Page 1

PRSL Series IV Slushie Machine

User Manual

[Revision 2.0 July 2017]

READ THIS MANUAL CAREFULLY BEFORE USE – FAILURE TO DO SO MAY RESULT IN INJURY, PROPERTY

DAMAGE AND MAY VOID WARRANTY. • KEEP THIS MANUAL FOR FUTURE REFERENCE. • Products covered by

this manual may vary in appearance, assembly, inclusions, specifications, description and packaging.

E&OE ©2017 Polycool

Page 2

PRSL Series IV Slushie Machine

E&OE ©2017 Polycool 2

Safety

Safety messages are designed to alert you to possible dangers or hazards that could cause death, injury or

equipment or property damage if not understood or followed. Safety messages have the following symbols:

You WILL be KILLED or

SERIOUSLY INJURED if you

do not follow instructions.

You CAN be KILLED or

SERIOUSLY INJURED if you

do not follow instructions.

You CAN be INJURED if you

do not follow instructions or

equipment damage may occur.

It is important that you read and

understand the instruction manual before

use and keep the manual in a safe place

for future reference. Safety information

presented here is generic in nature –

some advice may not be applicable to

every piece of equipment.

All safety precautions must be observed

to reduce the risk of personal injury when

operating the equipment.

The term “equipment" refers to your

product, be it electrical mains, battery or

petrol engine powered.

IMPORTANT – Handle the equipment

safely and carefully.

BEFORE USE - If you are not familiar

with the safe operation/handling of this

equipment, or are in any way unsure of

any aspect of suitability or correct use it

for your application, you should complete

training conducted by a person or

organization qualified in safe use and

operation of this equipment.

• Read all safety warnings and

instructions. Failure to follow

warnings and instructions may result

in electric shock, fire and/or serious

injury.

• Do not operate the equipment in

flammable or explosive

environments, such as in the

presence of flammable liquids, gases

or dust.

• Keep clear of moving parts.

• This equipment may be a potential

source of electric shock if misused.

• Do not operate the equipment if it is

damaged, malfunctioning or is in an

excessively worn state.

• When using the equipment, basic

safety precautions detailed here

must always be followed to reduce

the risk of fire, electric shock,

personal injury and material damage.

• When wiring electrically powered

equipment, follow all electrical and

safety codes.

• Ensure all power sources conform to

equipment voltage requirements and

are disconnected before connecting

equipment.

• The equipment must be plugged into

a standard, earthed mains electrical

outlet. Do not plug into double

adaptors or multi-outlet extension

power boards.

• Children should be under adult

supervision whilst using the

machine.

Personal Safety

Keep packaging away from children - risk

of suffocation! Operators must use the

equipment correctly. When using the

equipment, consider conditions and pay

due care to persons and property.

Prevent unintentional starting of the

equipment - ensure equipment and power

source switches are in the OFF position

before connecting or moving the

equipment. Do not carry equipment with

hands/fingers touching any controls.

Remove any tools or other items that are

not a part of the equipment from it before

starting or switching on.

General Equipment Use and Care

Do not force the equipment. Use the

correct equipment for your application.

The correct equipment will perform better

and be safer within its design parameters.

Do not use the equipment if the ON/OFF

switch malfunctions – any equipment that

cannot be controlled with the ON/OFF

switch is dangerous and must be

repaired.

General Service Information

• Have the equipment serviced or

repaired at authorized service

centers by qualified personnel only.

• Replacement parts must be original

equipment manufacturer (OEM) to

help ensure that equipment safety is

maintained.

• Do not attempt any maintenance or

repair work not described in this

instruction manual.

• After use, the equipment and

components may still be hot – allow

the equipment to cool and

disconnect spark plugs and/or

electrical power sources and/or

batteries from it before making

adjustments, changing accessories

or performing repair or maintenance.

• Do not make adjustments while the

equipment is running.

• Perform all service related activities

under suitable conditions, such as a

workshop etc.

• Replace any worn, damaged or

missing warning labels immediately.

• Do not clean equipment with

solvents, flammable liquids or harsh

abrasives.

Slushie Machine Use and Care

WARNINGS

• Use only potable (drinkable) water in

the machine.

• Do not place body parts or any

object other than the recommended

liquids into the drink tanks while the

machine is running.

• Use only recommended liquids and

at the correct mixture ratio in the

drink tanks. Failure to follow to this

warning can result in serious

personal injury, death and/or

property damage.

• Do not operate the machine without

liquid in the drink tanks.

• Operate the machine on solid, level

surfaces only.

• At least 30cm (12”) free space

around the machine is required to

prevent machine overheating.

• Do not operate the machine in direct

sunlight or near heat generating

equipment.

Always clean all machine components

that come into contact with the drink

mixture thoroughly with food grade

disinfectant or mild detergent and warm

water. This must be done:

• Before first use.

• Weekly whilst the machine is in use.

• Before placing the machine into

storage.

• When commissioning the machine

after being in storage.

If an ice crust forms on the surface of

liquid in the drink tanks when the beater

(auger or spiral) has been off for an

extended period, it should be removed

before turning on the mixer.

Failure to follow the recommended

maintenance schedule may lead to

conditions or damage that will void any

product warranty.

Page 3

PRSL Series IV Slushie Machine

E&OE ©2017 Polycool 3

Table of Contents

Safety ............................................................................................................................................. 2

Applicable Models ........................................................................................................................ 4

Parts Identification ........................................................................................................................ 5

Assembly ....................................................................................................................................... 6

Operation ....................................................................................................................................... 7

Using the Tank Controls for Slush and Juice Modes ................................................................................... 7

Adjusting Tank Temperature ........................................................................................................................ 8

Filling the Tanks ........................................................................................................................................... 8

Adjusting Slush Consistency ........................................................................................................................ 9

Emptying Drip Trays ..................................................................................................................................... 9

Maintenance ................................................................................................................................ 10

Maintenance Schedule ............................................................................................................................... 10

Cleaning ..................................................................................................................................................... 10

Compressor Servicing ................................................................................................................................ 13

Seal Replacement ...................................................................................................................................... 13

Transportation and Storage ....................................................................................................................... 13

Troubleshooting .......................................................................................................................... 14

Specifications ............................................................................................................................. 15

PRSL-3000 ................................................................................................................................................. 15

PRSL-4500 ................................................................................................................................................. 15

Fill and Clean Quick Reference .................................................................................................. 17

Page 4

PRSL Series IV Slushie Machine

PRSL-3000 Series IV [ICESLHPLYA24L] Twin Tank

PRSL-4500 Series IV [ICESLHPLYA36L] Triple Tank

Applicable Models

This manual applies to the following Polycool slushie machines:

E&OE ©2017 Polycool 4

Page 5

PRSL Series IV Slushie Machine

No.

Name

No.

Name

1

Machine Body

7

Dispenser Handle Pivot Pin (1 per tank)

2

Control Panel

8

Dispenser Plunger (1 per tank)

3

Tank

9

Cooling Drum (1 per tank)

4

Tank Cover/Light Box (1 per tank)

10

Beater (1 per tank)

5

Dispenser Handle (1 per tank)

11

Drip tray (1 per tank)

6

Plunger Spring (1 per tank)

2

1 4 106 8 7 5 9 3

11

Parts Identification

The slushie machine comes mostly assembled, with minor assembly required to make the machine ready for

operation. Some machine may include spare seals and seal lubricant (shown below), which can be installed

as required (see Maintenance).

It is strongly recommended that you familiarise yourself with all major components of the machine before

using it or performing any maintenance tasks.

Products detailed in this manual may vary in appearance, inclusions, description and packaging

from those shown or described. This section shows typical major components common to most

slushie machines.

E&OE ©2017 Polycool 5

Page 6

PRSL Series IV Slushie Machine

2 2 1

Fig. 1

Fig. 3

6

B

Fig. 4

C

7 9 8

5

4

A

3

Fig. 2

Assembly

The machine requires installation of the dispenser mechanisms and drip trays only. Before assembly, unpack

all items.

After assembly, the machine must be cleaned before being put into use (see Cleaning).

1. Position the machine with a gap of at least 30cm (12”) behind and to

the sides of it. This is to allow adequate ventilation and prevent

overheating of the machine.

2. See Fig. 1. Smear a small amount of food grade silicone lubricant onto

the dispenser plunger (1) O-ring (2). Check that the plug (3) at the

bottom of the dispenser plunger is fully seated (the plug does not

require lubricant).

3. See Fig. 2. For each tank, place a plunger spring (4) on the top of the

dispenser plunger (3). Ensure that the recess (A) in the plunger is facing

forward (the handle hooks into this), then push the plunger and spring into the

tank dispenser housing (5).

4. See Fig. 3. Whilst holding the plunger assembly in position, bring the handle

into position – the hook part of the handle (B) fits into the recess in the

plunger.

5. Secure the handle by pushing the handle pivot pin (6) through the flange on

the tank dispenser housing, through the handle and out again through the

opposite flange on the tank dispenser housing.

6. Perform steps 2 to 6 for each tank.

7. See Fig 4. Hook the drip tray (7) to the slots in the machine body (C).

8. Ensure that the drip tube (8) is in the drip tray, then place the tray cover (9) on to the drip tray.

9. Perform steps 8 to 9 for each tank.

E&OE ©2017 Polycool 6

Page 7

PRSL Series IV Slushie Machine

10

D

Fig. 5

10. See Fig. 5. Place the tank cover (10) into

position on the top of the tank.

11. Plug the tank cover cable (D) to the connector at

the rear of the machine.

12. Perform steps 11 to 12 for each tank.

Operation

Using the Tank Controls for Slush and Juice Modes

The machine has control panel on the side that allows you to individually

control each tank as required. There are two basic modes of operation:

• Juice Mode – Cools the drink solution, however, not to the point of

making ice.

• Slush Mode – Cools the drink solution to the point of being ice.

For each tank, there is a switch panel. When a switch is placed in the ON

position, the red lamp on the switch illuminates. For each set of switches,

the tank that they apply to is labelled next to the switches. The

configuration of switches determine the tank function, as follows:

Always place the beater switch in the ON position for either juice or slush mode. • For Slush mode,

place the slush mode switch in the ON position and the juice mode switch in the OFF position. • For

Juice mode, place the slush mode switch in the OFF position and the juice mode switch in the ON

position.

The machine compressor (cooling unit) and tank cover lights for all tanks are controlled by a single set of

“master” switches at the bottom of the control panel. When a switch is placed in the ON position, the red

lamp on the switch illuminates.

E&OE ©2017 Polycool 7

Page 8

PRSL Series IV Slushie Machine

1

3

2

Adjusting Tank Temperature

Note: The factory settings should be suitable for most uses. Adjust the thermostats only if required. If you

adjust the thermostat, it is recommended to monitor the change – is the solution at the right temperature? –

and adjust until the desired result is reached.

Each tank has a thermostat for setting the

“coldness” of the drink solution. Depending on

ambient temperatures (climate or operating

environment temperature), drink solution etc, the

coldness of the tanks may need adjusting for the

desired coldness and consistency of slush ice and

coldness of juice etc.

The tank thermostats (1) are located on the control

panel side of the machine, behind the plastic guard

(2). Use a Phillips head screwdriver to remove the

screw (3) fastening the guard. Gently pull the guard

out from the bottom edge until it unhooks from the

machine. The lower control is for the right-side tank,

the middle control is for the left-side tank on 2-tank

models or the middle tank for 3-tank models, the

upper control is for the left-side tank on 3-tank models. Left to right is taken when looking at the front of the

machine.

Rotate the thermostat knob as required – rotate right (clockwise) to increase coldness; rotate left (anticlockwise) to reduce coldness. It is recommended to not change the thermostat setting too much in a single

adjustment – make small changes and monitor the result. When finished adjusting, re-install the plastic

guard.

Filling the Tanks

Ensure that the drink solution is less than 35°C (95°F) when filling the tanks otherwise machine

damage may result. • Always mix the drink solution so that is a minimum of 13% sugar (ratio

approximately 6.5 parts water to 1 part sugar), otherwise the consistency of slush ice will be

incorrect and damage to machine may result. • Never allow the level of the drink solution to remain below the

minimum level or above the maximum level as machine damage may result. Failure to carry out the

procedures correctly may result in making the product warranty void.

1. Thoroughly mix the drink solution according to its instruction. Mix in a

container that is clean and suitable for handling food and drink for human

consumption.

2. Switch OFF the slush or juice mode switch and beater for the tank before

refilling. If you are filling all tanks, turn OFF the compressor using the “master”

switch.

3. Switch OFF the tank lights.

4. Unplug and remove the tank cover.

5. Carefully pour the mixture into the tank. Do not fill to less than the

“MIN LEVEL” indicator or over the “MAX LEVEL” indicators on the

front of the tank.

6. When finished filling, place the tank cover in position and re-connect

the cable. Reconnect the machine to the electricity supply if

previously unplugged. Switch ON the slush or juice mode switch and

beater for the tank or at the “master” switch. Switch ON the tank

lights.

E&OE ©2017 Polycool 8

Page 9

PRSL Series IV Slushie Machine

A B A

B

1

3

2

Adjusting Slush Consistency

The mixer speed controls the “thickness” of the drink solution in slush mode. The

faster the speed, the “thinner” the slush mixture; the slower the speed, the

“thicker” the slush mixture.

To adjust beater speed, use a flat blade screwdriver to rotate the adjustment

screw (A) at the rear of the tank as required. Rotate the screw to the right

(clockwise) to increase mixing speed and create a thinner slush consistency.

Rotate left (anti-clockwise) to decrease mixing speed and create a thicker slush

consistency. The relative speed is shown by the indicator (B) below the screw.

Note: Mixing speed adjustment should not be required for juice mode operation.

Emptying Drip Trays

Drip trays require regular emptying as a result of spillage, dripping etc. The drip

tray has a small coloured float (A) – when it protrudes from the drip tray, the tray

must be emptied. To remove a drip tray, unhook it from the slots in the machine.

To re-install a drip tray (1), hook it to the slots in the machine body (B). Ensure

that the drip tube (2) is in the drip tray, then place the tray cover (3) on top of the

drip tray.

E&OE ©2017 Polycool 9

Page 10

PRSL Series IV Slushie Machine

Fig. 7

1

A

Fig. 8

2

3

4

5

6

Fig. 9

Maintenance

Maintenance Schedule

Failure to follow the recommended maintenance schedule may lead to conditions or damage

that will void any product warranty.

The following schedule must be followed in order to keep the machine running efficiently and to maximise its

service life.

• Clean the tanks every week whilst the machine is in use.

• Check seals and O-rings during each tank clean – always replace worn or damaged seals.

• Clean the cooling fan and compressor heat exchanger at least once every 6 months.

• Always ensure there is at least 30cm (1’) behind and to the sides of the machine for ventilation.

Cleaning

Clean all machine components that come into contact with the drink solution with mild detergent or

food grade disinfectant and clean water. This must be done before first use and on a weekly basis

when the machine is in use. Cleaning should also be performed before placing the machine in

storage, and when commissioning the machine after being in storage. • When cleaning, do not immerse the

tank cover or any electrical components in water. • Do not use solvents, harsh detergents or abrasives for

cleaning as these may damage the machine. • The seal lubricant should be a food grade silicone type.

1. Switch OFF the slush or juice mode switch and beater for the tank before

cleaning. If you are cleaning all tanks, turn OFF the compressor using the

“master” switch and unplug the machine from the electricity supply.

2. Switch OFF the tank lights.

3. Disconnect the tank cover cable from the connector at the rear of the

machine.

4. Remove the tank cover. If the cover requires cleaning, use a damp cloth to

clean its surfaces. Clean the surface that sits above the drink solution

first. Do not immerse the tank cover in water.

5. Unhook and remove the drip tray.

6. Use the dispenser tap to drain the tank of any remaining drink solution.

Drain the liquid into a suitable container.

7. Fill the tank with hot (not boiling), clean water, then drain completely.

8. See Fig 7. Lift the front of the tank (1) enough for it to clear the lip at the

front of the machine (A) then gently pull it from the machine.

9. See Fig 8. Gently pull the beater (2) from its driveshaft

(3), then slide it off the cooling drum (4).

10. See Fig 9. Pull the driveshaft seal (5) from the end of the

beater (it may have remained attached to the end of the

driveshaft). Pull the tank seal (6) from the end of the

cooling drum. Inspect both seals for wear or damage

and replace if necessary.

E&OE ©2017 Polycool 10

Page 11

PRSL Series IV Slushie Machine

Fig. 12

3

1

Fig. 11

2

4

Fig. 13

4

5

2

Fig. 14

Fig. 15

6

A

8 9 7

Fig. 16

Fig. 10

7

8 B 9

10

11

11. See Fig 10. Pull the handle pivot pin (7) from the tank and remove it and

the handle (8). The dispenser plunger (9) should drop from the tank

dispenser housing – if it remains in place, use an object to push it down

from the hole (B) at the top of the housing. Remove the O-ring (10) and

rubber end plug (11) from the plunger for cleaning. Inspect the O-ring and

rubber end plug for wear or damage and replace if necessary

12. Thoroughly clean all tank parts in warm, clean water and food grade

disinfectant or mild detergent, then rinse several times with hot water.

Note: Do not use solvents, harsh detergents or abrasive cleaners. • When

cleaning in a sink, use the sink plug or a strainer to prevent losing small

parts through the drain hole.

13. Use paper towel to wipe away any residual lubricant on the cooling drum

where the seals are located (around the mixer driveshaft and back of the

cooling drum).

14. Using warm water and a clean cloth, thoroughly clean the cooling drum

and the machine body beneath the tanks.

15. Clean the drain tube using a suitable pipe cleaner or similar. Additionally, hot (not boiling) water can be

poured through the tubes to aid cleaning. Pour through the hole in the machine beneath the front of each

tank and use a suitable container to catch the water.

Once all parts are cleaned, rinsed and dry, reassemble

as follows:

1. See Fig 11. Place the tank seal (1) onto the cooling

drum. Ensure that the larger diameter side sits up

against the rear of the cooling drum (2) and that the

seal is properly seated all the way around and is not

twisted.

2. See Fig. 11. Insert the driveshaft seal (3) into the

end of the beater (4).

3. See Fig 12. Smear a small amount of food grade silicone lubricant onto the

cooling drum where the beater driveshaft protrudes.

4. See Fig 13. Slide the beater (4) onto the cooling drum (2). Ensure that the flat

part of the beater driveshaft (5) fits correctly into the end of the beater,

otherwise it will not install fully. When installing the beater, when it reaches the

end of the driveshaft, rotate it until you feel it engage with the “flat” (A) on the

driveshaft. Once the beater and driveshaft are properly aligned you will be able

to slide the beater fully into position. Do not force the beater on as this may

damage it. When properly installed, the driveshaft seal should be up against

the cooling drum.

5. See Fig 14. Smear a small amount of food

grade silicone lubricant all the way around

the end of the tank, where it comes into

contact with the tank seal.

6. See Fig 15. Slide the tank (6) over the

beater and cooling drum. Ensure it fits

snugly over the tank seal without pinching.

When fully seated, place a little downward

pressure at the front of the tank so that it

“clips” into position over the lip (A) at the front of the machine.

7. See Fig 16. Smear a small amount of food

grade silicone lubricant onto the dispenser

plunger (7) O-ring (8) and the sealing plug

(2) at the bottom of the dispenser plunger

(3).

E&OE ©2017 Polycool 11

Page 12

PRSL Series IV Slushie Machine

Fig. 19

D

19

21

20

11

10

B

7

Fig. 17

Fig. 18

12 C 22

E

Fig. 20

8. See Fig. 17. Place the plunger spring (10) on the top of the dispenser plunger (7). Ensure that the recess

(B) in the plunger is facing forward (the handle hooks into this), then push

the plunger and spring into the tank dispenser housing (11).

9. See Fig. 18. Whilst holding the plunger assembly in position, bring the

handle into position – the hook part of the handle (C) fits into the plunger

recess. Secure the handle by pushing the handle pivot pin (12) through the

flange on the tank dispenser housing, through the handle and out again

through the opposite flange on the tank dispenser housing.

10. See Fig 19. Hook the drip tray (19) to the slots in the machine body (D).

11. Ensure that the drip tube (20) is in the drip tray, then place the tray cover (21) on to the drip tray.

12. See Fig. 20. Place the tank cover (22) into

position on the top of the tank.

13. Plug the tank cover cable (E) to the connector at the rear of the machine.

14. Perform the above steps for each tank.

E&OE ©2017 Polycool 12

Page 13

PRSL Series IV Slushie Machine

4

2

1

3

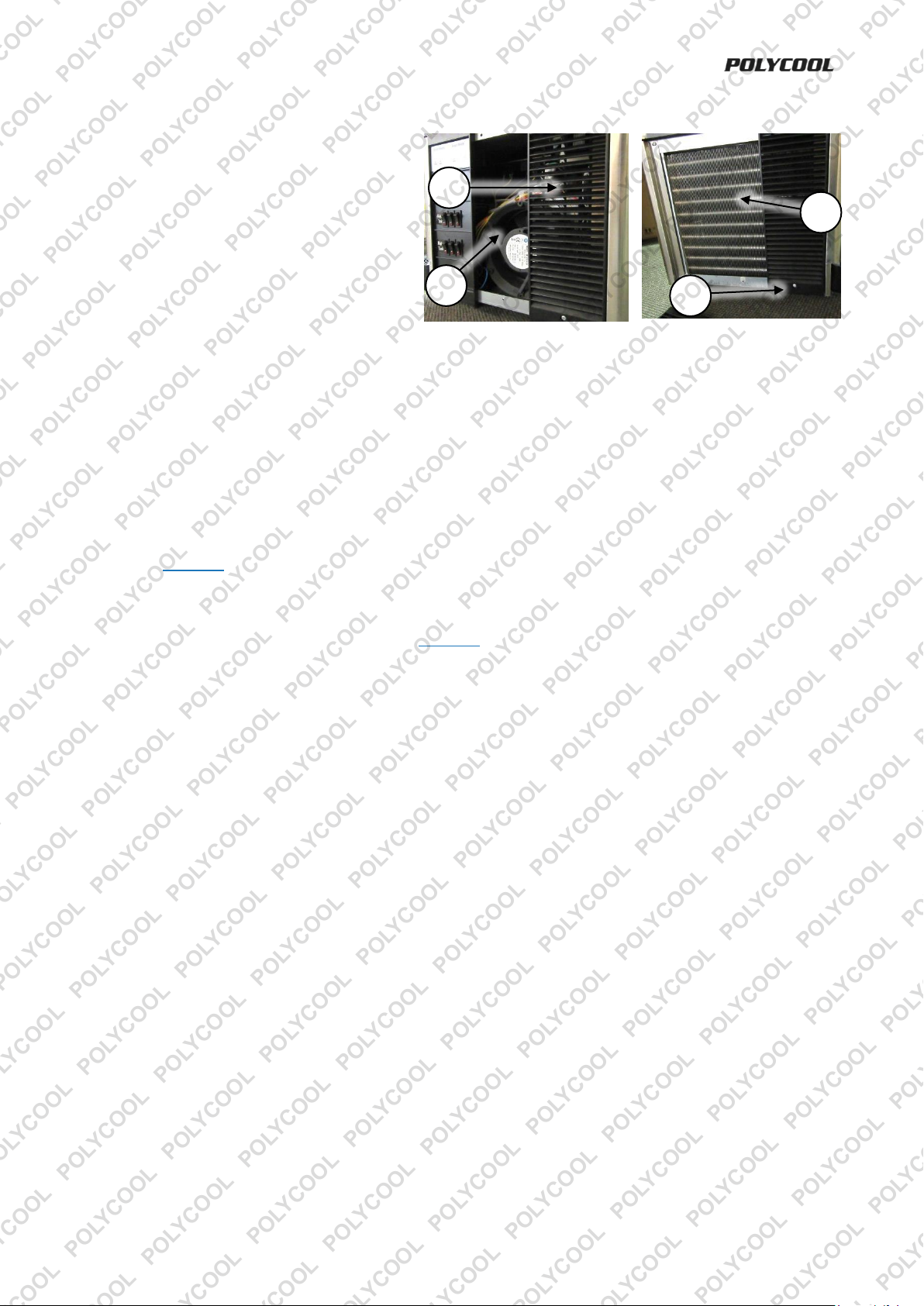

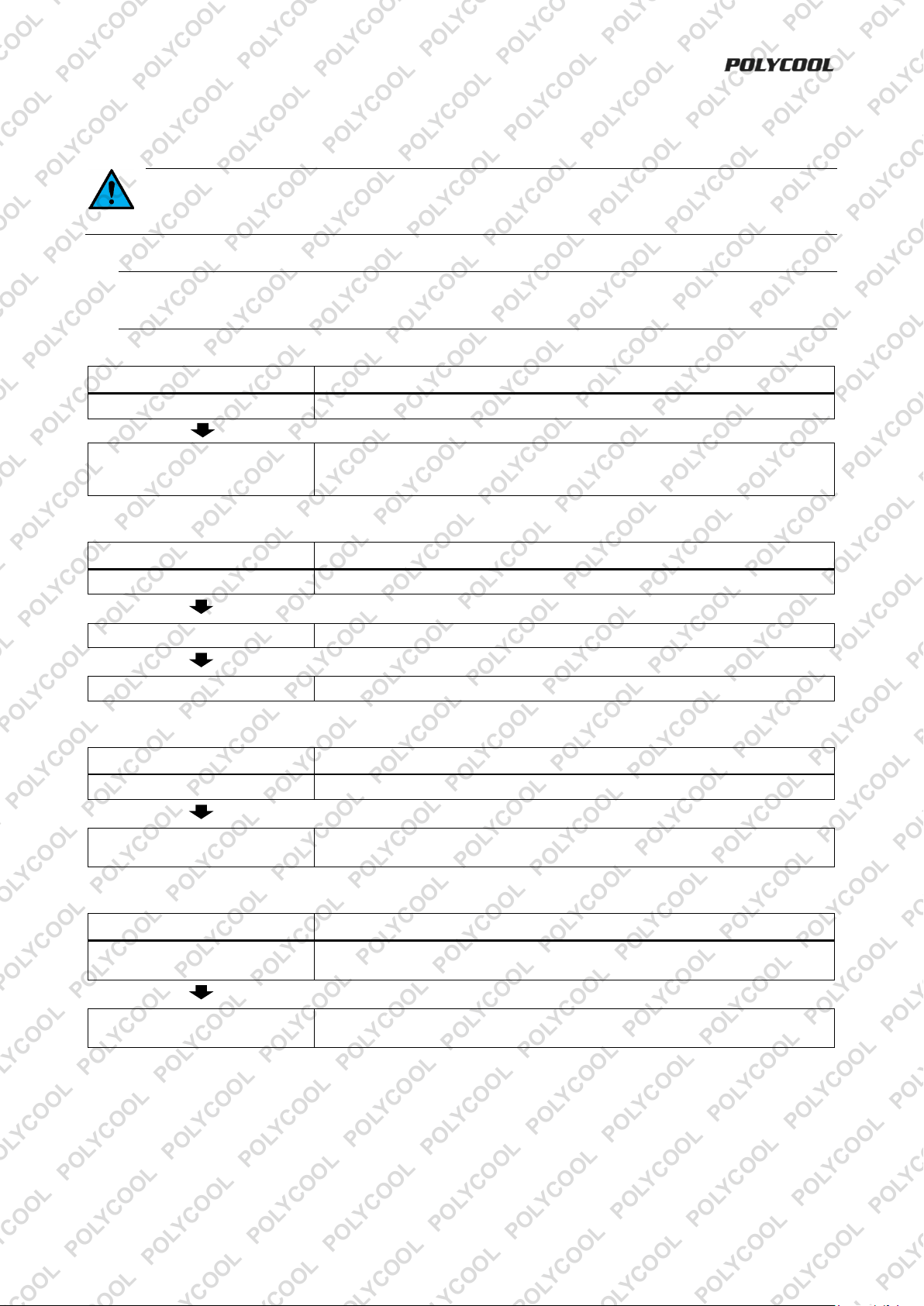

Compressor Servicing

Every 6 months, clean the cooling fan and

compressor heat exchanger fins of dirt and

dust to ensure best cooling efficiency of the

machine. Clean as follows:

1. Turn OFF the machine and disconnect it

from the electricity supply.

2. Use a Phillips head screwdriver to remove

the screws (1) fastening the plastic guards

(2) on either side of the machine. Gently

pull the guard out from the bottom edge until it unhooks from the machine.

3. Use a soft brush (such as a paintbrush) to remove any built up dust and dirt from the compressor cooling

fan (3) (this is located on the control panel side) and heat exchanger (4). When cleaning the heat

exchanger, brush up and down the fins, not across them.

4. When finished, re-install the plastic guards and secure with the screws. Do not over-tighten the screws.

Seal Replacement

Seals are essential to correct operation of the slushie machine. Leaks from the drink dispensers or the drip

tube is filling the drip tray often indicates faulty seals. Dispenser leaks indicate the dispenser O-ring may

need replacing. Excessive liquid through the drip tube indicates the tank seal may need replacing.

Follow the Cleaning procedure to remove and clean old seals and to install and lubricate new seals.

Transportation and Storage

• Drain the tanks and clean the machine (see Cleaning).

• Store the unit in a dry, well-ventilated area and out of the reach of children.

• Do not store in direct sunlight.

• Cover the machine to protect it from dirt and dust.

E&OE ©2017 Polycool 13

Page 14

PRSL Series IV Slushie Machine

Possible Fault

Action

No electrical supply

Check that mains electricity is available and the machine is properly connected to it.

Overload protector tripped

The machine overload protector has tripped due to overheating. The machine will switch on

again automatically once cooled. Ensure that the machine has enough space around it for

ventilation. Ensure that compressor cooling fan and heat exchanger are clean.

Possible Fault

Action

Cooling unit not ON

Ensure the compressor master switch is in the ON position.

Tank cooling switches not ON

Ensure the cooling mode switches are correctly set for slush or juice mode.

Tank thermostat not cool enough

Adjust thermostat to colder setting.

Possible Fault

Action

Machine not level

Ensure the machine is installed on a flat, level surface.

Drink solution lacks sugar

Correct the sugar to water ratio (6.5 parts water to 1 part sugar or 13% sugar minimum) of

the drink solution.

Possible Fault

Action

Dispenser not sealing

Check that dispenser is correctly assembled. Check O-ring for wear, dirt or damage – clean

or replace O-ring as required.

Tank not sealing

Check that tank seal and tank are correctly assembled. Check seal for wear, dirt or damage

– clean or replace seal as required.

Troubleshooting

Some maintenance activities described may be beyond the scope of some users. For procedures

that you are not comfortable with or have the tools or experience for, have the unit serviced by a

service center or qualified technician.

The following information may assist in identifying a problem and rectifying it.

Note: Some procedures listed here may need to be performed by a service center or qualified

technician. • If problems persist after following all suggested actions, contact a service center or

qualified technician.

Machine not operating.

Machine runs, but not cooling drink mixture.

Machine runs and cools, but vibrates, clicks on and off or is noisy.

Drips trays filling and/or dispensers leaking.

E&OE ©2017 Polycool 14

Page 15

PRSL Series IV Slushie Machine

Input Voltage

240VAC / 50Hz

Current Consumption

5.8A

Drink Tank Capacity

2 x 12l

Drink Tank Temperature

-4 to -2°C (24.8 to 28.4°F)

Refrigerant Agent

R134a / 400g

Frothing Agent

HCFC-141b

Ambient Operating

Temperature Range

5 to 35°C (41 to 95°F)

Humidity

90% maximum

Weight

Approximately 65kg without liquids

Input Voltage

240VAC / 50Hz

Current Consumption

5.4A

Drink Tank Capacity

3 x 12l

Drink Tank Temperature

-4 to -2°C (24.8 to 28.4°F)

Refrigerant Agent

R404a / 480g

Frothing Agent

HCFC-141b

Ambient Operating

Temperature Range

5 to 35°C (41 to 95°F)

Humidity

90% maximum

Weight

Approximately 46kg without liquids

Specifications

PRSL-3000

PRSL-4500

E&OE ©2017 Polycool 15

Page 16

PRSL Series IV Slushie Machine

E&OE ©2017 Polycool 16

Some experts believe the incorrect or prolonged use of almost any product could cause serious

injury or death. For information that may reduce your risk of serious injury or death, consult the

points below and additionally, the information available at www.datastreamserver.com/safety

• Consult all documentation, packaging and product

labelling before use. Note that some products feature

online documentation which should be printed and kept

with the product.

• Check product for loose / broken / damaged / missing

parts, wear or leaks (if applicable) before each use.

Never use a product with loose / broken / damaged /

missing parts, wear or leaks (if applicable).

• Products must be inspected and serviced (if applicable)

by a qualified specialist every 6 months assuming

average residential use by a person of average weight

and strength, above average technical aptitude, on a

property matching average metropolitan specification.

Intended use outside these guidelines could indicate

the product is not suitable for intended use or may

require more regular inspection or servicing.

• Ensure all possible users of the product have

completed an industry recognized training course

before being given access to the product.

• The product has been supplied by a general merchandise retailer that

may not be familiar with your specific application or your description

of the application. Be sure to attain third-party approval for your

application from a qualified specialist before use regardless of prior

assurances by the retailer or its representatives.

• This product is not intended for use where fail-safe operation is

required. As with any product (take an automobile, aircraft, computer

or ball point pen for example), there is always a small chance of

technical issues that needs to be repaired or may require replacement

of the product or a part. If the possibility of such failure and the

associated time it takes to rectify could in any situation inconvenience

the user, business or employee then the product is not suitable for

your requirements. This product is not for use where incorrect

operation or a failure of any kind, including but not limited to a

condition requiring product return, replacement, service by a

technician or replacement of parts could cause a financial loss, loss of

employee time or an inconvenience requiring compensation.

• If this item has been purchased in error after considering the points

above, simply contact the retailer directly for details of their returns

policy, if required.

©2017 Polycool. All rights reserved. No part of this document, including descriptive content, concepts, ideas,

diagrams or images may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying, scanning or recording, or any information storage and retrieval system,

without express permission or consent from the publisher.

Page 17

PRSL Series IV Slushie Machine

E&OE ©2017 Polycool 17

Fill and Clean Quick Reference

It is recommended to print this page, laminate it and attach it to the machine for easy reference. For

further information on the following procedures, read the manual.

Drink Solution Mixing and Tank Filling

Water to sugar ratio of drink solution must be a minimum 13% sugar.

That is, 6.5 parts water to 1 part sugar. Incorrect ratios will either cause

the drink solution to be too icy (not enough sugar) or not icy enough (too

much sugar).

Never allow the drink solution level to exceed the maximum level

mark or fall below the minimum level mark.

• Thoroughly mix the drink solution in a suitable container (1).

• Turn OFF the beater and compressor (2).

• Unplug tank cover and remove (3).

• Fill tank to “MAX LEVEL” (4).

• Install tank cover and plug in (3).

• Turn ON beater and compressor (2).

Tank Cleaning

Tanks must be cleaned weekly using food grade disinfectant or mild

detergent. Seal lubricant must be food grade silicone.

• Turn OFF the beater and compressor (1).

• Remove drip tray (2).

• Empty tank of drink solution (3).

• Unplug tank cover and remove (4).

• Rinse tank with hot water (5).

• Drain tank (6).

• Lift front edge of tank to clear lip at front of machine, then pull off (7).

• Pull beater (8) from driveshaft (9).

• Remove driveshaft seal (10).

• Remove tank seal (11).

• Disassemble tap dispenser (12) (handle, pin, spring, plunger, O-ring,

plunger end plug).

• Clean and rinse all parts thoroughly (13).

• Install tank seal (14).

• Lubricate cooling drum around driveshaft (15).

• Insert driveshaft seal (16) to end of beater (17), then push beater onto

driveshaft.

• Lubricate tank around tank seal (18), then push tank firmly over tank

seal then push down until tank “clicks” into position (19).

• Reassemble dispenser plunger and

lubricate O-ring (20), then re-install

dispenser (21).

• Re-install drip tray (22).

• Fill tank (see above).

Loading...

Loading...