Page 1

110-031 PSC/EN

Operator’s Manual

General Purpose Water Baths

110-031 PSC/EN 25 February 2014

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

110-031 PSC/EN

Table of Contents

Introduction ........................................................................................... 2

General Safety Information .............................................................. 2

Safety Recommendations ................................................................ 3

Regulatory Compliance & Testing .................................................... 4

Unpacking Your Water Bath ............................................................. 4

Contents ........................................................................................... 4

LCD Display ..................................................................................... 5

Keypad ............................................................................................. 5

Installation and Startup ......................................................................... 6

General Site Requirements ............................................................... 6

Adding Liquid to the Reservoir .......................................................... 6

Electrical Power ................................................................................ 8

Controller Setup ................................................................................ 8

Power On .......................................................................................... 8

Selecting the Temperature Unit ........................................................ 8

Setting the High Limit Value .............................................................. 9

Setting the Temperature Presets ...................................................... 9

Normal Operation .................................................................................10

Keypad Controls ............................................................................... 10

Turning Your Water Bath ON ............................................................ 10

Adjusting the Set Point Temperature ................................................10

Setting and Using the Timer ............................................................. 11

Using the Temperature Presets ........................................................11

Entering a Calibration Offset ............................................................12

Resetting the Factory Default Values ............................................... 13

Loss of Power Restart ...................................................................... 13

Displaying the Firmware Version ......................................................13

Display Messages and Alarms ............................................................14

Routine Maintenance & Troubleshooting ...........................................15

Draining the Bath Reservoir ............................................................. 15

Resetting the Over Temperature / Low Liquid Level Safety .............15

Cleaning the Bath ............................................................................16

Troubleshooting Chart ......................................................................16

Technical Information ..........................................................................17

Performance Specications .............................................................17

Reservoir Fluids ...............................................................................18

Application Notes .............................................................................19

Equipment Disposal (WEEE Directive) ............................................... 20

Service and Technical Support ...........................................................21

Warranty ................................................................................................21

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

110-031 PSC/EN

Introduction

Thank you for choosing this Water Bath. It is designed to handle a wide

range of laboratory procedures including: incubation, inactivation and agglutination as well as most pharmaceutical, serological, biomedical and

industrial procedures.

To ensure optimium temperature uniformity, your Water Bath features

an energy efcient, large-area heater and thermostatic control. Its PID

microprocessor control (Proportional Integral Derivative) system provides

proportional heat control by anticipating the approach to your set point

temperature and preventing overshoot. A redundant safety thermostat is

standard on all models.

General Safety Information

When installed, operated and maintained according to the directions in

this manual and common safety procedures, your Water Bath should

provide safe and reliable temperature control. Please ensure that all

individuals involved in the installation, operation or maintenance of this

Water Bath read this manual thoroughly prior to working with the unit.

This symbol marks chapters and sections of this instruction

manual that are particularly relevant to safety. When attached

!

to the unit, this symbol draws attention to the relevant section

of the instruction manual.

!

This symbol indicates that hazardous voltages may be

present.

This symbol indicates that hot surfaces or liquids may be

present.

This symbol marks information that is particularly important.

This symbol indicates alternating current.

These symbols on the Power Switch indicate that they place

the main power supply ON/OFF.

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

110-031 PSC/EN

This symbol on the Power Button indicates that it places the

unit in a standby mode. IT DOES NOT fully disconnect the

unit from the power supply.

This symbol indicates a protective conductor terminal.

Read all instructions pertaining to safety, set-

up and operation. Proper operation is the user’s

responsibility.

Safety Recommendations

To prevent injury to personnel and/or damage to property, always follow

your workplace’s safety procedures when operating this equipment. You

should also comply with the following safety recommendations:

WARNING:

• Always connect the power cord on this Water Bath to a

grounded (3-prong) power outlet. Make certain that the

outlet is the same voltage and frequency as your unit.

• Never operate the Water Bath with a damaged power

cord.

• Always turn the Water Bath Off and disconnect mains

power before performing any maintenance or service.

WARNING:

• Never operate the Water Bath without bath uid in the

reservoir. Periodically check the reservoir to ensure that

the liquid depth is within acceptable levels. Always rell

the reservoir using the same bath uid type that is already

in the reservoir. Bath oil must not contain any water

contaminants and should be preheated to the actual bath

!

temperature before adding as there is an explosion hazard

at high temperatures.

• Use compatible bath uids only.

• Always drain all uid from the reservoir before moving

or lifting your Water Bath. Be sure to follow your

organization’s procedures and practices regarding the

safe lifting and relocation of heavy objects.

WARNING: Always allow the bath uid to cool to ambient

temperature before draining.

WARNING: It is the user’s responsibility to properly

decontaminate the unit in the event hazardous materials are

spilled on exterior or interior surfaces. Consult manufacturer

!

!

Find Quality Products Online at: sales@GlobalTestSupply.com

if there is any doubt regarding the compatibility of

decontamination or cleaning agents.

CAUTION: If the equipment is used in a manner not

specied by the manufacturer, the protection provided by the

equipment may be impaired.

3

www.GlobalTestSupply.com

Page 5

110-031 PSC/EN

Regulatory Compliance & Testing

This product has been tested to the requirements of CAN/CSA-C22.2

No. 61010-1, second edition, including Amendement 1, or a later

version of the same standard incorporating the same level of testing

requirements.

ETL (60 Hz units)

UL 61010-1 / CSA C22.2 No. 61010-1, 2nd Edition 07/12/04 (R

10/28/2008)

IEC 61010-2-010: 2003, CSA C22.2 No. 61010-2-010:2004/07/01 Ed:2

(R2009)

CE (50 Hz units)

Low Voltage Directive 2006/95/EC

EN 61010-1, 2nd Edition Issued March, 2001

EN 61010-2-010 2nd Edition Issued October, 2003

EMC Directive 2004/108/EC

EN 61326-1: 2006

Machinery Directive 2006/42/EC Annex I

All Units - RoHS2 2011/65/EU

Unpacking Your Water Bath

Your water bath is shipped in a special carton. Retain the carton

and all packing materials until the unit is completely assembled and

working properly. Set up and run the unit immediately to conrm proper

operation. Beyond one week, your unit may be warranty repaired, but not

replaced. If the unit is damaged or does not operate properly, contact the

transporation company, le a damage claim, then contact the company

where your unit was purchased.

WARNING: Keep unit upright when moving. Be sure to follow

!

your company’s procedures and practices regarding the safe

lifting and relocation of heavy objects.

Contents

The items included with your Water Bath are:

• Water Bath

• Gabled Reservoir Cover Assembly

• Sample Tray

• Operator’s Manual

• Quick-Start Guide

• Selection Guide

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

110-031 PSC/EN

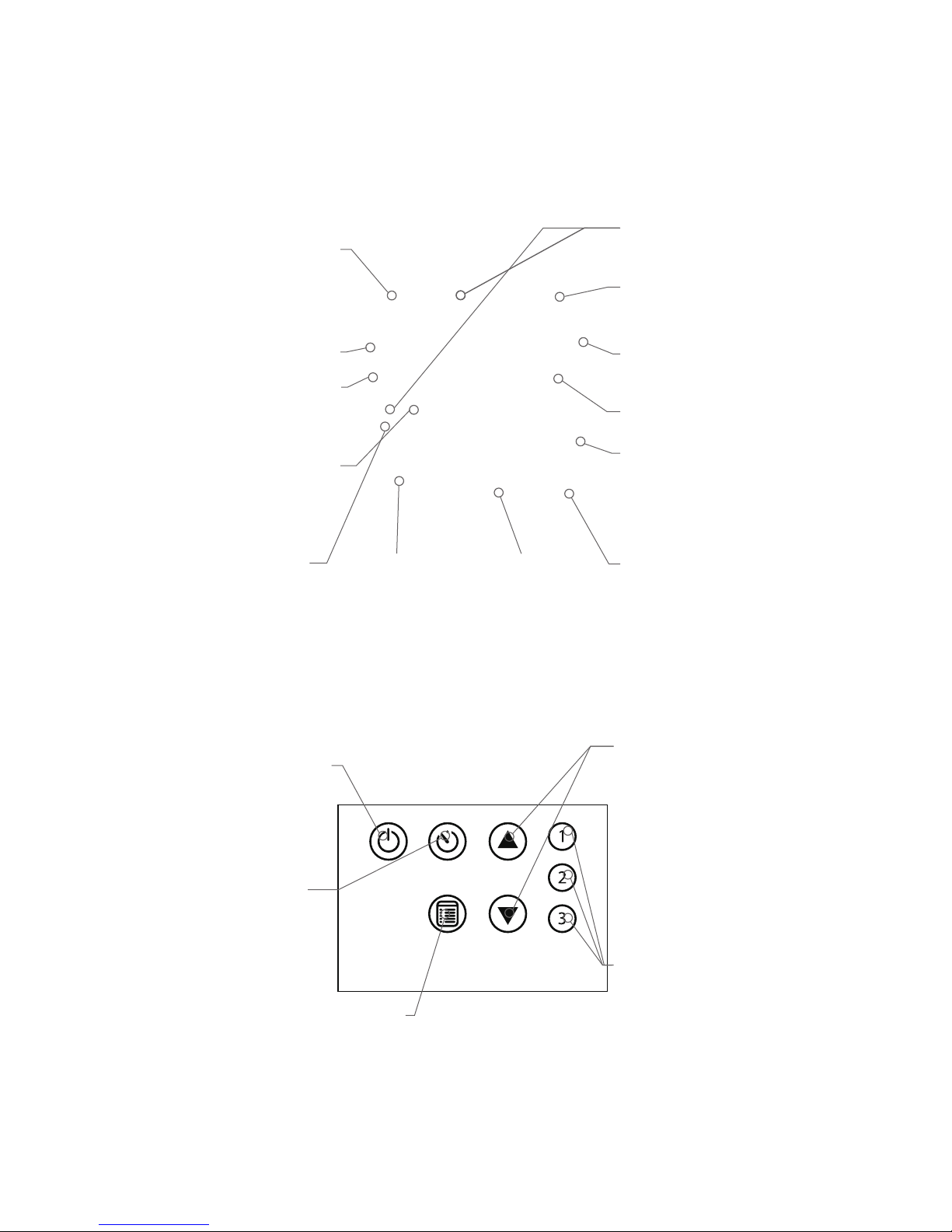

LCD Display

High Limit Warning

set point higher than

the High Limit value.

Lit steady when High

Limit value is being

warning condition is

Set Point Indicator

changed; lit steady

Timer Symbol

Lit when timer

is being set or

Indicator

Flashes if you

attempt to enter a

set

Heating Symbol

Lit when heater is

Fault / Warning

Lit when fault or

set point is being

active

Symbol

detected

Flashes when

during normal

operation

is in use

Over-Temperature /

Low Liquid Symbol

Lit when over-

temperature or low

liquid level fault is

detected

Loss of Power

Indicator

Lit when electrical

power is restored

after power disruption

Calibration Mode

Indicators

Lit when unit

calibration offset is

being set

Version Indicator

Lit when rmware

version ID is being

displayed on the

lower readout

Temperature Unit

Symbol

Shows

temperature unit in

use when lit

Upper Readout

Displays actual

bath temperature

Lower Readout

Displays set point

temperature

during normal

operation; displays

operational

information when

Menu button is

pressed

Temperature

Resets Indicator

Lit when preset

is being set or is

in use

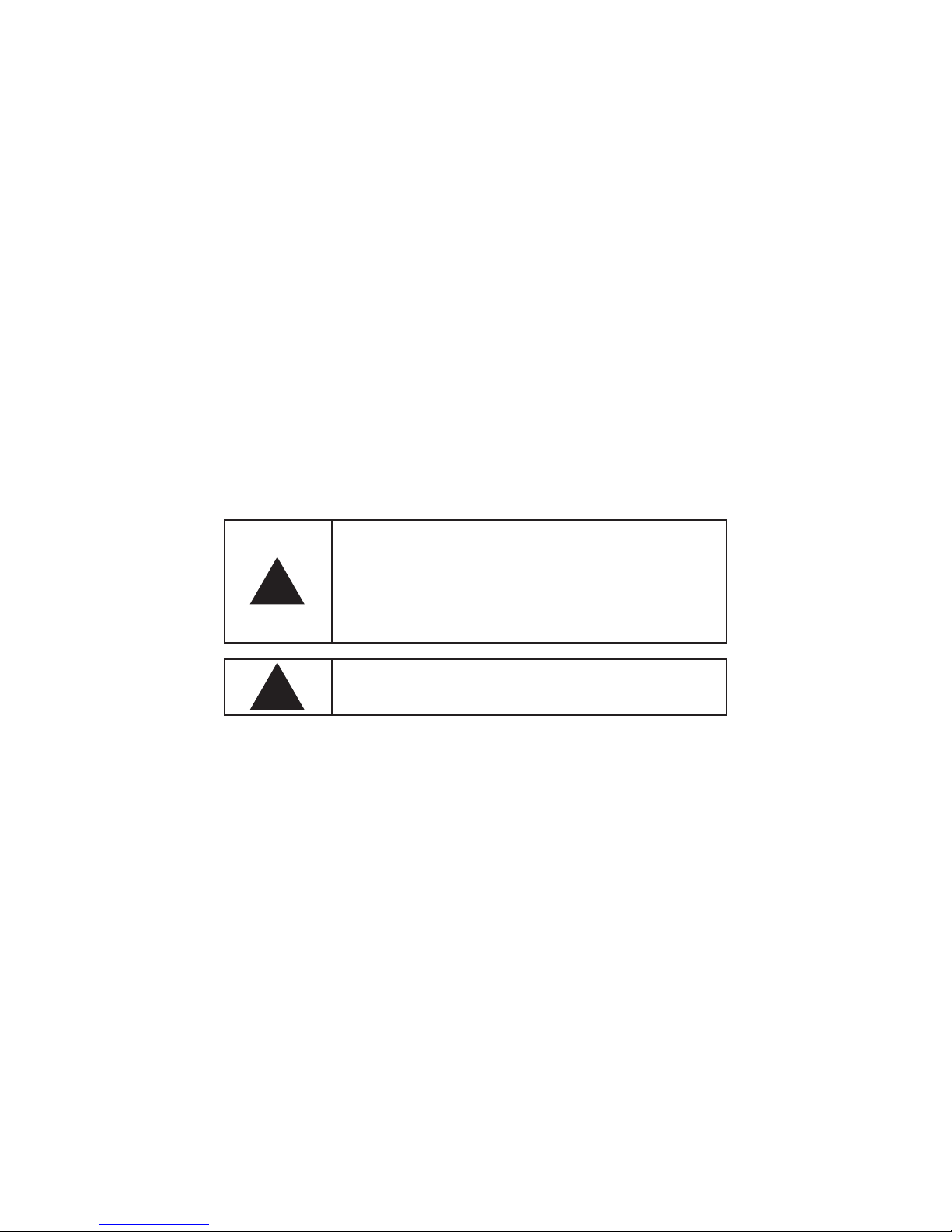

Keypad

Power Button

Turns power to

the Controller On

and Off

Timer Button

Used to start

and stop the

timer

Menu Button

Used to select and set various

operational parameters

Selection Buttons

Used to increase

or decrease

temperature

settings and

operational

parameters

Temperature

Preset Buttons

Used to select

frequently used

user-dened

set point

temperatures

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

110-031 PSC/EN

Installation and Startup

Your Water Bath is designed to be simple to setup and install. All that is

required is a container for adding water or another suitable uid to the

bath reservoir.

General Site Requirements

Locate your Water Bath on a level surface in an area that is free from

drafts and wide ambient temperature variations, such as near heater or

air conditioning vents. Do not place it where there are corrosive fumes,

excessive moisture, or in excessively dusty areas.

Avoid voltage drops by using properly grounded power outlets wired with

14 gauge or larger diameter wire and, if possible, be close to the power

distribution panel. the use of extension cords is not recommended; this

will reduce the potential for problems caused by low line voltage.

Adding Liquid to the Bath Reservoir

WARNING: Read the safety data sheet for the bath uid

being used carefully before lling reservoir.

WARNING: See Technical Information, Reservoir Fluids

!

(page 18) for a list of compatible liquids.

WARNING: If the proper uid level is not maintained, the unit

could possible by damaged (uid level too low) or the bath

may overow (uid level too high).

CAUTION: Fumes from acidic solutions may cause corrosion

!

Fill bath so that the liquid level is approximately one inch (2.54 cm) from

top when samples are placed in the bath.

To ensure accurate reading of temperature, the uid level should not be

less than 2 inches (5.08 cm) from the bottom of the unit. Operation of the

bath without uid will not damage the heater, but will cause permanent

discoloration of the tank and will not provide accurate temperature

information.

Distilled water is preferred for temperatures from 10° to 90°C (50° to

194°F). A variety of uids can be used with the bath depending on the

application. The uid must be compatible with 300 series stainless

steel. See Technical Information, Reservoir Fluids (page 18) for a list of

compatible uids.

If using water, a few drops of polyclean Algaecide (part number 004-

300040) should be used to help prevent algae formation.

of the stainless steel reservoir. Care should be taken to

maintain a neutral pH at all times.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

110-031 PSC/EN

WARNING: Always drain all uid from the reservoir before

moving or lifting your Water Bath. Be sure to follow your

!

organization’s procedures and practices regarding the safe

lifting and relocation of heavy objects.

WARNING: To avoid the potential for burns, allow the Water

Bath to cool completely before cleaning or performing any

maintenance.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

110-031 PSC/EN

Electrical Power

WARNING: The Water Bath’s power cord must be connected

to a properly grounded electrical receptacle. Make certain

that this electrical outlet is the same voltage and frequency as

your Water Bath. The correct voltage and frequency of your

Water Bath are indicated on the identication label on the

rear of the unit.

CAUTION: The use of an extension cord is not

recommended. If one is necessary, it must be properly

!

Insert the power cord into a properly grounded

electrical outlet.

Place the Mains Switch on the rear of the unit in the

On position. The three decimal points in the upper

readout light to indicate that the Water Bath is in the

Standby mode.

grounded and capable of handling the total wattage of the

unit. The extension cord must not cause more than a 10%

drop in voltage to the unit.

Controller Setup

Power On

1. Place the Mains Switch on the rear of the unit in the On position. The

three decimal points in the upper readout light to indicate that the

Water Bath is in the Standby mode.

2. Press . The actual bath temperature is displayed on the upper

readout and the set point temperature is displayed on the lower

readout. Both values are displayed to one decimal point. If the actual

bath temperature is lower than the set point temperature, the unit will

automatically begin heating and the heating symbol will light.

Selecting the Temperature Unit

1. Press until ºC or a ºF appears on the lower readout.

2. If ºC is shown, press to change it to ºF. If ºF is shown, press to

change it to ºC.

3. Press or allow the display to timeout (~10 seconds) to accept the

displayed temperature unit.

8

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

110-031 PSC/EN

Setting the High Limit Value

This menu item allows you to enter a high temperature alarm value, and

can establish a temperature above which a set point temperature cannot

be entered. If you try to increase the set point to a temperature higher

than the High Limit value, further increases will be blocked and the words

HIGH LIMIT on the LCD will ash.

1. Press until the words HIGH LIMIT appear on the LCD; the current

High Limit value will appear on the lower readout.

2. Use the and buttons to set the high limit value to the desired

temperature; this value may be set as high as 105ºC (221ºF).

3. Press or allow the display to timeout (~10 seconds) to accept the

displayed High Limit value. The words HIGH LIMIT will no longer be

lit.

Setting the Temperature Presets

1. Press until PRESET appears on the lower readout.

2. Use the and buttons to adjust the set point displayed on the

lower readout to the desired temperature.

!

3. Press until the word TIMER is displayed on the LCD; the two left

hand digits in the lower readout will begin ashing.

4. Use the and buttons to set the time duration in hours; this value

may be set anywhere from 00 to 99 hours.

5. Press again; the two right hand digits in the lower readout will

begin ashing.

6. Use the and buttons to set the time duration in minutes; this

value may be set anywhere from 00 to 59 minutes.

7. Press or allow the display to timeout (~10 seconds) to accept the

displayed Time Duration value.

8. Press and hold the Preset button ( , or ) you wish to associate

with the set point and time optional timer values you entered for ten

seconds to accept. The unit will beep to indicate the Preset has been

accepted.

NOTE: Steps 3 through 7 below are optional.

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

110-031 PSC/EN

Normal Operation

Keypad Controls

Power Turns the Controller On and Off.

Used to select and set temperature

Menu

units, timer time duration, high limit

temperature and calibration offset. Also

used to display the rmware version ID.

Timer

Selection

Temperature

Presets

(1, 2, 3)

Used to start, pause and reset the

timer.

Used to increase/decrease temperature

set point and other operational settings/

values.

Used to select one of three user-

dened set point temperatures and

optional time duration.

Turning Your Water Bath On

1. Place the Mains Switch on the rear of the unit in the On position. The

three decimal points in the upper readout light to indicate that the

Water bath is in the Standby mode.

2. Press . The actual bath temperature is displayed on the upper

readout and the set point temperature is displayed on the lower

readout. Both values are displayed to one decimal point. If the actual

bath temperature is lower than the set point temperature, the unit will

automatically begin heating and the heating symbol will light.

Adjusting the Set Point Temperature

This is the temperature at which the uid in your bath will be maintained.

It may be set to one-tenth of a degree. The factory default set point is

+20.0ºC/+68ºF.

1. Press the or button. The word SET on the LCD will begin

ashing.

2. Use the and buttons to adjust the set point temperature to the

desired value. Press or allow the display to timeout (~10 seconds)

to accept the new value; the word SET on the LCD will be lit steady.

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

110-031 PSC/EN

Setting and Using the Timer

1. Press until TIMER appears on the LCD; the two left hand digits in

the lower readout will begin ashing.

2. Use the and buttons to set the time duration in hours; this value

may be set anywhere from 00 to 99 hours.

3. Press again; the two right hand digits on the lower readout will

begin ashing.

4. Use the and to set the time duration in minutes; this value may

be set anywhere from 00 to 59 minutes.

5. Press or allow the display to timeout (~10 seconds) to accept the

displayed Time Duration value.

6. Press to start the timer; and the word TIMER on the LCD will

light. To pause the Timer, press a second time; press again to

restart the Timer from the point at which it was stopped. To reset the

Timer to 00:00, press and hold for two seconds.

The Timer counts down until it reaches 00:00, beeps and then begins

counting up. This is intended to inform you about how much time has

elapsed since the timer reached 00:00. To clear the Timer Value, place

the unit in Standby mode and press to return from Standby mode.

NOTE: When the Timer is operating, the lower readout

!

alternates between the time remaining (or elapsed) and the

temperature set point at 5 second intervals.

Using the Temperature Presets

Press the desired Preset button ( , or ). The word PRESET and

the number associated with that preset will light on the LCD. If the Preset

includes a Timer function, the word TIMER and will also light. The

actual bath temperature and the set point temperature / time (alternating)

will be displayed on the upper and lower readouts, respectively (set point

only if there is no timer function associated with the Preset).

NOTE: When the Preset includes a Timer function, will

light and the timer will begin counting down when the actual

!

bath temperature is within ±0.5° of the set point temperature.

The Timer can also be activated manually by pressing the

Timer button.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

110-031 PSC/EN

Entering a Calibration Offset

This menu item allows you to offset all bath temperature readings by -7

to +7ºC. For example, if the Calibration Offset is set to +0.5º the bath will

display temperature readings of 20ºC, 50ºC and 70ºC as 20.5ºC, 50.5ºC

and 70.5ºC, respectively.

The Calibration Offset is always set in ºC. If you have selected ºF as

the temperature unit, the Water Bath automatically converts the ºC

calibration offset value to the correct ºF value when normal operation is

resumed.

To prevent the Calibration Offset from being changed unintentionally,

the following power down/power up sequence is required to enable the

Calibration Offset function:

NOTE: If the operator tries to enter a Calibration Offset

!

1. Place the Mains Switch on the rear of the unit in the Off position.

2. Press and hold while returning the Mains Switch to the On

position.

3. When the unit enters Standby (the three decimal points in the upper

display lit), release .

4. Press .

5. Press until the words CALIBRATION OFFSET light on the LCD.

The actual bath temperature will be displayed in degrees C on

the upper readout and the current Calibration Offset value will be

displayed in degrees C on the lower readout.

6. Use the and buttons to set the Calibration Offset to the desired

value. As the Calibration Offset value is entered, the reading on the

upper display will also change to reect the new calibration offset

value.

7. Press or allow the display to timeout (~10 seconds) to accept the

displayed Calibration value. The words CALIBRATION OFFSET will

no longer be lit.

without following the proper power down/power up sequence,

the words CALIBRATION OFFSET on the LCD will ash.

The Calibration Offset function will remain enabled until the unit is turned

Off by pressing .

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

110-031 PSC/EN

Resetting the Factory Default Values

1. Press to turn the Circulator Off.

2. Place the Mains Switch on the rear of the unit in the Off position.

3. Return the Mains Switch to the On position while pressing and

holding either the or button.

The factory default values are:

Operational Parameter Factory Default Value

Temperature Set Point 20ºC/68ºF

Temperature Scale ºC

Timer 00:00

High Limit 99.9ºC/211.8ºF

Calibration Offset 0.0ºC

Preset 1

Preset 2

Preset 3

Set Point: 37°C

Timer: 0

Set Point: 44°C

Timer: 0

Set Point: 70°C

Timer: 0

Loss of Power Restart

In the event that electrical power is lost while your Water Bath is in use,

it will begin operating automatically at the set point temperature once

power is restored. The timer will begin counting up from the point at

which power was restored. POWER FAIL will appear on the display to

alert you that there was a power disruption. To clear the message, turn

the bath Off and then back On again by pressing .

Displaying the Firmware Version

The version number for the Water Bath’s rmware is accessed by

pressing until the word VERSION appears on the LCD. The version

number will be displayed on the lower readout; this is a read-only value.

Press or allow the display to timeout (~10 seconds) to exit the Menu

function.

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

110-031 PSC/EN

Display Messages and Alarms

Symbol and/or Word Description Comments/Corrective Action

HIGH LIMIT

(ashing)

!

CALIBRATION

OFFSET

(ashing)

POWER FAIL

SET

(ashing)

°C or °F

on lower readout.

TIMER

HIGH LIMIT

(steady)

CALIBRATION

OFFSET

(steady)

PRESET

1, 2 or 3

TIMER

Warning: The operator is attempting

to enter temperature set point that

is above the High Limit temperature

value.

Fault: The liquid in the bath has

dropped too low or the temperature

of the bath uid has exceeded the

Safety Set temperature. Power to

the heater will remain Off until the

over-temperature thermostat resets.

Warning: The operator is attempting

to enter a Calibration Offset value

without rst performing the proper

power down/power up sequence.

Informational: Indicates that there

was a loss of electrical power during

operation.

Informational: Indicates that the

temperature set point is being

changed.

Informational: Indicates that the

temperature unit is being changed.

Informational: Indicates that the

timer is being set.

Informational: Indicates that the

high limit value is being changed.

Warning: Indicates that the bath

temperature has exceeded the high

limit value for more than 5 seconds.

Informational: Indicates that the

calibration offset value is being

changed.

Informational: Indicates that the

bath is operating using the indicated

Preset set point temperature and

timer (optional) values.

Informational: Indicates that the

timer is being used.

Informational: Indicates that heat is

being applied to the bath.

Increase the High Limit temperature value or

decrease the set point temperature.

Fluid level in the reservoir has fallen below

minimum level; remove power, allow bath to

come to room temperature and add uid.

Fluid temperature is higher than one or

both Over-Temperature Safety thermostats.

Remove power and allow bath to come to room

temperature; if problem persists, consult factory.

Controller failure; consult factory.

Place Mains Switch on rear of unit in Off

position. Press and hold while returning

Mains Switch to On position. Release when

unit enters Standby mode.

Press on keypad and then press until

CALIBRATION OFFSET appears on LCD.

Press to turn the Water Bath Off and then

back On. This will clear the message.

Press

or until desired set point

temperature is displayed on lower readout.

Press or allow the display to timeout to

accept.

Press

to change ºC to ºF; press to

change ºF to ºC. Press or allow the display

to timeout to accept.

Use the

or buttons to increase/

decrease the time duration. Press or allow

the display to timeout to accept.

Press

or until desired high limit

temperature is displayed on lower readout.

Press

or allow the display to timeout to

accept.

Allow bath temperature to fall below the High

Limit Value.

Place unit in Standby mode and press to

return from Standby mode. Reset factory default

values

Press

or until desired calibration offset

is displayed on lower readout. Press

allow the display to timeout to accept.

No action required.

Press and release

and hold for two seconds to reset to 00:00.

This symbol is lit steady while the bath is

heating to the set point temperature and

ashes when the set point temperature is being

maintained.

to pause timer. Press

or

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

110-031 PSC/EN

Symbol and/or Word Description Comments/Corrective Action

- - -

Beeping Pattern

Warning: Sensor Failure Turn the Water Bath Off. Place mains switch

in the Off position. Unplug the unit and contact

Routine Maintenance & Troubleshooting

WARNING: Hazardous voltages may be present. Disconnect

power before performing maintenance.

WARNING: Always allow the bath to cool to ambient

temperature before performing any maintenance.

Draining the Bath Reservoir

Water Baths with 10, 20 and 28 liter

reservoirs have a drain port located

on the rear of the unit. To drain uid

from the bath reservoir, place a

suitable container beneath the drain

port and remove the cap and o-ring.

Drain

WARNING: Be sure to reinstall the cap on the drain outlet

!

before relling the bath reservoir. Always verify the o-ring is

properly installed inside the cap.

Resetting the Over-Temperature/Low Liquid Level Safety

Also see Display Messages and Alarms (page 14) and the

Troubleshooting Chart (page 16).

For optimal protection, your Water Bath incorporates redundant overtemperature safeties. These over-temperature/low liquid level safeties

automatically remove power from the heater in the event that the bath

temperature exceeds their factory set temperature settings.

While these safeties are designed to automatically reset when the

bath returns to a temperature below the factory set safety settings,

we recommend that you take the following actions when the overtemperature/low liquid level warning is activated.

1. Press to place the Water Bath in the Standby mode.

2. Allow the liquid in the Water Bath to cool to ambient temperature.

3. If the liquid level in the bath is too low, add liquid as required.

4. Press .

If the problem persists, contact

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

110-031 PSC/EN

Cleaning the Bath

Thoroughly clean the bath before each use. Use only mild soap and

water when cleaning. Do not use steel wool as damage to the unit may

result. Non-steel scouring pads are acceptable.

The entire unit is housed in a tough, well-insulated powder-coated steel

casing that is corrosion and chemical resistant.

Troubleshooting Chart

Problem Cause Corrective Action

Check that power cord is

No display

No heating

No power to unit

Mains Switch in Off

position

Set point lower than bath

temperature

Bath temperature above

High Limit temperature

Liquid level in bath is

too low

Improper line voltage

plugged into an operating

electrical outlet

Check that Mains Switch on

the rear of the unit is in the On

position

Check set point temperature;

increase as required.

Verify that High Limit

temperature is higher than

current set point temperature;

adjust as required (see page 8).

Check that liquid level is at

least 2 inches (5.08 cm) above

bottom of tank; add uid as

required.

Check that line voltage meets

specications.

Allow sufcient time for bath

Insufcient

heating

Inaccurate bath

temperature

Find Quality Products Online at: sales@GlobalTestSupply.com

Recent change in set

point or heat load

Bath cover not in place

Incorrect calibration

temperature to stabilize when

changes in heat load or set

point are made.

Check that bath cover is in

place.

Adjust Calibration Offset as

required (see page 10).

www.GlobalTestSupply.com

16

Page 18

110-031 PSC/EN

Technical Information

Performance Specications

Working Temperature:

Ambient +5ºC to 100ºC (ambient +10º to 212ºF)

60ºC (140ºF) without cover

Temperature Uniformity:

Temperature Stability:

Reservoir

Size

2 liter

5 liter

10 liter

20 liter

28 liter

Environmental Conditions Indoor use only

Maximum Altitude:

Operating Ambient:

Relative Humidity:

Installation Category:

Pollution Degree:

Reservoir Dimensions

(L x W x D)

3.9 x 4.3 x 6”

9.9 x 10.9 x 15.2 cm

5 x 10.8 x 6”

12.7 x 27.4 x 15.2 cm

10.6 x 11.6 x 6”

26.9 x 29.5 x 15.2 cm

9.5 x 17.5 x 5”

24.1 x 44.5 x 15.2 cm

9.5 x 17 x 8”

24.1 x 43.2 x 20.3 cm

±0.2°C @ 37°C (±0.4°F @ 98.6°F)

±0.1°C (±0.2°F)

Heater

Wattage

120

360

1000

1400

1400

Electrical Requirements

120 V, 60 Hz 240 V, 50 Hz

WB02**1*

1.1 A

WB05**1*

3.3 A

WB10**1*

8.6 A

WB20**1*

12.0 A

WB28**1*

12.0 A

2000 meter

5° to 40°C (41° to 104°F)

80%, non-condensing

II

2

WB02**2*

0.5 A

WB05**2*

1.6 A

WB10**2*

4.5 A

WB20**2*

6.0 A

WB28**2*

6.0 A

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

110-031 PSC/EN

Reservoir Fluids

WARNING: Do not operate unit with any potentially

!

ammable materials, as a re hazard may result.

Specific Heat

Fluid Description

distilled water 50°C 1.00 4.18 10° to 90°C 2° to 100°C

polyclear MIX 30 50°C 1.00 4.18 15° to 90°C 2° to 100°C

polycool HC-50 -30°C 0.62 2.59 -50° to 100°C -62° to 118°C

polycool EG-25 (50/50

mix with distilled H

polycool EG-25 (30/70

mix with distilled H

polycool PG-20 (50/50

mix with distilled H

polycool PG-20 (30/70

mix with distilled H

polycool MIX-25 (50/50

mix with distilled H20)

polycool MIX-25 (30/70

mix with distilled H20)

O)

2

O)

2

0)

2

0)

2

@ Fluid

Temperature

-20°C 0.78 3.26 -25° to 100°C -30° to 115°C

0°C 0.89 3.72 0° to 95°C -15° to 107°C

-10°C 0.83 3.47 -20° to 100°C -30° to 115°C

5°C 0.92 3.85 5° to 90°C -10° to 107°C

-20°C 0.78 3.26 -25° to 100°C -30° to 115°C

0°C 0.89 3.72 0° to 95°C -15° to 107°C

BTU/lb

°F

KJ/Kg °C

Normal

Temperature

Range

Extreme

Temperature

Range

WARNING: DO NOT USE THE FOLLOWING

LIQUIDS:

• Automotive antifreeze with additives**

• Hard tap water**

• Deionized water with a specific resistance >1 meg

ohm

• Any flammable fluids

• Concentrations of acids or bases

• Solutions with halides: chlorides, fluorides,

!

bromides, iodides or sulfur

• Bleach (Sodium Hypochlorite)

• Solutions with chromates or chroium salts

• Glycerine

• Syltherm fluids

** At temperatures above 40°C, additives or mineral

deposits can adhere to the heater. If deposits are allowed

to build up, the heater may overheat and fail. Higher

temperatures and higher concentrations of additives will

hasten deposit build up.

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

110-031 PSC/EN

CAUTION: Fumes from acidic solutions may cause corrosion

!

Stay within the uid’s normal range for best temperature stability and low

vaporization. At uid’s high temperature extreme:

• A fume hood may be required to prevent the buildup of vapors inside

the room.

• Fluid loss from vapor will have to be frequently replenished.

• Caution must be taken to stay well below the uid’s ashpoint.

of the stainless steel reservoir. Care should be taken to

maintain a neutral pH at all times.

Application Notes

For optimum results, maintain uid level throughout the operating period,

adding uid as needed. Attempt to rell uid at same temperature as

bath.

Use the bath lid and/or hollow plastic oating balls (part number 060301)

to help prevent heat and vapor loss.

This unit is designed for indoor use only with an allowable ambient

temperature between +5°C to 40°C (41° to 104°F) and relative humidity

not greater than 80%.

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

110-031 PSC/EN

Equipment Disposal (WEEE Directive)

This equipment is marked with the crossed out wheeled bin

symbol to indicate it is covered by the Waste Electrical and

Electronic Equipment (WEEE) Directive and is not to be disposed

of as unsorted municipal waste. Any products marked with

this symbol must be collected separately, according to the

regulatory guidelines in your area.

It is your responsibility to correctly dispose of this equipment

at lifecycle-end by handing it over to an authorized facility for

separate collection and recycling. It is also your responsibility to

decontaminate the equipment in case of biological, chemical and/

or radiological contamination, so as to protect the persons involved

in the disposal and recycling or the equipment from health hazards.

By doing so, you will help to conserve natural and environmental

resources and you will ensure that your equipment is recycled in a

manner that protects human health.

Requirements for waste collection, reuse, recycling and recovery

programs vary by regulatory authority at your location. Contact

your local responsible body (e.g., your laboratory manager) or

authorized representative for information regarding applicable

disposal regulations.

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

110-031 PSC/EN

Service and Technical Support

If you have followed the troubleshooting steps outlined previously

and your Circulator still fails to operate properly, contact the supplier

from whom the unit was purchased. Have the following information

available for the customer service person:

• Model, Serial Number and Voltage (from back panel label)

• Date of purchase and purchase order number

• Supplier’s order number or invoice number

• A summary of the problem.

Warranty

The manufacturer agrees to correct for the original user of the product, either by repair

(using new or refurbished parts), or at the manufacturer’s election, by replacement

(with a new or refurbished product), any defects in material or workmanship which

develop during the warranty period. The standard warranty is twenty-four (24) months

after delivery of the product. In the event of replacement, the replacement unit will

be warranted for the remainder of the original warranty period or ninety (90) days,

whichever is longer. For purposes of this limited warranty, “refurbished” means a

product or part that has been returned to its original specifications. In the event of a

defect, these are your exclusive remedies.

If the product should require service, contact the manufacturer’s/supplier’s office for

instructions. When return of the product is necessary, a return authorization number is

assigned and the product should be shipped, transportation charges pre-paid, in either

its original packaging or packaging affording an equal degree of protection to the

indicated service center. To insure prompt handling, the return authorization number

must be placed on the outside of the package. A detailed explanation of the defect

should be enclosed with the item.

The warranty shall not apply if the defect or malfunction was caused by accident,

neglect, unreasonable use, improper service, acts of God, modification by any part

other than PolyScience or other causes not arising out of defects in material or

workmanship.

EXCLUSION OF IMPLIED WARRANTIES. THERE ARE NO WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THOSE OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE WHICH EXTEND

BEYOND THE DESCRIPTION AND PERIOD AS STATED IN THE OPERATOR’S

MANUAL INCLUDED WITH EACH PRODUCT.

LIMITATION ON DAMAGES. THE MANUFACTURER’S SOLE OBLIGATION

UNDER THE WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT OF

A DEFECTIVE PRODUCT AND POLYSCIENCE SHALL NOT, IN ANY EVENT, BE

LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND

RESULTING FROM USE OR POSSESSION OF THIS PRODUCT.

Some states do not allow: (A) limitations on how long an implied warranty lasts; or

(B) the exclusion or limitation of incidental or consequential damages, so the above

limitations or exclusions may not apply to you. This warranty gives you specific legal

rights and you may have other rights that vary from state to state.

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...