Page 1

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard Controller MGC2-20

Multi-Point Controller

Serial Number – S00

User Manual

September 29, 2011

November 19, 2013 – Revision

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 2

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

Page 02

1 Description ............................................................................................................................................. 4

2 Operating Instruction ............................................................................................................................ 5

2.1 Description Keypad User Interface ................................................................................................... 5

2.2 Setting / Change Parameters ........................................................................................................... 5

2.3 Password Level ................................................................................................................................ 6

3 Menu Overview ...................................................................................................................................... 7

3.1 Malfunction management ................................................................................................................. 8

3.1.1 Acknowledge a malfunction ....................................................................................................... 8

3.1.2 History error summary ............................................................................................................... 8

3.1.3 System Errors ............................................................................................................................ 9

3.2 Stage Status ..................................................................................................................................... 9

3.3 Relay Status ..................................................................................................................................... 9

3.3.1 Manual operation of the relays ................................................................................................ 10

3.4 Menu Sensor Readings .................................................................................................................. 10

3.5 Menu Relay Setup .......................................................................................................................... 11

3.5.1 Relay Mode ............................................................................................................................. 11

3.5.2 Relay Action Steady / Flash ..................................................................................................... 11

3.5.3 Latching Mode ......................................................................................................................... 12

3.5.4 Horn Function .......................................................................................................................... 12

3.5.5 External operation of Relay. .................................................................................................... 13

3.5.6 Delay operation of Relay. ........................................................................................................ 13

3.6 Menu SP Setup .............................................................................................................................. 14

3.6.1 Activate – Deactivate SP ......................................................................................................... 15

3.6.2 Selection Type ......................................................................................................................... 16

3.6.3 Measuring range...................................................................................................................... 16

3.6.4 SP Signal ................................................................................................................................. 16

3.6.5 Stage/Setpoint / Hysteresis ..................................................................................................... 17

3.6.6 Delay time ON or OFF ............................................................................................................. 17

3.6.7 Control Mode ........................................................................................................................... 17

3.6.8 Assigned SP Fault to Relay ..................................................................................................... 17

3.6.9 Assign Relay to a Stage .......................................................................................................... 18

3.6.10 Assigned SP Signal to analog Output ...................................................................................... 18

3.7 Menu System Setup ....................................................................................................................... 19

3.7.1 Service Mode .......................................................................................................................... 20

3.7.2 Software Version ..................................................................................................................... 21

3.7.3 Maintenance Concept .............................................................................................................. 21

3.7.4 Average Value Function .......................................................................................................... 21

3.7.5 Time, Date ............................................................................................................................... 21

3.7.6 Customer Password (Code 1) ................................................................................................. 22

3.7.7 Analog Output ......................................................................................................................... 22

3.7.8 Define the Failure Relay .......................................................................................................... 22

3.7.9 Power On Time ....................................................................................................................... 22

3.7.10 Activation of expansions modules............................................................................................ 23

4 Mounting / Electrical Connection ....................................................................................................... 24

4.1 Electrical Connection ...................................................................................................................... 24

4.2 Unit position – Connection diagram ................................................................................................ 25

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 3

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

5 Start-up Operation ............................................................................................................................... 29

5.1 Start-up ........................................................................................................................................... 29

5.2 Checklist Start-up operation ........................................................................................................... 30

6 Configuration- and Parameter card .................................................................................................... 31

6.1 Configurations System Setup ......................................................................................................... 31

6.2 Relay Setup .................................................................................................................................... 32

6.3 Sensor Setup .................................................................................................................................. 33

7 Specifications MGC2-20 ...................................................................................................................... 34

8 Notes and General Information ........................................................................................................... 36

8.1 Intended product application ........................................................................................................... 36

8.2 Installers` responsibilities ................................................................................................................ 36

8.3 Maintenance ................................................................................................................................... 36

8.4 Limited warranty ............................................................................................................................. 36

Page 03

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 4

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

Multi Point Controller MGC2

1 Description

The PolyGard® Multi Point Controller MGC2 is used for the monitoring and warning of sensor points exceeding

their stage setpoints. External Transmitters can monitor and warn of toxic, combustible and refrigerant gases as

well as temperature and humidity. The Controller MGC2 can measure up to twenty analog 4 to 20 mA (Gas)

Transmitters.. Each Sensor Point (SP) can have five stage thresholds. Each stage threshold can be assigned to

anyone of the relays (R1…R20). The Controller can interface via ten 4 to 20 mA outputs to any compatible

electronic analog control, DDC/PLC control or automation system.

The adjustable parameters and staged thresholds make this system very flexible for sensor measuring and

control.

The configuration of parameter settings and operation is easy to do without any programming knowledge.

PolyGard

®

Multi Point Controller MGC2 must not be used in areas requiring explosion proof equipment.

Page 04

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 5

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

A

User Manual - MGC2-20

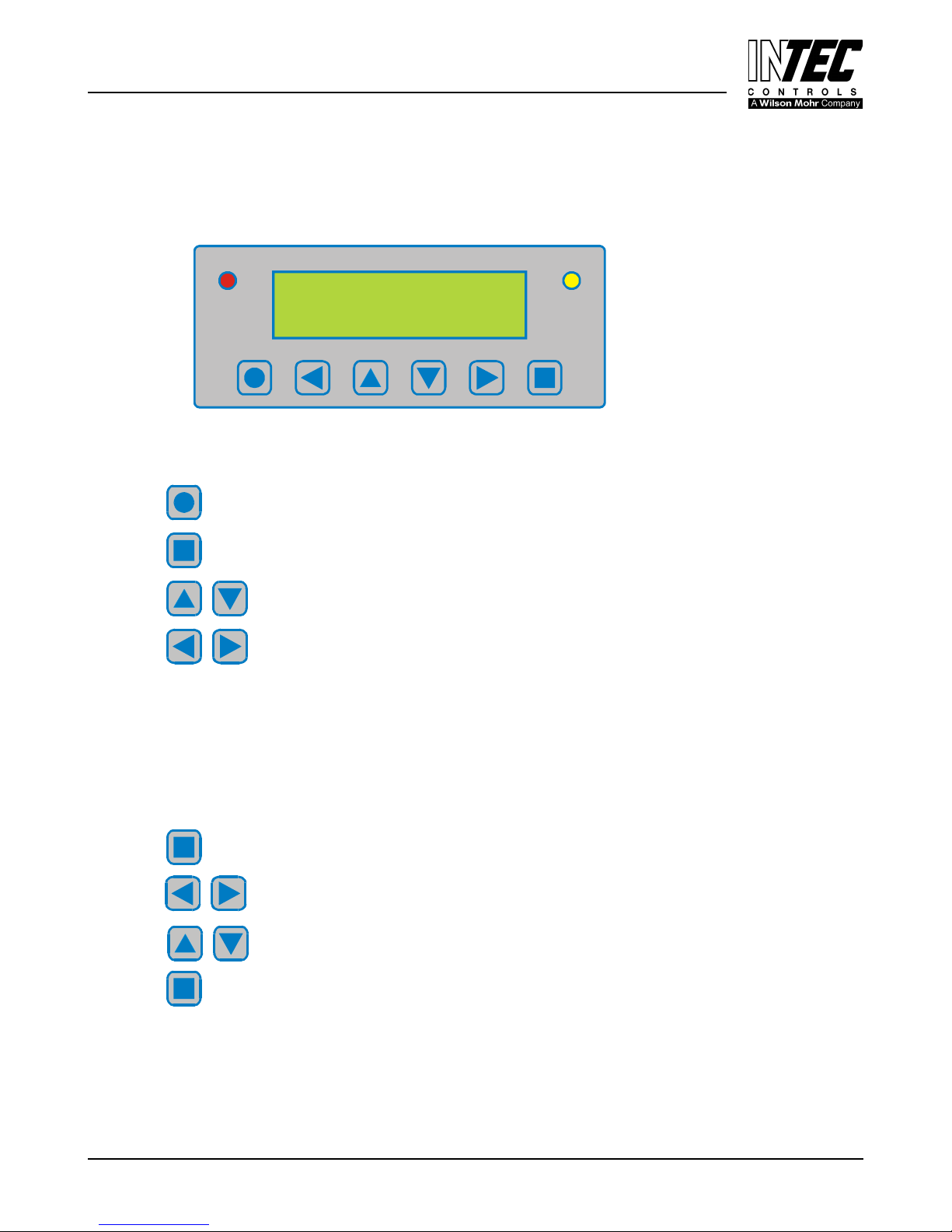

2 Operating Instruction

The complete configuration, parameterization and service are made via the keypad user interface in combination

with the display screen. Security is provided via two password levels.

Page 05

Fault

larm

INTEC Controls

01.22.05 10:28 am

2.1

Description Keypad User Interface

Exits programming and saves settings, returns to the previous menu level.

Enter sub menus, stores changed values.

Scrolls down & up in Main menu and Sub menus, increases or decreases a value.

Moves cursor left or right.

LED yellow Flashes when one or more stages have been exceeded or steady if the operator has manually

overridden any relays.

LED red: Flashes when a System or Sensor Failure is detected or when the Maintenance Date is needed.

2.2 Setting / Change Parameters

Desi

red menu window open.

Opens menu window, if the password is approved the cursor jumps to the first segment

position

Moves the cursor right or left to a segment position

Changes the parameter or value

Saving the changed parameter or value.

Finish

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 6

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

2.3 Password Level

All changes of parameters and staged setpoint values are protected by four digit numeric Code (= password).

The code level 1 permits the operation of the MGC2. This code level is intended for the customer. It can be

changed in the System Setup Menu “Change Customer Password”

With the code level 2 all parameters and set points can be changed, this code level is reserved for the service

technician.

A password must be re-entered if there is 15 minutes of inactivity.

All menu windows are visible without a password.

Factory preprogrammed system password "9001".

Page 06

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 7

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

or

Page 07

Gas concentration

User Manual - MGC2-20

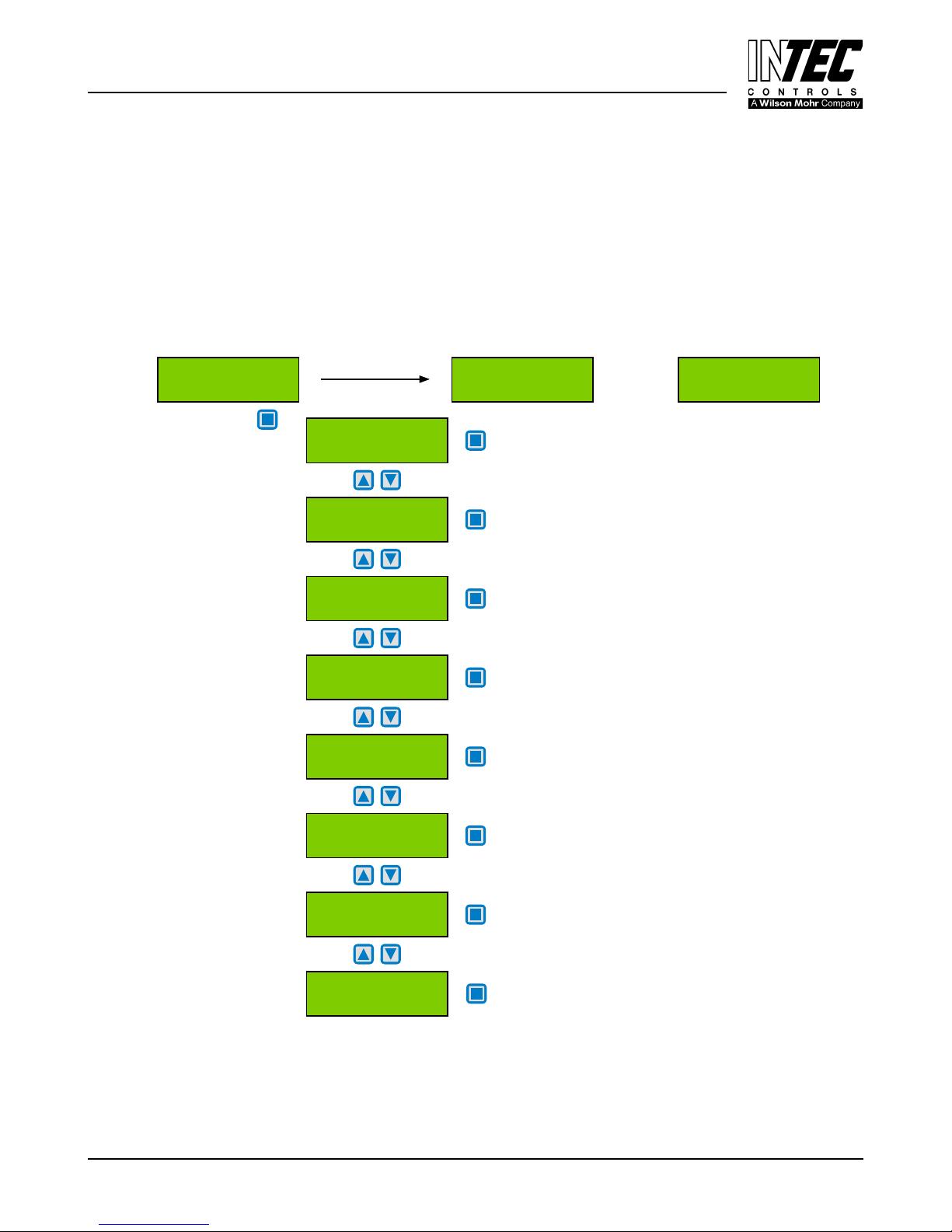

3 Menu Overview

The Multi-Point Controller MGC2 is operated via a simple and logical menu structure which is easy to learn. The

operating menu contains the following levels:

● StartingmenuwithdateandtimeifnoSPisregistered,otherwisescrollingdisplayofthegasconcentrations

of all registered transmitters in 5-second intervals

● Mainmenu

● Submenu1and2

Starting menu Sub menuMain menu

Power On Time Display of

After 30 sec.

INTEC

10.23.13 12:53

System Errors

Stage Status

Relay Status

Sensor Readings

Relay Setup

SP Setup

Reading and reset of errors

See Section 3.1

Display of the status of actual alarms

See Section 3.2

Display of the relay status

Manual operation of the relays

Reset function of the relays

See Section 3.3

Display of the sensor values

See Section 3.4

Reading and change of the relay parameters

See Section 3.5

Reading and change of sensor point parameters

Activate or Deactivate SP

Assignment of the alarms to the alarm relay

See Section 3.6

Data Logger

System Setup

Polygard® is a registered trademark of MSR MGC2-20

Not applicable to standard MGC2 controllers;

available as a special order option

Reading and change of the system parameters

See Section 3.7

Printed in USA 131119

Page 8

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.1 Malfunction management

Malfunction management records the last 15 malfunctions with date and time stamps. In addition, “System Errors”

are recorded in “Error Memory” when the malfunction occurs. This history can be selected and cleared only by the

service technician level 2 password.

A malfunction will display a text message in the Starting Menu. When a failure occurs the relay defined in the

system setup as “Failure relay” is activated. The red LED in the front of the Controller flashes.

During the malfunction of a sensor point (SP) stages that are assigned for sensor failure are activated. Relays that

are assigned to these stages perform as if the stage has been exceeded. These assignments are programmed in

the menu “SP Setup”.

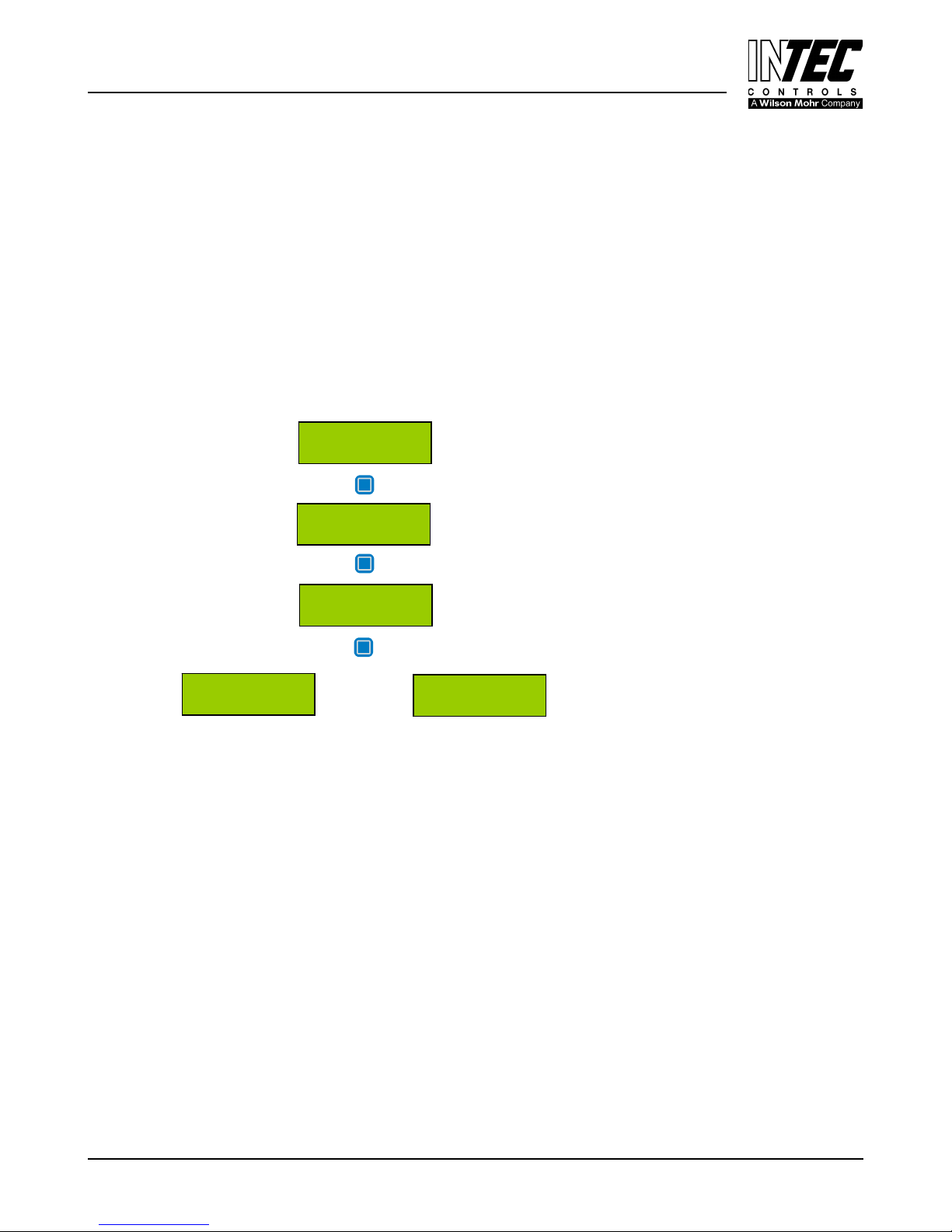

3.1.1 Acknowledge a malfunction

Note:

Resetting a malfunction is only possible if the problem is corrected.

System Errors

Select Menu “System Errors”

Page 08

SP 01 < 3mA

Example: Failure SP 01 < 3 mA

05.02 10.38

SP 01 < 3mA

Malfunction Reset?

Reset ??

Malfunction Reset

SP 01 < 3mA

Error Cleared

Malfunction Cleared Problem not corrected

or

Error still

exists

Reset not possible

3.1.2 History error summary

The code level 2 password can open the menu “Hist Error Sum” in the main menu “System Errors”.

The last 15 error messages are listed for the service technician even if they have already been reset. These error

messages can be deleted individually

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 9

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

(SP)

User Manual - MGC2-20

3.1.3 System Errors

System Error Messages:

SP XX > 22 mA Current signal at analog Input XX > 22 mA.

Cause: Short-circuit at analog Input or Transmitter not calibrated, Transmitter defective.

Solution: Check cable to Transmitter, Perform Calibration, Change the Transmitter.

SP XX < 3 mA Current signal to analog Input XX < 3 mA.

Cause: Open circuit at analog Input or Transmitter not calibrated, Transmitter defective.

Solution: Check cable to Transmitter, Perform Calibration, Change the Transmitter.

GC Error: Internal Communication Error I/O Board to LCD Board.

Cause: Internal Error.

Solution: Change the Controller.

EP 0X Com Error: Communication error to expansion module (EP 0X).

(Only active, if EP module announced).

Cause: EP module address not correct. (See Start up Operation 5.0)

Bus cable to EP 0X module disconnected.

No power supply at the EP 0X module.

EP module defective.

Solution: Check the EP module address.

Check the bus cable and the power supply.

Change the EP 0X module.

Maintenance: System maintenance is necessary.

Cause: Maintenance date exceeded.

Solution: Perform maintenance.

Page 09

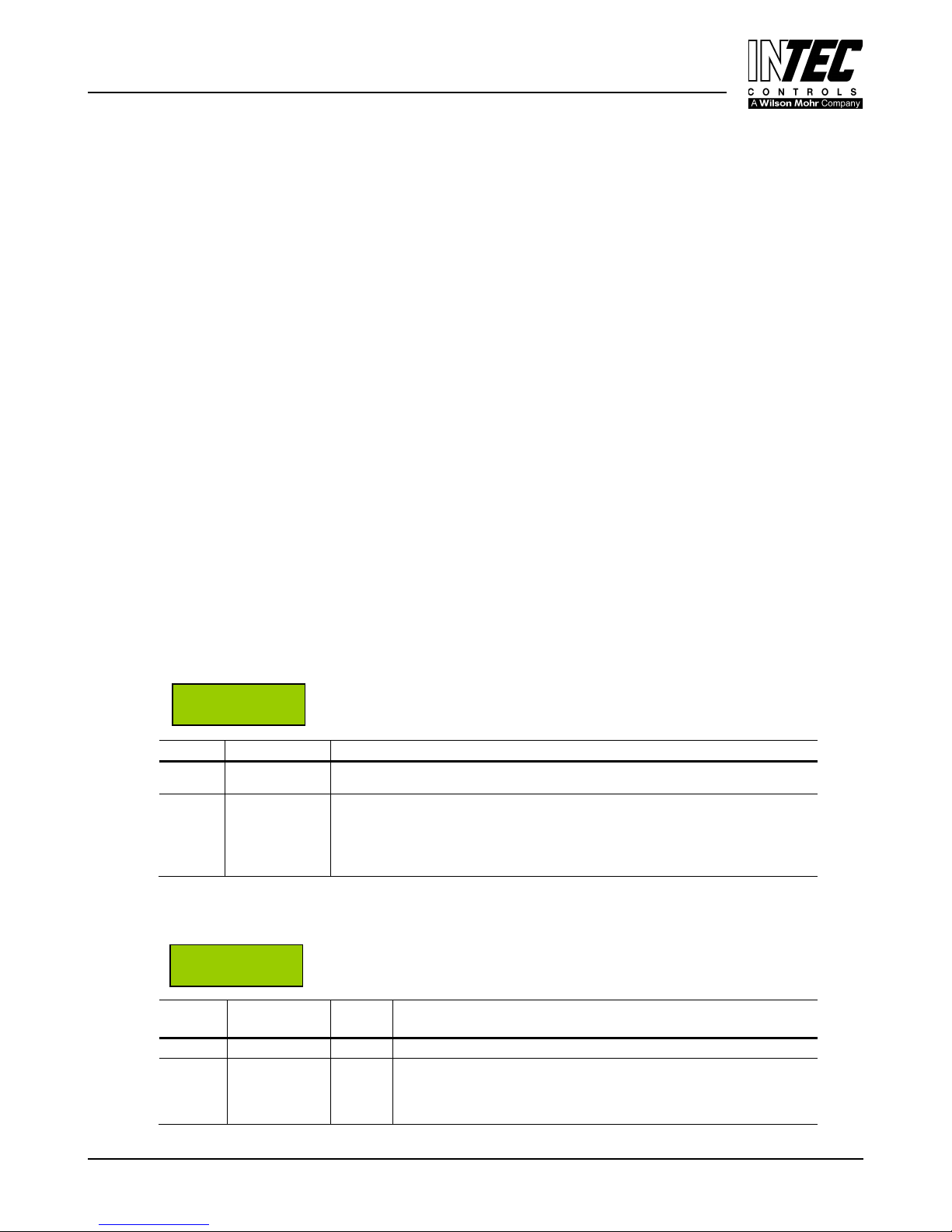

3.2 Stage Status

Displays the actual stages exceeded in the sequence that they happen. The sensor point displays with the stages

that have been exceeded. Changes can not be made in this menu.

SP 01

S1 S2

Symbol Description Function

SP 01

SX Stage Status

Sensor Point

No.

S1 = Stage 1 ON

S2 = Stage 2 ON

S3 = Stage 3 ON

S4 = Stage 4 ON

S5 = Stage 5 ON

3.3 Relay Status

Display the actual status of each relay and changes can be made for manual operation of the relays.

R 01

OFF

Symbol Description

R 01 Relay No. 01

OFF Status Relay OFF

Setting

Status

Function

Select Relay No.

OFF

ON

Manual OFF

Manual ON

= Relay Off (Not Activated by Stage Setpoint)

= Relay On (Activated by Stage Setpoint)

= Relay manual Off

= Relay manual On

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 10

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

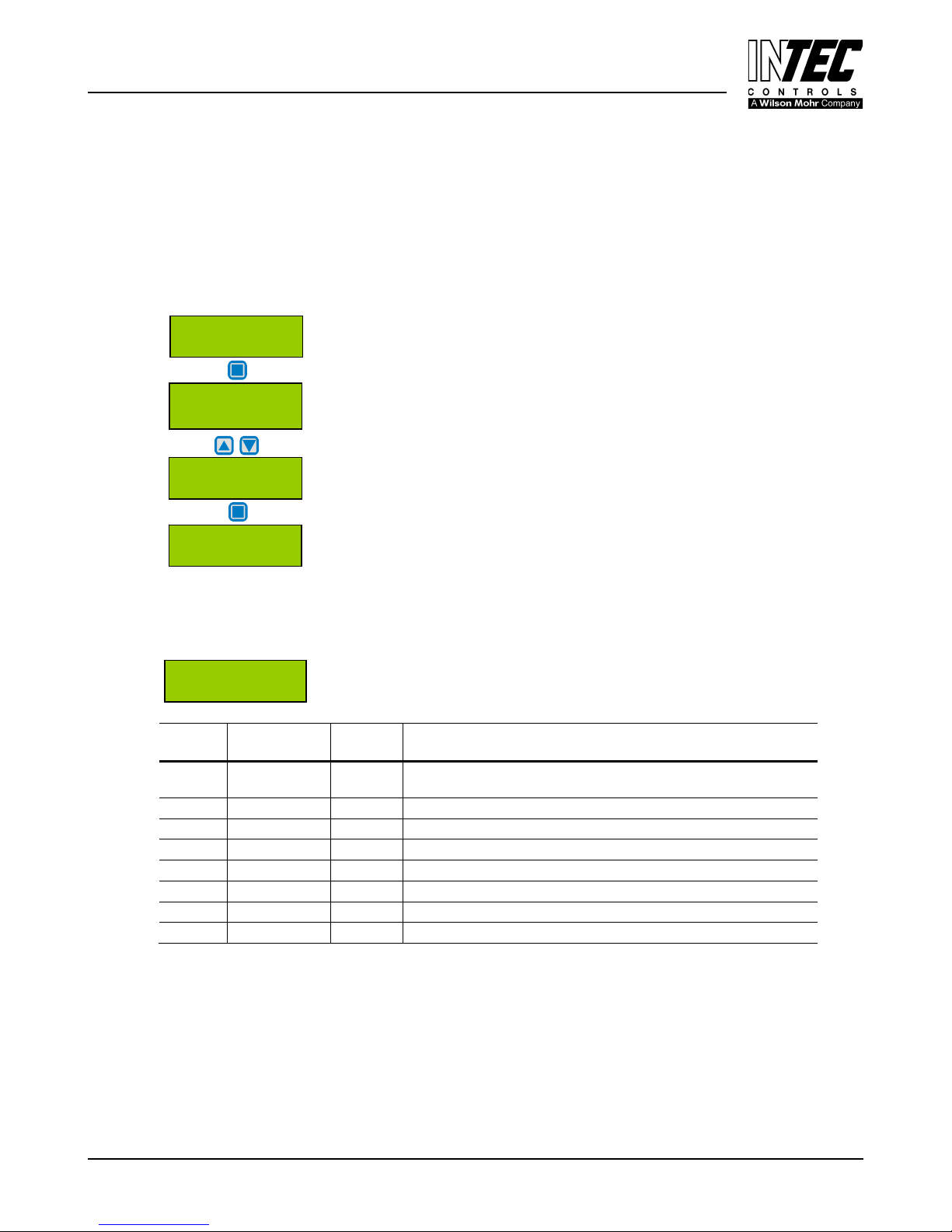

3.3.1 Manual operation of the relays

The manual operation of the relays can be accomplished in the menu “Relay Status”. If a relay is in the Manual ON

or Manual OFF status, the yellow LED at the Controller is on continuously.

The external operation of a relay by an assigned digital input has priority before the manual operation or the Stage

set point of a sensor point being exceeded.

Manually operated relays can be reset by selecting the “Automatic” mode.

The reset of Latching relays also is a function in this menu.

R 01

Select Relay

OFF

Page 10

Manual ON

Manual OFF

Select Function Manual OFF = Relay OFF

Man

ual OFF

Select Function Manual operation

Manual ON = Relay ON

Automatic = Automatic operation restored

Reset ? = Reset of latched relay

Relay forced to OFF Condition

3.4 Menu Sensor Readings

In this menu it displays the current value (CV) and average value (AV) with sensor unit and type for each active

sensor point (SP) as well as the defined mode of control (CV or AV mode) with “*” .

SP 01 NH3 ppm

50 *AV 33 CV

Symbol Description

SP 01

NH3 Type NH3 See 3.6.2

ppm Unit See 3.6.2

CV Current value CV Current value of Gas Concentration

AV Average value Average value (10 measured values within the time unit)

* Control mode Display for the Control mode selected. (CV or AV)

Not active SP Status Not active SP disabled

Error SP Malfunction Current signal < 3 mA or > 22 mA

Sensor Point

No.

Setting

Status

Function

Select SP No.

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 11

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

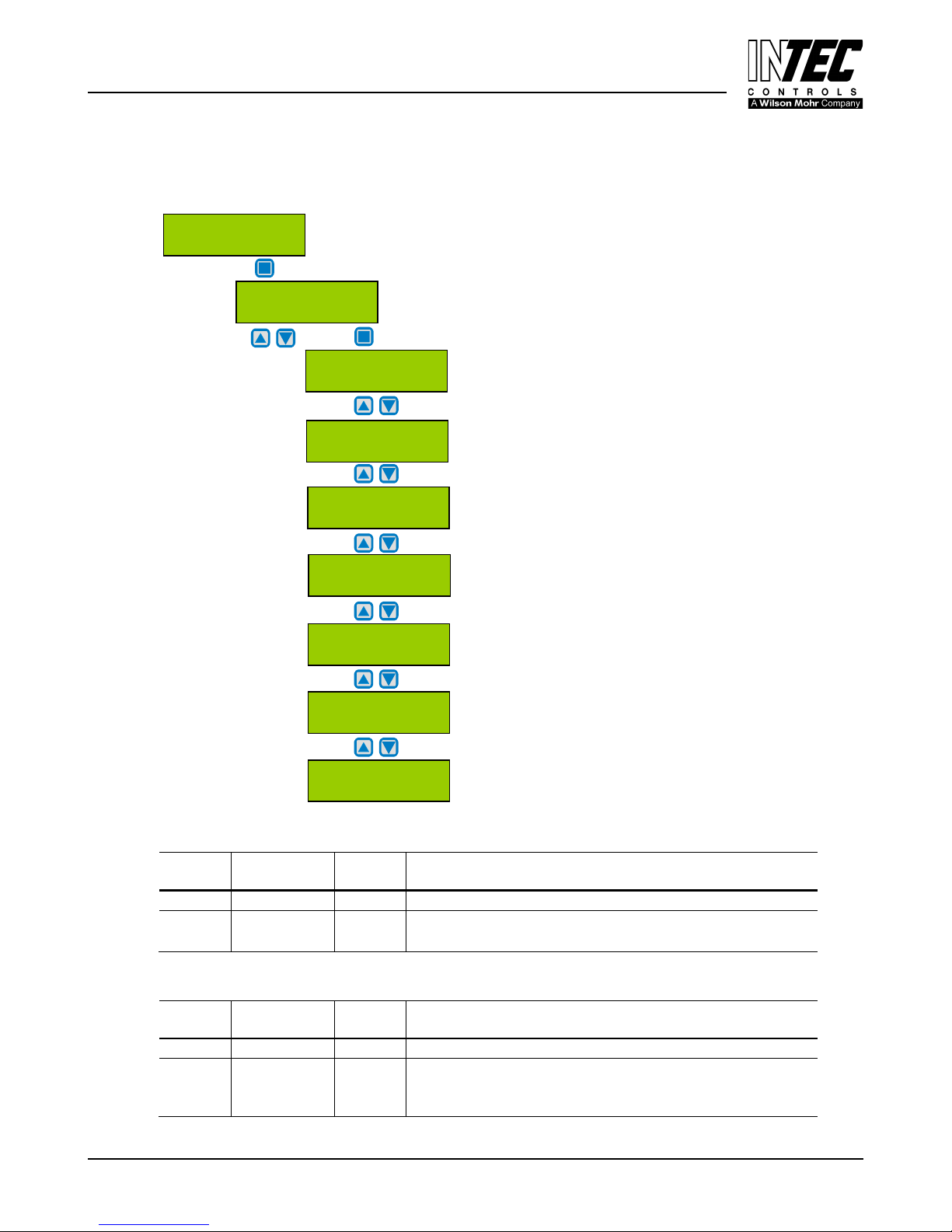

3.5 Menu Relay Setup

Display and change the parameters for each relay.

Page 11

Relay Setup

R 01

(Main menu)

(Selection Relay No.)

Relay Mode

Relay Mode

De- energized

Steady / Flash

Relay Function

0 s

See 3.5.2

Latching mode

Activate Latching Mode

No

Time Reset DI

Definition of Horn Functions

0s 0 0

External mode

Definition of external Relay Operation

DI: ON = 0: OFF = 0

See 3.5.1

See 3.5.3

See 3.5.4

See 3.5.5

Delay ON time

Set Delay ON time

0 s

Delay OFF time

Set Delay OFF time

0 s

See 3.5.6

See 3.5.6

3.5.1 Relay Mode

Symbol Description

Setting

Status

Function

R 01 Relay No. Selection Relay

Deenergized

3.5.2

Relay Action Steady / Flash

Symbol Description

R 01 Relay No.

Relay Mode

Deenergized

Setting

Status

De-energized

Energized

Function

Selection Relay

= Stage ON = Relay ON

= Stage ON = Relay OFF

0 = Relay Function steady

0 Function 0

> 0 = Relay Function flashing (= Periods time sec.)

Impulse / Break = 1:1

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 12

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.5.3 Latching Mode

Definition of Latching Function

Page 12

Symbol Description

R 01 Relay No.

No Latching Mode No

Acknow

ledging of a latching relay in the menu “Relay Status” is possible only if the sensor value is smaller than

Setting

Status

Function

Selection Relay

No

Yes

= Latching Mode non active

= Latching Mode active

the Staged set point including hysteresis. With this condition then latching is activated.

Example: Relay R2 assigned to Latching mode

Alarm 2

Display in the Menu

Status Relay

Relay 2

Reset in the Menu

Status Relay

3.5.4

Horn Function

On

Off

R2

OffR2On

On

Off

On

Off

Gas Concentration greater smaller as Threshold

R2

On

R2

OnR2Latching

R2

Off

With this parameter the relay is defined as a horn relay and can be acknowledged with the following possibilities.

By pressing one of the arbitrary 6 pushbuttons. (Only possible in the starting menu)

Automatic acknowledging when the time runs out.

.

By an external pushbutton. (Assigned to an appropriate digital input).

The horn function is activated only if at least one of the two parameters (time or digital input) is set.

Special function Response

After acknowledging the relay via Pushbutton or external DI the time starts. If this time runs out and if the stage is

still exceeded, the relay is energized again.

Symbol Description

R 20 Relay No.

Reset Mode 0

Time 120

DI 0 Assignment of the digital input used for remote reset of the horn.

Polygard® is a registered trademark of MSR MGC2-20

Setting

Status

Function

Selection Relay

0 = Acknowledge the relay at time run out, or via Pushbutton

1 = Acknowledge the relay via a Pushbutton, after time runs out

and the alarm is still active, then the relay is reactivated.

Time in seconds for Automatic acknowledging or before

reactivating alarms defined by Reset function

Printed in USA 131119

Page 13

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

Acknowledge the horn relay

Page 13

Alarm 4

Relay 4

Acknowledging

signal

On

On

Off

On

Off

Of

Time

Gas Concentration greater smaller as Threshold

Special function “Response”. (Return of the horn relay)

Alarm 4

Relay 4

Acknowledging-

signal

On

Off

On

Off

On

Off

Gas Concentration greater smaller as Threshold

Time Time

3.5.5 External operation of Relay.

Assign one digital input (DI) for external setting of the relay ON and/or OFF.

This function has priority before a

stage threshold is exceeded and/or manual switching in the menu “Relay Status”.

tting

Symbol Description

Se

Status

R 01 Relay No. DI

Function

Selection Relay

DI-ON External On 0 If digital input closed, relay switch ON

DI-OFF External Off 0 If digital input closed, relay switch OFF

3.5.6 Delay operation of Relay.

Delay ON time begins when the Stage is exceeded and/or Delay OFF time when the Stage returns to normal

condition.

Symbol Description

R 01 Relay No.

0 s Delay Time ON 0

0 s Delay Time OFF 0

Polygard® is a registered trademark of MSR MGC2-20

tting

Se

Status

Function

Selection Relay

Stage ON: Relay is only activated at expiration of the defined

time (sec.) 0 sec. = No Delay

Stage OFF: Relay is only deactivated at expiration of the defined

time (sec.) 0 sec. = No Delay

Printed in USA 131119

Page 14

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.6 Menu SP Setup

Display and Change Parameters, Assign Stage value, Assign relays to stages and activate each Sensor Point

(SP).

Page 14

SP Setup

SP 01

(Selection of a sensor point)

active

SP Mode

Activate or deactivate SP

active

See 3.6.1

SP Type

Define Type

NH3

See 3.6.2

Measuring range

Define Measuring range

300 ppm

SP-Signal

Define signal type of transmitter

linear

See 3.6.4

Stage 1

Define Stage/Setpoint 1

100 ppm

(Main Menu)

See 3.6.3

See 3.6.5

Stage 2

Define Stage/Setpoint 2

100 ppm

Stage 3

Define Stage/Setpoint 3

200 ppm

Stage 4

Define Stage/Setpoint 4

200 ppm

See 3.6.5 Stage/Setpoint

Stage 5

Define Stage/Setpoint 5

300 ppm

See 3.6.5

Hysteresis

Hysteresis

15 ppm

See 3.6.5

Delay ON time

Set Delay ON time

0 s

Polygard® is a registered trademark of MSR MGC2-20

See 3.6.5

See 3.6.5

See 3.6.6

Printed in USA 131119

Page 15

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

Delay OFF time

Set Delay OFF time

0 s

AV Mode

Define Control Mode

CV

See 3.6.7

Stage - 1 2 3 4 5

Assign a SP Fault to a Stage

Fault - 1 1 0 0 0

See 3.6.8

S1; S2; S3; S4; S5;

Assign a relay to a Stage

01; 02; 03, 04; 05;

See 3.6.9

Analog Output

Assign SP signal to a Analog Output

0

See 3.6.10

3.6.1 Activate – Deactivate SP

Page 15

See 3.6.6

Symbol Description

SP 01 Sensor point

Active SP Status

Setting

Status

not

active

Function

Selection SP No. (SP01 is the internal Transmitter)

active = Sensor point enabled for reporting

not active = Sensor point disabled for reporting

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 16

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.6.2 Selection Type

Assign sensor Type to active transmitters.

Page 16

Symbol Description

Se

tting

Status

Ty

pe Unit

Measuring

1

range

SP 01 Sensor point

0 – 300

0 – 100

0 – 50

0 – 25

0 – 300

0 – 25

0 – 2000

0 – 100

0 – 200

0 – 100

0 – 20

0 – 100

0 – 2000

0 – 2000

0 – 2000

0 – 2000

0 – 300

0 – 300

0 – 300

0 – 300

0 - 300

0 – 300

0 – 300

0 – 300

0 – 300

0 – 150

0 – 100

NH3 Type NH3

1

Range Recommendations for PolyGard sensors

2

During oxygen measurement falling signal!

CO

Ex

NO

NO

2

NH

3

O2

CO

2

SO2

H

S

2

CL

2

ETC

VOC

R401

R402

R408

R409

R404

R416

R502

R410

R411

R11

R123

R134

R22

TEM

RH

Carbon monoxide

Combusible gas

Nitrogen oxide

Nitrogen dioxide

Ammonia

Oxygen

2

Carbon dioxide

Sulphur dioxide

Hydrogen sulphide

Chlorine

Ethylene oxide

Air quality

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Refrigerant gas

Temperature

Humidity

ppm

%LEL

ppm

ppm

ppm

%V/V

ppm

ppm

ppm

ppm

ppm

%

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

ppm

°C

% RH

3.6.3 Measuring range

The measuring range can be defined from 10 to 10000. The measuring ranges in the above table are typical and

only recommendations. For actual ranges see the sensor manufacturing specifications.

The measuring range must agree with the signal (4 to 20 mA) for active transmitters.

(4 mA = Display=0, 20 mA = Display Measuring range = max. point)

3.6.4 SP Signal

Gas transmitter with electro-chemical or catalytic bead sensors are linear for gas concentration proportional to the

4 to 20 mA signal.

Semiconductor gas sensors that are not linear and have a (exponential) signal. This signal is non-linear 4 to 20

mA signal from the gas transmitter.

The Controller MGC2 has the capability to monitor both types of gas transmitters, and other linear 4-20 mA

sensors. The type of signal is defined in this menu.

Symbol Description

SP 01 Sensor Point Selection SP No.

Linear SP Signal linear

Polygard® is a registered trademark of MSR MGC2-20

tting

Se

Status

Function

linear = Transmitter with linear Output signal

not linear = Transmitter with non linear Output signal (future).

Printed in USA 131119

Page 17

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.6.5 Stage/Setpoint / Hysteresis

Each sensor point can have five stages with set point values. If the measured level is greater than the defined

stage/set point, the associated stage is set. If the level falls below the stage/setpoint plus the hysteresis then the

stage returns to original condition.

It is recommended that the unused stages be set to max of sensor range to avoid the alarm light from false

reporting.

For O2 measurement on depletion consider when defining stage setpoints that stages will be set on a falling

measuring signal!

Page 17

Sy

mbol Description

SP 01 Sensor Point Selection SP No.

100

ppm

3.6.6

Delay ON time begins when the Stage is exceeded and/or Delay OFF time when the Stage returns to normal

condition.

3.6.7

Definition of the alarm evaluation by Current value (CV) or Average value (AV).

Delay time ON or OFF

Symbol Description

SP 01 Sensor point Selection SP No.

0 s Delay Time ON 0

0 s Delay Time OFF 0

Control Mode

Threshold

Default

Status

100

100

200

200

300

15

Default

Status

Stage/setpoint1

Stage/setpoint2

Stage/setpoint3

Stage/setpoint4

Stage/setpoint5

Hysteresis

Function

Concentration > Stage Threshold: Relay is only activated at

expiration of the defined time (sec.). 0 sec. = No Delay

Concentration < Stage Threshold: Relay is only deactivated at

expiration of the defined time (sec.). 0 sec. = No Delay

Function

Sensor Value > Stage/Set point1 = Stage 1

Sensor Value > Stage/Set point1 = Stage 2

Sensor Value > Stage/Set point1 = Stage 3

Sensor Value > Stage/Set point1 = Stage 4

Sensor Value > Stage/Set point1 = Stage 5

Sensor Value < (Stage/Set pointX –Hysteresis)

= Stage X OFF

Symbol Description

SP 01 Sensor Point Selection SP No.

CV Evaluation CV

t / Average Value Function See: 3.7.4

Curren

3.6.8 Assigned SP Fault to Relay

Define which stages are activated with a failure of the sensor point.

Symbol Description

SP 01 Sensor Point Selection SP No.

Stage - 1 2 3 4 5

Fault - 1 1 0 0 0

Polygard® is a registered trademark of MSR MGC2-20

Failure SP 1 1 0 0 0

Default

Status t

Function

CV = Control the Current value

AV = Control the Average value

Default

Status

Function

0 = Stage not ON at SP Failure

1 = Stage ON at SP Failure

Printed in USA 131119

Page 18

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.6.9 Assign Relay to a Stage

Any of the 5 Relays can be assigned freely to any Stage. Stages that do not activate relays receive an

assignment of 00.

Defaul

Symbol Description

SP 01 Sensor Point Selection SP No.

S1

S2

1

S3

S4

S5

Status

01

02

03

00

05

t

Function

01 = Stage 1 activate relay R 01

02 = Stage 2 activate relay R 02

03 = Stage 3 activate relay R 03

00 = Stage 4 does not activate a relay

05 = Stage 5 activate relay R 20 (internal horn)

Page 18

3.6.10

Assigned SP Signal to analog Output

The sensor point signal can be assigned to one of the ten analog Outputs. The signal defined in the control

mode (Current Value or Average Value) is transmitted.

Analog output see also: 3.7.2

Symbol Description

Default

Status

Function

SP 01 Sensor Point Selection SP No.

0 = SP Signal not assigned to any analog output

0 A 0

1 = SP Signal assigned to analog output 1

X = SP Signal assigned to analog output X

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 19

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.7 Menu System Setup

Display and change the System Parameters for the Controller

Page 19

System Setup

Service Mode

OFF

Software Version

GC02- XX

Next maint. Date

MM.DD.YY

Service Phone

858 578-7887

AV Overlay

See 3.7.4

0 s. 120 ppm

AV Time

1800 s

(Main Menu)

See 3.7.1

See 3.7.2

See 3.7.3

See 3.7.3

See 3.7.4

Time system

See 3.7.5

US

Time

See 3.7.5

hh:mm:ss

Date

See 3.7.5

MM.DD.YY

Customer Pass

Change ****

Failure Relay

See 3.7.8

19

Power On Time

See 3.7.9

30 s

Polygard® is a registered trademark of MSR MGC2-20

See 3.7.6

Printed in USA 131119

Page 20

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

EP Module 1

See 3.7.10

active

EP Module 2

See 3.7.10

active

EP Module 3

See 3.7.10

active

EP Module 4

See 3.7.10

active

EP Module 5

See 3.7.10

Not active

Page 20

GC- Address

Controller address

1

(Reserved for future expansion; value should be left at “1”)

Analog Output

See 3.7.7

Analog Output 1

See 3.7.7

Max.

Calibration AO 1

Siehe See 3.7.7

4.0=4 mA 20 = 20.0

Analog Output XX

See 3.7.7

Max.

Calibration AO XX

See 3.7.7

4.0=4 mA 20 = 20.0

3.7.1 Service Mode

the Service mode is set to (ON) then the stage/setpoints are disabled so relays are not activated during

If

calibration or service work. The service mode is Reset automatically after 60 minutes or when the service mode is

set to Off.

Symbol Description

Off Service Mode Off

Polygard® is a registered trademark of MSR MGC2-20

Default

Status

Function

Off = Stages exceeded will activate the assigned relays

On = Stages exceeded will not activate the assigned relays

Printed in USA 131119

Page 21

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.7.2 Software Version

Page 21

Symbol Description

GC02XX

3.7.3

Maintenance Concept

Software

Version

Default

Status

Function

XX = Software Version

The MGC2 system monitors the maintenance intervals as required, by local Regulations or Customer

requirements.

During startup and/or after maintenance the date for next maintenance is entered. When this date is reached at 9

o'clock the next morning a failure signal is activated and Start Menu displays the phone No. of the service

company. The failure signal (maintenance) can be acknowledged by the operator. The maintenance message

(Service Phone No.) is reset after maintenance is accomplished and a new maintenance date is entered.

The service phone number can be individually entered in the next menu.

Symbol Description

MM.DD.YY

Maintenance

Defaul

Status

Function

MM.DD.YY = Input date for next maintenance.

t

8585.... Phone No. Input the individual service phone No.

3.7.4

Average Value Function

The Controller calculates for each active sensing point the arithmetic average value from 10 measurements within

the time unit defined in this menu “AV-time”. This average value is indicated in the menu “Sensor Readings” near

the Current Value. During each Sensor Point Setup the control mode of Current Value or Average Value for the

Stage/Setpoint evaluation is defined.

The evaluation of the control mode Average Value is overlaid by the Current Value, if this exceeds Stage/Setpoint

defined in the menu “AV-Overlay”. The overlay is delayed by the time factor set in this menu.

Defa

Symbol Description

120 s

120pm

AV- Overlay

ult

Status

120 s

120 ppm

Function

sec. = Delay time average value Overlay. 0 = No overlay Function

ppm = Threshold average Overlay

1800 s AV-Time 1800 s sec. = Time to calculate average value

3

.7.5 Time, Date

Input and correction of the system time and date. Selection of the time and date format.

t

Symbol Description

US Time format US

hh.mm.ss Time

MM.DD.YY Date

Polygard® is a registered trademark of MSR MGC2-20

Defaul

Status

Function

EU = Display time and date in EU format

US = Display time and date in US format

hh.mm.ss = Input the correct time (EU format)

hh.mm.ss am = Input the correct time (US format)

TT.MM.JJ = Input the correct date (EU format)

MM.DD.YY = Input the correct date (US format)

Printed in USA 131119

Page 22

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.7.6 Customer Password (Code 1)

Change the System Password for level 1

Symbol Description

1234

Factory preprogrammed system password "9001".

Customerpassword

3.7.7 Analog Output

The Controller has two analog outputs (AO) with 4 to 20 mA signal per control module. Each of the ten analog

outputs can be assigned the signal of one or more sensor points. The assignment occurs in the menu “SP

Setup” for each SP. The sensor point sends the signal that is defined in the menu “C/A Mode”.

The Controller determines from the signal of all assigned sensor points the minimum, the maximum or the average

value and sends this value to the analog output. The determination of which value is sent is defined in this menu

“Analog Output X”. The analog output can be calibrated for 4 and 20 mA using an ampere meter attached (with

measuring range 25 mA) then respective AO factor can be changed to adjust the analog output 4 and/or 20 mA

During AO calibration no evaluation is made of the sensor point signals. This calibration is factory-set. The factors

should only be changed if you have an accurate amp meter.

Symbol Description

Max.

4.0

20.0

Select

Output mode

Calibration

Default

Status

1234 1234 = Define the Customer Password with 4 characters

Default

Status

Max.

4.0

20.0

Function

Function

Min. = Spends the minimum value of all assigned SP

Max. = Spends the maximum value of all assigned SP

Average = Spends the average value of all assigned SP

4.0 = Calibration factor at 4 mA

20.0 = Calibration factor at 20 mA

Page 22

3.7.8 Define the Failure Relay

Define the Failure Relay. See also malfunction management (3.1)

Symbol Description

19 Failure Relay R19 R19 = Define the failure relay

3.7.9 Power On Time

Sensors need a warm up period until the chemical process of the sensor reaches a stable condition. During this

warm up period the current signal can cause unwanted false alarms. Therefore, the Controller starts reporting

alarms after the Power ON Time delay once power is applied. While this time runs off, the Controller does not

report alarms. The Power On status is displayed.

Symbol Description

30 s Power On Time 30 s XX = Define the Power On Time (sec.)

Default

Status

Default

Status

Function

Function

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 23

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

3.7.10 Activation of expansions modules

The Gas Controller can manage, up to five expansions modules (EP-02). Each EP-02 has four analog inputs and

five alarm relays and two analog outputs. Each attached EP-02 is announced in this menu. The Controller checks

the communication to the registered EP-02 modules and shows a fault signal in case of a communication error. To

recognize the position of the EP-02 modules a module address is assigned to each module by the address

selector. See table.

The table shows the assignment of the MP and relay numbers to the individual modules.

Symbol Description

EP- Module No 1 active

EP- Module No 2 active 2 11 to 15 09 to 12 05 to 06

Not

active

EP- Module No 3 active 3 16 to 20 13 to 16 07 to 08

EP- Module No 4 active 4 ---- 17 to 20 09 to 10

EP- Module No 5 Not active 5 ---- ----- ------

Default

Status

Function

Active

= EP announced.

Not active

= EP not announced

Module

Addr.

Relay

No.

1 06 to 10 05 to 08 03 to 04

Page 23

SP No.

Output

No.

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 24

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

4 Mounting / Electrical Connection

The Controller is installed through the 4 marked mounting holes at the back of the housing. These mounting holes

are accessible after opening the housing. See Fig. 01

The mounting holes should be covered with the enclosed caps after installation.

Please consider the following when selecting the mounting place:

Avoid locations where water, oil etc. may influence proper operation and where mechanical damage might

be possible.

Install cables only from the Topside.

On the left side keep at least 150 mm distance to open the transparent door.

Consider any unusual condition or requirements of the Customer.

Fig. 01

8.7 in. (220 mm)

21,1in. (536mm)

Page 24

4.1 Electrical Connection

Installation must be done per local electrical codes with the consideration of the technical requirements of the

product.

The alarms are available as SPDT, potential free contacts.

For the exact position of the terminations of the relays see the following connection diagram.

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 25

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

4.2 Unit position – Connection diagram

GGreen/Ye

XGray

HGray

120 VAC

(see ill. 1)

(see ill. 4)

NBlue

Input Power

GGreen/Ye

Binary - Relay Outputs

R01 R03R02 R04 R05

2 345678910 11 12 1314 151

1

2

X1

FaultFault AlarmAlarm

X2

INTEC Controls

05.07.10 10: 28am

X10 X11

12345678910111 2 1 23456789101112

Sensor

Inputs

Digital

Inputs

Analog

Outputs

(see ill. 2)

DIN Rail

Optional:

Modbus Interface

(see ill. 8)

345678

12

X2

C5 Comm.

Coupler

Optional:

BACnet

(see ill. 7)

Page 25

X1

1234

X2

X2

2

Power Unit

(see ill. 5) (see ill. 6)

1

2

X1

EP-02-2EP-02-1

12345678910111 2 123456789101112

Analog

Outputs

Sensor

Inputs

(see ill. 6) (see ill. 4)

1

2

X1

EP-02-4EP-02-3

12345678910111 2 123456789101112

Analog

Outputs

24 VDC1

Output

Sensor

Inputs

LNG

V-

Top Bottom

Binary - Relay Outputs

R11R13R12R14 R15

2345678910 11 12 1314 151

X10 X11

2345678910 11 12 1314 151

X10 X11

V+

(see ill. 2)

Binary - Relay Outputs

R06 R08R07 R09 R10

2345678910 11 12 1314 151

1

2

X1

X10 X11

12345678910111 2 1 23456789101112

Sensor

Inputs

(see ill. 4) (see ill. 6)

1

(see ill. 2)

Binary - Relay Outputs

R16R18R17 R19R20

2345678910 11 12 13 14 151

2

X1

X10 X11

(see ill. 4)

12345678910111 2 123456789101112

Sensor

Inputs

(see ill. 3)

Terminal

block “X1”

Circuit breaker

1F1

Horn

(see ill. 2)

X2

X2

DIN Rail

Analog

Outputs

ill. 1

)”

2

DIN Rail

Analog

Outputs

(see ill. 6)(see ill. 6) (see ill. 4)

120 VAC Input Power Supply

120 VAC (90...230 VAC), 50/60 Hz

AC hot

AC neutral

Earth ground

G

H N

• Resettable breaker, max 10 A,

rated current approx. 2 A

• “Min wire size 16 AWG (1.5 mm

Terminal block

Green/Yellow

Blue

Gray

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 26

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

Page 26

Binary - Relay Outputs “R01 to R15”

Stage-level control & alarming

= Relay status LEDs D1 to D5 located below terminal connection of sensor inputs (X10)

Stage-level control & alarming

#5

#4

#3

#2

#1

#10

#9

#8

#7

#6

“EP-02-1”

(Located at Controller module, EP-02-1

& EP-02-2 modules)

NO

NC

COM

COM

NC

NO

1 2 4 5 6 7 8 9 11 12 13 14 15

3

NO

NC

COM

COM

NO

10

NC

NO

NC

R01 R02 R03 R04 R05

Normal condition (factory default)

D1 D2 D3 D4 D5

NO

NC

COM

COM

NC

NO

1 2 4 5 6 7 8 9 11 12 13 14 15

3

NO

NC

COM

COM

NO

10

NC

NO

NC

COM

X2

COM

X2

R06 R07 R08 R09 R10

Normal condition (factory default)

D1 D2 D3 D4 D5

= Relay status LEDs D1 to D5 located below terminal connection of sensor inputs (X10)

#15

#14

Stage-level control & alarming

#13

#12

#11

NO

NC

COM

10

NO

NC

“EP-02-2”

NO

NC

COM

COM

NC

NO

1 2 4 5 6 7 8 9 11 12 13 14 15

3

R11 R12 R13 R14 R15

Normal condition (factory default)

D1 D2 D3 D4 D5

= Relay status LEDs D1 to D5 located below terminal connection of sensor inputs (X10)

COM

NO

NC

COM

X2

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 27

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

Page 27

Binary - Relay Outputs “R16 to R20”

Built-in horn alarming***

factory wired, 24 VDC

Fault (fail) alarming

Stage-level control & alarming

“EP-02-3”

***Factorypre-conguredhornandfault(fail-safe),

can be reassigned/converted for remote control,

stage-level #19 and/or #20

= Relay status LEDs D1 to D5 located below terminal connection of sensor inputs (X10)

24 VDC Output Supply

24 VDC max 0.5 A

(+)

for remote alarm

(-)

display units

1 2

(–)

(+)

***

#18

#17

#16

ill. 2 (cont...)

(Located at EP-02-3 module)

NO

NC

COM

COM

NC

NO

1 2 4 5 6 7 8 9 11 12 13 14 15

3

NO

NC

COM

COM

NO

10

NC

NO

NC

R16 R17 R18 R19 R20

Normal condition (factory default)

D1 D2 D3 D4 D5

1H1

COM

X2

Terminal block X1

ill. 3

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 28

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

Page 28

Sensor Inputs “SP01 to SP20”

1 2 4 5 6 7 8 9 103 X10

SP01

SP02

SP03

SP04

SP05

SP06

SP07

SP08

SP13

SP14

SP15

SP16

4-20 mA

24 VDC

SP01/02- (–)

4-20 mA

24 VDC

4-20 mA

24 VDC

SP03/04- (–)

4-20 mA

24 VDC

“EP-02-1”

4-20 mA

24 VDC

SP05/06- (–)

4-20 mA

24 VDC

4-20 mA

24 VDC

SP07/08- (–)

4-20 mA

24 VDC

“EP-02-3”

4-20 mA

24 VDC

SP13/14- (–)

4-20 mA

24 VDC

4-20 mA

24 VDC

SP15/16- (–)

4-20 mA

24 VDC

1 2 4 5 6 7 8 9 103 X10

1 2 4 5 6 7 8 9 103 X10

(Located at Controller module, EP-02-1, EP-02-2,

2-wire sensor / transmitter

“EP-02-2”

SP09

SP10

SP11

SP12

SP17

SP18

SP19

SP20

4-20 mA

24 VDC

SP09/10- (–)

4-20 mA

24 VDC

4-20 mA

24 VDC

SP11/12- (–)

4-20 mA

24 VDC

“EP-02-4”

4-20 mA

24 VDC

SP17/18- (–)

4-20 mA

24 VDC

4-20 mA

24 VDC

SP19/20- (–)

4-20 mA

24 VDC

EP-02-3 & EP-02-4 modules)

3-wire sensor / transmitter

4-20 mA

24 VDC

1 2 4 5 6 7 8 9 103 X10

1 2 4 5 6 7 8 9 103 X10

4-20 mA

24 VDC

(–)

Digital Inputs “DI01 to DI04”

(Located at Controller module)

1 2 3 4 5 6 7 8 9 10 11 12

Polygard® is a registered trademark of MSR MGC2-20

ill. 4

X11

ill. 5

Printed in USA 131119

Page 29

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

5 Start-up Operation

5.1 Start-up

Before beginning start-up the wiring of the Controller including all field devices must be completely terminated!

After switching the power supply “ON” and the end of the Power On Time, then the Controller is ready for use.

The electrochemical sensor needs a warm up time of 1 hour to reach its highest accuracy.

The Controller is delivered with standard parameters and stages/set points. The assignment of the relays to the

individual stages can occur at start-up unless arrangements have been made with the factory for programming. All

other parameters are to be examined and adapted to the local conditions.

Page 29

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 30

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

5.2 Checklist Start-up operation

System Setup

Parameters

Registration of existing EP-02 modules

Time and Date

Parameter Average Function

Password level 1 (Customer Password)

Function analog output

Define failure relay

Power On Time

Service Phone No.

Maintenance date

Relay Setup

Parameters

Relay R 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Relay Mode

Function Steady / Flash

Latching Mode

Horn function

External Relay operation

Delay ON time

Delay OFF time

SP Setup

Parameters

SP No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

SP Mode

Type

Measuring range

SP- Signal

Stage/Setpoint 1

Stage/Setpoint 2

Stage/Setpoint 3

Stage/Setpoint 4

Stage/Setpoint 5

Hysteresis

Delay ON time

Delay OFF time

C/A Mode

Assigned Failure <> Stage

Assigned Stage<> Relay

Assig. SP <> Anal. Output

Finish

Finish

Finish

Page 30

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 31

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

6 Configuration- and Parameter card

Commission: Project No.

Customer:

Start-up - company

Start-up - date: Service Technician

6.1 Configurations System Setup

Page 31

Service Software

Version

Default 15 06.06.06 858 578-7887 120 120 1800 US 1234 30 s 19

Analog output 1 Analog output 2 Analog output 3 Analog output 4

Calibration Calibration Calibration Calibration

Mode = 4 = 20 Mode = 4 = 20 Mode = 4 = 20 Mode = 4 = 20

Max. 4.0 20.0 Max. 4.0 20.0 Max. 4.0 20.0 Max. 4.0 20.0

Mainten-

ance date

Service

Phone

AV- Overlay Time

ppm Time AV-

Time

system

Customers

pass

Analog output 5 Analog output 6 Analog output 7 Analog output 8

Calibration Calibration Calibration Calibration

Mode = 4 = 20 Mode = 4 = 20 Mode = 4 = 20 Mode = 4 = 20

Max. 4.0 20.0 Max. 4.0 20.0 Max. 4.0 20.0 Max. 4.0 20.0

Analog output 9 Analog output 10

Calibration Calibration

Mode = 4 = 20 Mode = 4 = 20

Max. 4.0 20.0 Max. 4.0 20.0

Power

On

Time

Failure

Relay

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 32

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

6.2 Relay Setup

Page 32

Relay

No.

Mode Steady

Flash

Latching

mode

Horn

Function

External Delay time

ON OFF ON OFF

Ti Reset DI DI DI Time Time

Defaul Energize 0 s No 0 0 0 0 0

R01

R02

R03

R04

R05

R06

R07

R08

R09

R10

R11

R12

R13

R14

R15

R16

R17

R18

R19

R20

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 33

Customer Services (858) 578-7887 & (888) GO INTEC

(

)

y

INTEC Controls, 12700 Stowe Dr., Suite 110, Poway, CA 92064

Polygard® is a registered trademark of MSR MGC2-20

17

18

19

20

13

14

15

16

09

10

11

12

05

06

07

08

01

02

03

04

6.3 Sensor Setup

Default Not active CO 250 Linear 25 50 100 250 100 15 0 0 CV 1 1 0 1 0 R1 R2 R3 0 R5 0

No.

SP

Status

SP

Type Measur

PolyGard

User Manual - MGC2-20

range

ing

Signal

SP-

S1 S2 S3 S4 S1 ON OFF S1 S2 S3 S4 S5 S1 S2 S3 S4 S5

Stage/Setpoints Hyst Delay time

®

Multi-Point Controller

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specicationsubjecttochangewithoutnotice.

Printed in USA 131119

sec.

AV

AO

CV/

Assigned SP fault < >Stage

Page 33

Assigned Stage/Setpoint<>

Rela

AO

Page 34

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

7 Specifications MGC2-20

Page 34

Electrical

Power supply

Power Consumption 60 VA, max.

RF/RMI proteced 4.0 W @ 3 ft. (1 m) radiated

Type of control

General

Analog Input Twenty (20), 4 - 20 mA

Analog reading Current and mean (average) value

Power supply for Analog inputs 24 VDC max. 50 mA / channel

Stage level / setpoint

- hysteresis/ switching differential Selectable for each sensor point

Digital inputs

Relay outputs (R1-R20) w/ status LEDs

- each stage level (S1-S5) Assignable to any relay

- sensor fail-safe Assignable to any stage level

Time delay switching

VDC output supply 24 VDC, 0.5 A fused

Analog output

Audible alarm

Alarm acknowledgement

User Interface

Keypad type See 2.1 “Description Keypad User Interface”

Touch buttons Six (6)

Status LED’s Yellow: Alarm; Red: Fault (fail)

Digital display

- unit display

Environmental

Permissible ambient

- working temperature 23 °F to 104 °F (-5 °C to+ 40 °C)

- storage temperature -4 °F to 104 °F (-20 °C to + 40 °C)

- humidity 15 to 95 % RH non condensing

- working pressure Atmospheric ± 10%

120 VAC (90 to 230 VAC) 50/60Hz

resettable breaker

Five-stage (S1 to S5) control, assignable up to

twenty (20) binary/relay output, i.e.

Low-med-high-fault / fail-horn*, or low1-low 2med1-med2-high, or any other combinations

(* = horn/audible alarm built-in and factory preconfigured to relay output “R20”)

Field adjustable over full range, five (5) per

analog input, assignable to current or mean

(average) value

Four (4) each can be individually assigned to

any relay (R1..R20). Digital inputs are used for

remote audio/visual alarm reset

Twenty (20) SPDT, 8 A, 24 VAC/VDC -250

VAC contact resistance 100 m, max.

Selectable for make and brake of each sensor

point (SP1 to SP20) 0-9,999 seconds

Ten (10) independent 4 - 20 mA signal, 500

max. load, selectable as low, high or averaging

of sensor inputs

90 db, enabled or disabled, selectable;

assignable to stage level S1, S2, S3, S4 or S5

Menu-driven and system reset function for

latched relays

Liquid Crystal Display (LCD), two lines, 16

characters per line, 1 digit resolution, backlit

Menu selectable, per sensor;

ppm, %v/v, %LEL; °F or % RH

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 35

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

Page 35

Physical

Enclosure (panel) Plastic housing with view cover

- material

Polycarbonate, impact resistance

EN 50102/K08, flammability rating UL 94-5V

- conformity UL Type 1, UL508/UL 50 standards

- color Light gray, smoked gray for cover

- protection NEMA 4X (IP65)

- installation Wall (surface) mounted

Dimensions (H x W x D)

- base 22.8 x 12.0 x 5.7 in. (580 x 306 x 145 mm)

- Cable entry 10 holes for ½ in. conduit, covered

Wire connection

Wire size

- input

- output

Terminal blocks, Push-on connect and screw

type for lead wire

Min. 22 AWG (0.34 mm

Max. 16 AWG (1.5 mm

Min. 24 AWG (0.25 mm

Max. 14 AWG (2.5 mm

2

)

2

)

2

)

2

)

Weight 14.5 Ibs. (6.6 kg)

Approvals / Listings

City of Los Angeles Approved (pending)

- unit

VDI 2053, C-No. 418791, CE

EMV-Compliance 89/336/EWG

- power supply unit

UL Recognized, E183223

CSA Certified, E183223

UL Recognized, E5610 & E108658

- relays (R1 – R20)

CSA, C22.2 No. 14, LR35579

VDE

- enclosure (panel) UL Listed, E75645

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Page 36

Customer Services (858) 578-7887 & (888) GO INTEC

INTEC Controls, 12700 Stowe Dr., Suite 100, Poway, CA 92064

Fax (858) 578-4633 & (888) FX INTEC

www.inteccontrols.com

Specication subject to change without notice.

PolyGard® Multi-Point Controller

User Manual - MGC2-20

8 Notes and General Information

It is important to read this user manual thoroughly and clearly understand the information and instructions. The

PolyGard

appropriate operating and maintenance instructions and recommendations must be followed.

Due to ongoing product development, MSR reserves the right to change specifications without notice. The

information contained herein is based upon data considered to be accurate. However, no guarantee is expressed

or implied regarding the accuracy of this data.

8.1 Intended product application

8.2 Installers’ responsibilities

®

MGC2 monitoring, control and alarm system must be used within product specification capabilities. The

The PolyGard® MGC2 are designed and manufactured for control applications for energy savings and OSHA

air quality compliance in commercial buildings and manufacturing plants (i.e., detection and automatic exhaust

fan control for automotive maintenance facilities, enclosed parking garages, engine repair shops, warehouses

with forklifts, fire stations, tunnels, etc.).

It is the installer’s responsibility to ensure that all PolyGard® MGC2 are installed in compliance with all national

and local codes and OSHA requirements. Installation should be implemented only by individuals familiar with

proper installation techniques and with codes, standards and proper safety procedures for control installations

and the latest edition of the National Electrical Code (ANSI/NFPA70). It is also essential to strictly follow all

instructions as provided in the user manual.

Page 36

8.3 Maintenance

It is recommended that the PolyGard® MGC2 performance check is done on a routine schedule. Any

performance deviations may be serviced based on needed requirements. Part replacement may be

implemented in the field by a qualified individual and with the appropriate tools.

8.4 Limited warranty

MSR-Electronic-GmbH and INTEC Controls warrants the PolyGard® MGC2 for a period of two years from the

date of shipment against defects in material or workmanship. Should any evidence of defects in material or

workmanship occur during the warranty period, INTEC Controls will repair or replace the product at their own

discretion, without charge.

Thiswarrantydoesnotapplytounitsthathavebeenaltered,hadattemptedrepair,orbeensubjecttoabuse,

accidental or otherwise. The above warranty is in lieu of all other express warranties, obligations or liabilities.

This warranty applies only to the PolyGard

liable for any incidental or consequential damages arising out of or related to the use of the PolyGard

If the PolyGard

®

MGC2 needs to be returned to INTEC Controls for service, an RMA number must be obtained

®

MGC2. MSR-Electronic-GmbH and/or INTEC Controls shall not be

®

MGC2.

prior to sending.

Polygard® is a registered trademark of MSR MGC2-20

Printed in USA 131119

Loading...

Loading...