PolyScience Refrigerated Recirculating Chillers, 6206, 6306, 6506, 6706 Operator's Manual

...Page 1

Operators Manual

Refrigerated Recirculating Chillers

110-240 Rev. H

06/06

Page 2

EC Declaration of Conformity

The Products herewith complies with the requirements, as stated below, in accordance to the EC Low Voltage

Directive 73/23/EEC and EC Electromagnetic Compatibility Directive 89/336/EEC, and carries the marking

accordingly.

We herewith declare:

That the following equipment complies with the essential requirements in respect to safety and health, in

accordance to the EC Directives based on its design and type, as brought into circulation by us. In case of

alteration of the equipment, not agreed upon by us, this will lose its validity.

Product Description: Refrigerated Chillers

Testing Bodies:

PolyScience

Division of Preston Industries, Inc.

6600 West Touhy Avenue

P.O. Box 48312

Niles, Illinois 60714, USA

6206, 6306, 6506, 6706, 6106, 5206, 5306, 5706, 5106; 1171, 1173, 1175,

1177, 1179, 512CR, 517CR

Low Voltage Directive 73/23/EEC & Electromagnetic Compatibility

89/336/EEC and relevant transpositions into national law of the

member states, including, but not limited to the following

Harmonized Standards:

EN/IEC 61010-1: 2001

EN/IEC 61010-2

EN 61326: 1997 +A1: 1998 + A2:2001

CISPR 11/EN 55011 Class A, Group I

CSA International (Certification & Testing Division)

D.L.S. Electronic Systems Inc. ( EMC approval)

Signature on Behalf of

Manufacturer or Authorized

Representative:

Date of Validity:

Title of Signatory:

110-266 Rev. D 10/05

Brian Klotz

October 18, 2005

Engineering Manager

2

Page 3

WEEE Directive

A label with a crossed-out wheeled bin symbol and a rectangular bar indicates that the product

is covered by the Waste Electrical and Electronic Equipment (WEEE) Directive and is not to

be disposed of as unsorted municipal waste.

Any products marked with this symbol must be collected separately, according to the

regulatory guidelines in your area.

The objectives of this program are to preserve, protect and improve the quality of the

environment, protect human health, and utilize natural resources prudently and rationally.

Specific treatment of WEEE is indispensable in order to avoid the dispersion of pollutants into

the recycled material or waste stream. Such treatment is the most effective means of protecting

the customer’s environment.

Requirements for waste collection, reuse, recycling, and recovery programs vary by regulatory

authority at your location.

Contact your local responsible body (e.g., your laboratory manager) or authorized

representative for information regarding applicable disposal regulations.

Contact PolyScience at the web site listed below for information.

Web address: www.polyscience.com

Customer Care: 1-800-229-7569 (inside the USA)

(+1) 847-647-0611 (outside the USA)

Fax 1-847-647-1155

or

3

Page 4

Table of Contents

Section 1 - General Information

1.1 Warranty

1.2 Unpacking

Section 2 – Overview

2.1 Contents

2.2 Description

2.3 Chiller Specifications and Pump Performance

Section 3 – Installation and Startup

3.1 Site Requirements

3.2 Electrical Power

3.3 Optional Signal Inputs/Outputs

3.4 Plumbing

3.5 Closed System or Cooling Coil Setup

3.6 Open Bath System Setup

3.7 Startup

Section 4 – Operation

4.1 Selecting the Temperature Unit (°C or °F)

4.2 Displaying and Adjusting the Set Point

4.3 Displaying and Adjusting the Ambient Tracking Offset

4.4 Displaying and Adjusting Remote Control Temperature

4.5 Selecting the Pressure / Flow Rate Display and Units

4.6 Selecting Internal/External Temperature Display

4.7 Setting Operational Parameters

4.8 Display, Alarm, and Error Messages

4.9 Adjusting the High Pressure Bypass Setting

4.10 Enabling/Disabling the Local Lockout

Section 5 – Maintenance and Calibration

5.1 Standard Magnetic Drive Centrifugal Pump

5.2 Condenser, Air Vents, and Reusable Filter

5.3 Fluid Filter

5.4 Fluid Level

5.5 Temperature Calibration

5.6 Flow Rate Calibration

Section 6 - Troubleshooting

6.1 Unit Will Not Operate (No Cooling or Pumping)

6.2 No Pumping

6.3 Insufficient Pumping

6.4 No Cooling or Insufficient Cooling

6.5 Triac Failure

6.6 Internal Probe Failure

6.7 External Temperature Probe Failure

6.8 Diagnostic Mode

Section 7 - Service and Technical Support

7.1 Electrical Wiring Diagram

7.2 Process Flow Diagram

Section 8 - Replacement Parts

Section 9 – RS232

4

Page 5

Section 1 - General Information

1.1 Warranty

Thank you for purchasing this chiller. We are confident it will serve you for a long time. Our

warranty to you is as follows:

The manufacturer agrees to correct for the original user of this product, either by repair, or at the

manufacturer's election, by replacement, any defect that develops after delivery of this product within

the period as stated on the warranty card. In the event of replacement, the replacement unit will be

warranted for 90 days or warranted for the remainder of the original unit’s parts or labor warranty

period, whichever is longer.

If this product requires service, contact the manufacturer/supplier's office for instructions. When

return of the product is necessary, a return authorization number will be assigned and the product

should be shipped, transportation charges pre-paid, to the indicated service center. To insure

prompt handling, the return authorization number should be placed on the outside of the package

and a detailed explanation of the defect enclosed with the item.

This warranty shall not apply if the defect or malfunction was caused by accident, neglect,

unreasonable use, improper service, or other causes not arising out of defects in material or

workmanship. There are no warranties, expressed or implied, including, but not limited to, those of

merchantability or fitness for a particular purpose which extends beyond the description and period

set forth herein.

The manufacturer's sole obligation under this warranty is limited to the repair or replacement of a

defective product and shall not, in any event, be liable for any incidental or consequential damages

of any kind resulting from use or possession of this product. Some states do not allow: (A)

limitations on how long an implied warranty lasts; or (B) the exclusion or limitation of incidental or

consequential damages, so the above limitations or exclusions may not apply to you. This warranty

gives you specific legal rights. You may have other rights that vary from state to state.

1.2 Unpacking

Your Chiller is shipped in a special carton. Retain the carton and all packing materials until the unit is

completely assembled and working properly. Set up and run the unit immediately to confirm proper

operation. Beyond one week, your unit may be warranty repaired, but not replaced. If the unit is

damaged or does not operate properly, contact the transportation company, file a damage claim and

contact the company where your unit was purchased immediately.

This symbol marks chapters and sections of this instruction manual that are particularly relevant to safety. When

attached to the unit, this symbol draws attention to the relevant section of the instruction manual.

This symbol indicates that hazardous voltages may be present.

Read all instructions pertaining to safety, set-up, and operation.

Proper operation is the users’ responsibility.

5

Page 6

Section 2 -- Overview

2.1 Contents

— Recirculating Chiller

— Operators Manual

— Warranty Card

— IEC Power Cord

— Two sets of Inlet/Outlet Adapters: ½ inch male NPT, 5/8 inch male NPT

2.2 Description

These Refrigerated Recirculating Chillers provide cooling power for demanding applications and

serve as an economical alternative to tap water cooling systems. All models feature a

microprocessor-based controller, digital temperature display (°C or °F), one-touch set point display,

and digital pressure/flow rate display (PSI, kPa, GPM, LPM) with push-button selection.

To optimize cooling efficiency and performance, these sophisticated Chillers also feature a

modulated refrigeration system. As a result, temperature stability is greatly enhanced and

compressor life extended.

Refrigerated Recirculating Chillers are equipped with either a centrifugal, positive displacement, or

regenerative turbine pump. Wetted parts within the recirculation system are brass, stainless steel,

polyethylene, EPDM rubber, and nylon.

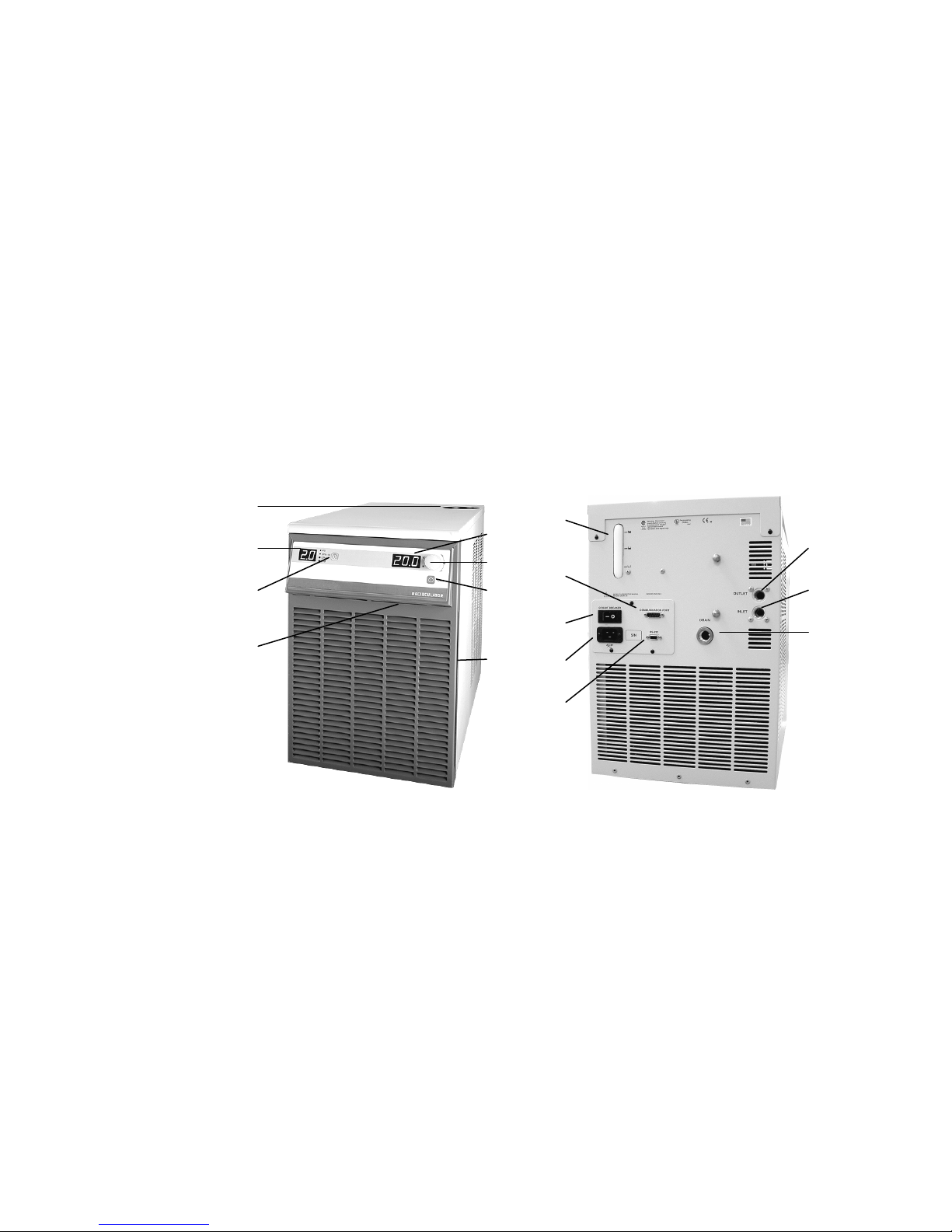

4

6

7

12

1

2

15

3

9

10

13

8

Front/Top Rear

1. Temperature Display 9. Fluid Outlet

2. Select/Set Knob 10. Fluid Inlet

3. Power Button 11. Drain

4. Reservoir Cap and Internal Fluid Filter (top) 12. Reservoir Fluid Level Gauge

5. Air Filter 13. Circuit Breaker / Power Switch

6. Pressure / Flow Rate Display 14. IEC Power Connection

7. Units / Menu Select Button 15. Remote I/O Connection (optional)

8. Ambient Tracking Probe Connection (optional) 16. RS232 / RS 485 Connection (optional)

5

14

16

11

6

Page 7

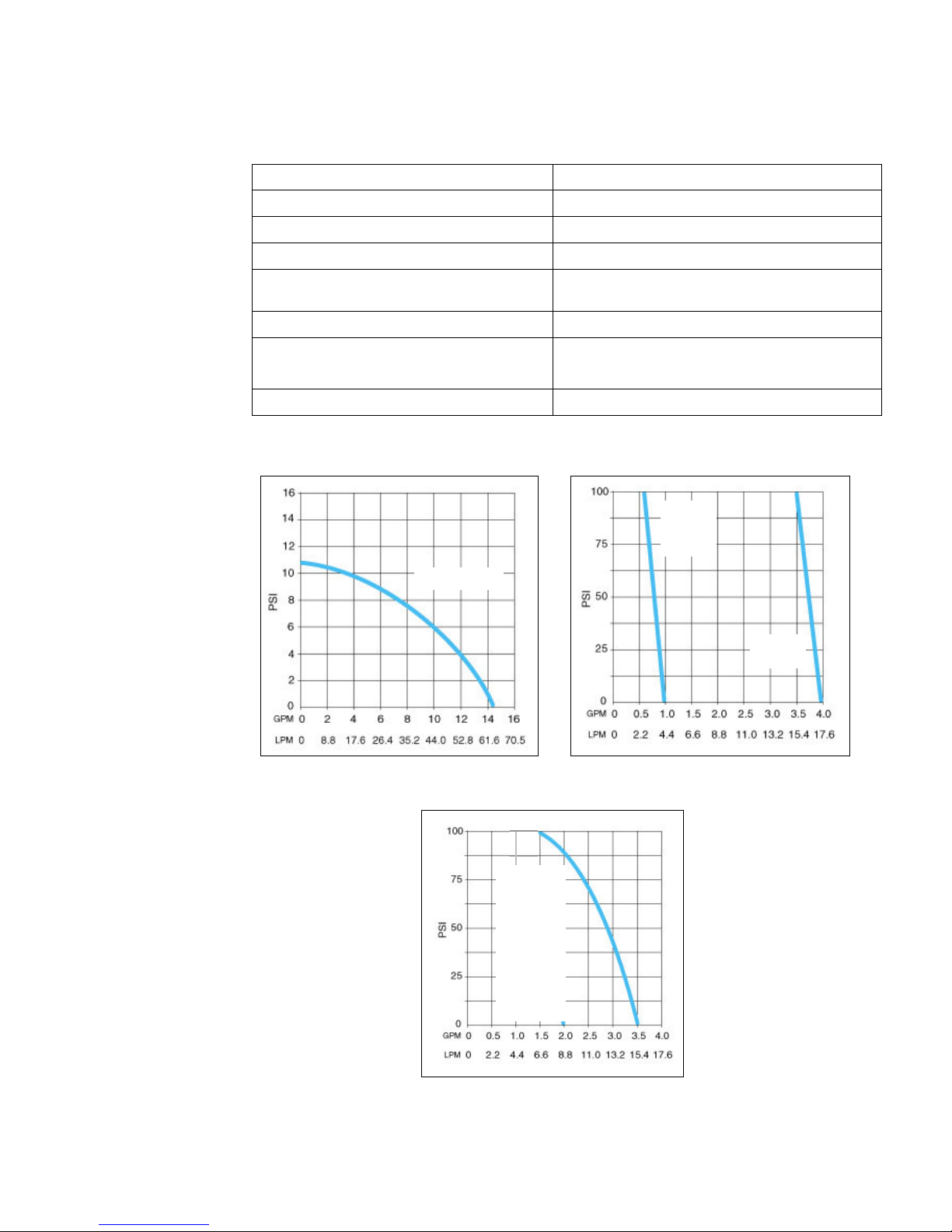

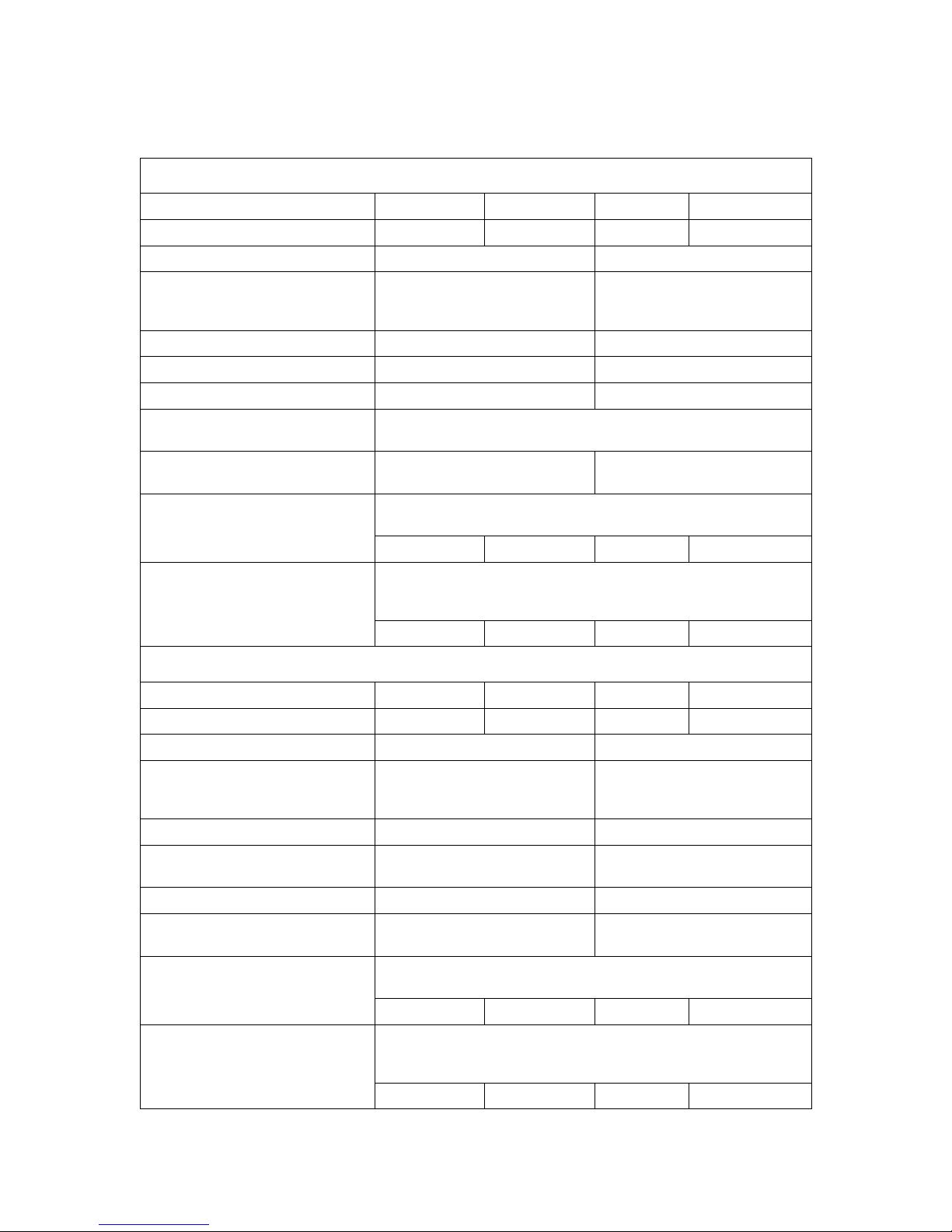

2.3 Chiller Specifications and Pump Performance

General Specifications (all Chillers)

Temperature Set Point Resolution ±0.1°C

Temperature Stability ±0.1°C

Temperature Units °C or °F

Pressure Units PSI or kPa

Pressure Display Resolution

Pressure Display Accuracy

1 PSI / 6.9 kPa

±3.5% of full scale (100PSI)

Flow Rate Units GPM or LPM

Flow Rate Display Resolution

Flow Rate Display Accuracy

0.1 GPM / 1 LPM

+/- 0.4 GPM / 1.5 LPM

Pump Inlet and Outlet ½ inch NPT

Pump Performance

¼ HP

1

/3 HP

½ HP

All Models

¾ HP

1 HP

Magnetic Drive Centrifugal Pump Positive Displacement Pump

¼ HP

1

/3 HP

½ HP

¾ HP

1 HP

Turbine Pump

7

Page 8

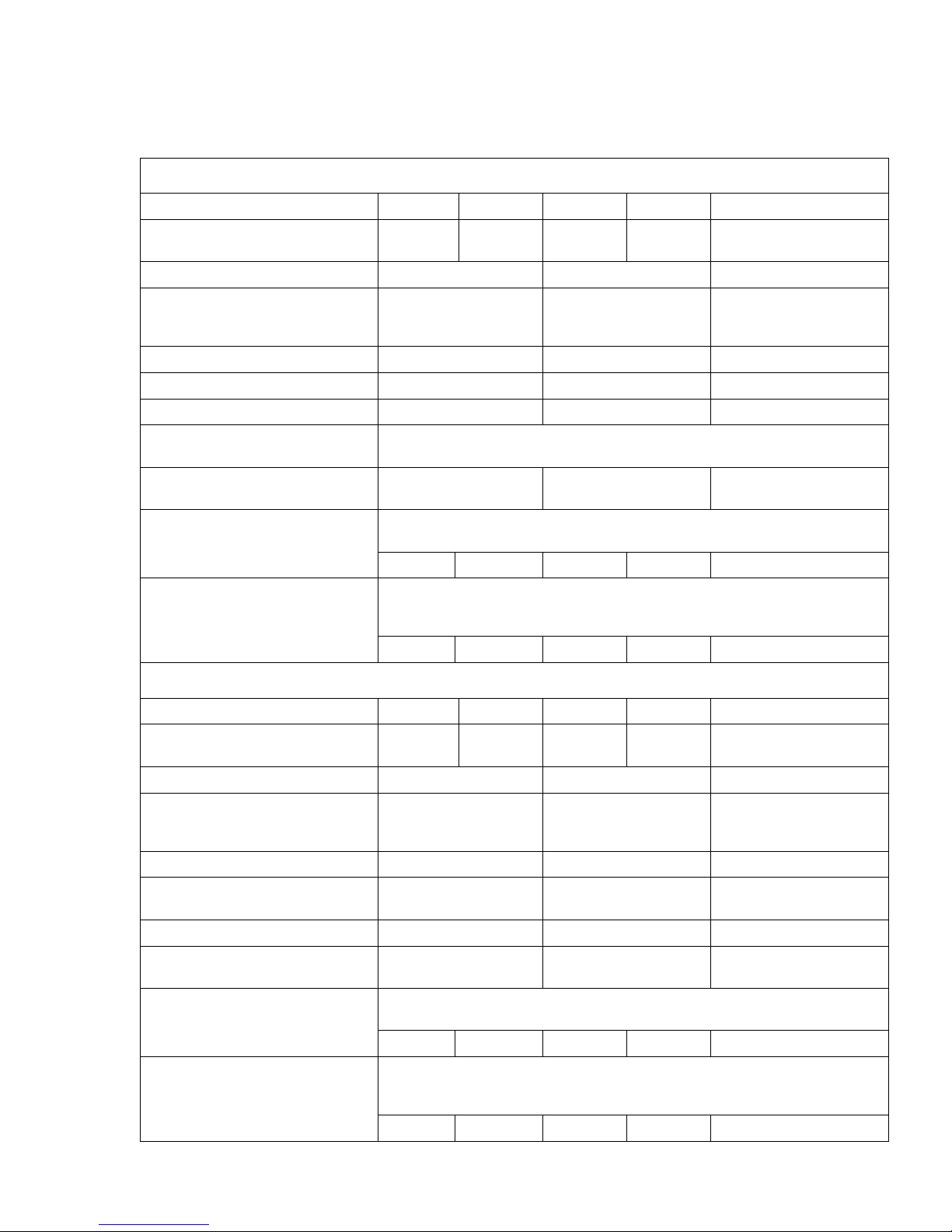

Specifications — 1/4-HP, 1/3-HP, and 1/2-HP Chillers

Model: Rfg = Refrigerating Only

Rfg / Htg = Refrigerating & Heating

Magnetic Drive Centrifugal Pump

Model Rfg Rfg / Htg Rfg Rfg / Htg Rfg

Operating Temperature

Compressor 1/4 HP 1/3 HP 1/2 HP

Cooling Capacity @ 20°C

10°C

0°C

Pressure at 0 Flow Rate 10 psi / 69 kPa 10 psi / 69 kPa 10 psi / 69 kPa

Flow Rate at 0 psi 4.1 gpm / 15.5 lpm 4.1 gpm / 15.5 lpm 4.1 gpm / 15.5 lpm

Reservoir Capacity 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters

Dimensions (h x w x d)

Shipping Weight

120 V, 60 Hz Chillers

Volts Range

Amps 9.5A 10.0A 10.4A 10.7A 13.5A

240 V, 50 Hz Chillers

Volts Range

Over Voltage

Amps 5.6A 5.9A 5.9A 6.2A 7.2A

Positive Displacement Pump (“P” Series Chillers)

-10° to

40°C

800 watts 2728 BTU/hr

500 watts 1705 BTU/hr

200 watts 682 BTU/hr

131 pounds

59.4 kg

-10° to

70°C

-10° to

40°C

1200 watts 4092 BTU/hr

900 watts 3069 BTU/hr

500 watts 1705 BTU/hr

22-5/8 x 14-1/2 x 27-5/8 in.

57.5 x 36.8 x 70.2 cm

143 pounds

108 to 132V

198 to 264V

Category II

-10° to

70°C

64.8 kg

-10° to 40°C

1700 watts 5797 BTU/hr

1100 watts 3751 BTU/hr

750 watts 2557 BTU/hr

168 pounds

76.2 kg

Model P Series Chillers Rfg Rfg / Htg Rfg P Rfg / Htg Rfg

Operating Temperature

Compressor 1/4 HP 1/3 HP 1/2 HP

Cooling Capacity @ 20°C

10°C

0°C

Flow Rate @ 0 psi 1 gpm / 3.75 lpm 1 gpm / 3.75 lpm 1 gpm / 3.75 lpm

Pump Pressure (adjustable)

Reservoir Capacity 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters

Shipping Weight

120 V, 60 Hz Chillers

Volts Range

Amps 12.2A 12.5A 13.1A 13.5A 16.0A

240 V, 50 Hz Chillers

Volts Range

Over Voltage

Amps 6.8A 7.1A 7.3A 7.6A 8.9A

-10° to

40°C

800 watts 2728 BTU/hr

500 watts 1705 BTU/hr

200 watts 682 BTU/hr

20 to 100 psi

138 to 689 kPa

141 pounds

64 kg

-10°C to

70°C

-10° to

40°C

1200 watts 4092 BTU/hr

900 watts 3069 BTU/hr

500 watts 1705 BTU/hr

20 to 100 psi

138 to 689 kPa

153 pounds

108 to 132V

198 to 264V

-10°C to

70°C

69 kg

Category II

-10° to 40°C

1700 watts 5797 BTU/hr

1100 watts 3751 BTU/hr

750 watts 2557 BTU/hr

20 to 100 psi

138 to 689 kPa

178 pounds

81 kg

8

Page 9

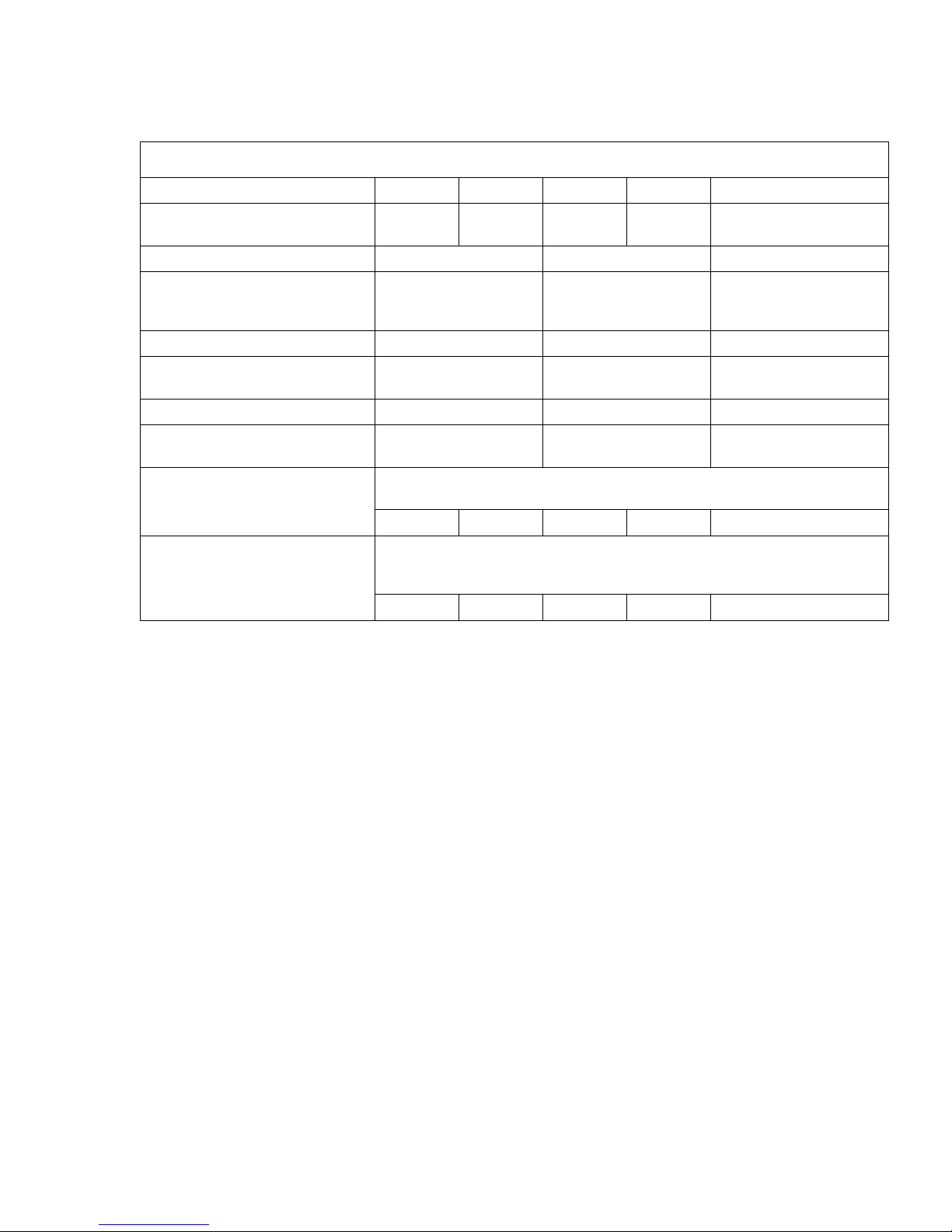

Model: Rfg = Refrigerating Only

Rfg / Htg = Refrigerating & Heating

Turbine Pump (“T” Series Chillers)

Model T Series Chillers Rfg Rfg / Htg Rfg Rfg / Htg Rfg

Operating Temperature

Compressor 1/4 HP 1/3 HP 1/2 HP

Cooling Capacity @ 20°C

10°C

0°C

Flow Rate @ 0 psi 3.5 gpm / 13.2 lpm 3.5 gpm / 13.2 lpm 3.5 gpm / 13.2 lpm

Pump Pressure (adjustable)

Reservoir Capacity 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters

Shipping Weight

120 V, 60 Hz Chillers

Volts Range

Amps 12.2A 12.5A 13.1A 13.5A 16.0A

240 V, 50 Hz Chillers

Volts Range

Over Voltage

Amps 6.8A 7.1A 7.3A 7.6A 8.9A

Specifications subject to change without notice.

-10° to

40°C

800 watts 2728 BTU/hr

500 watts 1705 BTU/hr

200 watts 682 BTU/hr

20 to 90 psi

138 to 621 kPa

143 pounds

65 kg

-10°C to

70°C

-10° to

40°C

1200 watts 4092 BTU/hr

900 watts 3069 BTU/hr

500 watts 1705 BTU/hr

20 to 90 psi

138 to 621 kPa

156 pounds

108 to 132V

198 to 264V

-10°C to

70°C

71 kg

Category II

-10° to 40°C

1700 watts 5797 BTU/hr

1100 watts 3751 BTU/hr

750 watts 2557 BTU/hr

20 to 90 psi

138 to 621 kPa

181 pounds

82 kg

9

Page 10

Specifications — 3/4-HP and 1-HP Chillers

Model: Rfg = Refrigerating Only

Rfg / Htg = Refrigerating & Heating

Magnetic Drive Centrifugal Pump

Model Rfg Rfg / Htg Rfg Rfg / Htg

Operating Temperature -10° to 40°C -10° to 70°C -10° to 40°C -10 to 70°C

Compressor 3/4 HP 1 HP

Cooling Capacity @ 20°C

10°C

0°C

Pressure at 0 Flow Rate 10 psi / 69 kPa 10 psi / 69 kPa

Flow Rate at 0 psi 4.1 gpm / 15.5 lpm 4.1 gpm / 15.5 lpm

Reservoir Capacity 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters

Dimensions (h x w x d)

Shipping Weight

208-230 V, 60 Hz

Volts Range

Amps 9.2A 9.5A 9.5A 9.8A

240 V, 50 Hz

Volts Range

Over Voltage

Amps 9.2A 9.5A 9.5A 9.8A

2500 watts 8525 BTU/hr

1700 watts 5797 BTU/hr

760 watts 2591 BTU/hr

22-5/8 x 14-1/2 x 27-5/8 in.

57.6 x 36.8 x 70.2 cm

187 pounds

84.8 kg

187 to 253V

198 to 264V

Category II

2900 watts 9889 BTU/hr

1950 watts 6649 BTU/hr

1000 watts 3410 BTU/hr

189 pounds

85.7 kg

Positive Displacement Pump (“P” Series Chillers)

Model P Series Chillers Rfg Rfg / Htg Rfg Rfg / Htg

Operating Temperature -10° to 40°C -10° to 70°C -10° to 40°C -10° to 70°C

Compressor 3/4 HP 1 HP

Cooling Capacity @ 20°C

10°C

0°C

Flow Rate @ 0 psi 3.5 gpm / 13.2 lpm 3.5 gpm / 13.2 lpm

Pump Pressure (adjustable)

Reservoir Capacity 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters

Shipping Weight

208-230 V, 60 Hz

Volts Range

Amps 11.9A 12.2A 12.2A 12.5A

240 V, 50 Hz

Volts Range

Over Voltage

Amps 11.9A 12.2A 12.2A 12.5A

2500 watts 8525 BTU/hr

1700 watts 5797 BTU/hr

760 watts 2591 BTU/hr

20 to 100 psi

138 to 689 kPa

197 pounds

89 kg

187 to 253V

198 to 264V

Category II

2900 watts 9889 BTU/hr

1950 watts 6649 BTU/hr

1000 watts 3410 BTU/hr

20 to 100 psi

138 to 689 kPa

199 pounds

90 kg

10

Page 11

Model: Rfg = Refrigerating Only

Rfg / Htg = Refrigerating & Heating

Turbine Pump (“T” Series Chillers)

Model T Series Chillers Rfg Rfg / Htg Rfg Rfg / Htg

Operating Temperature -10° to 40°C -10° to 70°C -10° to 40°C -10° to 70°C

Compressor 3/4 HP 1 HP

Cooling Capacity @ 20°C

10°C

0°C

2500 watts 8525 BTU/hr

1700 watts 5797 BTU/hr

760 watts 2591 BTU/hr

2900 watts 9889 BTU/hr

1950 watts 6649 BTU/hr

1000 watts 3410 BTU/hr

Flow Rate @ 0 psi 3.5 gpm / 13.2 lpm 3.5 gpm / 13.2 lpm

Pump Pressure (adjustable)

20 to 90 psi

138 to 621 kPa

20 to 90 psi

138 to 621 kPa

Reservoir Capacity 1.1 gal / 4.2 liters 1.1 gal / 4.2 liters

Shipping Weight

197 pounds

89 kg

199 pounds

90 kg

208-230 V, 60 Hz

Volts Range

187 to 253V

Amps 11.9A 12.2A 12.2A 12.5A

240 V, 50 Hz

Volts Range

Over Voltage

198 to 264V

Category II

Amps 11.9A 12.2A 12.2A 12.5A

Specifications subject to change without notice.

Notes: Refer to the serial number plate on the rear of the Chiller for model and electrical data.

Cooling capacity (watts x 3.41) = BTU/hour. Performance specifications determined at ambient temperature of 20°C (68°F).

For 50Hz models, derate cooling capacity 17%.

Positive Displacement Pump Models: External pressure reducing assembly (Cat. No. 060302) steps down high outlet

pressure to 10 to 45psi.

Environmental Conditions Indoor use only

Maximum Altitude: 2000 meter

Operating Ambient: 5° to 30°C

Relative Humidity: 80% for temperatures to 30°C

Pollution Degree: 2

Class 1: Residential, Commercial, Light Industrial

Class 2: Heavy Industrial

11

Page 12

Section 3 – Installation and Startup

WARNING: Be sure all power is off before proceeding.

3.1 Site Requirements

Ambient Temperature and Relative Humidity

The Chiller is designed for indoor installation in ambient temperatures between 5° and 30°C

(41° and 86°F); relative humidity should not exceed 80% (non-condensing).

Location

The Chiller should be installed on a strong, level surface. It should be located as close to possible to

the process requiring cooling. It should not be installed closer than 4 feet (1.4 meters) to a heatgenerating source, such as heating pipes, boilers, etc. If possible, the Chiller should be located near

a suitable drain to prevent flooding in the event of leaks. Do not place it where corrosive fumes,

excessive moisture, excessive dust, or high room temperatures are present.

For ease of positioning and maneuverability, the Chiller is supplied with casters. The front wheels

can be locked to keep the Chiller in place while in use.

To help prevent voltage drops, position the Chiller as close as possible to the power distribution

panel. Avoid voltage drops by using a properly grounded power outlet wired with 14 gauge or larger

diameter wire. The use of an extension cord is not recommended.

NOTE: The Chiller may be located at a level below that of the equipment being cooled. As long as

the process remains closed, overflow will not occur when adding cooling fluid to the Chiller reservoir.

Clearance

Adequate clearance should be allowed on the front, sides, and rear of the Chiller for access to

connections and components. The front and rear vents of the Chiller must be a minimum of 24

inches (61 cm) away from walls or vertical surfaces so air flow is not restricted.

3.2 Electrical Power

An IEC power cord is provided with the Chiller. It should be attached to the receptacle on the rear of

the enclosure. Make sure that the power outlet used for the Chiller is properly grounded and

matches the voltage and frequency indicated on the identification label on the back of the Chiller.

The use of an extension cord is not recommended. However, if one is necessary, it must be properly

grounded and capable of handling the total wattage of the unit. The extension cord must not cause

more than a 10% drop in voltage to the Chiller.

WARNING: DO NOT plug the Chiller into the electrical outlet until the

unit is ready for Startup (Section 3.7 below).

3.3 Optional Signal Inputs/Outputs

External Temperature Probe

This option allows you to control cooling fluid temperature using an external temperature

measurement (ambient room/machine temperature or process temperature). A 4-pin connector is

provided on the underside of the local control panel for connecting the external temperature probe.

NOTE: In order for the Chiller to properly recognize the presence of the external temperature probe,

the probe must be connected to the unit before power is applied.

RS232 / RS-485 Serial Output

This option allows you to remotely control the Chiller and/or output temperature readings to an

external recorder or other auxiliary device. The maximum communications distance for Chillers

equipped with the RS232 option is 50 feet (15 meters). The maximum distance for units equipped

with the RS485 option is 4000(1200 meters). A 9-pin D-connector is provided on the rear of the

instrument enclosure for this connection.

12

Page 13

Remote I/O Port

This option allows you to use an external 12 VDC signal to turn the Chiller on and off. A 9-pin Dconnector is provided on the rear of the instrument enclosure for this connection.

3.4 Plumbing

Process Piping

The Chiller has two internally threaded (1/2 inch ID NPT) fittings on the rear of the instrument

housing for the process water connections. Two sets of adapters (1/2 inch ID and 5/8 inch ID) are

supplied with the unit for connecting these fittings to the process piping.

To maintain a safe workplace and avoid leaks, special care should be taken when choosing hoses

and connectors for the Chiller. It is the user’s responsibility to ensure that the tubing and fittings

connected to the Chiller are compatible with the fluid, temperature, and pressure being used.

• Pressure Ratings — Hoses should be able to withstand the largest pressure that they will

encounter. For “P” Series (positive displacement pump) and “T” Series (turbine pump)

Chillers, this is 100 psi (689 kPa).

• Flexible Tubing — Avoid tubing that will expand and take up fluid volume when operating at

the desired pressure.

• Hose Diameter — Process piping/hosing with a diameter smaller than ½ inch ID can be

used if desired. However, keep in mind that using smaller diameter hosing increases

pressure in the circulating system.

• Couplings and Clamps — The use of screw-tightened hose clamps is necessary on all

joints to insure good, tight connections. Quick connectors are not recommended as they

have the potential for restricting flow rate.

Reservoir Drain

• A ½ inch NPT connection is provided for the reservoir’s gravity drain. It should be piped to

a drain or receptacle positioned below the bottom of the reservoir. If a receptacle is used,

be sure it is of sufficient volume to hold all the water in the reservoir, process, and process

lines.

3.5 Closed System or Cooling Coil Setup

Connect the Chiller’s inlet and outlet to the external apparatus with hoses or pipes. The direction of

the flow through the system can be controlled by the way the connections are made. Fluid is drawn

into the Chiller through the “Inlet” connection; fluid is pumped out of the Chiller through the “Outlet”

connection.

NOTE: When Chillers with the standard magnetic drive centrifugal pump are connected to an

external apparatus with a built-in shutoff, an external bypass loop assembly (Cat. No. 510-147) may

be needed if operating below 20°C (68°F). This bypass assembly continues flow circulation to and

from the pump even though the main flow to the external apparatus has been blocked.

3.6 Open Bath System Setup

Connect the Chiller’s inlet and outlet to the external bath using tubing of the same diameter and

length. The same size fittings should also be used on both the inlet (suction) and outlet (pressure).

This helps ensure a balanced flow. A restricting valve or pinch clip should be installed in the outlet

tubing and adjusted to match the return (inlet) flow rate.

Cut the external end of the suction tube into a “V” shape so that the tube will not seal itself against

the wall of the external tank. Both the pressure and suction tubing should be securely fastened to

the external tank to prevent movement during use.

When using flexible tubing, the suction tubing must have a wall thickness that will not collapse under

vacuum, particularly when going around bends.

Fill the external bath (see Section 3. 7 below for suitable fluids). The bath fluid must be at a level at

least slightly above the opening of the inlet tubing.

13

Page 14

3.7 Startup

Process Coolant

Suitable Fluids

IMPORTANT: Only use fluids that will satisfy safety, health, and equipment compatibility

requirements. Caustic, corrosive, or flammable fluids must never be used.

The Chiller is designed to accommodate a variety of coolant fluids (water, glycol mixtures, etc). For

most applications above 20°C (68°F), distilled water is satisfactory. For operation at or below 20°C

(68°F), the Chiller must be protected with an antifreeze solution. Ethylene glycol (laboratory grade)

and water in a 50/50 mixture is satisfactory from +20° to -15°C (68° to 5°F). Select a fluid that is

compatible with the Chiller’s wetted parts (see Section 2.2).

Filling the Reservoir

Remove the filler cap from the reservoir and, using a funnel, add fluid until it reaches the MAX line

on the reservoir’s fluid level gauge. When full, remove the funnel, but do not replace the cap at this

time.

Electrical Power

Plug the Chiller’s power cord into an appropriate electrical outlet (see Section 3.2).

Place the Circuit Breaker/Power Switch on the rear of the instrument enclosure in the “On” position.

Three decimal points will appear on the Temperature display; two decimal points will appear on the

pressure/flow rate display.

WARNING: Do not use caustic, corrosive, or flammable fluids.

WARNING: Operation below 20°C (68°F) requires antifreeze in the

circulation fluid.

WARNING: FOR CHILLERS WITH MAGNETIC DRIVE PUMPS ONLY.

A low temperature fluid, such as a mixture of 50% ethylene or

propylene glycol / 50% water, or equivalent, must be used under all

operating conditions.

Starting Process Fluid Flow

Press the Power Button on the front panel. The system startup sequence will begin and proceed as

follows:

The pump will turn on and fluid will begin circulating through the system. The set point

temperature will appear briefly on the Temperature display; after a few seconds, it will be

replaced by the actual fluid temperature. Fifteen to 20 seconds after power up, the compressor

will begin operating.

Check for leaks.

With the pump running, the reservoir’s fluid level will drop as the process and/or process cooling

lines fill with fluid. Add fluid as follows:

Closed Systems: Slowly add fluid to the reservoir until the liquid level remains stable.

Open Bath Systems: Adjust the restriction (pinch) valve until the liquid level in both

the bath and the reservoir remain stable. Add fluid as needed to bring liquid levels in

the bath and reservoir up to the desired level. Make sure the fluid level in the bath is

above the opening on the Chiller’s inlet hose.

Replace the reservoir cap.

. .

. . .

14

Page 15

Section 4

Section 4 ––––Operation

Section 4 Section 4

4.1 Selecting the Temperature Unit (°C or °F)

4.2 Displaying and Adjusting the Set Point

Operation

OperationOperation

NOTE: The Chiller incorporates a special “lockout” feature that can be enabled to prevent

unauthorized or accidental changes to set point and other operational values. This feature is

described in detail in Section 4.8. It should not be enabled until all operational parameters are set.

The LEDs adjacent to the Temperature Display indicate the unit (°C or °F) used for temperature

displays. To change from °C to °F or vice versa, proceed as follows:

To change to °F — Place the Circuit Breaker/Power Switch on the rear of the instrument in

the “Off” position. Press and hold the Units/Menu Select Button while returning the Circuit

Breaker/Power Switch to the “On” position.

To change to °C — Place the Circuit Breaker/Power Switch on the rear of the instrument

in the “Off” position. Press and hold the Power Button on the front panel while returning

the Circuit Breaker/Power Switch to the “On” position.

IMPORTANT: All user settings, except baud rate and calibration offset, return to the original factory

defaults when the unit in which temperature is displayed is changed. The Chiller’s temperature set

point and various alarm settings should be reset to the desired values.

Press the Select/Set Knob on the front panel. The current set point temperature will be displayed

and the decimal point at the bottom right of the display will flash, indicating the temperature can be

changed.

Rotate the Select/Set Knob until the desired set point temperature is displayed. The setting is

accepted after either pressing the Select/Set Knob a second time or will be accepted automatically

after a few seconds of inactivity.

NOTE: This function is not available when the optional ambient tracking probe or remote

temperature control probe is installed and enabled. See Sections 4.3, 4.4, and 4.7.8.

4.3 Displaying and Adjusting the Ambient Tracking Offset

NOTE: Ambient tracking is an optional function that may or may not be available on your Chiller. It

permits you to control cooling fluid temperature based on room or machine temperature plus or

minus a user-adjustable offset temperature.

When the optional ambient tracking probe is installed and enabled (AtC) (see Section 4.7.8), the

ambient tracking offset rather than the set point temperature is displayed when the Select/Set Knob

on the front panel is pressed.

To change the displayed offset value, rotate the Select/Set Knob until the desired offset value is

displayed. An offset value from -5.0° to +5.0°C (-9.0° to +9.0°F) may be entered. The setting is

accepted after either pressing the Select/Set Knob a second time or will be accepted automatically

after a few seconds of inactivity.

4.4 Displaying and Adjusting Remote Control Temperature

NOTE: Remote temperature control is an optional function that may or may not be available on your

Chiller. It permits you to control cooling based on the temperature of an external process.

When the optional remote control external probe is installed and enabled (rPC) (see Section 4.7.8),

the external temperature set point is displayed when the Select/Set Knob on the front panel is

pressed.

To change the external temperature set point, rotate the Select/Set Knob until the desired set point

temperature is displayed. The setting is accepted after either pressing the Select/Set Knob a second

time or will be accepted automatically after a few seconds of inactivity.

4.5 Selecting the Pressure / Flow Rate Display and Units

The Chiller can be set up to display either fluid pressure (in PSI or kPa) or flow rate (in GPM or

LPM). Pressing the Units/Menu Select button briefly toggles through the available selections.

15

Page 16

Note: The flow readout is intended as a reference only. If accurate flow readings are required

an external flow meter is recommended.

NOTE: Metric pressure reading output must be multiplied by 100 for kPa.

4.6 Selecting the Internal/External Temperature Display

NOTE: This section applies only when the ambient tracking probe or remote temperature control are

installed and enabled. It allows the user to check or continuously display either the Chiller’s internal

outlet fluid temperature or the external ambient/process temperature.

When the ambient tracking probe is selected (AtC) (see Section 4.7.8), the Chiller normally displays

the internal outlet fluid temperature. To display the external ambient temperature, press and release

the Units/Menu Select button until P2 appears on the pressure/flow rate display.

When the remote temperature control probe is selected (rPC) (see Section 4.7.8), the Chiller

normally displays the external process temperature. To display the internal outlet fluid temperature,

press and release the Units/Menu Select button until P1 appears on the pressure/flow rate display.

NOTE: P1 or P2 will remain on the pressure/flow rate display until the Units/Menu Select button is

pressed and released. The displayed temperature will revert to the default condition (internal

temperature for the ambient probe, external temperature for the remote temperature control probe).

16

Page 17

4.7 Setting Operational Parameters

The Chiller’s various operational parameters, such as temperature, flow rate, and pressure alarm

values, are all user-adjustable. They are accessed by pressing and holding the Units/Menu Button

until HL appears on the pressure/flow rate display. Pressing and releasing the Units/Menu Button

once HL appears allows you to scroll through the various parameters; rotating the Select/Set Knob

allows you to change the displayed setting. You can accept the displayed value by either pressing

the Select/Set Knob or allowing the display to timeout.

Menu Item Description Choices / Ranges / Comments

HL

LL

HA

FP w/psi LED lit

FP w/kPa LED

lit

FL w/gpm LED

lit

FL w/lpm LED

lit

Sd

AF

rP

High Temperature Limit

Alarm Set Point

Low Temperature Limit

Alarm Set Point

Front Panel High

Ambient Temperature

Alarm Set Point

Maximum Fluid

Pressure Alarm Set

Point

Maximum Fluid

Pressure Alarm Set

Point

Minimum Flow Rate

Alarm Set Point

Minimum Flow Rate

Alarm Set Point

Establishes the cooling

and heating rate by

setting a desired

differential between the

measured internal and

external temperature.

Auto-Refrigeration

Temperature Set Point

External temperature

probe status

Default

Setting

+20° to 42°C / 68° to 108°F

(Refrigerating Chillers)

+20° to 72°C / 68° to 162°F

(Refrigerating / Heating Chillers)

-14°C to +15°C / 7° to 59°F (all units) 0.0ºC

+30° to 45°C.

Always displayed and set in °C.

40 to 100 PSI 80 PSI

270 to 680 kPa 550 kPa

0 or 0.8 to 2.0 GPM 0.0 GPM

0 or 3 to 7 LPM 0.0 LPM

4°C to 20°C

Always displayed and set in °C

NOTE: Sd is displayed only if the optional

remote temperature control probe is installed.

+20° to 40°C (Refrigerating Chillers)

+20° to 50°C (Refrigerating / Heating Chillers)

Always displayed/set in °C.

AtC (ambient temperature control probe

enabled)

rPC (remote temperature control probe

enabled)

NO (external temperature control probe

disabled)

35ºC

50ºC

40ºC

5°C

40ºC

50ºC

NO

(optional)

c

1

c

2

F c

PC

Internal Probe

Calibration Offset

External Probe

Calibration Offset

Fluid Flow Rate

Calibration Gain

Coefficient

Communications Baud

Rate

NAP (external temperature control probe not

installed)

±2.9°C.

Always displayed/set in °C.

Special access procedure required.

See Section 4.7.9.

±2.9°C.

Always displayed/set in °C.

Special access procedure required.

See Section 4.7.10.

0.2 to 50.0

See Section 4.7.11.

0, 2400, 4800, 9600, 19200.

Zero should be entered if RS232 is not being

used.

17

NAP

0.0ºC

0.0ºC

1.0

9600

Page 18

4.7.1 High Temperature Limit (HL)

This menu item serves two functions. First, it establishes the maximum allowable set point

temperature and thus helps prevent an operator from inadvertently setting the temperature set point

above a pre-established temperature. Secondly, it serves as a high temperature alarm,

automatically activating both audio and visual alarm indicators when the measured fluid temperature

reaches the HL setting. The compressor, heater, fan, and pump will also turn off.

To change the high limit value, rotate the Select/Set Knob until the desired high limit value is

displayed on the temperature display.

HL

4.7.2 Low Temperature Limit (LL)

This menu item also serves a dual function. First, it establishes the minimum allowable set point

temperature and thus helps prevent an operator from inadvertently setting the temperature set point

below a pre-established temperature. Secondly, it serves as a low temperature alarm, automatically

activating both audio and visual alarm indicators when the measured fluid temperature drops to the

LL setting. The compressor, heater, fan, and pump will also turn off.

To change the low limit value, rotate the Select/Set Knob until the desired low limit value is displayed

on the temperature display.

LL

4.7.3 High Ambient Temperature Limit (HA)

This menu item protects the Chiller from overheating due to a high ambient temperature. Should the

ambient temperature rise above the limit value, the audio and visual alarms will activate and the

compressor, heater, fan, and pump will turn off.

To change the high ambient temperature value, rotate the Select/Set Knob until the desired high

ambient temperature limit value is displayed on the temperature readout.

NOTE: This value is always displayed/set in °C.

HA

4.7.4 Maximum Fluid Pressure (FP)

This is the maximum allowable fluid pressure and can be set in either PSI or kPa (the LED adjacent

to the display indicates the active unit of measure). Should the fluid pressure rise above the

maximum fluid pressure value, the audio and visual alarms will activate and the compressor, heater,

fan, and pump will turn off.

To change the fluid pressure limit value, rotate the Select/Set Knob until the desired maximum fluid

pressure value is displayed on the temperature readout.

NOTE: When FP first appears, the PSI LED will be lit. To view or change the FP value in kPa, press

the Units/Menu Button again. The FP will remain on the display and the kPa LED will light.

FP

FP

•

PSI

•

kPa x 100

35.0

0.0

35

80

5.5

NOTE: The Chiller also incorporates a built-in safety that automatically maintains fluid pressure

below a valve-regulated pressure value. It maintains this maximum outlet pressure by diverting the

flow of process fluid to the reservoir (i.e., begin internally recirculating the fluid). A maximum

18

Page 19

pressure value is set at the factory, but is user-adjustable. See Section 4.9 for information on

changing the maximum outlet pressure value.

4.7.5 Minimum Flow Rate (FL)

This is the minimum allowable flow rate and can be set in either GPM or LPM (the LED adjacent to

the display indicates the active unit of measure). Should the fluid flow rate drop below the minimum

flow rate value, the audio and visual alarms will activate and the compressor, heater, fan, and pump

will turn off.

To change the minimum flow rate value, rotate the Select/Set Knob until the desired flow rate value

is displayed on the temperature readout.

NOTE: When FL first appears, the GPM LED will be lit. To view or change the FL value in LPM,

press the Units/Menu Button again. The FL will remain on the display and the LPM LED will light.

With FL set to “0” the flow alarm is disabled and the chiller will continue to operate with the output

flow blocked.

Note: If flow rates are below 1.5 GPM this feature is not recommended as nuisance alarms may

result.

•

FL

GPM

0.8

FL

4.7.6 Maximum External / Internal Temperature Differential (Sd) (optional)

NOTE: This menu item (Sd) appears only when the remote temperature control probe is installed

and enabled (see Section 4.7.8). Values are always displayed in °C.

This value helps establish the cooling/heating rate when the remote temperature control probe is

being used. Maximum external/internal differential temperature values from 4° to 20°C may be

entered. The higher the setting, the more rapidly the Chiller will achieve the external temperature set

point. Low differential temperature settings minimize the amount of temperature

overshoot/undershoot that occurs when the measured external temperature reaches the external set

point temperature.

Sd

4.7.7 Auto-Refrigeration Temperature (AF)

This menu item allows you to select the temperature at which refrigeration is activated. To change

the displayed value, rotate the Select/Set Knob until the desired auto-refrigeration temperature is

displayed.

NOTE: This value is always displayed/set in °C.

AF

•

LPM

3.0

5.0

35.0

4.7.8 Remote Probe (rP)

NOTE: If an external temperature probe is not installed, NAP will be displayed when this menu item

is selected.

This menu item allows you to enable/disable the Chiller’s optional ambient temperature probe (AtC)

or remote temperature control probe (rPC).

If you wish to operate the Chiller using the ambient tracking probe, rotate the Select/Set Knob until

AtC is displayed. When this setting is selected, the cooling fluid temperature will be controlled at the

19

Page 20

temperature sensed by the ambient tracking probe (this may be room or machine temperature) plus

or minus a user-set offset temperature (see Section 4.3).

rP

If you wish to operate the Chiller using the remote temperature probe, rotate the Select/Set Knob

until rPC is displayed. When this setting is selected, the temperature will be controlled using the

temperature sensed by the external probe. The rate of cooling will be controlled using the maximum

differential temperature setting (Sd) (see Section 4.7.6).

rP

If you do not wish to operate the Chiller using either of these external probes, rotate the Select/Set

Knob until NO is displayed.

rP

4.7.9 Internal Calibration Offset (C1)

This menu item allows you to adjust the Chiller’s internal temperature reading to match that of a

traceable standard. It allows you to offset the displayed temperature value by as much as ±2.9°C.

NOTE: Calibration offset values are always set and displayed in °C. To prevent the operator from

accidentally changing the calibration offset, a special sequence of keystrokes is required to access

this function.

1. Press and hold the Units/Menu Button until HL appears on the display.

2. Press and release the Units/Menu Button until rP appears on the display.

3. Press and hold the Units/Menu Button.

4. While holding the Units/Menu Button, press and release the Select/Set Knob.

5. When CAL appears on the temperature readout, release the Units/Menu Button. The

current calibration offset value will appear on the temperature readout.

6. Rotate the Select/Set Knob until the desired calibration offset is displayed. Press the

Select/Set Knob or simply allow the display to time out to accept the displayed value.

AtC

rPC

NO

4.7.10 External Calibration Offset (C2)

This menu item allows you to adjust the Chiller’s external temperature reading to match that of a

traceable standard. It allows you to offset the displayed temperature value by as much as ±2.9°C. It

appears only if the external temperature probe is installed.

NOTE: Calibration offset values are always set and displayed in °C. To prevent the operator from

accidentally changing the calibration offset, a special sequence of keystrokes is required to access

this function.

1. Press and hold the Units/Menu Button until HL appears on the display.

2. Press and release the Units/Menu Button until C2 appears on the display.

3. Press and hold the Units/Menu Button.

4. While holding the Units/Menu Button, press and release the Select/Set Knob.

5. When CAL appears on the temperature readout, release the Units/Menu Button. The

current calibration offset value will appear on the temperature readout.

C

1

0.0

20

Page 21

6. Rotate the Select/Set Knob until the desired calibration offset is displayed. Press the

Select/Set Knob or simply allow the display to time out to accept the displayed value.

C

2

4.7.11 Flow Rate Calibration (F c )

This menu item allows you to adjust the Chiller’s displayed flow rate reading to match that of a

traceable standard. It allows you to change the gain coefficient displayed value from 0.2 to 50.0.

1. Press and hold the Units/Menu Button until HL appears on the display.

2. Press and release the Units/Menu Button until C1 (C2 if the Chiller is equipped with an

external temperature probe) appears on the display.

3. Press and hold the Units/Menu Button.

4. While holding the Units/Menu Button, press and release the Select/Set Knob.

5. When CAL appears on the temperature readout, release the Units/Menu Button. The

current gain coefficient value will appear on the temperature readout.

6. Rotate the Select/Set Knob until the desired flow rate is displayed on the flow readout.

Press the Select/Set Knob or simply allow the display to time out to accept the displayed

value.

0.0

c

F

4.7.12 Baud Rate (PC)

This menu item allows you to establish the baud rate for serial communication. Allowable settings

are 0 (no serial communication), 24 (2400 baud), 48 (4800 baud), 96 (9600 baud), 192 (19200

baud).

To change the displayed setting, rotate the Select/Set Knob until the desired baud rate is displayed.

Press the Select/Set Knob or allow the display to time out to accept the displayed value.

PC

1.0

96

21

Page 22

4.8 Display, Alarm, and Error Messages

When certain conditions are detected, a message code flashes on the display and the local audio

alarm sounds. Depending on the nature of the condition, power to various systems components,

such as the compressor, heater, fan, and pump, is removed. When condition is rectified, push front

panel Power button or turn circuit breaker off then on to clear the fault or error.

Message

Code

EAF

E C

E-C

EFL

EHA

Description Action Required

Rear panel high ambient

temperature

(select models only)

External remote control active,

Chiller in standby (for units with

remote control by 12 VDC option)

(select models only)

External remote control active,

Chiller in standby

Only appears when Chiller is

equipped for remote control using

a dry contact)

(select models only)

Low fluid level warning / alarm

(for units with optional float

switch)

(select models only)

Front panel high ambient

temperature warning.

Warning - The ambient temperature is higher than the

set ambient limit.

Lower ambient temperature.

Normal — Unit idle until remotely activated.

Normal — Unit idle until remotely activated.

Warning/Alarm — Fluid level is too low. An alarm will

sound once every 8 seconds for 5 occurrences. If the

fluid level has not been raised 8 seconds after the fifth

alarm, the unit will shut down.

Warning - The ambient temperature is higher than the

set ambient limit.

Lower ambient temperature or raise temperature limit.

EHL

ELL

LLO

CAn

LO-

H2O

High temperature set point

warning

Low temperature set point

warning

Local Lockout

Cancel Local Lockout

No fluid flow and no fluid

pressure

Warning — The temperature set point is higher than

the high temperature limit value. If not corrected, the

high temperature limit alarm will be activated when

fluid temperature rises above established the HL

value.

Lower temperature set point or increase high

temperature limit value.

Warning — The temperature set point is lower than

the low temperature limit value. If not corrected, the

low temperature limit alarm will be activated when

fluid temperature falls below the established LL value.

Increase temperature set point or decrease low

temperature limit value.

Normal — Indicates that Local Lockout feature (see

Section 4.10) is enabled. Appears momentarily when

Select/Set Knob is pressed to view/change set point

value.

Normal — Indicates the Local Lockout feature (see

Section 4.10) has been disabled. Appears

momentarily when Local Lockout status is changed

from enabled (LLO) to disabled.

Warning — Indicates that the Chiller did not detect

any fluid flow or pressure upon startup. Unit will

normally run after 5 minutes after power on.

22

Page 23

Message

Code

Description Action Required

01

02

03

04

05

06

Factory Reserved None.

Alarm — Process fluid temperature has dropped to

low temperature limit value. Compressor, heater, fan,

Low limit temperature alarm

High limit temperature alarm

Over-temperature protection

alarm

Low liquid level alarm

(select models only)

High bath temperature alarm

and pump turned off.

Increase heat load on Chiller or decrease low

temperature limit value.

Alarm — Process fluid temperature has reached high

temperature limit value. Compressor, heater, fan, and

pump turned off.

Decrease heat load on Chiller or increase high

temperature limit value.

Alarm — Process fluid temperature is above Chiller’s

factory set high temperature safety cutoff. Power to

compressor, heater, and fan turned off; pump remains

on.

Lower process temperature.

Delayed Alarm — Activated when the liquid level in

the reservoir falls below an acceptable level for 30

seconds of longer. Compressor, heater, fan, and

pump turned off.

Add fluid to reservoir.

Alarm — Fluid temperature has exceeded 82°C

(180°F). Compressor, heater, fan, and pump turned

off.

Lower fluid temperature.

07

08

09

10

11

12

Low flow alarm

High pressure alarm

System fault

Electronic power component fault

(Triac)

Internal probe fault

External temperature probe fault

(select models only)

Alarm — Flow rate has dropped below minimum flow

rate setting. Power to compressor, heater, fan, and

pump turned off. Note: Disabled during first 2 minutes

of operation.

Correct cause of low flow rate or decrease minimum

flow rate setting.

Delayed Alarm — Activated when fluid outlet pressure

has exceeded high-pressure limit value for 30

seconds. Compressor, heater, fan, and pump turned

off.

Decrease outlet pressure by removing blockage or

increase high-pressure limit value.

Fault — Power to compressor, heater, fan, and pump

turned off. Contact service representative for

corrective action.

Fault — Power to compressor, heater, fan, and pump

turned off. Contact supplier.

Fault — Faulty temperature probe. Power to

compressor, heater, fan, and pump turned off.

Contact supplier.

Fault — Faulty external temperature probe. Power to

compressor, heater, fan, and pump turned off.

Replace ambient tracking probe or operate instrument

using internal temperature probe. Contact supplier if

fault persists.

23

Page 24

Message

Code

13

14

15

16

17

Communications fault

ADC fault, internal probe

ADC fault, external probe

Front panel high ambient

temperature alarm

Rear panel high ambient

temperature alarm

(select models only)

Description Action Required

Fault — Internal electronics failure. Power to

compressor, heater, fan, and pump turned off.

Contact supplier.

Fault — ADC for internal probe faulty. Power to

compressor, heater, fan, and pump turned off.

Contact supplier.

Fault — ADC for external probe faulty. Power to

compressor, heater, fan, and pump turned off.

Contact supplier.

Alarm — Ambient temperature at front panel is higher

than high ambient temperature limit. Compressor,

heater, fan, and pump turned off. Occurs when the

ambient temperature exceeds the set ambient limit by

5ºC or more.

Lower temperature in area in which Chiller is located

or increase high ambient temperature limit value. See

“High Ambient Temperature Limit” Section.

Alarm — Ambient temperature at rear panel is higher

than high ambient temperature limit. Compressor,

heater, fan, and pump turned off. Occurs when the

ambient temperature exceeds the ambient limit.

Lower temperature in area in which Chiller is located.

Temperature limit is not adjustable.

24

Page 25

4.9 Adjusting the High Pressure Bypass Setting

The Chiller incorporates an automatic safety to maintain outlet pressure below a valve-regulated

pressure. This valve is adjustable and is located inside the Chiller housing.

CAUTION: There are exposed fan blades inside the Chiller housing. Exercise extreme care

when accessing or adjusting any interior components.

WARNING: Hazardous voltages are present.

To access the high-pressure bypass valve, remove the two bolts at the upper left and right corners

of the Chiller’s rear panel, slide the top panel back about 2-3 inches, and lift off. The regulator valve

is located in the left rear corner of the unit.

The high-pressure bypass is adjusted as follows:

1. Set the low flow rate alarm value to zero (see Section 4.3.5, above). This will prevent the unit

from activating the flow alarm while you are adjusting the maximum pressure setting.

2. Completely block the Chiller’s outlet flow. This should cause the outlet pressure to rise.

3. Set the Pressure/Flow Rate display to read either PSI or kPa.

4. Rotate the handle on the pressure valve until the desired maximum pressure setting is

displayed on the Pressure/Flow Rate display.

5. Reset the flow alarm value to the previous setting.

6. Return the Pressure/Flow Rate display to the previous setting.

7. Replace the top panel of the Chiller, being sure to secure the bayonet-style prongs on the front

of the panel in the openings at the front of the unit. Reinsert the two bolts that secure the top

panel to the rear panel of the unit.

4.10 Enabling/Disabling the Local Lockout

This feature is used to prevent unauthorized or accidental changes to set point and other operational

values. When enabled, the values for the functions described in Sections 4.1, 4.2, 4.3, and 4.5 can

be displayed, but not changed.

To enable the local lockout, press and hold the Select/Set Knob until LLO is displayed

(approximately 5 seconds). Once enabled, LLO will appear momentarily when the Select/Set Knob

is pressed to display the set point.

To disable the local lockout, press and hold the Select/Set knob until CAn appears momentarily as

local lockout status changes from enabled (LLO) to disabled (approximately 5 seconds).

NOTE: The Local Lockout feature does not prevent set point changes entered via the RS232

interface.

25

Page 26

Section 5 - Maintenance and Calibration

The Chiller is designed to require a minimum of periodic maintenance.

5.1 Standard Magnetic Drive Centrifugal Pump

When used under continuous operating conditions, this pump should be oiled every six (6) months

with SAE 20 oil. The pump incorporates two oil ports for this purpose.

To access the pump:

1. Turn both power switches off and unplug the power cord.

2. Remove the top panel of the housing (held in place with two bolts at the upper left and right

corners of the rear panel).

3. Remove the housing’s side panels by lifting them out of the housing frame.

5.2 Condenser, Air Vents, and Reusable Filter

To keep the system operating at optimum cooling capacity, the condenser, the air vents, and

reusable filter should be kept free of dust and dirt. They should be checked on a scheduled basis

and cleaned as required.

The reusable filter is easily accessed from either the left or right side of the unit. Use a mild

detergent and water solution to wash off any accumulated dust and dirt and then rinse and dry

thoroughly before reinstalling.

5.3 Fluid Filter

A removable, highly efficient fluid filter is integrated into the fluid reservoir. To remove it for cleaning,

simply remove the reservoir cap and lift the filter out of the reservoir. Rinse off accumulated

particulate and reinstall.

5.4 Fluid Level

The fluid level gauge on the rear of the Chiller should be periodically checked to determine if the

fluid level needs to be topped off. Generally, fluid should be added whenever the level in the

reservoir is at or near the “Low” gauge mark.

5.5 Temperature Calibration

At times, there may be a minor temperature difference between the Chiller’s displayed temperature

and the actual temperature as determined by a certified temperature measurement device. There

may also be situations where you want the displayed temperature to match a particular value to

have standardization between different instruments. These adjustments can be performed using the

Chiller’s internal and/or external temperature calibration offset functions. See Sections 4.7.9 and

4.7.10.

5.6 Flow Rate Calibration

There may be minor differences between the Chiller’s displayed flow rate and the actual flow rate as

determined by a certified flow rate measurement device. The Chiller’s displayed flow rate reading

can be adjusted to match an external device by changing the flow rate gain coefficient setting. See

Section 4.7.11.

26

Page 27

Section 6 – Troubleshooting

WARNING: Refer servicing to qualified service personnel. When power is on, dangerous

voltages exist within chassis components. Use extreme care when measuring voltages on live

circuits.

6.1 Unit Will Not Operate (no cooling or pumping)

• Check that the power cord is plugged in to an operating electrical outlet.

• Check that the Circuit Breaker/Power Switch is ON.

• Check that the front panel Power Switch is ON.

6.2 No Pumping

• Check the fluid level in the whole system to make sure the pump is receiving fluid.

• Check if the pump motor is operating.

• Check for blockage within the circulating system.

6.3 Insufficient Pumping

• Check for low line voltage.

• Check for too small of a hose diameter.

• Check for too high of a fluid viscosity.

• Check for restrictions in the connecting tubing.

6.4 No Cooling or Insufficient Cooling

• Check for low or high line voltage.

• Check for blocked airflow through ventilation screens.

• Check ambient air temperature. High air temperature may cause the refrigeration compressor to

temporarily shut down.

• Check for excessive heat being transferred to the cooling fluid liquid as this may exceed the

cooling capacity of the refrigeration system.

6.5 Triac Failure

• Triac fault message appears on the display, indicating that the triac has failed or the line supply

voltage has a source of extreme interference from other equipment. Plug the unit into another

power source. If it still displays triac failure, a triac or triac driver needs replacement.

6.6 Internal Probe Failure

• The Internal Probe failure message appears on the display, indicating that the internal probe has

failed or there is a problem with the circuitry reading the probe signal. Contact supplier.

6.7 External Temperature Probe Failure

• The External Temperature Probe failure message appears on the display, indicating that a

problem with the probe has been detected.

• Check the integrity of the external temperature probe connection to make certain that the probe

has not been unplugged.

• Replace the external temperature probe.

• If the problem persists, operate Chiller using internal temperature probe and contact supplier.

27

Page 28

6.8 Diagnostic Mode

NOTE: The Chiller must be set up to display temperature in °C in order to access the diagnostic

mode.

The Chiller incorporates a Diagnostic mode, which displays important operational information that

can aid in troubleshooting. To access the Diagnostic mode, place the Circuit Breaker/Power Switch

in the “Off” position and then return it to the “On” position while pressing and holding the Select/Set

Knob. The diagnostic menu appears on the Pressure/Flow Rate display; the current value for the

diagnostic item appears on the temperature readout. Pressing the Units/Menu Button toggles

through the various Diagnostic menu items

NOTE: Diagnostic items are display values only; they cannot be changed.

Menu Item Description

EC External voltage control

Ut Upper (head) temperature

Li Percentage of Line voltage

Ct Chiller type

Fb Fuse bits (remote control voltage, contact closures, etc.)

EP

03 (variable numeric value)

At Ambient temperature at front panel

External probe temperature and “---.” displayed when external

probe is not installed

Fluid flow rate or pressure.

Temperature display shows current fluid temperature.

Section 7 - Service and Technical Support

If you have followed the troubleshooting steps outlined in Section 6 and your Chiller still fails to

operate properly, contact the supplier from whom the unit was purchased. Have the following

information available for the customer service person:

— Model, Serial Number, and Voltage (from back panel label)

— Date of purchase and purchase order number

— Supplier’s order number or invoice number

— A summary of the problem

28

Page 29

7.1 Electrical Wiring Diagram

29

Page 30

7.2 Flow Diagram

30

Page 31

Section 8 - Replacement Parts

Air Filter

ALL 1/4 HP UNITS 120V, 60Hz 240V, 50Hz ALL 1/3 HP UNITS 120V, 60HZ 240V, 50HZ

Part Description Part No. Part No. Part Description Part No. Part No.

Condensing Unit, ¼ hp 750-157 750-158 Condensing Unit, ⅓ hp 750-306 750-189

Magnetic Drive Pump

(for models without heat)

Magnetic Drive Pump

(for models with heat)

Positive Displacement Motor 215-102 215-102 Positive Displacement Motor 215-102 215-102

Positive Displacement Pump

(for models without heat)

Positive Displacement Pump

(for models with heat)

Turbine Pump 215-305 215-308 Turbine Pump 215-305 215-308

Circuit Breaker 215-388 215-330 Circuit Breaker 215-330 215-330

PC Board w/ Ambient

Temperature Tracking

PC Board without Ambient

Temperature Tracking

ALL 1/2 HP UNITS 120V, 60HZ 240V, 50HZ ALL 3/4 HP UNITS 120V, 60HZ 240V, 50HZ

Part Description Part No. Part No. Part Description Part No. Part No.

Condensing Unit, ½ hp, 750-155 750-156 Compressor, ¾ hp 750-304 750-303

Magnetic Drive Pump

(for models without heat)

Magnetic Drive Pump

(for models with heat)

Positive Displacement Motor 215-103 215-103 Positive Displacement Motor 215-103 215-103

Positive Displacement Pump

(for models without heat))

Positive Displacement Pump

(for models with heat)

Turbine Pump 215-305 215-308 Turbine Pump 215-305 215-308

Circuit Breaker 215-388 215-388 Circuit Breaker 215-330

PC Board w/ Ambient

Temperature Tracking

PC Board without Ambient

Temperature Tracking

Fan 215-450 215-450

ALL 1 HP UNITS 120V, 60HZ 240V, 50HZ

Part Description Part No. Part No.

Compressor, 1 hp 750-304 750-303

Magnetic Drive Pump

(for models without heat)

(for models with heat)

Positive Displacement Motor 215-103 215-103 Flow Indicator Turbine 330-082

Positive Displacement Pump

(for models without heat))

Positive Displacement Pump

(for models with heat)

Turbine Pump 215-305 215-308

Circuit Breaker 215-330 215-330

PC Board w/ Ambient

Temperature Tracking

PC Board without Ambient

Temperature Tracking

Fan 215-450 215-450

Fan motor 525-578 525-578

525-551 525-552

525-553 525-554

215-105 215-105

215-099 215-099

500-247 500-248

500-245 500-246

525-551 525-552

N/A N/A

215-105 215-105

N/A N/A

500-247 500-248

500-245 500-246

525-551 525-552

525-553 525-554

215-106 215-106

215-099 215-099

500-247 500-248

500-245 500-246

Magnetic Drive Pump

(for models without heat)

Magnetic Drive Pump

(for models with heat)

Positive Displacement Pump

(for models without heat))

Positive Displacement Pump

(for models with heat)

PC Board w/ Ambient

Temperature Tracking

PC Board without Ambient

Temperature Tracking

Magnetic Drive Pump

(for models without heat)

Magnetic Drive Pump

(for models with heat)

Positive Displacement Pump

(for models without heat))

Positive Displacement Pump

(for models with heat)

PC Board w/ Ambient

Temperature Tracking

PC Board without Ambient

Temperature Tracking

Fan motor 525-578 525-578

Additional Parts (for all units)

Operations Manual 110-240

Tubing adapter kit 510-288

400-643 Magnetic Drive Pump

Fluid Filter 565-102

Reservoir Cap 300-460

Reservoir Spill Cup 300-459

525-551 525-552

525-553 525-554

215-105 215-105

215-099 215-099

500-247 500-248

500-245 500-246

525-551 525-552

525-553 525-554

215-106 215-106

215-099 215-099

500-247 500-248

500-245 500-246

31

Page 32

Section 9 - RS232

Serial Connector — A 9-pin D-connector is provided on the back panel of the Chiller for RS232 data

communication. A serial cable that uses only the following pins should be used to connect the Chiller

to the computer:

Pin #2 — data read (data from computer)

Pin #3 — data transmit (data to computer)

Pin #5 — Signal ground

RS232 Protocol — The Controller uses the following RS232 protocol:

Data bits — 8

Parity — None

Stop bits — 1

Flow control — None

Baud rate — Selectable (Chiller and PC baud rates must match).

Communications Commands — Commands must be entered in the exact format shown. Do not send a

[LF] (line feed) after the [CR] (character return). Be sure to follow character case exactly. A response

followed by an exclamation point (!) indicates that a command was executed correctly. A question mark

(?) indicates that the Chiller could not execute the command (either because it was in an improper

format or the values were outside the allowable range). A response must be received from the Chiller

before another command can be sent. All responses are terminated with a single [CR].

Command Description Command Format Values Return Message

Set Commend Echo SEi[CR]

Set On / Off SOi[CR]

Echo: i = 1

No Echo: i = 0

On: i = 1

Off: i = 0

![CR]

![CR]

Set Set Point SSxxx[CR] x = ASCII digit ![CR]

Read Set Point Temperature RS[CR]

Read Temperature RT[CR]

+xxx.x[CR] or

-xxx.x[CR]

+xxx.x[CR] or

-xxx.x[CR]]

Read Temperature Units RU[CR] C or F C[CR] or F[CR]

Read Status RW[CR]

1 = Run

0 = Standby

1[CR] or 0[CR]

Read Pressure in PSI RP[CR] +nnn.n[CR]

Read Pressure in kPa RK[CR] +nnn.n[CR]

Read Flow in GPM RG[CR] +nnn.n[CR]

Read Flow in LPM RL[CR] +nnn.n[CR]

Read Remote Control

Voltage

Read Compressor

Discharge Temperature (°C)

Read Remote Probe

Temperature

Read Ambient temperature

on PCB

Read internal temperature R1[CR]

Read external temperature R2[CR]

Read fault status

(see Section 4.8 for fault

message codes)

RC[CR] +nnn.n[CR]

RH[CR]

RR[CR]

RA[CR]

+xxx.x[CR] or

-xxx.x[CR]]

+xxx.x[CR] or

-xxx.x[CR]]

+xxx.x[CR] or

-xxx.x[CR]]

+xxx.x[CR] or

-xxx.x[CR]]

+xxx.x[CR] or

-xxx.x[CR]]

00 = System OK

RF[CR]

18 = Standby mode

![CR]

02 – 17 = Fault

Loading...

Loading...