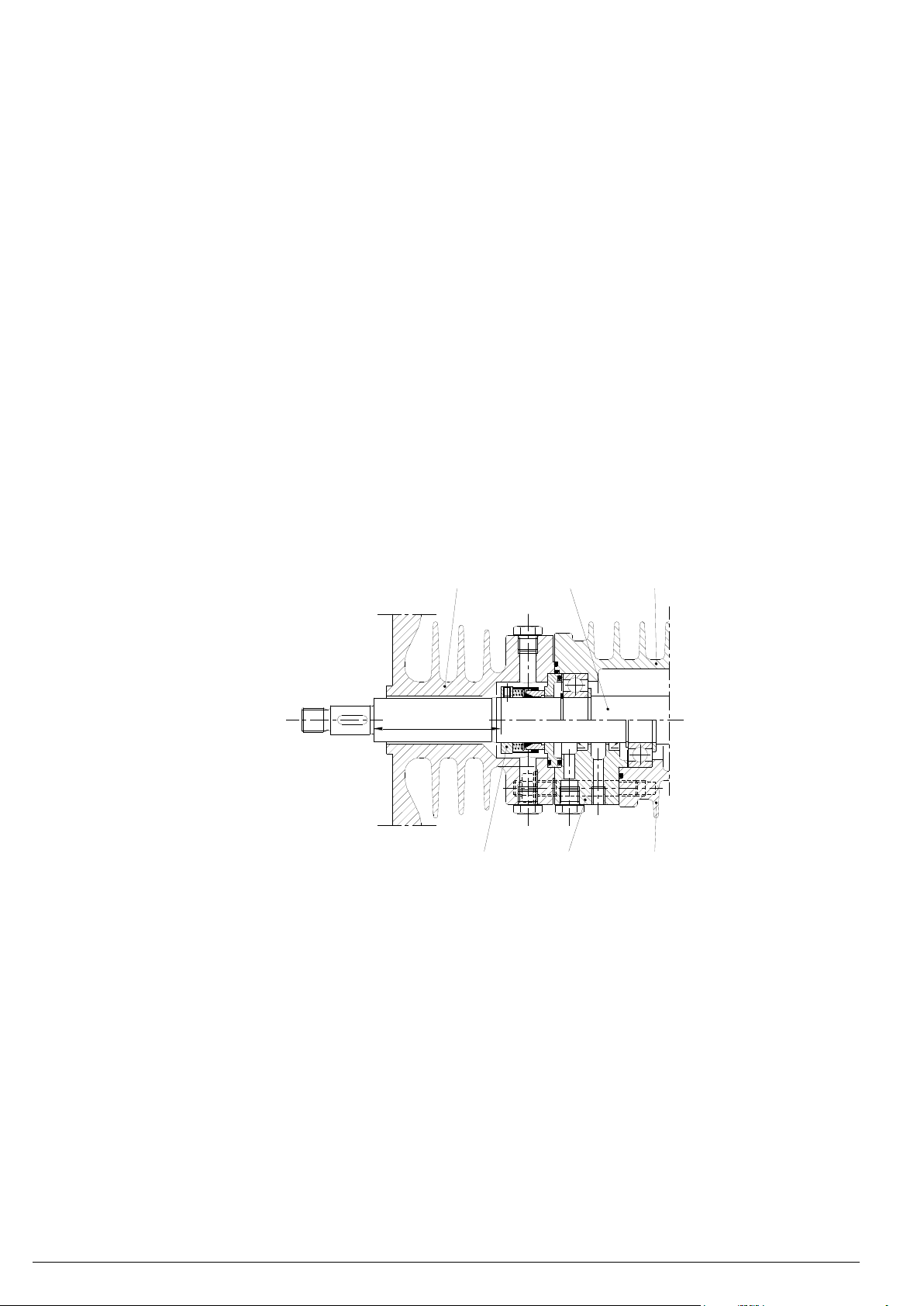

Fig. 1

330

184 330

163 210

84,5/109

TCD

MCU-OD

TCD/SP

MCU-OD/SP

433.2

gaskets and the pre-assembled shaft sleeve.

Prior to finalise the mechanical seal assembly, already fitted on the shaft sleeve, it is recommended to clean both seal

faces with a clean and soft tissue. Finally proceed with the assembly of the complete pump avoiding stress on the seal

assembly which could damage the fragile components of the mechanical seal.

“CARTRIDGE” TYPE MECHANICAL SEALS

These type of seals are easy to install because they are pre-assembled on a seal sleeve.

To install the “cartridge” simply slide the assembly over the shaft sleeve or the shaft itself depending upon the design,

paying particular attention not to damage the seal O-Ring.

Complete the pump assembly, lock the cartridge flange with the studs, lock the set screws of the seal sleeve on to the

shaft or shaft sleeve, remove the sleeve/cartridge spacers that have allowed the correct location of the total seal

assembly.

5.2 - Pumps series TCD - TCD/SP - MCU-OD - MCU-OD/SP

Clean the stationary seal element of any encrustations, oxidation or residues from the handled liquid.

Lubricate the seal cavity and the elastomers with a compatible light oil.

Place the bearing frame VDMA 330 in the vertical position with the shaft drive end at the bottom, (in the case of pump /SP

the bearing frame should have attached the extension flange VDMA 184), install the seal stationary element with the

pertaining O-Rings, the lapped seal face should be at the top, clean the seal face with a soft tissue.

Lubricate the shaft and the Viton booth of the seal rotating element. Clean seal face with a soft tissue and slide the

rotating seal element on to the shaft VDMA 210 with the carbon face to the bottom.

Pumps of the Group 1, position the seal rotating element 84.5 mm from the shaft shoulder (against which the impeller

VDMA 230 will rest), pumps of the Group 2 this distance should be 109 mm, tighten the set screws to lock the seal to

the shaft (see fig. 1).

Place the O-Rings required and install the casing cover VDMA 163 on the bearing frame VDMA 330 (on the extension

VDMA 184 for pump design /SP). Tighten the 4 bolts or studs and proceed then with assembling the balance of the

pump.

Disassembly & assembly instructions single stage centrifugal pumps TC… - MCU-…

Loading...

Loading...