PolyGard SPC-1110

Carbon monoxide (CO) gas detection and control system

serial no. SPC-1110-0 00 0

User Manual

April 01, 2004

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Carbon monoxide (CO) gas detection and control system

Page 2

1 General Overview

2 Description

3 Installation

3.1 Mounting locations.................................................................................................................. 5

3.2 Enclosure ............................................................................................................................... 5

............................................................................................................................... 3

................................................................................................................................5

4 Electrical Connection

4.1 Instructions............................................................................................................................. 6

4.2 Wiring connection................................................................................................................... 7

5 Start-up Operation

5.1 Set trip/setpoints..................................................................................................................... 8

5.1.1 Set low and high trip/setpoints without optional digital display ............................................. 8

5.1.2 Control trip/setpoint voltage calculation............................................................................... 9

5.1.3 Set low and high trip/setpoints with optional digital display .................................................. 9

5.2 Select switching differential of the trip/setpoints...................................................................... 9

5.3 Calibration.............................................................................................................................. 9

5.3.1 Control span voltage calculation ....................................................................................... 10

5.4 Calibration of digital display range (optional display)............................................................. 10

5.5 Motherboard jumper selection table ...................................................................................... 11

5.6 Displayboard jumper selection table ..................................................................................... 11

.................................................................................................................. 3

.......................................................................................................... 6

................................................................................................................ 8

6 Inspection and Service

6.1 Inspection............................................................................................................................. 12

6.2 Calibration sensor................................................................................................................. 12

6.3 Replacing sensor element .................................................................................................... 12

7 Troubleshooting

7.1 Diagnostics........................................................................................................................... 13

................................................................................................................... 13

..................................................................................................... 12

8 Cross-sensitivity Data...................................................................................

9 Specifications

10 Wiring Configuration and Enclosure Dimensions

11 Notes and General Information

11.1 Intended product application ............................................................................................. 22

11.2 Installers’ responsibilities................................................................................................... 22

11.3 Maintenance ..................................................................................................................... 22

11.4 Limited warranty ............................................................................................................... 22

11.5 Return instructions ............................................................................................................ 22

........................................................................................................................ 15

............................................ 17

.................................................................................. 22

14

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Page 3

Carbon monoxide (CO) gas detection and control system

1 General Overview

The PolyGard

CO analog single point controller is used for detection of carbon monoxide in the ambient air to

warn of the presence of carbon monoxide gas and to control ventilation systems.

2 Description

Gas sensing

The sensor portion of the PolyGard CO analog single point controller is a micro-fuel cell, which is completely

sealed. The measurement is a gas-in-liquid chemical reaction rather than a surface area measurement. With no

surface area to coat, this sensor retains its sensitivity to carbon monoxide even after prolonged exposure to clean

air.

The cell consists of a diffusion barrier, O-ring seal, electrolyte reservoir and three electrodes: sensing, counter and

reference. The target gas, carbon monoxide, enters the cell through a diffusion barrier. The chemical process of

the measurement is one of oxidation where one molecule of the target gas is exchanged for one molecule of

oxygen. The reaction drives the oxygen molecule to the counter electrode, generating a DC microampere signal

between the sensing and counter electrodes. This signal is linear to the volume concentration of the sensed gas

rather than the partial pressure.

The integrated two-wire transformer converts this DC microampere signal to a standard 4-20 mA signal. In some

cases, biasing is required to maintain a voltage differential between the reference and sensing electrode in order

to facilitate the necessary reaction in the cell.

The transmitter electronics will provide the necessary bias voltage when configured for one of these sensor types.

Most sensors produce a small amount of baseline current in clean air. This is adjusted out with the zero

potentiometer on the transmitter.

This oxidation at the electrodes causes wear of the sensor. Typical life for this sensor is approximately five years in

normal operation. This will vary somewhat from sensor to sensor, with some working lifetimes less than five years

and some greater than 5 years. This wear also changes the characteristics of the sensor, requiring periodic recalibration. It is recommended that the sensor accuracy be verified every six months and recalibrated as

necessary

.

Relay output

The controller output provides two (2) adjustable trip/setpoints within the sensing range. If the CO concentration

exceeds any trip/setpoint value the respective alarms will be activated. The low or high alarm trip/setpoint level

correspond to the relay outputs 1K1 (R1) and 1K2 (R2). The output relay R3 can be assigned to either low alarm

or high alarm.

The controller has a self-diagnostic to detect any power supply voltage or sensor failures. When a failure occurs it

triggers relay output R4. The fail-safe relay R4 will close in case of loss of supply voltage or sensor failure.

Analog output

The 1-5 VDC output is linear and represents the range of 0-250 ppm actual sensor proportional value. This signal

can be used with any external DDC/PLC control or automation system.

Test button

With this button pushed, it simulates the maximum gas concentration. Low and high alarms will be activated and

the display will show the maximum value.

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Page 4

Manual override of low alarm relay

Manual switch for “Auto” or “On” function of the relay 1K1 (R1)

Switch position:

Auto = alarm relay 1K1 normal operation

On = alarm relay 1K1 manually on

Caution!

Replacement sensor elements, which are not bias types, are shipped with a tiny spring of wire shorting the sensor

and reference electrodes.

This spring MUST BE REMOVED prior to installing the element into the sensor assembly.

Optional Display

3.5 digits display of concentration

LED power: green Power on, and normal operation

red Failure operation

LED alarm: orange Low alarm level active

red Low and high alarm level active

nd

Button “Reset 2

Alarm” Reset high alarm, when relay is set to latched

Button “Reset Audible” Reset internal horn and relay R3 for remote alarm

Optional time delay relay for low alarm

Time delay relay for delayed activation of relay 1K1

RTE-P11 analog timer = on-delay, adjustable from 0.1 min to 10 min

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

3 Installation

Note:

Avoid any force (e.g. by thumb) during operation or installation on the sensor element. This could destroy

•

the element.

Electronics can be destroyed through static electricity. Therefore, do not work on the equipment without a

•

wrist strap connected to earth ground or standing on conductive floor.

3.1 Mounting locations

The specific weight of carbon monoxide is almost the same as that of air (factor 0.967).

•

Location of the SPC 1110 must conform to the layout of the area being monitored.

•

Disregard the ventilation ratio! Do not mount SPC 1110 in the center of the airflow. In larger rooms, it

•

might be necessary to install two or more SPC 1110 where there is not adequate air movement. Do not

mount in corners or directly in front of air inlets (e.g. doors, windows, open ramps, dampers, etc.). In

areas with undefined air movement, it might be necessary to distribute several SPC 1110 in a vertical and

horizontal direction over the whole area to be monitored.

Avoid locations where water, oil etc. may influence proper operation and where mechanical damage

•

might be possible.

Mounting height is 5 feet to max. 6 feet (1.5 to 1.8 m) above floor.

•

Provide adequate space around SPC 1110 for maintenance and calibration work.

•

Page 5

3.2 Enclosure

The door of the enclosure is lockable with supplied key (5/16 in. (8 mm) triangle key).

•

Use the provided template for locating position of wall mounting holes.

•

Screw the enclosure vertically on wall. (see Fig. 2, page 18).

•

When wiring is completed, put back the wire track cover and close the door of the enclosure. (see Fig. 1,

•

page 17).

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Page 6

4 Electrical Connection

4.1 Instructions

Note:

Electrostatic discharge (ESD) may damage electronic components. During wiring, open the cover only when

completely grounded via grounding strap or standing on conductive floor.

Connections should be made without any power applied to conductors.

•

Installation of the electrical wiring should be according to the connection diagram and only performed by a

•

trained specialist.

For the 1-5 VDC analog output signal use shielded cable to avoid any influence from external interference.

•

Recommended cable: 18 AWG shielded, maximum resistance 20.8 Ω/1000 ft (73 Ω/1000 m)

•

Cable for power and relay outputs do not need to be shielded.

•

Power terminal block X1

Connector H 120 VAC 50/60Hz (24V AC/DC without transformer)

Connector N 0 VAC/DC

Connector G Earth ground

Motherboard terminal strip X2

Connector 1 1-5 VDC sensor output signal (common)*

Connector 2 1-5 VDC sensor output signal (positive)

Connector 3 Power supply 24 VAC

Connector 4 0 VAC/DC

Connector 5 Power supply 24 VDC (19 - 28 VDC)

Connector

* Note:

When the SPC analog output signal is conntected to an external controller, the controller’s analog input must

provide isolation for the 1-5 VDC signal. If the 1-5 VDC signal is used, then remove Jumper JP1 located on the

motherboard.

Motherboard terminal strip X3 (relay output without optional time delay relay 1K1):

Connector 1-2 R1, low alarm relay activates the 1K1 relay via internal wiring

Connector 3

Connector 4

Connector 5

Connector 6-7 R3, potential free contact for remote alarming

Connector 8-9 R4, potential free contact for remote fail-safe alarming

Low alarm relay socket 1K1 (DPDT)

Contact set 1 of DPDT Contact set 2 of DPDT

Connector 5

Connector 1

Connector 9

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

NO

NC

R2, high alarm relay activates the 1K2 relay via internal wiring

COM

Connector 8

Connector 4

Connector 12

NO

NC

COM

User Manual - PolyGard® CO SPC-1110

High alarm relay socket 1K2 (DPDT)

Contact set 1 of DPDT Contact set 2 of DPDT

Connector 5

Connector 1

Connector 9

Optional low alarm time delay relay socket 1K1 (DPDT)

Contact set 1 of DPDT Contact set 2 of DPDT

Connector 6

Connector 5

Connector 8

4.2 Wiring connection

Static electricity (see section 4.1).

Open the door of the enclosure.

•

Pull cables via the conduit openings into the enclosure, and connect cable leads to the appropriate

•

terminal connectors.

Connector 8

Connector 4

Connector 12

Connector 3

Connector 4

Connector 1

NO

NC

COM

NO

NC

COM

Page 7

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

5 Start-up Operation

Only trained technicians should perform the following:

Check mounting location.

•

Check power voltage.

•

Check for correct sensor element (7 MSR) at sensorboard terminal X3 PCB EC-C.

•

Check and/or select the appropriate jumpers for remote alarm function, relay R3 (see section 5.5,

•

motherboard jumper selection table).

Check and/or select the appropriate jumper for failure function, relay R2 (see section 5.5, motherboard

•

jumper selection table).

Check and/or select the appropriate jumper for latched function, relay R2 (see section 5.5, motherboard

•

jumper selection table).

Check and/or adjust trip/setpoints for low and high alarm levels (see section 5.1, motherboard

•

potentiometers R31and R32).

Check and/or put switch into “Auto” position, manual override of low alarm.

•

Verify sensor/transmitter operation by mearsuring approximately 200 mV (about 0 ppm CO) on

•

sensorboard terminal -X6 and +X6.

Required instruments to start-up and calibrate the SPC:

Test gas bottle with synthetic air.

•

Test gas bottle with 200 ppm CO.

•

Gas pressure regulator with flow meter to control the gas flow at 300 ml/min.

•

Sensor head calibration adapter with tubing.

•

Digital voltmeter with a range of 0-2 VAC and 0-10 VDC, accuracy 1%

•

Small screwdriver.

•

Page 8

Note:

Please observe proper handling procedures for test gas bottles!

5.1 Set trip/setpoints

5.1.1 Set low and high trip/setpoints without optional digital display

Set low trip/setpoint

Connect a digital voltmeter to test jacks J1 (red) and JM (black) on the motherboard with a range selected

•

that will display 10 VDC maximum.

Adjust the low trip/setpoint voltage, with potentiometer ”R31” at the motherboard, until the signal reads the

•

appropriate mVDC ± 2 mV (see section 5.1.2, calculation for trip/setpoint control voltage).

Set high trip/setpoint

Connect a digital voltmeter to test jacks J2 (red) and JM (black) on the motherboard with a range selected

•

that will display 10 VDC maximum.

Adjust the high trip/setpoint with potentiometer ”R32” at the motherboard until the signal reads the

•

appropriate mVDC ± 2 mV (see section 5.1.2, calculation for trip/setpoint control voltage).

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

5.1.2 Control trip/setpoint voltage calculation

= 0.016 V x trip/setpoint (ppm) + 1.20 VDC

(ppm)

Example

Trip/setpoint value 50 ppm

5.1.3 Set low and high trip/setpoints with optional digital display

Control voltage 2.0 V

0.016 (V) x 50 (ppm) + 1.20 (V) = 2.0 V

(ppm)

•

Set display jumper on displayboard into position “JP1” to “JP 1.2”. This will provide a display value with +/sign.

Set low trip/setpoint

Set mode-operating switch “S1” on displayboard into position 1 (far left position). The digital display

•

indicates the low trip/setpoint value.

Adjust the low trip/setpoint with potentiometer “R31” on the motherboard. The trip/setpoint value can be

•

read on the digital display.

Page 9

Set high trip/setpoint

Set mode-operating switch “S1” on displayboard into position 2 (second position from the left). The digital

•

display indicates the high trip/setpoint value.

Adjust the high trip/setpont with potentiometer “R32” on the motherboard. The trip/setpoint value can be

•

read on the digital display.

Set mode-operating switch “S1” on displayboard into position 4 (far right position). This is the normal

•

operating mode (see Fig. 5, page 18).

Set display jumper on displayboard back into position “JP1” to “JP1.1”. This provides a display value

•

without any +/- sign.

5.2 Select switching differential of the trip/setpoints

Individual switching differentials can be selected per trip/setpoint via jumpers “JP6” and “JP8” on the

motherboard, either 4% or 10% differential of full transmitter range (see section 5.5, motherboard jumper

selection table). For example, with factory standard range 0-250 ppm CO, 4% differential =10 ppm, and 10%

differential = 25 ppm.

5.3 Calibration

Note:

If calibration is necessary, the sensor element must be powered and be fully stabilized for at least 1 hour.

Zero adjustment (After sensor warm-up)

Zero-point calibration (4mA):

Connect digital voltmeter to test pins – and + at sensorboard (with a range selected that will display 2 VDC

•

max.).

Connect the calibration adapter to sensor element.

•

Apply sensor element zero calibration gas, (300 ml/min; 14.5 psi ± 10%), or other clean air source.

•

Wait two minutes until the signal is stable; adjust signal with zero potentiometer ”Zero” until the signal is

•

200 mV ± 2 mV and stable (sensorboard).

Remove calibration adapter carefully by turning lightly.

•

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Span adjustment

Note:

CO calibration gas is toxic; never inhale the gas!

Symptoms: Dizziness, headache and nausea.

Procedure if exposed: Bring into fresh air at once, consult doctor.

Connect calibration adapter to the sensor element.

•

Apply sensor element span calibration gas (200 ppm CO), (300 ml/min; 14.5 psi ± 10%).

•

Wait two minutes until the signal is stable, adjust signal with span potentiometer ”Span” until the signal

•

reads the appropriate mVDC (± 3 mV, see calculation for control voltage 5.3.1) and is stable

(sensorboard).

Remove calibration adapter with a careful light turn. Inspect the seating of the sensor element!

•

5.3.1 Control span voltage calculation

800 (mV) x test gas concentration (ppm) + 200 (mV)

Sensing range CO (ppm)

Example

Sensing range CO concentration 250 ppm

Test gas concentration 200 ppm

Control voltage 840 mV

800 (mV) x 200 (ppm) + 200 (mV) = 840 mV

250 (ppm)

Page 10

5.4 Calibration of digital display range (optional display)

Note:

The display range is factory set and normally does not require any field adjustment.

Adjustment can only be made when the sensorboard test pins “X6+” and “X6-“ read 200 mV. This represents a

0 ppm CO value.

Calibrate maximum display range of 250 ppm CO

Connect digital voltmeter to test pins “J3+” and “J4-“ on the displayboard with a range selected that will

•

display 300 mVDC maximum.

Adjust the maximum display range voltage with potentiometer “R31” on the displayboard until the signal

•

reads 120 mVDC ± 1 mVDC.

Calibrate zero point display of 0 ppm CO

Adjust the zero point with potentiometer “R32” on the displayboard until the digital display reads 0 ppm.

•

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

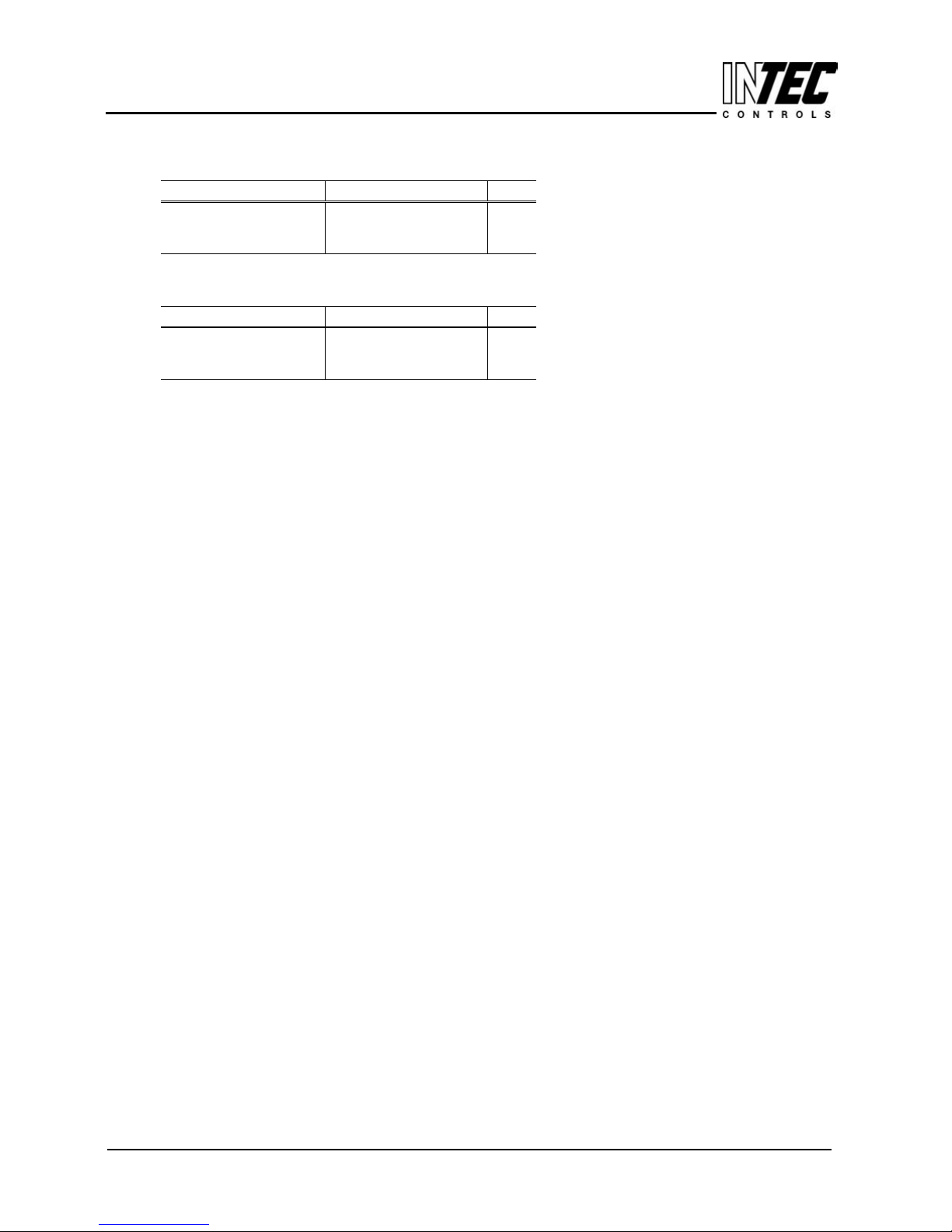

5.5 Motherboard jumper selection table

Function

1-5 VDC signal for external use X

1-5 VDC not used X

Relay R3 will be active with low alarm X*1 Jumper JP3

Relay R3 will be active with high alarm X*1 Jumper JP4

Relay R3 will be not active X*1 Jumper JP5

System failure also activates high alarm X

System failure does not activate high alarm X

High alarm without latch function 1-2

High alarm with latch function 2-3

With optional digital display X

Without optional digital display X

Switching differential of low trip/setpoint, 4% 1-2

Switching differential of low trip/setpoint, 10% 2-3

Switching differential of high trip/setpoint, 4% 1-2

Switching differential of high trip/setpoint, 10% 2-3

Internal function X Jumper JP7*2

Internal function 2-3 Jumper JP10*2

Internal function 1-2 Jumper JP11*2

Note:

*1 Only one of the three jumpers can be installed.

*2 Do not change the factory jumper position setting.

Page 11

Element

Jumper JP1

Jumper JP9

Jumper JP12

Jumper JP2

Jumper JP6

Jumper JP8

Factory

Set

5.6 Displayboard jumper selection table

Function

Display value without sign +/- X

Display value with sign +/- X Jumper JP1.2

Button “Reset 2 (high) alarm” enabled X

Button “Reset 2 (high) alarm” disabled X

Internal function X Jumper JP71

1 Do not change the factory jumper position setting

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

Element

Jumper JP1.1

Jumper JP12

Factory

Set

User Manual - PolyGard® CO SPC-1110

Page 12

6 Inspection and Service

6.1 Inspection

Inspection and service of the single point controller should be done by a trained technician and executed on a

periodic interval. It is recommended that the sensor operation be verified at least every six months.

6.2 Calibration sensor

(See part 5.3)

Service at periodic intervals is to be decided by the person responsible for the gas detection system.

•

If span calibration voltage of 840 mV (see note below) is no longer attainable when applying 200 ppm

•

carbon monoxide in air, then the sensor element has to be replaced. After the sensor element has been

replaced, a calibration is required.

Note:

If using a different level of span test gas ppm, or different sensor range, then the mV needs to be calculated.

6.3 Replacing sensor element

Static electricity ( see section 4.1).

Sensor should always be installed without power applied, remove fuse “1F1”.

Unplug old sensor element out from the sensorboard.

•

Take new sensor element out of original packing and remove the shorting wire on the sensor element

•

contacts.

Plug sensor element in the connector X3 at the sensorboard.

•

After sensor warm-up, turn potentiometer “Span”, located on sensorboard, to its center position.

•

(Turn the pot 25 rotations counter-clockwise, then 11 rotations clockwise to be centered.)

Calibrate (see section 5.3).

•

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

7 Troubleshooting

7.1 Diagnostics

Trouble Reason Solution

Page 13

No indication of power

(opional with display),

and/or

test button does not

function

No indication value at

digital display

Cannot calibrate

sensorboard

Power not applied Measure power on terminal block X1

terminal H / N for 120 VAC (24

Fuse failure Check miniature fuses 1F1, 1F2 or F1 on

motherboard

Interruption in the cable

Check cable connections for tight fit

connection between motherboard

and displayboard

Failure on displayboard Replace displayboard

Mode operating switch S1 on

displayboard, position 3 = OFF

Set switch in position:

1 = low trip/setpoint

2 = high trip/setpoint

4 = sensed value

Interruption in the cable

Check cable connections for tight fit

connection between motherboard

and displayboard

Failure on displayboard Replace displayboard

Interruption in the cable

Check cable connections for tight fit

connection between motherboard

and displayboard

Sensor sensitivity too low Replace sensor

Failure on sensorboard Replace sensorboard

Cannot set trip/setpoints

Trip/setpoint values are set too

high

Adjust trip/setpoint values again

(see section 5.1 to 5.3)

Failure on motherboard Replace motherboard

Fail-safe alarm

Interruption of sensor cable or

sensor sensitivity too low

Control span voltage lower then

200mV

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

Check cable connection, or if necessary

replace and calibrate sensor

Recalibrate the sensor, or if necessary

replace sensor element

User Manual - PolyGard® CO SPC-1110

Page 14

8 Cross-sensitivity Data

This table shows the typical response to be expected from the sensor when exposed to the following gases.

Gas

Acetone (CH3)CO(CH3) 200 ppm < 0.46 ppm

Ammonia NH3 100 ppm 0 pmm

Chlorine CL2 1 ppm 0 ppm

Ethanol C2H5OH 200 ppm 0 ppm

Chemical mark Gas concentration Tolerance ppm CO

Ethylene C2H4 100 ppm

Hydrogen H2 100 ppm

Hydrogen chloride HCI 5 ppm 0 ppm

Hydrogen cyanide HCN 10 ppm < 2 ppm

Hydrogen sulphide H2S 15 ppm

Nitric oxide NO 35 ppm

Nitrogen dioxide NO2 5 ppm

Sulphur dioxide SO2 5 ppm 0 ppm

Toluene C6H5CH3 200 ppm 0 ppm

Trichloraethane C2HCL2 200 ppm < 10 ppm

≤ 100 ppm

< 60 ppm

< 0.3 ppm

≤ 7 ppm

≤ - 1 ppm

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

9 Specifications

Page 15

Electrical

120 VAC, -10%/ +20%, 50/60 Hz, or

Power supply:

24 VAC/DC, –10%/ +20%, without built-in transformer

resettable 1.6 A fuse

Power consumption: 0.6 A (15 VA), max.

- w/optional heater 1.6 A (39 VA), max.

RFI/EMI protection 5.0 W @ 1ft. (0.31 m) radiated

Sensor Performance

Gas detected Carbon monoxide (CO)

Sensor element Electrochemical, diffusion

Range 0 – 250 ppm factory sete

0 – 150 to 0 – 300 ppm, adjustable via calibration

Stability & resolution

± 0.5 ppm of reading

Repeatability ± 1% of reading

Long term output drift

Response time

< 0.4% signal loss/month

t90 ≤ 30 sec.

Sensor life expectancy 5 years, normal operating environment

Sensor coverage 5,000 sq.ft. (465 m2) to 10,000 sq.ft. (930 m2) under “ideal conditions”

Installation Location

Mounting height 5 to 6 ft. (1.5 to 1.8 m) above floor

Relay outputs

Low alarm (1K1)

DPDT, 10 A (optional time delay relay, 10 A) potential free, 250 VAC

High alarm (1K2) DPDT, 10 A, potential free, 250 VAC max.

Remote alarm (R3) SPST, 5 A, potential free, 250 VAC max.

Fail-safe (R4) SPST, 5 A, potential free, 250 VAC max.

Type of Control

General Two-stage, low and high alarm Trip/setpoints

Trip/setpoints

- Low alarm 50 ppm CO (factory calibrated, user adjustable)

- High alarm 100 ppm CO (factory calibrated, user adjustable)

Switching differential 4% or 10% of sensing range, selectable

Analog output signal

1-5 VDC for external controller (the controller’s analog input must

provide isolation for the 1-5 V DC signal), load > 50 kOhm

Audible alarm 90 dB, enabled or disabled, selectable

Visual Indications and Reset

Push Buttons, optional

Digital display 3.5 digit, ppm reading

Power/operating status LED Green = power on / Red = failure

Alarm status LED Orange = low alarm / Red = high alarm

Reset 2nd alarm button LED on = w/high alarm on (only w/latched relay configuration)

Reset audible button LED on = w/internal horn and/or relay R3 for remote alarm is on

Alarm acknowledgement / reset

function

Low alarm: auto reset

High alarm: auto reset or manual reset, selectable

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Page 16

Operating Environment

Working temperature 23 °F to 104 °F (-5 °C to + 40 °C)

Storage temperature -4 °F to 104 °F (-25 °C to + 40 °C)

Humidity 15 to 95% RH non-condensing

Pressure range Atmospheric ±10%

Optional

Heater, built-in

For low temperature environment

Ambient temperature -22 °F to 104 °F (-30 °C to 40 °C)

Thermostatic control 32 °F (0 °C) ± 5 °F (3 °C)

Physical Characteristics

Enclosure material Steel case

Enclosure color Light beige

Protection NEMA 4 (IP 55)

Installation Wall (surface) mounted

Dimensions, enclosure (HxWxD) 9.06 x 8.27 x 5.6 in. (230 x 210 x 142 mm)

Dimensions, splash guard (HxDia.) 0.63 x 2.56 in. (16 x 65 mm)

Cable entry 3 holes for ½ in. conduit, covered

Wire connection Terminal blocks, screw type for lead wire

Wire size Min. 24 AWG (0.25 mm2) max. 14 AWG (2.5 mm2)

Weight 8.8 Ibs. (4.0 kg)

Approvals/Listings

- unit City of Los Angeles Approved

CE

VDI 2053 (pending)

EMV Compliance 89/336/EWG

- sensor UL Recognized

- relays

UL Recognized, CSA Certified, TÜV

- transformer UL Listed, CSA Certified

Warranty

Two years material and workmanship

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

10 Wiring Configuration and Enclosure Dimensions

Wiring Configuration Fig. 1

Low alarm level option, with time delay relay (instead of standard relay)

8

5

6

1

4

3

Common

NC

NO

Common

NC

NO

Low alarm level

time delay DPDT relay

"1K1 (R1)"

Relay 1K1 (R1)

NO

Low Alarm

Time Delay

NCNCNO

Note: NC-NO connection is

reversed on the relay socket

compared to the standard relay

Page 17

RTE-P11

C

coilcoil

C

9

1

5

12

4

8

9

1

5

12

4

8

7

6

X3

9

8

X3

G

2

1

X2

Common

NC

NO

Common

NC

NO

Common

NC

NO

Common

NC

NO

NO

Common

NC

Common

Ground shield

(+)

1-5 VDC analog output signal

to remote controller or BAS

(–)

Low alarm level

standard DPDT relay

"1K1 (R1)"

High alarm level

standard DPDT relay

"1K2 (R2)"

Remote strobe/horn/

display alarm

actuation "R3"

Remote

fail-safe "R4"

Relay contact positions 1K1 (R1), 1K2 (R2), R3 and R4:

– Power off, as drawn

– Power on and no alarm condition, as drawn,

and R4 is open

– Power on and alarm condition for 1K1 (R1), 1K2 (R2)

and R3, contacts are closed between common and

NO, and R4 stays open

– Power loss or system failure, R4 is closed

Recommended

Twisted, shielded wire

for 1-5 VDC output signal

Grounded housing

NONONC

NONONC

X1

Motherboard

X1 = Ribbon cable connection to transmitter and display (factory installed)

Low Alarm

Standard

Relay 1K1 (R1)

NC

High Alarm

Standard

Relay 1K2 (R2)

NC

Power

Terminal

Block X1

1F1 FUSE

1F2 FUSE

1-5

VDC24VAC24VDC

(–) (+) (+) (–) (+)

12345

X2

C

coilcoil

C

C

coilcoil

C

H

N

G

*

X3

Wire Track

per fuse holder

1.6 A replaceable fuse is installed

R1 R2 R3 R4

123456789

Power terminal block "X1"

Gray

Blue

Green/yellow

H

N

G

AC hot

AC neutral

Earth ground

120 VAC or 24 VAC/DC

power supply

* With 24 VAC/DC power supply:

– Remove factory installed transformer "1T1"

and transformer wires

– Disconnect lead wire from " 1F2" fuse

block terminal and connect to

"1F1 *(right hand)" fuse block terminal

1F1 FUSE

1F2 FUSE

– Add wire and connect between AC neutral

"N (leftside)" of power terminal block and

"X2 - terminal 4" of motherboard

(–)

4

X2

Terminal

Block X1

Transformer

1T1

*

Power

H

N

G

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Page 18

Assembly

Fig. 2

8.27 in. (210 mm)

6.70 in. (170 mm)

NONONC

NONONC

Mounting hole

d = 0.2 in. (5 mm)

X1

JP1

JP2

S1

R31

Low Alarm

Standard

Relay

NC

1K1 (R1)

High Alarm

Standard

Relay

NC

1K2 (R2)

Power

Terminal

Block X1

Fuse

(1,6 A)

Fuse

(1,6 A)

1-5

VDC24VA C24VDC

F1

(+) (~) (-)

(-) (+)

800mA

X2 X3

JP7

JP5

JP4

JP3

Motherboard

23050167

C

C

COIL COIL

C

C

COIL COIL

H

N

G

1F1

*

1F2

R1 R2 R3 R4

12345678912345

R1 R2 R3 R4

1

JP12

JP6

1

J1

1

JP9

JP11

J2 JM

1

JP10

Wire Track

1T1

Transformer

4011MWSH

Mounting hole

d = 0.2 in. (5 mm)

Low alarm override

S1

ON

AUTO

JP8

1

R32

9.06 in. (230 mm)

5.90 in. (150 mm)

Horn

0.40 in. (10 mm)

Dimensions

Fig. 3

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

8.27 in. (210 mm)

0.63 in.

(16 mm)

Page 19

)

m

m

0

3

2

(

.

in

6

0

.

9

0.63 in.

(16 mm)

//

MSR

0 8 0

green = Power orange= 1. Alar m

Power

red = Trouble

2. Alarm

Reset

Reset

Audible

PolyGard

ppm

Alarm

red = 2. Alarm

)

m

m

2

4

1

(

.

in

6

.

5

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Motherboard

Fig. 4

1-5

VDC24VAC24VDC

ly

d

a

r

p

a

o

is

b

d

r

r

o

o

s

t

n

c

e

e

s

n

n

d

o

n

C

a

F1

800mA

1

X

JP1

Analog output

w/without display

JP2

S1

R31

(-) (+)

(+) (~) (-)

X2

7

P

J

JP5

JP4

JP3

Motherboard

23050167

R1 R2 R3 R4

12345678912345

R1 R2 R3

JP11

J1

JP6

1

1

9

P

J

J2 JM

1

JP10

1

JP8

R4

R32

X3

R3 = not active

R3 = w/High alarm active

R3 = w/Low alarm active

Testpin JM (Common)

Testpin J2 High trip/setpoint value

Testpin J1 Low trip/setpoint value

Switching differential of

High trip/setpoint value

Adjustment trip/setpoint

High trip/setpoint

Page 20

Adjustment trip/setpoint

Low trip/setpoint

Displayboard

Fig. 5

R31

R32

JP7

JP12

ANZEXST.CDR

JP12

JP1.2

Display w/without sign

J3

J4

Testpin display range

Changing display range

Button “Reset Alarm High” activates

JP1.1

Mode operating switch

1 = set trip/setpoint Low

2 = set trip/setpoint High

3 = NC

4 = Normally operating mode

Adjusted max. value

Adjusted min. value

Displayboard

2305001

S1

1

1

System failure actives high alarm

High alarm latch

234

X1

ly

d

a

r

p

a

o

is

b

d

r

r

o

s

to

n

c

e

e

s

n

n

d

o

n

C

a

Switching differential of Low trip/setpoint valueTest button

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Sensorboard

Fig. 6

1

X2

+

X6

-

EC-C 003

VR3

VR2

230398

Span

Zero

C

Sensor

Platin310

S

RX3

X9

Page 21

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

User Manual - PolyGard® CO SPC-1110

Page 22

11 Notes and General Information

It is important to read this user manual thoroughly and clearly understand the information and instructions. The

PolyGard® single point controller must be used within product specification capabilities. The appropriate operating

and maintenance instructions and recommendations must be followed.

Due to ongoing product development, MSR reserves the right to change specifications without notice. The

information contained herein is based upon data considered to be accurate. However, no guarantee is expressed

or implied regarding the accuracy of this data.

11.1 Intended product application

The PolyGard® CO SPC-1110 single point controller is designed and manufactured for control applications for

energy savings and OSHA air quality compliance in commercial buildings and manufacturing plants (i.e.,

detection and automatic exhaust fan control for automotive maintenance facilities, enclosed parking garages,

engine repair shops, warehouses with forklifts, fire stations, tunnels, etc.).

11.2 Installers’ responsibilities

It is the installer`s responsibility to ensure that all PolyGard® single point controller is installed in compliance with

all national and local codes and OSHA requirements. Installation should be implemented only by individuals

familiar with proper installation techniques and with codes, standards and proper safety procedures for control

installations and the latest edition of the National Electrical Code (ANSI/NFPA70). It is also essential to strictly

follow all instructions as provided in the user manual.

11.3 Maintenance

It is recommended that the PolyGard® single point controller performance check be done on a routine

schedule. Any performance deviations may be serviced based on needed requirements. Re-calibration and

part replacement may be implemented in the field by a qualified individual and with the appropriate tools.

Alternatively, the easily removable plug-in transmitter card with the sensor may be returned for service to

INTEC Controls.

11.4 Limited warranty

MSR and INTEC Controls warrant the PolyGard

®

single point controller for a period of two (2) years from the

date of shipment against defects in material or workmanship. Should any evidence of defects in material or

workmanship occur during the warranty period, MSR or INTEC Controls will repair or replace the product at

their own discretion, without charge.

This warranty does not apply to units that have been altered, had repair attempted, or been subjected to

abuse, accidental or otherwise. The warranty also does not apply to units in which the sensor element has

been overexposed or gas poisoned. The above warranty is in lieu of all other express warranties, obligations or

liabilities.

This warranty extends only to the PolyGard® single point controller. MSR and INTEC Controls shall not be

liable for any incidental or consequential damages arising out of or related to the use of the PolyGard® single

point controller.

11.5 Return instructions

If the PolyGard

®

single point controller needs to be returned to INTEC Controls for service, an RMA number

must be obtained prior to sending.

PolyGard is a registered trademark of MSR SPC1110I01

Phone (858) 578-7887 & (888) GO INTEC Fax (858) 578-4633 & (888) FX INTEC Specification subject to change without notice.

INTEC Controls, Inc., P.O. Box 12506, La Jolla, CA 92039 www.inteccontrols.com Printed in USA 040401

Loading...

Loading...