Title

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

User Manual

Laser Doppler Vibrometer

Controller OFV-3001

Sensor Heads OFV-303/-353

OFV-511/-512

Warranty and Service

The warranty for this eq uipmen t com plies with the regul ations in our gener al terms an d

conditions in thei r r es pecti ve val id v er sion .

This is conditiona l on the equ ipmen t bein g used as it is in tende d and as desc ribe d in this

manual.

The warranty does not apply to dam age caus ed by in correct usa ge, ex terna l mechani cal

influences or by not keeping to the operating conditions. The warranty also is invalidated in the

case of the equipme nt being tampere d with or m odified wi thout aut horiza tion .

To return the equipme nt always use the origina l packagi ng. Other wise we r eserve th e righ t to

check the equipment for transport damage. Please mark the package as fragile and sensitive to

frost. Include an explanation of the re ason for returning it as wel l as an exact description o f t he

fault. You can find advi ce on fa ult diag nosis in c hap ter 6.

Trademarks

Brand and product na mes ment ioned i n this ma nual could be trade marks or reg istere d

trademarks of th eir respe ctiv e companie s or organi zation s.

Identification Labels

Controller Sensor Head

Contents

Contents

1 Safety Information 1-1

1.1 Laser Safety .......................................................................................................................1-1

1.2 Laser Warning Labels......................................................................................................... 1-2

1.2.1 EC Countries ............................................................................................................ 1-2

1.3 Laser Warning Labels.........................................................................................................1-4

1.3.1 Non-EC Countries..................................................................................................... 1-4

1.4 Electrical Safety..................................................................................................................1-6

2 Introduction 2-1

2.1 System Overview................................................................................................................2-1

2.2 Component Summary .........................................................................................................2-2

3 First Steps 3-1

3.1 Operating and Maintenance Requirements ......................................................................... 3-1

3.2 Unpacking and Inspection...................................................................................................3-2

3.3 Control Elements of the Vibrometer .................................................................................... 3-3

3.3.1 Controller.................................................................................................................. 3-3

3.3.2 Sensor Head OFV-303.............................................................................................. 3-7

3.3.3 Sensor Head OFV-353.............................................................................................. 3-8

3.3.4 Sensor Head OFV-511.............................................................................................. 3-9

3.3.5 Sensor Head OFV-512.............................................................................................3-11

3.4 Installation and Functional Test ......................................................................................... 3-13

3.4.1 Vibrometer with Sensor Head OFV-303/-353........................................................... 3-13

3.4.2 Vibrometer with Sensor Head OFV-511/-512........................................................... 3-14

4 Making Measurements 4-1

4.1 Start-up...............................................................................................................................4-1

4.1.1 Vibrometer with Sensor Head OFV-303/-353.............................................................4-1

4.1.2 Vibrometer with Sensor Head OFV-511/-512.............................................................4-2

4.1.3 Displaying the Output Signals ................................................................................... 4-3

4.2 Selecting Suitable Settings .................................................................................................4-4

4.2.1 Velocity or Displacement Measurement? ..................................................................4-4

4.2.2 Settings for Velocity Measurement............................................................................4-5

4.2.3 Settings for Displacement Measurement (optional) ................................................. 4-10

4.2.4 Optimal Stand-Off Distances for the Sensor Heads................................................. 4-14

i

Contents

5 Operating the Vibrometer 5-1

5.1 Switching On and Off ...........................................................................................................5-1

5.2 Beam Shutter and Emission Indicator..................................................................................5-1

5.3 Signal Level Display ............................................................................................................5-2

5.4 Focusing the Laser Beam....................................................................................................5-2

5.5 Exchanging the Front Lens..................................................................................................5-4

5.6 Making Single Point Measurements with the Sensor Head OFV-512 ...................................5-5

5.7 Fixing the Focus (only OFV-353).........................................................................................5-5

5.8 Transport Safety Mechanism (only OFV-511/-512)...............................................................5-6

5.9 Operating the Vibrometer via the Display of the Controller...................................................5-7

5.9.1 Operating Philosophy.................................................................................................5-7

5.9.2 Organization of the Menus.........................................................................................5-8

5.9.3 The Individual Menus .................................................................................................5-9

5.10 Setting Measurement Ranges and Filters ........................................................................5-11

5.11 Displaying the Configuration of the Controller ..................................................................5-11

5.12 Configuring the Interfaces................................................................................................5-11

6 Fault Diagnosis 6-1

6.1 General Tests......................................................................................................................6-1

6.2 No Laser Beam....................................................................................................................6-2

6.3 No Measurement Signal ......................................................................................................6-3

6.4 Checklist for Fault Diagnosis ...............................................................................................6-5

6.4.1 Controller OFV-3001 with the Sensor Head OFV-303/-353 ........................................6-5

6.4.2 Controller OFV-3001 with the Sensor Head OFV-511/-512.........................................6-6

7 Technical Specifications 7-1

7.1 Controller OFV-3001............................................................................................................7-1

7.1.1 General Data .............................................................................................................7-1

7.1.2 Interfaces...................................................................................................................7-1

7.1.3 Low Pass Filter..........................................................................................................7-2

7.1.4 Signal Voltage Output VELOCITY OUTPUT...............................................................7-2

7.1.5 Signal Voltage Output DISPLACEMENT OUTPUT (optional) .....................................7-5

7.2 Sensor Head OFV-303/-353 ................................................................................................7-6

7.2.1 General Data .............................................................................................................7-6

7.2.2 Optics........................................................................................................................7-6

7.3 Sensor Head OFV-511/-512.................................................................................................7-8

7.3.1 General Data .............................................................................................................7-8

7.3.2 Optics........................................................................................................................7-8

Appendix A: Optional Accessories for the Sensor Head OFV-30 3/-35 3

Appendix B: Optional Accessories for the Sensor Head OFV-511/-512

Appendix C: Basics of the Measurement Procedure

Appendix D: Functional Description of the Cont roller

Appendix E: Interface Operation RS-232 and IEEE-488/GPIB

ii

1 Safety Information

1.1 Laser Safety

The light source of the vibrometer is a helium neon laser. It is important to

understand that laser light has different properties than ordinary light sources.

Laser radiation is genera lly extr emely intense due to th e beam 's low

divergence and gr eat care sh ould be taken when hand ling laser instrume nts

that the direct or re flec ted bea m does no t ente r the ey e. To ensure this , the

following precauti ons have bee n taken:

•

In general, Polytec equipm ent comp lies with t he standards

(DIN VDE 0837) and

•

The optical output of the laser is less than 1mW for the sensor heads

OFV-303/-353

manner for which it was in tende d. This mea ns that th e vibrom eter

conforms with

optimally focused, the laser radiation is not intense en ough to har m the

skin.

•

The optical output of the laser is less than 5mW (<1mW per fibre) f or the

sensor head

which it was intended. T his mea ns that th e vibrome ter confo rms with

laser class 3R (IIIa)

focused, the lase r radi ation is not inten se enou gh to ha rm the sk in.

•

The sensor head has bee n equippe d with a

used to block t he l as er b eam du ring t he w arm -up pha se or whe n th e

vibrometer is not in us e, a ltho ugh s witc hed on.

•

The

emission indica tor

laser and thus pote ntial ha rm cause d by emit ted lase r beams .

•

The beam shutt er is alway s

laser beam. Special editions of th e fibe r optica l sensor he ads wit h fiber

lengths of 3m are fitted wi th an addi tion al e m ission in dic ator w hich is

integrated in th e fibe rs.

•

The laser is switched on via a

only be removed when th e control ler is swit ched off.

•

It is

not necessary to open

the vibrometer as intend ed. Ope ning the housing wi ll invalidat e the

warranty.

CFR 1040.10

and

OFV-511

laser class 2 (II)

OFV-512

providing the eq uipment i s used in the mann er for

and is generally very sa fe. Ev en when opti mally

on the sensor head ind icates the ac tivity of the

1 Safety Information

EN 60825-1

(US).

providing the equi pment is us ed in the

and is generally very sa fe. Even wh en

beam shutter

less then 2m away

key switch

on the controller. The key can

from the apertu re of th e

which can be

the housing of the senso r head whe n using

Please pay attention

to the following

safety precau ti ons

when using the

vibrometer:

•

Never look directly int o the lase r beam with the nake d eye or with the aid

of mirrors or op tic al i nstr ume nts!

•

Only switch the beam shut ter to the ON pos ition when yo u are mak ing

measurements!

•

To position the sensor head, switch the beam shutter to the OFF position.

Only when the sensor he ad is rough ly in pla ce and has bee n fixe d in a

stable position, switch t he beam sh utter t o ON.

•

Do not use any reflective t ools, watch es etc. whe n you are working i n the

path of the laser beam!

1-1

1 Safety Information

1.2 Laser Warning Labels

1.2.1 EC Countries

Warning

labels

The laser warning labels for th e sensor heads in EC coun tries ar e shown in

figure 1.1. Label 2, 3 and 4 are affixed or encl os ed i n the la nguag e of t he

customer’s country . Their position on the sensor head OFV-303/-353 is shown

in figure 1.2 and on the sensor head OFV-511 resp. OFV-512 in figu re 1.3.

Laser class 2 for

OFV-303/-353 and OFV-511

Laser class 3R for

OFV-512

1

2

3

4

Figure 1.1: Laser warning label s for th e vibrometer in EC count ries

1-2

1 Safety Information

Position

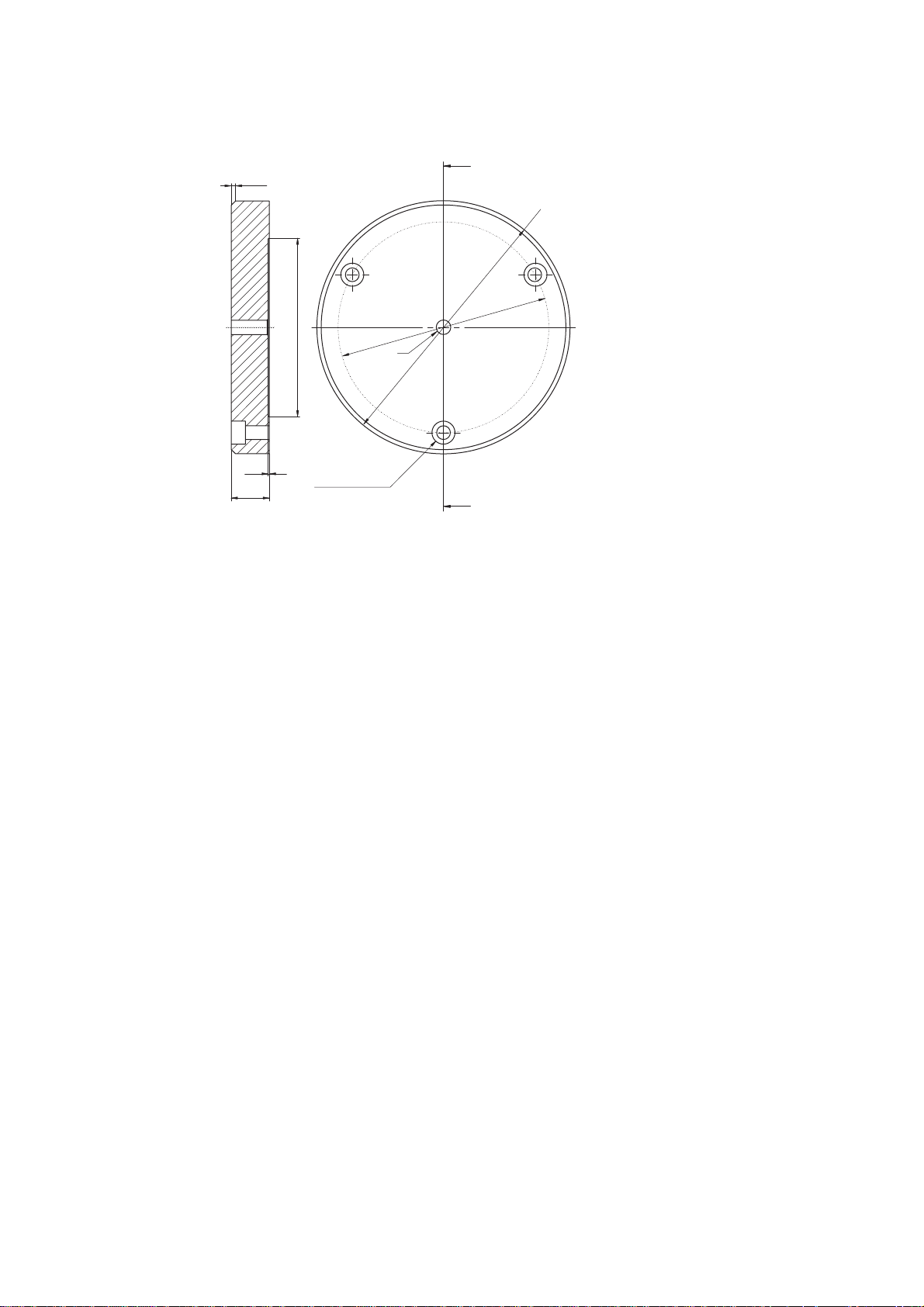

The position of th e laser war ning lab els in E C count ries on th e senso r head

OFV-303/-353 is shown in figure 1.2.

1

3

B e a m

2 4

Figure 1.2: Position of t he la ser war ning l abels o n the sensor head OFV-303/ -353 in EC

countries

The position of th e laser war ning lab els in E C count ries on th e senso r head

OFV-511 resp. OFV-512 is shown in figure 1.3.

For the sensor head OFV-511, label 3 is affixed inside.

For the sensor head OFV-512, label 4 is affixed inside and label 3 is enclosed

with the sensor hea d as it is not pos sible to affix it on the mini senso r due to

its size. Please affi x thi s la bel c le arly visi ble near th e mo un te d mi ni s ens or or

fiber head.

1

A C H T U N G !

B i t t e v o r d e m T r a n s p o r t

d i e T r a n s p o r t s i c h e r u n g b e t ä t i g e n

S I G N A L

P R O C E S S O R

M E A S U R E M E N T

B e a m

Figure 1.3: Position of the laser war ning labels on t he senso r he ad OFV-511/-512 in EC countries

C A U T I O N !

P l e a s e s e c u r e t r a n s p o r t m e c h a n i s m

b e f o r e s h i p m e n t

2

T R A N S P O R T

1-3

1 Safety Information

1.3 Laser Warning Labels

1.3.1 Non-EC Countries

Warning labels

The laser warnin g l abels for the sensor heads i n non-EC countries are shown

in figure 1.4. Their position on the sensor head OFV- 303/-3 53 is shown in

figure 1.5 and on the sensor head OFV-511 resp. OFV-512 in figure 1.6.

Laser class II for

OFV-303/-353 and OFV-511

Laser class IIIa for

OFV-512

1-4

Figure 1.4: Laser warning

labels for the vibrometer in non-EC

countries

1 Safety Information

Position

The position of th e laser war ning lab els in non -EC coun tries on the sens or

head OFV-303/- 353 is s how n in figure 1.5.

3

B e a m

Figure 1.5: Position of the laser warning labels on the sensor head OFV-303/-353 in non-EC

countries

1 4 2

The position of th e laser war ning lab els in non -EC coun tries on the sens or

head OFV-511 resp. OFV-512 is shown in figure 1.6.

Label 4 is affixed inside. Labe l 3 is enclosed with th e senso r head as it is not

possible to affix it on the mi ni sensor due to its size. Pleas e affix this lab el

clearly visible near the moun ted m ini sens or or fibe r head.

1

A C H T U N G !

B i t t e v o r d e m T r a n s p o r t

d i e T r a n s p o r t s i c h e r u n g b e t ä t i g e n

S I G N A L

P R O C E S S O R

M E A S U R E M E N T

C A U T I O N !

P l e a s e s e c u r e t r a n s p o r t m e c h a n i s m

b e f o r e s h i p m e n t

T R A N S P O R T

B e a m

2

Figure 1.6: Position of the laser war ning labels on t he senso r ea d OFV-511/-512 in non-EC countries

1-5

1 Safety Information

1.4 Electrical Safety

The vibrometer comp lies with t he electr ical safet y class I. Electrica l shock

protection is achi eved by a fully metalli c housing connec ted to protect ive

ground. Please pay atten tion to the f ollowing sa fety precau tions whe n using

the vibrometer:

•

The vibrometer sh ould only be conn ecte d via a th ree pin ma ins cabl e to

an AC mains supply 50/60Hz with a grounded protective conductor with a

nominal voltage which correspo nds to the vo ltage set on the vo ltage

selector.

•

Defective ma ins fuses may only be repl aced by fus es of th e same ki nd

with their ratin g given on the ba ck of the con troll er.

•

None of the equipment may be used with open housing. As a general rule,

before remov ing parts of the hou sing, t he mains cable has t o be

unplugged.

•

Air inlets and outlets must al ways be ke pt uncove red to ensure effective

cooling. If the co oling fa n stops workin g, the vibro meter is to be switch ed

off immediately.

1-6

2 Introduction

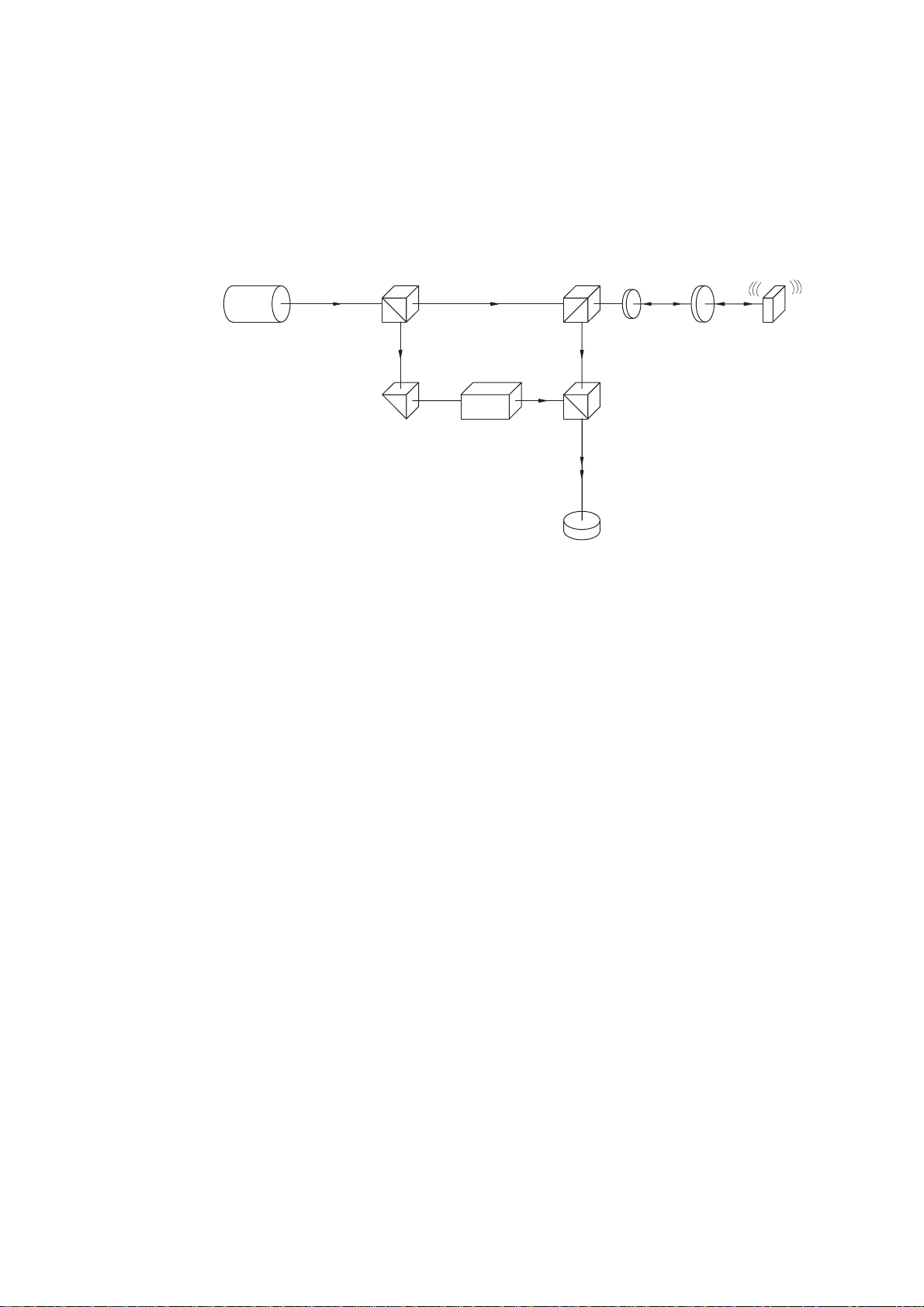

2.1 System Overview

Polytec vibrome ters are inst rumen ts for non-contact measur ement of surfac e

vibrations bas ed on l ase r in ter fero met ry. The vibrometer co nsis ts of the

controller OFV-30 01 and th e sensor he ad OFV-3 03/-353 or OFV-511/-512.

The signal path s in the v ibro met er a re show n sch ema tica lly in fi gu re 2.1.

2 Introduction

S e n s o r h e a d

f

m o d

j

f

0

j

0

Figure 2.1: Signals in the vibro meter

m o d

F r e q u e n c y

P h a s e

V e l o c i t y

d e c o d e r

f

D

D i s p l a c e m e n t

d e c o d e r ( o p t i o n a l )

D j

V

V

O b j e c t

x ( t )

v ( t ) = d x / d t

v ( t )

x ( t )

The beam of a helium neon laser is focused on the object under investigation,

scattered back f rom the re and coupl ed bac k into the interfero meter in the

sensor head. The in te rfer ome ter com pares t he phas e

of the object beam wi th tho se of th e intern al refer ence be am

ϕ

and frequency f

mod

ϕ

and f0. The

0

mod

frequency difference is propor tional to the instantan eous ve locity and the

phase difference is prop ortion al to the i nstantaneou s position of the ob ject.

In the controller, the resulting sign al is decod ed usi ng the vel ocity dec oder

and optional ly th e d is plac emen t deco der. Two voltage signals are g enera te d

which are respectivel y proport ional to th e instantaneou s VELOCITY an d to

the instantaneous po siti on ( DI SPLACEM ENT) o f the ob ject . Bo th s igna ls are

available at the front of the contr oller as an analog vo ltage and can be

processed further external ly. Additional functions such as filters an d signal

level display rai se the level of comfort for the vibrometer user. The settings of

the vibrometer are se lected via the displ ay of the con troller or via PC

interfaces.

To display and an alyz e m ea surem ent res ul ts on a w orkstat ion, the P olyt ec

Vibrometer Software (VibSoft) is availab le optiona lly. The software is

described in a s eparat e m a nual.

2-1

2 Introduction

2.2 Component Summary

Polytec assemb les the vi brome ter on the modular princip le thus pe rmit ting a

user-specific config uration . The com bination of the control ler OFV-3 001 with

the most useful decode rs as wel l as a suitable se nsor he ad provid e the

solution to a m ul titu de of m eas urem ent tasks. Th us a ma nage ab le nu mbe r of

components cover a wide r ange of a pplica tions. A sum mary of the

components is sh own in figu re 2.2.

F i b e r o p t i c a l

s e n s o r h e a d s

V e l o c i t y d e c o d e r s

O F V - 5 1 1

O F V - 5 1 2

O V D - 0 1

O V D - 0 2

O F V - 3 0 0 1

S t a n d a r d

s e n s o r h e a d s

D i s p l a c e m e n t d e c o d e r s

O F V - 3 0 3

O F V - 3 5 3

O V D - 1 0

O V D - 2 0

O V D - 3 0

O V D - 4 0

Figure 2.2: Compatibility of the contr oller OFV -3001 with se nsor heads a nd decod ers

The modularity is achiev ed initia lly thro ugh st rict separa tion of optics and

electronics. E very de cod er c an be com bi ned w it h ev ery sen sor hea d.

The controller is equi pped with one of th e two availa ble veloci ty decod ers as

standard. A maximum of two veloc ity decod ers ca n be installed. The veloci ty

decoders are descr ibed in se ctio n D.4.1.

As an option, the contr oller can be fitted with one of the f our availab le

displacement decod ers as we ll as be supple mente d by a PC-b ased

displacement dec oder (re fer to section D.5.2).

The various standard an d fibe r op tica l senso r he ads comp ly wit h the di fferent

requirements of t he vi bro meter’s optics. For eve ry se nso r h ead a sel ecti on of

lenses covers a wide ran ge o f stand -o ff distances .

2-2

3 First Steps

3.1 Operating and Maintenance Requirements

3 First Steps

Operating

environment

Mains

connection

Warming-up

Assembly

Transport

The vibrometer can be operated in dry rooms under normal climate conditions

(refer to chapter 7). In particular the op tical co mponen ts in the senso r head

are sensitive to m oisture , high tem peratur es, jo lting and di rt. When t he

vibrometer is taken into operation after being stored somewhere cool, a

sufficient acclimatizatio n period sh ould be allo wed for befor e switching it on.

Avoid condensation on the optical com ponents cau sed by a r apid chan ge in

temperature.

Before taking t he vib ro meter in to op erat ion, ple as e ensur e that the s up ply

voltage set with the voltage selector corresponds with the local mains voltage.

Only replace defe ctive fu ses by fuse s of the sam e kind an d equal rating.

The helium neon lase r in th e sensor he ad requ ires a certai n period of time to

reach optimum stabi lity. The vibrometer should th us be swit ched on 20

minutes before the first measurements are made to ensure that it is in thermal

equilibrium wi th t he surr ou ndin gs.

The sensor head OFV-3 03 shou ld not be po sitioned pr ovisio nally bu t

mounted proper ly on a stable tripod usi ng the th reads provi ded.

The sensor head OFV-5 11/-512 is equipped with a tran sport sa fety

mechanism which always has to be activated before moving the sensor head

(refer to section 5.8).

Connecting

cables

Cleaning

Optical

components

Cooling

Opening up

the equipment

As a general rule th e vibromet er must not be switch ed on unti l all cables are

connected. Make sure that all jacks are connected properly and firmly. Protect

the cables from mech anic al damag e and from high temp eratur es.

The housing surfa ces of the ins trume nt can be c leaned wi th mild de terge nt

solutions. Org anic solven ts must not be used.

Handle all optical componen ts with great care. Dirt may only be removed very

carefully with a soft, dry cloth, an optics brush and bellow.

It is very important to en sure that there is sufficient air circu lation to keep the

controller and the sensor head cool. The air vents of the sensor head must

never be covere d up and th e back panel of the contr oller mus t be at leas t

50mm away from the wa ll.

Opening up of the e qu ipm ent wi thout aut ho riza tion i s no t nece ssa ry for its

operation and will invalid ate the war ranty.

3-1

3 First Steps

3.2 Unpacking and Inspection

The vibrometer consi sts of the follo wing com ponents:

•

controller OFV-3001

•

sensor head OFV-303/ -353 or OFV-511/-512

•

connecting cab le from the con troller t o the sen sor he ad (lengt h 5m )

•

earthed mains cable

Protect the unpacked sensor head from hard jolts as these can lead to misalignment of the

Handle the front lens of the senso r head w ith grea t care! Dirt may on ly be removed very

carefully with a soft, dry cloth, an optics brush and bellow !

Caution!

interferometer!

Caution!

Please pay attention to the following s teps when unpack ing:

1. After unpacki ng, chec k all com ponen ts for external dam age (scratches ,

loose screws, da maged lens etc.).

2. Chec k the packa ging for sig ns of unsui table handlin g during transp ort.

3. In the case of a wrong delivery, damage or missing parts, inform your local

Polytec representative immediately and give them the serial number of the

sensor head and th e contr oller. The identificati on labe ls can be fo und on

the back of the instruments and also on the inside cover of this manual.

4. Car efully retain the ori ginal packa ging in case yo u have to re turn the

instrument.

5. Install the vibrom eter and carry out a f irst funct ional test as desc ribed in

section 3.4.1 (sensor head OFV-303/-353) or section 3.4 .2 (sensor head

OFV-511/-512).

3-2

3.3 Control Elements of the Vibrometer

3.3.1 Controller

The front panel of the co ntroller is show n in figure 3.1.

3 First Steps

V I B R O M E T E R C O N T R O L L E R

P O W E R

O

Figure 3.1: Front view of the contr oller

O F V 3 0 0 1

I

2 1 3 1 2 1 1 1 0

1

1

POWER

L L O

- L

The LED lights up when th e k ey s witch o n th e co nt roll er i s t urn ed to

position I and indicate s that th e control ler is ready to operat e.

2

Mains Switch

This key switch disconnec ts the vibrom eter from the mains (p ositio n O)

and is used to switch it off in the case of danger.

ED

3

R E M O T E

F U N C T I O N

4 5 6 7

V E L O C I T Y

+

S E T T I N G

-

R E S E T

O V E R

D I S P L A C E M E N T

C L E A R

O U T P U T

O U T P U T

9 8

Caution!

Always connect the connecting cable to t he sen sor h ead before switching the control ler

on !

3

Liquid Crystal Display (LCD)

with background lighti ng

This display shows the configurat ion and th e sett ings of th e vibrome ter.

The organization o f the displa y and how to use it to oper ate the

vibrometer are des cribed i n detail in sectio n 5.9.

4

FUNCTION

Using these keys the cursor is moved vertically up (

- keys

↑)

or down (↓) on the

display. This is used to s el ect param e ters o r to chan ge b et wee n men us

(refer to se ct ion 5.9.1).

5

SETTING

- keys

Using these keys the set tings are cha nged t o higher (+) or lower (−)

values (refer to se ct ion 5.9.1).

3-3

3 First Steps

6

OVER

- indicator for the velocity

The LED lights up when the o utput vol tage exce ed s eith er o f the po siti ve

or negative full sc ale of th e velocit y measu rement range . If it lights up

permanently, the next highest veloci ty meas uremen t rang e must be

selected (refer also to section 4 .2 .2).

7

Analog voltage

OUTPUT

for the

VELOCITY

signal (BNC jack)

The voltage at this outp ut is prop ortion al to the instan taneous vibr ation

velocity of the object under investigation. The voltage is positive when the

object is moving tow ards the se nsor he ad.

8

CLEAR

- input for th e di splac eme nt deco de r (B NC ja ck)

This input is only ac tive , if a displa cement decoder i s installed. I t allows

synchronized resetti ng of the di splacem ent dec oder. This can be used to

remove a DC c omp onent w hich is sup erimp os ed on a p erio dic vibr atio n

(refer to section 4.2 .3 ).

9

Analog voltage

OUTPUT

for the

DISPLACEMENT

signal (BNC jack)

This output is only active, if a displacement decoder is installed. The

voltage at th is ja ck is p ro port ional to t he ins tantaneous d isp lace men t of

the object to be measu red. The vo ltage increas es when the ob ject is

moving toward s the se nsor head .

10

CLEAR

- key for the displacement decoder

This key is only active, if a displacement decoder is installed. Using this

key the displacement decoder can be reset manually (refer to

section 4.2.3).

11

RESET

- key

Using this key th e control ler proc essor can be reset . The se tting of th e

controller is subsequently the same as it was straight after switching on

the mains.

12

REMOTE

- L

ED

The LED is lit when the controller is being operated remotely via one of the

PC interface s (refer to appe ndix E). Manual op erat ion with the k eys ↑, ↓,

+, - is a lso st ill p oss ible ( as o pp ose to t he stat us Lo cal Lo ck Ou t).

13

LLO

- L

ED

This LED is lit when th e status Local Lock Out has been act ivat ed vi a one

of the PC interfaces (refer to appendix E). The keys ↑, ↓, +, − are then

deactivated an d the cont roller can only be op erate d via the PC in terfac es.

3-4

The back panel of the contro ller is show n in figure 3.2.

6 7 8 1 2

3 First Steps

G P I B / I E E E - 4 8 8

S I G N A L

Figure 3.2: Rear view of the contr oller

R E M O T E F O C U S

5 4 3

1

INTERFEROMETER

Jack for the connect ing cabl e to the sen sor hea d

2

Mains connection combi nati on

Socket for standard pow er cord with built -in fuse s and main s voltage

selector (refer to section 3.1)

Always disconnect from the mains before checking the fuses !

R S 2 3 2

E X T . D E C .

I N T E R F E R O M E T E R

- connector (Sub- D jack)

Warning!

Caution!

Always check the setting of the voltage selecto r as wel l as the f uses before installing the

controller!

3

EXT

ernal

DEC

oder - inte rfac e

Interface for an ex tern al PC-bas ed disp lace ment deco der (re fer to

section D.5.2)

4

REMOTE FOCUS

- interface

Interface for th e optiona l hand terminal OFV-310 to focus t he laser be am

(refer to se ct io n A.1)

5

SIGNAL

- output (BNC jac k)

The DC voltage at this output is proportional to the logarithm of the optical

signal level.

6

GPIB/IEEE-48 8

- interface

Jack for the IEEE-488/GPIB cable (refer to a ppend ix E)

3-5

3 First Steps

7

Cooling Fan

This opening must always be kept free to ensure sufficient coolin g. The distance f rom the

8

RS-232

Caution!

wall should be at least 50mm!

- interface (Sub-D jack)

Jack of the ser ial inte rface (r efer to ap pendi x E)

3-6

3.3.2 Sensor Head OFV-303

The back panel and the front panel of the sensor head OFV-303 are shown in

figure 3.3.

3 First Steps

1

O F F

Figure 3.3: Rear view and fro nt vie w of t he sensor head OFV -303

2

C O N T R O L L E R

O N

E M I S S I O N

1

Beam shutter

3

S

L A S E R

4

I

G

N

A

L

A U T O

M A N

In position OFF the laser be am is bl ocked.

Warning!

Only switch the beam shutter to position ON when you ar e making measurements!

5

6

7

&

2

CONTROLLER

- connector (Sub-D jack)

Jack for the connect ing cabl e to the control ler

3

Signal level displ ay

The length of the bar is a measure of the amount of light scattered back

from the surfac e of the obj ect.

4

LASER

- L

ED

The LED lights up when the laser is sw itched on (key switc h on the

controller in positi on I) i.e. ev en if the be am shutt er is clo sed (ref er to

section 5.2).

5

Switch

AUTO/MAN

This knob is used to switch be tween remote -contro lled and manu al

focusing (refer to se ctio n 5.4).

6

Front lens

Exchange of the fron t lens is descri bed in section 5.5.

7

Focusing ring

Focusing ring for manua l focusi ng of the l aser beam (refer to se ctio n 5.4)

3-7

3 First Steps

3.3.3 Sensor Head OFV-353

The back panel and the f ron t pa nel of the sensor head OFV-353 are shown in

figure 3.4.

1

O F F

Figure 3.4: Rear view and fron t view of th e sensor hea d OFV-353

2

C O N T R O L L E R

O N

E M I S S I O N

1

Beam shutter

3

B R A K E

S

L A S E R

4

I

G

N

A

L

O F F

O N

In position OFF the lase r beam is blocked.

Warning!

5

6

7

&

Only switch the beam shutter to position ON when you ar e making measurements!

2

CONTROLLER

- connector (Sub-D ja ck)

Jack for the co nnectin g cable to the cont rolle r

3

Signal level di splay

The length of the ba r is a measur e of the am ount of light scatt ered back

from the surface of the object .

4

LASER

- L

ED

The LED lights up when t he las er i s switche d on (ke y switch on the

controller in pos ition I) i.e. eve n if the bea m shu tter is clo sed (refe r to

section 5.2).

5

Switch

BRAKE ON/OFF

This knob is used to fix th e focu s (refer t o sect ion 5.7).

6

Front lens

Exchange of th e front l ens is de scribed in section 5.5.

7

Focusing ring

Focusing ring for f ocusi ng of the lase r beam (refer to sectio n 5.4)

3-8

3.3.4 Sensor Head OFV-511

The front panel of the sens or head OFV-511 is shown in figure 3.5.

3 First Steps

O F V - 5 1 1

F I B E R I N T E R F E R O M E T E R

L A S E R

Figure 3.5: Front view of the sensor head OFV-511

O N

S T A N D B Y

1 2 3 4

1

LASER

S I G N A L

- beam shutter key

Pressing this key t he beam sh utter i s opene d and pre ssing this ke y a

second time the be am shut ter is closed aga in (re fer to sec tio n 5.2). The

beam shutter is clos ed autom atica lly when th e contro ller is sw itched on

(key switch on the controller in position I).

2

LASER

STANDBY

- L

The LED goes on when the controller is switched on. This then shows that

the laser is operatio nal. Howe ver, no laser beam is emitt ed yet as the

beam shutter is still closed (LED ON is out). The LED goes out w hen the

beam shutter k ey is pres sed a nd t hu s th e laser beam is em itte d (LED ON

is then on).

ED

5

6

3

LASER ON - L

ED

The LED goes on when the beam sh utter ke y LASER is pre ssed an d thus

the laser beam is em itted. At the sa me time the LED STANDBY goes out.

Pressing the beam shutter key LASER a se cond time the beam shu tter is

closed and the LED ON goes out and the LED STANDBY goes on again.

4

Signal level displ ay

The length of the bar is a measure of the amount of light scattered back

from the surfac e of the obj ect.

3-9

3 First Steps

5

Fiber optic cable

6

Mini sensor

(Diameter 10 mm)

The mini sensor contains a lens to focus the laser beam. Exchang e of the

mini sensor with a fiber head is describe d in section B .3.

Note !

Each mini sensor is exactly adjusted to its fiber . Never exchange the mini sensor with a mini

sensor of another sensor head!

The back panel of the sensor head OFV- 511 is shown in figure 3.6.

4

S I G N A L

P R O C E S S O R

1

Figure 3.6: Rear view of the senso r he ad OFV -511

3

A C H T U N G !

B i t t e v o r d e m T r a n s p o r t

d i e T r a n s p o r t s i c h e r u n g b e t ä t i g e n

P l e a s e s e c u r e t r a n s p o r t m e c h a n i s m

M E A S U R E M E N T

C A U T I O N !

b e f o r e s h i p m e n t

T R A N S P O R T

2

3-10

7

Transport handle

Always activate the transport safety me chanism be fore movin g th e sensor hea d!

8

Sensor mount

Caution!

To transport the senso r head, th e min i sensor can be plug ged int o this

sensor mount.

9

SIGNAL PROCESSOR

- connector (Sub-D jack)

Jack for the co nnectin g cable to the cont rolle r

10

Transport safety mechanism

The transport safety mechanism is (de)activated by turning the screw with

the Allen key provided (refer to section 5.8 ).

3.3.5 Sensor Head OFV-512

The front panel of the sens or head OFV-512 is shown in figure 3.7.

3 First Steps

O F V - 5 1 2

F I B E R I N T E R F E R O M E T E R

S T A N D B Y

1

O N

1

LASER

L A S E R

Figure 3.7: Front view of the sensor head OFV-512

S I G N A L

2 3 4

- beam shutter key

Pressing this key t he beam sh utter i s opene d and pre ssing this ke y a

second time the be am shut ter is closed aga in (re fer to sec tio n 5.2). The

beam shutter is clos ed autom atica lly when th e contro ller is sw itched on

(key switch on the controller in position I).

2

LASER

STANDBY

- L

The LED goes on when the controller is switched on. This then shows that

the laser is operatio nal. Howe ver, no laser beam is emitt ed yet as the

beam shutter is still closed (LED ON is out). The LED goes out w hen the

beam shutter k ey is pres sed a nd t hu s th e laser beam is em itte d (LED ON

is then on).

ED

5

6

3

LASER ON - L

ED

The LED goes on when the beam sh utter ke y LASER is pre ssed an d thus

the laser beam is em itted. At the sa me time the LED STANDBY goes out.

Pressing the beam shutter key LASER a se cond time the beam shu tter is

closed and the LED ON goes out and the LED STANDBY goes on again.

4

Signal level displ ay

The length of the bar is a measure of the amount of light scattered back

from the surfac e of the obj ect.

5

Fiber optic cable

The fiber optic cable branches off via a Y-piece. The reference fiber is

marked with a red do t.

3-11

3 First Steps

6

Mini sensors

(Diameter 10 mm)

Each mini senso r contains a lens to focus th e lase r beam. The mini

sensor of the ref erence fi ber is m arked with a red do t. Exc hange of th e

mini sensors with fi ber he ads is desc ribed in section B.3.

Note !

Each mini sensor is exactly adjusted t o its fibe r. Never exchange the mini sensors of a

sensor head with each other or w ith mini sen sors of ot her sensor heads!

The back panel of the sensor head OFV- 512 is shown in figure 3.8.

4

S I G N A L

P R O C E S S O R

1

Figure 3.8: Rear view of the senso r he ad OFV -512

3

A C H T U N G !

B i t t e v o r d e m T r a n s p o r t

d i e T r a n s p o r t s i c h e r u n g b e t ä t i g e n

P l e a s e s e c u r e t r a n s p o r t m e c h a n i s m

M E A S U R E M E N T T R A N S P O R T

C A U T I O N !

b e f o r e s h i p m e n t

2

3-12

7

Transport handle

Always activate the transport safety me chanism be fore movin g th e sensor hea d!

8

Sensor mount

Caution!

To transport the senso r head the m ini sen sors can be plugge d into thi s

sensor mount.

9

SIGNAL PROCESSOR

- connector (Sub-D jack)

Jack for the co nnectin g cable to the cont rolle r

10

Transport safety mechanism

The transport safety mechanism is (de)activated by turning the screw with

the Allen key provided (refer to section 5.8 ).

3.4 Installation and Functional Test

3.4.1 Vibrometer with Sensor Head OFV-303/-353

For the installation and an in itial func tional test of the vi brome ter, proceed as

follows:

3 First Steps

Preparing

Cabling

Switching on

1. Make su re that the key switch on th e cont roller is i n position O an d the

beam shutter on the se nsor he ad is in pos ition OFF.

2. Check the se tting on the mai ns voltage selec tor on the back of the

controller as well as the fuses.

3. Plug the connecting cable into the Sub-D jack CONTROLLER on the back

of the sensor head and into the Su b-D jack IN TERFEROME TER on th e

back of the controller. Fix the connections with the screws provided.

All connections must be easy to plug in. If not, check the plug for bent

contact pins to avoid serious damage being incurred.

4. Use the earthed mains cable to connect the controller to a wall outlet

providing prote ctive gr oundi ng.

5. Switch th e controll er on by tur ning the key swi tch to posit ion I.

On the front of the controller the LED POWER lights up. Providing the

connecting cable has been installed correctly, the LED LASER on the

sensor head also lights up. Laser light is not yet emitted as the beam

shutter is still closed.

6. Before now opening the b eam shutter, remember the information on laser

safety provided in sectio n 1.1!

Test

7. Open the beam shutter on the sensor head by turning the knob to position

ON.

The laser beam is now emitted from the sensor head.

8. Put a piece of reflective film (enclosed in this manual) at approximately

45cm from the fron t panel of the sensor head in the beam path .

9.

OFV-303

: Pull the knob AUTO/M AN out until it cl icks into plac e and turn

the focusing ring until the adjus tment mech anism clicks into pla ce.

OFV-353

: Pull the knob BRAKE ON/OFF out until it cli cks into plac e and

turn the focusing rin g until the adjust ment m echan ism cli cks into plac e.

Now the laser beam can be focused.

10. Focus the l aser be am on the reflecti ve film usi ng the foc using ring on the

sensor head.

Providing the sensor head and the input section of the controller are

working correct ly, the signal level dis pla y wi ll full y l ight up.

1 1. If you have not been able to observe the effect described under 10 ., check

the signal level again after 20 minutes. After this warm-up phase the laser

has reached its working tem peratur e (refer also to section 4.2.4).

3-13

3 First Steps

If the functional test has bee n succe ssfu l you can now m ake mea sure ments

as described in chapter 4.

If your vibrometer do es not perform as descri bed abo ve, read throu gh the

information on fault diagnosis provided in chapter 6 and, i f necessary, contact

your local Pol ytec r epres entativ e.

3.4.2 Vibrometer with Sensor Head OFV-511/-512

For the installation and an init ial func tional test of the vi bromet er, proceed as

follows:

Preparing

Cabling

Switching on

1.

Only OFV-512

: Unscrew the mini senso r from the r eferenc e fiber. The

reference fiber is mar ked with a red do t. Mou nt the refer ence head

OFV-151 on the re ferenc e fibe r as desc ribed in section 5.6.

2. Deac tivate the tr anspo rt safet y mechan ism on t he back of the se nsor

head by turning the sc rew with the All en key provi ded to po sition

MEASUREMENT (refer to sec tion 5.8).

3. Make s ure th at t he key s witch o n the co ntrol ler is in pos ition O.

4. Chec k the se tti ng on t he ma ins vo ltage s elec to r on the b ack o f t he

controller as well as the fuses.

5. Plug the conne cting cable into the Sub- D jack SIGNAL PROC ESSOR on

the back of the sensor head and into the Sub-D jack INTERFEROMETER

on the back of the co ntroll er. Fix the connections with th e screw s

provided.

All connections must be easy to plug in. If not, check the plug for bent

contact pins to avoid serious damage being incurred.

6. Use the ea rthe d mai ns c abl e t o conne ct the c ontr olle r to a w all ou tlet

providing protective grounding.

7. Swi tch the con troll er on by turn ing th e key switc h to posit ion I.

3-14

On the front of the con troller th e LED POWER lights up. Providing the

connecting cable has been installed correctly, the LED STANDBY on the

sensor head also lights up. Laser light is not yet emitted as the beam

shutter is still closed.

8. Bef ore now opening the beam shutter, remember the information on laser

safety provided in secti on 1.1!

9. Open the beam shutter on the sensor head by pressing the key LASER on

the front of the s ensor h ead.

The LED ON on the sensor head lights up. At the same time the LED

STANDBY goes out. The laser beam is now emitted from the mini

sensor.

3 First Steps

Test

10. Put a piece of reflective film (enclosed in this manual) at approximately

12cm from the f ront lens o f the mi ni s en sor in th e b eam pa th.

11. Focus the laser be am on the reflect ive film by turn ing the m ini sens or.

Providing the sensor head and the input section of the controller are

working correct ly, the signal level dis pla y wi ll full y l ight up.

12. If you have not been able to observe the effect described under 11., check

the signal level again after 20 minutes. After this warm-up phase the laser

has reached its working tem peratur e (refer also to section 4.2.4).

If the functional test has be en succ essful yo u can now make me asure ments

as described in cha pter 4.

If your vibro met er d oes not p erfo rm as d esc ribe d ab ove, read t hrou gh the

information on fault diagnosis provided in c hapte r 6 and, if necessary, contact

your local Pol ytec repr es entative.

3-15

3 First Steps

3-16

4 Making Measurements

4.1 Start-up

4.1.1 Vibrometer with Sensor Head OFV-303/-353

4 Making Measurem ents

Setup

Switching on

1. Make su re that the key switch on th e cont roller is i n position O an d the

beam shutter on the se nsor head are in positi on OFF.

2. Fix the sensor head as appropriate with the M6 or 1/4" threaded mounting

holes onto a universal tr ipod with a fl uid head. This ensu res sec ure

support and makes it easier to focus on the object.

3. Position the sensor head according to the information on optimal stand-off

distances in section 4.2.4.

4. Align the sen sor hea d such that the laser beam points al ong th e velocity

vector to be measure d i.e. in ge neral pe rpend icular to the surf ace of the

object.

5. Switch th e controll er on by turni ng the key swi tch to positi on I. Please

allow 20 minutes for the las er t o warm up b efor e making m eas urem ents.

On the front of the controller the LED POWER lights up. Providing the

connecting cable has been installed correctly, the LED LASER on the

sensor head also lights up. Laser light is not yet emitted as the beam

shutter is still closed.

6. Before now opening the b eam shutter, remember the information on laser

safety provided in sectio n 1.1!

Measuring

7. Open th e beam shu tter on th e senso r head.

The laser beam is now emitted from the sensor head.

8. Focus the l aser be am on the surface of th e obje ct.

The signal-to-noise ratio is maximal if the signal level display fully lights

up. You can often still make measurements even if none of the bar LEDs

is lit up. The output signal in this case, however, contains more noise.

9. If the signal level is low or highly fluctuating, change the stand-off distance

by 10cm as it may be that the se nsor head has been positio ned at an

unsuitable distance (refer to sect ion 4.2.4).

4-1

4 Making Measurements

4.1.2 Vibrometer with Sensor Head OFV-511/-512

Setup

Switching on

1.

OFV-511

: If desired, exchange the mini sensor with a fiber head (refer to

section B.3).

OFV-512

: If desired, exchange both mini sensors with fiber heads (refer to

section B.3) or for single point m easu rements exc hange the min i sensor

of the reference fi ber with a refer ence he ad (refe r to section 5 .6 and

section B.1) and the other mini se nsor with a fiber hea d.

2. Make s ure th at t he key s witch o n the co ntrol ler is in pos ition O.

3. Fix the mini se nsor as a ppropri ate to th e flexib le arm OFV -039 (ref er to

section B.4) or to the OFV- 036 . This ensur es a se cur e positi on an d make s

it easier to focus on the object.

4. Pos ition th e mini sensor or fi ber he ad acco rding to the infor mati on on

optimal stand-off distance s in section 4.2.4.

5. Align the min i sensor or fiber head su ch that th e laser bea m points along

the velocity ve ctor to be me as ured, i. e. i n ge ne ral per pend icul ar t o the

surface of the object.

6. Swi tch the con troll er on by turn ing th e key switch to positi on I. Please

allow 20 minutes for the laser to warm up before making measurements.

On the front of the con troller th e LED POWER lights up. Providing the

connecting cable has been installed correctly, the LED STANDBY on the

sensor head also lights up. Laser light is not yet emitted as the beam

shutter is still closed.

Measuring

7. Bef ore now opening the beam shutter, remember the information on laser

safety provided in secti on 1.1!

8. Open the beam shutter on the sensor head by pressing the key LASER on

the front of the s ensor h ead.

The LED ON on the sensor head lights up. At the same time the LED

STANDBY goes out. The laser beam is now emitted from the mini

sensor or fiber head.

9. Foc us the lase r beam on the sur face of th e object.

The signal-to-noise ratio is maximal if the signal level display fully lights

up. You can often still make measurements even if none of the bar LEDs

is lit up. The output signal in this case, however, contains more noise.

10. If the signal level is low or highly fluctuating, change the stand-off distance

by 10cm as it ma y be that th e mini sensor or fi ber he ad has be en

positioned at an unsuitable distance (refer to section 4.2.4).

4-2

4.1.3 Displaying the Output Signals

To display the out put sign als, p rocee d as f ollow s:

4 Making Measurem ents

Velocity

signal

Displacement

signal

(optional)

1. Connect an oscillosc ope to the BNC jac k VELOCITY OUT PUT on the

front of the controller.

With a suitable selected measurement range, the expected signal form

should be visible at the VELOCITY OUTPUT.

2. Select t he next hig hest me asurem ent ra nge if the LED OVER is

continuously lit up at the front of the controller (refer to section 4.2.2).

Then the maximum velocity exceeds the full scale range. The display

may light up briefl y while a di fferen t velocit y measur emen t range is

being set or due to noise spikes.

3. Incre ase th e intens ity of the light sca ttered back by va rious su rface

materials.

The noise level of the velocity output decreases. The minimum noise

level shows the optimal alignment and focusing for the surface quality

present.

4. Connect an oscilloscope to the BNC jack DISPL ACEMEN T OUTPUT on

the front of the con trolle r.

At the DISPLACEMENT OUTPUT, as a general rule the expected signal

form can not be seen initia lly.

5. Press the CLEAR k ey seve ral ti mes .

Sign

convention

After pres si ng t he k ey sever al t i mes, t he expe cted signa l fo rm shoul d be

visible on the oscilloscop e (refer to section 4.2.3, CLEAR fun ctio n). I f

not, then the displ acement measurement range i s unsuit able and shou ld

be selected according to the information provided in sec tion 4.2.3.

The following sign co nventi on for direct ion appl ies to th e output si gnals:

A movement

towards

the sensor head is con sidered as bein g

positive

. In

this case the ve locity outpu t voltage is positi ve and the dis place ment ou tput

voltage is increasing.

4-3

4 Making Measurements

vˆ2πfx

ˆ

v

ˆ

velocity amplitude

x

ˆ

displacement amplitude

f…frequency

m

3

13–

4.2 Selecting Suitable Settings

4.2.1 Velocity or Displacement Measurement ?

The vibrometer can p rovide both veloc ity and disp laceme nt signa ls

independently of ea ch other. If the vibrometer is equipp ed with both ve locit y

and displacement decode rs, for m any mea sure ments a deci sion then has to

be made on which is th e optimal quantit y to be me asured. This appli es in

particular to harmo nic vibrat ions, as i n this case the vel ocity an d the

displacement si gnal prov ide the sa me info rma tion acc ording t o

Dynamic

range

⋅⋅=

Equation 4.1

…

…

In contrast, transient movements in most cases are shown much more clearly

by the displacement signal.

Apart from these applica tion -specif ic aspec ts, there are som e asp ects

affecting the cho ice of the q uanti ty to be m easur ed wh ich depen d on the

measurement proce dure. The se are expl ained in the following .

Due to the 12 bit digital resolution of the fringe counter system, the relative

resolution of each di splace ment mea sureme nt rang e is 2048 steps with a

symmetric outp ut voltage sw ing. This corre spond s to a dyn amic ra nge of

approximately 6 6dB. Th e backg round noise lies ge neral ly below the

resolution a nd ther efor e do es no t a ffect t he m e asure m ent.

In contrast, the resolution in velocity measurement is only limited by the

background noise . Wi th good o pt ical si gna ls ( e.g . o n refl ec tive fi lm) and a

spectral resol ution ban dwidth of s ev eral Hert z, t he b ac kgrou nd n oise is

typically more than 100dB below fu ll scale ran ge. This co rres ponds to a

dynamic range whi ch i s a bo ut 1 00 time s h ig her t han th at o f th e dis plac em ent

measurement.

Resolution

Signal-tonoise ratio

4-4

If the absolute, noise limited resolution of the velocity decoder (approximately

µ

--------

0.2 ) is rearranged according to equatio n 4.1 to obtain th e

Hz

⁄

s

corresponding amplitude of a sinusoidal vibration with a frequency of 100kHz,

this results to approximately mm or 0.3pm! This means that with high

10

⋅

frequencies in part icular, significan tly h igher res ol utio ns c an be attai ne d wit h

the velocity meas uremen t.

The vibration to be meas ured is usually sup erimp osed by int erfer ence

vibrations from th e surroun dings or fr om the o bject itself. The se back grou nd

vibrations (e.g. bui lding vibr ations ) often hav e low frequ encies bu t hig h

displacement amplitudes. To prevent overranging, the displacement

measurement range must be selected taking the amplitude of the background

vibrations into co nsidera tion. I f the requ ired sig nal is then re solve d at all, at

least a bad signal-t o-noise ratio is o btained at th e outp ut.

4 Making Measurem ents

f

100kHz=

x

ˆ

1µm

v

ˆ

/s

f

100Hz

x

ˆ

10µm

v

ˆ

/s

aˆ2πfv

ˆ

a

ˆ

acceleration amplitude

v

ˆ

velocity amplitude

f…frequency

The situation for the velocity measurement is however quite different. For the

same displacem ent amp litude but a higher fr equen cy, the velocity amplitude

of the required sign al is a fact or of 2π⋅f higher than the backg roun d vibrat ion

(refer to equation 4.1). Thus at velocity measurement the signal-to-noise ratio

is higher per defini tion. A real istic ult rasound applica tion should m ake this

clearer:

Vibration to be measured: e.g.

Background vibr ation: typically

Thus the signal-to-noise ratio here for velocity measurements is two orders of

magnitude highe r, even with a 10 times higher am plitude of the backg round

vibrations. If the di splacem ent signa l is expre ssly required , it can be

calculated very pr ecisely by exte rnal sig nal inte gratio n after cutting off the

interference frequ encies be low 1kH z with a suitable hig h pass filter.

4.2.2 Settings for Velocity Measurement

Measurement

range

When selecting a sui table velo city me asurem ent rang e the m aximu m

expected values for velocity, acceleration and frequency have to be taken into

consideration. Or ientat ion purel y on t he v el ocity i s often n ot eno ugh , as t he

various velocity decode rs and m easu rement ranges ha ve different

bandwidths and maxim um acce lera tions. The resp ective val ues are given in

the specifications (refer to section 7.1.4 ).

⇒

⇒

Signal

Signal

Background

Background

,

628, 101–m

⋅=

<

628, 103–m

,

⋅<

=

Signal

(refer to equation 4.1)

Background

<

It is easiest to select the velocity measurement range for the universal

decoder

OVD-02

. As long as the frequency remains below 250kHz, any of the

four measurement ranges can be selected. To maximize the signal-to-noise

ratio however, the smallest possible range should be used in which the output

signal is not clipped. For frequenc ies abov e 250kHz only the top three

measurement ra nges are su itable. Accel eratio n limits usually do not have to

be taken i nt o cons ider ati on. Even w ith ma ximu m amp litud e, i t can sti ll pr oce ss

the highest specif ied freq uency in ev ery meas ureme nt range.

With the decoder

OVD-01

the technical limits for acceleration have to be

taken into cons ider atio n in s ome v eloc ity m easur eme nt ran ge s. Ac co rd ing to

the relation

⋅⋅=

Equation 4.2

…

…

4-5

4 Making Measurements

in these ran ges t he per mis sibl e f reque ncy d ecre ase s wi th inc reasi ng

amplitude. If the co nditio n 4.2 is infringed upon, the signal is seriously

distorted. In this ca se, a highe r velo city me asurem ent rang e has to be

selected.

In all velocity me asurem ent ra nges the LED OVER on the front of the

controller lig hts up if either the po sitive or negative en d of range is exceeded.

As a general rule, the n ext highe st meas uremen t rang e should t hen be

selected. Please no te howe ver, that the LED is activated by very sho rt

overrange already which could be caused by noise spikes. In such cases the

velocity measur ement r ange ca n be retained as long as it is suitable for the

amplitude of the r e quired signal. Observing the signal on the oscilloscope will

provide clarificatio n on this (r efer to se ction 4.1.3).

Tracking filter

The tracking filter i s used to improve th e sign al-to-no ise rati o of the inp ut

signal from the sensor head. This is advantageous to bridge short dropouts in

particular, which always occur due to th e speck led natur e of the ligh t

scattered back from the object. The bridging capability is generally better with

a high time constant SLOW, however it may not be possibl e to follow highl y

dynamic signals any m or e. In th is cas e FAST or OFF has to be se lect ed. Th e

best setting therefore has to be determined from case to case or be estimated

based on the range di agram in 4.1 . The rang e diagram shows the dynam ic

limits for both settin gs of the tr acking filter, plotted versus t he freque ncy.

V e l o c i t y / m / s

1 0

3

1

0 . 3

0 . 1

v e l o c i t y l i m i t 3 m / s

S

L

O

W

a

c

c

e

l

e

r

a

t

i

o

n

l

i

m

i

t

f r e q u e n c y l i m i t 1 0 0 k H z

4-6

0 . 0 3

0 . 0 1 0 . 0 3 0 . 1 0 . 3 1 3 1 0 3 0 1 0 0 3 0 0

F r e q u e n c y / k H z

Figure 4.1: Range diagram of t he t racking filter

A constant velocity limit of approximately 3 m/s is characteristic for the lower

frequency range . If the vel ocity ex ceeds this value, the tr acking f ilter can

generally not be used and has to be swi tched off. For sp ecial ap plicatio ns a

tracking filter can be installed for which this velocity limit does not apply. This

is however coupled at wo rse noise suppr ession.

In the medium fre qu ency ra ng e, the velo city limi t chan ge s over t o be come an

acceleration li mit i .e. th e vel oc ity li mit decr ea ses inve rs ely p ro port ional to t he

frequency (refer to equ ation 4.2).

4 Making Measurem ents

mm

s

-

V

mm

s

-

V

In the upper frequ ency rang e, a cons tant velocit y limit be comes effec tive

again.

To set the tracking filter, the range diagram in figure 4.1 can be summarized

with the following rules of thumb:

•

Below a particular veloc ity, no dynamic limits have to be taken into

consideration. Thus in the lower measurement ranges (1 and

-------- -

5 ) the setting S LOW ca n gener ally be se lect ed.

•

For medium velocities and frequencies, the acceleration limits of the

-------- -

tracking filter have t o be taken in to cons ideratio n. The opt imal se tting

must be found with the range diagram. If the velocity or acceleration limits

are exceeded, th e tracki ng filter loses lock (refer t o sec t ion D.2). T his w i ll

cause serious signal distorti ons an exam ple of which can be see n on the

oscilloscope trac e in figure 4.2. The signal A sho ws a sinu soidal ve locit y

signal with the trackin g filter in position OFF. Signal B shows the signal

with the tracking filter in position SLOW. The tracking filter is on the limit of

the range where it loses lock, th e signa l is partly distor ted.

Figure 4.2: True velocity signal (A) and signal whe n th e tracking f ilte r lo ses lock (B)

•

For frequencies a bo ve 10 0k Hz as a gen eral rul e the tra ck ing f ilter shou ld

be switched off. In principle it can follow high er frequenc ies bu t in this

range amplitude er rors of up to appro ximat ely 10% can occ ur due to

dynamic errors .

With good o ptic al s i gnals , t he trac king fi lter can n ot i mpr ove th e signa l-t onoise ratio due to physi cal re asons . It shoul d be swit ched off if unfavor able

effects are observed.

4-7

4 Making Measurements

Low pass

filter

The controller is equi pped with an adjustable lo w pass filter which ad apts the

bandwidth of the mea sureme nt sig nal to the respe ctiv e applica tion. W hen

displaying a signal in the time domain, t he signal -to-no ise rati o can be

improved by limit ing the ba ndwidth to th e neces sary ex tent. W hen ana lyzing

in the frequency do main wi th an ex ternal FFT analy zer, filters only play a

subordinate role. Here they c an prev ent the FFT analyzer from ove rrangi ng

due to noise s pi kes.

In the OFV-3001 controller, low pass filters with 3rd order Besse l

characteristic s are used. Charac terist ic of thi s type o f filter is the phase

linearity from the frequency zero up to the cutoff frequency i.e. the phase shift

increases propo rtio nall y to t he f requ enc y. These filters howev er ca use

amplitude errors in the passband wh ich can be ro ughly est imated:

•

Up to 40% of the cutoff frequen cy, the amplitude error is les s than -5%.

This range can be considered to be exact for amplitude measurement.

•

Up to 70% of the cut off frequen cy, the amplitude error increas es to abo ut

-15%.

•

The upper 30% of the passban d should on ly be used f or orientatio n

measurements. At the cutoff frequ ency of the filter, the amplitude er ror is

-3dB (approx imatel y -30% ).

The phase shift increase s propo rtiona lly to the fr equen cy from close to ze ro

degree at a few Hertz to approxi mately -100 degrees at th e cuto ff frequency

(refer to figure 4.5). Due to this linear phase frequency response , the fi lter

shows optimal transm issio n behavio r for pul ses as all fre quencie s of a

complex wave a re s ubj ecte d to the s ame ti me del ay. Thus the sha pe of th e

pulse is n ot fal sif ied bu t it is me rely dela yed.

The complete amplitu de freque ncy respo nse of a 3rd or der Be ssel low pass

filter is shown in figure 4.3. The frequency is nor mali zed to the cu toff

frequency fc.

A m p l i t u d e / d B

1 0

0

- 1 0

- 2 0

- 3 0

- 4 0

- 5 0

- 6 0

0 . 1 0 . 2 0 . 5 1 2 5 1 0 2 0

f

f

C

4-8

Figure 4.3: Amplitude frequency response of a 3rd order Bessel low pass filter

4 Making Measurem ents

The amplitude e rror caus ed by th e filter can be de termi ned from figure 4.4.

A m p l i t u d e e r r o r / %

0

- 5

- 1 0

- 1 5

- 2 0

- 2 5

- 3 0

0 . 0 0 . 1 0 . 2 0 . 3 0 . 4 0 . 5 0 . 6 0 . 7 0 . 8 0 . 9 1 . 0

f

f

Figure 4.4: Amplitude error of a 3rd order Bessel low pass filter in the passband

The phase fre quenc y resp ons e of the f ilter is shown in figure 4.5.

P h a s e / d e g r e e s

0

- 2 0

- 4 0

- 6 0

- 8 0

C

- 1 0 0

0 . 0 0 . 2 0 . 4 0 . 6 0 . 8 1 . 0

f

f

C

Figure 4.5: Phase frequency respo nse of a 3r d or der Be ssel low pass filt er i n th e passband

4-9

4 Making Measurements

f

f

f…frequency in kHz

f

cutoff frequency of the low pass filter in kHz

p

specific phase roll-off

xˆvˆ2πfx

ˆ

const.

v

ˆ

velocity amplitude

x

ˆ

displacement amplitude

f…frequency

An additional time delay is caused by the velocity decoder. It depends on both

velocity decoder and velocity measurem ent range and is approx imately a few

microseconds. Th e resul ting ove rall phase shift ∆Φ can be estimate d using

the following simple eq uation :

∆Φ 100°

…

c

…

d

(refer to sectio n 7.1.4)

---

p

⋅+⋅=

d

f

c

4.2.3 Settings for Displacement Measurement (optional)

Measurement

range

The most important cons ider ation for se lectin g the displ aceme nt

measurement range is of course the maximum expected displacement. To

prevent the displac em ent de code r over ran ging h owever, a highe r

displacement mea surem ent ran ge often ha s to be selec ted if low fr equen cy

interference vib ration s are pre sent. Bas icall y the displ aceme nt meas uremen t

range should be se lected such th at the out put sign al is as hig h as possib le

but with its peak value s defini tely rem ainin g below th e maxim um sig nal

amplitude of ±8V (refer als o to section 4.2.3, CLEAR funct ion).

Another aspect is the m axi mum ex pec te d ve lo city. For technical reas ons , the

absolute veloci ty limit of the vibro meter (10m/s) can only be made us e of in

the upper displaceme nt meas uremen t rang es (80µm/V; 320µm/V; 1,280µm/

V; 5,120µm/V). In the lower displac ement measure men t ranges, howeve r,

several counts per frin ge are gene rated by i nterpol ation where by band width

and count frequen cy multip ly corre spond ingly (ref er to se ctio n D.5.3). As a

result, the maximum permissible v elocity decreases to about the same extent

as the displacement resolution increases. Due to this correlation, the peak

values of the lower displac ement measure men t ranges ( 0.5µm/V; 2µm/V;

8µm/V; 20µm/V) can onl y be made use of fo r freque ncies o f up to

approximately 2.5kHz. Above this value t he maxim um mea surable amplitud e

decreases with increasi ng frequ ency ac cording to eq uation

Equation 4.3

…

…

From the correlat ions desc ribed, it can be conc luded th at the fre quenc y also

has to be taken into consideration when selecting the displacement

measurement range. The specified maximum frequency can only be

measured in the uppe r disp lacem ent measur eme nt ranges . In the lo wer

ranges there are tech nical lim its which can not be excee ded, even when in

compliance with condition 4.4. Furthermore, attention must be paid to the fact

that the specified accur acy is only compli ed with up to a chara cteris tic

maximum frequency (refer to section 7.1.5).

The resulting rang e diagr am for al l measu remen t range s is show n in

figure 4.6.

4-10

⋅⋅

==

Equation 4.4

x / mm

1 0 0 , 0 0 0

5 0 , 0 0 0

4 0 , 0 0 0

2 5 , 0 0 0

4 Making Measurem ents

5 , 1 2 0 mm / V

1 0 , 0 0 0

5 , 0 0 0

2 , 5 0 0

1 , 0 0 0

6 4 0

5 0 0

2 5 0

3 2 0

1 0 0

1 , 2 8 0 mm / V

3 2 0 mm / V

8 0 mm / V

2 0 mm / V

x

m / s

v

m a x

=

1

0

v

m a

x

=

=

1 m

/

m / s

5

m / s

s

6 4

5 0

2 5

1 6

1 0

5

4

2 . 5

8 mm / V

2 mm / V

0 . 5 mm / V

v

m a

v

m a

x

=

0

. 2

v

m a

x

= 0 . 0 6

5

m /

s

1

0 . 5

0 . 2 5

0 . 1

p r a c t i c a l l o w e r a m p l i t u d e l i m i t

2 5 k H z

7 5 k H z

2 5 0 k H z

1 0 2 5 5 0 1 0 0 2 5 0 5 0 0 1 k 2 . 5 k 5 k 1 0 k 2 5 k 5 0 k 1 0 0 k 2 5 0 k

f / H z

Figure 4.6: Combined range diagr am fo r t he displacement decoder s OVD-1 0, OVD- 20 an d

OVD-40

When the measurement range limits shown in figure 4.6 are exceeded,

overrange effects and los s of lock ca n occur w hich ma ke a useful evaluat ion

of the signal impossi ble (refer also to figu re 4.8).

4-11

4 Making Measurements

mm

s

-

V

mm

s

-

V

Optimizing the

RF bandwidth

Using the

CLEAR

function

The input of the vibrom eter is equi pped with an RF band- pass filter (r efer to

section D.2). To ac hieve opti mal ada ptation to the FM -sign al bandwi dth, the

RF bandwidth is automat ically adjuste d accordi ng to the ve locity

measurement ran ge set. As this process also affects the inpu t signal of the

displacement dec oder, the setting of th e velocity measu rement range is

relevant, even i f only the displac emen t output is being us ed.

The signal-to-noise ratio of the displacement measurement can be improved

with targeted lim itation of t he R F ban dwidth which i s part icular ly i mpo rtant in

the case of weak opti cal signal s. This m eans th at the vel ocity mea sure ment

range should be sel ected to be as low as the appl ication al lows. Th e

maximum veloc ity mu st not e xceed t he r es pecti ve ful l s cale rang e i.e. 10

times the scaling factor ( e.g. 50mm/s for th e measur eme nt range 5 ). If

-------- -

the LED VELOCITY OVER l ights u p co ntin uou sly or t he d is plac eme nt s ignal

breaks down, the nex t highes t velo city me asurem ent rang e has to be

selected.

If however the optica l signal is constantly good, the r ange 1,00 0 should

-------- -

be selected as it does not limit the bandwidth and therefore its influence does

not need to be taken into consider ation.

As there is no lower freq uency limit for th e disp laceme nt decode r, it can also

measure stationary signals (DC). After setting a certain displacement

measurement ran ge, a certai n voltage is pres ent at the output (t he so-cal led

DC offset) which depends on th e distance of the objec t to the sen sor head

and on the thermal drift of the inte rferomet er. Dynamic displaceme nts of the

object (AC) are c or rect ly adde d to or subt ract ed fr om thi s DC o f fs et as lo ng a s

the output v oltage does n ot e xce ed ±8V. Otherwise the output voltage will

jump from the posi tive end of range to the neg ative and vice vers a as the

internal cou nter o verf low s (r ef er t o sect io n D.5.3), and as a resu lt the AC

signal is distorted. Thi s is shown as an exam ple in the osc illos cope trac e in

figure 4.7.

Figure 4.7: Displacement signal whe n the count er overfl ows due a DC offset

4-12

4 Making Measurem ents

Before ma king a me asu rem en t, t he D C o ffset s ho ul d th er efor e be re se t to

zero to make use of the full displ acemen t measu rement range . This can be

done by pressing th e CLEAR ke y on the fron t of the co ntroll er or by fee ding

an electrical pulse to the cor respond ing BNC jack . The la tter is partic ularly

advantageous in the case of periodic signals with a superimposed translation.

In such cases the cou nter quickl y overfl ows due to the DC signal of t he

translation. A higher di splacem ent meas ureme nt range m ust be sele cted

which then, howeve r, provides worse resolution of the vibration . The best AC

resolution can be maintain ed howe ver, by periodically resett ing the co unte r

and thus supp re ss ing unw anted D C d rift o f the s ignal .

The CLEAR signal does not necess arily have t o be provided external ly but

can in the simplest case be taken from the VE LOCITY OUTPUT itself. Eac h

zero crossing of a rising velocity signal then resets the displacement decoder.

This requires how ever a ce rtain qualit y of the vel ocity si gnal. If it is too noi sy,

the displacem ent sign al b eco mes u nstable . As t he CL EAR inp ut has a

relatively low input impeda nce, an am plitude er ror of -5% to -10% is indu ced

at the velocity out put in thi s type o f operatio n (refer to sect io n 7.1.5).

Tracking filter

The correlations sh own in sect ion 4.2.2 for the tra cking fi lter also ap ply in

principle for the displace ment mea surem ent. If the rang e limits shown in

figure 4.1 are exceeded the tracking filter loses lock and induces phase jumps

in the input signal whic h make th e displac ement signal disc ontinuo us.

The oscilloscope tr ace in figure 4.8 shows the distorted displacement signal

of a sinusoidal vibra tion at an ac ce lerat ion wh ere t he tra cking fil ter lose s lo ck.

Figure 4.8: Displacement signal when th e tr acking filte r lo ses lock

In this case the velo city sign al sho uld be eval uate d and the m ost suitable

setting for the tracking filter should be determined with the aid of figure 4.1.

4-13

4 Making Measurements

232mm n 203mm

+

135mm n 203mm

+

0mm n 203mm

+

63mm n 203mm

+

4.2.4 Optimal Stand-Off Distances for the Sensor Heads

OFV-303/-353

OFV-511

OFV-512

The stand-off distance is me asur ed from the fro nt pa nel of th e s en sor hea d

OFV-303/-353. Th e optimal stand-off distances are:

⋅

, n = 0; 1; 2 ; .. .

i.e. at 232 mm; 435mm; 638mm; etc.

The stand-off distance is measured from the shoulder of the connector for the