Edition: E1S20170601A

High Resolution Inkjet Printer

User Manual

POLY S1i

2

IMPORTANCE

To ensure the best printing quality, we recommend to use our specified cartridges and the

corresponding accessories. Any malfunction or poor printing quality caused by improper use

of inks or accessories which are not from Sojet will not be guaranteed.

Safety Precautions

High voltage inside the machine after electricity connection, Maintenance or disassembly

by unqualified or unprofessional person is strictly prohibited, in order to prevent any

accidents. Machine must be reliably grounded by connecting the grounding wire with the

machine when install equipment, wrong grounding will result in machine failure and the

machine don’t work normally.

Do not expose ink directly under sunlight or high temperature (35 ℃ above). The heat of direct

sunlight or high temperature will affect ink’s storage life and printing quality.

If get ink spill on the eyes or skin, please wash your eyes or skin with clean water.

Ink leakage inside printer will cause burnout damage to machine. Switch off the machine

and unplug it from power outlet when ink leakage inside printer. Contact qualified service

technician for test and repair.

Warning Signs

Caution: The sign “ ” indicates possible damage to hardware of inkjet printer or data

loss.

Attention: The sign “ ” indicates important notes helpful for your trouble-free operation

3

Content

Introduction

.............................................................................................................................................................

5

ChapterOne:ImportantPrecautionsforUsage

..............................................................................................................

6

1.1 Installation Notes

...............................................................................................................................

6

1.2 Operation Notes

................................................................................................................................

6

ChapterTwo:InstallationandSetupInstructions

............................................................................................................

7

2.1 Packing List for Spare Parts

.......................................................................................................................

8

2.2 Device installation

.....................................................................................................................................

9

2.2.1Side printing installation

..................................................................................................................

9

2.2.2 Down printing installation

..............................................................................................................

9

2.2.3 Springback mechanism installation (optional)

.............................................................................

10

Chapter Three: Device Introduction

......................................................................................................................

11

3.1 Controller Introduction

............................................................................................................................

11

3.2 Printer head Introduction

........................................................................................................................

11

3.3 Technical Specifications

...........................................................................................................................

11

Chapter Four: How to Use the Printer and check before/after Use

......................................................................

13

4.1 How to Use the Printer

...................................................................................................................

13

4.2 Check Work before Use

...........................................................................................................................

13

4.3 Check Work after Use

..............................................................................................................................

13

Chapter Five: Printer Operation Instructions

........................................................................................................

14

5.1 Main Interface

................................................................................................................................

14

5.2 Printing Management

..............................................................................................................................

15

5.2.1 Find/Preview Data (see Image 2)

.................................................................................................

15

5.2.2 Start Printing / Printing Report

.....................................................................................................

15

5.2.3 Printing Delay

................................................................................................................................

15

5.2.4 Print Initial Value

..........................................................................................................................

16

5.2.5 Stop Printing

.................................................................................................................................

16

5.3 Data Management

...................................................................................................................................

16

5.3.1 New/Edit Data

..............................................................................................................................

17

5.3.2 Add Text Object

............................................................................................................................

17

5.3.3 Add Production Date

....................................................................................................................

18

5.3.4 Add Expiry Date

............................................................................................................................

18

5.3.5 Add Image

.....................................................................................................................................

19

5.3.6 Add Counter

..................................................................................................................................

19

5.3.7 Add Shift

.......................................................................................................................................

20

5.3.8 Add Barcode

..................................................................................................................................

21

5.3.9 Add dynamic text

..........................................................................................................................

23

5.3.10 Add dynamic image

....................................................................................................................

23

5.3.11 Add Device Information

..............................................................................................................

24

5.3.12 Add String

...................................................................................................................................

24

5.3.13 Add CSV File

................................................................................................................................

25

5.3.14 Delete Object or Delete/Import /Data copy

..............................................................................

25

5.4 System Management

...............................................................................................................................

26

5.4.1System Setting

...............................................................................................................................

26

5.4.2 Edit Options

..................................................................................................................................

27

5.4.3 Printing Options

............................................................................................................................

28

5.4.4 User Management

........................................................................................................................

30

5.4.5 Special Features

............................................................................................................................

31

4

5.4.6 Screen Calibration

........................................................................................................................

32

5.5 Tools Management

...................................................................................................................................

33

5.5.1 Image Management

.....................................................................................................................

33

5.5.2 System Upgrade

............................................................................................................................

33

5.5.3 System Backup

..............................................................................................................................

33

5.5.4 System Logs

..................................................................................................................................

33

5.5.5 About Equipment

..........................................................................................................................

33

5.5.6 System Reset

.................................................................................................................................

34

5.6 Input Methods Introduction

....................................................................................................................

35

5.7 Status Bar

.................................................................................................................................................

36

Chapter Six: Maintenance

....................................................................................................................................

37

6.1 Printer Maintenance

.......................................................................................................................

37

6.2 Ink Cartridge Maintenance

.............................................................................................................

37

Chapter Seven: Common Troubles and Solutions

..................................................................................................

38

7.1 Troubleshooting and Solutions for Cartridge

..........................................................................................

38

7.2 Troubleshooting and Solutions forPrinter

..............................................................................................

39

Appendix 1: Termsand Definitions

........................................................................................................................

40

5

Please read manual carefully before you use our inkjet printers.

Introduction

Thank you for purchasing our high resolution printer. We want you to get helpful information with this

machine, please read the manual to learn more about our machine by the following content:

Important precautions for use of the machine

Introduction of printer: Parts and components of the machine

Setup and Installation Instructions: Instructions for Equipment Setup and Cartridge Installation.

How to use the printer and the check work before/after use of the printer: explanations of general

operation and startup/shutdown.

Operation instructions: explanations on how to new/edit data for printing, and how to adjust

printer settings.

Care and Maintenance: Care and maintenance for printer and cartridge

Troubleshooting: Common failures and solutions

Appendix 1 - Terms and Definitions: Definitions for terms used in this document.

Please read this user manual carefully before using the printer to get full understanding and

knowledge of importance so that you will get full play of our machine, This will also help you to

have a quick reference to related sections when you have some problems during operation.

Note 1: If you cannot solve the problem encountered during operation, please contact us

Note 2: The information contained herein is subject to change without notice. The user manual will be

updated and revised timely if necessary by publish new version

Note 3: Any machine failure or damage caused by user’s negligence, it is no warranty.

6

Chapter One: Important Precautions for Usage

Welcome to using Sojet Inkjet Printer. In order to protect your personal safety and user rights,

ensure correct installation and operation, and full play of our printer, it is important that you

read the precautions carefully.

1.1 Installation Notes

1.1.1 Use exclusive power supply for the machine. Do not share the same power with other

equipments. UPS is recommended to install.

1.1.2 Install the bracket in peace and stable position. shock or sway position is not allowed

1.1.3 Choose well-working conveyor belt for high print quality.

1.1.4 Install deflector in production line to avoid any printing object hitting the nozzle plate and

cause damage.

1.1.5 Make sure the printer is well grounded.

1.1.6 Set the recommended distance at 0.5-2.5mm between deflector and printing object.

1.1.7 Make sure to insert and remove the ink cartridge by an angle of 15 degree avoid to cause

damage to the cartridge.

1.1.8 Make sure the working environment is tidy and clean. Clean keep the room tidy if dusty

environment is unavoidable.

1.2 Operation Notes

1.2.1 Poke or impact the touch screen with sharp object is not allowed.

1.2.2 Do not cover up the built-in photocell. Otherwise the printer doesn’tprint.

1.2.3 Wipe the nozzle plate with non-dust cloth if printing is not clear or dots are missing.

1.2.4 Set print delay value to meet best print result when print position changes (see Section5.2.3).

1.2.5 Do not insert or remove ink cartridge while the machine is under printing, otherwise it may

cause cartridge damaged.

1.2.6 Do not use compressed air for cleaning the touch screen. High pressure of the compressed air

will damage the touch screen.

1.2.7 Compressed air using for direct or indirect cleaning of the ink cartridge is prohibited. High

pressureof the compressed air will damage the cartridge.

1.2.8 Read Chapter 7 for common troubles when there’s failure occurs. If the problems can’t be

solved, contact your local dealer or our after-sale service.

Note: It is necessary for some cartridges to be removed from machine after operation stop. Turn

off the machine and remove the cartridge from printer. Wipe the print head clean with Non- woven

cloth; lock the print head with the special cap to avoid the nozzles blocking (Contact our aftersale service for more about cartridges)

7

Chapter Two:Installation and Setup Instructions

This chapter is about how to install the machine and cartridge. Firstly please check the packing list

below

Packing Picture

8

2.1 Packing List for Spare Parts

Please check everything with packing list to make sure all required parts in the package when you

receive the products.

1、Controller 2、Printer head

3、USB

4、Power line

5、Power supply adapter

6、Printer head

connection line

7、Ground line 8、Round bar fixer X 2 9、Round bar

10、Bi-direction bracket 11、Bi-pass clamp x 2 12、A. M8*16 SCREW: 12PCS

B. M4*8 SCREW: 4PCS

13、Inner hexagon spanner

9

2.2 Device installation

2.2.1Side printing installation

2.2.2 Down printing installation

10

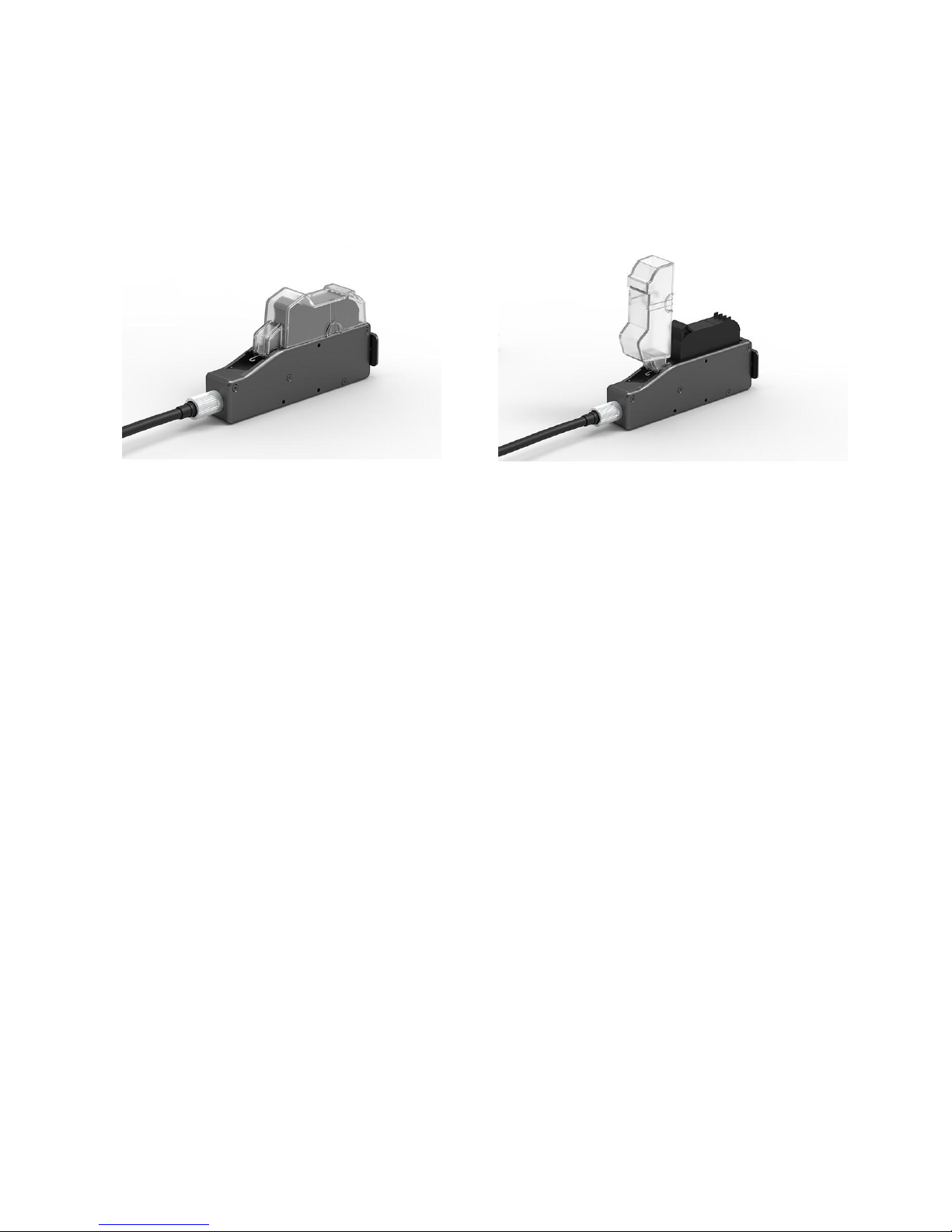

2.2.3 Springback mechanism installation (optional)

Springback mechanism installation Anti-shock plate installation

11

Chapter Three: Device Introduction

3.1 Controller Introduction

3.2 Printer head Introduction

Power switch

Touch screen

Indicator

light

Power port

Aerial socket

DB15 Port

Ethernet

port

USB1

USB2

Aerial socket

Dust cap

Anti-shock

plate

12

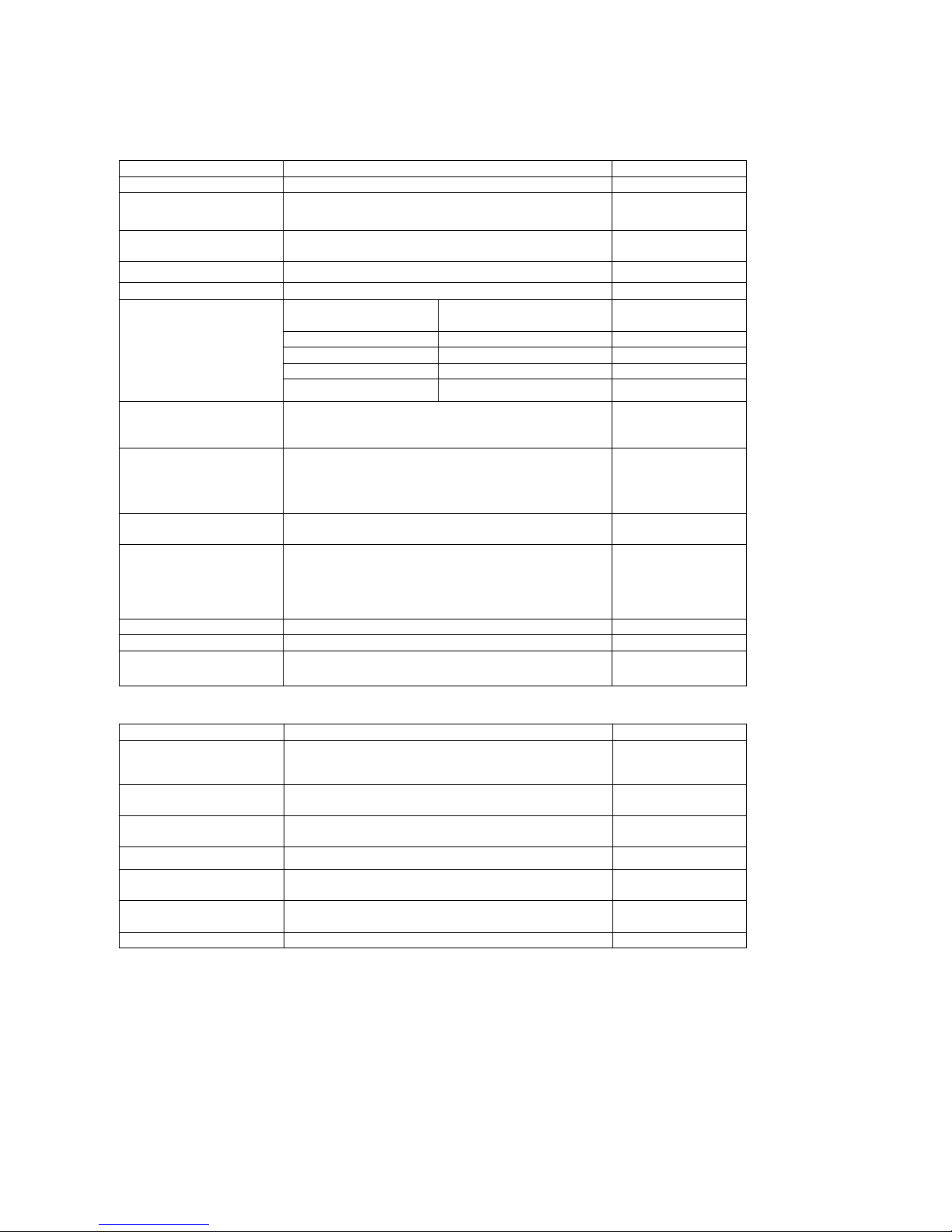

3.3 Technical Specifications

A. Performance Index

Items

Specifications

Note

Technical source

HP TIJ 2.5 Thermal Ink Jet technology

Dimension

Controller(H*W*D): 151*93*32mm

Printer head(H*W*D): 175*52*33mm

Bracket size

3pcs steel tubes with diameter at 16mm

1pcs with length 350mm, 2pcs with length 280mm

Clamp and bracket

not included

Power

30V/1A, 30W

With power adapter

Print height

1-12.7mm

Printing speed

and resolution

Horizontal resolution

(DPI)

Maximum speed (m/min)

600

30.4

400

45.7

300

60.9

150

121.9

Print application

Barcode, alphabetic, numeric, image logos,

date/time, expiration date, shift code, counter, lot-box

code

Connection Ports

1.Ethernet port;

2.USB2.0 port;

3.DB15 port.

4.DB25 port.

Interface

5inch full-color large LCD touch screen with

resolution 800*480.

Ink management

1.Automatically recognize ink types, and identify

optimum printing parameters for each ink type;

2. Guarantees genuine original HP ink using;

3. Automatic measure system for the usage condition

of ink.

Installation method

Side printing, down printing and anti-shock bracket.

Product Certification

CE, FCC.

Working

Environment

1. Working environment: -10°C~ +55°C; 10%-85%RH;

2. Storage environment: -25°C~ +80°C; 10%-90%RH.

B. Features:

Items

Specifications

Note

Language

Chinese, English, Japanese, French, German,

Spanish, Portuguese and Russian.

Font

Default font is Arial; allow users to load fonts they

need.

Barcode

UPCA, UPCE, EAN13, EAN8, INT25, CODE39,

CODE128, EAN128, PDF417, DATAMATRIX, QR.

Date format

Variety of date format available

Counter

Flexible setting for common counter, carton counters.

pallet number

Print speed

Print speed can be set up, automatically testing, or

speed testing by external encoder.

Built-in photocell

Suitable for simple print

C. Ink Solutions:

1. Support 42ml, 370ml, 350ml cartridges of HP TIJ2.5technology;

2. Support ink of various colors: black, red, green, yellow and blue;

3. Support porous, semi-porous and non-porous substrates.

13

Chapter Four: How to Use the Printer and check

before/after Use

In this Chapter, you will learn how to master and use printer quickly, including inspection work before

and after use.

4.1 How to Use the Printer

SN

Steps

Instructions

1

Cartridge

Installation

Insert cartridge into the printer by an angle of 15 degree, lock cartridge clip to

secure. (see 2.3 Cartridge Installation)

Connect power adapter

2

Power on

to printer power input,

switch on power, printer

enters initialization

3

Main Interface

---

Printing

Management

“main interface” enter after

initialization (see Section 5.1).

Click to enter

“Printing Management” (see

Section 5.2).

4

Select data Start printing

Select data, and click

to Start printing.

5

Printing

report

When printing start, the

button change to the icon

for printing stop,

meanwhile a printing report

appear.

6

Printing stop

Click to stop

printing, then return to “Start

printing” status

7

Switch off

Exit printing, and switch off power.

4.2 Check Work before Use

SN

Items

Check Work

1

Printer

bracket

Make sure the bracket mounted tightly?

2

Printer

position

Make sure the printer position correct? Is the nozzle plate parallel to printing

object? Is the throw distance controlled within 0.5-2.5mm?

3

cartridge

Is the cartridge wiped clean? is cartridge installed on printer?

4

Power input

Is the printer input voltage normal?

5

Printer status

Check status bar, does the machine run normally?

4.3 Check Work after Use

SN

Items

Check Work

1

Printer Power

Status

Is the printer power switched off?

2

Cartridge

Make sure the cartridge removed from printer, then clean and cap the print head?

14

Chapter Five: Printer Operation Instructions

This chapter is about how to operate printer interface, including Printing Management, Data

Management, System Management, Tool Management, and Status Bar.

5.1 Main Interface

Switch on power,

Setting

Manageme

nt

Printing

Manageme

nt

Data

Manageme

nt

Status bar

(Image 1)

printer starts

initialization

After

initialization

startup, “main

interface” appears

(see Image 1).

Printing

Management

ToFind/Preview, create-new, Edit, Copy, Delete data (see 5.2).

Dat

a

Management

Tomanage system setting, editing options, printing options, user authority,

and screen correction setting (see 5.3).

System

Management

Tomanage image logo, system upgrade, system backup, system record,

equipment default restoring, system resetting (see 5.4).

Tool

Management

Display information of ink, equipment, USB, encoder, external photocell,

Ethernet status and Clean Printhead (see 5.5).

Status bar

Display information of ink, equipment, USB, encoder, external photocell,

Ethernet status and Clean Printhead (see 5.7).

15

5.2 Printing Management

Click on main interface

to enter printing management

(see Image 2)

Preview

interface

Scroll bar

Start

printing

Printing

delay

Search

File name

Keywords enter bar

Page up

Page

Down

Return

(Image 2)

5.2.1 Find/Preview Data (see Image 2)

Preview data Preview data by locating or selecting a file or data to display on preview interface;

data located/selected will be displayed on preview interface, and you can view

them which beyond the page by dragging the slider.

5.2.2 Start Printing / Printing Report

Click

button to start

printing. When printing starts,

printing report appears (see Image 3).

Printing report: It is the timely record

of printing in process, including data

file name in process, print output

quantity, counter value, dynamic text

shift,,system time. The printing

report exits when printing stop

Stop

printing

Printing

report

(Image3)

5.2.3 Printing Delay

Click , printing delay

interface appears (see Image

4)

See Appendix 1: Terms

and Definitions 1 for more

information.

(Image 4)

A. Printing delay default value: 30mm;

B. Printing delay value range: 0.0-999.9mm;

C. Set printing delay value is allowed during printing operation: the newly setting value take effect

immediately from next printing.

D. Printing delay value for each message are independent from one another, the delay setting for current

data file will not affect another data file.

16

5.2.4 Print Initial Value

Click to enter

the

initial

value setting and repeated index

value interface

Hex switch: Click ,the current

counter value can be changed, but

the set value can’t be changed

DEC-10 decimal (0-9)

H36-36 hexadecimal (0-Z)

The Hex is editable; See 5.4.2

Hex switch

Counter

synchronized

Counter Synchronized: when multi

counter included in the same file,

click

, then all counters’

current value will be default value

1 synchronously .

Click “confirm”, Interface will

indicate the counter setting

interface, you can set counters

minimum, maximum, repeated

values, step values, and

hexadecimal rules.

String: all the same strings that

exist in the data are modified

synchronously after a string is

modified

CSV: If the document contains the

CSV file, you can modify initial

printing content at the start page

5.2.5 Stop Printing

Click

to stop printing and exit printing report, return to Start Printing status (see Image 2).

Note: Printer automatically stops printing when power off, cartridge empty, counter alarming etc.

5.3 Data Management

Clip on main interface to

enter data management interface

New

Modify

Delete

Copy

Delete all

17

5.3.1 New/Edit Data

Clip or on data

management interface to enter data edit

interface.

A. New data: text, counter, shifts,

production date, expiration date, image

logo, barcode, dynamic text, dynamic

logo, device information, string, CSV;

B. Edit: data in printing process cannot

be edited;

C. File name: maximum 15 characters,

empty file name or repeated file name

are not allowed.

Image Logo

Expiration date

Production

Page up

Text

Add objects

Delete object s

File name

Dynamic text

Counter

Barcode

Shift code

Click to save data when finish

edit, interface jump out to ask “Are you

sure you want to save the message?

Cancel, Yes, No”

If you click

the machine

will remain on editing interface.

Note: “MSG001” is default data in system. The system allows maximum 500 files or data (including default

“MSG001”); The system does not save empty or error messages.

5.3.2 Add Text Object

Click to add text object, see Image9.

Click

to enter text editing interface:

A. Font: including the default one, support

2 fonts, (the default one and another

alternative font).

B. 12-156mm height( adjust freely within

the scope of 1-12.7mm);

C. Text horizontal scale: 1-300%;

D. Text content , not exceed 78 words

Horizontal

scale

Height

Text

Edit

Vertical

scale down

and

location up

Vertical scale up and

location down

(Image 9)

Dynamic logo

String

Device

information

18

Note: Please refer to this Section ( 5.3.2) regarding how to add objects as “production date”,

“expiration date”, ”image”, ”counter”, ”shift code”, “dynamic text” "dynamical logo", but the content of

“production date”, “expiration date”, ”counter”, ”shift code”, “dynamic text” "dynamical logo" cannot be

revised or adjusted directly when you add, and the font, height, content and font effectof “image”

"dynamical logo" cannot be revised directly. There is no option for horizontal scale for “image”

“barcode”, "dynamical logo".

5.3.3 Add Production Date

Click

date”.

to add object “production

Click

to enter date format setting,

Select a set calendar format by Up and down

adjust.

Gregorian and Moslem calendar available

(Image 11).

Date format

Calendar Type

Settin

(Image 11)

5.3.4 Add Expiry Date

Click

to add expiry date

Click

to enter date format setting

It is available to set up Date format and valid

days (scope: 0~9999)

Gregorian and Moslem calendar available.

(Image 12).

Expired

Days

Calenda

r

19

5.3.5 Add Image

Click to add image

Selecta image on file list by page

up and down ( Image13).

Image

file list

(Image 13)

Note: When there is no image file found,

a window jump out to remind you image

importing (Image 14).

See 5.5.1 Image Management for

image logo import.

(Image 14)

5.3.6 Add Counter

Click to add counter.

Click

for options of common

counter, box number, lot number.

A. Click

for common countersetting:

minimum value, maximum value, stepping

value, repeat number ( Image 15).

Common

counter

Box No.

Lot No.

Stepping

value

Repeat

number

(Image 15)

B. Click

to enter box number and

pallet number interface, current value, mini

value, max value, step value for cartonand

pallet number (see Image 16).

Note:

1. Please set up carton number at

first ,then set up pallet number

2. No duplicate value setting options for

carton and pallet number.

Minimum

value

Maximum

value

(Image 16)

value

20

5.3.7 Add Shift

Click to add “shifts code”.

Click enter the setting interface:

can set shifts interval, start time and shifts

numbers.

A. Shifts Interval : 9 options:

Start time

0、0.5H、1H、2H、3H、4H、6H、8H

、

12H,each option makes a day to the

responding shifts number.

Such as: interval value 8H, means 3 shifts

per day.

B. Start time: set the time for the first shift.

Note: 24-hour time system.

C. Shifts: set shifts numbers.

While interval value is 0, shifts can be

inputted freely from 2-48.

D. Click to view the detailed

information.

E. Shift: set the shit name, time.

F. Shift name: maximum 5 characters.

G. Shift time: can set different time, shifts

will be changed according to time.

Interval

Shifts

21

5.3.8 Add Barcode

Click to add object“barcode”.

A. Click to enter barcode edit:

Barcode type, horizontal scale level, barcode

height, barcode text ( Image 18).

Code text

(Image 18)

B. Click to enter barcode

adjustment: coordinate location, text

orientation( Image 19, ).

Note: Setting options may differ depending on

different barcode types.

C. Click Special, set bar code text hidden/

display, font switch, font size, error

correction level, blank space level, twodimensional code specification.

: Textdisplay;

: Texthide;

~

: error correction

level;

~

: white space

level.

Barcode specification: size of 2D code

Text height: barcode text height

Font type: choose barcode font

(Image19)

Code height

Code

width

Code

type

Error correction level

Code

specification

White

space

level

Text

height

White

space

Text

display

Font

type

22

D. Click

Enter barcodes setting interface:

User can create, edit and delete data sources

inthe barcode content.The data sources including

10 objects: text,production date expiry date

counter, shifts, dynamic text, device info, CSV,

string and carriage return.

After create a new object,

its name will show up in the list, user can sort the

objects by up and down arrows.

23

5.3.9 Add dynamic text

Clip to add dynamic text.

A. Clip to enter the interface of

dynamic text setting, and you can choose

dynamic transmission path and

communication protocol

B. Scan printing

Port is USB, selection modes are:

S1P1: scan one while printing one

S1PN:scan one while printing multiples

until next scan data

SNPN:scan multiples while printing

multiples, repeated print times also

available

SGPN: Fix scan numbers and print

numbers,repeated print times and scan

numbers available

5.3.10 Add dynamic image

Click

to add dynamic image

(Image 23)

Note: please refer to step 5.3.9 to add

dynamic text, set the data transmission

path and communication protocol.

(

Image

23)

24

5.3.11 Add Device Information

Click , add device information;

Clip , enter device information

setting interface, choose device name and

device SN No available

Device name can be defined by entering 5.4.5

user management to define and device SN

can’t be changed.

5.3.12 Add String

Click to add string.

Click to enter the string setting

interface. The system default can add 5

different strings. single data allows maximum

20 string objects, each string with maximum

75 character.

Note: when add the same string, other same

strings will be modified automatically once one

of strings modified.

25

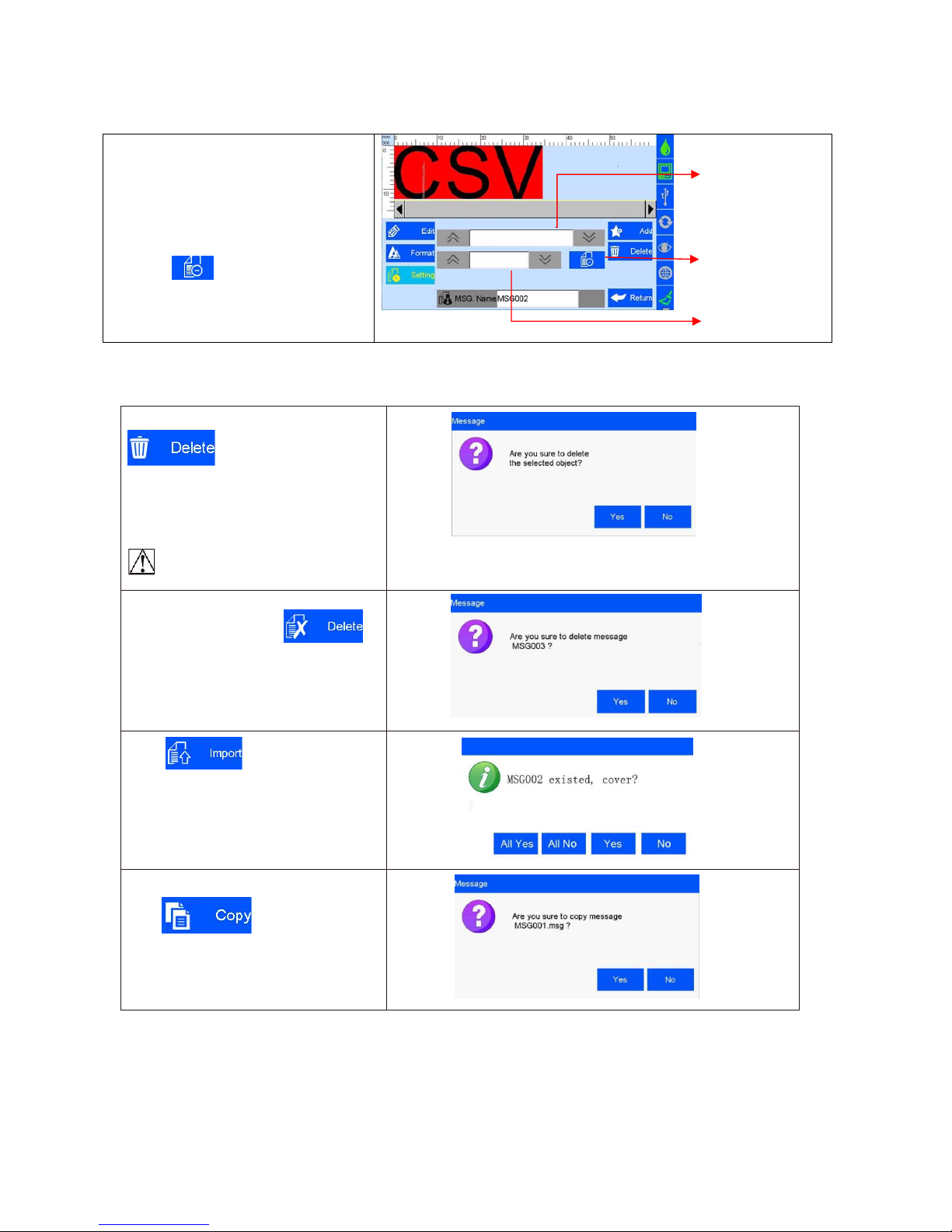

5.3.13 Add CSV File

Click CSV to add the CSV file

A. Put the CSV file under the U disk

(Inkjet/CSV/) path

B. Inserts the U disk into the device. The

device automatically identify the CSV file

and switch options

C. Select the file, Switch and choose the

required content

D. click on No print for the first line,

click again to switch to the first line to print

5.3.14 Delete Object or Delete/Import /Data copy

Select an object on data edit interface,click

to delete the object, and a

dialog box appears ,please refer (Image

24)

( Image 24)

Select the file on the file list of data

management interface , click

to delete the file, a dialog box appears,

please refer Image 25.

Note: All data in printing cannot be

Deleted

( Image 25)

Click in FileManagement

interface,it will import all files saved in U

disk under defined route. A dialog box

remind you to cover or not.

Select an object on data editing interface,

Click to copy data ,“C1”

be added on the original data name after

data copied. E.g. the files name of

MSG001 will changed to MSG001C1 .

Select CSV flies

First line not

print

Select filed

26

5.4 System Management

Click

to enter system

Management interface ( Image 26).

Special

Features

User

management

Printing options

Editing options

System setting

Screen

correction

(

Image

26)

5.4.1System Setting

Click on system management

interface to enter system setting

(Image 27).

System Language

System time

Screensaver time

Unit

Calendar Type

Daylight saving time

(Image 27)

A. System language

The language of Shipping country is standard language as default

B. System time

Manufacture time as default time, user also can set the time

C. Screensaver time

see Appendix 1: Terms and Definition 3.

1) System default 4hours, 4 cycle switching : 0.5H,2H,4H, off (8H)

2) If screensaver is optioned OFF, screen enters standby status

3) Screen becomes active when there’s alarm or error.

D. unit

Switch between mm and inch.

E. Daylight saving time Three setting modes: OFF, European summer time, US summer time.

F. Calendar Type

Two setting modes available: Persian, Gregorian & Moslem

calendar .Gregorian is default calendar; the System time will be updated

according to the calendar setting.

27

5.4.2 Edit Options

Click on system management interface to enter edit options setting interface.

A. Click to enter production date

Date format

and expiry date format setting.

New format

Note: Seven common date formats default,

Forty-three more formats addable for

user. The seven default date formats

Edit format

can not be deleted.

Delete format

Click I to modify date

format,

click

to delete the existing date format.

Note:

Year/Month/Hour/week have 2 hex

options: decimal/36 hex, before

operating first need to select hex and

Hex switch

1. Year, options are: ---4-Digit, ---Last 2 digit, ---Last 1 digit

2.

Month, options are: ---Full digit, ---Jan to Sep is1-9, Oct to Dec is O/N/D

---Abbreviations, ---Full English

3.

Hour,options are:

--24H system, ---12H system

B. Click to enter special time

Setting .

Date transition

time setting

see Appendix 1: Terms and

Definitions 4, 5.

Pre-zero in

date/time

Special time

setting

1) Date transition time setting: Off is system default, zero point is normal date transition, users can set

different time as date transition .

2) Pre-zero in date/time: four options: OFF, empty preposition, empty postposition, content centered

without blank. (e.g. 2012/05/09, 2012/_5/_2, 2012/5_/2_, 2012/5/2).

C. Click to enter counter

setting.

Capacity

counter

Counter

pre-zero

Counter alarm

Counter reset

Counter setting

1) Capacity counter: setting range: 0~99999999.

2) Pre-zero: Click the down button to switch the four options (e.g.:0001、1、1、1 ).

3) Counter alarm: ON or OFF option. When counter alarm is turned ON, the machine will stop printing

when print number reaches maximum value.

4) Counter reset: ON or OFF option. All counters will start from initial values if the counter reset is turned

ON. The printing value will continue from the last printing if the counter reset is turned OFF.

28

D: click ,enter the system

setting interface.

The system can be new-build,

modified, and deleted,

system default: DEC-10 decimal (0-9)

H36-36 hexadecimal(0-Z)

The default hex can't be modified or

deleted

New system

Modify system

Deletsystem

System setting

New-build and edit the system

1.

Input the system name with three

characters and Images only allowed.

2.

System content: Input Arabic number

from 0-9, 26 capital letters (A-Z) or

lowercase letters(a-z),non-repeated

input

System name

System content

29

5.4.3 Printing Options

Click

on system management interface to enter printing option setting.

A. Click to enter nozzle

maintenance setting.

Note: 1) Pre-purge Mode: 2 modes : both right & left nozzles; the working nozzles only.

2) Pre-purge:5 shifts: OFF, low, medium, high. see the following Images:

--Off;

--Low; --Medium; --High

--Custom Setting: User can set the interval from 1-3600 sec.

3) Object Width: After inputting the object width, the printer will not prepurge while the object passing to avoid

potential pollution.

4) One key clean: spit 300 ink dots one time; the function fail if the button is on during printing

B.

Click to enter print

head

setting.

C. Cache number: Printing numbers

in memory

D. Clear Buff: Clear the cache. This

function defaults to shutdown.

When set to open, The clear

cache button is displayed in the

printing report, and the cached

data is cleared by clicking the

button

E. Pre-Print: The pre-print

displayed when pre-purge is

open. Induction once ,Spray

once

Note: printing direction: system default from left to right.

1) Four directions optional: left-to-right,right-to-left, mirror sides of left-to-right and right-to-left, see image as follow:

--Left-to-right; --Right-to-left; -Mirror side of left-to-right; --Mirror side of

right-to-left.

2) Channel switch: Left channel is default, Left channel, Right channel, Dual channel, see the

image as follow: --Left channel; --Right channel; --Dual

channel.

3) Printing

Recovery: when the set is , The system automatically restores the printing

status before the power cut and automatically starts printing

,The default setting is .

Note: When the printing contains counter, operator need to check on

the counter value and do needful adjustment before the Printing Recovery is "ON",

see Appendix 1: Terms and Definitions 8.

Pre-purge

Pre-purge

Mode

Object Width

One key Clean

30

D. Click to enter production line

Setting.

Line speed

Line speed: system default 30m/min;

Adjustable scope 1~150m/min

;

DPI: system default 300DPI; adjustable

DPI

Scope 50~600DPI.

Line speed

setting

Run speed

test

31

Click on line speed setting

interface to run speed test

( Image 35, 36).

Line speed test: input test object length

0~3000mm, click

to enter speedtest

startup interface, then start production line,

put test object onto production line, the

photocell will be sensing the object, and the

machine will calculate line speed

automatically. Click to save current

speed test result. Click , current

speed test value will not be saved. If test

repeated, system will take average value of

multiple results. Click to stop speed

test, and click or to save or

give up test result.

Speed

Test object

length

Run speed test

Cancel

Save

(Image 35)

Stop speed

test

(Image 36)

Note: if external encoder is connected, system would detect encoder automatically, and

change line speed interface to encoder DPI setting interface. User will not be able to set

the line speed

5.4.4 User Management

Click on system management interface to enter user management

A. Device name: user-defined available, the

maximum is 15 characters.

B. User permission management switch:

system

default OFF. A dialogue box requests user

name and password for access to log in.

C. User name : Create user name according

to different permissions, managers as the

highest authority, can set up and modify the

password; engineers can edit the data and turn

off printing; the operator only open and close

the print data available.

D. Password and confirmation:

administrator creates user name and

password. Maximum 15 characters for

password.

888888 is default password for administrator

(Image 37)

Note: Please contact local dealer or Sojet for printer unlocking when youforget

administratorpassword.

32

5.4.5 Special Features

Click on system management interface to enter “Special

“Features

“ setting.

A. Click to enter “Special printing”

Setting .

Special

printing

Continuous printing:

Continuou

s

output

Output

See Appendix 1: Terms and

interval

Definitions 9 for more information.

1) Continuous output times: system default

0 (OFF). Adjustable scope 0~9999.

Note: 0 means OFF; 9999 means infinite

Continuous printing

2) Continuous Output interval: “off’ is default

adjustable scope 0~999mm.

Round printing:

Two-way printing, from left to right(forward

print) or from right to left (reverse print)

1)Reverse frequency : printing direction can

be reversed automatically when the system

Reach the set printing times. For example,

the set printing times is 3, when printing

finished from right to left, the printing

Reverse frequency

will be changed automatically from left to right

Reverse delay

system default : 0 (off)

Round printing

adjustable range: 0 -9999

2)Reverse delay : printing delay according

to the set direction

system default : 0 (off)

adjustable range: 0 -999.9

it should be set before printing not during

printing process

Note: normal delay (from right to left) set in

the printing interface. see: 5.2.3

B. Click

to enable “Value-added

function ( Image 39).

Value-added

function

Note: Enable special features by

registration code like (1/2 ink saving,1/4 ink

saving, Probation period)

Registration code

(Image 39)

33

C.

Click and enter Alarm

settings. Three options as below: Red

Light, Buzzer or Line Control ( Image

40 ).

Red Light: When the device is in

the following selected state, the

tricolor light for warning

Buzzer: The tricolor light will issue

a buzzer alarm.

Line Control: The tricolor light will

turn to yellow for warning and stop

operation.

When the above situation happen,

printer will transfer the error signal to the

production line via DB15 ports, user can

set up the production operation like stop

or etc.

5.4.6 Screen Calibration

Click

on system

Management interface to enter screen

Calibration ( Image 41).

Note: Please calibrate screen when

inaccurate screen position occur, click

Icon “+” as screen hint ,it will exits

automatically after screen calibration

finished, a verification message indicates

success or failure operation.

(Image 41)

34

5.5 Tool Management

Click on main interface to enter

Tool management interface

About printer

System logs

Backup

management

Upgrade

management

Image Logo

System reset

(

Image

42)

5.5.1 Image Management

Click to enter image Logo

management interface

( Image 43).

Image import: importing image from

USB or Ethernet.

Image format: Monochrome BMP;

Image height: 0-150 pixel point.

Image length

:

0-1000000 pixel point.

File list of

Image Logo

Import image

(Image 43)

Note: 1) System indicates and cuts the excess part if the imported image exceeds borders.

2) Image import cannot be executed when images exceed 100 pcs.

3) Image Logo restore route at U Disk: \InkJet\Logo.

5.5.2 System Upgrade

Click to enter upgrade

management interface

( Image 44).

User can use USB to upgrade the

software and add or change

languages and fonts.

(Image 44)

A. Software

upgrade

System automatically searches for software upgrade documents in designated folder and displays

the upgrade documents by list. User can select and upgrade any file in the list.

Document route under U disk : :\InkJet\Upgrade\Appliction

B. Language

upgrade

The machine is with multi- languages upon delivery. Special extra language can

be added if reques t.

Document route under U disk:\InkJet\Upgrade\Language

C.Resource

upgrade

Custom resource packs, Select the resource pack in the list and perform the

upgrade.

Document route under U disk: \InkJet\Upgrade\Res

D. Font

upgrade

System supports two fonts; user can add another font besides the default

Document route under U disk: \InkJet\Upgrade\Font

Note: Software upgrade documents, language documents, font documents can only be identified by

using the conversion tools provided by our company. The default language, font can’t be replaced and

deleted.

Delete image

Delete all

35

5.5.3 System Backup

5.5.4 System Logs

Click to enter system logs interface.

All operation content including operator,

operation and operating time

System logs include:

1)Printing function: Set up Log from initial value

2) New data management, modify, delete logs, import data

3) All logs in system management (including

screen calibration logs).

4) Image importing and delete logs, system upgrade, system

backup logs, and system reset logs.

Note: Enquiries, reading, and other logs are not included.

5.5.5 About Equipment

Click to enter equipment information

View interface

Information displays current hardware

version, software version, machine serial

number, dealer code, company Logo,

company name and website.

Clip to enter backup management.

Clip to enter backup operation

interface;

Export backup: including backup

documents, Image and Parameter

setting

C

lip to enter the backup restore

interface; can restore the message,

image and Parameter which in U disk to

the device;

Data optional:

1、 New: copy the data of U disk to the

device

2 、 Replace: replace the same name

data

3、Delete: delete existing data of device

4、Cancel: Not choose data

Options for image: new, replace, delete

and cancel

Optionsfor parameter: replace and

cancel

Note: Please check U disk connection status and disk space is normal when execute backup import and

export.

Backup document route under U Disk :/InkJet/Backup

36

5.5.6 System Reset

Click fromtools

management interface to enter the

system reset operation management

interface ( Image 48).

Click to execute system

reset. You need administrator

password for permission to reset

(Image 49).

(Image 48)

(Image 49)

Note: System reset is to restore all defaults.

1) Restore all to defaults, all data andimages are deleted.

2) All software version maintain current version; restore all languages and font to default.

After system be reset, relative parameters are as follows:

Item #

Items

Parameters

1

Language

English

2

System time

Manufacture time

3

Screen saver time

4 hours

4

Unit

Metric/mm

5

Daylight saving time

OFF

6

Date change

OFF

7

Pre-zero in date/time

OFF

8

Pre-zero in counter

OFF

9

Counter alarm

OFF

10

Counter reset

OFF

11

Pre-purge

OFF

12

One key cleaning

Standby

13

Printing direction

Left-to-right

14

Channel switch

Left channel

15

Print Recovery

OFF

16

Buffers number

5

17

Line speed

30m/min

18

DPI

300DPI

19

User permission management

OFF

20

Repeated output times

0 OFF

21

Data management

Only system default data Msg001

22

Printing delay

30mm

23

Printing initial value

Counter initial value and data source current value.

37

5.6 Input Methods Introduction

When click the input value in the input bar, the system interface automatically pops up the

keyboard input method. You can enter uppercase English, lowercase English, Chinese, numbers,

and common symbols (see Image 50, 51, 52, 53).

A. Uppercase: the system default

uppercase English input when

keyboard pops up

( Image 50).

(

Image

50)

B. Lowercase: click to

change between uppercase and

lowercase (Image 51).

(Image 51)

C. Numeric and common symbols:

Click to change

between numeric or common symbols

input ( Image 52).

(Image 52)

D. More symbols: click on

numeric/common symbols keypad for

more symbols (Image 53).

(Image 53)

Input method change

Numeric/common symbols and alphabetic input change

Reset (clear all input)

Delete (delete one character)

Hide keyboard

NOTE:

English for Arial fonts, characters in uppercase letters and numbers as the benchmark, lowercase letters

and symbols are not at same height

38

5.7 Status Bar

Ink

information

Ink information including dynamic and static information.

Static information including cartridge serial number, client

code, cartridge type.

Dynamic information:

1) Ink original volume , output volume for current printing data.

2) Ink used in percent, the remaining ink available for current data.

Ink status icons include:

1) Normal ( ): Normal ink status.

2) warning ( ): ink volume lower than 10%;

3) Error ( ): use wrong cartridge, cartridge uninstall, or ink use out.

Equipment

status

Hardware and software status of printer.

USB

information

Automatically displays the corresponding icons based on the type and status

of the device that the USB is connected .

Support three connection: USB , mouse, and keyboard.

Status: disconnection (gray), normal connection (green), warning (yellow)

These icons USB mouse keyboard will display once

device connected successfully

Encoder

information

Displays encoder

or photocell

connection status

like

disconnection

(gray) and

normally

connection(green

).

When encoder is

connected, click

to enter encoder

signal testing

interface

,

Photocell

information

When photocell is

connected, click

to enter photocell

signal testing

interface

,

Ethernet

information

The printer connection to computer is realized by

Ethernet port, therefore realizes device operation

and upgrade transmission on PC end.

Information including IP, mask code, gateway,

MAC; IP, mask code and gateway can be gained

automatically or manual input

Status including: disconnection (gray color);

Normally connection (green color, interaction with PC software normal);

Warning (yellow color, abnormal interaction with PC software ,

connection failure, the PC software not open, computer not turn on etc.)

One key

cleaning

Status including:

Failure status(gray)and one key cleaning

invalid while printing going on

Valid status (green) one key cleaning

available

39

Chapter Six: Maintenance

Inkjet printer is a kind of precision machine, if the daily maintenance is not timely and in place, it easily cause different

kinds of faults and bring a lot of inconvenience! In order to prolong the service life and improve the utilization rate, it is

necessary to arrange special personnel for the management and maintenance.

6.1 Printer Maintenance

6.1.1 Make sure power cable, power adapter cable, grounding cable is in good condition. Make sure the connection of

each cable is reliable.

6.1.2 Make sure the screw for grounding wire is secured and the grounding is reliable.

6.1.3Make sure the equipment is not displaced before turn on. Make sure the nozzle is parallel to printing object, and

printing distance is controlled within 0.5-2.5mm. (Please use the designed tools provided by sojet to secure the

mounting support).

6.1.4 Clean ink cartridge: wipe nozzle with Non-woven cloth to keep nozzles clean and unclogged. (Please refer to ink

cartridge care and maintenance for instructions).

6.1.5 Keep touch screen clean. Do not hit touch screen sharply.

6.1.6 Keep machine surface and ports clean.

6.1.7 Check status bar, make sure machine icon is normal and no alarm on status bar. (In case of alarm status, check

troubleshooting for solutions)

6.1.8When machine is turned off, make sure to remove the cartridge from printer, clean the nozzle and capthe print

head, place the cartridge in safe environment. (Please refer to cartridge care and maintenance for instructions).

6.2 Ink Cartridge Maintenance

Maintain correct methods for use and storage of the cartridge will keep the cartridge work with best print quality and extend

cartridge life. Please always follow instructions for Ink Cartridge Maintenance. The warranty will not cover damage or

failure caused by negligence not following our maintenance instruction..

6.2.1 Ink will volatilize slowly if the cartridge is decapped. Keep new and unopen cartridge in its original package.

6.2.2 Try to use up ink as soon as possible once the cartridge is open to prevent blocked because nozzle become dry in

short time. Note: Due to feature different, different inks have different dry time and maintenance ways. Contact our

after-sale service for more information.

6.2.3 If ink in cartridge is not used out at a time after open, remove the cartridge from printer and lock the print head with

customized cap and store in proper environment. Note: Do not use adhesive tape to seal the printhead, and do not

store cartridge in soft plastic bag.

6.2.4 Nozzle plate is delicate. Do not touch or clean nozzle with anything sharp or rough as not to scratch nozzle.

6.2.5 Use the Non-woven cloth provided by Sojet to wipe and clean nozzle.

Note: Wipe nozzle with the printhead facing down. Move the printhead in the direction of nozzle channel. Move the

printhead in the direction across nozzle channel will damage the nozzles.

6.2.6 Do not shake ink cartridge or expose in shocking environment. Shake or vibration will get air run into cartridge and

affect print quality.

To ensure best print quality, contact Sojet after-sale service for more instructions of different inks usage.

40

Chapter Seven: Common Troubles and Solutions

Note 1: The table below listing the most commonly seen problems and the solutions, If there’s any other problems, contact

your local dealer or our after-sale service for assistance.

Note 2: The table below is for reference only because each problem may differ depending on individual situation such as

installation environment and operation.

7.1 Troubleshooting and Solutions for Cartridge

SN Problems Analysis Solutions

Comments

1

The print has

broken line or

white line.

1. Nozzle blockage

or damage.

A. See Section 6.2 Ink

cartridge maintenance,

wipe and clean nozzle

with Non-woven cloth;

B. See Section 5.4.3,

Clean the nozzle using

one key cleaning

function

If the problem is still

unsolved:

Please check that the

drive panel contacts are

sunken and not bounce;

Check if dirty on cartridge

contacts

2. Cartridge not in

good connection

with printer.

Remove the cartridge and

re-insert.

2

The first half

print is

complete and

late half print

incomplete

Ink out or air

bubbles blocking

nozzles.

A. Check status bar if

there’s alarm of low ink.

B. Return to Sojet

for testing.

3

The print is

totally blank.

Ink used up

or nozzle total

blockage.

See Section 5.7 to check

ink status: is ink used up?

4

Unable to

identify ink

cartridge.

1. Connectivity

problem on printer

(defect or damage)

Remove cartridge and

re-insert.

If the problem is still

unsolved:

1,Please check that the

drive panel contacts are

sunken and not bounce;

2,Check if dirty on cartridge

contacts

3, Check if there’s

contamination on ISM card.

4, Check if there’s any

sunken connector on ISM

2. Cartridge dealer

code mistake.

Change new cartridge

and re-insert.

41

7.2 Troubleshooting and Solutions for Printer

SN Problems Analysis Solutions Comment

1

Printer

cannot be

turned on

1.No power input;

A. Make sure AC power

input on adapter is

correct, DC output on

adapter is well connected

with printer.

B. Check if power adapter

light is normal. Replace a

new adapter if light is

dead, dim or blinking.

2. Printer switch not

turned on.

Make sure the printer

power switch is turned

ON.

3. Device

damaged.

Contact local dealer or

after-sale service.

2

Printer

does not

print

1. Printing not started.

Click “Start printing”

button to start printing.

2. No printing data.

Select a file and click

“Start printing” button.

3. Printing delay value

too long

Check if the printing delay

value is normal.

4. Cartridge not

installed.

Install a cartridge.

5. Cartridge installed

but used up or

damaged.

Check cartridge status

according to Section 5.7,

is ink used up or cartridge

dealer code wrong?

If ink used up, or cartridge

dealer code wrong, replace a

new cartridge.

6. Photocell not works.

Testing Photocell refer

Section 5.2.2 to see if

output counter is working

in printing report

interface.

When connect with external

photocell, click for

photocell signal test interface

7. Encoder is

connected but

damaged.

Check if the encoder and

its connection wire are in

good condition; check if

the production line is

running well.

When the external equipment

is encoder, click for

encoder signal test interface,

move encoder to check if the

encoder works.

Appendix 1: Terms and Definitions

SN

Terms

Definition

Comment

1

Printing delay

It is the distance from the point when

photocell senses the printing object

to the point when printing starts.

User can adjust the right print

position on printing object.

E.g. Printing delay value is 30mm,

printer starts printing at 30mm point after

the photocell senses the printing object.

2

Printing

initial value

Counter Initial value during

printing

E.g. Set the initial value as 9, the counter

counting starts from 9 for first print.

3

Screen

saver time

It is a power saving function, the

screen will automatically turn off and

enter standby mode when the screen

is inactive for a while as set.

E.g. Set the screen saver time as one

minute. The screen will automatically

turn off and enter standby mode if the

screen becomes inactive for one minute.

4

the date

transition

time

customer can set a date for change

For example: Date change setting is

“08:00” ,Current date is 10/07 change

the time to 07:59,then the time of last

printing out before that is recorded as

09/07 07:59, after that is 10/07,8:00. If

the date transition time is 12:01,then the

time of last printing out before that is

recorded as 10/07 12:00,after that is

11/07.

5

Pre-purge

Nozzles become dry and cause

first half charactera unclear. user

can turn this function ON to

prevent the situation,

When Pre-purge function is turned ON,

printer will spray a little ink during idle

printing status to keep nozzle wet and

prevent dry.

6

One key

cleaning

Customer can use this function to

purge nozzles.

Purge whole nozzle to make sure

nozzles unblocked.

7

Channel

switch

Customer can switch different

channels to achieve best print

quality according to print need and

nozzle condition.

E.g. Option for single-channel printing,

when damage in left channel nozzle or

missing dots in print by left channel,

user can switch to right channel

printing.

Option for dual-channel printing to

achieve darker print and best print

quality.

8

Continuous

printing

Continuous same data printing

during the period that photocell

sensing the print object.

9

Printing

Recovery

When there is a power failure, and

the setting is "ON", system will go

back to the last printing status and

resume printing when power gets

back. The default setting for this

function is "OFF"

When the printing contains counter,

and the Printing Recovery setting is

"ON", operator need to check on the

counter value and do needful

adjustment.

42

Loading...

Loading...