Pompetravaini BORA HV 233, BORA HV 73, BORA FP 583, BORA FP 363, BORA HV 353 Operating Manual

...Page 1

®

(Rev. 1.3_01-2018)

HIGH VACUUM PUMPS,

EXHAUSTERS AND BLOWERS

OPERATING MANUAL

Page 2

2

Thank you for purchasing a Pompetravaini-BORA product and congratulation on your choice.

This manual has been compiled to give you all the necessary information for the correct use of the products.

Please read it thoroughly, follow carefully the instructions and keep it intact.

This manual refers to vacuum pumps, blowers, exhausters, AC, HV and FP Series.

All pumps and systems are manufactured by:

POMPETRAVAINI S.p.A.

Via per Turbigo, 44 - Zona Industriale - 20022 CASTANO PRIMO - (Milano) – ITALIA

Tel. +39 0331 889000 - Fax. 0331 889090

www.pompetravaini.it

Divisione BORA, sede operativa:

Via della Scienza, 56 - 41122 MODENA – ITALY

Tel. +39 059 284210 - Fax +39 059 284042

WARRANTY: All products manufactured by Pompetravaini - BORA are guaranteed to meet the conditions listed on the

general terms and conditions of sale and/or conditions listed on the Order Confirmations.

Failure to strictly adhere to the instructions and recommendations listed in this manual will void the manufacturer’s

warranty.

Guarantee will be preserved only if the pump maintenance is carried out by Pompetravaini or an authorized service. Any

modification introduced to the pump without the authorization of Pompetravaini will lead to the loss of the guarantee.

If it is strictly necessary to dismantle the pump, please consult Disassembling Instructions on our

website "www.pompetravaini.it".

High vacuum pumps, exhausters and blowers operating manual

Page 3

3

INDEX

1

INTRODUCTION

7.2.3.1

REPLACEMENT OF THE 1ST SUPPLY OIL OF SEAL

1.1

GENERAL INFORMATION

SHAFT

1.2

MANUFACTURER’S INFORMATION

7.2.4

CLEANING THE FAN MOTOR PROTECTION

1.3

METHOD OF CONSULTATION

7.2.5

GENERAL EXTERNAL CLEANING OF PUMP

1.4

PERSONNEL QUALIFICATIONS

7.2.6

CHECK OF THE TRANSMISSION ELASTIC ELEMENT

1.5

PERSONAL PROTECTION EQUIPMENT

7.2.7

REPLACEMENT OF THE GEAR AND BEARING OIL

1.6

NAME PLATE

7.2.8

REPLACEMENT OF THE SHAFT SEAL OIL

2

SAFETY

7.2.9

FILTER MAINTENANCE

2.1

GENERAL WARNINGS

7.2.10

TRASMISSION

2.2

RESIDUAL RISK

7.3

PAINTING

2.3

PICTOGRAPHS

7.4

SPARE PARTS

2.4 IN CASE OF EMERGENCY

8

HOW TO RETURN THE PUMP

2.4.1

BASIC FIRST AID

9

DISMANTLING

3

DESCRIPTION

9.1

TROUBLESHOOTING BLOWERS

3.1

DESCRIPTION OF TYPES

9.2

TROUBLESHOOTING EXHAUSTERS

3.1.1

BLOWERS

9.3

TROUBLESHOOTING HV and FP SERIES

3.1.2

EXHAUSTERS AC

10

DIMENSIONS AND CHARACTERISTICS

3.1.3

HIGH VACUUM PUMPS, BOOSTER HV

and FP SERIES

3.2

INTENDED USE AND CONTRAINDICATIONS

3.2.1

INTENDED USE

3.2.2

CONTRAINDICATIONS

3.3

NOISE EMISSIONS

3.4

VIBRATIONS

4

INSTALLATION

4.1

RECEIPT AND CONTENT VERIFICATION

4.2

PACKAGING

4.3

TRANSPORT AND HANDLING

4.4

STORAGE

4.5

ENVIRONMENTAL CONDITIONS

4.6

PUMP INSTALLATION

4.7.1

MOTOR INSTALLATION ON BLOWERS AND

EXHAUSTERS

4.7.2

MOTOR INSTALLATION ON BOOSTER HV

and FP SERIES

4.8

USER SYSTEM

4.9

CONNECTION

4.9.1

INTAKE AND OUTLET CONNECTIONS

4.9.2

ELECTRICAL CONNECTION

5

ACCESSORIES

5.1

RV VACUUM RELIEF VALVE SETTING

5.2

SETTING OF THE OVER PRESSURE VALVE

5.3

AIR FILTER ON SUCTION

5.4 CHECK VALVE

5.5

SILENCERS

5.6

SOUNDPROOFING BOOTH

5.7

ANTISHOCK MOUNTS

5.7.1

ELASTIC HOSE

5.8

VACUUM AND PRESSURE GAUGES

5.9

CHOKED AIR FILTER GAUGE

5.10

MOTOR ELECTRICAL PROTECTION

5.11

ANTI ACCIDENT DRIVE COVER

6

INSTRUCTIONS FOR USE

6.1

OPERATION

6.2

START UP

6.3

STOP

6.4

DECOMMISSIONING AND PROLONGED

7

MAINTENANCE

7.1

GENERAL WARNINGS

7.2

OPERATIONS TABLE

7.2.1

CHECK OF THE LUBRICANT LEVELS

7.2.2

GEARS AND BEARINGS 1ST SUPPLY OIL

REPLACEMENT

High vacuum pumps, exhausters and blowers operating manual

Page 4

4

1 - INTRODUCTION

Pompetravaini S.p.A.

Via per Turbigo, 44 - Zona Industriale

20022 Castano Primo

(Milano - ITALY)

Tel. +39 0331 889000

Fax +39 0331 889057

www.pompetravaini.it

Divisione BORA

Sede operativa:

Via della Scienza, 56

41122 Modena, ITALY

Tel. +39 059 284210

Fax +39 059 284042

1.1 – GENERAL INFORMATION

This manual is a reference point to:

- the safety of use

- the installation and maintenance of pump or system.

- Start-up, laying-up and shutdown of pump or system.

N.B.: All the indications referred to the individual pump are effective also for systems that are using them, where not

explicitly specified.

This manual must be completed by the user taking note of the pump characteristics in the last page, it must be

preserved with care and it must be at qualified technician’s disposal.

This manual, originally written in ITALIAN, is an integral part of the pump and must be preserved with care for the life of

the pump itself. In the event of sale, lease or loaned use of the pump, it must be delivered to the new user along with

EC declaration of conformity. Carrying out any operations on the pump before reading and fully understanding all

instructions written in this manual is prohibited.

The pumps is designed for an industrial and continuous use by trained and authorized personnel, in

appropriate plants. It’s not allowed to use it in inappropriate plants or without appropriate protective

measures to prevent contact with children or untrained personnel.

The images contained in this manual are for an example purposes only and are not binding for the Supplier.

The Supplier reserves the right to modify components and/or parts in order to improve or for any other reason, without

updating this manual if operation and safety of the pump are not changed.

1.2 - SUPPLIER INFORMATION

Please always include the following information in all communications regarding the pump:

• pump model and serial number

• year of manufacture

• date of purchase

• detail information regarding problems verified

1.3 - METHOD OF CONSULTATION

For improved understanding of the information provided in this manual, warnings or instructions considered critical or

hazardous are marked with the following symbols:

DANGER

Failure to comply with these instructions may cause danger to persons.

WARNING

Failure to comply with these instructions may cause damage to the pump.

High vacuum pumps, exhausters and blowers operating manual

Page 5

5

1.4 - PERSONNEL QUALIFICATIONS

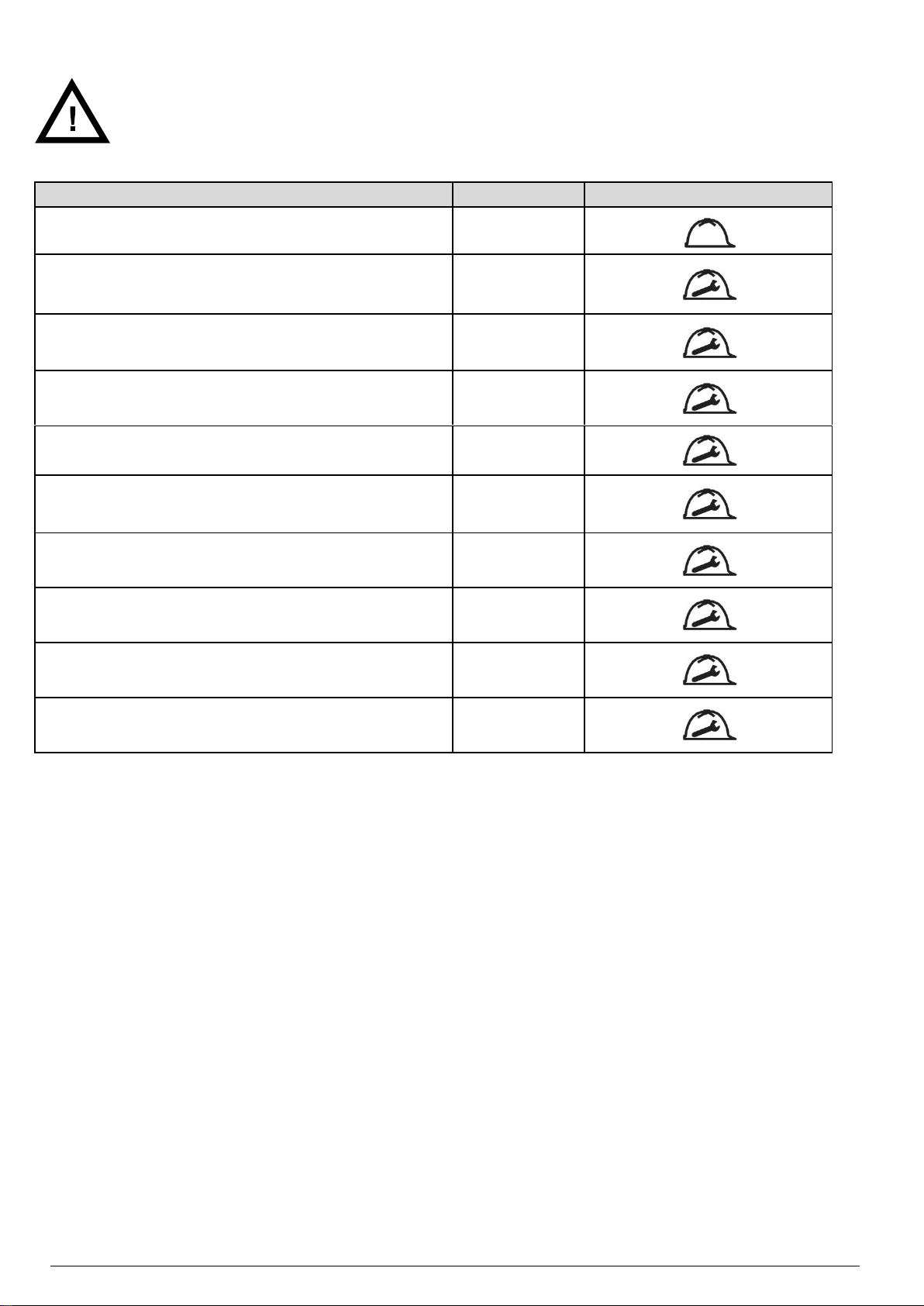

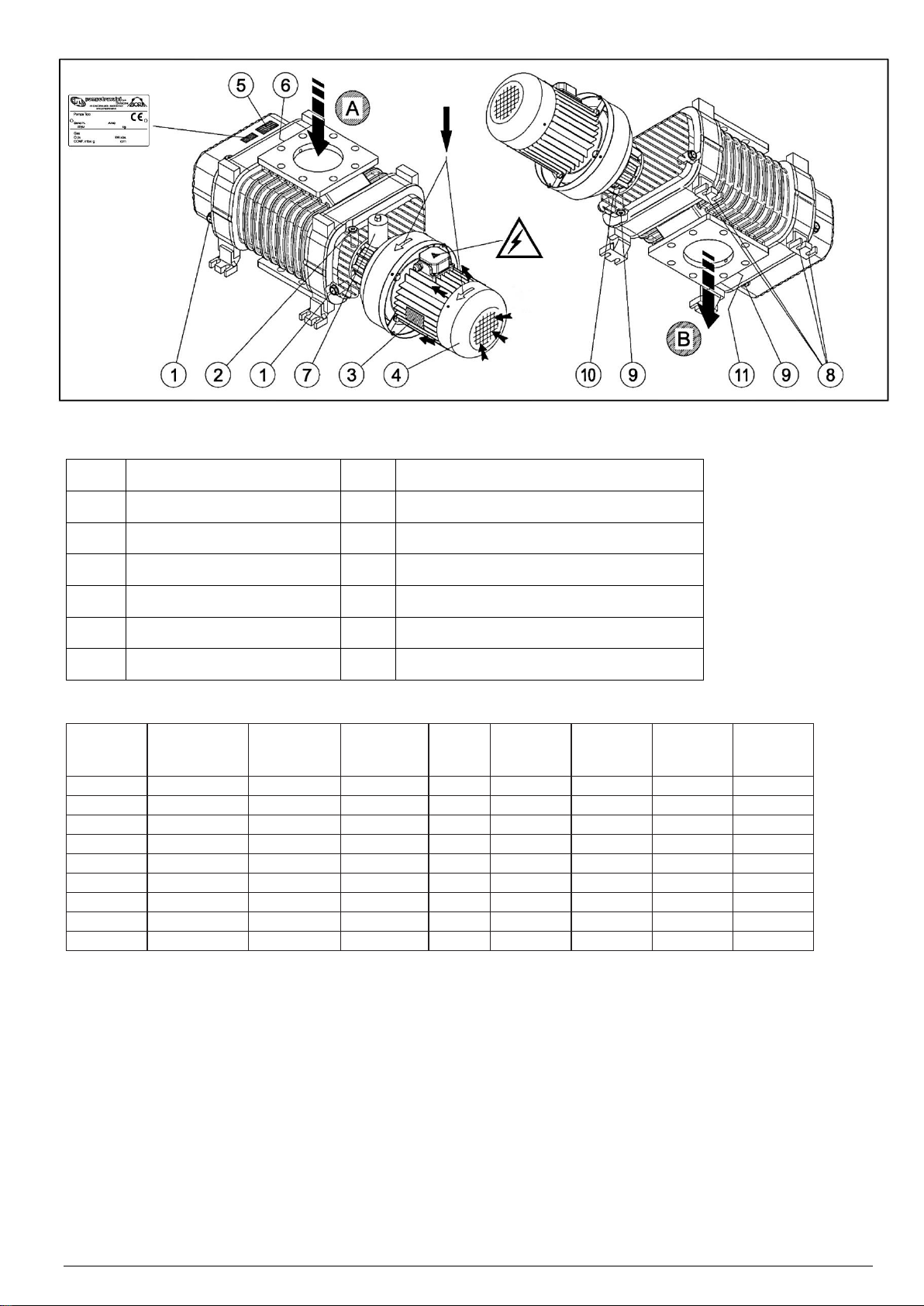

Fig. 1

To ensure that all operations performed on the pump are carried out safely, operators must have the qualifications and

requirements to carry out its operations. Operators are classified as follows:

FIRST LEVEL OPERATOR: Unqualified personnel, having no specific skills, able to perform simple tasks only.

MECHANICAL MAINTENANCE OPERATOR: Technician qualified to work on mechanical parts to carry out

any necessary adjustments, maintenance or repairs. Not qualified to work on electrical systems in the

presence of voltage.

ELECTRICAL MAINTENANCE OPERATOR: Technician in charge of all operations of an electrical nature. Can

operate in the presence of voltage inside cabinets and connector boxes

1.5 - PERSONAL PROTECTION EQUIPMENT

This manual assumes that the pump has been installed in workplaces, which comply with all mandatory safety

requirements; in particular, it is mandatory that personnel are equipped with personal protective equipment in relation to

the activities that must be performed.

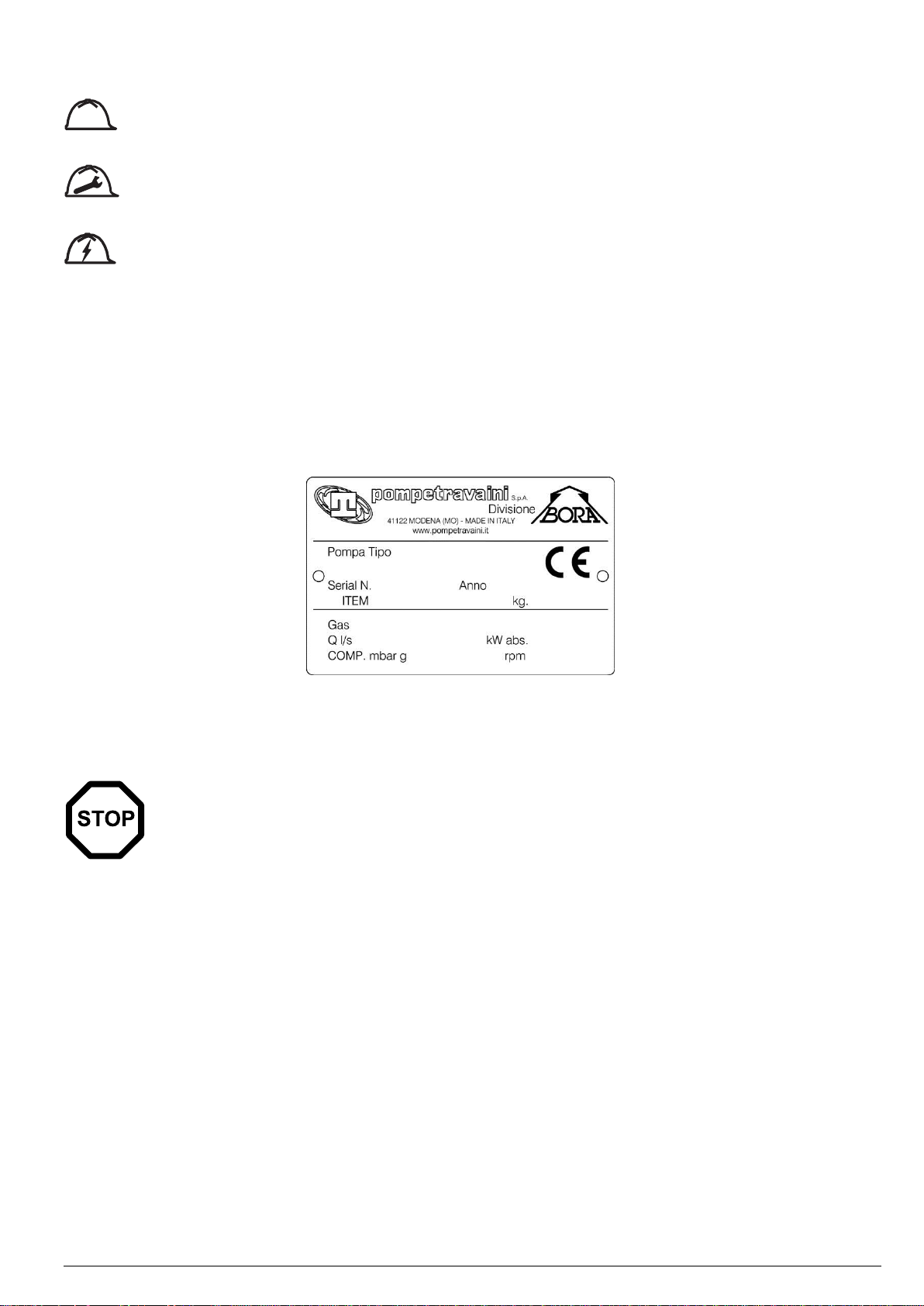

1.6 – NAME PLATE

The pump has an identification plate which shows the Supplier’s name, address, EC label, construction year and its

technical data.

WARNING

Removing or tampering with the identification plate is strictly forbidden.

High vacuum pumps, exhausters and blowers operating manual

Page 6

6

2 - SAFETY

2.1 - GENERAL WARNINGS

WARNING!

CAREFULLY READ FOLLOWING INSTRUCTIONS.

Strictly adhere to the instructions listed below to prevent personal injuries and/or equipment damage.

- ALWAYS apply the pump for the conditions outlined on the confirming order.

- Be ALWAYS informed on locations of first aid sites inside the company and carefully read safety and medical first aid

prescriptions in force.

- ALWAYS have a fire extinguisher in the vicinity of the pump installation.

- Any work on the pump must ALWAYS be carried out by at least 2 qualified people and expressly authorized.

- Electrical connections on the motor or accessories must ALWAYS be carried out by authorized personnel and in

accordance to the local codes.

- When approaching the pump ALWAYS be properly dressed (avoid use of clothes with wide sleeves, neckties,

necklaces, etc.) and/or wear safety equipment (hard hat, safety glasses, safety shoes, etc.) adequate for the work to

be done. Also refrain from wearing long and loose hair.

- DO NOT attempt to remove the safety guards when the pump is operating.

- After completion of the work ALWAYS re-install the safety guards previously removed.

- DO NOT operate the pump in the wrong direction of rotation.

- NEVER put hands or fingers in the pump openings or holes.

- I collegamenti elettrici del motore della pompa devono essere SEMPRE eseguiti da personale specializzato, qualificato

ed autorizzato seguendo le norme vigenti.

- ALWAYS disconnect the power to the motor prior to working or removing the pump from the installation.

- Make sure you have taken the necessary steps to prevent a possible inadvertent return of tension.

- Ensure the proper isolation of the components and ground connection before inserting the tension.

- ALWAYS stop the pump prior to touching it for whatever the reason. Wait for the complete pump stopping and make

sure that all the installation control devices are properly set in order to avoid any return flow.

- Pump and piping connected to the pump must NEVER be under pressure when maintenance or repair is carried out.

- NEVER work on the pump when it is hot.

- ALWAYS be careful when handling pumps that convey acids or hazardous fluids.

- NEVER step on pump and/or piping connected to the pump.

- ALWAYS make sure that the pump is permanently fixed and steady to the installation (i.e. during removal, handling,

installation, etc.).

Pompetravaini-Bora srl disclaims any liability for damage to persons or property resulting from improper use of the pump

from tampering with its safety apparatus or failure to observe operational safety standards.

DANGER!

Possible contact with hazardous media and hazardous substances There are certain components in the

pump which may be dangerous to people coming in their contact even during normal operation procedures

and/or maintenance, see table 1.

Take care of their possible disposal according to the laws into force and to a safe local environment management..

WARNING!

Danger due to smokes or vapors. In case smokes or vapors are released by the pump do not inhale and

immediately stop the pump for inspection.

2.2 RESIDUAL RISKS

DANGER

This pump has been designed to minimize residual risks to personnel. We urge you, however, to take the

utmost care and attention in carrying out maintenance operations. The confidence gained with frequent

contact with the pump too often leads users to forget or underestimate risks.

High vacuum pumps, exhausters and blowers operating manual

Page 7

7

Danger of Entangling

There is a permanent impending danger of entangling or entrapping hair and clothing in the cooler fan inside the

protection itself near the fan cover casing on the electric motor. Tie long hair up and do not wear baggy clothing, long

laces or other items that could get caught up..

Danger Of Crushing and/or Shearing Caused By Moving Rotor Lobes

Through the openings in the intake and outlet it is possible to access the rotating lobes. Never insert your hands or any

kind of object through the openings. This danger also exists when the machine is not moving, when it is rotated manually.

Danger caused by the pump Seizure

If the use of the pump is NOT compliant with what is indicated in this manual, could cause pump seizure. If you hear an

unusual noise, that might be lobes’ pump seizure, move away and turn the machine off immediately.

Danger caused by a Noise created by the pump

If the use of the pump is NOT compliant with what is indicated in this manual, during operation the pump could

generate sound emissions exceeding 80dB (A). If this is the case follow the relative instructions given in this manual.

High Temperature danger

If the use of the pump is NOT compliant with what is indicated in this manual, during normal operation, the pump

surfaces could exceed a temperature of 70°C. In this case follow the relative instructions given in this manual.

Moreover, install the pump in a protected area that follows the environmental conditions indicated in point 3.3 and that

can be accessed only by authorized personnel. Do not touch the pump surfaces during its operations and carry out

works only when the pump has stopped and cooled down.

Danger caused by Low Pressure

Avoid contact with pump intake while operating. Use fitting and connecting parts to the system’s piping that can

sufficiently resist the vacuum that arises. Let air into the intake circuit before any intervention. Contact with vacuum

points can result in accidents due to hair and/or clothing being sucked in.

Danger from the emission of Harmful Substances

Whenever air containing hazardous substances is sucked in (for example biological or microbiological agents), use

abatement systems located in front of the pump.

Slip and/or Fall danger

The pumps use oil to lubricate the motion transmission rotating parts and the seal on the shaft. NON conforming use

with respect to the indications of this manual can damage the gaskets of the compartments containing the lubricating

oil that spilling on the floor could cause personnel to slip and/or fall.

Electrical danger

Electrical equipment in the pump includes live parts which, upon contact, can cause serious damage to persons and

property. Any kind of repair work on the electrical system should only be done by specialized personnel and only after

insulating the pump from the mains power supply.

Fire danger

Use of the pump for any unforeseen uses or prohibited by this manual as well as a lack of proper maintenance can

cause malfunction with a risk of overheating and fire. In case of fire, do not use water to extinguish the flames, but use

a dry extinguisher or CO2 or other means compatible with the presence of electrical equipment

Danger caused by the Projection of Parts or Part of them

Arrange the installation of the pump in order to avoid those in charge of works being directly hit by parts or bits of parts

flying through the fan cover casing due to the cooling fan breaking.

High vacuum pumps, exhausters and blowers operating manual

Page 8

8

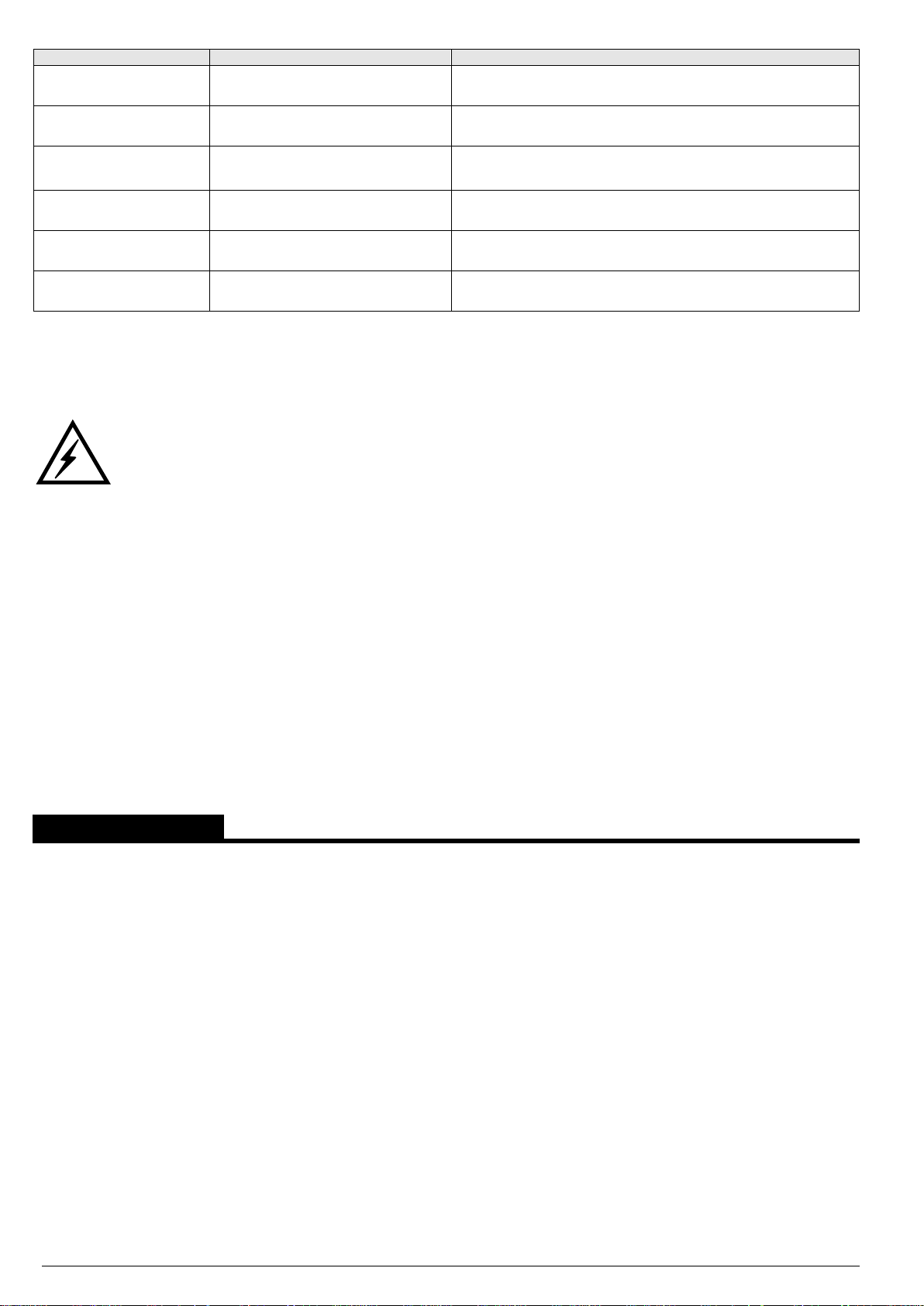

MATERIAL

USE

MAJOR RISKS

Oil and grease

General lubrication, ball bearings

Skin and eye rash

Plastic & elastomer

components

O-Ring, V-Ring, splash ring,

Coupling dowels

Smoke & vapors in case of overheating

Teflon & Kevlar fibbers

Packing rings

Release of dangerous powder, release of smoke if

overheated

Paints & varnishes

Pump outside surface

Release of powder and smoke if working the painted

areas. Flammable

Anaerobic adhesive

Gasket between planels

Skin, eye and breathing apparatus rash

Protective liquid

Pump inside surface

Skin and eye rash

Tab. 1

2.3 - PITTOGRAPHS

Pictograms concerning warning and safety symbols are applied on the pump, for the good of for operators.

Read carefully and take note of the symbols and their meaning before using the pump.

ELECTRICAL DANGER

The pump is near protected electrical connections but where accidental contact can cause electric shock

and death.

Pompetravaini - BORA disclaims any liability for damage to persons or property due to non-compliance with

instructions indicated in pictograms or their improper preservation.

2.4 - IN CASE OF EMERGENCY

In the event of pump break-down and/or loss of pumped fluid, immediately disconnect the electrical power to the motor

and contact the responsible personnel in charge of the installation, which should intervene with at least

two people paying particular attention to the fact that the pump may be handling dangerous fluids, hazardous to the

health and environmentally unsafe.

After the causes for the emergency have been addressed and resolved, it will be necessary to follow the starting

procedures for the start-up of the pump/motor assembly..

2.4.1 - BASIC FIRST AID

In the event dangerous substances have been inhaled and/or come in contact with the human body, immediately follow

the instructions given in the company’s internal medical safety procedures.

3 – DESCRIPTION

The lobe pumps are volumetric machines that, thanks to the rotation of two rotors with three lobes within a suitably

shaped chamber, create volumes and transfer air through the intake manifold to the outlet one. The rotor lobe rotation

without contact is synchronized by means of gears and it occurs completely dry without any lubrication or residues

generated by brushing or contact during rotation.

The gear toothed wheels that allow the rotors and their bearings to rotate are lubricated with oil and are inside two

compartments (separated from the rotor rotation chamber by means of gaskets) and they function as a tank for

the lubricating oil. During operation they are at the same pressure of the pump work chamber. For this reason it is

forbidden to open the oil filler and drain plugs during operation or until the atmospheric pressure has not been restored

inside the pump.

3.1 – DESCRIPTION OF TYPES

This manual includes all the pumps belonging to the series described below. The available models and their variants are

always evolving. The manufacturer reserves the right to update the range of pumps, consequently.

3.1.1 - BLOWERS

Blowers are pumps operating without oil inside the hydraulic chambers. They include the centrifugal-volumetric blowers

series, from size 73 to size 103 and the volumetric series from size 163 to size 883. They are intended to be used as a

component of a more complex system that processes clean air or not aggressive/explosive gases. These machines are

suitable to operate with positive back pressure in delivery, pressure Max 1 bar(g), or negative in suction, depression Max

–0,5 bar(g), within the permitted temperature limits. The temperature at suction inlet must be from 12 to 40 ° C.

For more information about features and performance of pumps, please refer to the available documentation.

They can be run by belt through a pulley mounted overhanging on the shaft or direct with flexible coupling.

High vacuum pumps, exhausters and blowers operating manual

Page 9

9

WARNING

The lack of the overpressure/depression valve can cause serious damages, the valve must be installed next to

the machine flanges without the interposition of non return valve.

3.1.2 - EXHAUSTERS – AC EXHAUSTERS

Exhausters are pumps operating without oil inside the hydraulic chambers. They include the centrifugal-volumetric

blowers series, from size 73 to size 103 and the volumetric series from size 163 to size 883. They are intended to be

used as a component of a more complex system that processes clean air or not aggressive/explosive gases. They are

suitable to operate with positive back pressure in delivery, pressure Max 1 bar(g), or negative in suction, depression Max

–0,5 bar(g), within the permitted temperature limits. The temperature at suction inlet must be from 12 to 40 ° C.

For more information about features and performance of pumps, please refer to the available documentation.

They can be run by belt through a pulley mounted overhanging on the shaft or direct with flexible coupling.

3.1.3 – HIGH VACUUM PUMPS, BOOSTER HV e FP SERIES

The high vacuum centrifugal-volumetric pumps , from size 103 to size 1083 described in this manual, are pumps operating

without oil inside the hydraulic chambers. They are intended to be used as a component of a more complex system that

processes clean air or not aggressive/explosive gases and small quantities of water vapors. They are suitable to operate

in series upstream of a primary vacuum pump in order to improve the reachable vacuum, or rather to accelerate the

attainment. For the HV series, the lowest attainable pressure is 0.01 mbar (a).

The FP series is optimized for the food packaging and can reach a pressure of 0.5 mbar (a).

The applications must remain within the limits of permissible suction temperature from 12 to 40 ° C.

Pompetravaini- BORA can provide vacuum systems composed by a vacuum volumetric pump in combination with a liquid

ring vacuum pump with Hydrotwin system series.

They can be run by flexible coupling with coupling insert.

3.2 - INTENTED USE AND CONTRAINDICATIONS

3.2.1 - INTENTED USE

The volumetric pumps described in this manual are intended to be used as components of a more complex system

that works with clean air, inert gas or small amounts of water vapor in the low and medium vacuum, or in low pressure.

The pump transfers a gas from the suction-inlet to the blowing-outlet with a delivery consistent with the characteristic

performance curve applicable for each size/version in the machines available range.

The temperature at suction inlet must be from 12 to 40 ° C

Any other use is prohibited. The Supplier is not liable for any damage to persons and/or property caused by improper

use of the pump..

3.2.2 – CONTRAINDICATIONS

Any use other than that for which the pump was constructed is to be considered an abnormal

condition and therefore can cause damage to the pump and pose a serious danger to the operator.

Below is a series of operations involving improper use of the pump, which are not permitted under any circumstance.

• Do not use the pump in non-industrial installations unless all necessary precautions and protective measures

have been taken (e.g. protection against contact for child safety).

• Do not use the pump in conditions other than those indicated in the tables shown in point 3.3 of this manual.

• Do not operate the pump Booster, HV/FP if the priming pressure has not been reached.

• Do not use the pump in an explosive (classified areas according to ATEX 94/9 CE Directive) or aggressive atmosphere

or in an atmosphere with a high concentration of dust or oily substances and do not use it to pump explosive, flammable

or corrosive gases or gases that form particles. The pumps in the standard version are not suitable for evacuating

oxygen at higher concentrations than that of atmospheric concentrations. Using the pump in these atmospheres and

with these types of gases can cause injury, explosion, fire or seriously damage the pump.

• Do not use the pump without installing an intake filter suitable for the applications for which it has been intended.

• Do not change or transform the pump, carry out repair or maintenance work of your own initiative. Maintenance work

can only be carried out in compliance with Maintenance chapter of this manual.

• Only use original spare parts or parts provided by the Supplier.

• Do not use the pump to pump solid materials, chemicals, powders, solvents or other substances differing from those

permitted. These kinds of materials may damage the unit, limit its performance or reduce its lifespan.

• Do not expose the pump to rain, steam, excessive humidity or direct sunlight.

• Do not install the pump in places subject to possible flooding.

• Do not place or store near flammable or combustible materials or substances.

• Do not open oil fill or drain plug while pump is working.

High vacuum pumps, exhausters and blowers operating manual

Page 10

10

3.3 - NOISE EMISSIONS

Unlimited use

Preventive

Maintenance

Extraordinary

Maintenance

V1 Class

<3,5

> 3,5÷ < 7

> 7

Tab. 2

The pump described in this manual were designed and built in order to reduce noise level at source.

The actual sound emission while operating depends, however, on the installation conditions, position and the

operating pressure that can be upper than 85 Db(A). If required, appropriate solutions can be supplied by Pompetravaini

in order to comply with the legislative provisions in force in the Country of use of the user system. Otherwise, the user

must take any appropriate devices for the reduction of the noise level. If there is personnel close by while the machine is

working it is necessary to use adequate personal protective equipment. If the noise level is not compatible with the

installation environment, Pompetravaini - BORA can provide adequate soundproofing booth made on specific needs.

3.4 - VIBRATION

The pump described in this manual were designed and built in order to reduce the presence of vibrations at source.

Their vibration class is V1, rms mm/s values indicate the limit values for a continuous use of the machine in terms of an

adequate installation.

For upper values it is necessary to begin the pump maintenance, according to the following table.

4 – INSTALLATION

4.1 - RECEIPT AND CONTENT VERIFICATION

Upon receipt of the pump, verify that the packaging is intact. If everything is intact, unpack the contents and check the

pump. The pump is delivered with the proper oil amount necessary for its operation and it is already present inside the

gear casings and in the shaft seal bell. Do not overturn or tilt the packing excessively (Max. 10°) and check that it has

no oil stains. If everything is intact, unpack and control the contents.

If packaging shows signs of damage due to transport or storage conditions, immediately notify the shipping agent and

the Supplier. It is always necessary to check that the material received corresponds to its accompanying document.

Packages should be opened taking all precautions to avoid harm to people and the contents thereof.

4.2 - PACKAGING

Depending on the transportation method, the pump can be packed in the following modes:

• On wooden platform with protective film or cardboard cover;

• In wooden cage;

The wood for the platforms, pallets and cage can be reused or recycled in compliance with the current legislation in

the country where the pump is being installed. Other materials such as cardboard, plastic or protective film must be

disposed of in accordance with local regulations.

Do not burn or discard packaging parts in the environment.

4.3 - TRANSPORT AND HANDLING

DANGER

All transportation, lifting and handling operation must be performed by experienced personnel;

Should the packaging or pump overturn or fall, it can cause serious harm to personnel.

Never stand under suspended loads and keep at a safe distance.

It is strictly forbidden to lift the pump in any way other than that foreseen.

DANGER

It is strictly FORBIDDEN to manually lift and handle the pumps.

WARNING

During the handling phases keep the load as near to the ground as possible.

Do not tilt the pump more than 10° on the rotation axis to prevent the oil in the casings from entering into

the pump work chamber.

High vacuum pumps, exhausters and blowers operating manual

Page 11

11

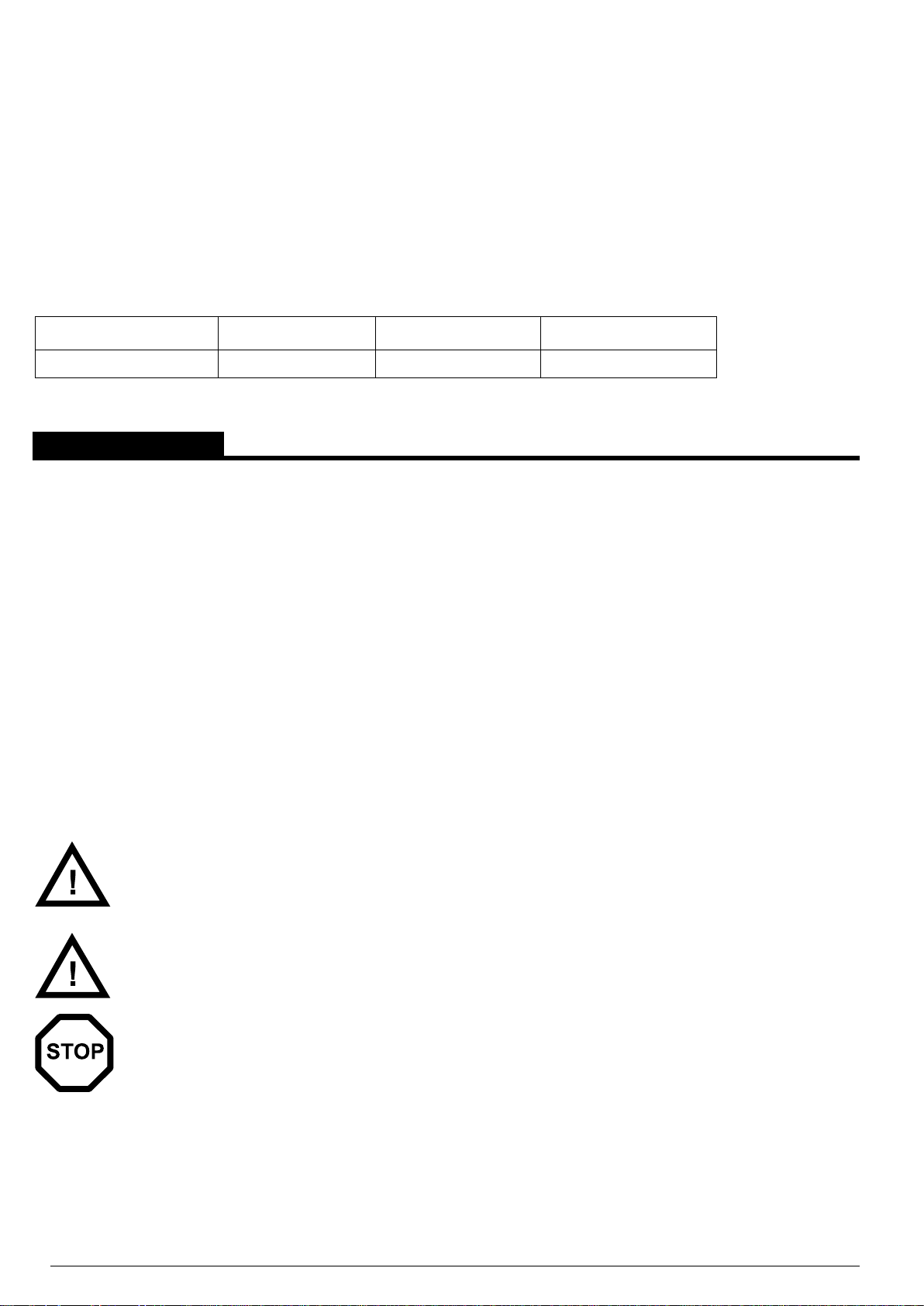

The pump can be lifted and handled using a fork-lift truck and hoisting means (e.g. ropes, hooks, etc.) suitably sized

BORA 163 HV - FP

BORA 163 HV - FP

BORA 233 HV → 1083 HV

BORA 233 HV → 1083 HV

Fixing point (with installed motor)

BORA MODEL

Fixing point (without motor)

A + B

163 HV

C + B

B + C

233 HV → 353 HV

E + D

A + C

463 HV → 1083 HV

E + D

BORA 243 FP → 543 FP /BORA 73HV-153HV

BORA 243 FP → 543 FP/BORA 73HV-153HV

Fixing point

(with installed motor)

BORA MODEL

Fixing point

(without motor)

(A + B) +

(C+D)

243 FP → 543 FP

73HV-153H

A + B

Fig. 2

Fig. 3

Tab. 3

Fig. 4

Tab. 4

for its weight (indicated in the technical data table and on the rating plate) and applied as indicated in the following

diagram to obtain the best harness in terms of safety and center of gravity.

High vacuum pumps, exhausters and blowers operating manual

Page 12

12

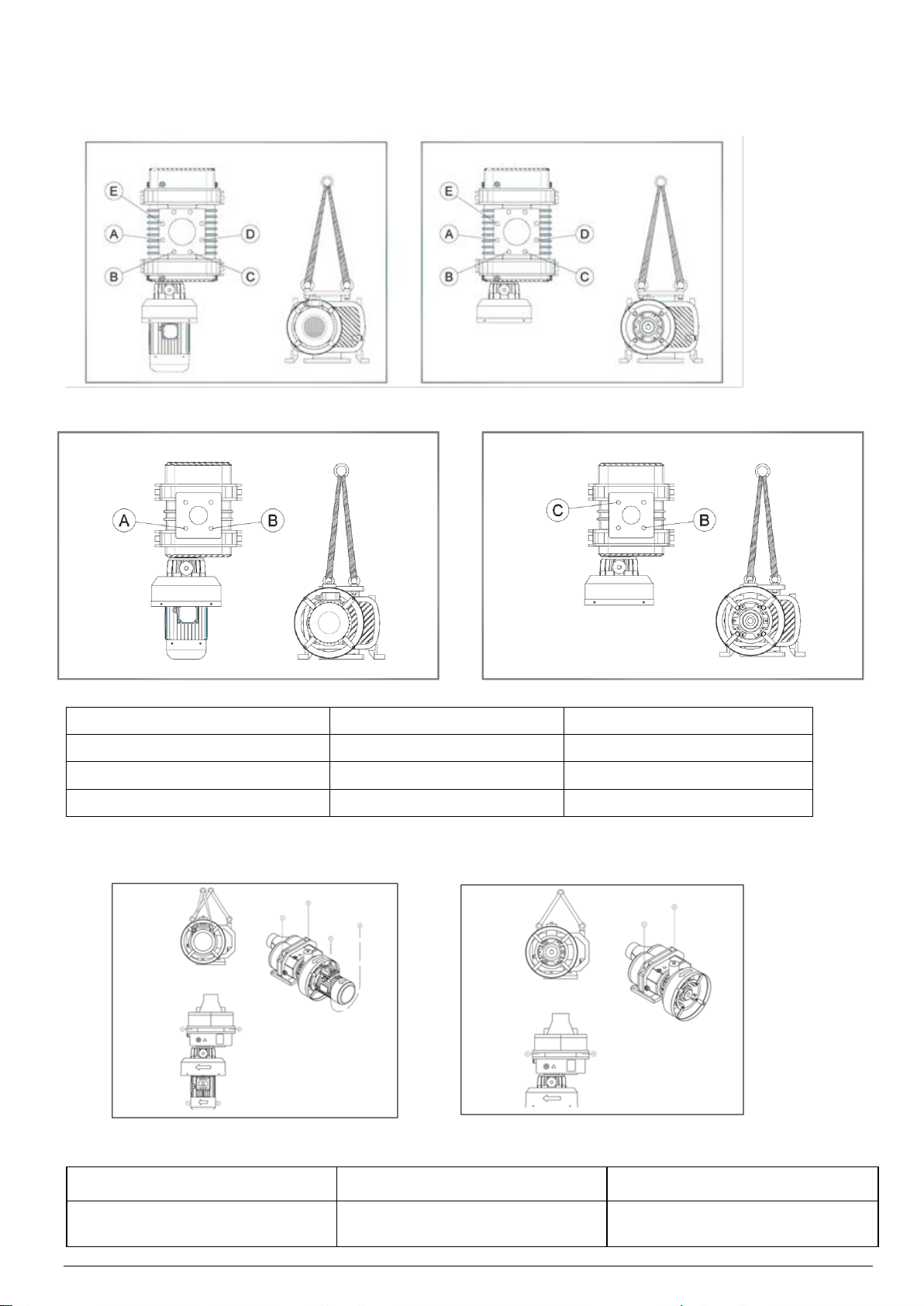

HOISTING PLANT ON BENCH

Fig. 5

WARNING

In order to transport the pump, we recommend you to prepare it as shown in the following paragraph.

4.4 – STORAGE

Shut down the inlet and outlet ports with the specific protections. The pump has to be stored in its packaging and kept

in covered, dry, protected places that are not exposed to bright sunlight, with temperatures in the range indicated in

point 3.3 of this manual..

If you are planning a long break before the assembly on the user system, moisten the internal parts with anti-rust oil.

4.5 – ENVIRONMENTAL CONDITIONS

The pump must be installed and used in a covered and adequately lit location. The installation area must meet all

requirements of height, air circulation and meet the requirements imposed by existing legislation.

Temperature, Humidity and Altitude

The corresponding limit values are shown in the technical specifications (10). Please contact the Supplier if

environmental conditions are different from those prescribed.

Lighting.

All areas must be illuminated evenly and sufficiently to ensure all operations included in this manual and must be

without shadows, reflections, glare or eyestrain.

4.6 – PUMP INSTALLATION

The pump can be installed and supported using the delivery flange or, alternatively, the appropriate feet. However,

it should be secured to a perfectly horizontal, solid surface in order to avoid tilting and/or subsidence in case of

transportation of the system user. If using feet to secure the pump, check that all four feet are resting on the surface (<

0,2mm) and if necessary use thicknesses before tightening them onto the supporting structure. We recommend that

you install the pump securing it by means of shock mounts.

In order to guarantee the perfect, safe running of the pump, position it according to the following guidelines:

• Leave sufficient space on the pump’s perimeter sides and make sure you keep the motor’s fan side free

following the indications in point 10 of this manual.

• Make sure the free space adjacent to the pump allows easy access to components for inspection or

maintenance and also allows access for suitable lifting equipment.

• Install the pump on a structure or system that does not transmit or amplify vibrations or sound emissions;

we recommend the use of anti-vibration systems.

• Ensure there is ventilation in the room or inside the machine housing the pump and prevent air coming in

from the motor cooling fans from stagnating in the room, changing the environmental conditions or causing

discomfort to personnel.

The position with horizontal axis flow and direction of rotation standard, usually adopted for direct drive, can find application

in compact systems.

WARNING

Store the pump on a perfectly horizontal surface. Tilting could cause the oil inside the gear and bearing

casings to enter into the pump work chamber.

High vacuum pumps, exhausters and blowers operating manual

Page 13

13

Installation with horizontal f/flow

Installation with vertical f/flow

Fig. 6

DANGER

Use an intake filter to protect the pump from dust, sand, masonry debris, cutting filaments and threadings,

drops and welding dirt and sealant residue produced when connecting the pipes that could damage rotor

lobes causing seizure.

DANGER

Position the pump and relative control systems in order to see the installation area during any operation in

order to prevent the machine from starting up while personnel are still carrying out work on it.

Failure to comply with these points could cause serious injury.

WARNING

Installing the pump on misaligned surfaces can jeopardize its operation when tightening the bolts.

When tightening make the shaft turn manually to check that the initial slipping remains unchanged.

WARNING

Do not install the pump in an area with dust or other materials that could clog and/or quickly cover the

motor fan or pump’s cooling surfaces.

4.7.1 - MOTOR INSTALLATION ON BLOWERS AND EXHAUSTERS

The blower can be installed and supported using either the discharge flange or the proper feet. If the feet are used, before

tightening them to the frame, check that all four feet touch properly the base (< 0.2 mm) and, if needed, use appropriate

shims.

WARNING

If the blower is placed on an irregular base, malfunctioning may be occur. During tightening operation

check the free manual rotation of the shaft.

Use just one bolt per foot. The alignment of the coupling or of the belts and the tensioning of the belts shall be carried out

as prescribed by the supplier of these components. The blower may transmit vibrations to the frame on which it is installed.

If they give problems to the surrounding environment and / or machinery , please isolate the frame with damping devices.

WARNING

Excessive tension of the belts can damage the compressor and/or the motor.

Excess of clearance in the coupling or worm flexible coupling causes damages to the blower not covered

by warranty.

High vacuum pumps, exhausters and blowers operating manual

Page 14

14

BELT DIRECTION

BORA HV 73

M90/2 B5 IEC-72, 1.5-2,7 kW 50-60Hz

BORA FP 243

M90/2 B5 IEC-72, 1.5-2,7kW 50-60Hz

BORA HV 103

M90/2 B5 IEC-72, 2.2-2.7kW 50-60Hz

BORA FP 363

M90/2 B5 IEC-72, 2.2-2.7kW 50-60Hz

BORA HV 163

M90/2 B5 IEC-72, 2.2-2.7kW 50-60Hz

BORA FP 583

M90/2 B5 IEC-72, 2.2-2.7kW 50-60Hz

BORA HV 233 - 293

M100/2 B5 IEC-72, 3.0-3.6kW 50-60Hz

BORA FP 813

M100/2 B5 IEC-72, 3.0-3.6kW 50-60Hz

BORA HV 353 - 463

M112/2 B5 IEC-72, 4.0-4.8kW 50-60Hz

BORA FP 1043

M100/2 B5 IEC-72, 3.0-3.6kW 50-60Hz

BORA HV 673

M132/2 B5 IEC-72, 5.5-6.6kW 50-60Hz

BORA FP 1263-1673

M112/2 B5 IEC-72, 4.0-4.8kW 50-60Hz

BORA HV 883 - 1083

M132/2 B5 IEC-72, 7.5-9kW 50-60Hz

BORA FP 2313

M132/2 B5 IEC-72, 5.5-6.6kW 50-60Hz

Fig. 8 - direction of the V-Belt for 103 series

Fig.8.1 - - direction of the V-Belt for 103-883 series

233 HV - 1083 HV

813 FP - 2313 FP

73HV - 163 HV

243 FP - 583 FP

X

50 mm

42 mm

Tightening torque (A)

20 Nm

20 Nm

Tab. 5

Fig. 9

Tab. 6

Fig. 8 shows the only correct direction of the V-Belt for the specified specified series.

WARNING

Any other direction of the V-Belt may reduce bearing’s life and is not covered by warranty.

4.7.2 - MOTOR INSTALLATION ON BOOSTER HV AND FP SERIES

It is possible to install any type of electric or hydraulic motor that has the features described in the table of technical

data, with flange and shaft corresponding to:

ATTENZIONE

The motor coupling alignment should be carried out following the indications and measures indicated

below. The excessive clearance in the coupling and flexible couplings cause damages to the pump

that are not covered by the warranty.

Fit the half-coupling on the motor shaft until you reach the stated measure.

Tighten the screws “A”, applying the torque indicated to firmly fix the half-coupling to the motor shaft.

4.8 - USER SYSTEM

Make sure that no harmful substances contaminate the user system during installation. If you wish the system to

maintain vacuum even when pump is stopped, install a cutoff valve between pump and system.

High vacuum pumps, exhausters and blowers operating manual

Page 15

15

4.9 - CONNECTION

DANGER

Pump connections should be performed by skilled and trained personnel only.

4.9.1 - INTAKE AND OUTLET CONNECTIONS

All the pump’s openings are protected in order to prevent extraneous parts entering it. Only remove these protections

positioned on the intake and outlet points shortly before connecting to the user system. Using thick steel hoses

reduces the noise. Clean the hoses thoroughly especially remove welding fluxes to prevent foreign bodies from

reaching the pump and damaging it.

The connection to the user system (intake and outlet) should be carried out using strain neutralizers to prevent

tensions and/or deformations on the flanges. The couplings and piping should have a diameter equal or greater than

that of the pump intake/outlet opening..

WARNING

Thoroughly clean the intake and delivery flanges checking the status of the seal surfaces and make sure

that the couplings, piping or flanges connected to the pump intake/outlet are firmly tightened and that there

are no leaks.

The weight of pipes or any expansions must not burden the pump connections. We recommend you to carry out the

final connection to the pump using flexible pipes or fittings, thus avoiding rigid connections that can induce tensions

and cause harmful vibrations. It is important to tighten all pipes and couplings. Extreme long piping or one with a

diameter that is too small and with tight, regular curves reduces the pump’s performance.

Employing the machine as a blower, the use of thick-walled steel pipes has a lowering noise effect. Clean accurately the

pipes, removing, in particular, welding debris particles in order to avoid that foreign objects get inside the compressor and

damage it. Avoid narrowing the pipes and creating short radius curves. The weight of the pipes must not rest on the

compressor but must be supported separately.

An expansion joint, on the pressure side, eliminates pressure on the machine caused by thermal elongation of the pipes.

We recommend the fitting of accessories described in chapter 5 ‘ACCESSORIES’.

WARNING

Little amounts of fluid are enough (coming from the container or the piping) to produce blows on the rotors

inside the pump chamber. The blows can deform the rotors and cause the pump to seize. Possibly take

suitable protective measures on the piping of the intake line (e.g. separator, T- fittings, etc..).

WARNING

Make sure that vibrations or loads are not transmitted on the pump’s attachments.

WARNING

Use an intake filter, especially if the pump works with unclean air flows.

4.9.2 - ELECTRIC CONNECTION

WARNING

Check that voltage and frequency correspond to values shown on the motor plate.

The connection cable must be in line with the power absorbed by the motor pump (the pump’s absorption levels

are shown on the electric motor plate) bearing in mind the environmental operating conditions. Use the cable clamp

openings to pass the power cables inside the terminal board.

DANGER

Always earth the pump. Always connect the earth cable to the relative clamp before connecting to the

mains supply and check the dispersion capacity.

High vacuum pumps, exhausters and blowers operating manual

Page 16

16

Fig. 10

DANGER

Lay the pump power cable in such a way that it cannot cause the risk of tripping or falling or can be

damaged.

Always install an electric protection system between the pump and power supply; the pump’s absorption levels are

shown on the electric motor plate. The fuses do not protect the motor, but are only a protection against short-circuiting.

Select a suitable kind and size of fuses bearing in mind the peak current, especially in the case of direct start-up.

The protection with motor protection is essential against overloading risks, in the absence of a network phase,

excessive variation of the voltage or pump block. Adjust the motor protection on the plate’s nominal current as the

maximum level. The pump is normally supplied without an electrical cable and switch. For electrical connection, see

the diagram contained within the terminal board or on the motor rating plate.

DANGER

The rotation direction determines also the flow direction (see figure 10).

Check that the direction of rotation is correct before starting the pump for the first time or after resetting the

electrical connections.

WARNING

In the event of incorrect rotation direction wait for the pump to come to a complete halt, before changing the

connection and supplying power again.

In the matter of blowers and exhausters, the correct rotation direction can be verified with a brief start-up.

Briefly start up the Bora pump motor, observing that the rotation direction of the motor cooling fan is counterclockwise

(arrow). If this is not the case disconnect the network cables and reverse the two phases. You can see if the sense of

rotation is correct, as soon as the rotation begins. Turn it off immediately and go on with the installation procedures.

In the matter of booster, the correct rotation direction can be verified bringing the pressure inside the pump to a value of

< 20 mbar, by switching on the primary pump. Then briefly start up the Bora pump motor and immediately turn it off,

making sure that the rotation direction of the motor cooling fan is counterclockwise (arrow). If this is not the case

disconnect the network cables and reverse the two phases.

High vacuum pumps, exhausters and blowers operating manual

Page 17

17

5 – ACCESSORIES

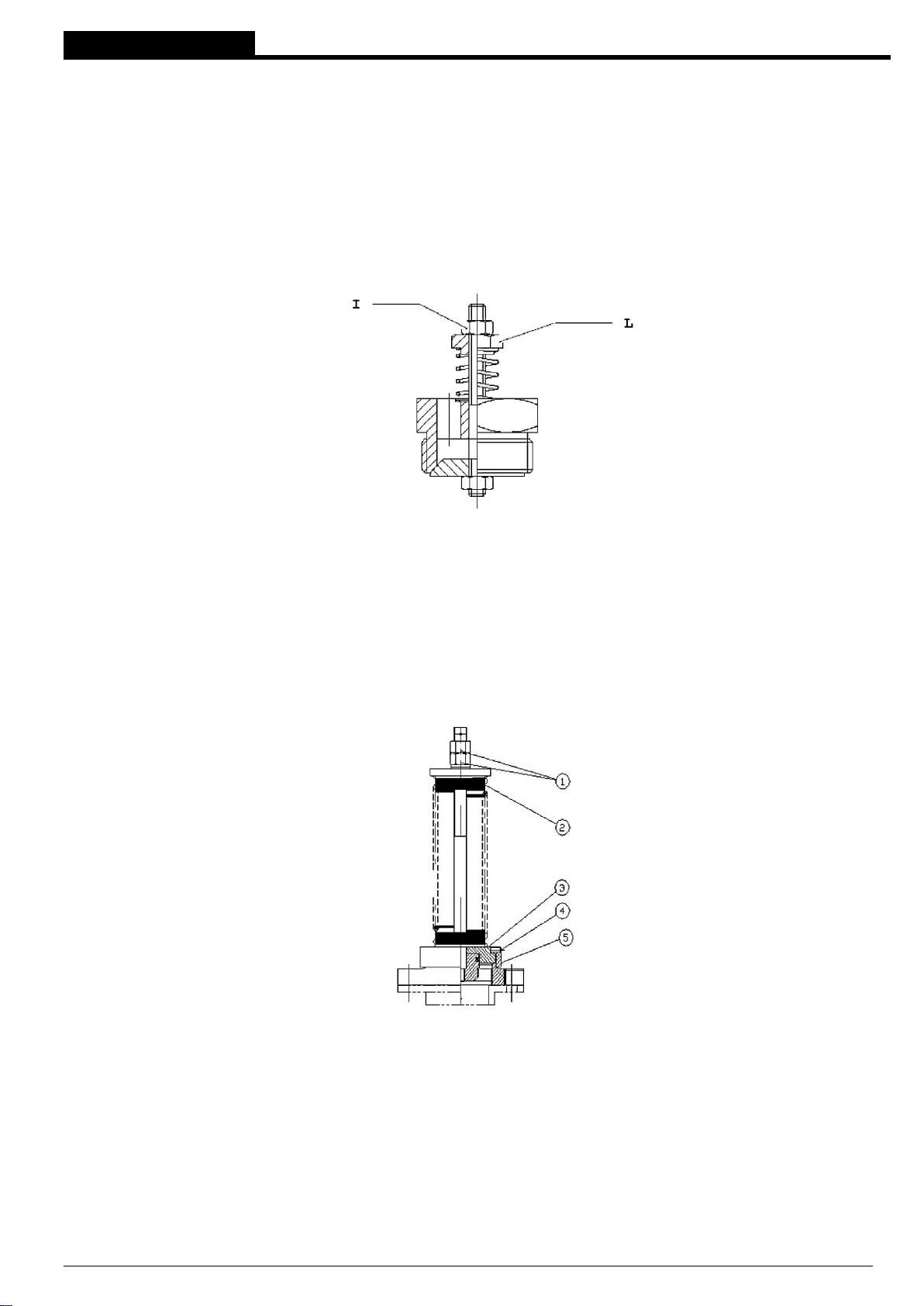

Fig. 11

Fig. 12

5.1 – RV VACUUM RELIEF VALVE SETTING INSTRUCTIONS

The vacuum relief valve is an accessory available for blowers and exhausters in order not to generate an excessive

lowering of absolute pressure on suction side. Fit the valve on suction side of the blower/exhauster and prearrange a

pressure take-off closed to the suction side of the same. Release screw ‘I’ and discharge the valve spring by screwing off

nut ‘L’.

Start the blower and throttle the suction upstream the valve till you get the worst working conditions (usually pipe line

completely closed ).

Screw in nut ‘L’ till you get the maximum vacuum allowed; this can be noticed from the pressure intake on blower's head.

Tighten nut ‘I’ by keeping steady nut ‘L’.

Remove the choking from suction pipe. See fig. 11.

5.2 – SETTING OF THE OVER PRESSURE VALVE

The overpressure valve is an accessory available for blowers in order to avoid overloading of the pump, if there were

any conditions of excessive backpressure in delivery.

The valve is usually supplied non-adjusted.

The setting adjustment is to be performed on the operating system: start the system with a minimum pre-load of the spring

increasing it by tightening the nut 1 until the desired pressure is reached. Then rotate the threaded ring 5 in order to

stabilize the discharge. Tighten finally the nut 1 and bolt 4 (Fig. 12).

5.3 – AIR FILTER ON SUCTION

It is always recommended but it is needed when the blower works in a dusty environment or when there is risk of foreign

objects. (filtering degree < = 0,005 mm)

5.4 – CHECK VALVE

It prevents counter flow or attraction of foreign objects or liquid into the machine.

5.5 – SILENCERS

The noise emission level of the compressor depends on the rotation speed and the back pressure.

In case of use as a blower, it is necessary to apply a silencer on the intake side in order to reduce the noise. A further

reduction is achieved with a silencer on the delivery side.

High vacuum pumps, exhausters and blowers operating manual

Page 18

18

WARNING

Fig. 10

The silencers must be installed on the blower flanges making sure that their weight is not supported by the

machine itself and they do not cause any deformation to the machine. During flange’s bolts tightening

operation check the free manual rotation of the shaft.

5.6 - SOUNDPROOFING BOOTH

In case of high speed and/or high back-pressure the use of a soundproofing booth may be needed.

WARNING

Said booths shall allow air circulation for an appropriate cooling of the machine. Forced ventilation may be

necessary.

5.7 - ANTISHOCK MOUNTS

They allow to damp the vibration that otherwise would be transmitted to the foundation. They are recommended for the

positioning between pump bracket and support plane for blowers and exhausters.

5.7.1 - ELASTIC HOSE

Must be used in case of antishock mounts: it avoids the transmission of mechanical vibrations to the pipes and allows

their free heat elongation.

5.8 - VACUUM AND PRESSURE GAUGES

Their use is recommended to check that the system is operating correctly and to check the adjustment of the overpressure valve.

5.9 - CHOKED AIR FILTER GAUGE

It is particularly recommended for machines that are not constantly checked or closed in a soundproofing booth.

A pressure switch installed in the appropriate boss on the suction flange shall actuate an alarm signal and in case

shut off the motor, keeping under control the vacuum level given by filter.

5.10 – MOTOR ELECTRICAL PROTECTION

On the electric feed line, install a thermo-magnetic switch properly adjusted as a protection against feed problems.

5.11 - ANTI ACCIDENT DRIVE COVER

If the coupling between the pump and the electric motor is not made by Pompetravaini - Bora, please note that, in all

cases a protection must be provided in order to avoid contact with moving parts using a cover conforming to the

regulations in force. Pompetravaini - Bora does not assume any responsibility for anti accident drive not manufactured

or supplied by itself.

6 – INSTRUCTIONS FOR USE

6.1 - OPERATION

Blowers, exhausters and vacuum pumps described in this manual are rotary machines equipped with lobe rotors,

symmetrically arranged and counter rotating, contained inside a housing. The rotor rotation is synchronized by means of

a gear transmission so as to move forward without a mutual contact with little clearance between them and with respect

to the housing. The operating principle is indicated below.

High vacuum pumps, exhausters and blowers operating manual

Page 19

19

In stage 1 the volume generated by the rotor rotation increases. As the rotor rotation continues, in stage 2 the two

volumes are isolated and transferred to the outlet area. Then, in stage 3 these volumes come into contact with the

delivery flange. Thanks to the operation without contact inside the chamber the lobe volumetric pumps can work at

high speeds. In this way you can obtain high flows even using small pumps.

WARNING

The pressure differential and the compression ratio between the intake and outlet sides represent a limit

for the volumetric pumps described in this manual. Exceeding the allowed pressure differential causes the

pump to overheat and/or its seizure

The use of High vacuum pumps Booster HV must be installed in series with a primary vacuum (backing) system that

guarantees a Maximum absolute pressure of 50 mbar in order to avoid overheating of the pump.

It is suggested that the starting is operated by a vacuum switch placed between the booster and the backing pump.

It is possible to use by-pass valves in order to drive short time vacuum cycles: long lasting gas recirculation may cause

overheating of the pump.

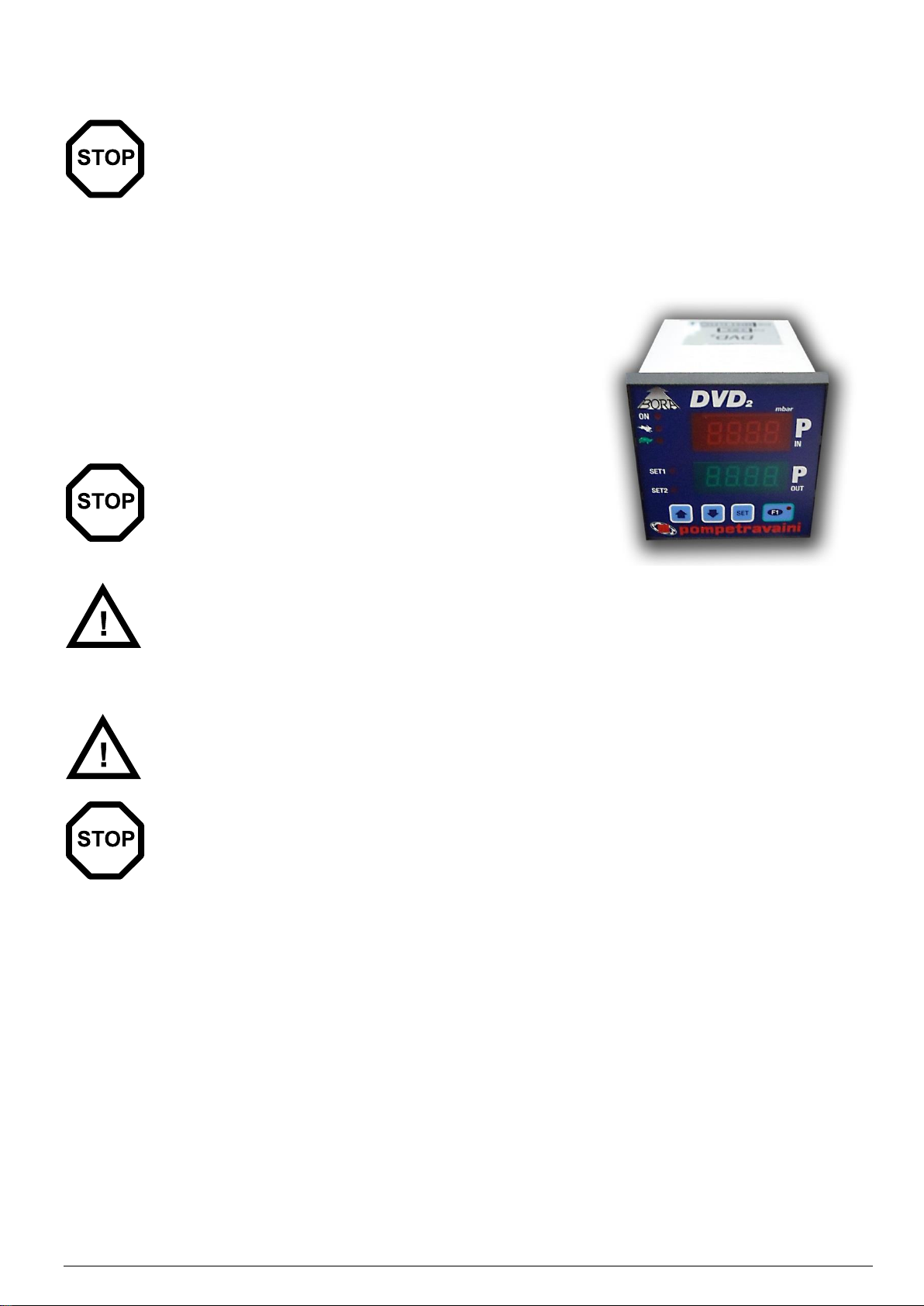

Performances active control through frequency inverter is maximized by

POMPETRAVAINI - BORA DVD-2 system that guarantees minimum time

to vacuum and safety of the pumps.

For more information please contact POMPETRAVAINI - BORA.

WARNING

Operation without lubricant causes serious damage to the

pump.

DANGER

The pump may reach high temperatures when operating. Special precautions should be taken in order to

avoid personnel and/or equipment and electric parts nearby coming into contact with it.

6.2 – START UP

DANGER

The pump can only be started up after all the indications, requirements and prohibitions indicated in this

manual have been carefully read, understood and respected.

WARNING

Regarding HV and FP volumetric pumps, start up the volumetric pump only after the primary pump has

brought the system to the correct outlet pressure specified for operating.

Checks to be performed before start-up:

If an excessively long period of time has elapsed before starting up the pump, check its preservation status and

operation. Remove any dust deposits from the external surfaces and check that the rotor lobes of the pumps can

turn freely without obstacles and that they are not oxidized.

The pump is supplied complete with lubricating oil inside the casings of gears and bearings. For the HV and FP

pumps series also in the motion transmission shaft seal lubrication bell. However, check that the visible oil level is

correct using the oil sight glass and vessels. If necessary, top up the oil following the indications given in point 7

(Maintenance) of this manual.

Make sure that the pump’s intake and outlet are not blocked by connectors and/or protections and/or closure

valves.

Check that the adjustment of the motor protection corresponds with the motor’s nominal current indicated on the

relative plate.

Check that the room temperature and that of the conveyed gas intake is within the levels indicated in point 10 of this

manual.

After carrying out the preliminary controls listed above, the pump can be started up.

With the started up pump check that the electric motor absorption complies with the values indicated on the

motor plate.

High vacuum pumps, exhausters and blowers operating manual

Page 20

20

WARNING

In order to reducing energy consumption and not damaging the pump, it is advisable not to start up

more than 6 times / hour and that they are equally distributed.

DANGER

The pump working temperature depends on the characteristic of the processed fluid. High temperature levels

can be due to room temperature or gas intake that is too high, pressure differential that is greater than that

allowed, low or high oil level, installation is in constricted spaces, exposure to direct sun rays, dust deposits

on the motor’s cooling fan or on the fan cover casing.

DANGER

Full rotation speed pump operation must be without vibration or unusual noise. If these are present, stop

the pump immediately, search for the cause and eliminate it.

WARNING

Use the pump only in the working conditions indicated in this manual. If the working parameters change

(for example intake pressure, intake temperature, ratio with the primary pump) the volumetric and primary

pump could overheat and get seriously damaged.

Starting acceleration must not exceed the torque T Max (Nm) obtainable from performance charts as follows:

P - Power (kW) at max pressure - Max Speed

n - Revolution per minute (rpm)

T max (Nm) = P (kW) x 20000 n (rpm)

Start / delta starting is recommended.

If the blower is started against full counter-pressure, it will be impossible to operate the star-delta starting method due to

lack of torque should the start up be with star-delta, the blower should then be fitted with a centrifugal coupling or, even

better, a clutch coupling, to be engaged when the motor has reached its full power.

6.3 – STOP

The pump must be stopped by cutting off the power supply and isolated from the system by closing the valve (see 5).

WARNING

Per le pompe delle serie Booster HV/FP, spegnere prima la pompa volumetrica e successivamente la

pompa per vuoto preliminare.

6.4 - DECOMMISSIONING AND PROLONGED STOPPAGE

If the pump is placed out of order and/or stopped for a prolonged period of time, proceed as follows:

• Stop it following the procedure indicated in point 6.3 of this manual

• Insulate the electrical power supply

• Insulate it from the user system cutting off the intake and outlet connection

• Gradually release the pressure or vacuum that may be inside

• Disconnect the connections to the system

• Shut off the intake and outlet using the specific protections

High vacuum pumps, exhausters and blowers operating manual

Page 21

21

7 - MAINTENANCE

7.1 - GENERAL WARNINGS

WARNING

It is important and essential that the operating pump is periodically inspected in order to avoid breakages

that can directly or indirectly cause damage to the pump itself or create hazardous situations for personnel.

For good maintenance:

• Immediately verify the causes of any malfunctions (excessive noise, overheating, etc.)

• Pay particular attention to the efficiency of safety devices

• Make use of all documentation provided by the Supplier (instruction manuals, wiring diagrams, etc.)

• Use only appropriate tools and original spare parts

• Use suitable individual protective equipment.

If failing to understand fully the information or procedures contained in this chapter, contact Pompetravaini - BORA for

clarification before proceeding.

Only trained or authorized personnel have the necessary expertise to perform tasks with the skills appropriate for

intervention.

DANGER

Do not perform any type of operation, modification and/or repair of any kind, except for those listed in this

manual.

DANGER

All maintenance work must be carried out with the pump disconnected from the power supply and

measures must be adopted to prevent it being reconnected. Only open the terminal board of the electric

motor after ensuring that there is definitely no voltage present. Attach a notice to the pump’s system

command and command elements which states.

DANGER

The user is forbidden to carry out repair or maintenance work that requires the replacing of seized parts

that may have become deformed to the extend that they become unusable. In these cases, contact the

Supplier or authorized dealer for assistance.

DANGER

If the pump maintenance has been performed in a manner inconsistent with instructions, with non-original

spare parts or otherwise so as to impair its integrity or modify its characteristics, Pompetravaini - BORA will

be released from any liability relating to the safety of persons and malfunction of the pump.

High vacuum pumps, exhausters and blowers operating manual

Page 22

22

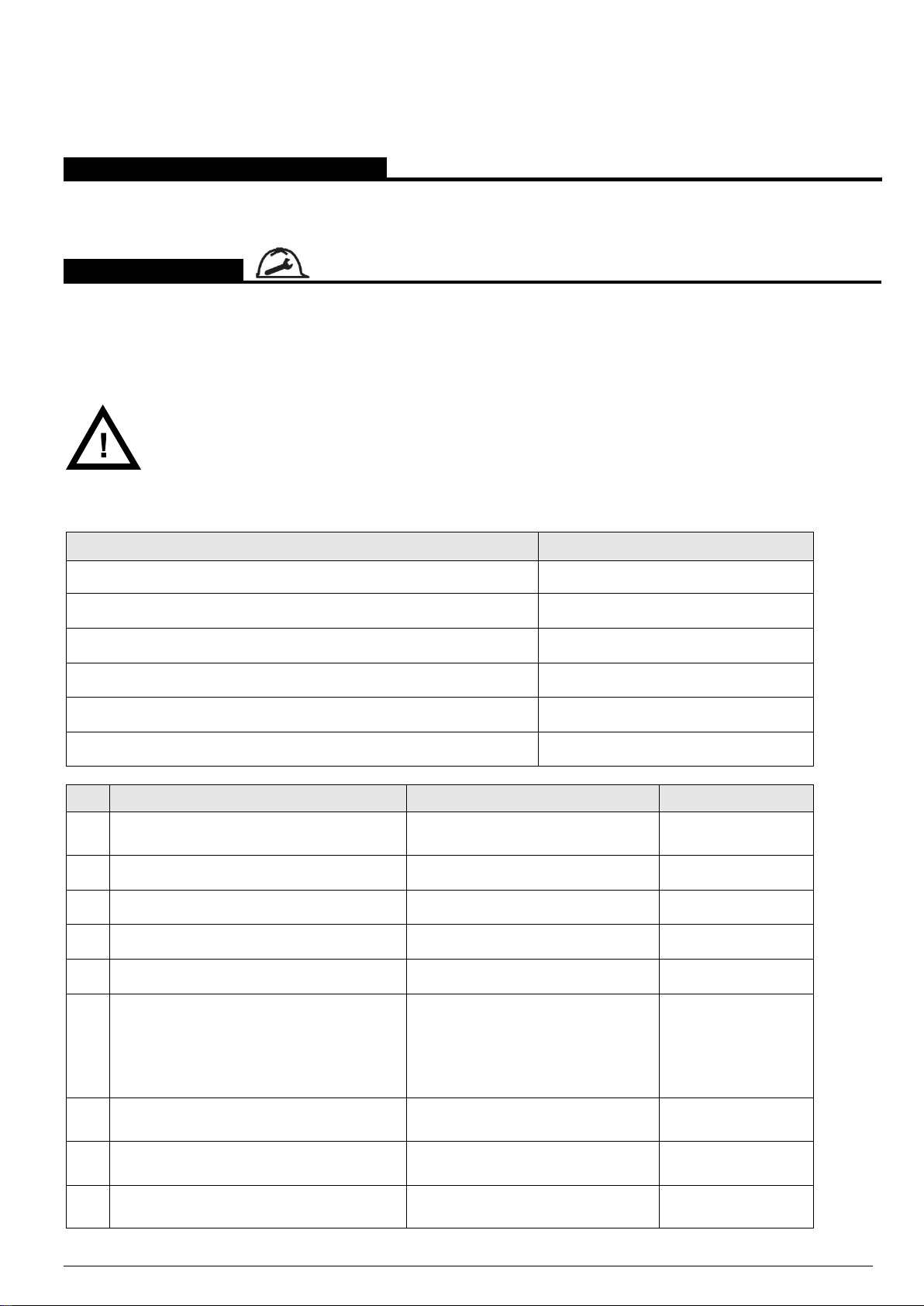

7.2 – OPERATIONS TABLE

OPERATION TYPE

FREQUENCY

OPERATOR QUALIFICATION

Check of the lubricant levels

24 h

Replacement of the 1st supply gear and bearing oil

1 x 500 h

Replacement of the 1st supply shaft seal oil (HV/FP series only)

1 x 500 h

Clean the motor fan protection

1000 h

General external cleaning of the pump

1000 h

Check of the transmission elastic element

2500 h

Replacement of the gear and bearing oil

5000 h

Clean the suction filter

According

to the system

Check of the transmission belts

2500h

Replacement of the shaft seal oil (HV/FP series only)

5000 h

Tab.7

The following table shows all required periodic operations to maintain pump efficiency.

DANGER

Wear suitable protection equipment when carrying out maintenance work

More frequent maintenance may be necessary depending on the kind of use and environment where the pump is

installed (high temperature of intake gases and/or workplace, presence of condensable vapors in the intake gases,

very dusty workplace, etc.).

7.2.1 - CHECK OF THE LUBRICANT LEVELS

Check that the lubricating oil level of the gears and bearings reaches half of the oil sight glass. Alternatively follow the

instructions provided in this section. Check oil conditions. When dark or cloudy, oil has been contaminated and must

be changed. Regarding HV/FP pumps series, If oil topping up is frequent it means that the pump internal seals might be

damaged. Check that the lubricating oil level of the front seal of the motion inlet shaft respects the correct level indicated

in the expansion vessel:

• Cold machine – 1/4 max

• Hot machine – 3/4 max

A reduction of the oil level in the oil viewer indicates that the seals of the shaft are damaged. If with the oil level decreasing

in the oil viewer there are no oil leaks or spillage under the motor coupling bell, the internal seal on the shaft might be

defective and the oil might flow inside the casing of the bearings making the lubricant level rise. If this is the case

immediately turn off the pump to repair it. If instead, with the oil level decreasing in the oil viewer there are oil leaks or

spillage under the motor coupling bell, the external bell lip seal might be defective.

7.2.2 - REPLACEMENT OF THE 1ST SUPPLY GEAR AND BEARING OIL

The bearing life span depends also on the lubricant contamination. The lack of contaminants in the lubricating oil is

essential. The oil has to be changed after the first 500 hours and then periodically when reaching 5000 hours of use or

at least every 18 months, whichever comes first. The oil needs to be replaced more frequently in case of cyclic operation

when frequently switching from the atmospheric pressure to the working pressure.

High vacuum pumps, exhausters and blowers operating manual

Page 23

23

WARNINGE

Use exclusively the following oils to lubricate the pump bearings:

• MOBIL SHC 624.

• TEXACO CETUS PAO 46

Change the gear and bearing oil as follows:

Disconnect the pump from the mains and bring the work chamber to the atmospheric pressure

Undo the oil filler plug

Get a container large enough to hold all oil and open the oil drain plug

Drain out all oil

Close drain plug and fill in fresh oil through the filler plug up to mid-range on the oil sight glass.

Close the oil filler plug and remove any oil spillage from the pump and/or floor

Connect to mains again and verify correct rotation direction of the pump (see 4.9)

WARNING

Regarding HV/FP pumps series, the oil filler plugs should be leak-tight. During vacuum running the

introduction of outside air through plug leakages could cause air containing oil to enter into the pump work

chamber through the rotor seals increasing the consumption of oil in the pump.

WARNING

A too low oil level jeopardizes the lubrication of gears and bearings, while a too high level might

contaminate the oil free work chamber of lobe rotors.

DANGER

Wear appropriate personal protection equipment to perform said operations.

DANGER

Comply with local regulations regarding the collection and disposal of used or polluted oil.

7.2.3 - REPLACEMENT OF THE 1ST SUPPLY SHAFT SEAL OIL

The pump is supplied complete with oil of first topping up. Bearing’s life is also depending on the degree of contamination

of the lubricant. It is vital that the oil does not get contaminated and it must be changed after the first 500 hours, and then

periodically every 5000 hours of usage or at least every 18 month.

Change the gear and bearing oil as follows (repetition of the previous chapter):

Disconnect the pump from the mains and bring the work chamber to the atmospheric pressure

Undo the oil filler plug

Get a container large enough to hold all oil and open the oil drain plug

Drain out all oil

Close drain plug and fill in fresh oil through the filler plug up to mid-range on the oil sight glass.

Close the oil filler plug and remove any oil spillage from the pump and/or floor

Connect to mains again and verify correct rotation direction of the pump (see 4.9)

WARNING

Use exclusively the following oils to lubricate the pump bearings:

• MOBIL SHC 624.

• TEXACO CETUS PAO 46

Check frequently the oil level trough the transparent plug. If adding is needed use upper vent plug; lower plug to drain.

The position of the plugs is shown in the dimensional drawings later in this manual.

The pump is supplied complete with oil of first topping up also in the cavity of the pump/motor connection where

the

motion transmission shaft seal is housed.

WARNING

To lubricate the motion transmission shaft seal of the pump use the same type of oil used for the gears

and bearings, such as:

• MOBIL SHC 624.

• TEXACO CETUS PAO 46

High vacuum pumps, exhausters and blowers operating manual

Page 24

24

7.2.4 - CLEANING THE MOTOR FAN PROTECTION

Cleaning the motor fan protection is done in order to remove any dust. This must be done using a blow of compressed

air and a dry cloth. Do not use fluids or substances other than those indicated.

7.2.5 - GENERAL EXTERNAL CLEANING OF THE PUMP

General cleaning of the pump is done in order to remove any dust. This must be done using a blow of compressed air

and a dry cloth. Do not use fluids or substances other than those indicated.

7.2.6 - CHECK OF THE TRANSMISSION ELASTIC ELEMENT

Check according to the frequency indicated in the table in point 7.2 of this manual, or at least once a year, the wear

status of the elastic element of the motion transmission coupling of the pump/motor and replace it if necessary.

7.2.7 - REPLACEMENT OF THE GEAR AND BEARING OIL

To replace the bearing oil proceed as indicated in point 7.2.2 of this manual.

7.2.8 - REPLACEMENT OF THE SHAFT SEAL OIL IN BOOSTER HV AND FP

To replace the shaft seal oil in booster HV and FP proceed as indicated in point 7.2.3 of this manual.

7.2.9 - FILTER MAINTENANCE

Replace the paper filters or wash the spongy material filters, with frequency proportional to the degree of environmental

contamination of the working area or whenever the vacuum gauge on the intake shows loss of pressure.

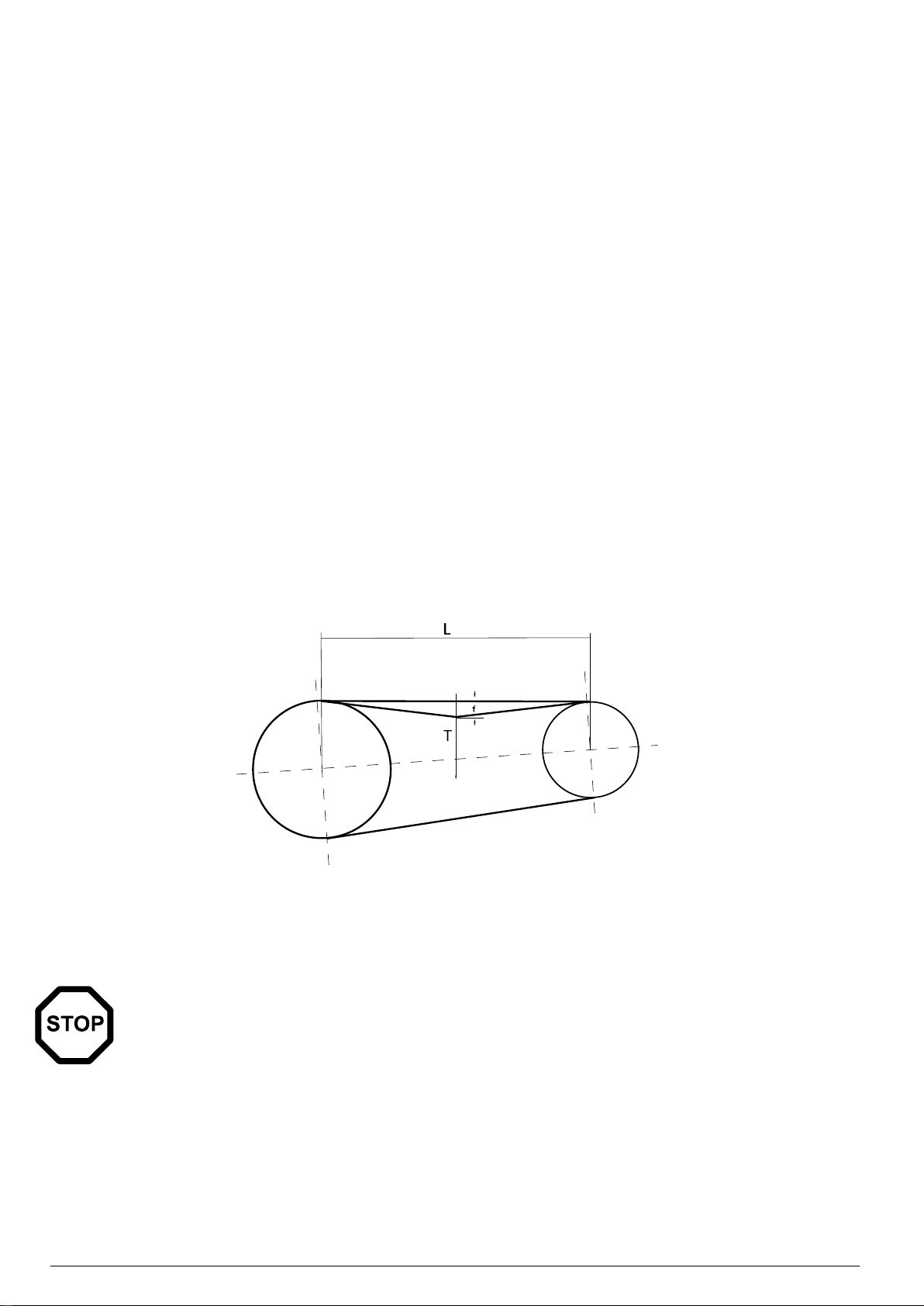

7.2.10 - TRASMISSION

Check every 2500 hours of work or at least once a year the wear of the rubber blocks in the flexible coupling and in case

replace them. In case of V-belt drive check wear and tension.

The right tensioning of the V-belts is reached acting on the motor slide as follows (see figure below). Apply a T force

square to the centre point of the free part of the belt L' in order to obtain an elastic deformation f of a distance equal to

1.5% of the free part itself. SPB V-belt profile, if T load is higher than 6 kgf the belt is over tensioned: release the tension;

if T load is lower than 3.7 kgf the belt is under tensioned: tight the tension.

For different V-belts profiles see specific manufacturer 's manual.

7.3 – PAINTING

The machine is originally painted with properly selected paint that allows the highest heat exchange with the air. Even in

case of esthetical deterioration we advise to have paint retouches made only in case of a reconditioning performed by

Pompetravaini - BORA.

WARNING

Do not re-paint the compressor in order not to jeopardize the correct heat exchange needed in the heaviest

duty use of the machine.

High vacuum pumps, exhausters and blowers operating manual

Page 25

25

PROBLEMS

LIST OF POSSIBLE CAUSES

Vain or scarce performance, insufficient outlet pressure.

1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 17

Excessive performance, outlet pressure higher than expected.

3, 7, 13, 14

High power absorption.

1, 2, 3, 5, 7, 8, 9, 13, 14, 15, 16, 19

Raised noise and high vibrations.

3, 4, 11, 13, 14, 19, 20, 21, 22, 23, 24, 28

Overheating.

1, 2, 3, 5, 13, 14, 15, 16, 17, 18, 19

Nonfunctional seal system.

15, 25, 26, 27

CAUSES

REMEDY

PERSONNEL

1

Too small diameter of piping.

Replace piping with larger diameter

ones.

Qualified technician

2

Obstructed piping.

Remove the obstructions.

Operator

3

Not correctly adjusted valve.

Adjust the valve (see 5,2).

Qualified technician

4

No airtight machinery.

Look for the leaks and remove them.

Qualified technician

5

Intake filter clogged.

Clean or replace the filter (see 7.2.9).

Qualified technician

6

Speed of rotation lower than expected.

Check tension belts, if they are slack,

regulate (see 7.2.10). Check their

sizing, improve if they are undersized.

Check the ratio of pulleys and correct,

if it is wrong.

Qualified technician

7

Inappropriate Blower/booster sizing.

Check the machine selection and

correct it.

Qualified technician

8

Electric motor improperly connected.

Check the electric connection and the

rotation direction. If it is wrong, correct.

Qualified technician

9

Wrong supply voltage.

Check the electric motor supply. If it is

wrong, correct.

Qualified technician

7.4 – SPARE PARTS

In order to replace the pump parts we recommend the use of Original Spare Parts. When purchasing spare parts

always quote the pump’s Type and Serial number (you will find these on the identification plate) .

Pompetravaini - BORA disclaims all responsibility for any deterioration of pump performance or for damages caused

due to use of non original spare parts.

8 – HOW TO RETURN THE PUMP

The product may only be returned after prior agreement with the Supplier, who will provide the authorization number

that must accompany the material delivered and should be duly complete in its entirety.

9 – DISMANTLING

Demolition of the pump must be performed by authorized technicians.

Metal parts can be disposed of as scrap metal.

All materials deriving from demolition must be disposed of according to regulations in the country where the pump will

be demolished.

DANGER

Disposal operations involve risks of cutting, shavings projection, entanglement, contact with moving parts

and contact with chemicals. Operators should use the appropriate personal protective equipment.

9.1 – TROUBLE SHOOTING BLOWERS

High vacuum pumps, exhausters and blowers operating manual

Page 26

26

10

Damaged motor.

Check the motor operation. Replace, if

it is damaged.

Qualified technician

11

V-belts degraded.

Check tension V-belts and correct it, if

necessary. Replace V-belts if they are

consumed.

Qualified technician

12

Speed of motor rotation is not sufficient.

Check direction and speed of rotation.

Check the electrical connection and

correct it, if necessary.

Qualified technician

13

Speed of rotation is higher than the target.

Check the ratio of pulleys and correct,

if it is wrong.

Qualified technician

14

Speed of motor rotation is excessive.

Check the speed of rotation. Check the

electrical connection and correct it, if

necessary.

Qualified technician

15

Exceeding quantity of lubricant in the casing.

Drain any excess lubricant, restoring

the correct level.

Qualified technician

16

Deformation caused by foot tightening.

Check the uniformity of the supporting

surface of feet machinery (within 2

mm). If necessary, use some shims to

correct it.

Qualified technician

17

Intaked gas temperature too high.

Check the suction conditions are within

the established parameters (see

3,1,2). Correct, if necessary.

Qualified technician

18

Too high machine-room temperature.

Machine-room has to be appropriately

ventilated to dissipate the produced

heat. If ventilation is deficient, correct.

Operator

19

Frictions inside the blower/booster.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

20

Rotors out of phase after seizure.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

21

The contact of rotors is caused by fouling.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

22

The contact of rotors is caused by oxidation.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

23

Bearings or gears deterioration is caused by

lack of lubricant.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

24

Blower/booster damage is caused by seizure.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

25

No airtight plugs or seals.

Pick out the damaged external

tightness elements and replace them.

Qualified technician

26

Damaged internal tightness organs.

Stop the machine and call assistance.

Qualified technician

27

Clogged vent plugs.

Clean or replace vent plugs.

Qualified technician

28

Degraded silencers.

Replece the degraded silencer

components.

Qualified technician

High vacuum pumps, exhausters and blowers operating manual

Page 27

27

9.2 – TROUBLE SHOOTING EXHAUSTERS OR AC

PROBLEMS

LIST OF POSSIBLE CAUSES

Vain or scarce performance, insufficient outlet pressure.

1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 17

Excessive performance, outlet pressure higher than expected.

3, 7, 13, 14

High power absorption.

3, 4, 5, 7, 8, 9, 13, 14, 15, 16, 19, 20

Raised noise and high vibrations.

3, 4, 13, 14, 20, 21, 22, 23, 24, 25, 29

Overheating.

1, 2, 3, 13, 14, 15, 16, 17, 18, 19, 20

Nonfunctional seal system.

15, 26, 27, 28

CAUSES

REMEDY

PERSONNEL

1

Too small diameter of pipes.

Replace piping with larger diameter

ones.

Qualified technician

2

Obstructed piping.

Remove the obstructions.

Operator

3

Not correctly adjusted valve.

Adjust the valve (see 5,2).

Qualified technician

4

No airtight machinery.

Look for the leaks and remove them.

Qualified technician

5

Intake filter clogged.

Clean or replace the filter (see 7.2.9).

Qualified technician

6

Speed of rotation lower than expected.

Check tension belts, if they are slack,

regulate (see 7.2.10). Check their

sizing, improve if they are undersized.

Check the ratio of pulleys and correct, if

it is wrong.

Qualified technician

7

Inappropriate Blower/booster sizing.

Check the machine selection and

correct it.

Qualified technician

8

Electric motor improperly connected.

Check the electric connection and the

direction of rotation. If it is wrong,

correct.

Qualified technician

9

Wrong supply voltage.

Check the electric motor supply. If it is

wrong, correct.

Qualified technician

10

Damaged motor.

Check the motor operation. Replace, if

it is damaged.

Qualified technician

11

V- belts degraded.

Check tension V-belts and correct it, if

necessary. Replace V-belts if they are

consumed.

Qualified technician

12

Speed of motor rotation is not sufficient.

Check direction and speed of rotation.

Check the electrical connection and

correct it, if necessary.

Qualified technician

13

Speed of rotation is higher than the target.

Check the ratio of pulleys and correct, if

it is wrong.

Qualified technician

14

Speed of motor rotation is excessive.

Check rotation speed. Check the

electrical connection and correct it, if

necessary.

Qualified technician

15

Exceeding quantity of lubricant in the casing.

Drain any excess lubricant, restoring

the correct level.

Qualified technician

16

Deformation caused by foot tightening.

Check the uniformity of the supporting

surface of feet machinery (within 2

mm). If necessary, use some shims to

correct it.

Qualified technician

High vacuum pumps, exhausters and blowers operating manual

Page 28

28

17

Intake gas temperature too high.

Check that the suction conditions are

within the established parameters (see

3,1,2). Correct, if necessary.

Qualified technician

18

Too high machine-room temperature.

Machine-room has to be appropriately

ventilated to dissipate the produced

heat. If ventilation is deficient, correct it.

Operator

19

Cooling air filter clogged.

Replace filter cartridge.

Operator

20

Frictions inside the blower/booster.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

21

Rotors out of phase after seizure.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

22

The contact of rotors is caused by fouling.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

23

The contact of rotors is caused by oxidation.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

24

Bearings or gears deterioration is caused by lack

of lubricant.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

25

Blower/booster damage is caused by seizure.

Stop the machine and rotate slowly

by hand. If there is friction or contact

between the parties, call assistance.

Assistance

26

No airtight plugs or seals.

Pick out the damaged external

tightness elements and replace them.

Qualified technician

27

Damaged internal tightness organs.

Stop the machine and call assistance.

Qualified technician

28

Clogged vent plugs.

Clean or replace vent plugs.

Qualified technician

29

Degraded silencers.

Replace the degraded silencer

components.

Qualified technician

High vacuum pumps, exhausters and blowers operating manual

Page 29

29

9.3 – TROUBLE SHOOTING HV e FP SERIES

PROBLEMS

LIST OF POSSIBLE CAUSES

Vain or scarce performance, insufficient outlet pressure.

1, 2, 3, 4, 5, 6, 7, 8, 11, 12, 13, 14, 15, 16, 18, 19, 24