Pompetravaini TBAK Series, TBK Series, TBK 200, TBK 290, TBK 310 Disassembly And Assembly Instructions

...

(Rev. 2.0_10-2010)

DISASSEMBLY AND

ASSEMBLY INSTRUCTIONS

FOR MAGNETIC DRIVE

MULTISTAGE SELF-PRIMING

CENTRIFUGAL

PUMPS

TBK - TBAK

INTRODUCTION

f

These instructions are f or the m aintenance per sonnel f or m aintenance and/or r epair of the indic ated pum p s eries.

Disassembly and assembly procedures should be carried out by qualified personnel. Prior to working on the pumps the

maintenance person should be fully knowledgeable of the material outlined in this manual. Instructions relating to safety

of operation, installation and m aintenance will be f ound in the “ OPERATING MANUAL F OR CENT RIFUGAL PUMPS”

and in the “ DISASSEMBLY AND ASSEMBLY INST RUCTIONS F OR SELF -PRIMING MULT ISTAGE CENT RIFUGAL

PUMPS” which is usually supplied with the pump or it can be requested from your POMPETRAVAINI representative.

CAUTION!

Pumps series TBK and TBAK create a high magnetic field. Personnel should take proper precautions i

they are wearing pace-makers or if they are using instrumentation sensitive to magnetic fields.

The listed below minimum distances must be kept:

- When the magnetic rotor parts are disassembled:

users of pace-maker = 2 meters

floppy disk; magnetic cards, etc. = 1 meter

- When the magnetic rotor is mounted in the pump:

users of pace-maker = 1 meter

floppy disk; magnetic cards, etc. = 0,5 meter

Proper attire is necessary prior to beginning any work on the pum ps. Therefore, for your safety, always wear safety hat,

eyeglasses, gloves, shoes etc. and be sure to have proper tools necessary for the work to be done.

Do not f orce or s ubject pum p or any of its c omponents to s udden s hocks or violent im pact. Do not dam age w ith

markings or scratches the mechanical seal surface areas, the engagement surfaces and sealing areas. Do not damage

gaskets, and O-Rings. Do not leave in the pump foreign matter such as screws, nuts, bolts, washers, rags, etc.

When requesting spare parts or technical information for the pum p, always quote the pum p model number and s erial

number which is printed on the pump nameplate: therefore it is recommended not to remove the pump nameplate or, in

case this action will be necessary, write the serial number on the pump (for example on the flange).

Should additional inf ormation be r equired, pleas e do not hes itate to c ontact PO MPETRAVAINI or the closest

representative. Should there be any difficulties in repairing the pum p, it is recommended to send the pump for repair to

POMPETRAVAINI or the local authorised representative.

POMPETRAVAINI will not and c annot be r esponsible f or w ork done on the pum p by the c ustomer or non-authorised

personnel.

NOTE: Pump parts are identified by item numbers (VDMA). Item numbers can be found in the parts list under chapter

10 and cross-referenced with the sectional drawings under chapter 11.

All drawings given in these instructions are only schematics and not certified.

INDEX

1 - Actions to be taken prior pump disassembly

2 - “TBK” pump s eries dis assembly to r eplace

bushing

3 - “TBK” pump series bushing support assembly

4 - “TBK” and “ TBAK” pum p s eries s upport

disassembly

5 - Complete disassembly for pumps series “TBK”

The liquids and gas handled by the pum ps and als o their par ts c ould be potentially danger ous for

persons and envir onment: provide their eventual disposal in c onformity with the law s into f orce and a

proper environment management.

The present m anual is not as signed for pum ps subjected to the ATEX 94/9/CE directive. In case the

pump is assigned in environments subjected to the application ATEX 99/92/CE directive or in case the

pump is provided with a nam eplate indicating the AT EX stamp, it s trictly forbidden proceed to start up

the pumps but necessary to consult POMPETRAVAINI for clarifications.

For pumps subjected to the ATEX 94/9/CE directive it is available a dedicated integrative manual.

In preparing this manual, every possible effort has been made to help the customer and operat or with t he proper i nstallation and operation of the

pump. Should you find errors, misunderstandings or discrepancies please do not hesitate to bring them to our attention.

2

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

6 - Complete disassembly for pumps series “TBAK”

7 - Internal m agnet r otor dis assembly f or “ TBK”

and “TBAK” pumps series

8 - Assembly of “TBK” and “TBAK” pumps series

9 - Spare parts

10 - Parts list

11 - Typical sectional drawings

1 – ACTION TO BE TAKEN PRIOR PUM P DISASSEMBLY

Prior starting disassembly activities it is required:

- Shut down the pump following usual shut down procedures.

- Disconnect electric motor from electric supply in order to make sure that it may accidentally start up.

- Close valves installed on pump suction and discharge.

- Wait and make sure that temperature is equal to ambient temperature prior to start any activity.

- Unlock the drain plug in order to drain completely the spiral casing.

Follow extra carefully this procedure in case pumped liquid is dangerous by contact or by inhalation.

At this regard it is mandatory to be provided with proper safety wear.

- Disassembly pipes and auxiliary connections in case connected to pump.

Remove coupling guard and, if present, spacer coupling.

- Loose the s upport foot VDMA 183 and, depending on needs , it is possible take away pump casing from piping and

baseplate and/or remove the electric motor.

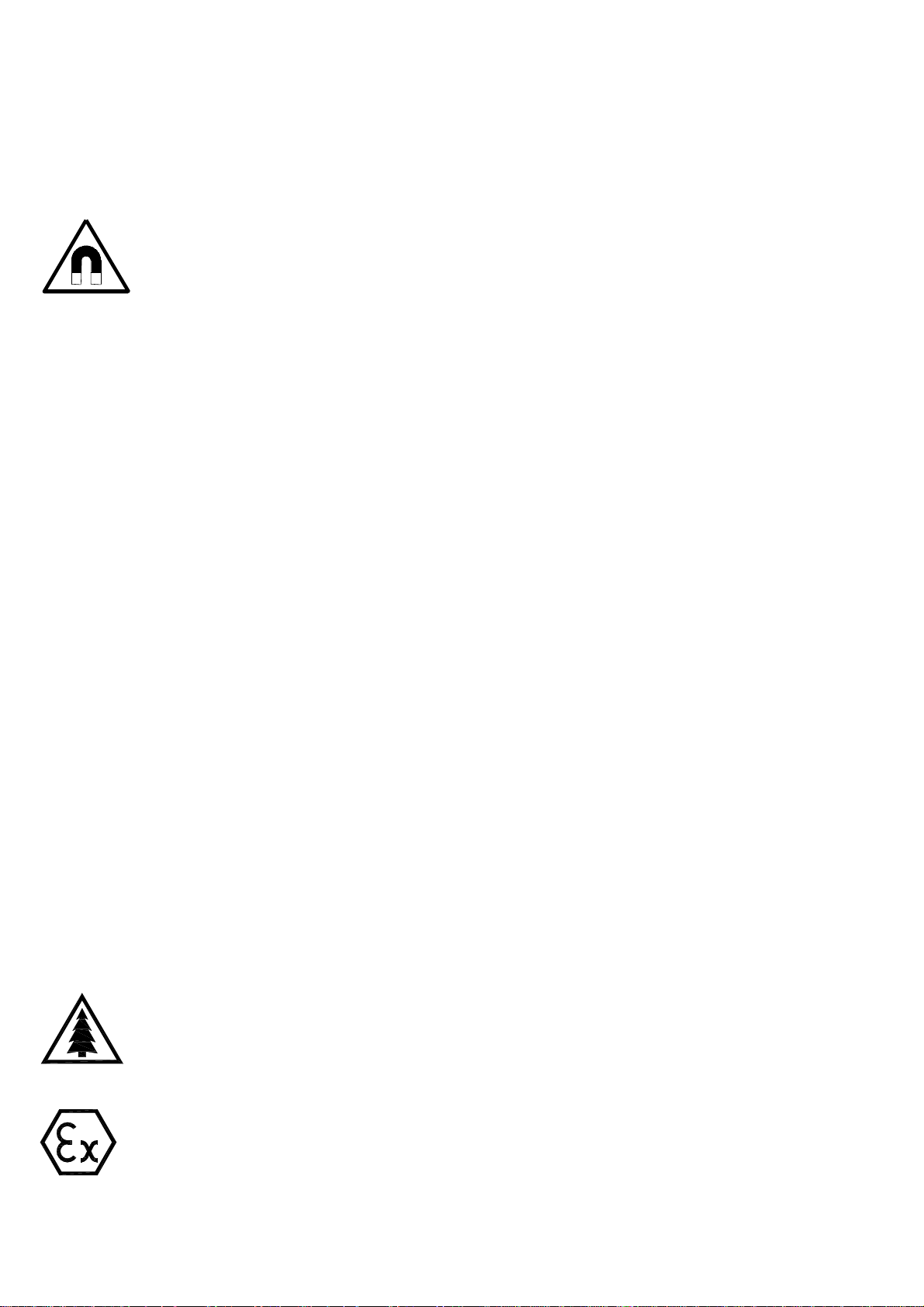

2 – “TBK” PUMP SERIES DISASSEMBLY TO REPLACE BUSHING

Loosen s crews VDMA 901 and ex tract the

bushing support VDMA 355 and its bushing

VDMA 310 or 310.3 ( in f unction if pum p

execution is /1 or /2) by means, if necessary,

of the s ame s crews as ex tractors in the

threaded holes available in the support self.

Later on, by m eans of a suitable extractor,

extract the bushing support (see fig. 1 or 2).

In case of execution /2 als o check the wear

of ceramic coated bushing VDMA 521 and if

necessary r eplace it loos ening the s crew

VDMA 914.5 and r emoving the washer

VDAM 554.

905

901

940.4

554

914.5

554.7

521

355

903

107

ØD

ØD

310

310.3

400.2

210.1903.1

F ig. 1 – Pumps series TBK/2 F ig. 2 – Pumps series TBK/1

3 – “TBK” PUMP SERIES BU SHING SUPPORT ASSEMBLY

Check wear of bushing VDMA 310 or 310.3 (in function of

execution /1 or /2) and, if nec essary, r eplace it w ith a

spare one: check the bushing internal diameter is the right

one for pump type indicated in obj ect (see fig. 1 or 2 and

tab. 1), then press it in the bushing support VDMA 355.

For execution /1 drill in the bus hing 3 radial holes Ø5 mm

at 120°, having c are that one hole is located in upper

position.

For ex ecution /2 dr ill in the bushing 1 crossing hole Ø3

mm loc ated in upper pos ition in c orrespondence of the

hole present in the bushing support VDMA 355.

After having loc ated the gas ket VDMA 400.2, assembly

the bus hing s upport on the dis charge casing VDMA 107

and tight the screws VDMA 901.

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

Tab. 1 - Dimensions of bus hings ( VDMA 310 or 310.3)

internal diam eters alr eady pr essed in bushing

support VDMA 355 (see fig. 1 or 2)

Construction /2 Construction /1

PUMPS SERIES

TBK 200 --- --- 16 D7

TBK 290 ÷ 310 24 E8 22 D7

TBK 400 30 E8

TBK 500 --- --- 28 D7

TBK 650 30 E8

ØD

VDMA 310.3

+0,073

+0,040

+0,073

+0,040

ØD

VDMA 310

+0,068

+0,050

+0,086

+0,065

--- ---

+0,086

+0,065

--- ---

3

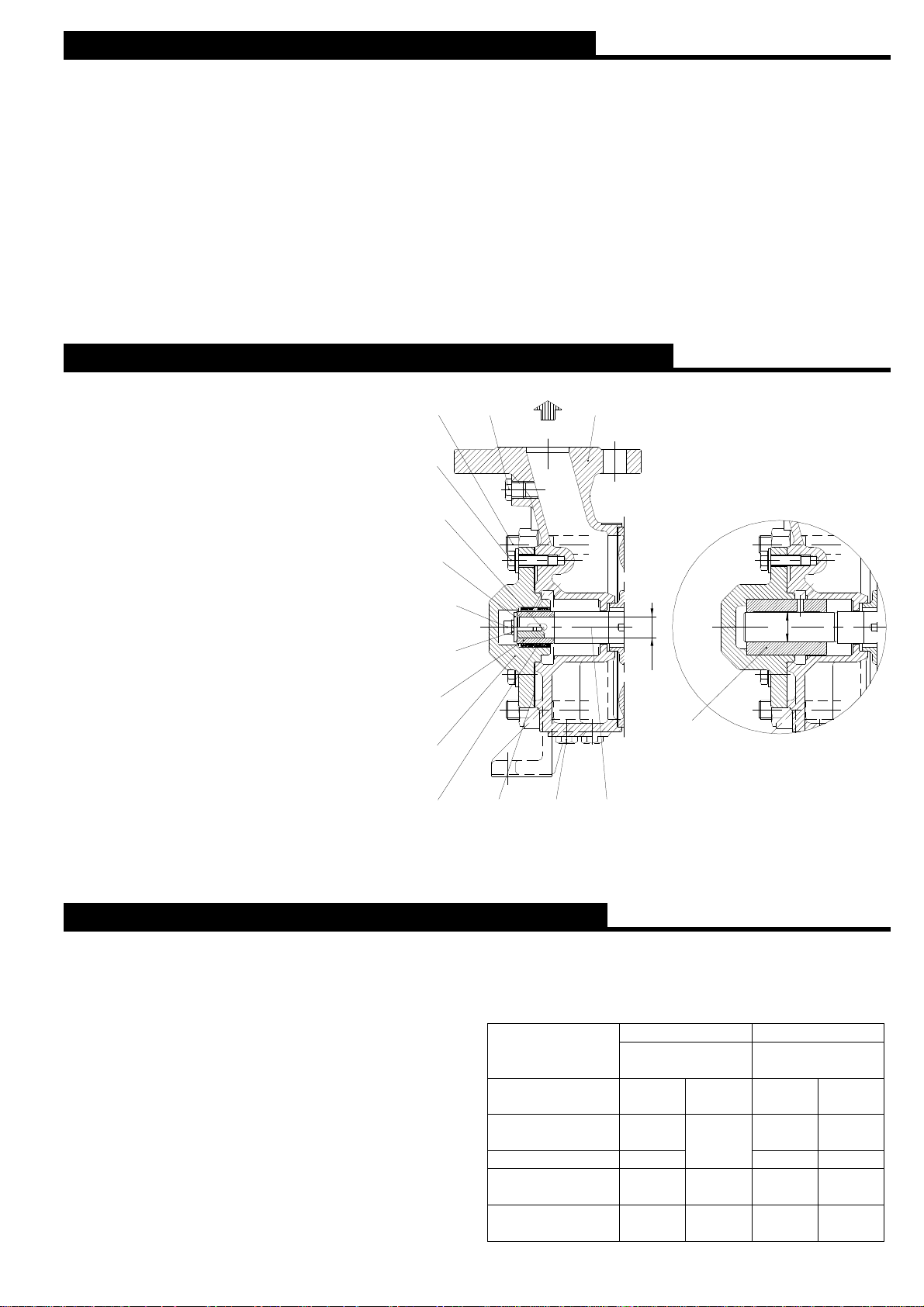

4 – “TBK” and “TBAK” PUMP SERIES SUPPORT DISASSEMBLY

(See fig. 5 and typical sectional drawings under chapter 11).

Remove stud nuts VDMA 902 and separate the s upport VDMA 330 f rom c asing c over VDAM 161 over coming the

magnets attraction force avoiding to damage the external rotor magnets VDMA 818.2.

To dis assembly the ex ternal m agnetic r otor w ith s mall s ize dr agging ( sealing c ontainer Ø 75, see fig. 6 and 10) is

necessary to remove the adaptor ring VDMA 502 loosening the grub screw VDMA 904.

Loosen screw VDMA 900.1 and remove the junk ring VDMA 550.1.

Extract then the fly wheel VDMA 132 with the external magnetic rotor VDMA 818.2.

Remove the half elastic coupling from pum p drive end and, unscrewing the s crews VDMA 914.4, r emove the ex ternal

bearing cover VDMA 360.1, the elastic ring VDMA 935 and circlip VDMA 932.1.

Loosen screws VDMA 900 and extract the internal bearing cover VDMA 360.2.

Apply now a strong pressure on the primary shaft VDMA 210 drive end to extract the bearing VDMA 320 and remove the

same shaft with bearing VDMA 320.1 from the support VDMA 330.

Remove circlip VDMA 932 and if necessary remove from shaft also bearing VDMA 320.1.

Verify that all parts are undamaged and w ear or tear scratches are not pr esent: if necessary replace those parts with

original spare parts before starting assembly, executing each step reverse to disassembly steps.

5 - COMPLETE DISASSEM BLY FOR PUMPS SERI ES “TBK”

Complete pump disassembly becomes necessary if, f or example, the pum p does not per form as expected due to an

excessive wear of impellers VDMA 230 and/or suction and discharge elements VDMA 109 and 114.

Replacing or machining the worn-out parts will be a question of economics and /or time available to complete the rapair.

This c hapter w ill c onsider the dis assembly of a pump without non-drive end s leeve bear ing hous ing and dr ive end

bearing and mechanical s eal hous ing ( see f ig. 3) : dis assembly and as sembly of thes e c omponents have been

addressed in chapters 2 – 3 – 4.

NOTE: where the mechanic is not familiar with the pump, it is advisable to draw a reference line along the pum p. Mark

each part with its location, rotation and assembly sequence; however the main components are already marked at

the ex ternal upper par t w ith reference logs to pr ovide the pr oper pos ition (see the attached “Disassembly and

assembly instructions for self-priming multistage centrifugal pumps”).

Disassembly work should be carried out w ith proper tools and using suitable disassembly sequence to pr event further

damage to the pump parts.

107 400.1 106 412914.1 914 914.2940.1

310.5230

920562.1

Fig. 3

Pumps series TBK

903

905

940.4

ØD1

310.2

ØD2

161210.1 903.1 940.2 114 109 310.1 562.2 818G

550

4

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

Loosen and remove the tie-bolts VDMA 905, place the pump in vertical position onto a s uitable base with the discharge

casing VDMA 107 on the top.

Remove once for all the tie-bolts (VDMA 905) nuts and washers and loosen the tie-bolts from the casing cover VDMA 161.

Remove the discharge casing VDMA 107 and its gasket VDMA 400.1, the discharge element VDMA 114 and its gasket,

the open im peller VDMA 230, the k ey VDMA 940.2 the s uction element VDMA 109 and its gasket. Go on following the

same sequence as many times as is the number of stages of the pump. Remove the suction casing VDMA 106 and its

gasket.

Take precautions not the dam age the s haft VDMA 210.1 and plac e it in a bench vice vertically and with the drive side

upward in order to disassemble the internal magnetic coupling assembly (see chapter 7).

6 - COMPLETE DISASSEM BLY FOR PUMPS SERI ES ”TBAK”

Complete pump disassembly becomes necessary if, f or example, the pum p does not per form as expected due to an

excessive wear of impellers VDMA 230 and/or suction and discharge elements VDMA 109 and 114.

Replacing or machining the worn-out parts will be a question of economics and /or time available to complete the rapair.

This chapter will consider the dis assembly of a pum p without drive end bearing and mechanical seal housing (see fig.

4): disassembly and assembly of this component have been addressed in chapter 4.

NOTE: where the mechanic is not familiar with the pump, it is advisable to draw a reference line along the pum p. Mark

each part with its location, rotation and assembly sequence; however the main components are already marked at

the ex ternal upper par t w ith reference logs to pr ovide the pr oper pos ition (see the attached “Disassembly and

assembly instructions for self-priming multistage centrifugal pumps”).

Disassembly work should be carried out w ith proper tools and using suitable disassembly sequence to pr event further

damage to the pump parts.

903 940.4905 400.1149 230 562.1

310

107 914.1

412 914 914.2 550

925

ØD1

ØD

Fig. 4

Pumps series TBAK

106

521

210.1

562.2161 818G903.1230.2 109310.1940.2 114

940.1

920

Loosen and r emove the tie- bolts VDMA 905, plac e the pump in vertical pos ition onto a s uitable base with the s uction

casing VDMA 106 on the top.

Remove once for all the tie-bolts (VDMA 905) nuts and washers and loosen the tie-bolts from the casing cover VDMA 161.

Remove the suction casing VDMA 106 and its gasket VDMA 400.1.

Loosen the impeller nut VDMA 925 ( pay attention to the lef t-handed thr eading) and r emove the c entrifugal im peller

VDMA 230.2.

Remove the diffuser VDMA 149, its gasket and its sleeve bearing VDMA 310.

Remove the shaft VDMA 210.1 the spacer sleeve VDMA 521 and the key VDMA 940.4.

Remove the s uction elem ent VDMA 114 and its gas ket VD MA 400.1, r emove the open im peller VDMA 230, the key

VDMA 940.2, the discharge element VDMA 109 and its gasket. Go on following the same sequence as many times as is

the number of stages of the pump. Remove the discharge casing VDMA 107 and its gasket.

Take precautions not the dam age the s haft VDMA 210.1 and plac e it in a bench vice vertically and with the drive side

upward in order to disassemble the internal magnetic coupling assembly (see chapter 7).

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

5

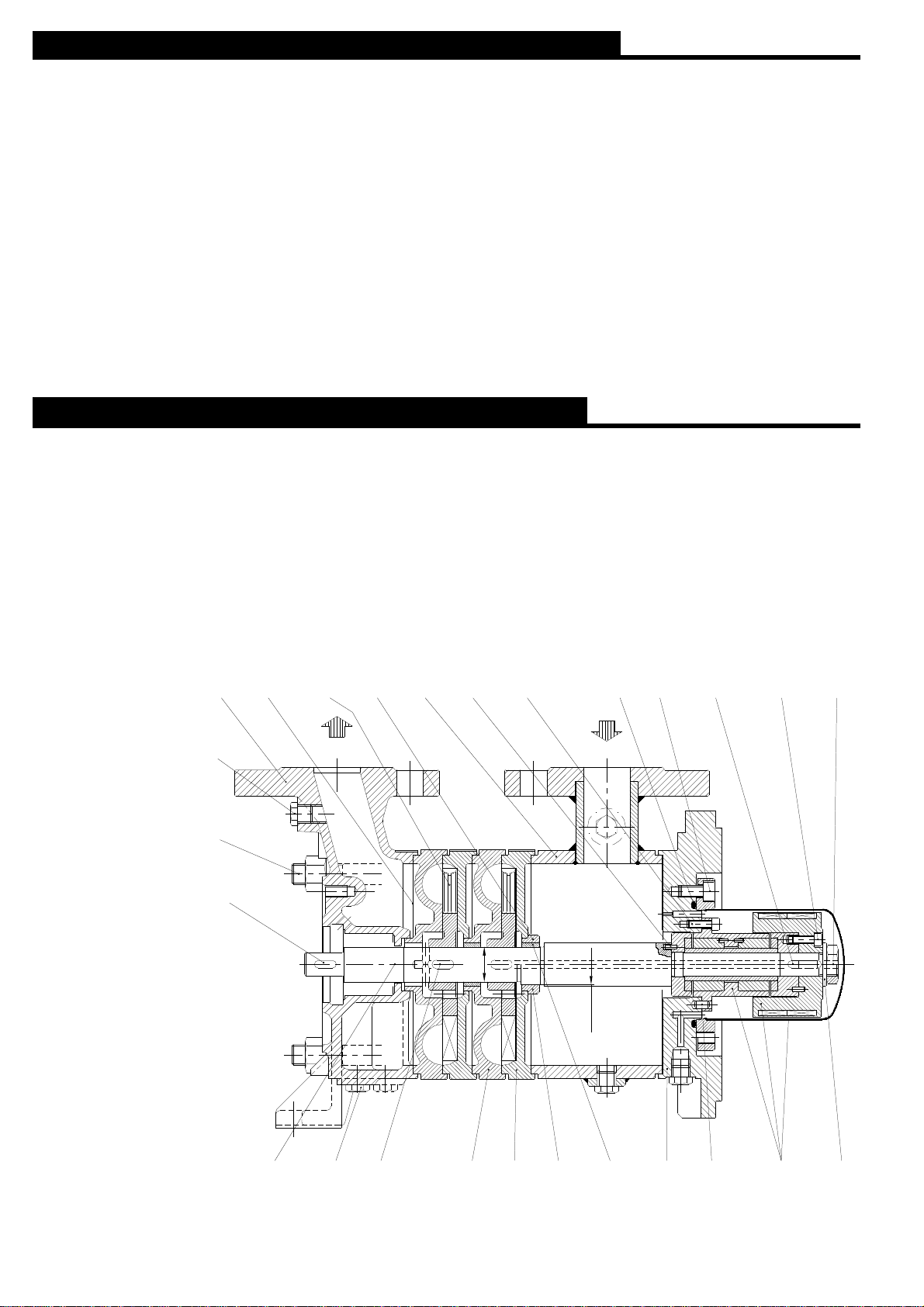

7 – INTERNAL MAGNET ROTOR DISASSEMBLY FOR

A particular attention it is required during disassembly because silicon carbide inserts, that are very fragile, may break,

chip off or going out of their seats.

562.1

412914.1 914

“TBK”

AND

“TBAK”

PUMPS SERIES

914.3914.2940.1 550 920 132

Fig. 5

Drawing of internal magnet

rotor.

(the dotted line shows

external magnetic rotor

component)

940.3

900.1

818.4

161

Undo VDMA 914 screws and remove the VDMA 813.3 cover and its sealing VDMA 412 O-Ring, undo the VDMA 920 nut

and the VDMA 550 washer.

Remove the internal magnet rotor VDMA 818.1 with the external cover VDMA 818.5.

Remove the body VDMA 161 with the rotor support bush VDMA 818: If it is nec essary to s eparate thes e tw o

components , undo VDMA 914.1 screws.

Remove VDMA 940.1 shaft key, slip off the VDMA 818.6 rotor bush and the internal cover VDMA 818.4.

Look carefully the magnet bushes f or scratches or beginning of s eizure marks, eventually replace with or iginal spare

parts.

Clean all the c omponents and pr oceed to as sembly them reversing the s tep f or the dis assembly. T he values f or the

torque wrench for the magnet screws are reported on the Tab. 2.

It is fundamental to lubricate all silicon carbide components that are in contact.

Tab. 2

Maximum torque wrench setting for magnet

component screws.

818 818.1 818.5 818.3 818.2562.2 818.6

Screw

Diameter

M5

M6

M8

M10

M12

M16

In contact with

pumped liquid

4 Nm

7 Nm

16 Nm

32 Nm

55 Nm

65 Nm

Dry

4,5 Nm

7,5 Nm

18 Nm

550.1

6

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

8 – ASSEMBLY OF “TBK” AND “TBAK” PUMPS SERIES

Check that all the pump components are in good condition, clean them with the proper clearing product.

If hydraulic components (VDMA 230 and 230.2 im pellers, VDMA 109 e 114, elem ents.) could be re-installed but require

machine tooling, please follow the included “Assembly and Disassembly of self-priming centrifugal pumps” instructions.

In case of assembly of old components with new original spare part sit is necessary to check full compatibility no matter

if old components have been machined or not.

For suggested spare parts please read chapter 9.

About bus h inner diam eter please r efer to tab 3 values considering pump type and bus h VDMA num ber. Pr oceed to

assembly the pum p following the “ Assembly and Dis assembly of self-priming centrifugal pumps” instructions reversing

the indic ated s teps of dis assembly. Be c areful about s equential s teps and components reference point for assembly

position.

Once pump assembly is completed, connect the pum p to s upporting assembly completed with external magnetic rotor,

being aware of the strong attraction between the two parts.

Finally make the pump r otating by ac ting by hand on VDMA 210 dr ive s haft. Pum p s hould r otate f reely w ithout

generating any noise and or crackling.

Tab. 3

Bush internal diameter (VDMA

310 or 310.1 or 310.2) already

pressed on VDMA 109 or 149

elements (see fig. 3 or 4)

PUMPS SERIES

ØD

VDMA 310

TBK & TBAK 200 --- --- 18 B9 18

TBK & TBAK 290 ÷ 310 24 E8 24 B9 28

TBK & TBAK 400 30 B9

TBK & TBAK 500 32 B9 32

30 E8

+0,073

+0,040

TBK & TBAK 650

ØD1

VDMA 310.1

+0,212

+0,160

+0,232

36 B9

+0,170

ØD2

VDMA 310.2

---

+0,20

+0,25

---

9 - SPARE PARTS

When ordering the pump it is good practice to also order the necessary spare parts, especially when there are no standby pum ps in the ins tallation. T his w ill m inimise unnec essary dow n tim es in the event of pum p f ailure or r outine

maintenance. Following spare parts are suggested for each pump size:

1 or more Impellers

1 or more Suction plates

1 or more Discharge plates

1 Shaf t assembly

1 Bear ing set

2 Sets gaskets

1 Set of bearing spacer rings

However for proper parts management, consult the VDMA 24296 standard that recommends the quantity of spare parts

to be stocked in relation to the number of pumps installed.

On the pum p nam eplate ar e pr inted the pum p m odel, the y ear of m anufacture and the pump serial number: always

provide this information when requesting spare parts.

Specify also the VDMA num ber of the required part, as seen on the pum p sectional drawing (chapter 11) and parts list

(chapter 10) for proper identification of spare parts.

We recommend the use of original spares: in case this is not respected, POMPETRAVAINI declines any responsability

for eventual damages caused by not original spare parts.

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

7

10 – PARTS LIST

VDMA

No.

DESCRIPTION

106 Suction casing 554.6 Elastic washer

107 Dis charge casing 554.7 Washer

109 Suc tion plate 562… Pin

114 Dis charge plate 730 Elbow

132 F ly-wheel 731.8 Fitting

149 Centr ifugal diffuser 735 M.M. fitting

161 Casing cover 818 Rotor bearing housing

183 Support foot 818.1 Internal magnetic rotor

210 Primary shaft 818.2 External magnetic rotor

210.1 Sec ondary shaft 818.3 Sealing can

230 Stellar impeller 818.4 Internal cover

230.2 Centr ifugal impeller 818.5 Ex ternal cover

310 Bear ing 818.6 Rotor sleeve

310.1 Plate bearing 818G Magnetic coupling assembly

310.3 Hous ing bearing 900… Screw

310.5 Bearing holder sleeve 900.5 Eyebolt

320 Single row ball bearing 901… Screw

320.1 Single row ball bearing 902 Stud wit nut

330 Ball bearings housing 903… Plug

355 Bear ing housing 904 G rub screw

360.1 External ball bearing cover 905 Tie-bolt with nuts and washers

360.2 Internal ball bearing cover 914… Screw

400.1 Plate gasket 920 Nut

400.2 Bearing housing gasket 925 Cap nut

412 O -Ring 932… Circlip

502 Reduc tion ring 935 Elas tic ring

521 Cer amic sleeve 940… Key

550 Rotor bottom ring

550.1 Fly-wheel bottom ring

554 Shaft bottom ring STM Thermometric probe

VDMA

No.

DESCRIPTION

8

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

11 – TYPICAL SECTIONAL DRAWINGS

932.1904

900920 132

210

932

935

360.1

940

320

914.4

330

901.1

183

914.3

903.S

900.5 914.2940.1

902

360.2730 900.1550.1 940.3 320.1

550

502

731.8735 STM

562.1310.5230

107 400.1 106 412914.1 914 554.6

903

905

901

940.4

554

Fig. 6 - Pumps series TBK/2 Fig. 7 - Pumps series TBK/1

Only for construction with Thermometric Probe

914.5

554.7

521

355

310.3

With sealing can (VDMA 818G) Ø75

400.2

161

940.2 114 109310.1 562.2 818G

210.1 903.1

310

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

9

932.1310.5230

900920 132

914.3

900.5 914.2940.1 550

902

210

932

935

360.1

940

320

901.1

330

914.4

183

360.2730 900.1550.1 940.3 320.1

STM731.8 735

562.1 903.S

400.1 106 412914.1 914 554.6

107

903

905

901

940.4

554

Fig. 8 - Pumps series TBK/2 Fig. 9 - Pumps series TBK/1

With sealing can (VDMA 818G) Ø110 o 135

Only for construction with Thermometric Probe

161

940.2 114 109310.1 562.2 818G

903.1

914.5

554.7

521

355

310.3

400.2

210.1

310

10

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

900914.3 330920914.2 550940.1

502904902 900.5

360.2

932

932.1

935

940

360.1

210

320

320.1

183940.3550.1 900.1562.3562818G 730 132

901.1

554.6

161107 914.1 914400.1

905903106 310149

412562.1

210.1

109230310.1

114

940.2 562.2

230.2

Only for construction with Thermometric Probe

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

Fig. 10 - Pumps series TBAK

With sealing can (VDMA 818G) Ø75

925

903.1

940.4

521

11

NOTES

PUMP model

.........................................................................

LIQUID handled

.........................................................................

Lethal Toxic Nox ious Corrosive Ir ritant Malodor ous ...................

Clean Dirty With suspended parts Spec. Gravity........... Viscosity.............. PH..........

TOTAL WEIGHT

MAX IMUM DIMENSIONS

...................KGs.

INSTALLATION SERVICE

Ins ide O utside Continuous Inter mittent

Ex plosive area ............................. ......................................................................

MOTOR type / Frame

..................................

Frequency

.............................Hz

No Poles

................................

Supply

..........................Volt

COMMENTS

Serial Number

......................

Capacity

...............m

3

/h

X =................c m

Y =................c m

Z =................c m

No Revolutions

........................RPM

Enclosure

IP............................

Computer Number

........................................................

Suction Pressure

........................m

Discharge Press.

........................m

NOISE (measured at 1 m)

Pressure =...................dB(A)

Power =...................dB(A)

Absorbed power

.........................Amp

Insulation class

...............................

Installed Power

...............kW / ..............HP

Absorbed Power

..............kW / ..............HP

Year of manuf.

......................

Temperature

..................°C

NA4.SM.TBAK.GB00 / PRINTED IN ITALY

Continuing research of POMPETRAVAINI results in product improvements: therefore any speci fications may be subject to change wit hout notice.

20022 CASTANO PRIMO (Milano) ITALY

Via per Turbigo, 44 – Zona Industriale

Tel. 0331 889000 – Fax 0331 889090

www.pompetravaini.

12

Disassembly and assembly instructions for magnetic drive multistage self-priming centrifugal pumps

com

Smontaggio TBK-TBAK Inglese

S.p.A.

Loading...

Loading...