a3 CERAMICSTEEL WORKWALL TECHNICAL GUIDE

PolyVision a3™ CeramicSteel Workwall maximizes the use of vertical space

while eliminating the need for multiple boards. A series of vertically oriented

whiteboard panels are spline jointed together and trimmed with an aluminum

extrusion on the “wall” outer edges. Floor-to-ceiling Workwall is a custom/special

order product. The following provides guidelines for installing your new system.

Safety Requirements

3

Handling + Storing Instructions

Required Equipment

Key to System Details

Standard Extrusions

D1 - D4 Systems

Installation

Limited International Warranty

4

5

6

7

8

12

19

2

polyvision.com

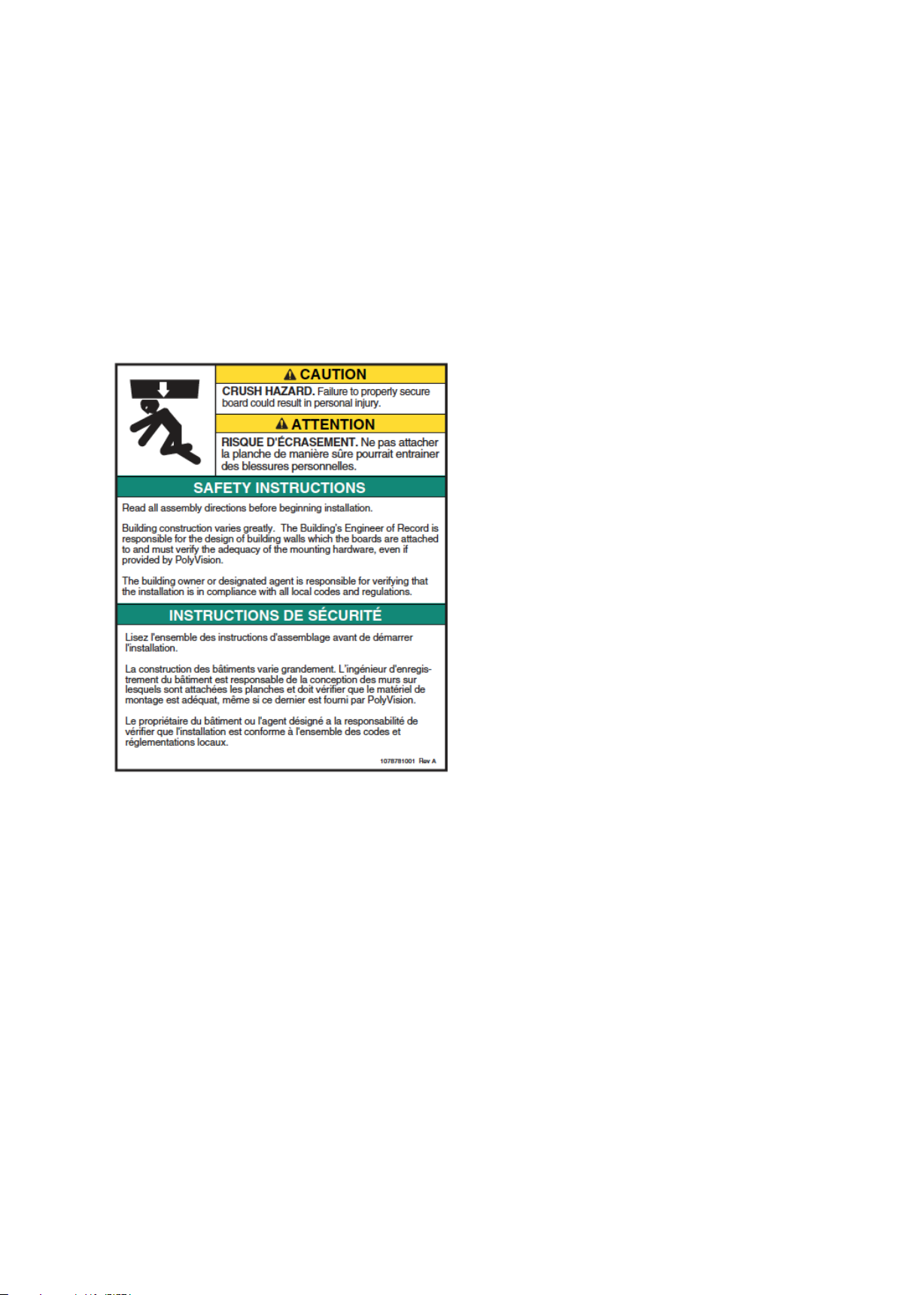

SAFETY REQUIREMENTS

a3 CeramicSteel Workwall - Wall Mounted Dry Erase Board, Non-Seismic Applications

The building’s Engineer of Record must be consulted to determine if there are any seismic requirements.

Verify Wall Construction

CAUTION: Adequate wall construction is required to support the weight of the board. Minimum wall

construction must be capable of supporting weight amounts listed in Table 1 on page 12.

Minimum Required Wall Construction

Drywall with metal studs:

• Must be at least 25 ga. (0.018” or .5 mm thk.)

33 ksi steel studs 38 mm x 89 mm (1.5” x 3.5”)

• Studs on maximum 610 mm (24”) centers

• Must be at least 16 mm (5/8”) thick Type X

gypsum drywall for the US or 12 mm (1/2”)

for EU

• 32 mm (#6 x 1-1/4”) drywall screws on

305 mm (12” ) centers

Drywall with wood studs:

• Stud grade SPF, DF-L, or Hem-Fir

38 mm x 89 mm (1.5” x 3.5”)

• Studs on 610 mm (24”) centers

• Must be at least 16 mm (5/8”) thick Type X

gypsum drywall for the US or 12 mm (1/2”)

for EU

• 32 mm (#6 x 1-1/4”) drywall screws on

305 mm (12” ) centers

polyvision.com

3

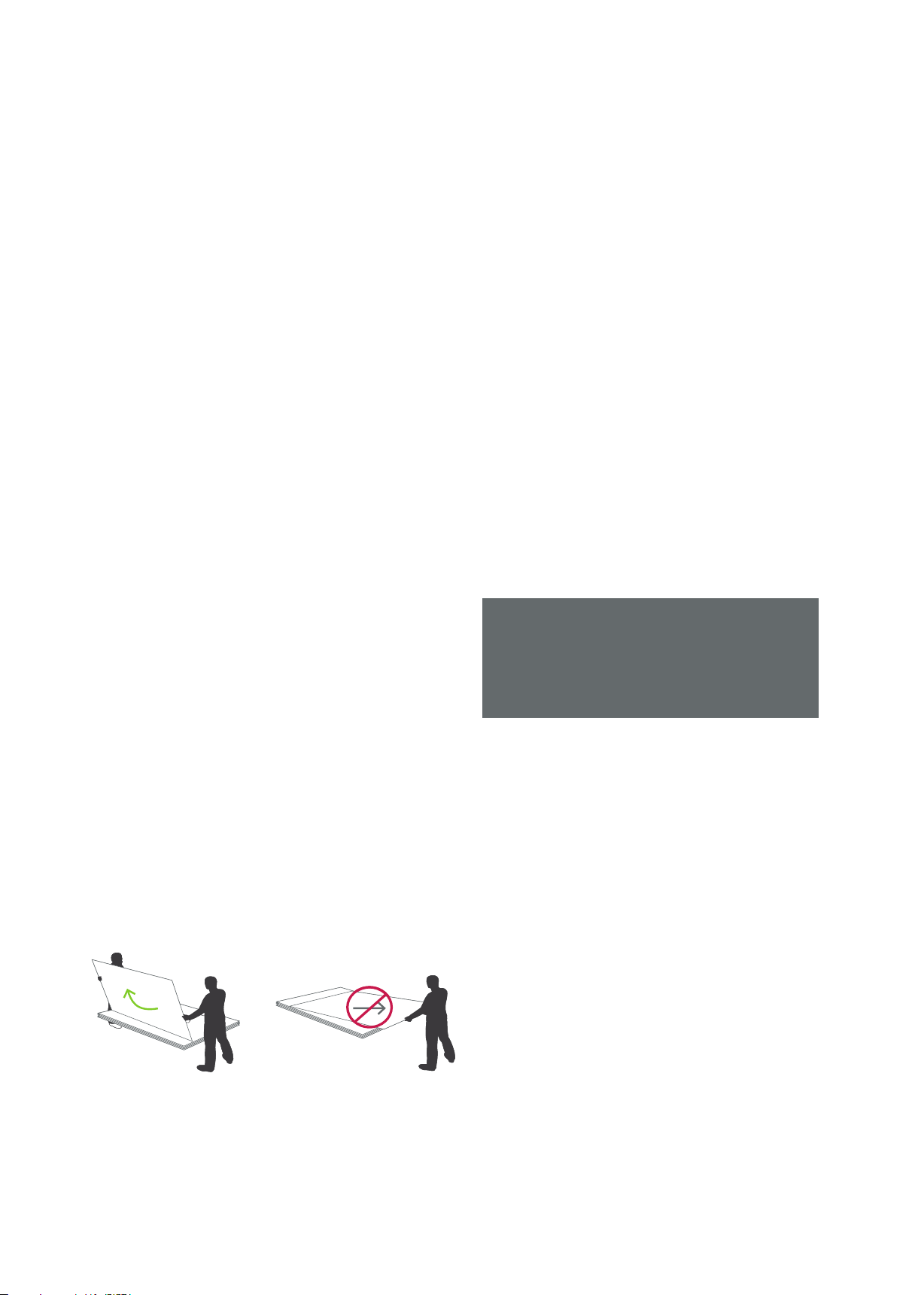

HANDLING + STORING OF PANELS

Handling

•

When a3 CeramicSteel panels are shipped, they are

protected by craft paper or a self-adhesive transparent

polyethylene film. Keep panels in the original package

until installation.

•

Handle with care to prevent damage.

•

Never slide panels off the stack during handling. Panels

should always be lifted and moved in a vertical position.

•

Never place an a3 panel in a vertical position on the

floor. This is to prevent damage to the edges.

•

Prevent dirt from settling on and between panels to avoid

surface damage, scratches or defects.

•

Follow all safety instructions regarding personal protection

when processing the panels.

Protect panel surface against sawdust and sparks

•

(metal particles).

•

a3 CeramicSteel will chip when cut or drilled with power

tools. Hand-cutting can cause chipping up to approx.

2 mm from the edge. When chipping is in excess of 2

mm, please check the state of cutting tools and check

that the panel is adequately supported and clamped to

prevent it from vibrating.

•

All cut or drilled sections should be protected against

humidity with PVC tape and/or by covering/sealing

profiles or sealing washers.

•

For detailed processing instructions, please refer to the

a3 processing instructions.

Storing

•

Keep panels dry and free of debris.

•

Store panels inside temps 50-90 °F (10-32 °C).

•

Any panels stored outside should be protected

from inclement weather conditions.

•

Place panels on hard, flat surfaces that are not

subject

to standing water.

•

a3 CeramicSteel panels should be stacked no more

than three high.

•

Panels should never be stored vertically or in such

a way that the corners are vulnerable to damage.

If you have a problem, question, or a request, call

your local fabricator, your regional sales manager

or PolyVision Customer Service. PolyVision’s

global customer service team can be contacted

on polyvision.com.

4

polyvision.com

REQUIRED EQUIPMENT

Electrical Equipment

1. Drill

2. Miter saw

3. Grinder

4. Jigsaw

5. Industrial vacuum cleaner

6. Panelsaw with guide

Hardware Equipment

1. Level (laser level recommended)

2. Aluminum straight guide

3. Chalk line

4. Anchors adapted to wall

• For gypsum walls, use #8 plastic wall anchor with #8 x 1-1/4” (4 mm x 35 mm) self drilling screws.

• For stone walls, anchors and screws must be provided by installer per conditions.

• Recommended anchor spacing is 406 mm (16”) to 610 mm (24”) on center

5. Shims 1 mm - 2 mm - 3 mm (1/32” - 1/16” - 1/8”)

6. Soft wood block ± 50 mm x 25 mm x 300 mm (2” x 1” x 12”) length or rubber mallet to knock in the coverstrip

7. Glass suction cup lifters (2)

8. New and unused cemented carbide (tungsten carbide, titanium carbide...) saw blade with a minimum of 60 teeth

9. Scrap lumber

Included Hardware

1. Anchors

2. Screws

3. Temporary cover trims (2)

polyvision.com

5

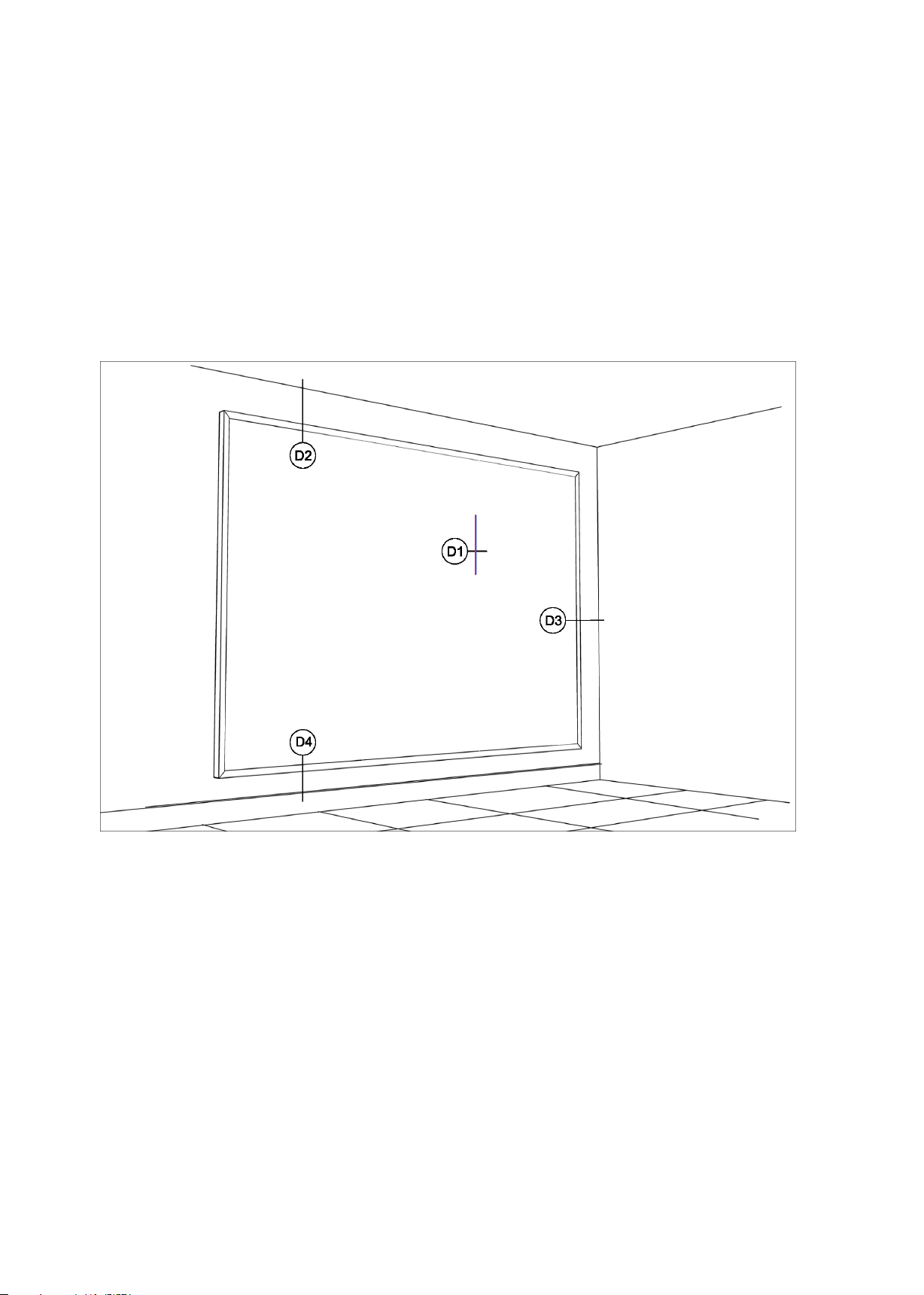

KEY TO SYSTEM DETAILS

The details listed in the image below show placement for panel profiles and how the material can be installed.

IMPORTANT: Profiles must be secured to studs in as many locations as possible and at least 24” o.c. for

horizontals and 18” o.c. for verticals.

6

polyvision.com

STANDARD EXTRUSIONS

509825 Joint spline extrusion

509821 End stop spline extrusion

509822 Snap in trim extrusion (clear anodized)

polyvision.com

7

D1

VERTICAL BUTT JOINTS

structural support max

24” o.c. (by others)

509825

extrusion

CeramicSteel

interior panels

type S bugle head screws

@ 16” o.c. (by erector)

factory edges on both panels

panel dimension panel dimension

Grid

8

polyvision.com

D2

PANEL HEAD AT CEILING

509822 anodized extrusion

gypsum board plug or

screw if located over stud

CeramicSteel

interior panels

509821

structural support max

24” o.c. (by others)

extrusion

polyvision.com

9

D3

PANEL TERMINATOR AT WALL

509821

extrusion

structural support max

24” o.c. (by others)

type S bugle head screws

@ 16” O.C. (by erector)

CeramicSteel

interior panels

509822 anodized extrusion

10

polyvision.com

D4

PANEL BOTTOM LINE

CeramicSteel

interior panels

gypsum board plug or

screw if located over stud

509821 extrusion

polyvision.com

11

INSTALLATION

Height - 3/8” (9 mm)

Before starting the installation of a3 CeramicSteel Workwall

1. Verify that the required equipment is available and material provided is accurate.

2. Provide adequate protection for finished floor surfaces.

3. If cutouts are required for electrical outlets or switches, refer to the following instructions.

• Square penetrations for light switches and electrical outlets can be made

by first drilling a pilot hole and then cutting with a jig saw using a metal

cutting blade minimum 14 TPI (teeth per inch).

• All cutouts should be made with the finish side up, through the protective

polyfilm and a layer of common masking tape. Apply masking tape to

the entire area. Be sure to apply enough to protect the surface from the

baseplate of the saw.

• Metal burrs left after cutting can be removed with a file or fine sand paper.

TABLE 1

Product Weight (kgs/lbs)

Workwall

183 0

Workwall

2420

28 kgs/61.7 lbs

37 kgs/81.5 lbs

Step One

1. Your panels will likely need to be cut to fit the wall. Make an accurate measurement of the area you want to

cover with the panels, mark the height and width of the final workwall surface.

Width

Height

2. Sketch the panel arrangement. Panel height should be the wall height less 3/8” (9 mm). Each panel provided

is 46 5/8” (1185 mm) wide. The final total width of all panels should be the wall width less 3/8” (9 mm).

Width - 3/8” (9 mm)

Width

12

Height

polyvision.com

INSTALLATION

3. The panels must be cut according to this arrangement. When cutting the panels, use a panelsaw

with guide equipped with a new, unused cemented carbide saw blade. Place the panel on scrap

wood at least 1” (25 mm) thick with the CeramicSteel (smooth side) facing down. Cut the panel using

the saw guide penetrating the scrap wood beneath approximately ¼” (6 mm).

CeramicSteel Face

¼” (6 mm) penetration

CeramicSteel Panel

Scrap Wood

Step Two

1. Start with a leveled line for the bottom profile. A laser level is recommended. Be sure to allow a

minimum of 3 mm (1/8”) space between the profile and the wall base molding.

2. Mark and drill the holes in the wall.

3. Attach the profile (509821) using the provided anchors. Refer to Table 2 for profile dimensions.

TABLE 2

Panel Qty Horizontal Profile

1 panel 2 1195 mm (47 1/16”)

2 panel 2 2380 mm (93 11/16”)

3 panel 2 3565 mm (140 5/16”)

4 panel 2 4750 mm (187”)

polyvision.com

13

INSTALLATION

Step Three

1. Start with a leveled line for the vertical profile. A laser level is recommended. Be sure to allow a

minimum of 3 mm (1/8”) space between the profile and any existing wall.

2. Mark and drill the holes in the wall.

Step Four

1. Repeat steps 1 and 2 for top and adjacent vertical profiles.

2. Mark and drill the holes in the wall.

14

polyvision.com

INSTALLATION

Step Five

1. Before installing the first panel, locate the panel with the logo in the bottom right corner. (Note

that the logo is not drawn to size.) This panel will need to be the furthest right panel. This

installation guide shows the logo panel as the first to be installed. Installation Workwalls from

right to left.

2. Place the first panel (with logo) into position and hold the panel into position with a temporary

piece of cover trim 8” (200 mm). The panel must fit against the vertical end profile and the

horizontal bottom profile.

polyvision.com

15

INSTALLATION

Step Six

1. Insert the H-profile (509825) into the vertical side of the panel opposite from the vertical end profile by

sliding the metal extrusion into the groove on the side of the panel.

2. Depending upon the type of wall, either anchor directly through the flat part of the H-profile or predrill

the wall for the appropriate type of anchor.

Step Seven

1. Repeat step 5 for the remaining panels.

2. Place the final panel into position and hold in place with a temporary piece of cover trim 8” (200 mm).

16

polyvision.com

INSTALLATION

Step Eight

1. Place the temporary snap on cover trim pieces on each end of the verticals.

2. Measure and miter cut the top and bottom horizontal cover trim (509822).

3. Place snap on cover trim being sure to install using a piece of soft wood blocking or a rubber mallet in order

to avoid damaging the exposed finish. Start the profile aligned with the bottom/top of the panel. Once the

profiles are fixed they will be difficult to remove without damaging.

polyvision.com

17

INSTALLATION

Step Nine

1. Measure and miter cut the vertical snap on cover trim (509822).

2. Place snap on cover trims being sure to install using a piece of soft wood blocking or a rubber mallet in

order to avoid damaging the exposed finish. Start the profile aligned with the panel. Once the profiles are

fixed they will be difficult to remove without damaging.

Step Ten

1. Installation for a3 CeramicSteel Workwall is complete.

18

polyvision.com

LIMITED INTERNATIONAL WARRANTY

Surfaces and Architectural Panels have a limited warranty for 20 and 10 years, respectively,

valid from the date of shipment. The limited warranty provides that the products, under normal

atmospheric conditions and when sealed from moisture, will not fade, stain, discolor, craze,

crack, flake, corrode or delaminate from the substrate or warp for the applicable period. Please

see the full PolyVision a3 CeramicSteel Surfaces and Architectural Panels: Limited International

Warranty for specific details, applicability and limitations.

Warranty effective 08.01.2011

polyvision.com

19

PolyVision Americas

10700 Abbotts Bridge Rd.

Suite 10 0

Johns Creek, GA 30097 USA

Tel. 1-888-325-6351

info@polyvision.com

PolyVision Europe

Zuiderring 56

3600 Genk, Belgium

Tel. +32 (0) 89 32 31 30

EMEAsupport@polyvision.com

©2017 PolyVision Corporation. All rights reserved. Trademarks used herein are the property

of PolyVision Corporation or of their respective owner. PolyVision Corporation reserves the

right to make chang es in prod uct design, cons truction or detail, and to discontinu e any

product or material without notice. No part of this document may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language in any form by any means

without prior written permission from PolyVision.

11- 0 9 -17 EN G

PolyVision Asia-Pacific

15th Floor, Kinwick Centre

32 Hollywood Road, Central District

Hong Kong

Tel. +852 2520 0160

APACsupport@polyvision.com

Loading...

Loading...